Page 1

Installation, Operation and Maintenance Instructions

Model VS

Page 2

2

Page 3

IMPORTANT SAFETY NOTICE

To: Our Valued Customers

User safety is a major focus in the design of our products. Following the precautions outlined in this

manual will minimize your risk of injury.

ITT Goulds pumps will provide safe, trouble-free service when properly installed, maintained, and

operated.

Safe installation, operation, and maintenance of ITT Goulds Pumps equipment are an essential end user

responsibility. This Pump Safety Manual identifies specific safety risks that must be considered at all

times during product life. Understanding and adhering to these safety warnings is mandatory to ensure

personnel, property, and/or the environment will not be harmed. Adherence to these warnings alone,

however, is not sufficient — it is anticipated that the end user will also comply with industry and corporate

safety standards. Identifying and eliminating unsafe installation, operating and maintenance practices is

the responsibility of all individuals involved in the installation, operation, and maintenance of industrial

equipment.

Please take the time to review and understand the safe installation, operation, and maintenance guidelines

outlined in this Pump Safety Manual and the Instruction, Operation, and Maintenance (IOM) manual.

Current manuals are available at

your nearest Goulds Pumps sales representative.

www.gouldspumps.com/literature_ioms.html or by contacting

These manuals must be read and understood before installation and star t-up.

For additional information, contact your nearest Goulds Pumps sales representative or visit our Web site at

www.gouldspumps.com.

S-1

Page 4

SAFETY WARNINGS

Specific to pumping equipment, significant risks bear reinforcement above and beyond normal safety precautions.

WARNING

A pump is a pressure vessel with rotating parts that can be hazard o us. An y press ure vessel can explode,

rupture, or discharge its contents if sufficiently ove r press u r i zed causi n g deat h, personal injury, property

damage, and/or damage to the environment. All necessary measures must be taken to ensure over

pressurization does not occur.

WARNING

Operation of any pumping system with a blocked suction and discharge must be avoided in all cases.

Operation, even for a brief period under these conditions, can cause superheating of enclosed pumpage and

result in a violent explosion. All necessary measures must be taken by the end user to ensure this condition is

avoided.

WARNING

The pump may handle hazardous and/or toxic fluids. Care must be taken to identify the contents of the pump

and eliminate the possibility of exposure, particularly if hazardous and/or toxic. Potential hazards include, but

are not limited to, high temperature, flammable, acidic, caustic, explosive, and other risks.

WARNING

Pumping equipment Instruction, Operation, and Maintenance manuals clearly identify accepted methods for

disassembling pumping units. These methods must be adhered to. Specifically, applying heat to impellers

and/or impeller retaining devices to aid in their removal is strictly forbidden. Trapped liquid can rapidly

expand and result in a violent explosion and injury.

ITT Goulds Pumps will not accept responsibility for physical injury, damage, or delays caused by a failure to

observe the instructions for installation, operation, and maintenance contained in this Pump Safety Manual or the

current IOM available at www.gouldspumps.com/literature.

S-2

Page 5

SAFETY

DEFINITIONS

Throughout this manual the words WARNING, CAUTION, ELECTRICAL, and ATEX are used to indicate

where special operator attention is required.

Observe all Cautions and Warnings highlighted in this Pump Safety Manual and the IOM provided with

your equipment.

WARNING

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

Example:

Pump shall never be operated without coupling guard installed correctly.

CAUTION

Indicates a hazardous situation which, if not avoi ded, could result in minor or moderate injury.

Example: Throttling flow from the suction side may cause cavitation and pump damage.

ELECTRICAL HAZARD

Indicates the possibility of electrical risks if directions are not followed.

Example: Lock out driver power to prevent electric shock, accidental start-up, and physical injury.

When installed in potentially explosive atmospheres, the instructions that follow the Ex symbol must be

followed. Personal injury and/or equipment damage may occur if these instructions are not followed. If there

is any question regarding these requirements or if the equipment is to be modified, please contact an ITT

Goulds Pumps representative before proceeding.

Example:

parts, resulting in a spark and heat generation.

Improper impeller adjustment could cause contact between the rotating and stationary

S-3

Page 6

GENERAL PRECAUTIONS

WARNING

A pump is a pressure vessel with rotating parts that can be hazardous. Hazardous fluids may be contained by the

pump including high temperature, flammable, acidic, caustic, explosive, and other risks. Operators and

maintenance personnel must realize this and follow safety measures. Personal injuries will result if procedures

outlined in this manual are not followed. ITT Goulds Pumps will not accept responsibility for physical injury,

damage or delays caused by a failure to observe the instructions in this manual and the IOM provided with your

equipment.

WARNING

WARNING

General Precautions

NEVER use heat to disassemble pump due to risk of explosion from tapped liquid.

NEVER APPLY HEAT TO REMOVE IMPELLER. It may explode due to

trapped liquid.

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

NEVER operate pump without safety devices installed.

NEVER operate pump without coupling guard correctly installed.

NEVER run pump below recommended minimum flow when dry, or without

prime.

ALWAYS lock out power to the driver befo re per fo rming pump maintenance.

NEVER operate pump with discharge valve closed.

NEVER operate pump with suction valve closed.

DO NOT change service application without approval of an authorized ITT

Goulds Pumps representative.

Safety Apparel:

Insulated work gloves when handling hot bearings or using bearing heater

Heavy work gloves when handling parts with shar p ed ges, especially

impellers

Safety glasses (with side shields) for eye protection

Steel-toed shoes for foot protection when handling parts, heavy tools, etc.

Other personal protective equipment to protect against hazardous/toxic fluids

Receiving:

Assembled pumping units and their components are heavy. Failure to properly lift

and support equipment can result in serious physical injury and/or equipment

damage. Lift equipment only at specifically identified lifting points or as

instructed in the current IOM. Current manuals are available at

www.gouldspumps.com/literature_ioms.html or from your local ITT Goulds

Pumps sales representative. Note: Lifting devices (eyebolts, slings, spreaders, etc.)

must be rated, selected, and used for the entire load being lifted.

Alignment:

WARNING

Shaft alignment procedures must be followed to prevent catastrophic failure of

drive components or unintended contact of rotating parts. Follow coupling

manufacturer’s coupling installation and operation procedures.

S-4

Page 7

WARNING

CAUTION

General Precautions

Before beginning any alignment procedure, make sure driver power is locked out.

Failure to lock out driver power will result in serious physical injury.

Piping:

Never draw piping into place by forcing at the flan ged con necti on s of t he pump.

This may impose dangerous strains on the unit and cause misalignment between

pump and driver. Pipe strain will adversely effect the operation of the pump

resulting in physical injury and damage to the equipment.

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

CAUTION

CAUTION

WARNING

Flanged Connections:

Use only fasteners of the proper size and material.

Replace all corroded fasteners.

Ensure all fasteners are properly tightened and there are no missing fasteners.

Startup and Operation:

When installing in a potentially explosive environment, please ensure that the

motor is properly certified.

Operating pump in reverse rotation may result in contact of metal parts, heat

generation, and breach of containment.

Lock out driver power to prevent accidental start-up and physical injury.

The impeller clearance setting procedure must be followed. Improperly setting

the clearance or not following any of the proper procedures can result in sparks,

unexpected heat generation and equipment damage.

If using a cartridge mechanical seal, the centering clips must be installed and set

screws loosened prior to setting impeller clearance. Failure to do so could result

in sparks, heat generation, and mechanical seal damage.

The coupling used in an ATEX classified environment must be properly certified

and must be constructed from a non-sparking material.

Never operate a pump without coupling guard properly installed. Personal injury

will occur if pump is run without coupling guard.

Make sure to properly lubricate the bearings. Failure to do so may result in excess

heat generation, sparks, and / or premature failure.

The mechanical seal used in an ATEX classified environment must be properly

certified. Prior to start up, ensure all points of potential leakage of process fluid to

the work environment are closed.

Never operate the pump without liquid supplied to mechanical seal. Running a

mechanical seal dry, even for a few seconds, can cause seal damage and must be

avoided. Physical injury can occur if mechanical seal fails.

Never attempt to replace packing until the driver is properly locked out and the

coupling spacer is removed.

WARNING

WARNING

S-5

Dynamic seals are not allowed in an ATEX classified environment.

DO NOT operate pump below minimum rated flows or with suction and/or

discharge valve closed. These conditions may create an explosive hazard due to

vaporization of pumpage and can quickly lead to pump failure and physical injury.

Page 8

WARNING

WARNING

WARNING

WARNING

WARNING

CAUTION

CAUTION

WARNING

CAUTION

CAUTION

General Precautions

Ensure pump is isolated from system and pressure is relieved before

disassembling pump, removing plu gs, ope ni n g vent or drain valves, or

disconnecting piping.

