Page 1

McDONALD'S®

INSTALLATION, SERVICE

& PARTS MANUAL FOR

GEF-M&SM SERIES

GAS FRYERS

VULCAN-HART CORPORATION, 3600 NORTH POINT BOULEVARD, BALTIMORE, MARYLAND 21222

Page 2

OPERATING, INSTALLATION AND SERVICE PERSONNEL

Operating information for this equipment has been prepared for use by qualified and/or authorized operating

personnel.

All installation and service on this equipment is to be performed by qualified, certified, licensed and/or

authorized installation or service personnel, with the exception of any marked with a ? in front of the part

number.

Service may be obtained by contacting the Factory Service Department, Factory Representative or Local

Service Agency.

DEFINITIONS

QUALIFIED AND/OR AUTHORIZED OPERATING PERSONNEL

Qualified or authorized operating personnel are those who have carefully read the information in this manual

and are familiar with the equipment's functions or have had previous experience with the operation of the

equipment covered in this manual.

QUALIFIED INSTALLATION PERSONNEL

Qualified installation personnel are individuals, a firm, corporation or company which either in person or

through a representative are engaged in, and are responsible for:

1. The installation of gas piping from the outlet side of the gas meter, or the service regulator when the meter

is not provided, and the connection and installation of the gas appliance. Qualified installation personnel

must be experienced in such work, be familiar with all precautions required, and have complied with all

requirements of state or local authorities having jurisdiction. Reference in the United States of America National Fuel Gas code ANSI Z223.1 (Latest Edition). In Canada-Canadian Standard CAN1-B149.1 NAT.

GAS (Latest Edition) or CAN1-B149.2 PROPANE (Latest Edition).

2. The installation of electrical wiring from the electric meter, main control box or service outlet to the electric

appliance. Qualified installation personnel must be experienced in such work, be familiar with all

precautions required, and have complied with all requirements of state or local authorities having

jurisdiction. Reference: In the United States of America-National Electrical Code ANSI NFPA No. 70

(Latest Edition). In Canada-Canadian Electrical Code Part 1 CSA-C22.1 (Latest Edition).

QUALIFIED SERVICE PERSONNEL

Qualified service personnel are those who are familiar with Vulcan equipment who have been endorsed by

the Vulcan-Hart Corporation. All authorized service personnel are required to be equipped with a complete set

of service parts manuals and stock a minimum amount of parts for Vulcan equipment.

SHIPPING DAMAGE CLAIM PROCEDURE

For your protection, please note that equipment in this shipment was carefully inspected and packed by

skilled personnel before leaving the factory. The transportation company assumes full responsibility for safe

delivery upon acceptance of this shipment.

If shipment arrives damaged:

1. VISIBLE LOSS OR DAMAGE — Be certain this is noted on freight bill or express receipt and signed by

person making delivery.

2. FILE CLAIM FOR DAMAGES IMMEDIATELY — Regardless of extent of damage.

3. CONCEALED LOSS OR DAMAGE — If damage is unnoticed until merchandise is unpacked, notify

transportation company or carrier immediately, and file "concealed damage" claim with them. This should

be done within (15) days of date of delivery is made to you. Be sure to retain container for inspection.

We cannot assume responsibility for damage or loss incurred in transit. We will, however, be glad to furnish

you with necessary documents to support your claim.

PLEASE RETAIN THIS MANUAL FOR FUTURE REFERENCE

Page 3

IMPORTANT NOTES FOR ALL VULCAN APPLIANCES

1. These units are produced with the best possible workmanship and material. Proper installation is vital if best performance and

appearance are to be achieved. Installer must follow the installation instructions carefully.

2. Information on the construction and installation of ventilating hoods may be obtained from the "Standard for the installation of

equipment for the removal of smoke and grease laden vapors from commercial cooking equipment," NFPA No. 96 (latest

edition) available from the National Fire Protection Association, Battery March Park, Quincy MA 02269.

3. For an appliance equipped with a flexible electric supply cord, the cord is equipped with a three prong (grounding) plug. This

grounding plug is for your protection against shock hazard and should be plugged directly into a properly grounded three prong

receptacle. Do not cut or remove the grounding prong from this plug. If the appliance is not equipped with a grounding plug, and

electric supply is needed, ground the appliance by using the ground lug provided (refer to the wiring diagram).

(FOR GAS APPLIANCES ONLY)

4. Do not obstruct the air flow into and around the appliance. This air flow is necessary for proper combustion of gases and for

ventilation of the appliance. Provisions for ventilation of incoming air supply for the equipment in the room must be in accordance

with National Fuel Gas Code ANSI Z223.1 (latest edition).

5. Do not obstruct the flow of flue gases from the flue duct (when so equipped) located on the rear (or sides) of the appliance. It is

recommended that the flue gases be ventilated to the outside of the building through a ventilation system installed by qualified

personnel.

6. For an appliance equipped with casters, (1) the installation shall be made with a connector that complies with the Standard for

Connectors for Movable Gas Appliances, ANSI Z21.69 (latest edition), and Addenda, Z21.69a (latest edition), and a quickdisconnect device that complies with the Standard for Quick-Disconnect Devices for Use With Gas Fuel, ANSI Z21.41 (latest

edition), and Addenda, Z21.41a (latest edition) and Z21.41b (latest edition), and (2) adequate means must be provided to limit

the movement of the appliance without depending on the connector and the quick-disconnect device or its associated piping to

limit the appliance movement. If disconnection of the restraint is necessary, reconnect this restraint after the appliance has been

returned to its originally installed position.

7. The appliance and its individual shutoff valve must be disconnected from the gas supply piping system during any pressure

testing of that system at test pressures in excess of 1/2 psig (3.45 k Pa).

