Page 1

INSTALLATION &

OPERATION MANUAL

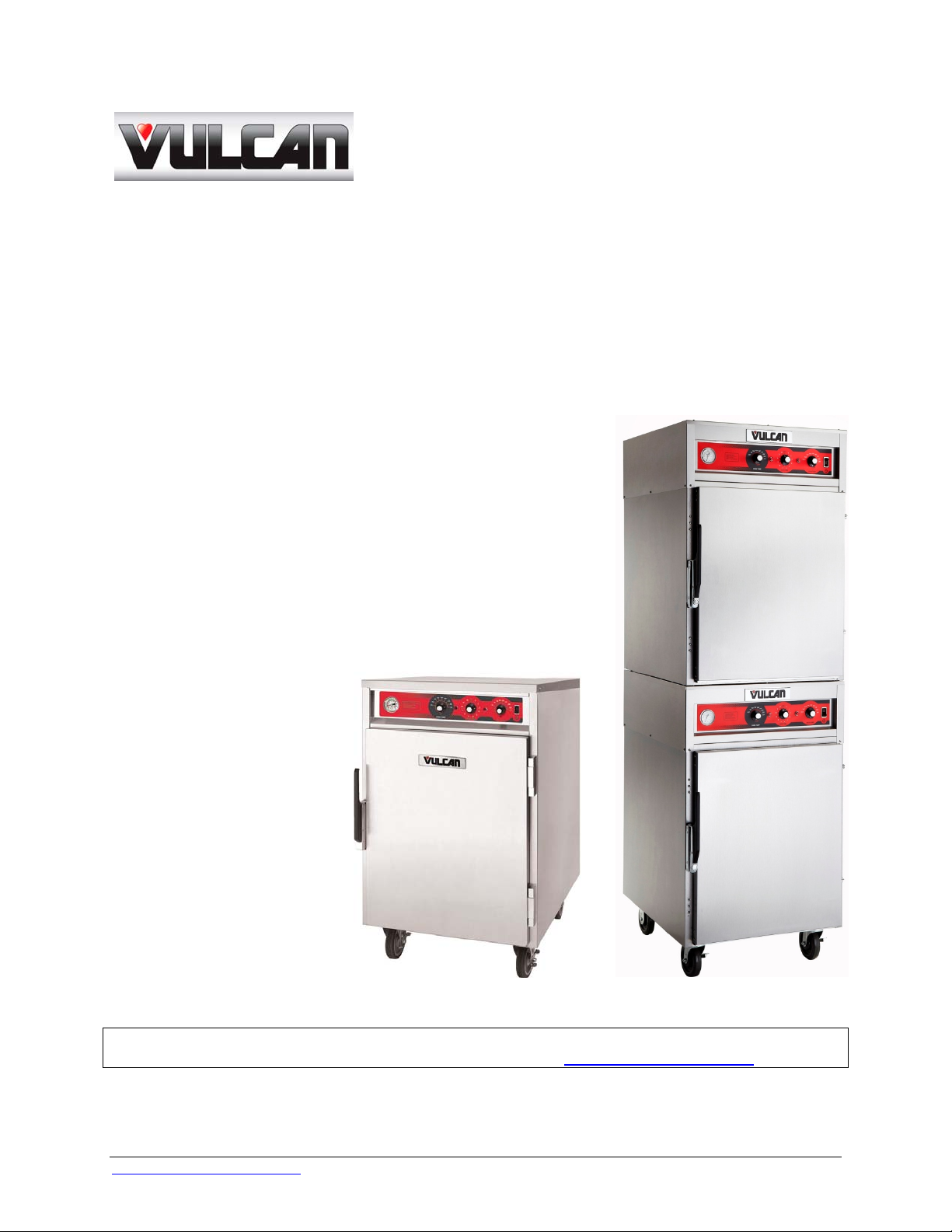

VRH SERIES

OVENS

MODELS:

VRH8 ML-152020

VRH88 ML-152021

For additional information on Vulcan-Hart or to locate an authorized parts

and service provider in your area, visit our website at www.vulcanequipment.com

VULCAN 3600 NORTH POINT BLVD.

DIVISION OF ITW FOOD EQUIPMENT GROUP, LLC BALTIMORE, MD 21222

www.vulcanequipment.com Vulcan ©2016 All Rights Reserved F-41207 (02-16)

Page 2

VRH SERIES OVENS F-41207 (02-16)

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL

ELECTRICAL EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD STARTUP AND ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS MANUAL.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE

VICINITYOF THIS OR ANY OTHER APPLIANCE.

Improper installation, adjustment,

alteration, service, or maintenance can

cause property damage, injury, or death.

Read the installation, operating and

maintenance instructions thoroughly

before installing or servicing equipment.

IN THE EVENT OF A POWER FAILURE,

DO NOT ATTEMPT TO OPERATE THIS DEVICE

1

Page 3

VRH SERIES OVENS F-41207 (02-16)

TABLE OF CONTENTS

IMPORTANT FOR YOUR SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

PRINCIPLES OF COOK & HOLD OVENS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

BENEFITS OF COOK & HOLD OVENS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

COMPARISON OF COOK & HOLD OVENS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

ELECTRICAL REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

OPERATING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

BEFORE FIRST USE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

TESTING THE OVEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

SHUTDOWN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

EXTENDED SHUTDOWN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

DOOR GASKET CARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

COOKING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

COOKING RACK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

COOKING AND HOLDING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 – 13

RETHERMALIZATION GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

GRAMS – LBS./OZ. CONVERSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

TEMPERATURES CONVERSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

LOCKOUT / TAGOUT PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

SERVICE & PARTS INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2

Page 4

VRH SERIES OVENS F-41207 (02-16)

GENERAL

INTRODUCTION

Vulcan Ovens are produced with quality

workmanship and material. Proper

installation, usage, and maintenance of

your oven will result in many years of

satisfactory performance.

