Page 1

©ITW Food Equipment Group, LLC

3600 North Point Blvd.

Baltimore, MD 21222

RETAIN THIS MANUAL FOR FUTURE USE

FORM F-47658 (10-15)

MODELS

VMCS-101

VMCS-102

VMCS-201

VMCS-202

VMCS-101

For additional information on Vulcan or to locate an authorized parts and

service provider in your area, visit our website at www.vulcanequipment.com

OPERATION AND FIELD INSTALLATION MANUAL

VMCS Heavy Duty Electric Griddle Top

Page 2

OPERATIONS

Installation…………………………………………………………………………………………...

Electrical specifications…………………………………………………………………………….

Controls……………………………………………………………………………………………...

Raising/lowering griddle top……………………………………………………………………….

Teflon wrap installation………………………………………………………………………….....

Plate gap adjuster…………………………………………………………………………………..

Using the griddle……………………………………………………………………………………

Care and cleaning……..…………………………………………………………………………...

Shutdown……………………………………………………………………………………………

Maintenance………………………………………………………………………………………...

FIELD INSTALLATION ASSEMBLY

Tools required………………………………………………………………………………………

Mounting bracket assembly……………………………………………………………………….

Mounting bracket installation……………………………………………………………………...

Griddle top installation……………………………………………………………………………..

Mounting plate installation…………………………………………………………………………

Bumper stop installation...…..……………………………………………………………………..

Range of motion.……………………………………………………………………………………

Electrical connections and specifications.……………………………………………………….

Wiring diagram..…………………………………………………………………………………….

Troubleshooting….…………………………………………………………………………………

3

3

5

6

6

7

8

8

9

10

10

11

11

14

14

17

17

18

19

20

TABLE OF CONTENTS

- 2 -

Page 3

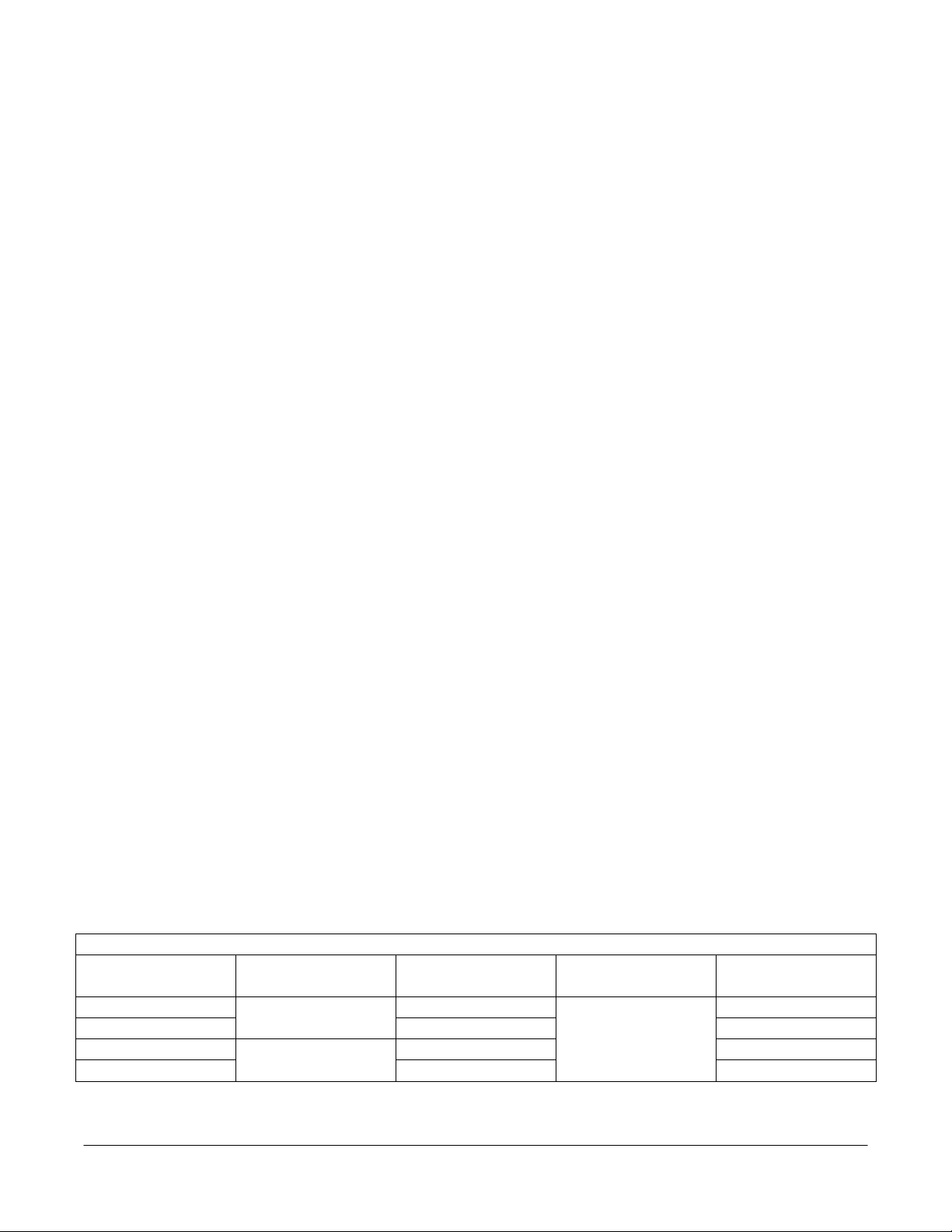

ELECTRICAL SPECIFICATIONS

Model No

Description

Voltage

Power

1 Phase Draw

VMCS-101

FLAT

PLATE

208V

3.6 KW

17.3 A

VMCS-102

240V

15.0 A

VMCS-201

GROOVED

PLATE

208V

17.3 A

VMCS-202

240V

15.0 A

VMCS HEAVY DUTY ELECTRIC GRIDDLE TOP

GENERAL

VMCS Heavy Duty Electric Griddle Tops are produced with quality workmanship and

materials. Proper installation, usage and maintenance of the griddle top will result in

many years of satisfactory performance.

Thoroughly read this entire manual before beginning and carefully follow all of the

instructions provided.

INSTALLATION

Before installing, check the electrical service to make sure it agrees with the

specifications on the rating plate. If the supply and equipment voltages do not agree, do

not proceed with the installation. Contact your dealer or Vulcan-Hart immediately.

INSTALLATION CODES AND STANDARDS

Your Vulcan griddle top must be installed in accordance with:

In the United States of America:

1. State and local codes

2. National Electrical Code ANSI/NFPA – 70 (latest edition) available from The National

Fire Protection Association,1 Batterymarch Park,Quincy, MA 02269.

3. NFPA Standard #96 Vapor Removal from Cooking Equipment, (latest edition) available

From the National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

In Canada:

1. Local code

2. Canadian Electrical Code C22.1 Part 1 (latest edition) available from the Canadian

Standard Association, 5060 Spectrum Way, Suite 100, Mississauga, Ontario, Canada,

L4W 5N6.

- 3 -

Page 4

UNPACKING

This griddle top was inspected before leaving the factory. The carrier assumes full responsibility for the

safe delivery upon acceptance of the shipment. Check for possible shipping damage immediately after

receipt.

If the griddle top is found to be damaged, complete the following steps:

1. Carrier must be notified within 5 business days of receipt.

2. Carrier’s local terminal must be notified immediately upon discovery (note time, date, and

who was spoken to), and follow up and confirm with written or electronic communication.

3. All original packing materials must be kept for inspection purposes.

4. The griddle top cannot have been moved, installed, or modified.

5. Notify Vulcan Customer Service immediately at 800-814-2028.

Check that the following have been included:

Bumper stop assembly(see page 16)

o (4) Bumper stop assembly mounting screws

(2) Mounting plates (see page 14)

o (4) M10 mounting plate screws

o (4) M10 mounting plate lock washers

Teflon sheet kit (see page 6)

o (2) Teflon sheets

o (2) Teflon clips

o Teflon bracket

The VMCS mounting bracket (see page 11) is a separate accessory and shipped in

another package. It is recommended that you specify factory mounting of the bracket if

you are purchasing a new griddle with the VMCS Heavy Duty Electric Griddle Top.

The griddle and its parts are hot. Use care when operating, cleaning

or servicing the griddle.

Disconnect power supply and follow lockout / tagout procedures

before cleaning and servicing the appliance.

BEFORE FIRST USE

Remove all packaging material and protective plastic from the unit. It is recommended

that you clean your Vulcan VMCS griddle top thoroughly with a mild soap and water. Wipe

the griddle surface thoroughly with water and wipe dry with a soft clean cloth.

SEASONING THE GRIDDLE

Each time, before turning the unit on, apply high temperature cooking oil – about two

ounces per VMCS top plate. Work the oil into the whole griddle surface.

- 4 -

Page 5

Amber Indicator Lights

Power Light (Left)

Heating Light (Right)

High Limit Reset Access Plug

Thermostat Cover

High Limit Reset Button

Thermostat Adjustment Knob

Handle

Power Switch (Center)

Plate Gap Adjuster

Fig. A

After cleaning your griddle with chemicals, you should repeat the seasoning procedure for

proper cooking.

CONTROLS

The heavy duty electric griddle top section is independently controlled by a power switch,

thermostat and high limit cutoff switch. When the power switch (red rocker switch) is

turned ON, the left amber light will illuminate and power will be supplied to the

thermostat. The thermostat cover must be removed to access the thermostat adjustment

knob.

When the thermostat is turned ON, the amber indicator light to the right of the power

switch will illuminate to indicate that the element is on. When the griddle plate reaches

the desired temperature set point, the element will be turned off and the amber indicator

light will go off. The high limit cutoff switch is a safety feature that will cut power to the

heating element to prevent overheating. The high limit switch can be reset by depressing

the high limit reset button. At the end of each day, you must push the power switch to the

OFF position to turn off power to the griddle top section. See Fig. A.

- 5 -

Page 6

To raise the assembly

1. Lift by the handle only

2. Hold handle until assembly holds in

place at the approximate 53° position.

Fig. B

Always hold handle to

maintain control of the unit until lifting

mechanism holds in the desired raised

position or rests in the lowered position.