8. The appliance must be isolated from the gas supply system by closing its individual manual shutoff valve during any pressure

testing of the gas supply system at test pressures equal to or less than 1/2 psig (3.45 k Pa).

CAUTIONS

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS

IN THE VICINITY OF THIS EQUIPMENT OR ANY OTHER APPLIANCE.

1. KEEP THE APPLIANCE FREE AND CLEAR FROM ALL COMBUSTIBLE SUBSTANCES.

2. IN THE EVENT A GAS ODOR IS DETECTED, SHUT UNIT(S) DOWN AT THE MAIN

SHUTOFF VALVE AND CONTACT THE LOCAL GAS COMPANY OR GAS SUPPLIER

FOR SERVICE.

3. POST IN A PROMINENT LOCATION, INSTRUCTIONS TO BE FOLLOWED IN THE EVENT

THE SMELL OF GAS IS DETECTED. THIS INFORMATION MAY BE OBTAINED FROM A

LOCAL GAS SUPPLIER.

Page 4

GEF INSTALLATION, SERVICE & PARTS MANUAL INDEX

DESCRIPTION PAGE

DEFINITIONS (Inside Front Cover)

CAUTIONS

IMPORTANT NOTES 1

INDEX 2

SECTION I INSTALLATION

UNCRATING INSTRUCTIONS 3

ELECTRIC CONNECTIONS 3

GAS SUPPLY CONNECTIONS 4

POSITIONING FRYER UNDER HOOD 4

SECTION II SERVICING

CONTROLS 5

AIR ADJUSTMENT 6

HIGH LIMIT TEST & PROCEDURES 6

CLEANING BLOWER INLET SCREEN & WHEEL 6

CALIBRATION PROCEDURES 7

TROUBLE SHOOTING 8-9

SECTION III PARTS

PARTS LIST 10-24

REVISION SHEET (Inside Back Cover)

NOTES

A Rating Plate is located on the inside fryer door panel stating the Model Number, Serial Number,

Type of Gas, Voltage and Amperage.

A complete set of Wiring Diagrams are included in the back of this manual. A Wiring Decal may

also be found on the inside lower front panel.

GEF-SM units all require an isolation relay to isolate each tank vat section of the fryer. The

isolation relay is located behind the front control panel.

This appliance is to be installed with a six inch clearance at the sides and rear to combustible

construction.

Fryer must be installed at least 16 in. away from open top flame units.

Motors in GEF fryers are permanently lubricated and require no additional maintenance.

The vent of this appliance should be checked every 6 months for restrictions.

2

Page 5

GEF UNCRATING

INSTRUCTIONS

ELECTRIC CONNECTION

The following procedure should be followed when

uncrating all GEF Fryers.

1. Pry right and left hand crate sides off of crate back

and front.

2. Pry crate back and front off of crate bottom.

3. Remove cardboard box containing component parts

from the 2x4 wood packaging braces.

4. Using caution, cut (2) straps and remove (2) 2 x 4

wood braces.

5. Remove protective plastic liner from unit.

6. Remove packaging material from unit.

7. Assemble legs and remove unit from crate bottom

as near to final resting place as possible.

8. Open cardboard box containing component parts

and unwrap parts. Care should be taken when

checking unit quantities. See chart below for correct

contents of parts.

UNIT

PART DESCRIPTION

Basket Hanger 1 2 3 1 2 3

Quick Disconnect 1 1 1 1 1 1

Rack Supports 2 4 6 2 4 6

Probe Tubes 1 2 3 2 4 6

Clean Out Rod 1 1 1 1 1 1

1M 2M 3M 2SM 4SM 6SM

QUANTITIES

Position fryer as near to final resting place as possible.

Connect 120V AC electric supply to fryer barrier strip.

Barrier strip may be connected from rear of unit. To

reach barrier, remove electric cover plate "A" from unit.

After connecting 120V AC electric supply to fryer

barrier strip, verify with a voltmeter that the following

condition exists. See Detail "A".

1. Black to White 120V AC.

2. Black to Ground 120V AC.

3. White to Ground 0.00V AC.

Make all other necessary electrical connections.

Improper grounding and/or polarity will result in lock

out of unit and eventual damage to the ignition

systems.

This unit is supplied with a 6 1/2 foot long 3 wire supply

cord. This appliance is equipped with a 3 prong

(grounding) plug for your protection against shock

hazard and should be plugged directly into a properly

grounded three prong receptacle. DO NOT cut or

remove the grounding prong from this plug.

