Page 1

INSTALLATION &

OPERATION MANUAL

VL2GSS & VL3GSS

MODEL

VL2GSS ML-52389

VL3GSS ML-52393

GA

S FOOD STEAMERS

Model VL2GSS

For additional information on Vulcan-Hart or to locate an authorized parts

and service provider in your area, visit our website at www.vulcanhart.com

VULCAN-HART P.O. BOX 696, LOUISVILLE, KY 40201-0696

DIVISION OF ITW FOOD EQUIPMENT GROUP, LLC TEL. (502) 778-2791

WWW.VULCANHART.COM

FORM 35409 Rev. A (Aug. 2004)

Page 2

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL GAS

EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD START-UP AND

ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN THE

EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE OBTAINED

FROM THE LOCAL GAS SUPPLIER.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT DOWN

UNITS AT MAIN SHUTOFF VALVE AND CONTACT THE LOCAL

GAS COMPANY OR GAS SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE

VAPORS OR LIQUIDS IN THE VICINITY OF THIS OR ANY

OTHER APPLIANCE.

WARNING: IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, INJURY OR DEATH. READ THE

INSTALLATION, OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT.

IN THE EVENT OF A POWER FAILURE, DO NOT ATTEMPT TO

OPERATE THIS DEVICE.

© VULCAN-HART, 2003

– 2 –

Page 3

TABLE OF CONTENTS

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Remove the Burner Shipping Restraint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation Codes and Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Requirements for Gas Appliances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Leveling and Anchoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Plumbing Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Water Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Water Supply Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Gas Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Testing the Gas Supply System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Flue-Gas Exhaust — A Ventilating Hood is Recommended . . . . . . . . . . . . . . 7

Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Drain Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Steamers with Electronic Ignition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Steam Cooking — Compartment Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Shut Down at End of Day. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

To Shut Off for an Extended Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Selection of Pans for Steam Cooking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Cooking Compartment Drains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Boiler Blowdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Compartments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Door Gaskets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Leave Compartment Doors Open . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Guidelines for Maintaining Stainless Steel Surfaces . . . . . . . . . . . . . . . . . . . 15

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Water Treatment System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Door Gaskets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Water Level Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Flue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Scale Related Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Service and Parts Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

– 3 –

Page 4

Installation, Operation and Care of

VL2 & VL3 GAS FOOD STEAMERS

SAVE THESE INSTRUCTIONS FOR FUTURE USE

GENERAL

Vulcan-Hart suggests that you thoroughly read this entire manual and carefully follow all of the

instructions provided. Your Vulcan Model VL Food Steamer is produced with quality workmanship and

materials. Its boiler is fully automatic with the heat input controlled by preset pressure switches. A

solenoid valve feeds makeup water as needed. The steamer is equipped with adjustable feet.

Proper installation, usage and maintenance of your food steamer will result in many years of

satisfactory performance.

INSTALLATION

Before installing, verify that the electrical service and gas supply (natural or propane) agrees with the

specifications on the rating plate located on the boiler access door. If the supply and equipment

requirements do not agree, do not proceed with the installation. Contact your dealer or Vulcan-Hart

immediately.

UNPACKING

This food steamer was inspected before leaving the factory. The

transportation company assumes full responsibility for safe delivery

upon acceptance of the shipment.

IMPORTANT: Immediately after unpacking, check for possible

shipping damage. If the food steamer is found to be damaged, save

the packaging material and contact the carrier within 15 days of

delivery.