Shutdown, Disassembly, and Reassembly:

Pump components can be heavy. Proper methods of lifting must be employed to

avoid physical injury and/or equipment damage. Steel toed shoes must be worn at

all times.

The pump may handle hazardous and/or toxic fluids. Observe proper

decontamination procedures. Proper personal protective equipment should be

worn. Precautions must be taken to prevent physical injury. Pumpage must be

handled and disposed of in conformance with applicable environmental

regulations.

Operator must be aware of pumpage and safety precautions to prevent physical

injury.

Lock out driver power to prevent accidental startup and physical injury.

Allow all system and pump components to cool before handling them to prevent

physical injury.

If pump is a Model NM3171, NM3196, 3198, 3298, V3298, SP3298, 4150, 4550,

or 3107, there may be a risk of static electric discharge from plastic parts that are

not properly grounded. If pumped fluid is non-conductive, pump should be

drained and flushed with a conductive fluid under conditions that will not allow

for a spark to be released to the atmosphere.

Never apply heat to remove an impeller. The use of heat may cause an explosion

due to trapped fluid, resulting in severe physical injury and property damage.

Wear heavy work gloves when handling impellers as sharp edges may cause

physical injury.

Wear insulated gloves when using a bearing heater. Bearings will get hot and can

cause physical injury.

S-6

Page 9

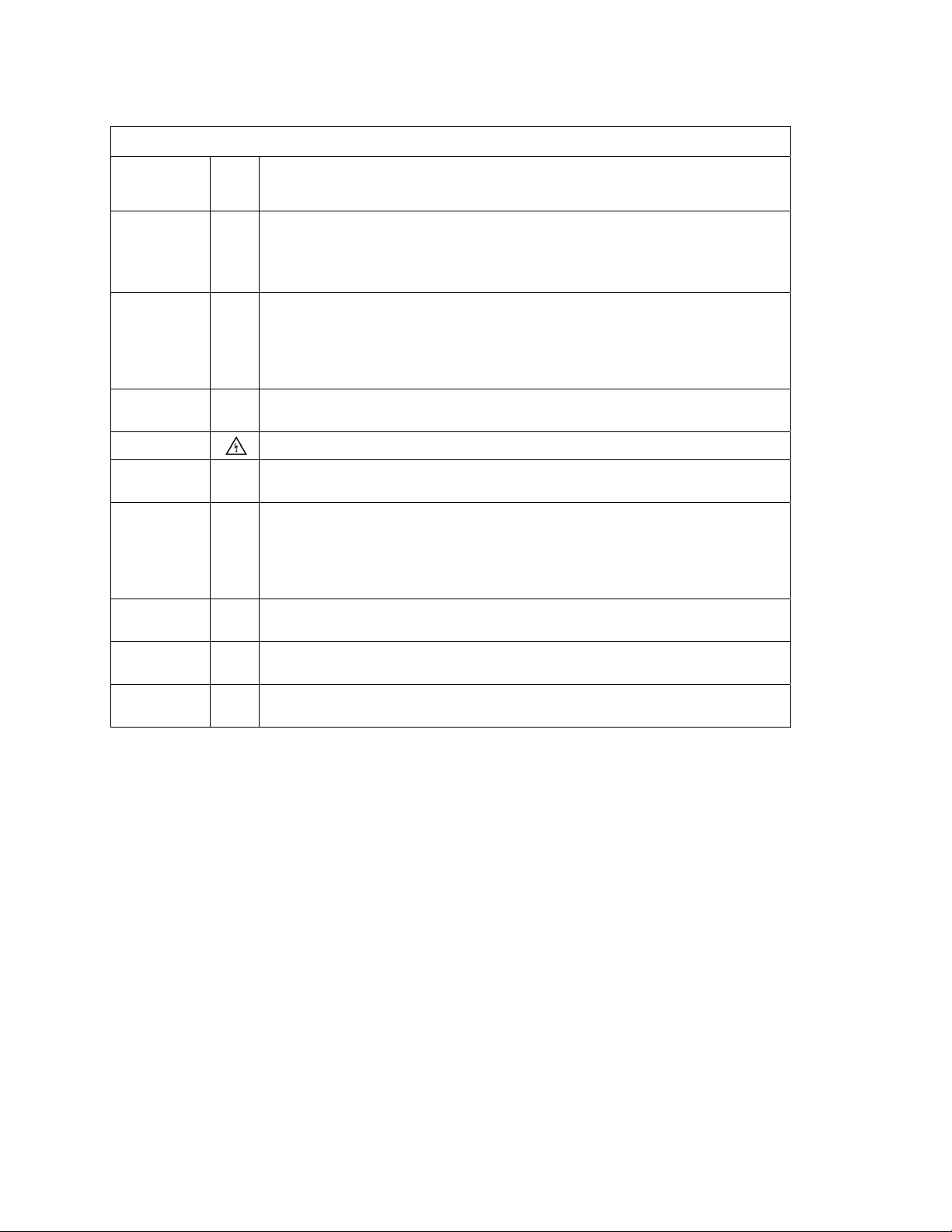

ATEX CONSIDERATIONS and INTENDED USE

Special care must be taken in potentially explosive environments to ensure that the equipment is properly

maintained. This includes but is not limited to:

1. Monitoring the pump frame and liquid end temperature.

2. Maintaining proper bearing lubrication.

3. Ensuring that the pump is operated in the intended hydraulic range.

The ATEX conformance is only applicable when the pump unit is operated within its intended use. Operating,

installing or maintaining the pump unit in any way that is not covered in the Instruction, Operation, and

Maintenance manual (IOM) can cause serious personal injury or damage to the equipment. This includes any

modification to the equipment or use of parts not provided by ITT Goulds Pumps. If there is any question

regarding the intended use of the equipment, please contact an ITT Goulds represe ntative before proceeding.

Current IOMs are available at

Pumps Sales representative.

All pumping unit (pump, seal, coupling, motor and pump accessories) certified for use in an ATEX classified

environment, are identified by an ATEX tag secured to the pump or the baseplate on which it is mounted. A

typical tag would look like this:

www.gouldspumps.com/literature_ioms.html or from your local ITT Goulds

The CE and the Ex designate the ATEX compliance. The code directly below these symbols reads as follows:

II = Group 2

2 = Category 2

G/D = Gas and Dust present

T4 = Temperature class, can be T1 to T6 (see Table 1)

Table 1

Max permissible

surface temperature

Code

T1 842 (450) 700 (372)

T2 572 (300) 530 (277)

T3 392 (200) 350 (177)

T4 275 (135) 235 (113)

T5 212 (100) Option not available

T6 185 (85) Option not available

o

F (oC)

The code classification marked on the equipment must be in accordance with the specified area where the

equipment will be installed. If it is not, do not operate the equipment and contact your ITT Goulds Pumps sales

representative before proceeding.

Max permissible

liquid temperature

o

F (oC)

S-7

Page 10

PARTS

The use of genuine Goulds parts will provide the safest and

most reliable operation of your pump. ITT Goulds Pumps ISO

certification and quality control procedures ensure the parts are

manufactured to the highest quality and safety levels.

Please contact your local Goulds representative for details on

genuine Goulds parts.

S-8

Page 11

SECTION 1 – GENERAL

INFORMATION

1-1 INTRODUCTION

The design, materials and workmanship incorporated in the construction of Goulds submersible

turbine pumps makes them capable of giving long,

trouble-free service. The life and satisfactory service of any mechanical unit, however, is enhanced

and extended by correct application, proper installation, periodic inspection, and careful maintenance. This instruction manual was prepared to

assist the operators in understanding the construction and correct methods of installing, operating,

and maintaining these pumps.

Study thoroughly Sections 1 through 8 and keep

this manual handy for reference. Further information can be obtained by contacting Goulds Pumps

sales office or your local branch office.

WARNING

GOULDS PUMPS SHALL NOT BE LIABLE FOR

ANY DAMAGES OR DELAY CAUSED BY FAILURE

TO COMPLY WITH THE PROVISIONS OF THIS

INSTRUCTION MANUAL.

1-2 RECEIVING AND CHECKING

The pump shall be carefully supported prior to

unloading from the carrier. Handle all components

carefully. Inspection for damage of the shipping

crate shall be made prior to unpacking the pump.

After unpacking, visually inspect the pump and

check the following:

A. Contents of the pump assembly against

shipping list.

B. All components against damage.

Any shortages or damages should be immediately called to the attention of the local freight

agent of the carrier by which the shipment

arrived and proper notation made on the bill.

This shall prevent any controversy when a claim is

made and to facilitate prompt and satisfactory

adjustment.

1-3 MATERIALS AND EQUIPMENT

REQUIRED

The material and equipment necessary for installation of the pump will vary with the size of the pump

and the type of installation. The following discussion and list of standard tools and supplies is

therefore offered only as a guide.