Do not allow unit to swing upward or

downward under its own power as this

may result in injury or equipment damage.

To lower the assembly

1. Grasp the handle and pull downward.

Continue to hold handle until the unit

stops in lowered position. Fig. C

Do not force unit if it does not

move up and down in the prescribed manner.

The assembly may be damaged by the

application of excessive upward or downward

force. Contact an authorized service

contractor if assembly becomes difficult to

move.

Fig. C

Fig. B

Raised Position

Lowered Position

The griddle and its parts

are hot. Use care when operating,

cleaning or servicing the griddle.

1. Clean off platen using soft cloth, water

and mild soap solution.

2. Slide the Teflon bracket (#944503) into

the sleeve of the Teflon sheet as shown

in Fig. D.

Fig. D

Teflon Bracket

Teflon Sheet Sleeve

TEFLON WRAP INSTALLATION

- 6 -

Page 7

3. Raise the platen to the 53° raised

position. Drape the Teflon sheet

from the right side of the platen by hooking the

front and back of the Teflon bracket to the

Teflon retaining pins. See Fig. E.

4. Pull the Teflon sheet from the right side

around the face of the platen cooking

surface to the left side.

5. Pull the Teflon sheet tight and ensure the

cooking surface of the platen is completely

covered by the Teflon sheet.

6. Secure the Teflon sheet to the left side of

the platen with the two Teflon clips. Push the

clips down over the Teflon sheet, clipping onto

the round rods underneath the sheet. See

Fig. F.

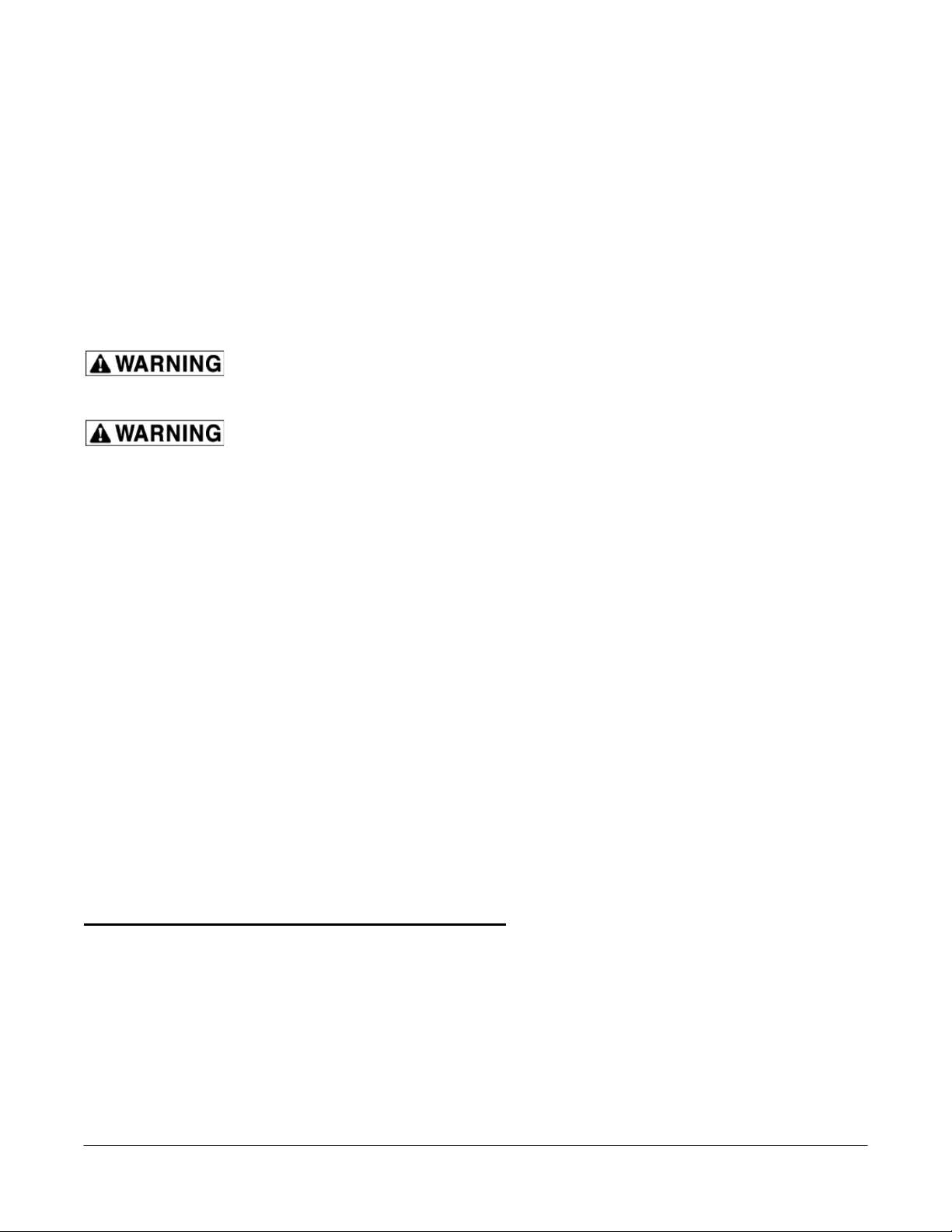

The plate gap adjuster is used to prevent soft

foods from being crushed by the downward force

of the unit. The “1” setting would be used for the

smallest or no gap with “4” being used to create

the largest gap.

Settings are changed by rotating the gap

adjuster body to the left or right until it locks in

place at the desired setpoint.

Fig. E

Fig. F

Teflon Retaining Pin

Teflon Clip

Fig. G

PLATE GAP ADJUSTER

- 7 -

Page 8

USING THE VMCS ELECTRIC GRIDDLE TOP

REAR

FRONT

REAR

FRONT

REAR

FRONT

REAR

FRONT

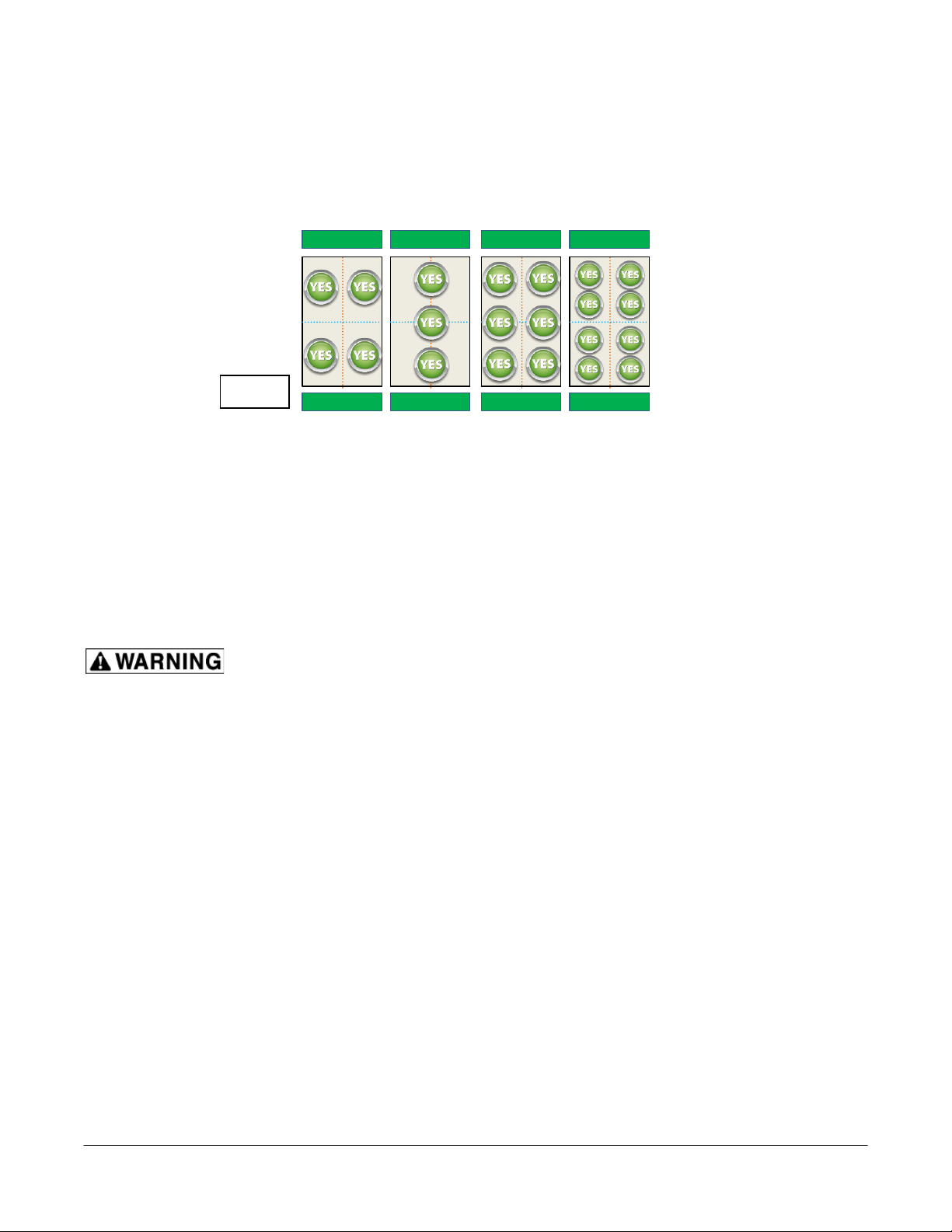

PRODUCT LOADING

Fig. H

To preheat, wipe the griddle top plate with cooking oil and set the thermostats for the

desired temperatures 10-12 minutes before cooking.

A uniform and systematic approach to loading the griddle will produce the most consistent

product results.

The flat cooking surface units f eat ure the Rapid R ecove r y™ plate which is a composite

material with a stainless steel surface. The grooved cooking surface units have plates

composed of standard, carbon steel. Both cooking surfaces can be scored or dented by

careless use of a spatula or scraper. Be careful not to dent, scratch, or gouge the plate

surface. Do not try to knock off loose food that may be on the spatula by tapping the

corner or the edge of the spatula on the griddle surface. Do not use hardened steel

spatulas. Use mild steel spatulas with rounded corners.