3

Page 6

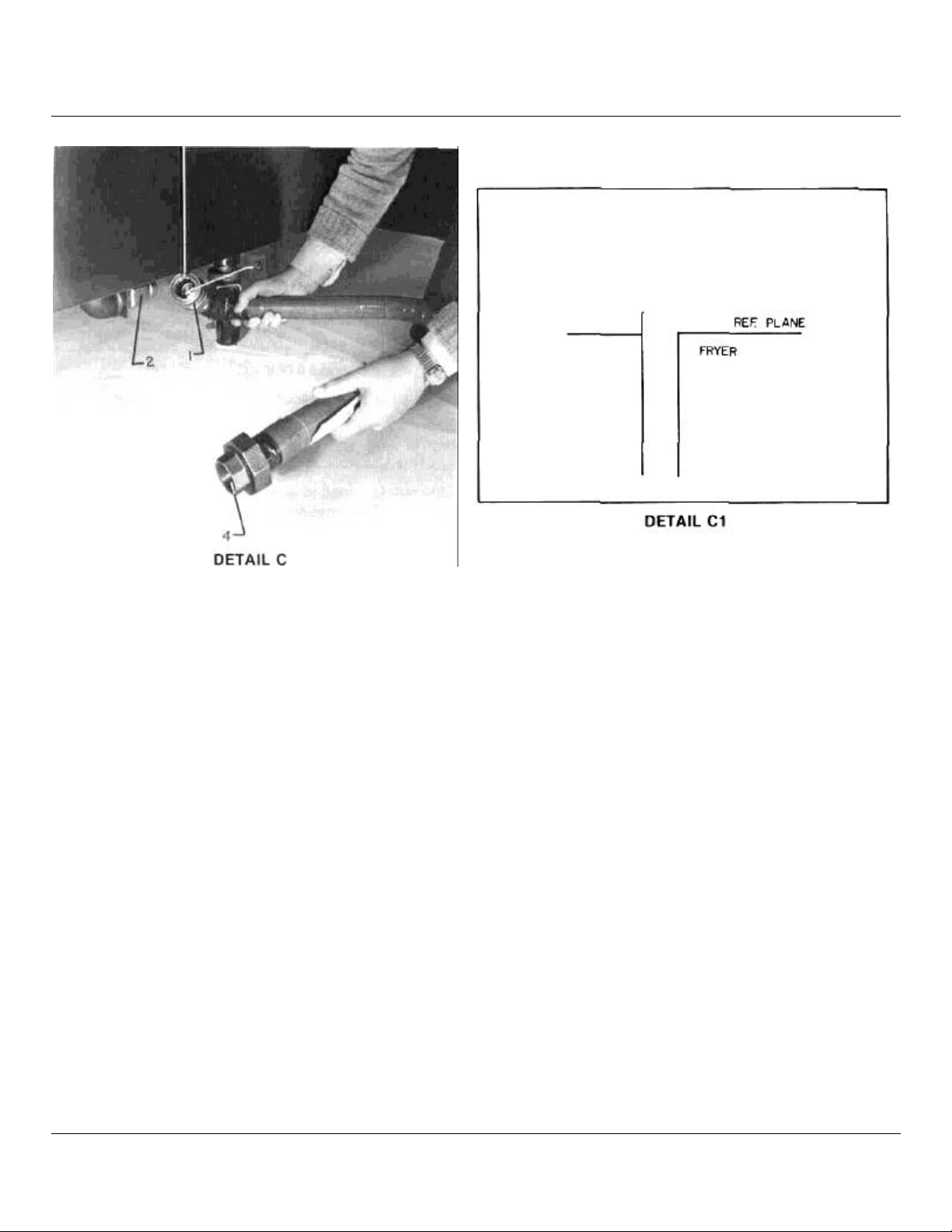

POSITIONING FRYER

GAS SUPPLY CONNECTION UNDER HOOD

SIDE ARM

See Detail "C"

All GEF Fryers are equipped with a 3.7"W.C. 3/4" reg-

ulator for natural gas and a 10" W.C. 3/4" regulator for

propane gas.

To connect unit to gas supply, attack quick disconnect

supplied with unit to male fitting as follows:

1. Pull disconnect collar #1 back.

2. Snap disconnect #2 on to male disconnect fitting "C"

supplied on unit.

3. Release disconnect collar when fitting #3 and disconnect #2 snap into place.

4. Connect union #4 to gas supply.

5. Turn main gas supply on and test for gas leakage at all

connecting points.

Fryer is supplied with four adjustable height legs. Legs

should be adjusted so that the fryer is level and at its

proper height in the hood. See Detail — C1.

Position fryer so that it may be pushed straight back

under the hood. Place main top onto fryer by tilting main

top while pushing fryer under hood. After the main top

has cleared the hood, position main top so that it rests

evenly on the unit.