A. BULK MATERIAL

Anti-galling lubricant, thread compound, lubrication oil, grease, petroleum based solvent.

B. HAND TOOLS

Pipe Wrenches, two chains tongs and

mechanic’s hand tools.

C. INSTRUMENTS

One megger, or similar instrument indicating

electrical resistance, clamp-on ammeter,

voltmeter and a good grade of pipe joint

compound should be available to facilitate

assembly and possible future disassembly.

D. INSTALLATION EQUIPMENT

Wooden friction blocks or steel clamps, steel

column lifting elevators of approved type and

of proper size for the column pipe, and cable

sling approximately 10 feet long of adequate

size for the loads involved.

Although portable derricks are sometimes

used, a properly designed pump setting rig is

recommended. It must be possible to erect

the crown block to a height so as to allow the

load hook to be raised about three feet higher

than the longest piece. The lifting device

must be of sufficient strength and rigidity to

raise the total weight of the unit safely.

CAUTION

REMEMBER – REGARDLESS OF THE TYPE

OF LIFTING EQUIPMENT, OR THE TYPE OF

PUMPING EQUIPMENT, THE PRIMARY RULE

IS: SAFETY FIRST.

SECTION 2 – STORAGE

2-1 STORAGE

Goulds Pumps carefully preserves and protects its

products for shipment. However, the effective life

of the preservatives applied at the factory can vary

from 3 to 18 months depending on the severity of

the environment in which the equipment is stored.

This section provides procedures for preparation

prior to storage and maintenance during storage

of Goulds’ Pumps. These procedures are necessary to protect the precision parts of the pumps.

Specific procedures for storing motors should be

obtained from the motor manufacturer. This section is intended to be of general assistance to

users of Goulds Pumps. It shall not modify,

amend, and/or otherwise alter the scope of Goulds

Pumps warranty in anyway whatsoever.

3

Page 12

2-2 STORAGE PREPARATION

Goulds’ submersible pumps require proper preparation for storage. The pump shall be considered

in storage when it has been delivered to the job

site and is awaiting installation. If a pump has

been installed, but is not in regular operation, such

as seasonal shutdown or an extended period of

time, it is suggested that the pump be operated for

at least 15 minutes every two weeks if possible.

2-3 RECOMMENDED STORAGE

PROCEDURES

A. Controlled storage facilities should be main-

tained at an even temperature 10°F or more

above the dew point with relative humidity

less than 50% and little or no dust. (If these

requirements cannot be met the pump is to

be considered in uncontrolled storage.)

B. For uncontrolled storage periods of six months

or less, the pump is to be inspected periodically

to insure that all preservatives are intact.

C. All pipe threads and flanged pipe covers are

to be sealed with tape.

D. The pump must not be stored closer than six

inches to the ground.

2-4 PREPARATIONS FOR UNCONTROLLED

LONG TERM STORAGE

Storage periods over six months require the preceding uncontrolled storage procedure plus the

following:

A. Inspect the assembly and re-coat periodically

to prevent corrosion.

B. Place ten pounds of moisture absorbing des-

iccant or five pounds of vapor phase inhibitor

crystals near the center of the pump. If the

pump is assembled, place an additional one

pound in the discharge nozzle securely fastened to the discharge flange.

C. Install a moisture indicator near the perimeter

of the pump. Cover the pump with 6 mils minimum thickness black polyethylene or equal

and seal it with tape. Provide a small ventilation hole approximately

1

/2 inch diameter.

D. Provide a roof or a shed shelter to protect

from direct exposure to the elements.

Fig. 3.1 Typical Submersible Pump Installation

4

Page 13

SECTION 3 – GENERAL

DESCRIPTION

3-1 GENERAL DESCRIPTION

Goulds’ model VS pump is a submersible turbine

pump designed for maximum dependability. The

VS pump also features capacities from 100 to

3000 GPM and larger, heads to 1000 feet. See

Figure 3.1 for typical VS pump.

3-2 DRIVERS

Goulds furnishes only internationally recognized

motors designed for continuous operation under

any thrust which may develop throughout the performance curve. Impeller adjustment and type of

coupling, splined or clamped, is dependent on the

specific motor being used.

3-3 DISCHARGE

The discharge bowl provides an NPT or BSP

thread for connecting to the well head or the first

section of column pipe.

3-4 BOWL ASSEMBLY

The bowls are generally flanged construction for

accurate alignment and ease of assembly and disassembly. (Except D-line which have threaded

joints.) Impellers may be enclosed or open type.

Impeller position is set at factory. No field adjustment is required.

SECTION 4 – PREPARATION FOR

INSTALLATION

4-1 WELL REQUIREMENTS

A. The well should be developed with a test

pump prior to installing the submersible

pump. Test pumping the well serves several

purposes. It removes the excess sand

encountered during the initial pumping of the

well. Pumping sand or other abrasives with a

submersible pump will shorten the life of the

pump and can void the warranty.

CAUTION

DO NOT INSTALL THE UNIT WITH THE MOTOR IN

THE MUD, SAND OR RESTING ON THE BOTTOM

OF THE WELL. IT IS IMPORTANT TO PREVENT

THE WELL FROM SANDING UP AT ANY TIME TO

THE POINT THAT THE MOTOR BECOMES EVEN

PARTIALLY BURIED.

B. The test pumping also provides a means of

determining the capacity and drawdown. The

well capacity should equal or exceed the

pump capacity. If the pump removes water at

a higher rate than the well produces, the

drawdown will be excessive and the pump

will cavitate or ‘starve’ resulting in damage to

the pump and motor.

C. The well must be deep enough so that the

pump suction is at least 10 ft below the

expected drawdown level. If the well screen

or water producing aquifer is above the

pumping level, the required submergence of

the pump suction would be over 20 ft.

CAUTION

NEVER INSTALL UNIT WITH THE BOTTOM OF THE

MOTOR CLOSER THAN FIVE FEET FROM THE

BOTTOM OF THE WELL.

D. The motor must always be immersed in flow-

ing water. The flow rate must be over 1

ft/sec. If the pump is set below the well

screen openings or other conditions exist that

caused the water to be supplied from above

the pump, a flow induce sleeve should be

used.

E. The inside diameter of the well casing must

be large enough to allow lowering the unit

into the well without damage to the power

cable, the splice between the power cable

and the motor leads. Many wells have more

than one size of casings installed and frequently the lower sections are smaller in

diameter than the upper casing.

F. The submersible pump/motor unit must be

operated in a straight portion of the well.

Exerted pressures can and will cause misalignment of bearings or coupling. When the

straightness of the well is not known, it is recommended to lower a test blank with the

same diameter and length as the pump/motor

assembly with electrical leads into the well to

the desired depth. If there is any doubt about

straightness, gaging and plotting are recommended.

4-2 PREPARING THE FOUNDATION

The foundation must be rigid, level, and of adequate strength to support the complete weight of

the pump, motor, column, plus the weight of the

liquid passing through it. It is recommended the

foundation be constructed of solid concrete, however, adequate beams or timbers may be used. A

common foundation consists of the following concrete mixture:

5

Page 14

A. One part cement

B. Two parts sand

C. Four parts gravel

D. With sufficient water to make a stiff mix

4-3 MOTOR AND CABLE CHECKS AND

PREPARATION

CAUTION

DO NOT USE MOTOR LEADS TO LIFT OR HAN-

DLE THE MOTOR. THE MOTOR LEADS ARE EASI-

LY DAMAGED. THEY SHOULD BE PROTECTED

AND HANDLED WITH CARE AT ALL TIMES.

A. MOTOR SERVICING

Consult the motor manual and perform any

pre-installation servicing that is required.

Some motors may require filling with oil or

water.

B. ASSEMBLE OF MOTOR TO PUMP

If the pump and motor have not already been

assembled, assemble per the instructions

given in Appendix A. For extra long units, it

may be more practical to assemble the pump

to the motor in the vertical position at the

installation site.

C. TESTING BEFORE SPLICING POWER

CABLE TO MOTOR LEADS

Perform the following tests before making the

splice between the motor leads and the drop

cable. Instructions for performing resistance

tests and evaluating the results are given in

Appendix C.

Motor Tests

• Measure the resistance between each motor

lead and ground with the motor submerged in

water. (See Appendix C)

• Measure the resistance of the motor windings.

(See appendix C) Record the values for future

reference.

• Secure the pump and motor with chain tongs to

resist torque. Energize the motor momentarily

(on and immediately off) to check the rotation.

WARNING

GROUND THE UNIT WHEN TESTING. FAILURE TO

GROUND THE UNIT PROPERLY CAN RESULT IN

SERIOUS OR FATAL SHOCK. ALSO,THE HIGH

STARTING TORQUE OF THE MOTOR WILL CAUSE

IT TO ‘KICK’WHEN POWER IS APPLIED. THE

UNIT SHOULD BE RESTRAINED SUFFICIENTLY

TO PREVENT DAMAGE TO THE EQUIPMENT OR

PERSONAL INJURY.