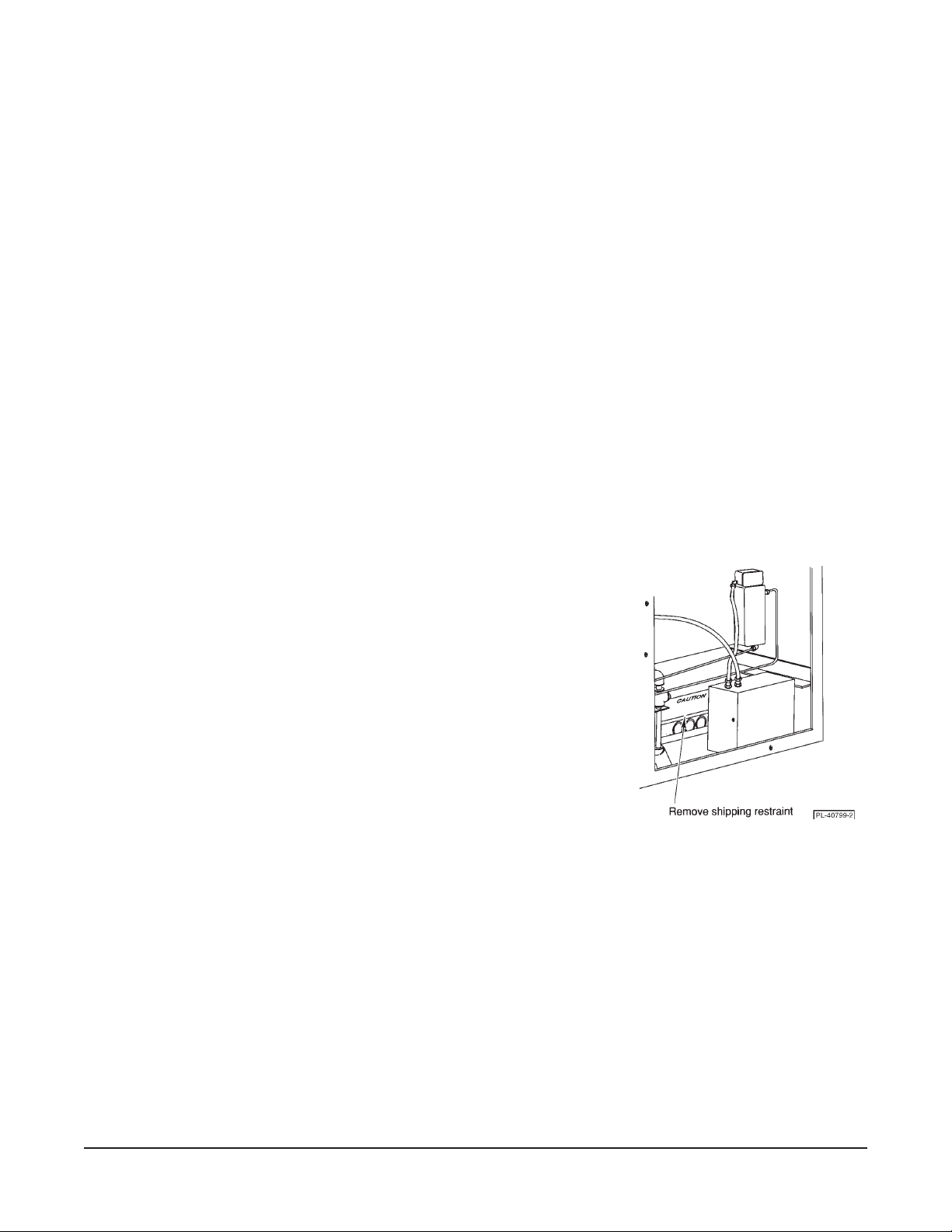

REMOVE THE BURNER SHIPPING RESTRAINT

The steamer is shipped as a complete unit and no assembly is

required. However, the burner shipping restraint must be removed

(Fig. 1). To do this, remove two hex nuts and two washers from the

weldstuds on the boiler shell.

LOCATION

Position the food steamer in its final location. Check that there are sufficient clearances to service the

controls, for door swings, etc., so there will be no problem in making the required supply and drain

connections. Recommended clearances for proper operation is 36" (

minimum clearance from combustible or noncombustible construction is 6" (

back. The recommended clearances for servicing the steamer are 18" (

and 36" (

during servicing at customer's expence.

91.4 cm) in the front. Clearances less than 18" may require removal of adjacent equipment

91.4 cm) at the front. The required

46 cm) on the sides and back,

Fig. 1

15 cm) at the sides and

Allow enough space between any other piece of equipment or a wall for access. All service on the

compartment controls begins by removing the panel on the left side of the food steamer.

Refer to the Installation Drawing on page 8 for installation location requirements.

– 4 –

Page 5

INSTALLATION CODES AND STANDARDS

In the United States, the Vulcan steamer must be installed in accordance with state and local codes,

with the National Fuel Gas Code, (ANSI-Z223.1, latest edition) available from the American Gas

Association, 1515 Wilson Boulevard, Arlington, VA 22209, with the National Electrical Code (ANSI/

NFPA No. 70, latest edition) available from the National Fire Protection Association, Batterymarch

Park, Quincy, MA 02269 and with

Vapor Removal from Cooking Equipment,

(NFPA-96, latest edition)

available from NFPA.

In Canada, the steamer must be installed in accordance with local codes, with the National Fuel Gas

Code (CAN/CGA-B149.1 latest edition) available from the Canadian Gas Association, 178 Rexdale

Boulevard, Etobicoke, Ontario, Canada M9W 1R3, and with the Canadian Electrical Code (CSA C22.2

No.3, latest edition) available from the Canadian Standards Association, 178 Rexdale Boulevard,

Etobicoke, Ontario, Canada M9W 1R3.

REQUIREMENTS FOR GAS APPLIANCES

Keep the food steamer free and clear from all combustible substances. Do not obstruct combustion

and ventilation openings on the steamer.