The Vulcan Cook & Hold Oven is more

than just an oven – it’s a “System”;

precisely controlled heat, regulated to

retain ascorbic acid and maximize the

nutritional value, taste and eye-appeal

of food. In this environment, virtually

any food product can be prepared to

delicious perfection in just ONE oven!

“System” food preparation eliminates

the need for multiple ovens with

duplicate features.

The Vulcan Cook & Hold Oven is the right choice for low temperature food

preparation.

This manual is provided to assist

persons responsible for the operation

and maintenance of the oven with a

simple, but comprehensive understanding of its proper use. We

recommend that you thoroughly read

this entire manual and carefully follow all

of the instructions provided prior to

placing the oven into operation.

As with any piece of food service

equipment, this oven system requires a

minimum of care and maintenance.

Recommended procedures are

contained in this manual and should

become a regular part of the operation

of the unit.

PRINCIPLES OF

COOK & HOLD OVENS

Vulcan Cook & Hold Ovens are

designed and perfected for cooking at a

lower temperature. The principles of

Low Temperature Cooking and Holding

can be summarized into several

objectives: increased product yields,

increased profits from increased

yields, increased moisture retention,

increased tenderization, and

consistency of doneness.

When the Vulcan Cook & Hold Oven

finishes the cooking cycle, it

automatically switches to the hold cycle.

Throughout this manual we recommend

holding temperatures such as 140⁰F

(60⁰C). This temperature refers to the

oven’s hold temperature setting and not

to the internal temperature of the food

being roasted. The internal product

temperature will run below the hold

temperature. (For example: roast beef

held at 140⁰F will be about 130⁰F

internally or medium rare.)

All meat products contain enzymes.

These enzymes perform the

important function of tenderizing the

meat when they reach temperatures

of 100⁰F (38⁰C) to 140⁰F (60⁰C). As

these enzymes are heated, they break

down the connective tissue that is

inherent in all red meat products.

The hold cycle allows this natural

tenderization process to proceed in an

orderly manner. As long as the internal

3

Page 5

VRH SERIES OVENS F-41207 (02-16)

temperature of the meat does not

exceed 140⁰F, the process will continue.

Once the temperature reaches 140⁰F

the process will stop, because the

enzymes will be deactivated.

BENEFITS OF

COOK & HOLD OVENS

Superior Results: Low temperature

roasting has been recognized as the

best method for preparing meat and

poultry because of increased

tenderness, more even roasting, and a

juicer product.

Increased Sales: You will attract more

customers and have more repeat

business because you are now

producing a superior product in your

market area. All of your products will be

unique, from prime rib and chicken to

BBQ ribs, pork roasts, and even bakery

items!

Reduced Energy Costs: It costs

significantly less to run a Vulcan Cook &

This tenderization process makes the

meat more flavorful. It is similar to aging

meat before it is sold. The longer the

hold, the higher degree of tenderization.

Each hour of holding is equal to one

day of aging.

hold Oven instead of a conventional

oven. Also, in most areas, no exhaust

hood is needed.

Reduced Shrinkage of Product: You

can cut your percent of shrinkage from

25 to 30% down to 5 to 10%. This

means more servings to sell to your

customers! The Vulcan Cook & Hold

Oven can pay for itself in just months,

depending on your volume.

Reduced Labor Cost: Your cooks do

not have to come in early to put roasts

in or stay late to take them out of the

oven. Holding banquet foods in a

Vulcan Cook & Hold Oven reduces that

last minute party prep to almost nothing.

COMPARISON OF

COOK & HOLD OVENS

“The Comparison Stops Here” – more than a catchy slogan, it’s a fact.

Convection ovens, unlike Vulcan Cook & Hold Ovens, blast high temperature dry air

over the product. The end result with convection oven cooking is excessive and

unnecessary shrinkage.

Vulcan Cook & Hold Oven Systems:

1. Offer a lifetime heating element

warranty.

2. Provide a natural roasted

brown, caramelized product

without coloring agents.

“You can taste the difference.”

3. Do not require a ventilation

hood. (See pg. 5)

4. Are accurate, plus or minus

5⁰F.

5. Are easy to clean.

6. Have

inside and out.

4

stainless steel construction

Page 6

VRH SERIES OVENS F-41207 (02-16)

INSTALLATION

Before installing, verify that the

electrical service agrees with the

specifications on the rating plate

located on the lower back corner of

the oven. (Fig. 4) If the supply and

equipment requirements do not agree,

do not proceed with unpacking and

installation. Contact your Vulcan

Customer Service Department

immediately.

UNPACKING:

The oven was inspected before leaving

the factory. The transportation company

assumes full responsibility for safe

delivery upon acceptance of the

shipment. Immediately after unpacking,

check for possible shipping damage to

the oven.

If the oven is found to be damaged,

save the packaging material and

contact the carrier within 15 days of

delivery.

Carefully unpack and place in a work

accessible area as near the installation

position as possible.

1. Open oven door(s) and remove

packing material.

2. Check under oven or separate

package for racks, pans, etc.

3. Peel off vinyl protection film from

oven.

CLEANING:

The oven should be thoroughly cleaned

prior to putting into service. Refer to

cleaning instructions in this manual.

LOCATION:

For efficient oven operation, choose a

location that will provide easy loading

and unloading without interfering with

the final assembly of food orders.

The installation location must be

level and allow adequate clearances

for servicing and proper operation.