NOTE

ROTATION WILL BE COUNTERCLOCKWISE

WHEN VIEWED FROM THE DISCHARGED BOWL.

On three phase unit, if rotation is wrong, interchange

any two of the motor leads at the control panel.

CAUTION

CORRECT ROTATION IS OF EXTREME IMPOR-

TANCE. EXCESSIVE OVER-LOADS MAY BE

DEVELOPED UNDER OPERATING CONDITIONS

WITH REVERSE ROTATION.

Drop Cable Test

• Measure the resistance between the cable

conductors and ground with the cable submerged in water. (See Appendix C)

D. SPLICING POWER CABLE TO MOTOR LEADS

A waterproof splice must be made to connect

the power cable to the motor leads. A properly made splice will last the life of the pump.

An improperly made splice will become a

service problem. Make the splice per instructions supplied with the drop cable or per

instructions in the pump motor manual. The

splice should be located above the pump

bowl. It should be as compact as possible. A

compact splice is less likely to be damaged

as the pump is being lowered into the well.

(See Appendix B for instruction on splicing

the cable.)

E. TESTING AFTER SPLICING POWER CABLE

TO MOTOR LEAD

Perform the following test after making the splice,

but before lowering the pump into the well.

• Check that the splice is waterproof by

immersing it in a container of water for

approximately one hour and then taking

resistance readings between each cable conductor and the water. (See Appendix C)

• Measure the total resistance of the complete

drop cable and motor circuit to insure that a

good splice was made. Record the values for

future reference.

CAUTION

THE MINIMUM READING FOR EACH LEAD TO

GROUND SHOULD BE 50 MEGOHMS.

6

Page 15

SECTION 5 – INSTALLING

THE PUMP

5-1 Check the pump and motor shaft to make

sure they turn free before installation. For some

models, it may be necessary to remove the suction screen in order to check the shaft. Be sure to

re-install the suction screen.

5-2 Raise the bowl/motor assembly with the shipping skids still in place. Remove the shipping

skids, and lower assembly into the well, clamping

the bowl assembly near the top.

5-3 Attach the elevators to the bottom column

pipe immediately below the column coupling.

Hoist the column section into place above the well

and the top of the bowl assembly, providing a soft

board or pipe dolly for the end of the column pipe

to slide in on so that threads will not be damaged

while the section is being raised. Clean all

threads with thread lubricant. Thread the pipe into

the discharge bowl connection and make up tight,

using one set of chain tongs for back-up.

CAUTION

THE PUMP MOTOR WILL EXERT A TORQUE THAT

WILL TEND TO UNSCREW THREADED COLUMN

PIPE CONNECTIONS. FOR THIS REASON,

THREADED COLUMN JOINTS MUST BE TIGHTENED. Following table gives the normal amount

of thread engagement necessary to make a tight

joint for the NPT thread joint:

Pipe size Length of thread (in.) No. of threads

3" 1" 8

4" 1-1/8" 9

5" 1-1/4" 10

6" 1-5/16" 10-1/2

8" 1-7/16" 11-1/2

10" 1-5/8" 13

5-4 Install a cable clamp on each side of the cable

splice. (See Figure 3.1.) Be careful not to damage the cable. If an air line is to be installed, route

it beside the cable, making sure that it is not

pinched by the clamps. If there is any danger that

the splice will rub against the well casing during

installation, it should be protected by thick rubber

chaffing pads or by a steel shield. Check that the

grounding system is in place.

WARNING

FAILURE TO GROUND THE UNIT PROPERLY CAN

RESULT IN SERIOUS OR FATAL SHOCK. REFER

TO ELECTRICAL CODE REQUIREMENTS.

5-5 Slowly lower the unit into the well (or sump)

adding joints of column pipe as the unit is lowered.

Tighten each joint securely. See note above.

Remove slack from the power cable and attach a

cable clamp approximately every 20 feet. For

units with large heavy power cable, additional

cable clamp may be required to give additional

support. Line up the cable on one side of the

pump and maintain as much clearance as possible on that side when lowering the pump in the

well. BE EXTREMELY CAREFUL NOT TO

SCRAPE OR DAMAGE THE POWER CABLE,

CABLE SPLICE, OR GROUNDING SYSTEM

WHEN LOWERING THE PUMP. Hold the power

cable up away from the well casing as lowering

the pump into the casing.

5-6 If the pump does not have a built-in check

valve, a line check valve should be installed within

25 feet above the pump bowl assembly. For a

deep setting pump, a line check valve is recommended for every 200 ft of column pipe. However,

no check valve should be installed above the

pumping level.

5-7 As soon as the splice joint is submerged in

the water, take a resistance reading between the

power cable conductors and ground to assure that

the insulation and the cable or the splice was not

damaged during installation.

5-8 After the last piece of column pipe has been

installed, install the well head. Install a cable

clamp between the last column pipe coupling and

the well head base. (See Fig. 3.1.) Route the

power cable and grounding system through the

large threaded hole in the head base. Route the

air line (if used) through one of the smaller threaded holes in the head base. The remaining small

threaded hole is for connection of a well vent or

other accessories. All of these holes are threaded

with standard NPT or BSP pipe threads. If a gasket is required between the head base and its

mounting surface, the gasket should be placed on

the foundation prior to installing the well head.

5-9 After the well head has been properly tightened, carefully rotate the entire unit in the well

until the discharge flange is facing in the desired

direction. Push the unit to one side of the well,

providing the maximum clearance for the drop

cable when rotating the unit.

5-10 Slowly lower the well head onto its mounting surface. BE CAREFUL NOT TO DAMAGE

THE GROUNDING SYSTEM OR PINCH THE

POWER CABLE BETWEEN THE SURFACE

7

Page 16

PLATE AND THE WELL CASING. If a gasket or

other seating device is used, be sure that it is

aligned properly and that it is not damaged. Install

the mounting bolts.

5-11 Before connecting the power cable to the

control panel:

Take a resistance reading between the power

cable conductors and ground to assure that the

insulation on the cable or splice was not damaged

during installation. (See Appendix C)

Measure the resistance of the power cable and

motor circuit. (See Appendix C) Compare these

readings with those taken in Section 4 to assure

that the splice is still intact. Make the electrical

connection between the power cable and the control panel. It may be desirable to use a terminal

box at the well head to simplify the electrical work

required when the pump is pulled. Be sure that

the unit is grounded properly.

WARNING

FAILURE TO GROUND THE UNIT PROPERLY CAN

RESULT IN SERIOUS OR FATAL SHOCK. REFER

TO ELECTRICAL CODE REQUIREMENTS.

Be sure to connect the leads as they were marked

previously in the procedure.

SECTION 6 – STARTING THE PUMP

CAUTION

INITIAL START-UP AND TESTING MAY REQUIRE

STARTING AND STOPPING THE PUMP SEVERAL

TIMES. BE SURE TO ALLOW ADEQUATE COOL-

ING OFF PERIOD BETWEEN STARTS. CONSULT

THE MOTOR MANUAL. IF NO INFORMATION IS

GIVEN, A GOOD RULE-OF-THUMB IS TO ALLOW

A MINIMUM OF 15 MINUTES BETWEEN STARTS.

For initial start-up allow the water to be pumped

out onto the ground. A throttle valve in the discharge line is recommended. Position the throttle

valve approximately one-forth open for start-up of

the pump. This will prevent surging the well or the

pump during start-up.

If the pump has been in the well for several days

before the start-up, check the resistance between

the cable conductor and ground to assure that

water has not penetrated the splice or the cable

insulation. (See Section 4)

Clamp the tongs of a clamp-on type ammeter

around one power lead to the pump. Set the

ammeter on the maximum scale. After the motor

starts, it can be reset to a lower scale as desired.

Refer to the motor manual and determine the normal operating amps for the installed motor.

Start the pump and observe and record the current readings on each conductor of the power

lead. If the current exceeds the normal value

determined in the motor manual, stop the pump

immediately. A high current reading indicates that

something is wrong. Among the potential problems are:

• Incorrect pump rotation (3 phase only)

• Improper voltage

• Sand locked pump

• Improper cable size or leak in cable

• Mechanical damage

In any case, the problem must be corrected before

the pump can be operated.

On three phase units if water does not appear

within one minute (deeper settings may require

approximately one half minute per 100 ft setting)

the motor may be running backwards. Stop the

pump and interchange any two of the three cable

connections. If there is any doubt about the proper rotation, run the motor in one direction and then

the other. The rotation that gives the highest pressure and flow is always the correct one.