Do not obstruct the air flow into and around the food steamer. This air flow is necessary for proper

combustion of gases and for ventilation of the food steamer. Provisions for ventilation and for incoming

air supply for the equipment in the room must be in accordance with the National Fuel Gas Code, ANSI

Z223.1 (latest edition).

Do not obstruct the flow of flue gases from the flue duct located on the rear of the food steamer. It is

recommended that the flue gases be ventilated to the outside of the building through a ventilation

system installed by qualified personnel.

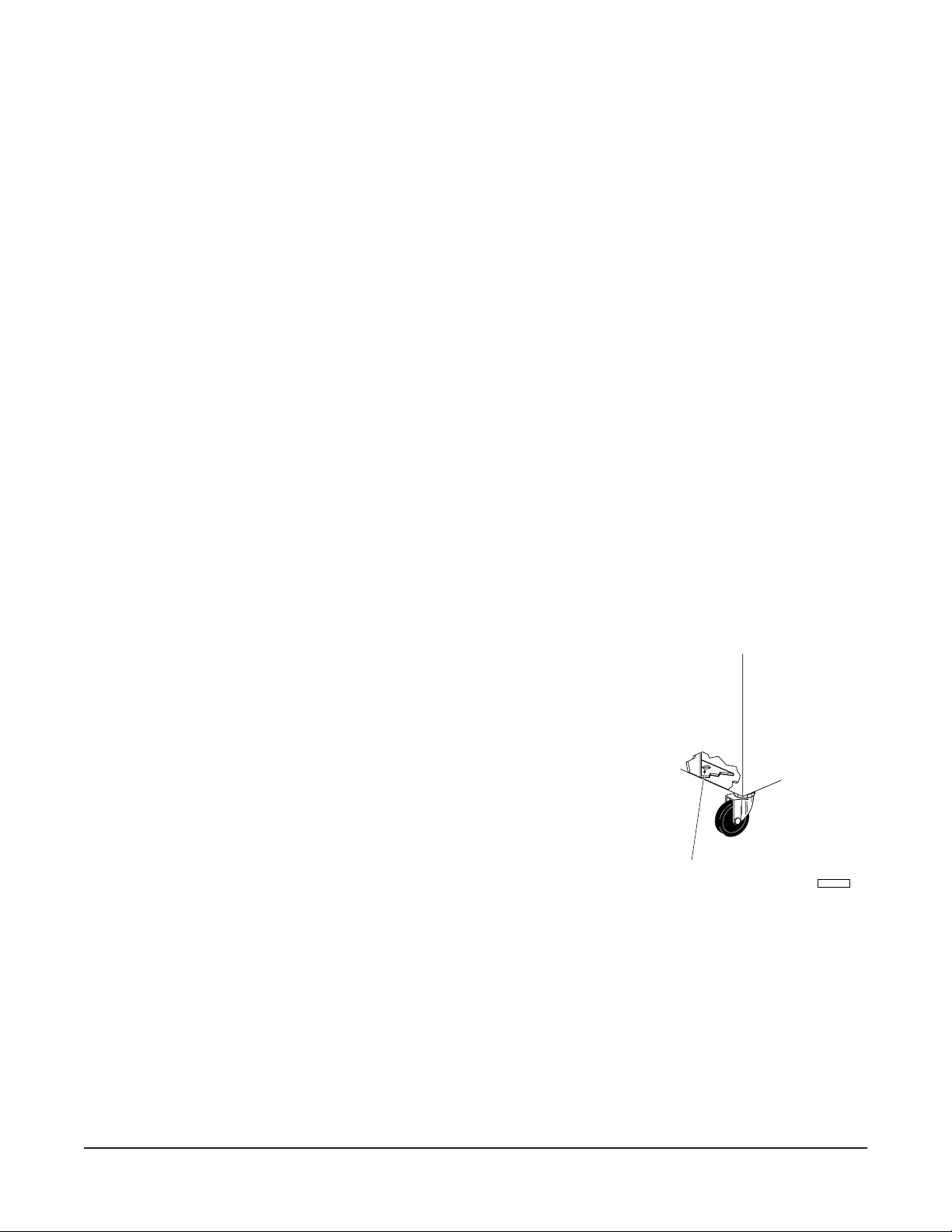

For steamers equipped with casters, the installation shall be made with

a connector that complies with the Standard for Connectors for Movable

Gas Appliances, ANSI Z21.69 (latest edition), and a quick-disconnect

device that complies with the Standard for Quick-Disconnect Devices for

Use With Gas Fuel, ANSI Z21.41 (latest edition). Provide a gas line strain

relief to limit the movement of the steamer without depending on the

connector and any quick-disconnect device or its associated piping to

limit the steamer movement. Attach the strain relief to the rear of the

steamer (Fig. 2).