4

Page 7

CONTROLS

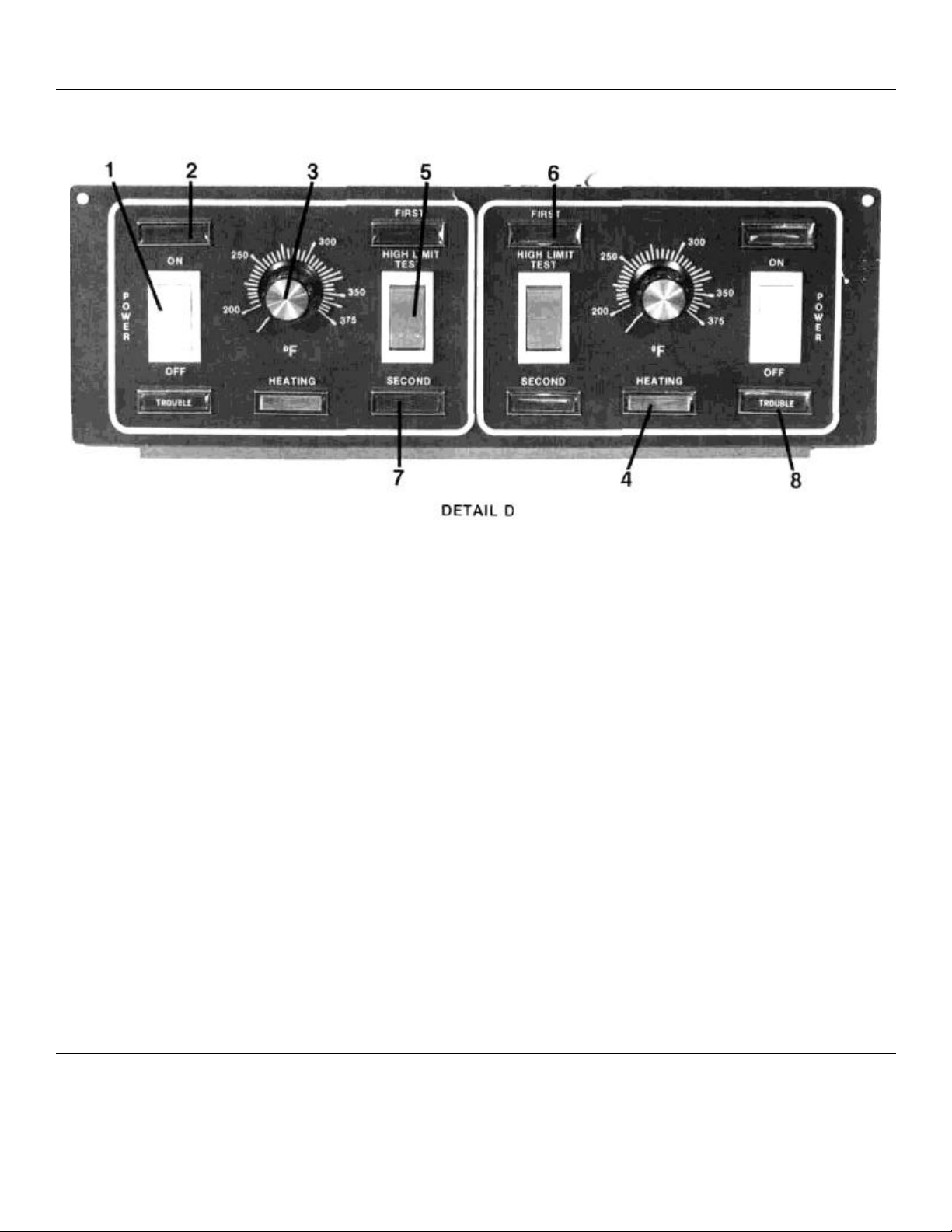

SWITCH PANEL CONTROLS

(Refer to Detail "D")

1. MASTER SWITCH — Controls electric supply to unit

2. POWER "ON" LIGHT — Light indicates when electrical supply is on.

3. TEMPERATURE CONTROL — Maintain frying temperature by controlling power supply.

4. HEATING LIGHT — When "ON" indicates temperature control is calling for gas to burners.

5. HIGH LIMIT TEST SWITCH — Bypasses temperature control for testing of high limit thermostats.

6. FIRST HIGH LIMIT LIGHT — When "ON" indicates first high limit thermostat has shut down unit.

7. SECOND HIGH LIMIT LIGHT — When "ON" indicates second high limit thermostat has shut down unit. (Reset required*)

8. TROUBLE LIGHT — Indicates solid state ignition device has "locked out". (Reset required*)

9. IGNITOR RESET BUTTON

*NOTE: To reset, turn main power switch off, then on.

— See Detail "D" — When up indicates excessive heat or current in control board, allow to cool push

down to reset. If tripping continues, contact service agency.

OPERATIONAL LIGHTING INSTRUCTIONS:

To turn on, push power switch to "ON" position; turn

thermostat dial to temperature desired.

To turn off, push power switch to "OFF" position.

NOTE: Service valve must be in "ON" position and

power cord connected to power source for unit operation.

For service or extended shut down, turn service valve to

"OFF" and disconnect power cord.

The above information may also be found on the inside of

fryer door panel.