Check the voltage. The voltage when the pump is

running should be within 5% of the pump motor

nameplate voltage.

Open the throttle valve. If a flow meter is available, open the throttle valve to rated flow of the

pump. If sand appears in the water, throttle the

pump at approximately 80% of full flow until the

sand clears. If excessive noise develops, pressure fluctuates, or water appears foamy white, the

pump is probably cavitating and the flow should

be throttled until the noise diminishes, the pressure remains steady, and the water is clear.

On three phase units check for current unbalance.

Details of the current unbalance test are given in

the Appendix C. THE MAXIMUM ALLOWABLE

CURRENT UNBALANCE IS 5%. If the current

unbalance exceeds 5% after rolling the leads and

connecting them for the lowest unbalance, the

pump should be stopped and corrective action

taken. Current unbalance in excess of 5% can be

expected to cause excessive heating in the motor

and premature failure. Operation with a current

unbalance in excess of 5% will void the warranty.

8

Page 17

After the unit is operating properly, a performance

test should be considered. If a performance test is

conducted when the pump is new, subsequent tests

can be used to determine the degree of wear or

deterioration of the pump without removing it from

the well. After the unit has been in operation for

approximately one week, perform the routine tests.

SECTION 7 – PUMP DISASSEMBLY

AND REASSEMBLY

7-1 Clear a large area adjacent to the pump

as storage space for pump parts as they are

disassembled. If the pump has a long column,

arrange parallel timbers on the ground to support

the pump column horizontally. After disassembly

for repair or replacement of pump components,

reassemble in all cases in the reverse order of

disassembly.

NOTE

PUMP COMPONENTS SHOULD BE MATCH-

MARKED PRIOR TO DISASSEMBLY.

7-2 It is recommended that maintenance person-

nel become thoroughly familiar with the VS pump

before performing any removal of the components.

Consult the manufacturer’s instructions for

detailed disassembly information for the motor.

A. Remove the electrical connection at the con-

duit box and tag electrical leads at the motor.

WARNING

BEFORE OPENING THE CONDUIT BOX OF AN

ELECTRICAL MOTOR, BE SURE THE CURRENT

TO THE MOTOR IS SHUT OFF. SEVERE INJURY

TO PERSONNEL COULD RESULT IF CONTACT

WITH LIVE MOTOR LEADS IS MADE

LOCK OUT SHOULD BE INSTALLED BEFORE

ANY ELECTRICAL WORK IS PERFORMED

NOTE

MATCH-MARK PARTS IN SEQUENCE OF

DISASSEMBLY TO AID IN THE REASSEMBLY

PROCEDURE.

B. Disconnect the discharge piping from well head.

WARNING

DO NOT WORK UNDER A HEAVY SUSPENDED

OBJECT UNLESS THERE IS A POSITIVE SUP-

PORT UNDER IT WHICH WILL PROTECT PER-

SONNEL SHOULD A HOIST OR SLING FAIL.

7-3 PUMP DISASSEMBLY

In the following pump disassembly procedures

references are made to installation sections of

this manual, these sections will aid in the disassembly of the pump.

Fig 7.1 Bowl and Motor Assembly

9

Page 18

A. Disconnect well head and begin removal of

column sections. Refer to Section 5-7.

B. For removal of bowl/motor assembly, hoist

the bowl/motor assembly from the well, using

elevator clamps. Hoist in the same manner

as for the column. For the keyed motor shaft,

loosen the setscrews on the motor end of the

shaft coupling. Remove the motor lead from

the cable guard. Disassemble the bowl

assembly from the motor by removing the

connecting bolts at the flange joint. For the

short assembly laying the bowl/motor assembly on the ground to perform these works.

For the long or large size assembly, it is recommended to perform these works while the

assembly is in the vertical position. Refer to

Section 4-3. Proceed to disassemble the

bowl assembly as follows.

7-4 BOWL DISASSEMBLY

The bowl assembly shown in Figure 7.1 is composed of a discharge bowl (For the model with

built-in check valve, it would be column adapter),

intermediate bowl, impellers with taper collects,

motor adapter, bearings and pump shaft.

A. Begin disassembly by removing the cap-

screws that secure the top stage intermediate

bowl and the 2nd stage intermediate bowl

and slide the discharge and top intermediate

bowls off the pump shaft together. Remove

the thrust washer.

B. Pull shaft out as far as possible and strike

impeller hub utilizing a taperlock driver or

equivalent sliding along the pump shaft to

drive the impeller off the taperlock

(see Figure 7-2).

Fig. 7-2 Disassemble the Impeller

C. After impeller is freed, insert a screwdriver

into the taperlock to spread it, Slide taperlock

and impeller off the pump shaft.

D. Use the preceding procedures until entire turbine

bowl assembly is completely disassembled.

7-5 TURBINE BOWL – WEAR RINGS

REMOVAL (OPTIONAL)

A. Utilizing a diamond point chisel, cut two ‘V’

shape grooves on the bowl wear ring approximately 180 degrees apart. Use extreme care

not to damage the wear ring seat.

B. With a chisel or equal, knock the end of one

half of the ring in, and pry the ring out.

C. On special materials such as chrome steel,

set up the bowl in a lathe and machine the

wear ring off, use extreme care not to

machine or damage the ring seat.

7-6 TURBINE BOWL – IMPELLER WEAR

RING REMOVAL (OPTIONAL)

Set up impeller in a lathe and machine wear ring

out, use extreme care not to machine or damage

ring seat or impeller hub. Impeller wear ring may

also be removed by following steps A and B

paragraph 7-5.

7-7 BOWL BEARING REMOVAL

Utilizing an arbor press and a piece of pipe or

sleeve with outside diameter slightly smaller than

bowl bearing diameter press the bearing out.

7-8 INSPECTION AND REPLACEMENT

A. Clean all parts thoroughly with a suitable

cleaner.

B. Check bearing seats for deformation and

wear.

C. Check pump shaft for straightness and exces-

sive wear on bearing surfaces. Check

straightness of the pump shaft. The straightness should within 0.0005”/ft TIR.

D. Visually check impellers and bowls for cracks

and pitting. Check all bowl bearings for

excessive wear and corrosion.

7-9 TURBINE BOWL AND IMPELLER

WEAR RING INSTALLATION

(OPTIONAL)

Place chamfered face of bowl or impeller wear

ring towards the ring seat and press. Use an

arbor press or equal. Make sure ring is flush with

edge of wear ring seat.

10

TAPERLOCK DRIVER

DISASSEMBLY POSITION

SHAFT

IMPELLER

BOWL

Page 19

7-10 BOWL BEARING INSTALLATION

Press the bearing into all the bowls by using an

arbor press or equivalent. Press the bearing in

from the bottom end of the hub until the bottom

end of the bearing is flush with the bottom end of

the hub.

7-11 TURBINE BOWL WITH TAPERLOCK

– REASSEMBLY

A. Secure the submersible assembly jig to the

motor end of the motor adapter (See fig. 7-3).

Be sure to use the proper jig for the motor

frame size the bowl assembly is intended to

adapt to.

B. Put some grease in the suction bearing of the

motor adapter. Slide the shaft through the

bearing. Secure the shaft in place by locking

the shaft to the assembly jig with a special

long bolt or all thread and a hex nut.

(See Fig. 7-3)

Figure 7-3 Assembly Jig

C. Slip impeller over the shaft. Then slip taper-

lock over the shaft with smaller end towards

impeller. A screwdriver can be used to

spread the taperlock for ease in slipping over

the shaft.

D. Hold impeller firmly against the motor adapter

and drive the taperlock into place with the

taperlock driver. (See Figure 7-3) After the

impeller is secured in position, the top end of

the taperlock should be 1/8” above the

impeller hub.

Fig. 7-4 Install the Impeller

E. Put a little grease on the shaft where the

intermediate bearing will be. Slip intermediate bowl over the shaft and bolt or screw it

onto the motor adapter.

F. Place the next impeller over the shaft and

continue to assemble as explained above.

G. After assembling the last impeller, slide the

upthrust washer over the shaft before assembling the top intermediate.

H. Slide the discharge case and top intermediate

bowl over the shaft and bolt it to the 2nd

intermediate bowl. If the pump has built-in

check valve, install the check valve before

installing the discharge adapter.

I. When the bowl is completely assembled,

unlock the shaft and remove the assembly jig.

Rotate the shaft by hand to see whether it

rotates freely. Push the shaft all the way in

and then pull it all the way out to check the

lateral clearance. The lateral should be

between 0.187" to 0.250".

J. Install the square key in the keyway at the

motor end of the pump shaft. Slide the shaft

coupling over the shaft and secure it to the

key with two setscrews.