CARE AND CLEANING

The griddle and its parts are hot. Use care when operating, cleaning

or servicing the griddle.

Clean the electric griddle top regularly. A clean griddle always looks better, lasts longer

and performs better. To produce evenly cooked, perfectly browned griddle products keep

the griddle plate clean and free of carbonized grease. Carbonized grease on the surface

hinders the transfer of heat from the griddle surface to the food, resulting in spotty

browning and loss of cooking efficiency. Carbonized grease tends to cling to griddle

foods, giving them a highly unsatisfactory and unappetizing appearance.

To keep the griddle clean and operating at peak efficiency, follow these procedures:

AFTER EACH USE

Clean the electric griddle top with a griddle scraper during the work shift. Keep the

griddle scraper head flat to avoid scratching or gouging the plate. Use a cooking release

agent to prevent product from sticking to the griddle top cooking surface.

ONCE PER DAY

Thoroughly clean all stainless steel exterior panels and surfaces. Clean the cooking

surface with a non-metallic scouring pad (Scotch-Brite™).

- 8 -

Page 9

ONCE PER WEEK

Clean the griddle surface thoroughly. A mild detergent solution may be used on the plate

surface to help clean it, but be sure the detergent is thoroughly removed by wiping down

with clear water. After removal of detergent from the surface of the plate, the griddle

should be coated with cooking oil according to the instructions in this manual. Clean

stainless steel surfaces with a damp cloth and polish with a soft dry cloth. To remove

discoloration, use a griddle cleaner. If the griddle usage is very high, consider conducting

this weekly cleaning procedure more than once per week.

Do not use a brick or griddle stone for cleaning.

Do not use metallic scouring pads for cleaning.

Do not use a water-jet to clean the griddle.

Do not use chlorine sanitizer in contact with griddle. Contact can cause

discoloration, corrosion and permanent damage.

Do not use cleaning agents including Sodium Hydroxide, which is common in

household oven cleaners. Contact can cause discoloration, corrosion and

permanent damage.

CARE AND CLEANING OF TEFLON WRAP

1. In between cooking runs and during idle periods, the Teflon sheet should be wiped off

with water and a clean soft cloth.

2. After each day the Teflon sheet should be removed from the platen(s), disassembled

and placed in water with mild soap solution (no abrasive or harsh chemical cleaners

should be used). Gently wash both sides of the Teflon sheet and the hardware with the

soft clean cloth in the mild soap solution.

3. Using water, rinse the Teflon sheet and hardware thoroughly on both sides.

4. Dry the Teflon sheet and hardware using a clean soft cloth.

5. Before reassembling the Teflon sheet to the platen, clean the platen as described in

Care and Cleaning section.

SHUTDOWN OF GRIDDLE

1. Set the power switch to the OFF position. This will shut down the griddle top

completely.

2. Leave unit in the raised, 53° position.

- 9 -

Page 10

EXTENDED SHUTDOWN

1. Set the power switch to the OFF position. This will shut down the griddle top

completely.

2. Leave unit in the raised, 53° position.

3. Apply a light coating of cooking oil on the grooved (steel) plate to inhibit rust.

4. Shut off the main electrical supply

MAINTENANCE

The griddle and its parts are hot. Use care when operating, cleaning

or servicing the griddle.

Disconnect power supply and follow lockout / tagout procedures

before cleaning and servicing the appliance.

LUBRICATION

There are no parts on this unit that require lubrication.

SERVICE AND PARTS INFORMATION

Contact the Authorized Service Contractor in your area to obtain service and parts

information. For a complete listing of Service and Parts depots refer to

www.vulcanequipment.com.

When calling for service the following information should be available from the appliance

serial plate: Model Number, Serial Number and voltage.

FIELD INSTALLATION ASSEMBLY

Contact the authorized service contractor in your area for field installation.

The field installation instructions are prepared for the use of trained service technicians and should only

be used by those who are properly qualified. These instructions are not intended to be all

encompassing. You should read, in its entirety, the installation instructions to determine if you have the

necessary tools, instruments and skills required to perform the procedure. The field installation should

not be attempted if you do not have the necessary tools, instruments and skills.