If disconnection of the gas line strain relief is necessary, turn off gas

supply before disconnection. Reconnect this strain relief before turning

the gas supply on and returning the steamer to its originally installed

5/16 IN. DIA. HOLE

PROVIDED FOR

STRAIN RELIEF

PL-52057

position.

Fig. 2

LEVELING AND ANCHORING

Place a level on the horizontal parts of the steamer. Adjust the feet at the base of the steamer to level

the steamer in both the left-to-right and front-to-rear directions. After leveling, raise up the steamer on

1

the right side about

adjustable flanged feet 1 to 1

/16" to 1/8" (0.16 to 0.32cm) to drain the cooking compartments by rotating the

1

/2 turns clockwise. Check by pouring a little water in the compartment;

all the water should drain.

The feet have holes in the flanges for anchor bolts.

– 5 –

Page 6

PLUMBING CONNECTIONS

WARNING: PLUMBING CONNECTIONS MUST COMPLY WITH APPLICABLE SANITARY, SAFETY

AND PLUMBING CODES.

Water Requirements

WATER REQUIREMENTS

Supply Pressure 20 — 60 psig

Proper water quality can improve the taste of the

food prepared in the steamer, reduce liming in the

steam generator and extend equipment life. Local

water contitions vary from one location to another.

Ask your municipal water supplier for details about

your local water supply prior to installation.

Hardness* less than 3 grains

Silica less than 13 ppm

Total Chlorine less than 4.0 ppm

pH range 7 — 8

Undissolved Solids less than 5 microns

* 17.1 ppm = 1 grain of hardness

Presence of sediment, silica, excess chlorides or other dissolved solids may lead to a recommendation

for alternate form(s) of water treatment. Test the water with the test strip included with the steamer.

Other factors affecting steam generation are iron content, amount of chloridation and dissolved gases.

A local water treatment specialist should be consulted before installation of steam generating

equipment.

Water Supply Connections

A water filter system is recommended for the water supply line going to the treated water inlet of your

steamer. Follow the recommendations for use and installation instructions shipped with the water filter.

If a water filter is not installed, the steamer or steam generator warranty may be limited.

1

Filtered Water Connection —

Unfiltered Water Connection —

/4" NPT. Used for boiler feed water.

1

/4" NPT. Used as cold water condenser on boiler blow-down line.

Drain

CAUTION: In order to avoid any back pressure in the steamers, do not connect solidly to any

drain connection.

The drain must be the open air gap type. Provide a suitable floor sink with a minimum depth of

30 cm). The floor sink is NOT to be located directly under the steamer. Local codes require that

12" (

the maximum temperature of drain water must be no greater than 140°F (

60°C). Refer to Fig. 4 on

page 9. The drain pipe should be either iron or copper. DO NOT use PVC pipe; PVC pipe may lose

its rigidity or glue may fail.

– 6 –

Page 7

GAS CONNECTION

CAUTION: All gas supply connections and any pipe joint compound used must be resistant to

the action of liquefied petroleum gases.

Codes require that a gas shutoff valve be installed in the gas line ahead of the steamer.

Connect the gas supply line to the gas valve on the steamer. Make sure the pipes are clean and free

of obstructions, dirt and piping compound.

The gas line must be capable of delivering gas to the steamer without excessive pressure drop at the

rate specified on the nameplate. Recommended gas line pressure is 7" W.C. (

gas and 11" W.C. (

3

/4" (1.9 cm) inside diameter black iron pipe to the steamer should be satisfactory. If adequate pressure

a

is not available, a larger line such as 1" (

27.9 cm W.C.) for propane gas. Refer to Fig. 3 on page 8. With adequate gas pressure,

2.5 cm) inside diameter may be used to assure adequate gas

17.8 cm W.C.) for natural

delivery.

1

IMPORTANT: Check burner manifold pressure with a manometer at the

/8" (0.32 cm) tap on the gas

valve to make sure it is 4" W.C. for natural gas or 9" W.C. for propane.

WARNING: PRIOR TO LIGHTING, CHECK ALL JOINTS IN THE GAS SUPPLY LINE FOR LEAKS.

USE SOAP AND WATER SOLUTION. DO NOT USE AN OPEN FLAME.

TESTING THE GAS SUPPLY SYSTEM

1

When test pressures exceed

/2 psig (3.45 kPa), the steamer and its individual shutoff valve must be

disconnected from the gas supply piping system.

1

When test pressures are

/2 psig (3.45 kPa) or less, the steamer must be isolated from the gas supply

system by closing its individual manual shutoff valve.

FLUE-GAS EXHAUST — A VENTILATING HOOD IS RECOMMENDED

DO NOT obstruct the flow of flue gases from the flue located on the rear of the steamer. It is

recommended that the flue gases be ventilated to the outside of the building through a ventilation

system installed by qualified personnel.