VRH88

The VRH88 oven is simply two (2)

VRH8 ovens stacked on top of each

other. One (1) oven will come with a

caster kit and a stacking assembly on

top. The oven without casters is

placed inside the stacking assembly.

VENTILATION HOOD REQUIREMENTS

The unit must be installed in accordance

with state and local codes, or in the

absence of state and local codes, with

the National Electrical Code

ANSI/NFPA-70 (latest edition) and

Standard for Ventilation Control and Fire

Protection of Commercial Cooking

Operations NFPA 96 (latest edition).

5

Both are available from The National

Fire Protection Association,

Batterymarch Park, Quincy, MA 02269.

In Canada refer to the Canadian

Electrical Code C22.1 Part 1 (latest

addition).

Page 7

VRH SERIES OVENS

ELECTRICAL REQUIREMENTS

ELECTRICAL CODES & STANDARDS:

The oven must be installed in

accordance with:

In the United States of America:

1. State and Local Codes.

2. National Electrical Code, ANSI/

NFPA-70 (latest edition.) Copies

may be obtained from: The

National Fire Protection

Association, 1Batterymarch Park,

Quincy, MA 02269.

1-617-770-3000 www.nfpa.org

In Canada:

1. Local Codes.

2. Canadian Electrical Code, CSA

C22.1 (latest edition.) Copies

may be obtained from: The

Canadian Standard Association.

www.csa.ca

F-41207 (02-16)

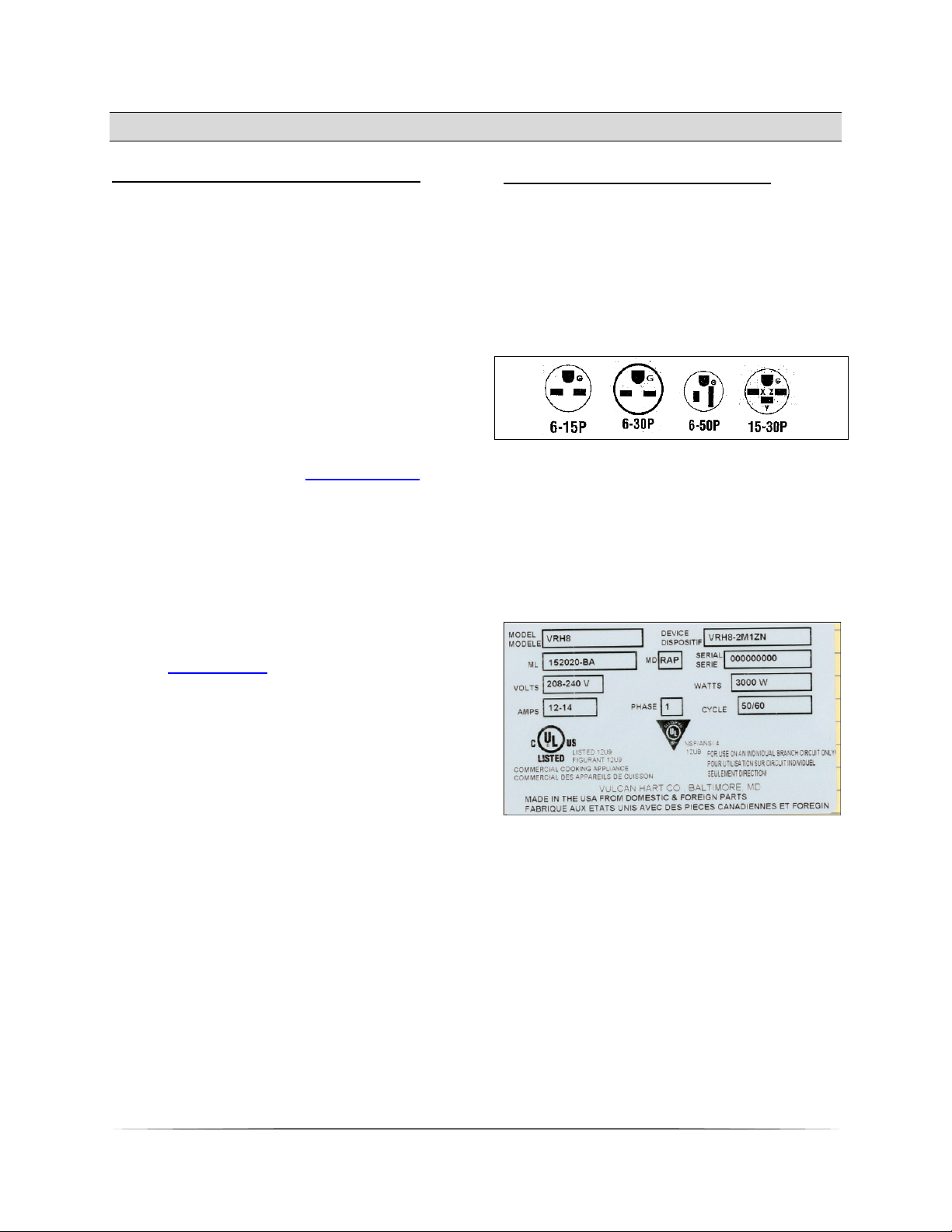

ELECTRICAL CONNECTIONS:

The oven is factory wired for single

phase 208/240 volt or three phase

operation. All ovens are equipped with

a 6 foot cord and NEMA 6-15, 6-30, 650, or a 15-30 plug as standard

equipment. (Fig. 3)

.

(Fig.3)

Refer to wiring diagrams and

Specification Chart in the back of this

manual.

The cord and plug supplied is a suitable

durable cord with a proper strain relief.