TOOLS REQUIRED FOR FIELD INSTALLATION

1. #2 Philips head screw driver

2. M10 socket driver

3. 7/16” socket driver

4. Rubber mallet

5. Power drill

6. 7/8” deep well socket wrench

7. (2) large “F” clamps

8. 5/32” drill bits for metal

9. Thread lock compound (Loctite Blue®)

10. ¾” wide masking tape

- 10 -

Page 11

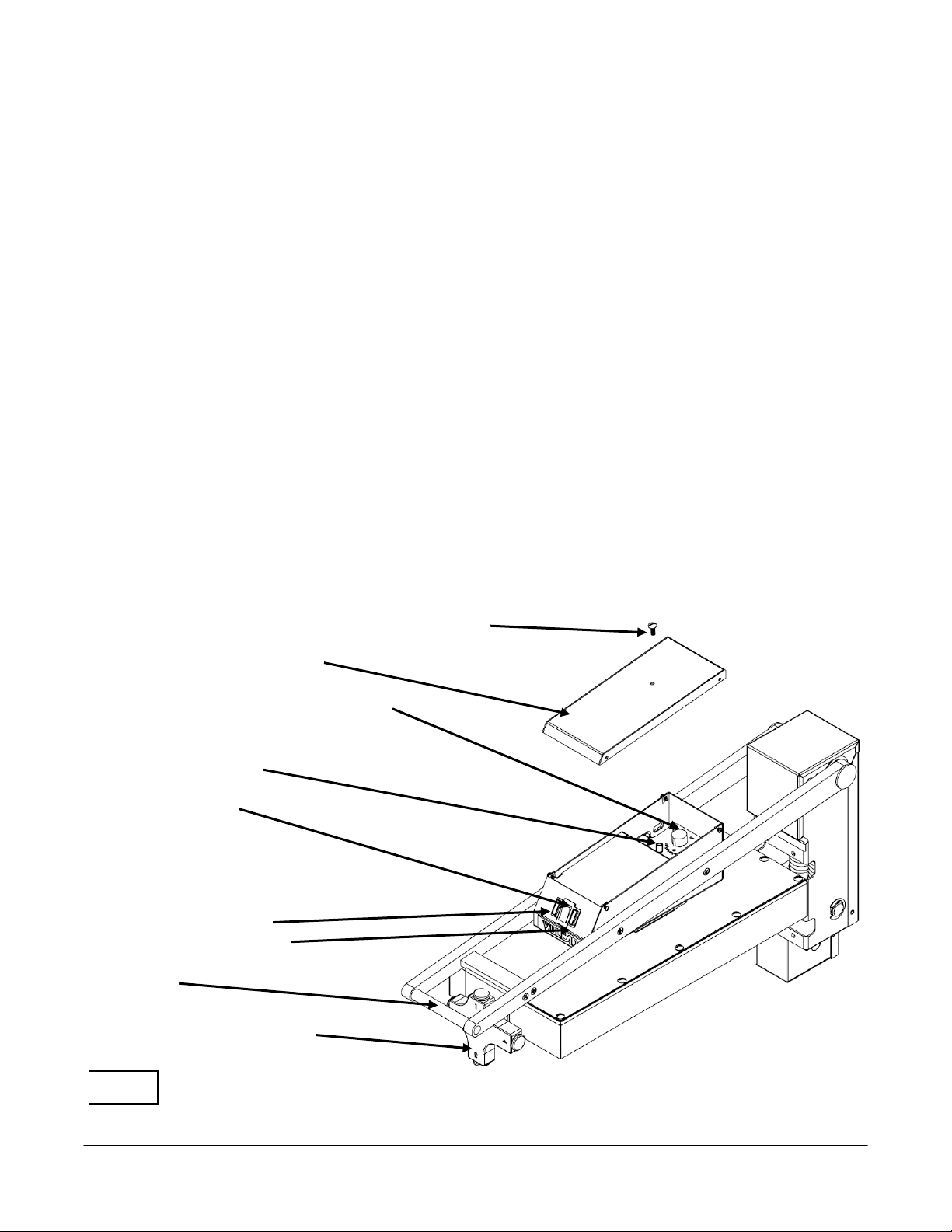

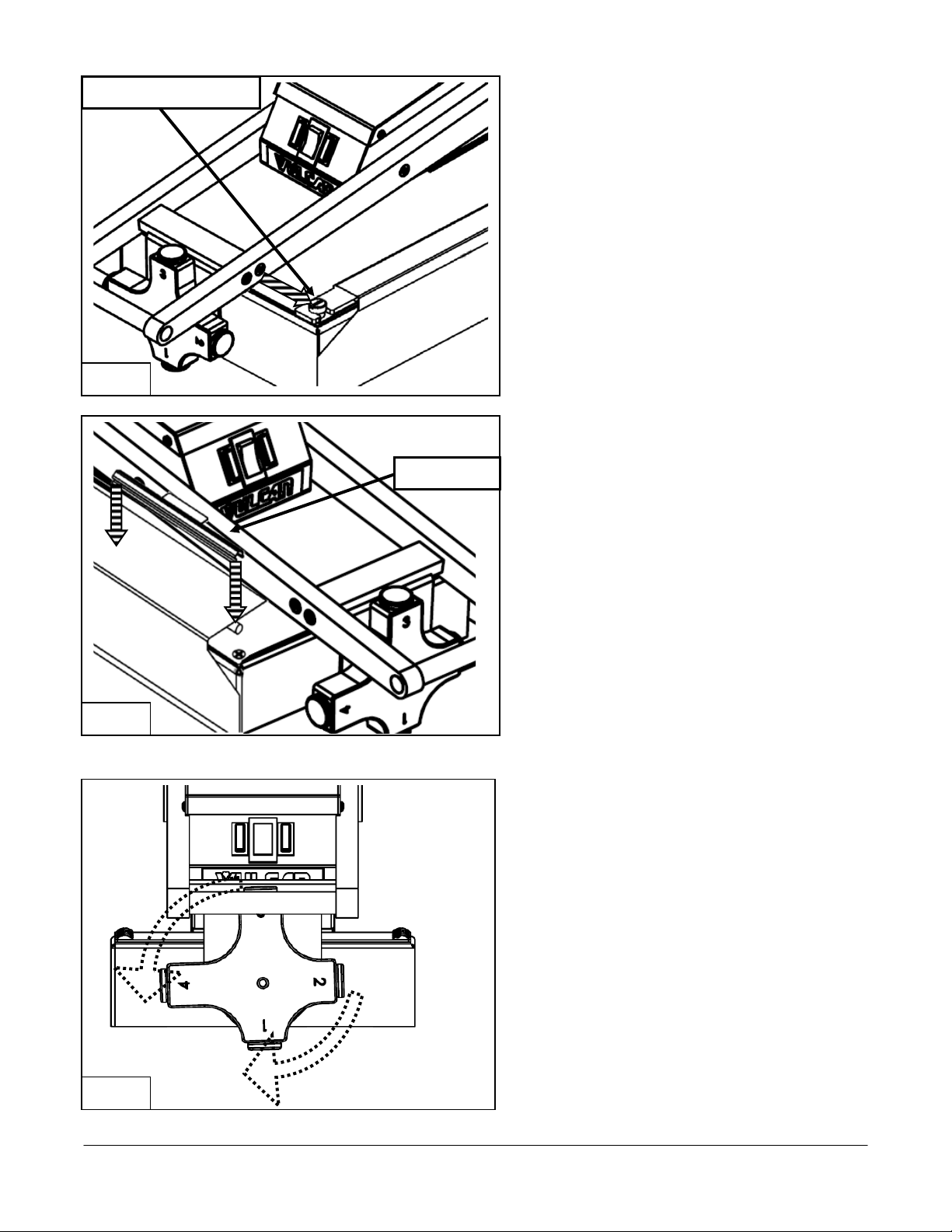

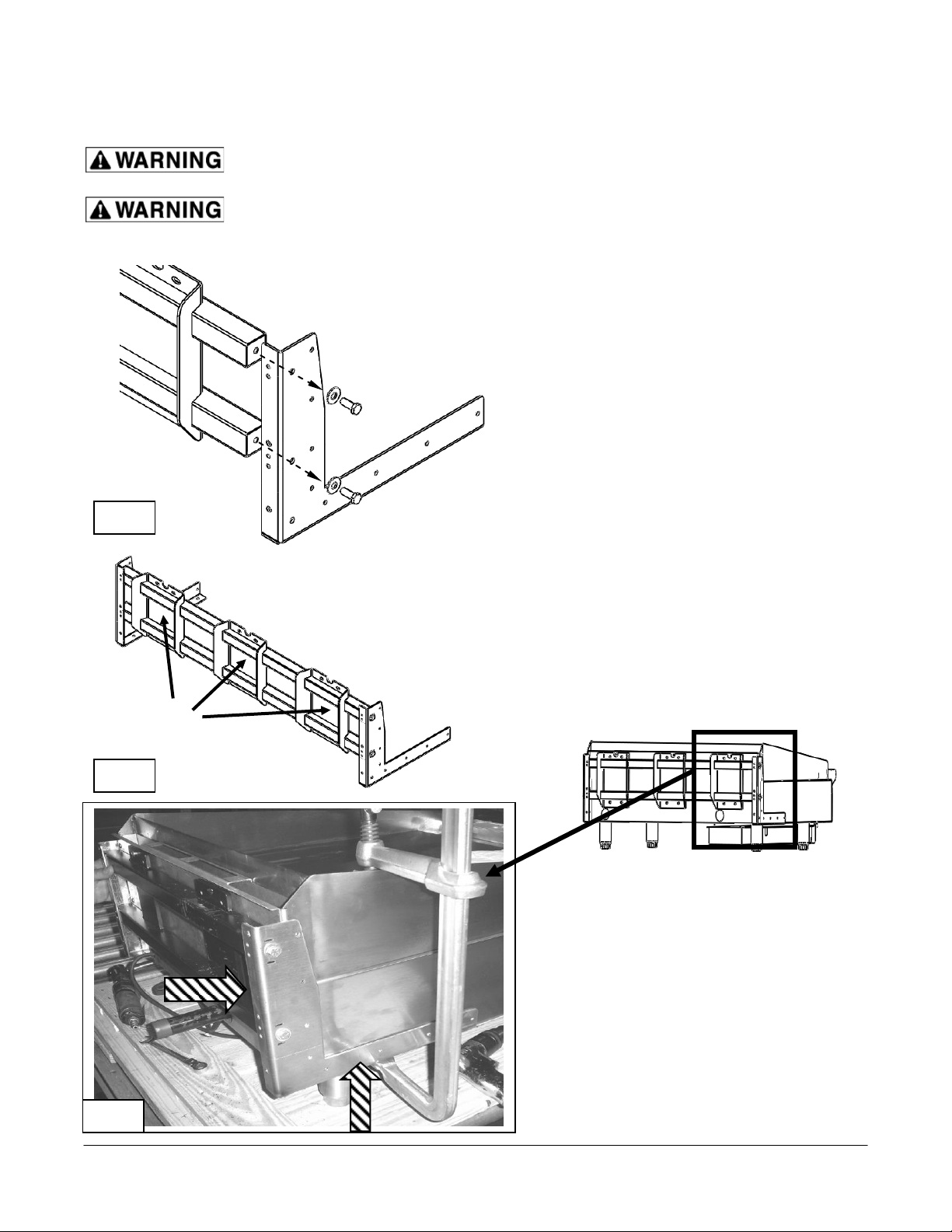

BRACKET ASSEMBLY AND INSTALLATION

Griddle Top

Assembly Mounting Points

Prior to assembly, make sure the

mounting bracket is the correct size. The

back bracket should match the width of

the griddle. Make sure the griddle top

electrical specifications match the

available service. Each griddle top will

require its own separate electrical service.

1. Using (2) washers and (2) ¼”-28 bolts,

assemble one of the side mount

brackets to the back bracket as shown

in Fig. 1. The bolts should be hand

tightened only at this point. Repeat

procedure to attach the other side

mount bracket to the other end of the

back bracket.

2. The entire mounting bracket system

should be assembled at this point as

shown in Fig. 2 with bolts hand

tightened only.

3. Slide mounting bracket system onto

back of the griddle as shown in Fig. 3.

The left and right side brackets should

be pushed up until stopped by the

bottom of the griddle and pushed

forward until stopped by the griddle

back panel. Secure the mounting

bracket system at this location with a

“F” clamp on each side of the assembly

as shown. Place a wood block or other

type of protection between clamp and

griddle plate.

Fig. 1

Fig. 2

Fig. 3

The griddle and its parts are hot. Use care when operating, cleaning

or servicing the griddle.

Disconnect power supply and follow lockout / tagout procedures

before cleaning and servicing the appliance.

- 11 -

Page 12

4. Securely tighten the mounting bracket

system assembly bolts at the left and

right side mounting brackets.

Fig. 4.

5. Check that the left and right mounting

brackets have not moved from position

while the assembly bolts were

tightened. The “F” clamps should still

be in place to prevent the assembly

from moving while drilling holes in the

chassis.

Check before drilling holes in chassis, it

is important that the assembly has not

moved from the location prescribed in

step # 3

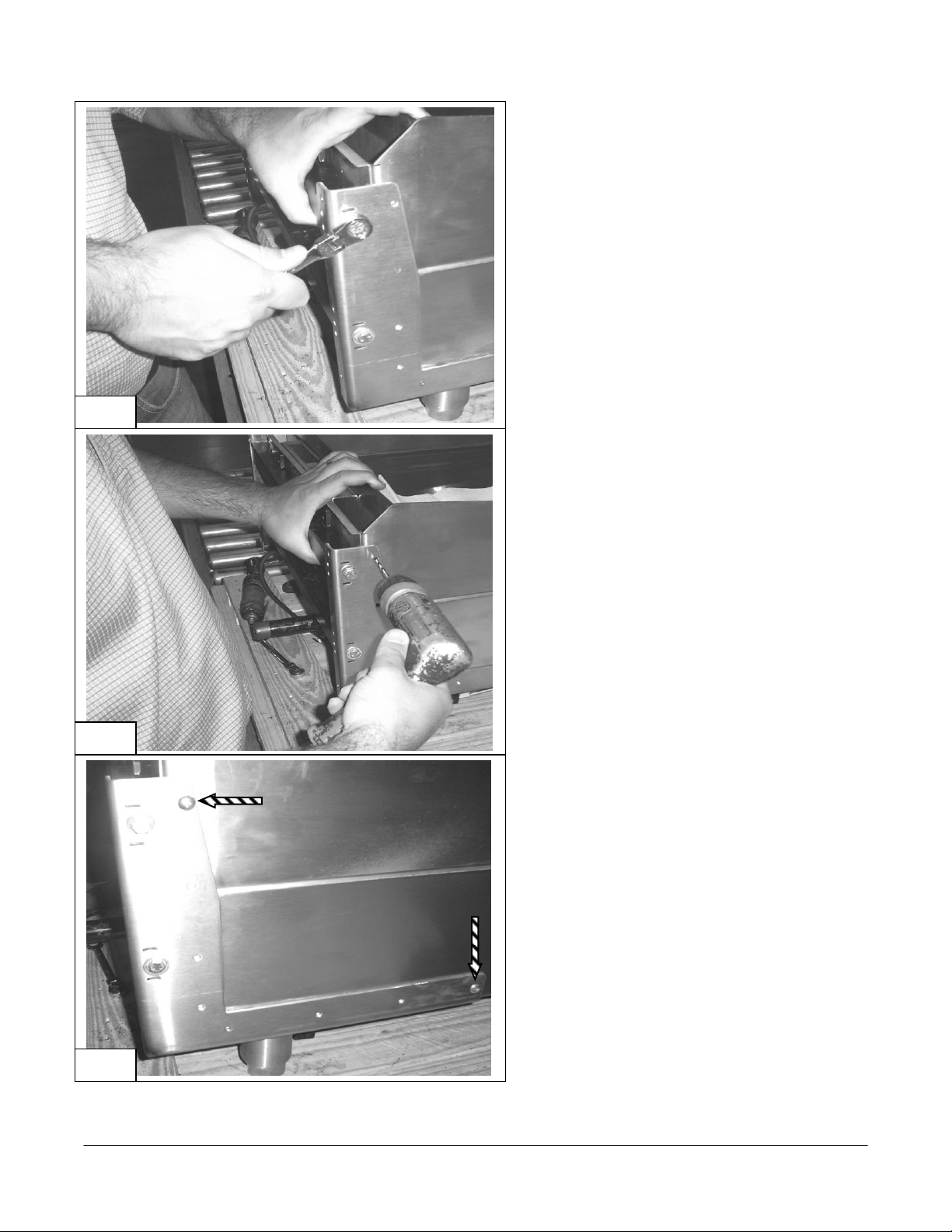

6. Using the side mounting bracket as a

guide, drill holes into the griddle chassis

with the 5/32” bits only at the highest

hole and the hole nearest the front of

the unit on the side bracket. See Fig. 5

and Fig 6. Repeat procedure for

opposite side of bracket system

assembly.