11

Page 20

12

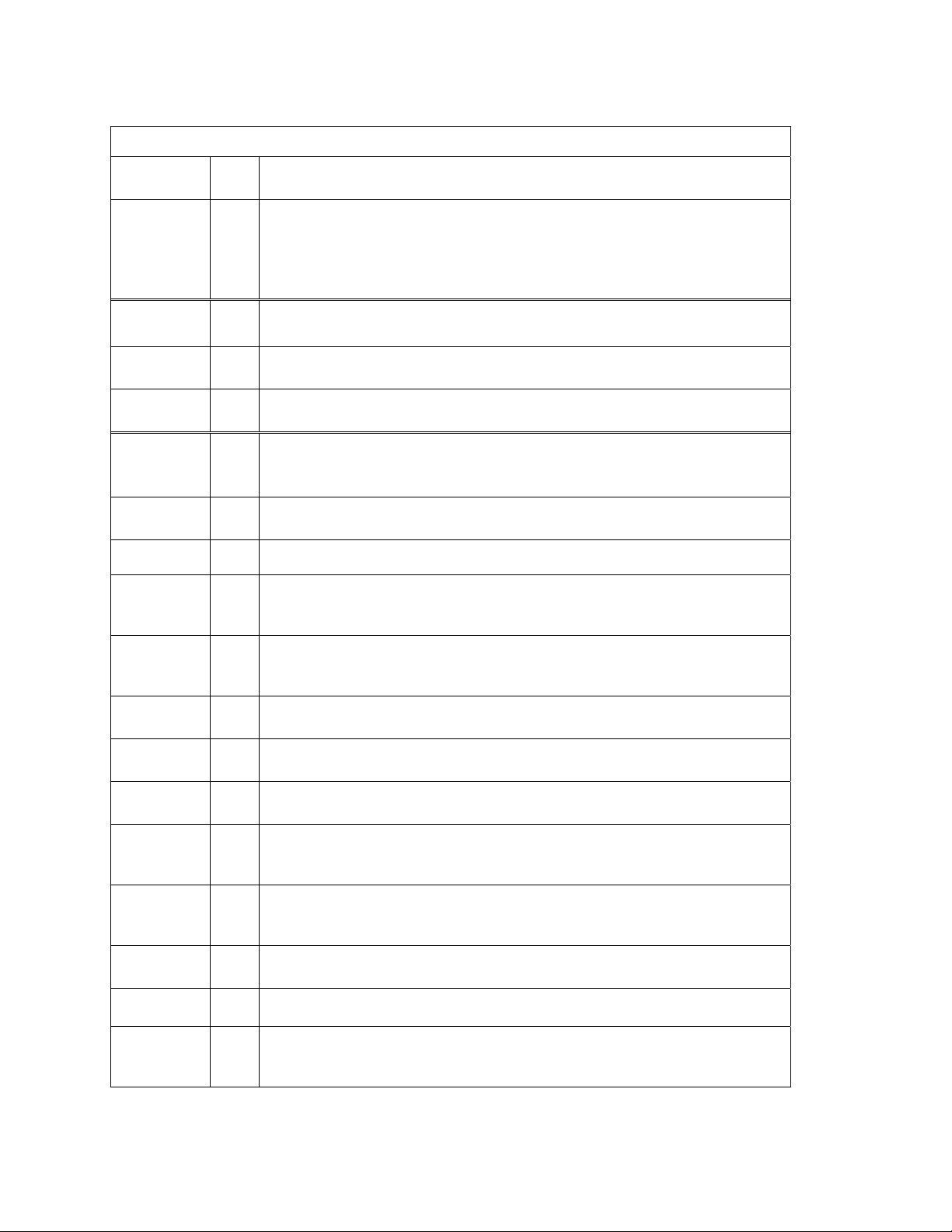

SECTION 8 – TROUBLE SHOOTING CHART

In case of difficulties, refer to the chart to locate basic problems with the system. Once the problem is

located, refer to specific sections in this manual for details.

PROBABLE CAUSE

1 Motor overload protector trip

a. Incorrect control box.

b. Incorrect connections.

c. Faulty overload protector.

d. Low voltage.

e. Ambient temperature of control

box or starter too low.

f. Pump bound by foreign matter.

2. Blown fuse, broken or loose electric

connections.

3. Motor control box or starter not in

proper position.

4. Cable insulation damaged.

5. Splice may be open or grounded.

6. Faulty pressure switch.

7. Faulty liquid level control.

1. Line check valve backward.

2. Pump is air-bound.

3. Lift too high for the pump..

4. Suction screen or impeller plugged, or

pump in mud or sand.

5. Pump not submerged.

6. Well may contain excessive amounts

of air or gas.

7. Three-phase unit running backwards.

1. Lift too high for the pump.

2. Screen or impellers partly plugged.

3. Scaled or corroded discharge pipe or

leaks anywhere in system.

4. Well may contain excessive amounts of

air or gas.

5. Excess wear due to abrasives

6. Three-phase pump running backward.

1. Incorrect set.

2. Switch opening plugged.

3. Leaks anywhere in system.

4. Three-phase unit running backward.

1. Water-logged tank.

2. Check valve leaking.

3. Pressure switch out of adjustment.

4. Leaks in service line.

REMEDY

1. Allow motor to cool, overload will

automatically reset. Investigate cause

of overload.

a– e Have a qualified electrician inspect

and repair, as required

f. Pull the pump, examine and clean.

Adjust set depth as required.

2. Check fuses, relays or heater elements

for correct size capacitor and all

electrical connections.

3. Make sure box is in upright position.

4. Locate and repair as per instructions.

5. Check resistance between cable leads

with ohmmeter. If open or grounded, pull

pump and re-splice.

6. Repair or replace.

7. Check relay, wires and electrodes.

1. Reverse check valve.

2. Successively start and stop pump until

water flows normally.

3. Review performance requirement.

4. Pull the pump and clean, check well

depth. Raise setting if necessary.

5. Check water level. Lower pump if

permissible.

6. Start and stop pump several times. If

this does not remedy conditions, pump

may not be able to co-operate because

of too much gas in the well.

7. Reverse rotation.

1. Check rating.

2. Pull pump and clean.

3. Replace pipe and repair leaks.

4. Start and stop pump several times. If

this does not remedy conditions, pump

may not be able to co-operate because

of too much gas in the well.

5. Replace worn parts.

6. Reverse rotation.

1. Change settings.

2. Clean opening or install new switch.

3. Repair leaks.

4. Reverse rotation.

1. Check tank for leaks (plug at top of tank

may be leaking air).

b. Be sure drain and ‘Y’ fittings are

functioning properly. Check operation of

snifter valve.

2. Replace check valve.

3. Readjust to correct setting or replace.

4. Locate and correct.

CONDITION

PUMP WILL NOT RUN

PUMP RUNS BUT

NO WATER

DELIVERED

REDUCED

CAPACITY OR

INSUFFICIENT

TANK PRESSURE

PRESSURE SWITCH

DOES NOT CUT OUT

PUMP STARTS TOO

FREQUENTLY

Page 21

APPENDIX A – ASSEMBLY OF

PUMP AND MOTOR

Most of the time, the pump and the motor are

shipped separately in two different boxes. They

need to be assembled together in the field prior to

being installed in the well. For the short pump

(lease than 5 stages), the motor and pump may

be assembled together on the ground horizontally.

If the pump is over 6 stages long, it is recommended to assemble them in the vertical position.

1. Check that the pump shaft and the motor

shaft turn freely.

2. Clean the flange faces and the registers on

the pump and the motor. Remove all burrs

from these areas. Clean the exposed portion

of the pump shaft and motor shaft. If the

pump is supplied with the coupling assembled

on the shaft, clean the inside of the motorend of the coupling.

3. Install the key on the motor shaft, if it is not

the splined shaft.

4. If the shaft coupling has setscrews in the

motor half of the coupling, loosen or remove

these setscrews.

5. Align the motor with the pump and slide the

motor shaft into the shaft coupling on the

pump until the shaft butts. Make sure the

motor shaft lifts the pump shaft by 1/8" to

1/4". (for enclosed impeller only) Be careful

not to damage the shaft, the coupling or the

key. Orient the motor so that the motor leads

are aligned with the notch provided in the

pump’s mounting flange. If the shaft coupling

has setscrews in the motor half the coupling,

install and tighten the setscrews.

6. Install and tighten the mounting bolts (or capscrews) on the flange.

7. Untie the cableguard on the pump and reassemble it with the motor leads under the

cableguard to prevent damaging the leads

when lower the pump into the well.

Appendix B – SPLICING POWER

CABLE TO MOTOR LEADS

A waterproof splice must be made to connect the

power cable to the motor leads. A properly made

splice will last the life of the pump. An improperly

made splice will become a service problem. In the

market, there are different materials and methods

to make water proof cable splices.