Information on the construction and installation of ventilating hoods may be obtained from the standard

for the

Removal of Vapors from Commercial Cooking Equipment

, NFPA No. 96 (latest edition),

available from the National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

ELECTRICAL CONNECTION

WARNING: ELECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY WITH THE

APPLICABLE PORTIONS OF THE NATIONAL ELECTRICAL CODE AND/OR OTHER LOCAL

ELECTRICAL CODES.

WARNING: DISCONNECT THE ELECTRICAL POWER TO THE MACHINE AND FOLLOW LOCKOUT

/ TAGOUT PROCEDURES.

The electrical diagram for the compartments is located on the inside of the upper left side panel. The

electrical diagram for the steam generator is located on the inside of the left front door.

The electrical supply (120 volt, 60 Hertz, 1 Phase) must be connected to the pigtail leads in the junction

box located next to the boiler control box. Use #18 AWG copper wire suitable for at least 105°C

temperature. Connect a grounding wire to the ground lug in the junction box.

– 7 –

Page 8

INSTALLATION DRAWING

Models VL2GSS & VL3GSS

LEGEND

3

GAS CONNECTION:

BOILER FEED CONNECTION FOR FILTERED WATER:

WATER CONNECTION FOR BOILER DRAIN CONDENSER:

/4" NPT

1

/4" NPT

1

/4" NPT

ELECTRICAL CONNECTION: 120 V, 60 HZ, 1 PH, 300 WATTS MAX

DRAIN: 3

1

/2" DIA.

PROVIDE FLOOR SINK FOR OPEN GAP TYPE DRAIN.

DO NOT PLACE FLOOR SINK DIRECTLY UNDER STEAMER.

DO NOT CONNECT SOLIDLY TO ANY DRAIN CONNECTION.

NOTE: DIMENSIONS WHICH LOCATE THE ABOVE

CONNECTIONS HAVE A TOLERANCE OF + OR - 3 IN. (75 MM).

NORMAL DIMENSIONS ARE IN INCHES. DIMENSIONS IN ( )

ARE IN MILLIMETERS.

EQUIPMENT CLEARANCES

TO COMBUSTIBLE CONSTRUCTION

REAR: 6 INCH (152 MM) MINIMUM

LEFT SIDE: 6 INCH (152 MM) MINIMUM

RIGHT SIDE: 6 INCH (152 MM) MINIMUM

WATER QUALITY MUST BE WITHIN THESE GUIDELINES:

SUPPLY PRESSURE: 20 - 60 PSIG

HARDNESS*: LESS THAN 3 GRAINS

SILICA: LESS THAN 13 PPM

TOTAL CHLORINE: LESS THAN 4.0 PPM

pH RANGE: 7 – 8

UNDISSOLVED SOLIDS: LESS THAN 5 MICRONS

* 17.1 PPM = 1 GRAIN OF HARDNESS

Fig. 3

– 8 –

Page 9

DRAIN REQUIREMENTS

The floor sink is not to be located under the steamer.

Fig. 4

– 9 –

Page 10

IGNITION SWITCH

OPERATION

WARNING: THE STEAMER AND ITS PARTS ARE HOT. USE CARE WHEN OPERATING,

CLEANING AND SERVICING THE STEAMER.

STEAMERS WITH ELECTRONIC IGNITION

1. Make sure all supply connections for electric, gas and water are on.

2. Turn the knob on the Gas Combination Valve (Fig. 7) counterclockwise to the ON position.

3. If equipped with the Manual Blow Down Valve (Fig. 7), make sure it is closed.

4. Keep both valves (one each at the top and bottom) of the gauge glass open at all times.

5. Press the top half of the Boiler On – Off switch (Fig. 5) to turn it on. The red light comes on.

6. Make sure the Ignition Switch is ON (Fig. 6).

7. The electrode will begin sparking, and the pilot will light.

8. Look at pilot flame to make sure the pilot light has lit. If not, turn Ignition Switch Off, wait 5 minutes

and repeat Step 6. If after the third attempt the pilot does not light, call for service.

9. The pilot light will remain lit as long as the Boiler On – Off switch is in the ON position.

10. When water level is satisfied, press Reset (Fig. 5). The Hi Limit Pressure and Low Water lights

should go off and the main Burner should light.

11. The cycling pressure switch will open and close the combination valve, which, in turn, will cycle the

main burner.

FOR SUPPLY CONNECTIONS

USE 18 AWG COPPER WIRE

SUITABLE FOR AT LEAST

221°F (105°C)

BOILER

RESET

DISCONNECT POWER

BEFORE REMOVING THIS

OR ANY PANEL GIVING

ACCESS TO PARTS.