7. Insert and tighten 10-24 x ½ screws into

the holes that were drilled in step 6.

Repeat procedure for opposite side of

bracket system assembly. See Fig. 6.

Fig. 4

Fig. 5

Fig. 6

- 12 -

Page 13

8. Drill the remaining holes through the

side mounting brackets into the griddle

chassis. Insert and tighten screws as

shown in Fig. 7. Repeat procedure for

the other side of the assembly.

9. Drill holes with 5/32” bits from the rear of

the side mounting bracket into the back

mounting bracket and install wall spacer

with (4) 10-24 x ½” screws as shown in

Fig. 8. Repeat procedure for the other

side of the assembly.

Wall Spacer

10. Install one bottom support bracket every

two feet of griddle width between griddle

top mounting points as needed for

additional support. Bottom support

brackets should be flush with bottom of

griddle chassis and back mounting

bracket. Drill two holes with 5/32” bits

and attach with 10-24 x 2” screws as

shown in Fig.9 to the back mounting

bracket. Repeat for each bottom

support bracket needed.

Cutaway

side view

Fig. 7

Fig. 8

Fig. 9

Bottom support

bracket

- 13 -

Page 14

It may be necessary to

angle the griddle and hang one of the

four legs off the edge of the table at a

time to complete step 11. Ensure that

the griddle is safely supported and this

step is accomplished with aid of a

second person.

11. Drill two holes with 5/32” bits through

bottom support brackets and into the

bottom of griddle chassis. Insert and

tighten 10-24 x 2” screws as shown in

Fig.10. Repeat as necessary for all bottom

support brackets.

GRIDDLE TOP INSTALLATION

12. Attach masking tape to mounting plate and

slide into position between the griddle back

panel and the top of the selected griddle

top mounting point as shown in

Fig. 11.

13. Use tape to align holes in mounting plate

with holes in griddle top mounting point as

shown in Fig. 12. Tape to hold in position

until installation of griddle top is complete.

Repeat steps 12 and 13 for the bottom

mounting point.

Fig. 10

Fig. 11

Mounting Plate

Griddle top

mounting point

Fig. 12

Mounting Plate

- 14 -

Page 15

14. Place cardboard or other protective

covering on the gas griddle surface to

prevent scratching.

Ensure that the unit is

safely supported and steps 15 through 20

are accomplished with aid of a second

person.

15. Remove top and rear spring armature

covers. Set into place in the raised

position. Fig. 13.

16. Remove the four retaining clips that

secure the lower pivot rod. Fig 14.

17. Remove the lower pivot rod, then

remove the spring assembly as shown

in Fig 15.

Fig. 13

Fig. 14

Fig. 15

Lower Pivot Rod

Spring Assembly

- 15 -

Page 16

Ensure that the unit is

safely supported and steps 15 through 20

are accomplished with aid of a second

person.

Apply a thread locking compound

to the mounting bracket screws in steps 18

and 19.

18. Insert and tighten the bottom mounting

bracket screws and washers. Fig.16.

Ensure the mounting screws fully

engage the mounting plate that is

referenced in steps 12 and 13.

19. Set unit to lowered position as shown in

Fig C on page 6. Insert and tighten the

top mounting bracket screws and

washers. Fig.17.

Ensure the mounting screws fully

engage the mounting plate that is

referenced in steps 12 and 13.

Recheck and tighten bottom mounting

screws as necessary.

20. Reverse steps 16 and 17 to reinstall the

spring assembly, lower pivot rod and four

retaining clips. Fig.18

Fig. 16

Fig. 17

Fig. 18

- 16 -

Page 17

21. Install the bumper stop assembly into top

of armature. Fig. 19

Bumper Stop Assembly

22. Check range of motion as shown in

Fig. 20. The assembly should hold in

place at the raised, 53˚ position and rest

under its own weight in the lowered

position. Refer to page 6 for proper

raising and lowering technique.

23. Reinstall the top and rear spring

armature covers. Fig. 21

24. Repeat proceeding steps as needed for

each griddle top head assembly.

Raised Position

Lowered Position

Fig. 19

Fig. 20

Fig. 21

- 17 -

Page 18

ELECTRICAL CONNECTIONS

ELECTRICAL SPECIFICATIONS

Model No

Description

Voltage

Power

1 Phase Draw

VMCS-101

FLAT

PLATE

208V

3.6 KW

17.3 A

VMCS-102

240V

15.0 A

VMCS-201

GROOVED

PLATE

208V

17.3 A

VMCS-202

240V

15.0 A

Electrical and grounding connections must comply with the

applicable portions of the National Electrical Code and/or other local electrical

codes.

Disconnect the electrical power to the griddle and follow lockout /

tagout procedures.

Since the griddle top is not fused, you must connect to a fused circuit equipped with a

suitable disconnecting means as required by local authorities.

Electrical Connections

1. Remove the small junction box cover plate on the back of the unit. This exposes the

VMCS clamshell griddle line leads.

2. Select a suitable knockout on the sides or bottom of the junction box.

3. Connect the griddle’s line leads to the supply wires with factory supplied wire connectors as shown

in the applicable wiring diagrams.

4. Push the excess wire into the junction box and replace the cover plate. Never operate griddle

without cover in place.

- 18 -

Page 19

- 19 -

Page 20

TROUBLESHOOTING

PROBLEM

POSSIBLE CAUSES

Heat does not come on

when power switch is

turned ON

1. Thermostat set too low. Turn to higher setting

2. High limit cutoff switch is tripped – depress reset button.

3. If power switch is not illuminated. Check breaker panel.

4. If power switch is not illuminated, check if main power

supply is disconnected (Call for service).

5. Problem with heating element, thermostat or power

switch. (Call for service)

Heat does not come on

when thermostat is turned

ON

1. Power switch not in the ON position.

2. High limit cutoff switch is tripped – depress reset button.

3. Power not supplied to unit. Check breaker panel.

4. Main power supply disconnected (Call for service).

5. Problem with heating element, thermostat or power

switch. (Call for service)

Unit will not hold or

remain in the raised

position.

1. Not raising high enough. Unit will only hold in place at the

53˚ position.

2. Problem with spring mechanism (Call for service)

Unit will not lower from

the raised position

1. Problem with spring mechanism (Call for service)

Unit will not raise from the

cooking or lowered

position

1. Problem with spring mechanism (Call for service)

Food under-cooked

1. Temperature set too low.

2. Food not cooked for long enough time.

3. Cooking surface not touching or partially touching food

when in the lowered position. Reset the plate gap

adjuster. See page 7.

Food over-cooked

1. Temperature set too high.

2. Food cooked for too long of a time.

3. Cooking surface pressing down too hard when in the

lowered position. Reset the plate gap adjuster. See page

7.

Food is being crushed

1. Cooking surface pressing down too hard when in the

lowered position. Reset the plate gap adjuster. See page

7.

Food sticks to cooking

surface

1. Temperature set too high or too low.

2. Cooking surface needs to be cleaned.

3. Cooking surface not covered with enough cooking oil.

- 20 -

Page 21

- 20 -

PROBLÈME

CAUSES POSSIBLES

Aucune chaleur n'est

produite lorsque

l'interrupteur est à la

position ON (marche).

1. Le thermostat est réglé à une température trop basse.

Choisissez une température plus élevée.

2. L'interrupteur de protection contre la surchauffe est déclenché

– enfoncez le bouton de réinitialisation.

3. Si l'interrupteur d'alimentation ne s'illumine pas : Vérifiez au

niveau du panneau de disjoncteurs.

4. Si l'interrupteur d'alimentation ne s'illumine pas, vérifiez si

l'alimentation et branchée (téléphoner pour obtenir du service).

5. Problème au niveau de l'élément chauffant, du thermostat ou

de l'interrupteur d'alimentation. (Téléphoner pour obtenir du

service)

Aucune chaleur n'est

produite lorsque le

thermostat est à la

position ON (marche).

1. L'interrupteur d'alimentation n'est pas à la position ON.

2. L'interrupteur de protection contre la surchauffe est déclenché

– enfoncez le bouton de réinitialisation.

3. L'appareil n'est pas alimenté en électricité. Vérifiez au niveau

du panneau de disjoncteurs.

4. L'alimentation électrique principale est débranchée (Téléphoner

pour obtenir du service).

5. Problème au niveau de l'élément chauffant, du thermostat ou

de l'interrupteur d'alimentation. (Téléphoner pour obtenir du

service)

L'appareil ne reste pas

verrouillé en position

surélevée.

1. Levage insuffisant. L’appareil reste en place seulement s’il

s’élève à un angle de 53°.

2. 2. Il y a un problème avec le mécanisme des ressorts.

(Téléphoner pour obtenir du service)

L'unité ne s'abaisse plus

lorsqu'elle est surélevée

ou verrouillée.

1. Il y a un problème avec le mécanisme des ressorts

(Téléphoner pour obtenir du service)

L'unité ne se relève plus

lorsqu'elle est en mode

cuisson ou abaissée.

1. Il y a un problème avec le mécanisme des ressorts (Téléphoner

pour obtenir du service)

Les aliments ne sont pas

suffisamment cuits.

1. La température a été réglée trop bas.

2. Le temps de cuisson est insuffisant.

3. La surface supérieure de cuisson ne touche que artiellement

ou pas du tout aux aliments lorsqu'elle est abaissée. Modifier

le régleur de l’écart de la plaque. Voir la page 7.