5

Page 8

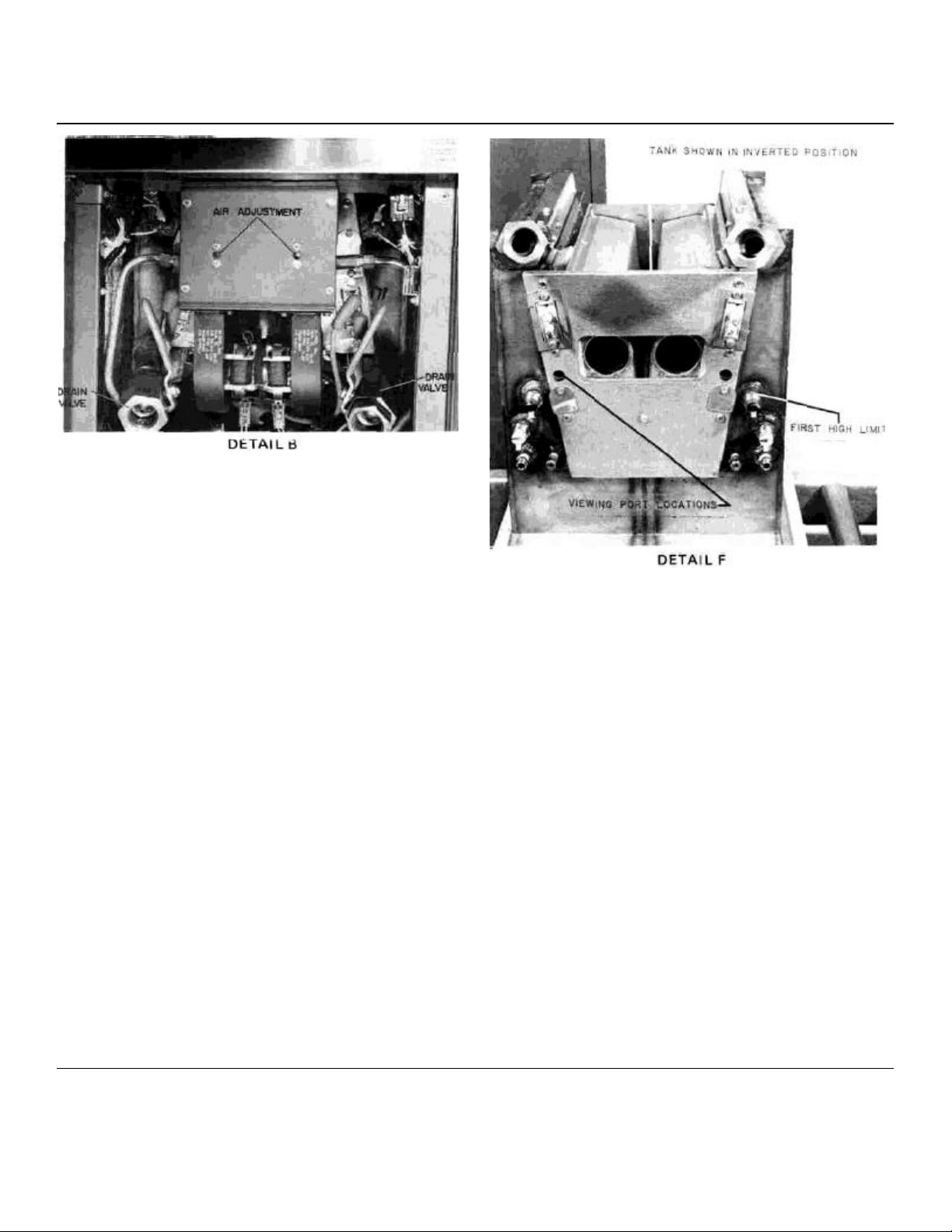

AIR ADJUSTMENT

HIGH LIMIT TEST

A blue flame seen out of the viewing port indicates

insufficient air. To correct this condition, remove plug

button from air adjustment plunger opening. Using a 1/8"

allen wrench, remove two set screws 1/4-28 NF X 3/8"

Long (one from each opening).

Replace allen wrench back into each opening and rotate

wrench counterclockwise to reduce flame in viewing port

and clockwise to increase flame. The air adjustment has

been properly made when flame is not seen out of the

viewing port and a maximum red glow is achieved on the

burners. (See Detail "B")

CLEANING BLOWER INLET

SCREEN AND WHEEL

For preventative maintenance and maximum performance

of the blower motor, the inlet screen and blower wheel

should be cleaned once a month as follows:

1. Turn power switch "OFF".

2. Remove two (2) wing nuts from side of blower motor.

3. Remove blower inlet screen.

4. Remove blower wheel.

5. Soak blower inlet screen and wheel in mild soap and

water solution. Dry thoroughly before replacing parts.

6. Reassemble screen and wheel to unit, and tighten wing

nuts.

7. Turn power switch to "ON" position and resume unit

operation.

PROCEDURE

A test to determine if the protection devices are properly

functioning. (See steps 1 thru 5)

1. Turn master switch on and set temperature knob to frying

temperature.

2. Heat shortening until heating light goes off.

3. Depress top of high limit test switch and hold until first high

limit comes on, then release switch. (Light will come on at

390 degrees F.-420 degrees F.)

4. Depress bottom of high limit test switch and hold until

second high limit light comes on, then release switch. (Light

will come on at 420 degrees F.-445 degrees F.)

5. Once unit cools down, reset by turning main power switch off

and then on, normal frying operation will then automatically

be resumed.

The above instructions may also be found on the inside fryer

door.

(Refer to Detail "F" for high limit location and viewing ports

location).

6

Page 9

CALIBRATION PROCEDURES

1. Place shortening pyrometer and pyrometer holding fixtures

or shortening digital and digital holding fixture in kettle

exactly where probe is located.

2. Turn power switch on and coming up from lower

temperature, set temperature control knob to frying

temperature.

3. Agitate shortening and allow unit to reach desired cooking

temperature (when heating light goes on), and maintain it for

15 minutes.

4. Check reading on pyrometer or digital thermometer. It should

be within 5 degrees of temperature control setting. If reading

is not within 5 degrees

of temperature control setting when the heating light turns

on, the following steps should be taken:

A. Loosen set screw in temperature control knob.

B. Rotate knob and set to read the same as pyrometer or

digital thermometer reading when the heating light turns

on.

C. Tighten set screw.

D. Allow unit to cycle and check readings.

E. Should for any reason calibration not be obtained in this

manner, call a service agency.

7

Page 10

TROUBLE SHOOTING

PROBLEM

(SPLIT VAT MODEL)

RIGHT SIDE HEATING NORMALLY.

LEFT SIDE LOCKS

OUT AFTER 3 SECONDS.

BLOWER DOES NOT RUN

WHEN LEFT SIDE CALLS

FOR HEAT.

POWER SWITCH ON, POWER

LIGHT ON, HEATING LIGHT

COMES ON, THEN TROUBLE

LIGHT COMES ON, HEATING

LIGHT GOES OUT.

CAUSE

A.

Defective blower relay. A. Call service agency.

A.

Ignition system did not sense A. Reset - Turn power switch off

flame.

1. Burner observation ports

left open.

2. Insufficient gas, check

pressure.

3. Improper ventilation.

4. Improper air adjustment.

5. Improper ignitor positioning.

6. Defective ignitor or wires.

7. Fryer gas shut off valve

closed.

8. Gas hose not connected

tightly to fryer.

REMEDY

then on.

1. Close observation ports &

tighten securing bolts.

2. Call service agency.

3. Adjust ventilator system

for proper fluing.

4. Adjust air shutter, see

instructions.

5. Call Service Agency.

6. Call Service Agency.

7. Open shut off valve.

8. Check and insure quick disconnect

fitting snaps on to fitting completely.

9. Loose connections at

ignitors.

A.

POWER SWITCH ON. POWER

LIGHT ON. 1ST HIGH LIMIT

LIGHT ON. 2ND HIGH LIMIT

ON. TROUBLE LIGHT ON.

NO HEAT.

FRYER DOES NOT GO INTO

FAT MELT (FULL HEAT

WHEN TURNED ON)

OUT OF FAT MELT FUNCTION.

SLOW RECOVERY. A. Improper ventilation. A. Adjust ventilator system

Oil temperature above 435 A. Allow fryer to cool to below 375

degrees F.

1. Temperature control out of

calibration.

2. Temperature control defective

A.

Defective fat melt timer. A. Call Service Agency.

B.

Defective fat melt thermostat. B. Call Service Agency.

