Page 1

SPECIFICATIONS:

Gas heated convection steamer, Vulcan-Hart Model No.

(VHX42GT) (VHX42G5). Two stainless steel cooking compartments with coved interior corners. Heavy duty stainless steel

doors can be opened and closed at anytime during the cooking

cycle. Steam shuts off when door(s) are opened. Tilting kettle

mounted to left of cooking compartments and interconnected to

steam generator. Deck mount dual temperature faucet with 12"

swing spout. Convection steamer mounted on 28" high base

cabinet with stainless steel front full height doors, stainless steel

sides, frame and aluminized rear panel with 6" adjustable legs

with anged feet for anchoring. 270,000 BTU/hr. high efciency

steam boiler with electronic ignition builds 5.5 BHP. Includes

CSD-1 compliant high pressure limit switch (15 psi), low water

cut-off, automatic water ll, automatic generator blowdown,

15 psi pressure relief valve and 15 psi kettle connection. Compartment controls include 60 minute dial timer with buzzer, green

"ready" and red "cooking" indicator lights. Stainless steel rear

ue. Service connections include 1" gas connection with gas

pressure regulator, 1/2" cold water connection for boiler feed and

1

/8" cold water condenser, 120 volt control circuit and 11/4" drain

connection.

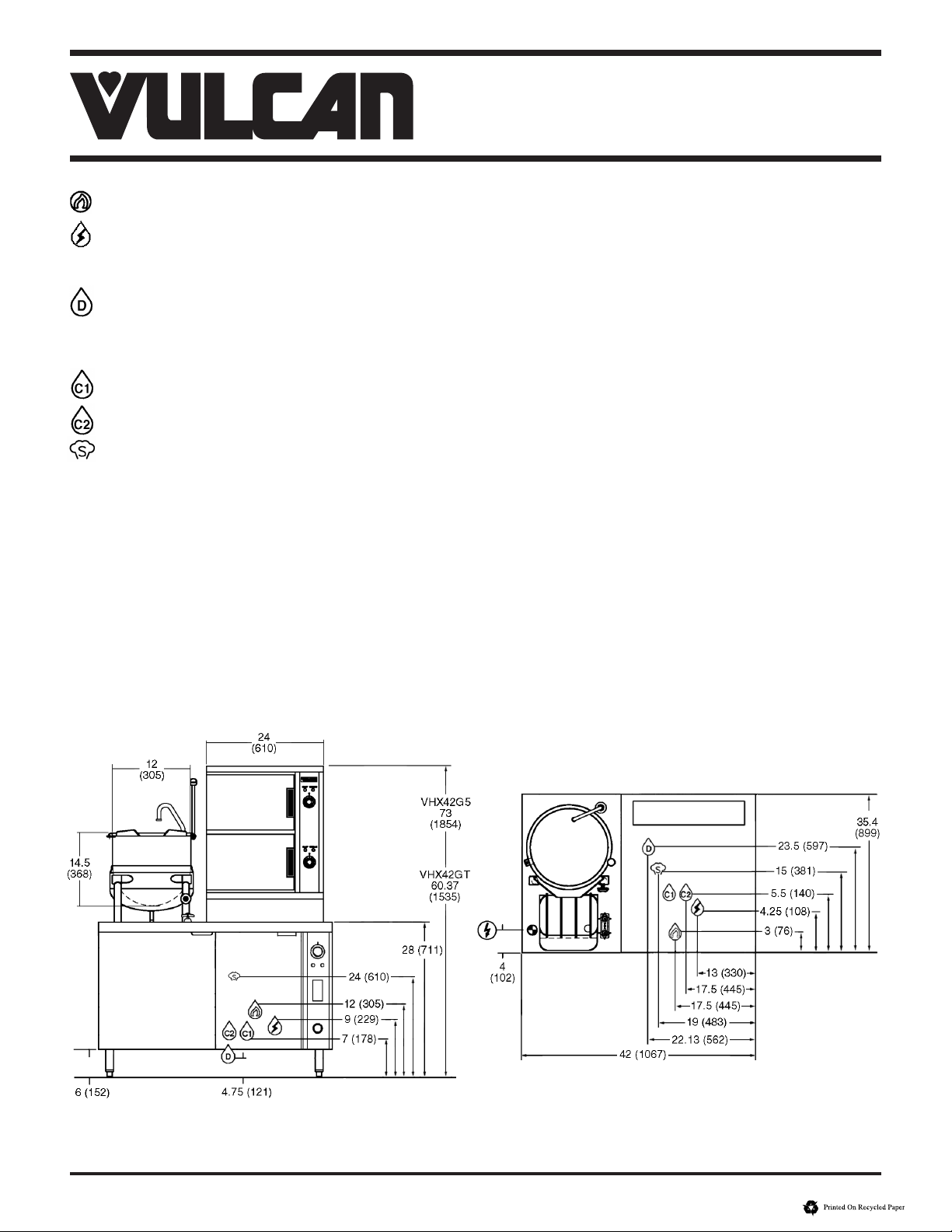

Exterior dimensions:

VHX42GT: 42"w x 35.4"d x 603/8"h.

VHX42G5: 42"w x 35.4"d x 73"h.

CSA design certied. Meets ASME code. Classied by U L to

NSF Std. #4.

SPECIFY TYPE OF GAS WHEN ORDERING.

SPECIFY ALTITUDE WHEN ABOVE 2,000 FT.

Item # _____________________________

C.S.I. Section 11420

VHX42G SERIES

GAS BOILER CONVECTION STEAMER

ON CABINET BASE WITH 24 QT. TILTING KETTLE

■ VHX42GT 6 pan capacity

■ VHX42G5 10 pan capacity

STANDARD FEATURES

■ Two stainless steel cooking compartments with coved interior