Les aliments sont trop

cuits.

1. Le réglage du thermostat est trop élevé.

2. Les aliments cuisent trop longtemps.

3. La surface supérieure de cuisson compresse trop les

aliments lorsqu'elle est abaissée. Modifier le régleur de

l’écart de la plaque. Voir la page 7.

Les aliments se font

écraser.

1. La surface supérieure de cuisson compresse trop les

aliments lorsqu'elle est abaissée. Modifier le régleur de

l’écart de la plaque. Voir la page 7.

Les aliments collent à la

surface de cuisson.

1. Le réglage du thermostat est trop élevé ou trop bas.

2. La surface de cuisson nécessite d'être nettoyée.

3. La surface de cuisson manque d'huile à cuisson.

DÉPANNAGE

Page 22

- 19 -

Page 23

- 18 -

CARACTÉRISTIQUES ÉLECTRIQUES

N˚ de modèle

Description

Tension

Puisssance

Courant

monophasé

VMCS-101

PLAQUE

PLATE

208V

3.6 KW

17.3 A

VMCS-102

240V

15.0 A

VMCS-201

PLAQUE

RAINURÉE

208V

17.3 A

VMCS-202

240V

15.0 A

jamais la plaque sans que le couvercle ne soit en place.

5. Poussez tout fil excédentaire à l'intérieur du boîtier et remettez le couvercle en place. N'utilisez

connecteurs fournis, tel qu'illustré au schéma de câblage applicable.

3. Raccordez les fils de sortie de la plaque chauffante aux fils d'alimentation électrique au moyen des

2. Sélectionnez l'alvéole défonçable appropriée sur l'un des côtés ou sous le boîtier de raccordement.

fils de sortie du dessus de plaque chauffante VMCS.

1. Retirez le couvercle du petit boîtier de raccordement situé à l'endos de l'appareil. Cela expose les

Connexions électriques

les autorités locales.

connecter à un circuit à fusible muni d'un dispositif de sectionnement tel que requis par

Puisque le dessus de plaque chauffante n'est pas protégé par un fusible, vous devez le

et suivez la procédure de verrouillage et étiquetage.

Débranchez l'alimentation électrique de la plaque chauffante

électriques locaux.

conformes aux parties applicables du Code électrique national et/ou d'autres codes

Les connexions électriques et de mise à la terre doivent être

CONNEXIONS ÉLECTRIQUES

Page 24

21. Installez le butoir dans l’armature

supérieure. Fig. 19

Ensemble du butoir

22. Vérifiez la plage de déplacement tel

qu’illustré à la Fig. 20. L’ensemble devrait

rester en place en position élevée à un

angle de 53° et reposer de son propre

poids en position abaissée. Référez-vous

à la page 6 pour connaître les bonnes

techniques de levage et d’abaissement

23. Remettez en place le couvercle des

ressorts supérieur et arrière. Fig. 21.

24. Répétez au besoin les étapes

nécessaires à l'installation de chaque

dessus de plaque chauffante.

Position Levée

Position Baissée

Fig. 21

Fig. 20

Fig. 19

- 17 -

Page 25

- 16 -

Assurez-vous que

l’appareil est supporté en toute sécurité

et faites-vous aider par une deuxième

personne avant de

procéder aux étapes

de 15 à 20.

AVIS

Appliquez un adhésif frein-filet

sur les vis du support de montage aux

étapes 18 et 19.

18. Insérez et serrez les vis et rondelles

inférieures du support de montage. Voir

Fig. 16.

Assurez-vous que les vis de montage

s’engagent pleinement dans la plaque de

montage référencée aux étapes 12 et 13.

19. Placez l’appareil à sa position abaissée

tel qu’illustré à la figure C de la page 6.

Insérez et serrez les vis et rondelles

supérieures du support de montage. Voir

Fig. 17.

Assurez-vous que les vis de montage

s’engagent pleinement dans la plaque de

montage référencée aux étapes 12 et

13.

Si nécessaire, vérifiez de nouveau les

vis de montage inférieures et resserrez-

les.

20. Refaites les étapes 16 et 17 à l’envers

pour remettre les ressorts, la tige de

pivotement inférieure et les quatre

agrafes de retenue en place. Fig. 18

Fig. 16

Fig. 17

Fig. 18

Page 26

14. Posez un carton ou autre couverture de

protection sur la surface du gril à gaz

pour prévenir les égratignures.

Assurez-vous que

l’appareil est supporté en toute sécurité

et faites-vous aider par une deuxième

personne avant de

procéder aux étapes

de 15 à 20.

15. Retirez les couvercles de l’armature des

ressorts supérieur et arrière. Fixez-les en

position élevée. Fig. 13.

16. Retirez les quatre agrafes de butée qui

retiennent la tige de pivotement

inférieure. Fig. 14

17. Retirez la tige de pivotement inférieure et

ensuite enlevez l’ensemble des ressorts

tel qu’indiqué à la figure 15.

Fig. 13

Fig. 14

Fig. 15

Tige de pivotement inf.

Ensemble des ressorts

- 15 -

Page 27

- 14 -

Il sera peut-être

nécessaire d'incliner la plaque et de

laisser l'une des quatre pattes pendre

au bout de la table pour compléter

l'étape 11. Assurez-vous alors que la

plaque est bien soutenue et de

procéder avec l'aide d'un assistant.

11. Percez deux trous avec une mèche de

5/32 po à travers les supports de fixation

inférieurs et dans le dessous du châssis

du gril. Insérez et serrez des vis 10-24 x 2

po tel qu'illustré à la fig. 10. Répétez

l'opération au besoin pour chacun des

supports inférieurs requis.

INSTALLATION DU GRIL PLATEFORME

12. Collez du ruban masque sur la plaque

d'assemblage, et glissez celle-ci en

position entre le panneau arrière du gril et

le haut du point d'assemblage sélectionné

de la plaque, tel qu'illustré à

qu'illustré à la Fig. 11.

13. Utilisez du ruban pour aligner les trous de

la plaque d'assemblage avec les trous du

point d'assemblage supérieur de la plaque,

tel qu'illustré à la Fig. 12. Fixez avec du

ruban pour maintenir en place jusqu'à ce

que l'installation soit achevée. Répétez les

étapes 12 et 13 pour le trou d'assemblage

inférieur.

Fig. 10

Fig. 11

Plaque d'assemblage

Trou d'assemblage

supérieur de la plaque

Fig. 12

Plaque d'assemblage

Page 28

- 13 -

8. Percez les derniers trous à travers les

supports de fixation latérale dans le

châssis de la plaque. Insérez et serrez

des vis tel qu'illustré à la Fig. 7. Répétez

la procédure de l'autre côté du système

de fixation.

9. Depuis l'arrière du support de fixation

latérale, percez des trous avec une

mèche de 5/32 po dans le support de

fixation arrière, et installez une cale

murale au moyen de (4) vis 10-24 x ½

po, tel qu'illustré à la fig. 8. Répétez de

l'autre côté du système de fixation.

Cale murale

10. Installez un support de fixation inférieur tous

les 60 cm de largeur de plaque, entre les

points de montage du dessus de plaque

chauffante, s'il y a lieu de croire qu'un

support additionnel est requis. Les supports

de fixation inférieurs doivent être au même

niveau que la partie inférieure du châssis du

gril et le support de fixation arrière. Au

moyen de la mèche de 5/32 po, percez

deux trous et fixez la pièce au support de

fixation arrière avec des vis 10-24 x 2 po tel

qu'illustré à la Fig. 2. Répétez pour chacun

des supports requis.

Vue de coupe

latérale

Fig. 7

Fig. 8

Fig. 9

Support de

fixation inférieur

Page 29

- 12 -

4. Serrez fermement les boulons

d'assemblage du système de fixation

aux supports de fixation gauche et droit.

qu'illustré à la Fig. 4.

5. Assurez-vous que les supports de

fixation latéraux sont bien restés dans

leur position pendant le serrage des

boulons. Les pinces en F doivent

demeurer bien en place pour empêcher

tout mouvement du système de fixation

pendant le perçage des trous sur le

châssis.

Procédez à une vérification avant de

percer les trous sur le châssis. Il

importe que le système de fixation n'ait

pas bougé de la position prescrite à

l'étape 3.

6. En vous servant du support de fixation

latérale comme gabarit, percez des

trous dans le châssis du gril au moyen

d'une mèche 5/32 po, mais seulement

au niveau du trou le plus haut et du trou

le plus rapproché de l'avant de l'appareil

sur le support latéral. Reportez-vous

aux figures 5 et 6. Répétez la procédure

du côté opposé du système de support

de fixation.

7. Insérez et serrez des vis 10-24 x ½ po

dans les trous percés à l'étape 6.

Répétez la procédure du côté opposé

du système de support de fixation. Voir

la Fig. 6.

Fig. 4

Fig. 5

Fig. 6

Page 30

- 11 -

Avant de procéder à l'assemblage,

assurez-vous que les dimensions du

support de fixation sont adéquates. Le

support arrière devrait être de même

largeur que la plaque. Assurez que les

caractéristiques électriques du dessus de

plaque chauffante correspondent aux

caractéristiques de la ligne électrique.

Chaque dessus de plaque chauffante

nécessite sa propre ligne électrique.

1. Au moyen de (2) rondelles et (2) boulons ¼ po -

28, assemblez l'un des supports de fixation

latérale au support arrière, tel qu'illustré à la Fig.

1. Contentez-vous pour le moment de serrer les

boulons à la main. Répétez cette procédure

pour fixer le second support de fixation latérale

à l'autre extrémité du support de fixation arrière.

2. À ce stade-ci, le système de support de fixation

devrait être complètement assemblé tel

qu'illustré à la figure 2, les boulons n'étant pour

le moment que serrés à la main.

3. Glissez le système de fixation sur l'arrière du

dessus de plaque chauffante, tel qu'illustré à la

Fig. 3. Les supports latéraux gauche et droit

doivent être ramenés vers le haut jusqu'à ce

qu'ils s'appuient contre le dessous de la plaque,

puis vers l'avant jusqu'à ce qu'ils reposent

contre le panneau arrière de la plaque.

Verrouillez le système de support de fixation

dans cette position au moyen d'une pince en F

de part et d'autre de l'assemblage, tel qu'illustré.