BOILER OPERATING INSTRUCTIONS

1) KEEP BOTH WATER GAUGE VALVES OPEN AT ALL TIMES

2) BE SURE WATER INLET VALVE IS OPEN. CLOSE ONLY

FOR SERVICE OR LONG SHUT DOWN

3) TO START UNIT, PRESS 'BOILER ON-OFF' SWITCH. THE

RED LIGHT WILL COME ON. WHEN THE WATER LEVEL IS

SATISFIED, PRESS RESET SWITCH. THE AMBER LOW

WATER INDICATOR AND THE HI LIMIT PRESSURE

INDICATOR WILL GO OUT.

4) ALLOW 15 MINUTES FOR HEAT UP TIME.

5) TO TURN OFF, PRESS BOILER SWITCH. THE RED

INDICATOR LIGHT WILL GO OFF.

6) BLOW DOWN BOILER DAILY. REFER TO OPERATING

MANUAL FOR INSTRUCTIONS.

ON - OFF

HI LIMIT

PRESSURE

LOW WATER

Fig. 5 Fig. 6

– 10 –

Page 11

OPTIONAL MANUAL BLOW DOWN VALVE

AUTOMATIC BLOW DOWN VALVE

GAS COMBINATION VALVE

Fig. 7

– 11 –

Page 12

STEAM COOKING — COMPARTMENT OPERATION

Refer to the

Steam Cooking with Vulcan Kettles and Steamers

(booklet packed with your steamer) for

suggested cooking times of various foods. All cooking times are approximate because size, weight,

pan loading and product quality will affect steamer cooking times. Use these suggestions and then

adjust cooking times to your own requirements.

1. Prepare vegetables, fruits, meats, seafood and poultry as you would for steam cooking or cooking

in water, clean, separate, cut, remove stems, and place in a pan.

2. Place loaded pans in the compartment and close the compartment door. Turn the door screw

handle clockwise to seal the door gasket. Additional tightening of the door screw may be needed

to eliminate leaks. The compartment pressure gauge typically reaches a maximum pressure of

(5 to 6 psi).

3. The timer knob must be turned to 5 minutes or beyond. The knob may then be turned back to a

lower setting if a shorter cooking cycle is desired. Set the timer to the sum of the desired cooking

time plus some minutes allowed for preheat. The preheat allowance will generally be 5 to 10

minutes. It will vary with the type, size, temperature and condition (frozen or thawed) of the load,

and must be determined from experience.

4. Press the top half of the red switch located under the timer; the cooking light will come on. This

closes the drain, allows steam to enter the compartment and starts the timer. The balance of the

cooking time sequence is automatic. If steam leaks around the door gasket, tighten the door screw.

Do not overtighten the door screw. Excessive tightening of the door screw may shorten gasket life

and result in steam leakage around the gasket.

5. Steam automatically exhausts one minute before the end of the cooking cycle, and the steam

supply shuts off. Never attempt to open the compartment door during the cooking cycle, when the

cooking light is lit or before the buzzer sounds.

6. At the end of the cooking cycle (and the 1 minute exhaust period), the cooking light shuts off and

the buzzer sounds. Turn the compartment switch off by pressing the bottom half of the red switch;

this also shuts off the buzzer. Loosen the door screw and allow moisture to escape. After a few

seconds, move the latch paddle to the left, then slowly open the door and remove the pans of food.

SHUT DOWN AT END OF DAY

WARNING: THE WATER BEING DRAINED IS HOT AND UNDER PRESSURE. USE CARE WHEN

SERVICING THE STEAM GENERATOR.

To prevent malfunction of controls from scale related clogging, it is essential to flush (blow down)

the steam generator every day. This will remove accumulated minerals from the feed water and

reduce internal scale build-up which could interfere with proper steam generator operation.

Failure to blow down the steam generator every day may void the steamer warranty.

1. Turn the power switch OFF. Steamers equipped with automatic blow down will blow down.

2. If your steamer is equipped with manual blow down, open the blow down valve.

TO SHUT OFF FOR AN EXTENDED SHUTDOWN

For an extended shutdown, turn the Boiler On-Off switch off; turn the Ignition Switch off. Allow to blow

down before water is shut off. Close the water inlet valve(s). Close the gas shutoff valve. Shut off the

electrical supply to the machine. Clean the compartments. Leave the doors open.

– 12 –

Page 13

SELECTION OF PANS FOR STEAM COOKING

VL steamer compartments are designed to accept

combinations of the following perforated or solid

cooking pans (Fig. 8):

PAN ACCOMODATION, PER COMPARTMENT

Max Qty Pan Size Pan Depth

4 12 X 20 6

6 12 X 20 4

8 12 X 20 21/2

6 18 X 26

(center support removed) 1

16 12 x 20 1

Fig. 8

The following chart lists the type of pan to use for various foods:

FRESH PRODUCT

Type Pan Product Examples

Solid 12" x 20" Dehydrated fruits and Dried peaches, prunes, apples, and appricots. Sliced onions

vegetables and sliced potatoes.