SERIAL DATA PLATE

(Fig. 4)

6

Page 8

VRH SERIES OVENS F-41207 (02-16)

OPERATION

CONTROLS

The Oven and its parts are hot. Be very careful when operating, cleaning,

or servicing the oven.

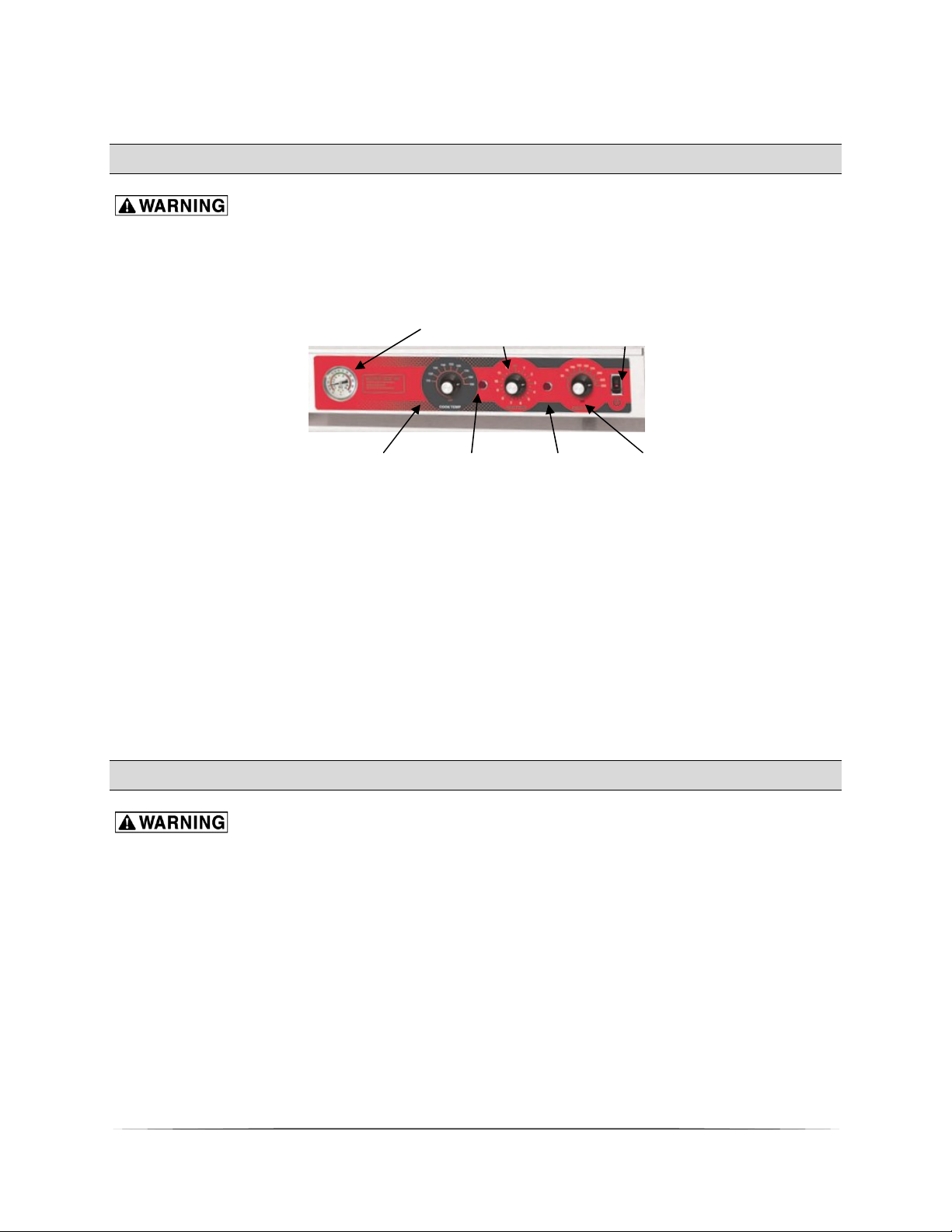

All operating controls are located on the front Control Panel(s). The oven is supplied

with individual operating controls for each oven cavity.

THERMOMETER COOKING TIME ON / OFF

KNOB SWITCH

POWER

COOKING COOKING HOLDING HOLDING

TEMP. MODE MODE TEMP.

KNOB LIGHT LIGHT KNOB

Thermometer: Indicates the interior

temperature of the oven.

Cooking Time Knob: Sets the desired

cooking time from ½ hour to 12 hours.

Power ON/OFF Switch: Turns the

oven On or Off.

Cooking Temperature Knob: Sets the

desired cooking temperature.

OPERATING INSTRUCTIONS

The Oven and its parts

are hot. Be very careful when operating,

cleaning, or servicing the oven.

1. Turn Cooking temperature

knob to desired Cooking

temperature.

2. Set Cooking timer knob(s) to

desired cooking time to include

30 to 60 minute preheat time.

Cooking Mode Light: Indicates oven is

in Cooking Mode.

Holding Mode Light: Indicates oven is

in Holding Mode.

Holding Temperature Knob: Sets the

desired holding temperature.

3. Turn Holdi ng Temperature knob

to desired holding temperature.

4. Turn On/Off Switch to ON

position. On/Off indicator Light

and Holding Temperature Light

will illuminate.

When the oven reaches the desired

cooking temperature it is ready for use.

Keep the oven door closed during the

preheating cycle.

7

Page 9

VRH SERIES OVENS F-41207 (02-16)

BEFORE FIRST USE

The Oven and its parts

are hot. Be very careful when operating,

cleaning, or servicing the oven.