corners. Each compartment accepts:

- 1" deep pans (6 - VHX42GT) (10 - VHX42G5)

- 21/2" deep pans (3 - VHX42GT) (5 - VHX42G5)

- 4" deep pans (2 - VHX42GT) (3 - VHX42G5)

■ 11/4" drain in each compartment.

■ Heavy duty stainless steel doors can be opened and closed

at anytime during the cooking cycle. Steam shuts off when

door(s) are opened.

■ Tilting kettle mounted to left of cooking compartments and

interconnected to steam generator.

■ Deck mount dual temperature faucet with 12" swing spout.

■ 270,000 BTU/hr. high efciency steam boiler with electronic

ignition builds 5.5 BHP. Includes CSD-1 compliant high

pressure limit switch (15 psi), low water cut-off, automatic

water ll, automatic generator blow down, 15 psi pressure

relief valve and 15 psi kettle connection.

■ Compartment controls include 60 minute dial timer with

buzzer, green "ready" and red "cooking" indicator lights.

■ Convection steamer mounted on 28" high base cabinet with

stainless steel front full height doors, stainless steel sides,

frame and aluminized rear panel with 6" adjustable legs with

anged feet for anchoring.

■ Stainless steel rear ue.

■ One year limited parts and labor warranty.

OPTIONS

■ Tilting kettle mounted to the right of the cooking compart-

ments.

■ Correction facility package:

a. Security type tamper resistant fasteners with tack welds.

b. Control cover with hasp (lock by others).

c. Cabinet door with hasp (lock by others).

d. Perforated ue cover.

■ Step down transformer for control circuit if higher than 120

volts.

■ Second year extended limited parts and labor warranty.

ACCESSORIES

■ Stainless steel back panel.

■ Interconnecting steam supply plumbing kit.

■ Removable sliding shelf. Qty. ____.

■ Water treatment system.

A2780

ISO9001

Vulcan-Hart Co.