Cereals and puddings Cream of wheat, rolled oats, rice.

Vegetables to be cooked Broccoli, brussels sprouts, peas, cauliflower.

in their own liquid

Meats and poultry To save broth, cook in solid pans.

Canned foods Place opened can in solid pan or pour contents into the pan.

Perforated Root vegetables* Potatoes, carrots, beets, turnips, onions, parsnips, rutabagas

12" x 20" oyster plant.

Sausages Frankfurters, weiners, garlic sausages, meat sausages.

Leaf vegetables* Spinach, kale, turnip greens, collard greens, cabbage.

Miscellaneous Corn on the cob, green beans, celery / celery hearts, green

pepper shells, squash, mushrooms. Eggs in their shells.

18" x 26" Precooked and partially Ham, meat loaf, roast beef, chicken, turkey, hamburger

cooked sliced meats patties.

* If you wish to save liquids from root or leaf vegetables, place them in a solid pan, or place a solid pan

undet the perforated pan.

– 13 –

Page 14

FROZEN PRODUCT

Perforated

Solid

Frozen Vegetables.

Loosen and spread

vegetable.

Precooked Dishes.

Remove wrapping and place

in pan.

Broccoli, asparagus spears, green beans, carrots,

brussel sprouts, turnips, potatoes, cut corn, lima beans,

peas, squash.

All precooked dishes, such as beef goulash, chicken

fricasse, etc., which cannot be cooked in the containers

in which they are packed.

Separate frozen food packs into smaller chunks.

If unpacked pre-cooked frozen dishes require more than 15 minutes to cook, cover the pan. When a

cover is used, about one-third more cooking time is required. This is true only of foods in either portion

size or in larger sizes which cannot be cooked in the covered containers in which they are packed.

Cooking time required for frozen foods depends upon the amount of defrosting required. If time

permits, allow the frozen foods to partially thaw overnight in a refrigerator. This will reduce their

cooking times.

CLEANING

WARNING: DISCONNECT THE ELECTRICAL POWER TO THE MACHINE AND FOLLOW LOCKOUT/

TAGOUT PROCEDURES BEFORE CLEANING.

COOKING COMPARTMENT DRAINS

Keep compartment drains running freely. Inspect compartment drains daily for blockage. Remove any

particles or debris from the perforated strainer daily (or more often if needed).

After cooking greasy foods or seafood, close the doors and operate each compartment for 15 to 30

minutes to flush any residual grease and oils down the compartment drain. Make a solution of warm

1

water and detergent and pour

1

/2 gallon (1.9 liters) of hot water down each compartment drain.

/2 gallon (1.9 liters) of it down each compartment drain. Rinse by pouring

BOILER BLOWDOWN

To prevent malfunction of controls from scale related clogging, it is essential to blow down the boiler

every day. This will flush out any accumulated minerals from the feed water. It will also aid in

preventing internal scale buildup which would interfere with proper boiler operation. Failure to blow

down the boiler every day may void the steamer warranty. The presence of minerals in suspension

is indicated by a murky or milky condition in the first portion of the water drained.

WARNING:

CLEANING

THE WATER BEING DRAINED IS HOT AND UNDER PRESSURE. USE CARE WHEN

OR SERVICING THE BOILER.

After the steamer boiler has been in operation, blow down the boiler for approximately 5 minutes. This

will remove sediment, scale or lime buildup in the boiler.

COMPARTMENTS

Wash the inside of the compartment with a solution of warm water and detergent. Rinse with warm

water.

Once a week, thoroughly clean the exposed surfaces (sides, front, door and top) with a damp cloth and

polish with a clean cloth. To remove discolorations, use a nonabrasive cleaner.

– 14 –

Page 15

DOOR GASKETS

Clean the gasket sealing surface of the compartment doors to remove harmful food acids for maximum

gasket life. Do not use any solvents. Wash with a cloth moistened in a solution of mild detergent and

warm water. Rinse with a fresh cloth moistened with warm water to remove all traces of detergent.

Wipe dry with a clean cloth. Never apply food oils or petroleum lubricants directly to the door gasket.

Petroleum-based solvents and lubricants will shorten gasket life.

LEAVE COMPARTMENT DOORS OPEN

CAUTION: Leave the compartment doors slightly open when the steamer is not in use. When

the compartment is idle, never latch the door and apply pressure to the door gasket. Leaving

the gasket under pressure can cause permanent deformation, greatly shortening gasket life.