For example: by waterproof tapes

by resin castings

by heat shrink tubes

All of these system are well-known and fieldproven for many years. It is installer’s decision to

choose one of the systems available. Following

are the procedures for waterproof tapes and resin

castings splices:

Taped Cable Splice:

1. Strip the insulation of each conductor of the

power cable back enough to allow the conductor to extend half way through a sleeve

type connector. Crimp connector to the conductor. Strip the insulation of the motor lead

same as the power cable. Fit it into the connector and butt against cable end. Crimp

connector as before. Pull on wire to make

sure connector is firmly crimped to both the

motor lead and the power cable. Scrape the

insulation to move any loose bits of tape or

thread and roughen surface. Thoroughly

clean surface with solvent. This will insure a

watertight splice.

2. Tape individual joints with rubber electrical tape

start at the center of the connector, and tape 2

inches past the end of conductor insulation

end. Stretching tape about 10% while taping.

Overlap tapes about one half of tape width.

Make two layers. The end of 2nd layer should

be 2 inches beyond the end of the first layer.

3. Tape over the rubber electrical tape with #33

Scotch electrical tape or equivalent, using two

layers as in step #2 and making each layer

overlap the end of the preceding layer by

2 inches.

Cast Cable Splice:

1. To prepare the 3-conductor power cable for

splicing, insert a sharp knife blade between

the cable jacket and lead insulation and strip

the jacket back 2.5” from the end. Taking care

not to cut the lead insulation. Strip the cambric wrapping (if any) off the conductors and

strip back rubber insulation 5/8” from the end.

Assemble the cable connectors and crimp

them in place using a crimping tool.

2. Cut off the motor leads to equal length. Clean

off the ends of the leads for about a foot,

using a cloth wet with gasoline or solvent.

Clean the end of the power cable also. Insert

13

Page 22

the three motor leads into the corresponding

holes in the bottom of the rubber casing and

push them several inches out the top. Crimp

the motor leads into the corresponding connectors, crimping the center one first. Bend

the cables into line with the holes in the casing

and slip the casing up until the connectors are

inside the holes and about

1

/

4" from the top.

3. Mix the resin as directed. Cut off a corner of

the bag and squeeze all of the resin into casing. With the roll of tape on hand, fold the

bag, and tape the top of the bag snugly to the

power cable until the resin runs out over the

top. This will assure maximum coverage of

the resin and minimum size of the finished

splice. When the resin is firm to touch, the

splice may be immersed for testing.

In case of splicing cables of a six-lead motor

for y-delta starting, be sure that the extension

cable continue with the same lead colors and

phase designation as original motor leads.

This will ease up above ground connection to

the Y-Delta panel or an external delta connection for DOL start.

APPENDIX C – ELECTRICAL TESTS

1. MEASURING INSULATION

RESISTANCE (GROUND TEST)

The condition of the insulation around a conductor

can be determined by measuring the electrical

resistance between the conductor and ground.

This measurement can be made with a meggar or

an ohm-meter. The value is stated in ohms or

megohms (ohms x 1,000,000). High ohm values

indicate good insulation.

The basic procedure for measuring insulation

resistance is given below:

a. Turn off all power and disconnect the leads to

be tested from the electrical panel. Lock out

the panel.

WARNING

FAILURE TO TURN OFF THE POWER WILL

DAMAGE THE METER AND CAN CAUSE

SERIOUS OR FATAL SHOCK.

Failure to disconnect the leads can result in false

readings.

b. Set the meter selector knob to RX 100K or

RX 100,000 (some meters may not have RX

100K in which case EX 10K or EX 10,000

scale can be used). Clip the meter leads

together and adjust the meter to zero.

c. Unclip the leads and attach one of the meter

leads to the one of power cable leads or

motor leads. The other meter to the ground.

d. Do not touch any bare wires or allow bare

wires to come in contact with the ground or

metal. False readings will result.

e. If the meter needle is at either extreme end of

the scale, a more accurate reading can be

obtained by switching the selector switch to

another scale. Re-zero the meter each time

the selector switch is moved.

The readings obtained from power cables and

motor leads should be within the range specified

in Table C.1. Low readings indicate that the motor

windings are grounded or that the cable or splice

insulation is damaged. If low or marginal readings

are obtained on a new installation the problem

should be corrected before proceeding with the

installation.

2. MEASURING RESISTANCE

BETWEEN LEADS (MOTOR

WINDING RESISTANCE)

The general conditions of motor windings can be

determined by measuring the resistance of the

motor windings (i.e. the resistance between the

motor leads) and comparing the measured resistance with values given in the motor manual. The

resistance is measured with an ohm-meter and

the value is stated in ohms.

The basic procedure for measuring motor winding

resistance is given below.

a. Turn off the power and disconnect the leads to

be tested from the panel. Lock out the panel.

WARNING

FAILURE TO TURN OFF THE POWER WILL

DAMAGE THE METER AND CAN CAUSE SERIOUS

OR FATAL ELECTRICAL SHOCK.

Failure to disconnect the leads can result in false

readings.

b. Set the meter selector knob to ‘Rx 1’. Clip the

meter leads together and adjust the meter to zero.

c. Unclip the meter leads and attach them to the

motor leads.

Resistance measured between the motor leads

prior to splicing the power cable to the motor leads

should be within the motor winding resistance

limits specified in the motor manual.

14

Page 23

15

Resistance measured between the power cable

leads after splicing the power cable to the motor

leads will indicate the resistance of the power

cable plus the motor windings. The motor winding

resistance is obtained by the formula below. The

calculated value should be within the limits specified in the motor manual.

Motor Winding = Reading taken - Cable resistance

Resistance = at Power Cable - from Table 2

A higher winding resistance than shown in the

motor manual indicates a possible burned (open)

winding, an open cable, a loose connection, or the

wrong motor (different HP or voltage than readings

being referenced).

A considerably lower winding resistance than

shown in the motor manual indicates a possible

shorted (burned together) winding or the wrong

motor.

Unequal resistance between the windings on a

three phase motor indicates a burned winding or a

faulty connection.

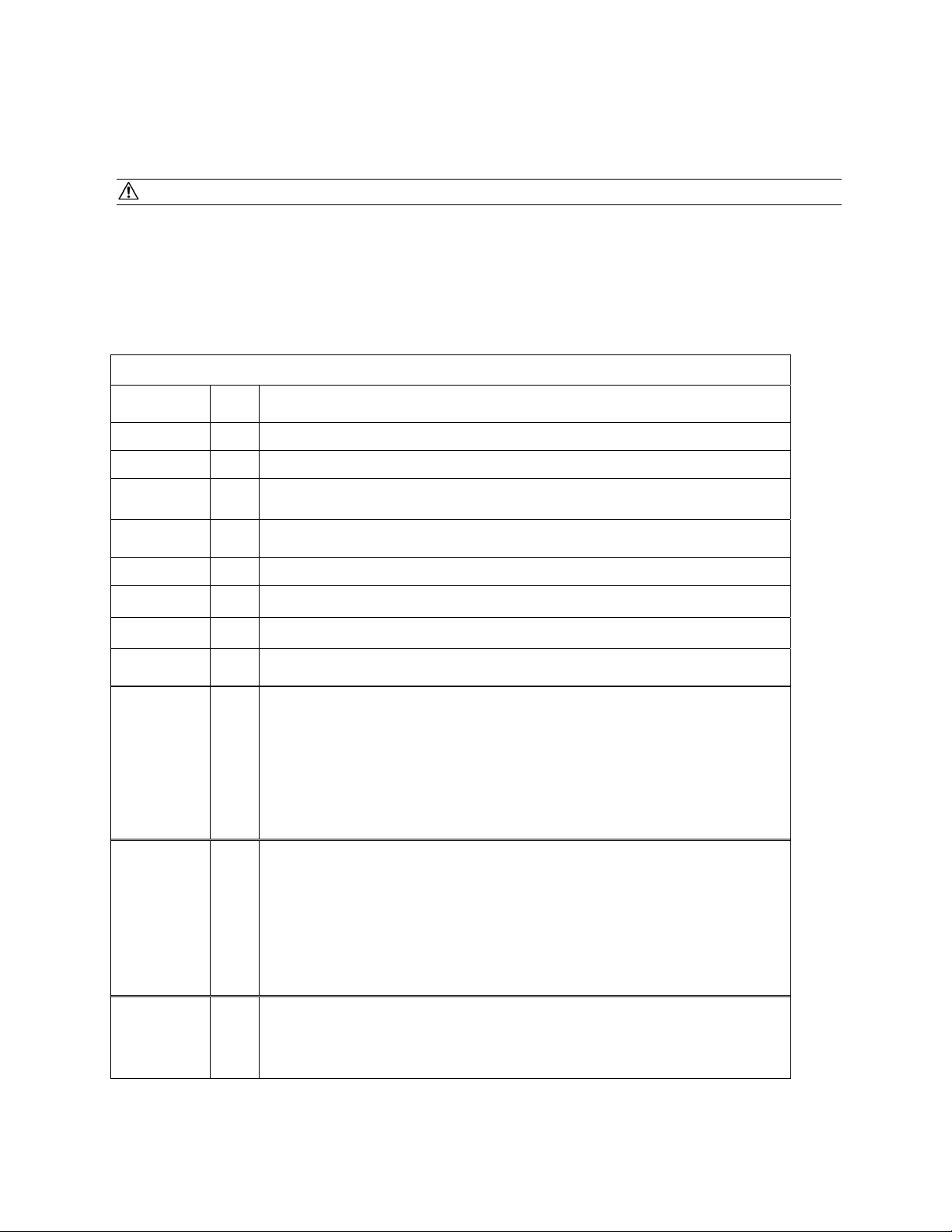

TABLE C. 1 – NORMAL INSULATION RESISTANCE VALUES BETWEEN ALL LEGS AND GROUND

Insulation resistance does not vary with rating. Motors of all HP, voltage, and phase rating have the same

insulation resistance ranges.

