Page 1

Item # _____________________________

C.S.I. Section 11420

VSCX2 SERIES

REGENERATED STEAM SERIES CONVECTION

STEAMER ON CABINET BASE

■ VSCX2-6 6-pan capacity

■ VSCX2-10 10-pan capacity

STANDARD FEATURES

■ Two stainless steel cooking compartments with coved interior

corners. Each compartment accepts:

- 1" deep pans (6 - VSCX2-6)(10 - VSCX2-10)

- 21⁄2" deep pans (3 - VSCX2-6)(5 - VSCX2-10)

- 4" deep pans (2 - VSCX2-6)(3 - VSCX2-10)

■ 11⁄4" drain in each compartment.

■ Heavy duty stainless steel "slammable" doors can be opened

and closed at anytime during the cooking cycle. Steam shuts

off when door(s) are opened.

■ Compartment controls include 60 minute dial timer with buzzer,

green "ready" and red "cooking" indicator lights.

■ Convection steamer mounted on 28" high base cabinet with

stainless steel front full height doors, slip-off stainless steel

side and aluminized steel rear panel with welded 6" stainless

steel legs rear with ange foot and front with bullet.

■ Direct steam supply at 15 to 50 PSI with a ow of 200 lbs.

steam/hr. Includes high pressure limit control and 15 psi safety

relief valve, low water control with automatic ll and blowdown.

■ One year limited parts and labor warranty.

A2780

ISO9001

Vulcan-Hart Co.

MODELS: VSCX2 SERIES Regenerated Steam Convection Steamer on Cabinet Base

SPECIFICATIONS:

Regenerated steam generator convection steamer, Vulcan-Hart

Model No. VSCX2. Two stainless steel cooking compartments

with coved interior corners. Each compartment accepts six

1" deep, three 21⁄2" deep or two 4" deep 12" x 20" pans. 11⁄4" drain

in each compartment. Heavy duty stainless steel "slammable"

doors can be opened and closed at anytime during the cooking

cycle. Steam shuts off when door(s) are opened. Compartment

controls include 60 minute dial timer with buzzer, green "ready"

and red "cooking" indicator lights. Convection steamer mounted

on 28" high base cabinet with stainless steel front full height

doors, slip-off stainless steel side and aluminized steel rear panel

with welded 6" stainless steel legs rear with ange foot and front

with bullet. Direct steam supply at 15 to 50 PSI with a ow of

200 lbs. steam/hr.