1. Thoroughly clean the oven

before initial use. Please refer

to cleaning instructions in this

manual.

2. Test the oven to verify that the

oven operates normally. Please

refer to “Testing The Oven”

procedure in this manual.

TESTING THE OVEN

The Oven and its parts

are hot. Be very careful when operating,

cleaning, or servicing the oven.

Before using the oven for the first time,

verify that the oven operates normally.

1. Check that the oven is connected

to the correct power source.

2. Set the COOKING TIME knob

to 0.

3. Turn the HOLDING TEMP-

ERATURE knob to 140⁰ F.

4. Set Power ON/OFF Switch to

ON position.

5. Check that the Oven Circulating

Fan(s) are running.

6. Check that the Holding

Temperature Indicator Light is

illuminated.

Each Oven is equipped with cooling

fans. The cooling fans may not operate

when the oven is first turned on. The

cooling fans operate only when the

thermostat, to which they are

connected, requires it.

7. Set the COOKING TIME knob

to 2 hours. The Holding

Temperature Indicator Light will

go out and the Cooking

Temperature Indicator Light will

illuminate.

8. Turn the COOKING TEMP-

ERATURE knob to 250⁰ F.

Check the interior rear of the

oven cavity to determine that the

oven is heating.

9. Turn the COOKING TIME KNOB

to 0 and set the HOLDING

TEMPERATURE knob at 250⁰ F.

10. Check that the Cooking

Temperature Indicator Light has

gone out and the Holding

Temperature Indicator Light has

illuminated.

11. Check the interior rear of the

oven to ensure that the oven is

heating. If all the functions

perform satisfactorily, the oven is

ready for operation.

8

Page 10

VRH SERIES OVENS F-41207 (02-16)

SHUTDOWN

The Oven and its parts

are hot. Be very careful when operating,

cleaning, or servicing the oven.

1. Turn Holdi ng Temperature knob

and Cooking Temperature

knob counter-clockwise until

they stop at the Off position..

2. Open door slightly to allow

ventilation and cool down period.

This is to allow oven to

properly cool down so

components are not

damaged.

Wait 15 minutes before turning

On/Off Switch to OFF because the

cooling fans need to operate during the

cool-down period.

3. Turn On/Off Switch to OFF

position.

The cooling fans will automatically turn

off when the proper cool-down

temperature is reached.

EXTENDED SHUTDOWN

The Oven and its parts

are hot. Be very careful when operating,

cleaning, or servicing the oven.

Perform the following procedure to shut

down the oven for an extended period of

time.

1. Perform the SHUTDOWN

procedure.

2. Unplug the oven.

3. Thoroughly clean the oven

according to the cleaning

procedures in this manual.

4. Leave the door(s) slightly open

to allow ventilation and

preservation of the gasket(s).

9

Page 11

VRH SERIES OVENS F-41207 (02-16)

MAINTENANCE

CLEANING

The Oven and its parts

are hot. Be very careful when operating,

cleaning, or servicing the oven.

Always unplug

electrical power supply before

cleaning.

Avoid splashing water into upper

areas of the oven to prevent damage

to electrical components or

connections.

Never spray the unit with a hose.

Never use harsh chemicals or

abrasive pads to clean the oven.

HEAT TINT:

Darkened areas, called “heat tint,” may appear on stainless steel exposed to excessive

heat. Excessive heat causes the protective film to thicken. This is unsightly, but is not

a sign of permanent damage.

DAILY:

1. Unplug electrical power supply.

2. Allow oven to go through cool down period before cleaning.

3. Remove the Interior Side Racks

4. Take the Interior Side Racks to a

sink or dishwasher for a thorough

cleaning. Use a mild soap and

water solution to clean these

items.

5. If necessary, clean the interior of

the oven with a damp cloth.

Wipe dry with a soft dry cloth.

6. Reassemble oven.

7. Clean the exterior of the oven

with a clean damp cloth.

DOOR GASKET CARE

DOOR GASKET:

At least once a week, thoroughly check

the door gasket for damage/wear. A

damaged gasket can cause inefficient

and unsatisfactory operation of the

oven.

If the gasket requires cleaning:

1. Gently wash gasket using a

moist cloth, a mild detergent

solution, and warm water.

2. Rinse with a fresh cloth

moistened in warm water to

remove all traces of detergent.

3. Gently wipe dry with a clean dry

cloth.

Never apply food oils, or petroleum

lubricants directly to the gasket(s).

Petroleum based solvents and

lubricants will reduce the gasket’s life.

10

Page 12

VRH SERIES OVENS

COOKING

INTRODUCTION

This cooking guide has been produced

for your Vulcan Cook & Hold Oven

System. It should be used as a handy

reference when using your oven. The

guide has been developed to help

answer questions which you may have

relating to product preparation as well

as making you familiar with the

operation of your Cook & Hold Oven.

When using your oven, experiment with

your own house specialties. The degree

of doneness varies based upon

individual preferences. These

preferences can be easily accomplished

by varying the recommended time

F-41207 (02-16)

guidelines in this manual. The

guidelines which are presented in this

manual are suggested and have been

tested to insure product preparation as

indicated.

The concept of “Low Temperature

Cooking” is not a science, it is an art.

Chefs from around the world vary in

terms of the doneness and appearance

in the products which they prefer.

Therefore, we suggest first

understanding what your Oven System

will do for the multitude of applications

available to you.