A.

Defective fat melt thermostat. A. Call Service Agency. FRYER DOES NOT COME

B.

Loose wire. B. Call Service Agency.

B.

Gas pressure low. B. Call Service Agency.

9. Turn fryer off and insure push

on connectors are on tight.

degrees F. Turn off main power

switch, then on.

1. Recalibrate. Follow calibration

instructions enclosed.

2. Call Service Agency.

for proper fluing.

8

Page 11

TROUBLE SHOOTING

PROBLEM

TROUBLE LIGHT FLASHES

MOMENTARILY THEN HEATING

LIGHT COMES ON WHEN SYSTEM

CALLS FOR HEAT.

POWER SWITCH ON POWER ON

LIGHT OFF. NO HEATING.

ON,

NO HEAT.

POWER SWITCH ON,

POWER LIGHT ON,

VENTILATOR OFF.

NOISY IGNITION.

1ST HIGH LIMIT LIGHT OR 2ND

HIGH LIMIT LIGHT DOES NOT COME

ON WHEN HIGH LIMIT TEST IS

PERFORMED, OIL TEMPERATURE

IS ABOVE 475 DEGREES F.

INDICATOR LIGHT "POWER ON

HEATING-1ST HIGH LIMIT

TROUBLE" DOES NOT COME ON

WHEN IT SHOULD.

CAUSE

This is normal operation

REMEDY

A.

No power to fryer. A.

B.

Defective On Switch. B. Call Service Agency.

C.

Loose wire. C. Call Service Agency.

A. Temperature controller set below frying

temperature.

B.

Defective fat melt timer. B. Call Service Agency.

C.

Defective temperature control system. C. Call Service Agency.

A.

Loose wire in interlock system. A. Call Service Agency.

B.

Defective power on switch (1/2) B. Call Service Agency.

C.

Ventilator circuit breaker off. C. Reset ventilator circuit breaker.

D.

Defective ventilator motor. D. Call Service Agency.

A.

Improper air. A. Adjust ventilator system for proper fluing.

B.

Ignitor in upside down. B. Call Service Agency.

C.

Ignitor location incorrect. C. Call Service Agency.

High limit defective.

1. Check power supply cord verify

plugged in.

2. Check store circuit breaker.

A.

Set knob to frying temperature. POWER SWITCH ON, POWER LIGHT

Shutdown fryer and tag it for non-use

until service is obtained.

Light defective.

Call Service Agency to replace light.

9

Page 12

GEF FRYER REPLACEMENT PARTS LIST & PHOTOGRAPHS

The following information must accompany a replacement parts order or it cannot be filled.

A. Model and style or serial number.

B. Type of gas, voltage and amperage.

C. Appliance finish, permafinish, stainless steel, etc. (if applicable to parts to be replaced).

This information can be found on the rating plate of the unit. Parts may be ordered from your dealer, service agency or the factory.

Orders to the factory should be addressed as shown below. Be sure to note on order form McDonald's parts.

VULCAN-HART CORPORATION, 3600 NORTH POINT BLVD., BALTIMORE, MD 21222

10

Page 13

PARTS LIST

11

ITEM

NO. DESCRIPTION NO. -1M -2M -3M 2SM 4SM 6SM

1 MYLAR CONTROL PANEL COVER (SINGLE 375 DEG.) 114194-2 1 2 3

1A MYLAR CONTROL PANEL COVER (SINGLE 400 DEG.) 114194-1 1 2 3

2 MYLAR CONTROL PANEL COVER (SPLIT 375 DEG.) 114043-2

2A MYLAR CONTROL PANEL COVER (SPLIT 400 DEG.) 114043-1

3 DOOR ASSEMBLY 114122-G2 1 2 3 1 2 3

4 DOOR HANDLE 114211-1 1 2 3 1 2 3

5 TANK ASSEMBLY (SINGLE) 113903-G2 1 2 3

6 TANK ASSEMBLY (SPLIT) 114090-G2

10 ELEC. SUPPLY CORD 115V (NS) 105016-1 1 1 1 1 1 1

11 ELEC. BOX COVER WITH HOLE 114219-2 1 2 3 1 2 3

12 PLUG BUTTON (N.S.) 3.0317-8 2 3 4 2 3 4

13A MAIN TOP ASSEMBLY (DOUBLE UNIT) (N.S.) 114325-G2

13 MAIN TOP ASSEMBLY (SINGLE UNIT) (N.S.) 114325-G1 1

13B MAIN TOP ASSEMBLY (TRIPLE UNIT) 114325-G3

14 HANGER BUTTON 111686-2

15 BASKET HANGER 114206-1 1 2 3 1 2 3

16 PROBE TUBE 114159-1 1 2 3 2 4 6

N.S. =NOT SHOWN BY PHOTOGRAPH

PART GEF GEF GEF GEF GEF GEF

1 2 3

1 2 3

1 2 3

1

1

1

4 6

1

4 6

1

Page 14

PARTS LIST

ITEM

NO. DESCRIPTION NO. -1M -2M -3M 2SM 4SM 6SM

2 MYLAR CONTROL PANEL (SPLIT 375 DEG.) 114043-2

2A MYLAR CONTROL PANEL (SPLIT 400 DEG.)

17 POTENTIOMETER KNOB 114254-1

25 CONTROL PANEL ASSEMBLY 114042-G2

19 SIGNAL LIGHT (RED) 111496-E4

20 ON-OFF SWITCH 111496-B1

21 TROUBLE LIGHT 111496-E6

22 HEAT LIGHT (AMBER) 111496-E3

23 TEST SWITCH 111496-B3

24 POTENTIOMETER 114147-1

12

PART GEF GEF GEF GEF GEF GEF

1 2 3

1 2 3

2 4 6

1 2 3

6 9 12

2 4 6

2 4 6

2 4 6

2 4 6

2 4 6

Page 15

PARTS LIST

ITEM

NO.