GUIDELINES FOR MAINTAINING STAINLESS STEEL SURFACES

There are four things that can break down stainless steel and allow corrosion to develop: 1) abrasion,

2) deposits, 3) water and 4) chlorides.

Avoid rubbing with steel pads, wire brushes or scrapers that can leave iron deposits on stainless steel.

Instead, use plastic scouring pads or soft cloths. For stubborn stains, use products such as Cameo,

Talc or Zud First Impression. Always rub parallel to the polish lines or with the grain.

Hard water can leave deposits that promote rust on stainless steel. Treated water from softeners or

certain filters can eliminate these mineral deposits. Other deposits from food or lubrication must be

properly removed by cleaning. Use mild detergent and nonchloride cleaners. Rinse thoroughly. Wipe

dry. If using chloride-containing cleaners or sanitizers,

corrosion. Where appropriate, apply a polish recommended for stainless steel (such as Benefit or

Super Sheen) for extra protection and lustre.

rinse repeatedly

to avoid stainless steel

MAINTENANCE

WARNING: THE STEAMER AND ITS PARTS ARE HOT. USE CARE WHEN OPERATING,

CLEANING AND SERVICING THE STEAMER.

WARNING: DISCONNECT THE ELECTRICAL POWER TO THE MACHINE AND FOLLOW LOCKOUT

/ TAGOUT PROCEDURES.

WATER TREATMENT SYSTEM

A water treatment system is recommended for steam generators. Refer to your supplier's manual for

normal maintenance procedures for proper scale-free operation recommendations.

DOOR GASKETS

If the door gasket is nicked or cut, it must be replaced. Damage to the gasket sealing surface will cause

steam leakage.

If a leak occurs in one corner only and the gasket appears serviceable, turn the stainless steel screw

on the gasket plate adjacent to the leaking corner one-half turn counterclockwise. Do not attempt

excessive turning of screws since misalignment of the door is possible. If the door is misaligned, call

your local Vulcan-authorized servicer.

– 15 –

Page 16

WATER LEVEL GAUGE

Check the water level gauge sight glass daily. The correct water level is approximately 1" (

2.5 cm) of

water visible in the water level gauge sight glass. Extremely murky water in the sight glass indicates

bad water conditions. The boiler should be blown down. If conditions persist, have the boiler inspected

and cleaned by your local Vulcan-Hart servicer.

FLUE

Annually, when the steamer is cool, check the flue and clear any obstructions.

SCALE RELATED MAINTENANCE

Periodic maintenance is necessary to keep your boiler clean and efficient. Initially, after three months

of steamer usage, it is recommended that you have your Vulcan-Hart authorized servicer inspect the

boiler and perform the descaler maintenance described below. Local water conditions and steamer

usage will determine the frequency that this service must be repeated; however, a minimum

recommendation is once a year. This maintenance is not covered by warranty.

Cathodic protector(s) are provided inside the boiler to reduce boiler and component corrosion and

reduce accumulation of scale from forming on the boiler interior walls. The cathodic protector(s) will

be consumed. How fast the cathodic protector(s) will be consumed depends upon the chemical

makeup of the feed water and the average volume of feed water used. An inspection by service

personnel is recommended so that the expected normal life of the cathodic protector(s) can be

estimated under your operating conditions. Thereafter, the cathodic protector(s) can be serviced at

the appropriate frequency for your situation.

LUBRICATION

The door screw was factory lubricated with high-temperature grease, but will require periodic

relubrication by applying a bead of lubricant across the door handle screw threads. When the door

screw is properly lubricated, the hand pressure required to seal the door is greatly reduced and the life

of the screw and nut are lengthened. Frequency of lubrication depends upon use. Lubricate monthly

at first and let experience determine the frequency. A high-temperature grease for the door screw can

be obtained from Vulcan-Hart.

TROUBLESHOOTING

Symptoms Possible Causes

Steamer will not heat or build pressure. 1. Water supply to steamer is not turned on.

2. Water filter may be clogged.

3. Main gas supply valve may be turned off.

4. Electrical supply may be off or disconnected.

5. Combination gas valve may be turned off.

6. Ignition switch may be turned off.

Water accumulates in compartment. Drain may be clogged. Clear drain.

Other problems. Contact Service.

SERVICE AND PARTS INFORMATION

To obtain service and parts information concerning this steamer, contact the Vulcan-Hart Service

Agency in your area (refer to listing supplied with the steamer), or contact the Vulcan-Hart Service

Department at the address or phone number shown on the front cover of this manual. Parts and service

manuals are also available at WWW.VULCANHART.COM

FORM 35409 Rev. A (Aug. 2004) PRINTED IN U.S.A.

– 16 –

Loading...

Loading...