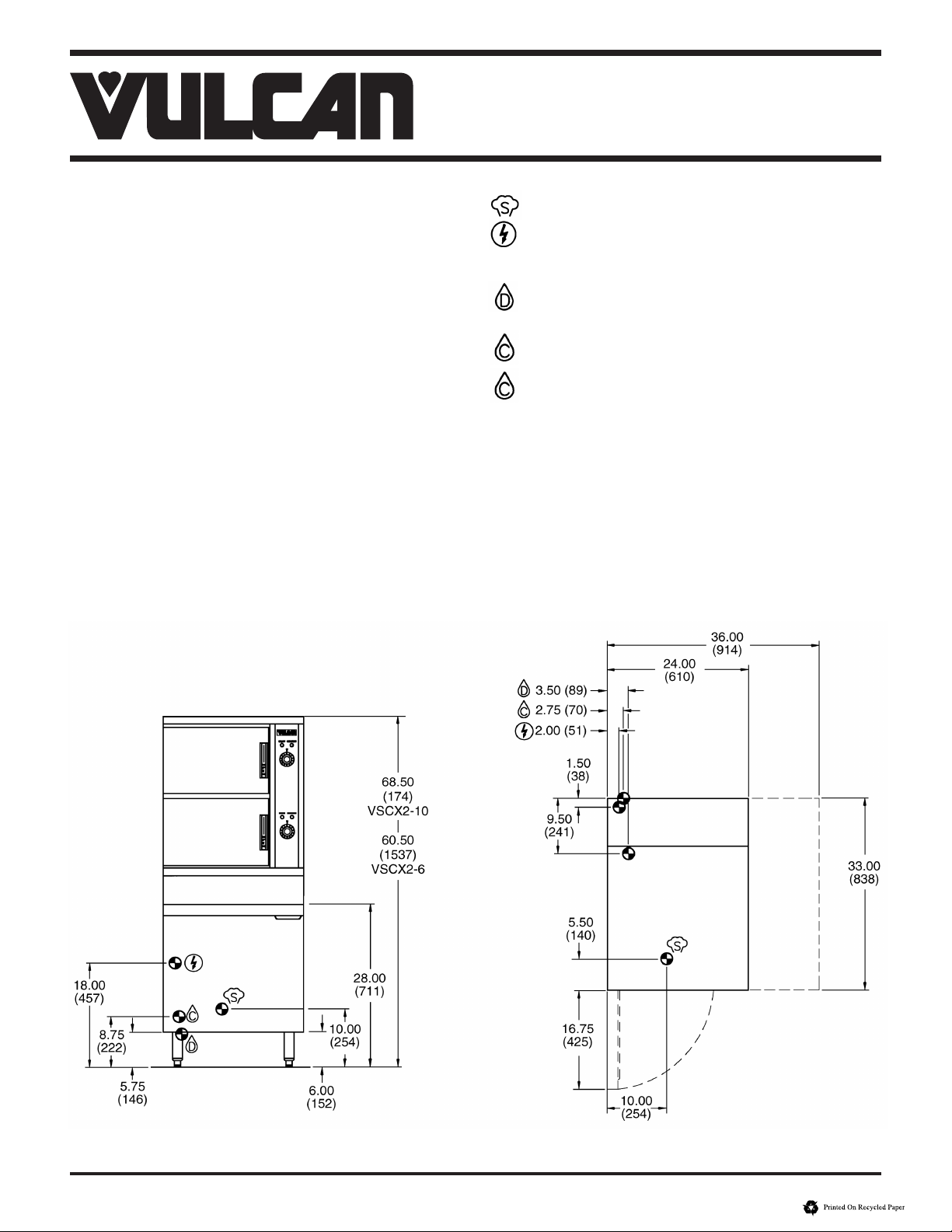

Exterior dimensions:

VSCX2-6: 24"w x 33"d x 601⁄2"h.

VSCX2-10: 24"w x 33"d x 681⁄2"h.

NSF listed. U L listed. Meets ASME code.

OPTIONS

■ Stainless steel cabinet back.

■ Correction facility package:

a. Security type tamper resistant fasteners with tack welds.

b. Control cover with hasp (lock by others).

c. Cabinet door with hasp (lock by others).

■ Step down transformer for control circuit if higher than

120 volts.

■ Second year extended limited parts and labor warranty.

ACCESSORIES

■ Water lter system.

■ Wire rack.

■ Pressure reducing valve.

■ Ball oat trap.

F-32482 (08-04)

VULCAN-HART COMPANY, P.O. BOX 696, LOUISVILLE, KY 40201, TEL. 1-800-814-2028

502-778-2791 QUOTE & ORDER FAX: 1-800-444-0602

Page 2

VSCX2 SERIES

REGENERATED STEAM SERIES CONVECTION

STEAMER ON CABINET BASE

DIRECT STEAM DATA:

Steam supply to the regenerated steamer must:

1. Maintain a steady 15 to 50 psi ow under operating conditions.

2. Have a minimum ow rate of 125 lbs. per hour, dry steam.

3. Be adequately trapped to provide dry steam. (See ball oat trap.)

4. Provide a service shut-off valve.

WATER QUALITY STATEMENT:

The fact that a water supply is potable is no guarantee that it is suitable

for steam generation. Your water supply must be within these general

guidelines:

SUPPLY PRESSURE 20 - 80 psig

HARDNESS* less than 3 grains

SILICA less than 13 ppm

CHLORIDE less than 30 ppm

pH RANGE 7-8

* 17.1 ppm = 1 grain of hardness

Other factors affecting steam generation are iron content, amount of

chloridation and dissolved gases. Water supplies vary from state to state

and from locations within a state. Therefore it is necessary that the local

water treatment specialist be consulted before the installation of any

steam generating equipment.

SERVICE CONNECTIONS:

Steam Supply: 3⁄4" NPT for 15 - 50 psi direct steam.

Electric Connection for Controls: 120/60/1, 300 watt maxi-

mum power supply with grounding wire required. (For other

than 120 volt supply, consult factory for location of this

connection.)

Drain: Condenser box, compartment and boiler, 2 " NPT.

(Provide an open air gap type drain within 12" of condenser

box. Do not connect solidly to any drain connection.)

Cold Water Connection: 3⁄8" NPT for boiler feed. Inlet water

pressure between 20 and 80 psi.

Cold Water Connection: 3⁄8" NPT for condensate box. Inlet

water pressure between 20 and 80 psi.

Water: For swing faucet, (single) (dual) temperature 1⁄4" IPS

tailpiece.

Steam Take-Off Connection: 3⁄4" NPT.

NOTE:

• Dimensionswhichlocatetheaboveconnectionshaveatoleranceof

+ or -3" (+ or -77 mm).

• Installation of backow preventers, vacuum breakers and other

specic code requirements is the responsibility of the owner and

installer. It is the responsibility of the owner and installer to comply with

local codes.

• Thisapplianceismanufacturedforcommercialinstallation onlyand

is not intended for home use.

NOTE: In line with its policy to continually improve its products, Vulcan-Hart Company reserves the right to change materials and

specications without notice.

F-32482 (08-04)

VULCAN-HART COMPANY, P.O. BOX 696, LOUISVILLE, KY 40201, TEL. 1-800-814-2028

502-778-2791 QUOTE & ORDER FAX: 1-800-444-0602

Loading...

Loading...