DESCRIPTION NO. -1M -2M -3M 2SM 4SM 6SM

1 MYLAR CONTROL PANEL (SINGLE 375 DEG.) 114194-2 1 2 3

1A

MYLAR CONTROL PANEL (SINGLE 400 DEG.) 114194-1 1 2 3

17

POTENTIOMETER KNOB 114254-1 1 2 3

18

CONTROL PANEL ASSEMBLY (SINGLE) 114042-G1 1 2 3

19

SIGNAL LIGHT (RED) 111496-E4 3 6 9

20

ON-OFF SWITCH 111496-B1 1 2 3

21

TROUBLE LIGHT 111496-E6 1 2 3

22

HEAT LIGHT (AMBER) 111496-E3 1 2 3

23

TEST SWITCH 111496-B3 1 2 3

24

POTENTIOMETER 114147-1 1 2 3

13

PART GEF GEF GEF GEF GEF GEF

Page 16

PARTS LIST

ITEM

NO. DESCRIPTION NO. -1M -2M -3M 2SM 4SM 6SM

5 TANK ASSEMBLY (SINGLE) 113903-G2 1 2 3

16 PROBE TUBE (N.S.) 114159-1 1 2 3

26 SECOND HI LIMIT (N.S.) 114145-1 1 2 3

27 FAT MELT CONTROL (N.S.) 114143-1 1 2 3

28 FIRST HI LIMIT (N.S.) 114143-2 1 2 3

13 MAIN TOP ASSEMBLY (N.S.) 114325-G1 1

13A MAIN TOP ASSEMBLY (N.S.) 114325-G2

13B MAIN TOP ASSEMBLY 114325-G3

N.S. = NOT SHOWN BY PHOTOGRAPH

14

PART GEF GEF GEF GEF GEF GEF

1

1

Page 17

PARTS LIST

ITEM

NO. DESCRIPTION NO. -1M -2M -3M 2SM 4SM 6SM

6 TANK ASSEMBLY (SPLIT) 114090-G2

25 PROBE 3" (N.S.) 114141-1

26 SECOND HI LIMIT 114145-1

27 FAT MELT CONTROL (N.S.) 114143-1

28 FIRST HI LIMIT (N.S.) 114143-2

13 MAIN TOP ASSEMBLY (N.S.) 114325-G1

13A MAIN TOP ASSEMBLY (N.S.) 114325-G2

13B MAIN TOP ASSEMBLY (N.S.) 114325-G3

N.S. = NOT SHOWN BY PHOTOGRAPH

PART GEF GEF GEF GEF GEF GEF

15

1 2 3

2 4 6

2 4 6

2 4 6

2 4 6

1

1

1

Page 18

PARTS LIST

ITEM

NO. DESCRIPTION NO. •1M •2M -3M -2SM -4SM -6SM

7 ORIFICE SPUD (NATURAL) (NS) 109290-31 2 4 6

7A ORIFICE SPUD (LP.) (NS) 109290-49 2 4 6

28 FIRST HIGH LIMIT 114143-2 2 4 6

32 DOOR MAGNET 108834-1 1 2 3

33 DOOR HINGE (BOTTOM) 112780-5 1 2 3

34 DOOR HINGE (TOP) 112780-6 1 2 3

35 BALL VALVE 1" LEFT 114212-1 1 2 3

36 BALL VALVE 1" RIGHT 114212-2 1 2 3

38 BLOWER BOX 114692-1 1 2 3

39 BLOWER BOX COVER 114691-1 1 2 3

37 COMPONENT BOX 114158-1 1 2 3

41 B DUAL BLOWER, LEFT HAND 114160-3 1 2 3

41 C DUAL BLOWER, RIGHT HAND 114160-4 1 2 3

56 SOLENOID 111497-F1 4 8 12

52 IGNITOR 114149-1 2 4 6

48 CONDUIT (NS) 114540-915 — 1 2

51 90° COMP. FITTING 3/8 NPT X 7/16CC (NS) 114800-4 2 4 6

53 115V SUPPLY CORD (NS) 105016-1 1 1 1

49C RIGHT BURNER TUBING 1/2" 114733-1 1 2 3

49D LEFT BURNER TUBING 1/2" 1 14733-2 1 2 3

62 300 TOMIC CONNECTOR (NS) 106774-6 1 2 3

63 90° FITTING (NS) 106774-7 1 2 3

87 PLUG BUTTON (NS) 114781-1 4 8 12

59 ELBOW 1" (NS) 114798-6 2 2 2

60 NIPPLE 1" X 2-3/8" LONG (NS) 113500-F19 1 1 1

61 FRONT MANIFOLD BRACKET 114112-1 1 1 1

NS = NOT SHOWN ON PHOTOGRAPH

16

PART GEF GEF GEF GEF GEF GEF

Page 19

PARTS LIST

ITEM

NO. DESCRIPTION NO. •1M -2M -3M -2SM •4SM •6SM

7 ORIFICE SPUD (NATURAL) (NS) 109290-31 2 4 6

7A ORIFICE SPUD (L.P.)(NS) 109290-49 2 4 6

28 FIRST HIGH LIMIT 114143-2 2 2 6

32 DOOR MAGNET 108834-1 1 2 3

33 DOOR HINGE (BOTTOM) (NS) 112780-5 1 2 3

34 DOOR HINGE (TOP) (NS) 112780-6 1 2 3

35 BALL VALVE 1" LEFT 114212-1 1 2 3

36 BALL VALVE 1" RIGHT 114212-2 1 2 3

37 COMPONENT BOX COVER 114691-1 1 2 3

38 BLOWER BOX 114692-1 1 2 3

39 BLOWER BOX COVER 114691-1 1 2 3