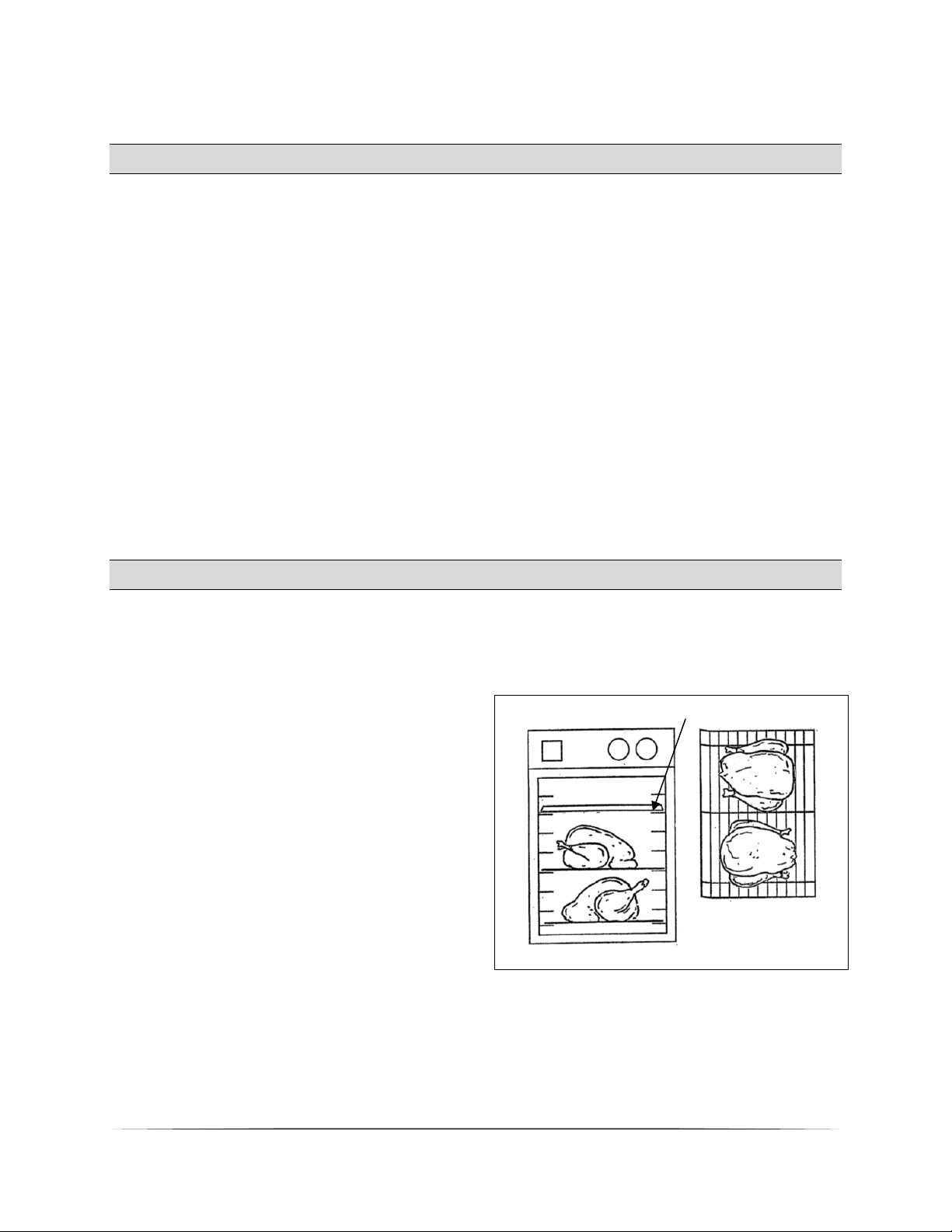

COOKING RACK

Depending upon the size of the Cook &

Hold Oven, each unit is supplied with a

specially designed cooking rack(s). The

cooking rack must be used when

cooking food products to insure absolute

product quality and integrity.

The cooking rack is simply placed inside

a standard 18” x 26” sheet tray (2/1

Gastronome) and the product which is

to be cooked and held is placed on top

of the cooking rack. When more than

one product is being prepared, the food

products should not be cramped

together onto one cooking rack.

Sufficient room should separate the

products on a single cooking rack to

insure proper circulation of air around

the product.

When loading the oven, an additional

18” x 26” sheet tray, in an inverted

position, (Fig. 5) should be placed

directly above the food product being

prepared. This creates the necessary

air flow pattern to produce highly

desirable carmelization and uniform

roasting of the product.

INVERTED SHEET TRAY

Fig. 5

A helpful hint when loading your food

product on the cooking rack is to either

line your 18” x 26” sheet tray with foil, or

spray with a quality vegetable oil. This

helps with easy clean up after use.

11

Page 13

VRH SERIES OVENS F-41207 (02-16)

COOKING AND HOLDING GUIDE

Please note that as products vary, as well as other elements such as altitude, so

shall actual cooking times and temperatures. These should be adjusted as

needed based upon your actual experience. Finished product temperatures

should be verified manually, prior to serving, in order to insure food safety.

PRODUCT

Prime Rib

Boneless Rib eye

Top Round

Steamship Round

Bottom Round

Boneless Strip Loin

Whole Tenderloin

Top Sirloin Butt

Beef Short Ribs 10 lbs. 4 hrs. 225⁰ F 4 hrs. min.

Cubed Steaks 10 lbs. 4 hrs. 225⁰ F 3 hrs. min.

Beef Back Ribs 30 lbs. 6 hrs. 225⁰ F 4 hrs.

Beef Stew

Corned Beef 12 lbs. 4 hrs. 250⁰ F 4 hrs. min.

Frozen Burgers 7-8 lbs. 45 min. 225⁰ F 4 hrs. max

Fresh Ham 12 lbs. 6 hrs. 250⁰ F 4 hrs.