Placez un bloc de bois ou tout autre type de

protection entre la pince et la plaque.

Fig. 1

Fig. 2

Fig. 3

Points de

montage

du dessus de

plaque

chauffante

Débranchez l'alimentation et suivez la procédure de

La plaque chauffante et ses pièces sont chaudes. Soyez

verrouillage-étiquetage avant tout nettoyage ou entretien de l'appareil.

prudent lors de l'utilisation, du nettoyage et de l'entretien de la plaque chauffante.

MONTAGE ET INSTALLATION DU SUPPORT

Page 31

- 10 -

10. Ruban masque ¾ po de largeur

9. Composé frein pour filets (Loctite Blue®)

8. Mèches à métaux 5/32 po

7. (2) grandes pinces en F

6. Clé à douilles à puits profond 7/8 po

5. Perceuse électrique

B. Maillet en caoutchouc

3. Clé à douilles 7/16 po

2. Clé à douilles M10

OUTILS REQUIS POUR L'INSTALLATION1. Tournevis crucifo rme n˚ 2

compétences requis, l'installation ne devrait jamais être tentée.

instruments et compétences requis pour effectuer l'installation. À défaut de posséder les outils, instruments et

recommandons de lire attentivement les directives d'installation afin de vous assurer que vous détenez les outils,

utilisées que par des personnes compétentes. Ces directives ne se veulent aucunement exhaustives. Nous

Les directives d'installation ont été rédigées à l'intention de techniciens autorisés qualifiés, et ne devraient être

Communiquez avec votre entrepreneur de service locale pour l'installation de l'appareil sur le site.

ASSEMBLAGE ET INSTALLATION SUR LE SITE

sur la plaque signalétique de l'appareil : Numéro de modèle, numéro de série et tension.

Lors de tout appel de service, veuillez avoir les renseignements suivants habituellement inscrits

www.vulcanequipment.com.

les pièces. Pour obtenir une liste complète de centre de service et de dépôt de pièces, consultez

Contactez le centre de service de votre région pour obtenir des renseignements sur le service et

RENSEIGNEMENTS SUR LE SERVICE ET LES PIÈCES

Cet appareil ne comporte aucune pièce qui nécessite une lubrification.

LUBRIFICATION

étiquetage avant tout nettoyage ou entretien de l'appareil.

Débranchez l'alimentation et suivez la procédure de verrouillage-

lors de l'utilisation, du nettoyage et de l'entretien de la plaque chauffante.

La plaque chauffante et ses pièces sont chaudes. Soyez prudent

ENTRETIEN

4. Coupez l'alimentation électrique principale

prévenir la rouille.

3. App liquez une légère couche d’huile de cuisson sur la plaque rainurée (en acier) pour

2. Laissez l’ appareil en pos it io n élevée, à u n angle de 53°

plaque chauffante.

1. Mettez l'interrupteur en position OFF (arrêt). Cela éteindra complètement le dessus de

ARRÊT PROLONGÉ

2. La is sez l’appareil en position élevé e, à un angle de 53°.

plaque chauffante.

1. Mettez l'interrupteur en position OFF (arrêt). Cela éteindra complètement le dessus de

ARRÊT DE LA PLAQUE CHAUFFANTE

Page 32

- 9 -

à la partie Entretien et nettoyage.

5. Avant de réassembler la feuille de Téflon au plateau, nettoyez ce dernier tel que décrit

4. Séchez la feuille de Téflon et sa quincaillerie au moyen d'un linge propre et doux.

3. Rincez la feuille de Téflon et sa quincaillerie sur tous leurs côtés avec de l'eau.

quincaillerie avec le linge propre imbibé d'une solution d'eau et de savon doux.

chimiques agressifs). Nettoyez doucement les deux surfaces de la feuille de Téflon et sa

trempée dans une solution d'eau et de savon doux (n'utilisez jamais d'abrasifs ou de produits

2. À la fin de chaque journée, la feuille de Téflon doit être retirée du plateau, désassemblée, et

essuyée avec un linge doux et propre imbibé d'eau.

1. Entre les séances de cuisson et les périodes d'inactivité, la feuille de Téflon doit être

ENTRETIEN ET NETTOYAGE DE L'ENVELOPPE DE TÉFLON

causer de la décoloration, de la corrosion et des dommages irréversibles.

dans les nettoyants domestiques pour le four. Tout contact avec ce produit peut

N'utilisez pas d'agents nettoyants tels l'hydroxyde de sodium, un produit courant

irréversibles.

telles substances peut causer des décolorations, de la corrosion et des dommages

N'utilisez pas non plus de désinfectant chloré sur la plaque. Tout contact avec de

Évitez d'utiliser un jet d'eau pour nettoyer le gril.

N'utilisez pas de tampon à récurer métallique.

N'utilisez pas de pierre à poncer ou à gril pour le nettoyage.

nettoyage plus d'une fois par semaine.

Si l'utilisation de la plaque chauffante est intensive, envisagez d'effectuer cette procédure de

et doux. Pour enlever la décoloration, utilisez un nettoyant à plaque chauffante.

Nettoyez les surfaces en acier inoxydable avec un chiffon humide et polissez avec un chiffon sec

à cuisson conformément aux directives du présent manuel.

Après avoir nettoyé le détergent de la surface de la plaque, la plaque doit être recouverte d'huile

détergent est soigneusement retiré en rinçant à l'eau claire.

être utilisée sur la surface de la plaque pour faciliter le nettoyage, mais assurez-vous que le

Nettoyez soigneusement la surface de la plaque chauffante. Un solution de détergent doux peut

UNE FOIS PAR SEMAINE

surface de cuisson avec un tampon récurant non métallique (tel Scotch-Brite™).

Nettoyez en profondeur tous les panneaux et surfaces extérieurs en acier inoxydable. Nettoyez la

UNE FOIS PAR JOUR

chauffante.

de cuisson pour empêcher les aliments de coller à la surface de cuisson du dessus de plaque

Page 33

- 8 -

ARRIÈRE

AVANT

ARRIÈRE

AVANT

ARRIÈRE

AVANT

ARRIÈRE

AVANT

OUI OUI

OUI OUI

OUI OUI

OUI OUI

OUI OUI

OUI

OUI

OUI

OUI

OUI

OUI

OUI

OUI

OUI

OUI

OUI

l'horizontal de façon à ne pas égratigner ou strier la plaque. Utilisez un agent antiadhésif

chauffante pendant la période de travail. Travaillez en gardant la lame du racloir à

Nettoyez le dessus de plaque chauffante électrique avec un racloir pour plaque

APRÈS CHAQUE UTILISATION

les procédures ci-après.

Afin de garder la plaque chauffante propre et apte à fournir un plein rendement, suivez

apparence très insatisfaisante et peu appétissante.

carbonisée tend à s'accrocher aux aliments de la plaque chauffante et à leur donner une

rôtissage très inégal et une perte d'efficacité énergétique de la cuisson. La graisse

le transfert de chaleur de la surface de la plaque chauffante aux aliments, et entraîne un

propre et exempte de graisse carbonisée. La graisse carbonisée sur la surface empêche

des aliments uniformément cuits et parfaitement rissolés, gardez la plaque chauffante

propre paraît toujours mieux, dure plus longtemps et est plus performante. Pour obtenir

Nettoyez régulièrement le dessus de plaque chauffante électrique. Une plaque chauffante

prudent lors de l'utilisation, du nettoyage et de l'entretien de la plaque chauffante.

La plaque chauffante et ses pièces sont chaudes. Soyez

NETTOYAGE ET ENTRETIEN

plutôt des spatules en acier doux aux coins arrondis.

surface de la plaque chauffante. N'utilisez pas de spatules en acier trempé. Utilisez

aliments qui peuvent être sur la spatule en tapant le coin ou le bord de la spatule sur la

ne pas bosseler, rayer ou rainurer la surface de la plaque. N'essayez pas de retirer des

spatule ou d’un grattoir peut marquer ou ébrécher les deux surfaces de cuisson. Veillez à

rainurée comportent des plaques en acier au carbone standard. L’usage négligent d’une

» en matériau composite et surface d’inox. Les appareils à surface de cuisson

MD

Les appareils à surface de cuisson lisse se démarquent par la plaque « Rapid Recovery

produira les résultats les plus uniformes du produit.

Une approche uniforme et systématique pour le chargement de la plaque chauffante

les thermostats à la température souhaitée de 10 à 12 minutes avant la cuisson.

Pour préchauffer, badigeonnez la plaque supérieure avec de l'huile à cuisson et réglez

UTILISATION DU DESSUS DE PLAQUE CHAUFFANTE ÉLECTRIQUE

Page 34

- 7 -

3. Élevez le plateau à la position verrouillée de

53°. Faites passer la feuille de Téflon à

partir du côté droit du plateau en fixant l'avant

et l'arrière du support téflonisé aux goupilles

de retenue en Téflon. Voir la Fig. E.

4. Depuis le côté droit du plateau, tirez sur la

feuille de Téflon jusque vers la gauche de la

surface du plateau.

5. Tendez bien la feuille de Téflon en vous

assurant qu'elle recouvre entièrement la

surface de cuisson du plateau.

6. Fixez la feuille de Téflon au côté gauche du

plateau au moyen des deux attaches en

Téflon. Poussez les clips par-dessus la

feuille de téflon en les agrafant aux tiges

rondes sous la feuille. Voir Fig. F.

Le régleur de l’écart de la plaque sert à

empêcher les aliments mous d’être écrasés par

la force descendante de l’appareil. Un réglage

de 1 serait utilisé comme l’écart le plus faible ou

sans écart, alors qu’un réglage de 4 servirait à

créer l’écart le plus marqué.

On peut modifier les réglages en tournant le

corps du régleur d’écarts à gauche ou à droite

jusqu’à ce qu’il se bloque en place au point

d’écart voulu.