MODELS: VHX42G SERIES Gas Heated Convection Steamer on Cabinet Base w/24 Qt. Tilting Kettle

F-35449 (04-06)

VULCAN-HART COMPANY, P.O. BOX 696, LOUISVILLE, KY 40201, TEL. 1-800-814-2028

502-778-2791 QUOTE & ORDER FAX: 1-800-444-0602

Page 2

VHX42G SERIES

GAS BOILER CONVECTION STEAMER

ON CABINET BASE WITH 24 QT. TILTING KETTLE

SERVICE CONNECTIONS

GAS CONNECTION: 1" NPT.

ELECTRICAL CONNECTION FOR CONTROLS: 120/60/1,

300 watt maximum, power supply with grounding wire

required. (For other than 120 volt supply consult factory for

location of this connection.)

DRAIN: Condenser box, compartment and boiler, 11/4" NPT.

Provide an open air gap type drain within 12" of condenser box

and for best results at a distance so that steam vapors will not

enter the steamer from underneath the control area. Do not

connect solidly to any drain connection.

COLD WATER CONNECTION: 1/2" NPT for boiler feed. Inlet

water pressure between 20 and 80 psi.

COLD WATER CONNECTION: 1/8" NPT for condensate box.

Inlet water pressure between 20 and 80 psi.

STEAM TAKE-OFF CONNECTION: 3/4" NPT.

NOTE:

• Dimensionswhichlocatetheaboveconnectionshaveatolerance

of + or -3" (+ or -75 mm).

• Installation of backow preventers, vacuum breakers and other

specic code requirements is the responsibility of the owner and

installer. It is the responsibility of the owner and installer to comply

with local codes.

• Plasticdrainsarenot recommendeddue toinherentlimitedtem

peratures of the plastic. Boiler purge temperatures may exceed

180°F. The installer may be required to provide means to reduce

boiler purge water temperature to be that of the condensate

tem perature of 140°F or less.

• This appliance is manufactured for commercial installation only

and is not intended for home use.

IMPORTANT

1. A pressure regulator sized for this unit is included. Minimum supply

pressure: Natural gas 7" W.C., Propane gas 11" W.C.

2. Gas line connecting to unit must be 1" or larger. If exible connectors

are used, the inside diameter must be at least the same as the 1"

iron pipe.

3. An adequate ventilation system is required for commercial cooking

equipment. Information may be obtained by writing to the National

Fire Protection Association, Batterymarch Park, Quincy, MA 02289.

When writing, refer to NFPA No. 96.

4. These units are manufactured for installation in accordance with

ANSZ223.1A (latest edition), National Fuel Gas Code. Copies may

be obtained from the American Gas Association, 1515 Wilson Blvd.,

Arlington, VA 22209.

5. Clearance: Combustible Non-Combustible

Rear 6" 6"

Left & Right Side 6" 6"

WATER QUALITY STATEMENT:

The fact that a water supply is potable is no guarantee that it is suitable

for steam generation. Your water supply must be within these general

guidelines:

SUPPLY PRESSURE 20 - 60 psig

HARDNESS* less than 3 grains

SILICA less than 13 ppm

TOTAL CHLORIDE less than 4.0 ppm

pH RANGE 7-8

UN-DISSOLVED SOLIDS less than 5 microns

* 17.1 ppm = 1 grain of hardness

Other factors affecting steam generation are iron content, amount of

chloridation and dissolved gases. Water supplies vary from state to state

and from locations within a state. Therefore it is necessary that the

local water treatment specialist be consulted before the installation of

any steam generating equipment.

NOTE: In line with its policy to continually improve its products, Vulcan-Hart Company reserves the right to change materials and

specications without notice.

F-35449 (04-06)

VULCAN-HART COMPANY, P.O. BOX 696, LOUISVILLE, KY 40201, TEL. 1-800-814-2028

502-778-2791 QUOTE & ORDER FAX: 1-800-444-0602

Loading...

Loading...