METER READING

R x 100K R x 10K

CONDITION OF MOTORS AND LEADS OHMS MEGOHMS or or

R x 100,000 R x 10,000

Scale Scale

BENCH TESTS

• A new motor (without drop cable). 20,000,000 + 20+ 200+ 2000 + or 2K +

• A used motor which can be reinstalled 10,000,000 + 10+ 100+ 1000 + or 1 K +

in the well.

• Cable splice after immersion for one 2,000,000+ 2+ 20+ 200+

hour in water.

WELL TESTS Ohm readings are for drop

cable plus motor.

• A new motor or used motor in good 2,000,000+ 2+ 20+ 200+

condition.

• A motor in reasonably good condition. 500,000- 0.5-2.0 5-20 50-200

2,000,000

• A motor which may have been

damaged by lightning or with 0.02-0.5 0.2-5 2-50

damaged leads. Do not pull the pump 20,000-500,000

for this reason.

• A motor which definitely has been

damaged or with damaged cable. 0.01-0.02 0.1-0.2 1-2

The pump should be pulled and 10,000-20,000

repairs made to the cable or the motor

replaced. The motor will not fail for

this reason alone, but will probably

not operate for long.

• A motor which has failed or with

completely destroyed cable insulation. 0-0.01 0-0.1 0-1

The pump must be pulled and the Less than 10,000

cable repaired or the motor replaced.

+ Indicates that the reading should be the value shown or greater. Higher readings indicate better insulation.

Page 24

16

The values below are for copper conductors. If aluminum conductor drop cable is used, the resistance

will be higher for each foot of cable of the same size.

To determine the actual resistance of aluminum drop

cable, divide the ohm readings from this chart by

0.61. This chart shows total resistance of cable from

control box to motor and back.

TABLE C. 2 – POWER CABLE RESISTANCE

Page 25

17

3. CURRENT UNBALANCE TEST:

For three phase units, after correct rotation has

been established, check the current in each of the

three motor leads and calculate the current unbalance as explained below. If the current unbalance

is 2% or less, leave the leads as connected. If the

current unbalance is over 2%, current readings

should be checked on each leg using one of three

possible hook-ups indicated in the Table below.

Roll the motor leads across the starter in the same

direction to prevent motor rotation reversal. This

procedure is commonly known as “rolling the

leads”. THE HOOKUP THAT RESULTS IN THE

LOWEST PERCENT CURRENT UNBALANCE

SHOULD BE USED FOR THE FINAL CONNECTION OF THE POWER LEADS.

b. Current unbalance is determined by measur-

ing the amperage of each of the three legs

and then calculating the percent current

unbalance using the formula below. This calculation must be performed using each of the

three hookups shown.

Percent Current Unbalance =

Maximum current difference in

any leg from average current

Average current

x

100

Measure current in

each leg.

Add leg currents to

determine total

current.

Calculate average leg

current.

Determine maximum

difference of any one

leg from the average.

Calculate percent

unbalance using

formula above.

Sample Calculation

T1 L1 51 amps

T2 L2 46 amps

T3 L3 53 amps

=======

150 amps

÷ 3

=======

50 amps

51 – 50 = 1

50 – 46 = 4 max

53 – 50 = 3

x 100 = 8%

4

50

T1 L1 ________

T2 L2 ________

T3 L3 ________

=======

___ - ___ = ___

___ - ___ = ___

___ - ___ = ___

___ x 100 = % ___ x 100 = % ___ x 100 = %

T3 L1 ________

T1 L2 ________

T2 L3 ________

÷3

=======

___ - ___ = ___

___ - ___ = ___

___ - ___ = ___

T2 L1 ________

T3 L2 ________

T1 L3 ________

÷3

=======

___ - ___ = ___

___ - ___ = ___

___ - ___ = ___

÷3

Page 26

18

c. THE CURRENT UNBALANCE BETWEEN

LEGS SHOULD NOT EXCEED 5% at service

factor load or 10% at rated input load. If the

unbalance cannot be corrected by rolling

leads, the source of the unbalance must be

located and correct.

d. By observing where the furthest current reading

from the average is for each leg of each of the

hookups, the cause of the unbalance can be

determined. If the leg furthest from average is

always on the same power lead, this indicates

that most of the unbalance is from the power

source. If the leg furthest from average is

always on the same motor lead, the primary

source of unbalance is on the “motor side” of

the starter. In this instance, consider a damaged cable, leaking splices, poor connection, or

faulty motor winding.

Page 27

19

WARRANTY – Company warrants title to the

product(s) and, except as noted with respect to

items not of Company’s manufacturer, also warrants the product(s) on date of shipment to

Purchaser, to be of the kind and quality described

herein, and free of defects in workmanship and

material. THIS WARRANTY IS EXPRESSLY IN

LIEU OF ALL OTHER WARRANTIES, INCLUDING BUT NOT LIMITED TO IMPLIED WARRANTIES OF MERCHANT-ABILITY AND FITNESS, AND CONSTITUTES THE ONLY WARRANTY OF COMPANY WITH RESPECT TO THE

PRODUCT(S).

If within one year from date of initial operation, but

not more than 18 months from date of shipment

by Company of any item of product(s), Purchaser

discovers that such item was not as warranted

above and promptly notifies Company in writing

thereof, Company shall remedy such nonconformance by, at Company’s option, adjustment or

repair or replacement of the item and any affected

part of the product(s). Purchaser shall assume all

responsibility and expense for removal, reinstallation, and freight in connection with the foregoing

remedies. The same obligations and conditions

shall extend to replacement parts furnished by

Company hereunder. Company shall have the

right of disposal of parts replaced by it. Purchaser

agrees to notify Company, in writing, of any

apparent defects in design, material or workmanship, prior to performing any corrective action

back-chargeable to the Company. Purchaser shall

provide a detailed estimate for approval by the

Company.

ANY SEPARATE LISTED ITEM OF THE PRODUCT(S) WHICH IS NOT MANUFACTURED BY

THE COMPANY IS NOT WARRANTED BY COMPANY and shall be covered only by the express

warranty, if any, of the manufacturer thereof.

THIS STATES THE PURCHASER’S EXCLUSIVE

REMEDY AGAINST THE COMPANY AND ITS

SUPPLIERS RELATING TO THE PRODUCT(S),

WHETHER IN CONTRACT OR IN TORT OR

UNDER ANY OTHER LEGAL THEORY, AND

WHETHER ARISING OUT OF WARRANTIES,

REPRESENTATIONS, INSTRUCTIONS, INSTALLATIONS OR DEFECTS FROM ANY CAUSE.

Company and its suppliers shall have no obligation as to any products which has been

improperly stored or handled, or which has not

been operated or maintained according to

instructions in Company or supplier furnished

manuals.

LIMITATION OF LIABILITY - Neither Company

nor its suppliers shall be liable, whether in contract

or in tort or under any other legal theory, for loss of

use, revenue or profit, or for cost of capital or of

substitute use or performance, or for incidental,

indirect, or special or consequential damages, or

for any other loss or cost of similar type, or for

claims by Purchaser for damages of Purchaser’s

customers. Likewise, Company shall not under any

circumstances be liable for the fault, negligence, or

wrongful acts of Purchaser or Purchaser’s employees, or Purchaser other contractors or suppliers.

IN NO EVENT SHALL COMPANY BE LIABLE IN

EXCESS OF THE SALES PRICE OF THE

PART(S) OR PRODUCT FOUND DEFECTIVE.

Warranty

Page 28

Print in U.S.A.

1/03

Goulds Pumps and the ITT Engineered Blocks

symbol are registered trademarks and trade

names of ITT Industries.

www.goulds.com

Loading...

Loading...