41 B DUAL BLOWER, LEFT HAND 114160-3 1 2 3

41C DUAL BLOWER, RIGHT HAND 114160-4 1 2 3

42 1/2" SOLENOID 111497-F6 2 4 6

43 3/4" TEE 114696-5 1 2 3

44 MALE 3/8" NPT TO 1/2" CC 109700-1 2 4 6

52 IGNITOR 114149-1 2 4 6

53 115V CORD(NS) 105016-1 1 1 1

55 REGULATOR(NATURAL) (NS) 108279-5 1 1 1

55A REGULATOR (L.P.) (NS) 108279-3 1 1 1

49 B BURNER TUBING 114736-1 2 4 6

87 PLUG BUTTON 114781-1 4 8 12

PART GEF GEF GEF GEF GEF GEF

NS = NOT SHOWN ON PHOTOGRAPH

17

Page 20

PARTS LIST

ITEM

NO. DESCRIPTION NO. -1M -2M -3M -2SM -4SM -6SM

39 BLOWER BOX COVER 114691-1 1 2 3 1 2 3

83 AIR ADJUSTOR PLUNGER 114703-1 2 4 6 2 4 6

84 ADJUSTMENT SLEEVE 114706-1 2 4 6 2 4 6

85 1/8" ALLEN SET SCREW 1/4-28 NF X 1-1/4" LG. 114737-1 2 4 6 2 4 6

86 1/8" ALLEN SET SCREW 1/4-28NF X 3/8" LG. (NS) 114737-2 2 4 6 2 4 6

NS = NOT SHOWN IN PHOTOGRAPH

18

PART GEF GEF GEF GEF GEF GEF

Page 21

PARTS LIST

ITEM

NO. DESCRIPTION NO. -1M -2M -3M 2SM 4SM 6SM

3 DOOR ASSEMBLY 114122-G2 1 2 3 1 2 3

64 RATING PLATE 111955-2 1 1 1 1 1 1

65 CLEARANCE PLATE 110694-1 1 1 1 1 1 1

66 IMPORTANT PLATE 113831-1 1 1 1 1 1 1

67 INSTALLATION DECAL (N.S.) 113681-1 1 1 1 1 1 1

68 DRAIN PIPE HOOK (BOTTOM) 114245-1 1 1 1 1 1 1

69 DRAIN PIPE HOOK (TOP) 114246-1 1 1 1 1 1 1

70 PRESSURE PLATE 108618-1 1 1 1 1 1 1

71 DRAIN PIPE 114094-2 1 1 1 1 1 1

72 OPERATING INSTRUCTIONS 114281-1 1 1 1 1 1 1

73 HIGH LIMIT TEST 114095-1 1 1 1 1 1 1

74 ELEC. RATING PLATE 108727-1 1 1 1 1 1 1

81 APPLIANCE DECAL 113681-1 1 1 1 1 1 1

NS= NOT SHOWN IN PHOTOGRAPH

PART GEF GEF GEF GEF GEF GEF

19

Page 22

PARTS LIST

ITEM

NO.

DESCRIPTION NO. -1M -2M -3M 2SM

53 115V SUPPLY CORD 105016-1

72 ELEC. BOX COVER WITH HOLE 114219-2

73 PLUG BUTTON (N.S.) 3.0317-8

75 UNIVERSAL BUSHING (N.S.) 112263-5

N.S. =

NOT SHOWN BY PHOTOGRAPH

20

PART GEF

GEF

GEF

GEF

GEF

4SM 6SM

1 2 3

1 2

2 4 6

2 4 6

GEF

Page 23

PARTS LIST

ITEM

NO.

*76

BASKET SUPPORT RACK (SPLIT) 114215-1 2 4 6 2 4 6

* (2) RACK SUPPORTS REPLACE 114215-1

* (1) RACK SUPPORT FOR SINGLE VAT FRYERS. 114216-1

21

DESCRIPTION

PART GEF GEF GEF GEF GEF GEF

NO. -1M -2M -3M 2SM 4SM 6SM

Page 24

PARTS LIST

ITEM

NO.

*77 BURNER ASSEMBLY - NATURAL 114226-G1 2 4 6 2 4 6

*77A BURNER ASSEMBLY- L.P. 114226-G2 2 4 6 2 4 6

77B BURNER ASSEMBLY - NATURAL (NS) 114707-G1 2 4 6 2 4 6

77C BURNER ASSEMBLY - L.P. (NS) 114707-G2 2 4 6 2 4 6

*BURNER CONSTRUCTION BEFORE 11-10-82 NS = NOT SHOWN IN PHOTOGRAPH

DESCRIPTION

PART

NO.

GEF GEF GEF GEF GEF GEF

-1M -2M -3M -2SM -4SM -6SM

22

Page 25

PARTS LIST

ITEM

NO.

DESCRIPTION NO. -1M -2M -3M 2SM 4SM 6SM

37 COMPONENT BOX 114158-1 2 4 6 2 4 6

76 IGNITOR BOARD 114148-1 2 4 6 2 4 6

77 SOLID STATE TIMER 114247-2 1 2 3 2 4 6

78 TEMP. CONTROL BOARD 114100-1 1 2 3 2 4 6

PART GEF GEF GEF GEF GEF GEF

23

Page 26

PARTS LIST

GEF

ITEM

NO.

79

TANK COVER ASSEMBLY (SINGLE) 114248-G1 1 2 3

80

TANK COVER HANDLE 107023-1 1 2 3 2 4 6

82

TANK COVER (SPLIT) 114541-G1

DESCRIPTION

PART NO.

-1M

GEF

-2M

24

GEF

-3M

GEF

2SM

2 4 6

GEF

4SM

GEF

6SM

Loading...

Loading...