Cooked Cured Ham 12 lbs. 4 hrs. 250⁰ F 4 hrs.

Pork Back Ribs

Pork Spare Ribs 30 lbs. 4 hrs. 250⁰ F 4 hrs.

Fresh Sausages 10 lbs. 2 hrs. 225⁰ F 5 hrs. max

Pre-Cooked Sausage 10 lbs. 1¾ hr. 250⁰ F 5 hrs. max

Roast Suckling Pig 30 lbs. 6 hrs. 250⁰ F 3 hrs. min.

(DETAILS)

WEIGHT

(USDA

#109)

20 lbs. 5 hrs. 225⁰ F 4 hrs. min.

(USDA

#112A)

12 lbs. 3 hrs 225⁰ F 4 hrs. min.

(USDA

#168)

18-20 lbs. 4½-5 hrs. 225⁰ F 4 hrs. min.

(USDA

#160)

60 lbs. 10 hrs. 225⁰ F 4 hrs. min.

(USDA

#170)

20 lbs. 5 hrs. 225⁰ F 8 hrs. min.

(USDA

#180)

12 lbs. 3 hrs. 225⁰ F 4 hrs. min.

(USDA

#190)

10 lbs. 2½ hrs. 225⁰ F 2 hrs. min.

(USDA

#184)

12-14 lbs. 3 hrs. 225⁰ F 4 hrs. min.

(Stew Meat)

10 lbs. 4 hrs. 225⁰ F 6 hrs. min.

(USDA

#422)

10 lbs. 4 hrs. 250⁰ F 3 hrs. max.

COOK

TIME

COOK

TEMP. HOLD TIME

HOLD

TEMP.

140⁰ F 135⁰ F

140⁰ F 135⁰ F

140⁰ F 130⁰ F

140⁰ F 130⁰ F

140⁰ F 130⁰ F

140⁰ F 130⁰ F

140⁰ F 130⁰ F

140⁰ F 135⁰ F

155⁰ F 165⁰ F

160⁰ F 160⁰ F

160⁰ F 160⁰ F

150⁰ F 175⁰ F

150⁰ F 165⁰ F

150⁰ F 165⁰ F

160⁰ F 165⁰ F

160⁰ F 135⁰ F

160⁰ F 175⁰ F

160⁰ F 175⁰ F

160⁰ F 175⁰ F

160⁰ F 160⁰ F

160⁰ F 170⁰ F

MAX.

INTERNAL

TEMP.

LOADING

GUIDELINES

2 per shelf

3 per shelf

2 per shelf

1 per shelf

2 per shelf

3 per shelf

4 per shelf

3 per shelf

1 per shelf

1 tray per shelf

4 per shelf

1 tray per shelf

2 per shelf

24 per shelf

2 per shelf

2 per shelf

6 slabs per shelf

5 slabs per shelf

10 lbs. per shelf

10 lbs. per shelf

1 per shelf

12

Page 14

VRH SERIES OVENS F-41207 (02-16)

PRODUCT

Chicken Pieces 10 lbs. 2¼ hrs. 250⁰ F 1 hr. max.

Whole Chickens 20 lbs. 2½ hrs. 250⁰ F 5 hrs. max

Whole Turkeys 20 lbs. 4½ hrs. 250⁰ F 5 hrs. max.

Turkey Breast₇

Rack of Lamb 18 lbs. 3½ hrs. 250⁰ F 3 hrs. max

Braised Lamb Shanks 10-12 lbs. 4 hrs. 250⁰ F 4 hrs. min.

Fish Filets 10 lbs. 40 min. 225⁰ F 4 hrs. max

Clear Soups

Rice 1 Quart Dry 2 hrs. 250⁰ F 18 hrs. max

Frozen Entrees 1 Quart Dry 3 hrs. 250⁰ F Overnight

(DETAILS)

WEIGHT

10 lbs. 4 hrs. 250⁰ F 1 hr.

12" x 20"

pans 3 hrs. 250⁰ F Overnight

COOK

TIME

COOK

TEMP. HOLD TIME

HOLD

TEMP.

150⁰ F 170⁰ F

150⁰ F 170⁰ F

170⁰ F 170⁰ F

160⁰ F 160⁰ F

140⁰ F 140⁰ F

160⁰ F 180⁰ F

160⁰ F 160⁰ F

160⁰ F 175⁰ F

150⁰ F 160⁰ F

160⁰ F 165⁰ F

MAX.

INTERNAL

TEMP.

LOADING

GUIDELINES

10 lbs. per shelf

6 per shelf

2 per shelf

3 per shelf

15 racks per shelf

1 tray per shelf

10 lbs. per shelf

1 pan per shelf

1 pan per shelf

2 pans per shelf

13

Page 15

VRH SERIES OVENS F-41207 (02-16)

RETHERMALIZATION GUIDE

ENTRÉE

Baked Rotini

Beef & Noodles

Breaded Chicken Pattie on Bun

Burrito

Cheesy Bread/Italian Dunker Sauce

Cheesy Chili

Chicken & Noodles

Chicken & Rice

Chicken Dippers

Chicken Fryz

Chicken Leg

Chicken Nuggets

Chik'n O's, Zesty

French Toast/Sausage Links

Grilled Cheese Sandwich

Grilled Chicken on Bun

Ham & Cheese English Muffin

Hamburger on Bun

Hot Dog on Bun

Italian Spaghetti

Macaroni & Cheese

Mexican Cheese Sauce

Mini Corndogs

Pancakes/Sausage Links

Pizza Dippers

Pizza, Cheese

Pizza, Pepperoni

Pizza, Sausage

Ravioli

Sausage Mini Bites

Steak Nuggets

Taco Boat

Tacos

Turkey & Noodles

Turkey Manhattan

OVEN

TEMP.