Fig. E

Fig. F

Fig. G

Goupille De Retenue

en Téflon

Attache en Téflon

RÉGLEUR DE L’ÉCART DE LA PLAQUE

Page 35

- 6 -

Pour soulever l’ensemble

1. Soulevez-le par la poignée seulement

2. Retenez la poignée jusqu’à ce que l’ensemble

reste en place à la position approximative de

53°. Fig. B

Tenez toujours la

poignée pour garder le contrôle sur l’appareil

jusqu’à ce que le dispositif de levage l’ait

monté à la position voulue ou qu’il repose en

position abaissée. Ne laissez pas l’appareil

basculer vers le haut ou le bas de lui-même

car cela peut se traduire par une blessure ou

par des dommages à l’équipement.

Pour faire descendre l’ensemble

1. Saisissez la poignée et tirez-là vers le bas.

Continuez à retenir la poignée jusqu’à ce que

l’appareil s’arrête en position abaissée. Fig. C

AVIS

Ne forcez pas l’appareil s’il ne

bouge pas de haut en bas de la façon prévue. Il

peut subir des dommages si une force excessive

est exercée vers le haut ou le bas. Contactez un

technicien d’entretien autorisé s’il devient difficile

de déplacer l’ensemble.

Fig. B

Support téflonisé

Fig. D

Position Levée

Position Baissée

Fig. C

Manchon de la feuille de Téflon

La plaque

chauffante et ses pièces sont chaudes. Soyez

prudent lors de l'utilisation, du nettoyage et

de l'entretien de la plaque chauffante.

1. Nettoyez le plateau avec un chiffon imbibé

d'une solution d'eau et de savon doux.

2. Glissez le support téflonisé (#944503) dans la

chemise de la feuille de Téflon, tel qu'illustré à la

Fig. D.

INSTALLATION DE LA GARNITURE EN TEFLON

Page 36

- 5 -

Fig. A

Bouchon d'accès à la

réinitialisation de l'interrupteur

de protection contre la

surchauffe

Couvercle du boîtier

du thermostat

Cadran de commande du thermostat

Bouton de réinitialisation de

l'interrupteur de protection

contre la surchauffe

Interrupteur d'alimentation(centre)

Voyants indicateurs ambrés

Voyant indicateur d'alimentation (gauche)

Voyant de chauffe (droite)

Poignée

Régleur de l’écart de la plaque

chauffante hors tension. Se reporter à la figure A.

l'interrupteur d'alimentation à la position OFF (arrêt) pour mettre le dessus de plaque

de l'interrupteur de protection contre la surchauffe. À la fin de la journée, il faut placer

prévenir les surchauffes. On peut le réinitialiser en enfonçant le bouton de réinitialisation

dispositif de sécurité de coupure de l'alimentation de l'élément chauffant servant à

indicateur ambré s'éteignent. L'interrupteur de protection contre la surchauffe est un

la plaque chauffante a atteint la température de réglage souhaitée, l'élément et le voyant

l'interrupteur d'alimentation s'illumine pour indiquer que l'élément est en marche. Lorsque

Une fois le thermostat en marche (ON), le voyant indicateur ambré à la droite de

retiré pour accéder au cadran de commande du thermostat.

thermostat est alimenté en électricité. Le couvercle du boîtier du thermostat doit être

basculant rouge) est en position ON (marche), le voyant ambré de gauche s'illumine et le

protection contre la surchauffe. Lorsque l'interrupteur d'alimentation (interrupteur

indépendamment par un interrupteur d'alimentation, un thermostat et un interrupteur de

Le dessus de plaque chauffante électrique de fabrication robuste est commandé

COMMANDES

Page 37

- 4 -

répéter la procédure de conditionnement pour assurer une cuisson adéquate.

Après avoir nettoyé votre plaque chauffante avec des produits chimiques, il convient de

sur toute la surface.

d'huile de cuisson à haute température par plaque de dessus VMCS. Étendez bien l'huile

Chaque fois avant de mettre en marche l'appareil, badigeonnez d'environ deux onces

CONDITIONNEMENT DE LA PLAQUE CHAUFFANTE

l'eau propre et asséchez avec un chiffon doux et propre.

solution d'eau et de savon doux. Essuyez ensuite la surface de la plaque chauffante avec de

recommandé de nettoyer à fond votre dessus de plaque chauffante Vulcan VMCS avec une

Retirez tous les matériaux d'emballage et les plastiques de protection de l'appareil. Il est

AVANT LA PREMIÈRE UTILISATION

étiquetage avant tout nettoyage ou entretien de l'appareil.

Débranchez l'alimentation et suivez la procédure de verrouillage-

lors de l'utilisation, du nettoyage et de l'entretien de la plaque chauffante.

La plaque chauffante et ses pièces sont chaudes. Soyez prudent

recommandé que vous fassiez monter le support par l’usine.

vous achetez un nouveau gril lisse en même temps que la plateforme-gril robuste VMCS électrique, il est

Le support de montage VCMS (voir la page 11) est un accessoire séparé et expédié dans un autre emballage. Si

o Support de téflon

o (2) clips de téflon

o (2) feuilles de téflon

Trousse de garniture en téflon (voir la page 6)

o (4) Rondelles frein M10 pour la plaque de montage

o (4) Vis M10 pour la plaque de montage

(2) Plaques de montage (voir la page 14)

o (4) Vis pour l’ensemble du butoir

Ensemble du butoir (voir la page 16)

Vérifiez si les articles suivants ont été inclus :

5. Avisez le Service à la clientèle de Vulcan immédiatement en faisant le (800) 814-2028

4. Le dessus de plaque chauffante ne doit pas avoir été déplacé, installé ou modifié.

3. Pour fins d’inspection, tout le matériel d’emballage original doit être conservé.

confirmant les faits par écrit ou par communication électronique.

découverte des dommages (indiquez l’heure, la date et à qui vous avez parlé) et assurez le suivi en

2. Les gens du terminus local du transporteur doivent être avisés immédiatement lors de la

1. Le transporteur doit être averti dans les 5 jours ouvrables suivant la réception.

S’il s’avère que le dessus de plaque chauffante a été endommagé, veuillez suivre les procédures suivantes :

s’il a effectivement subi des dommages pendant le transport.

transporteur prend l’entière responsabilité de le livrer en toute sécurité. Immédiatement après la livraison, vérifiez

Ce dessus de plaque chauffante a été inspecté avant de quitter l'usine. En acceptant sa livraison, le

DÉBALLAGE

Page 38

- 3 -

CARACTÉRISTIQUES ÉLECTRIQUES

N˚ de modèle

Description

Tension

Puisssance

Courant

monophasé

VMCS-101

PLAQUE

PLATE

208V

3.6 KW

17.3 A

VMCS-102

240V

15.0 A

VMCS-201

PLAQUE

RAINURÉE

208V

17.3 A

VMCS-202

240V

15.0 A

100, Mississauga (Ontario), Canada, L4W 5N6.

auprès de l'Association canadienne de normalisation, 5060 Spectrum Way, bureau

2. Code canadien de l'électricité, Première partie C22.1 (plus récente édition) disponible

1. Codes locaux.

Au Canada :

Park, Quincy, MA 02269.

édition), disponible auprès de la National Fire Protection Association, Batterymarch

3. Norme no 96 de NFPA, Vapor Removal from Cooking Equipment, (plus récente

National Fire Protection Association,1 Batterymarch Park, Quincy, MA 02269.

2. National Electrical Code ANSI/NFPA - 70 (plus récente édition) disponible auprès de la

1. Codes d'État et locaux.

Aux États-Unis d'Amérique :

codes et normes suivants :

Votre dessus de plaque chauffante de marque Vulcan doit être installé conformément aux

CODES ET NORMES D'INSTALLATION

Contactez immédiatement le détaillant ou Vulcan-Hart.

l'installation si la tension d'alimentation et celle de l'appareil ne correspondent pas.

correspond aux spécifications indiquées sur la plaque signalétique. N'effectuez pas

Avant l'installation, vérifiez le branchement électrique pour vous s'assurer qu'il

INSTALLATION

les directives fournies.

Lisez attentivement ce manuel en entier avant la première utilisation et suivez bien toutes

performance satisfaisante.

entretien approprié de votre dessus de plaque chauffante favoriseront des années de

main-d'œuvre qualifiée et des matériaux de qualité. Une installation, une utilisation et un

Les dessus de plaque chauffante de fabrication robuste VMCS sont produits par de la

GÉNÉRALITÉS

FABRICATION ROBUSTE VMCS

DESSUS DE PLAQUE CHAUFFANTE ÉLECTRIQUE DE

Page 39

- 2 -

UTILISATION DE L'APPAREIL

Installation ........................................................................................................................

Caractéristiques électriques ..............................................................................................

Commandes .....................................................................................................................

Soulèvement/abaissement du dessus de plaque chauffante .............................................

Installation de la garniture en téflon……………………………………………………………..

Régleur de l’écart de la plaque……………………………………………………………………

Utilisation du dessus de plaque chauffante…………………………………………………….

Nettoyage .........................................................................................................................

Arrêt ..................................................................................................................................

Entretien ...........................................................................................................................

ASSEMBLAGE ET INSTALLATION SUR LE SITE

Outils requis ......................................................................................................................

Assemblage du support de fixation ...................................................................................

Installation du support de fixation ......................................................................................

Installation du dessus de plaque chauffante .....................................................................

Installation de la plaque de montage…………………………………………………………….

Installation du butoir………………………………………………………………………………..

Amplitude de mouvement ................................................................................................

Branchements et spécifications électriques ......................................................................

Schémas de câblage ........................................................................................................

Dépannage .......................................................................................................................

3

3

5

6

6

7

8

8

9

10

10

11

11

14

14

17

17

18

19

20

TABLE DES MATIÈRES

Page 40

©ITW Food Equipment Group, LLC

3600 North Point Blvd.

Baltimore, MD 21222

CONSERVEZ CE MANUEL POUR UNE

UTILISATION ULTÉRIEURE

FORMULAIRE F-47658 (10-15)

VMCS-101 MODÈLES

VMCS-101

VMCS-102

VMCS-201

VMCS-202

Pour obtenir des renseignements supplémentaires au sujet de Vulcan-Hart

ou pour trouver un fournisseur de pièces et service autorisé dans votre

région, veuillez visiter notre site web à www.vulcanequipment.com

De Fabrication Robuste VMCS

MANUEL D'UTILISATION ET D'INSTALLATION

Dessus De Plaque Chauffante Électrique

Loading...

Loading...