225⁰F

225⁰F

225⁰F

250⁰F

200⁰F

225⁰F

225⁰F

225⁰F

225⁰F

225⁰F

225⁰F

225⁰F

225⁰F

225⁰F

200⁰F

225⁰F

200⁰F

250⁰F

225⁰F

250⁰F

225⁰F

200⁰F

225⁰F

225⁰F

225⁰F

200⁰F

200⁰F

200⁰F

250⁰F

225⁰F

225⁰F

225⁰F

225⁰F

225⁰F

225⁰F

REHEAT

TIME

60 min.

54 min.

60 min.

48 min.

54 min.

54 min.

54 min.

54 min.

54 min.

48 min.

60 min.

60 min.

54 min.

42 min.

42 min.

60 min.

54 min.

60 min.

54 min.

54 min.

48 min.

42 min.

54 min.

42 min.

54 min.

42 min.

54 min.

54 min.

60 min.

54 min.

60 min.

42 min.

42 min.

54 min.

54 min.

HOLD

TEMP.

160⁰F

160⁰F

165⁰F

160⁰F

155⁰F

160⁰F

160⁰F

160⁰F

160⁰F

160⁰F

155⁰F

160⁰F

160⁰F

160⁰F

155⁰F

165⁰F

160⁰F

165⁰F

160⁰F

160⁰F

155⁰F

155⁰F

160⁰F

160⁰F

160⁰F

160⁰F

160⁰F

160⁰F

165⁰F

160⁰F

160⁰F

160⁰F

160⁰F

160⁰F

165⁰F

MIN. HOLD

TIME

20 min.

20 min.

20 min.

20 min.

15 min.

15 min.

20 min.

20 min.

20 min.

20 min.

20 min.

20 min.

20 min.

15 min.

15 min.

20 min.

20 min.

20 min.

20 min.

20 min.

20 min.

20 min.

15 min.

15 min.

20 min.

20 min.

20 min.

20 min.

20 min.

15 min.

20 min.

20 min.

20 min.

20 min.

20 min.

14

Page 16

VRH SERIES OVENS

F-41207 (02-16)

15

Page 17

VRH SERIES OVENS

F-41207 (02-16)

16

Page 18

VRH SERIES OVENS

F-41207 (02-16)

LOCKOUT / TAGOUT PROCEDURE

Always perform the Lockout / Tagout Procedure before

removing any sheet metal panels or attempting to service this

equipment.

The Lockout / Tagout Procedure is used to protect personnel working on an electrical

appliance. Before performing any type of maintenance or service on an electrically operated

appliance, follow these steps:

1. In electrical box, place unit’s circuit breaker into OFF position.

2. Place a loc k or other device on electrical box cover to prevent someone from placing

circuit breaker ON.

3. Place a tag on electrical box cover to indicate that unit has been disconnected for

service and power should not be restored until tag is removed by maintenance

personnel.

4. Disconnect unit power cord from electrical outlet.

5. Place a tag on cord to indicate that unit has been disconnected for service and power

should not be restored until tag is removed by maintenance personnel.

SERVICE & PARTS INFORMATION

To obtain Service and Parts information concerning this model, contact the Vulcan Service

Department at the address listed on the front cover of this manual or refer to our website:

www.vulcanequipment.com for a complete listing of Authorized Service and Parts depots.

Customer Service 1-800-814-2028

Technical Service 1-800-814-2028

Service Parts 1-800-814-2028

When calling for service, have the model number and serial number available.

17

Page 19

VRH SERIES OVENS F-41207 (02-16)

TROUBLESHOOTING

SYMPTOMS POSSIBLE CAUSES REMEDY

Oven not operat i n g

Oven not connected t o

power source

ON/OFF switch not

ON

Connect oven to power

source

Press Power ON/OFF switch

to ON

IndicatorLights arelitbut

Cool i ngFa n(s )areNOT

operating

OvencompartmentISheati ng

andBlowerMotorISNOT

operatingwi thPowerSwitch

ON

OvencompartmentISNOT

heatingandBlowerMotorIS

operatingwi thPowerSwitch

ON

Incorrectoventemperature

No power

Oven is bel ow 150⁰F.

Defect i ve: connection,

wiring, fan, therm ost at

Defect i ve connec tion or

wiring to motor

Defective Cooking

Temperature

Thermostat

Defective Holding

Temperature

Thermostat

Defective High-Limit

Thermost at or Heat i ng

Element.

Thermos tat (s) req ui re

calibration

Check circuit breaker

This is normal when unit is

cold. If unit is above 150⁰F.,

Contac t Aut horized Service

Provider.

Contac t Aut horized Service

Provider

Contac t Aut horized Service

Provider

Set Cooking Thermostat to 250⁰F.,

wait several minutes and check

the rear of the oven for heating.

Both the Power Sw itch and

Cooking Temperature Indicator

Lights w ill be lit. If oven cavity

does not heat, Contact Authorized

Service Provider

Turn Holding Temperature knob to

250⁰F. and check for heat at rear

of oven cavity. Both the Po wer

Switch and Cooki ng Temperature

Indicator Lights w ill be lit. If the

oven cavity does not heat, Contact

Authorized Service P rovider.

Contac t Aut horized Service

Provider

Contac t Aut horized Service

Provider

18

Page 20

VRH SERIES OVENS F-41207 (02-16)

19

Page 21

VRH SERIES OVENS F-41207 (02-16)

20

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

Page 37

Page 38

Page 39

Page 40

Loading...

Loading...