Page 1

INSTALLATION, SERVICE AND

PARTS MANUAL FOR

ET4 ELECTRIC HALF SIZE

CONVECTION OVEN

VULCAN-HART COMPANY, P 0. BOX 696, LOUISVILLE, KY 40201 -0696, TEL. (502) 778-2791

Page 2

IMPORTANT

OPERATING, INSTALLATION AND SERVICE PERSONNEL

Operating information for this equipment has been prepared for use by qualified and/or authorized operating

personnel

All installation and service on this equipment is to be performed by qualified, certified, licensed and/or

authorized installation or service personnel, with the exception of any marked with a ? in front of the part

number

Service may be obtained by contacting the Factory Service Department, Factory Representative or Local

Service Agency

DEFINITIONS

QUALIFIED AND/OR AUTHORIZED OPERATING PERSONNEL

Qualified or authorized operating personnel are those who have carefully read the information in this manual

and are familiar with the equipments functions or have had previous experience with the operation of the

equipment covered in this manual

QUALIFIED INSTALLATION PERSONNEL

Qualified installation personnel are individuals, a firm, corporation or company which either in person or

through a representative are engaged in, and are responsible for

1. The installation of gas piping from the outlet side of the gas meter, or the service regulator when the meter

is not provided, and the connection and installation of the gas appliance Qualified installation personnel

must be experienced in such work, be familiar with all precautions required, and have complied with all

requirements of state or local authorities having jurisdiction Reference in the United States of America National Fuel Gas code ANSI Z223 1 (Latest Edition) In Canada-Canadian Standard CAN1-B149 1 NAT

GAS (Latest Edition) or CAN1-B149 2 PROPANE (Latest Edition)

2. The installation of electrical wiring from the electric meter, main control box or service outlet to the electric

appliance Qualified installation personnel must be experienced in such work, be familiar with all

precautions required, and have complied with all requirements of state or local authorities having

jurisdiction Reference In the United States of America-National Electrical Code ANSI NFPA No 70 (Latest

Edition) In Canada-Canadian Electrical Code Part 1 CSA-C22 1 (Latest Edition)

QUALIFIED SERVICE PERSONNEL

Qualified service personnel are those who are familiar with Vulcan equipment who have been endorsed by

the Vulcan-Hart Corporation All authorized service personnel are required to be equipped with a complete set

of service parts manuals and stock a minimum amount of parts for Vulcan equipment

SHIPPING DAMAGE CLAIM PROCEDURE

For your protection, please note that equipment in this shipment was carefully inspected and packed by

skilled personnel before leaving the factory. The transportation company assumes full responsibility for safe

delivery upon acceptance of this shipment

If shipment arrives damaged:

1. VISIBLE LOSS OR DAMAGE — Be certain this is noted on freight bill or express receipt and signed by

person making delivery

2. FILE CLAIM FOR DAMAGES IMMEDIATELY — Regardless of extent of damage

3. CONCEALED LOSS OR DAMAGE — If damage is unnoticed until merchandise is unpacked, notify

transportation company or carrier immediately, and file "concealed damage" claim with them This should

be done within (15) days of date of delivery is made to you Be sure to retain container for inspection

We cannot assume responsibility for damage or loss incurred in transit We will, however, be glad to furnish

you with necessary documents to support your claim

PLEASE RETAIN THIS MANUAL FOR FUTURE REFERENCE

Page 3

IMPORTANT NOTES FOR ALL VULCAN APPLIANCES

1. These units are produced with the best possible workmanship and material. Proper installation is vital if best performance and

appearance are to be achieved. Installer must follow the installation instructions carefully.

2. Information on the construction and installation of ventilating hoods may be obtained from the “Standard for the installation of

equipment for the removal of smoke and grease laden vapors from commercial cooking equipment,” NFPA No 96 (latest

edition) available from the National Fire Protection Association, Battery March Park Quincy MA 02269.

3. For an appliance equipped with a flexible electric supply cord, the cord is equipped with a three prong (grounding) plug. This

grounding plug is for your protection against shock hazard and should be plugged directly into a properly grounded three-prong

receptacle. Do not cut or remove the grounding prong from this plug If the appliance is not equipped with a grounding plug, and

electric supply is needed, ground the appliance by using the ground lug provided (refer to the wiring diagram).

(FOR GAS APPLIANCES ONLY)

4. Do not obstruct the air flow into and around the appliance This air flow is necessary for proper combustion of gases and for

ventilation of the appliance Provisions for ventilation of incoming air supply for the equipment in the room must be in accordance

with National Fuel Gas Code ANSI Z223 1 (latest edition)

5. Do not obstruct the flow of flue gases from the flue duct (when so equipped) located on the rear (or sides) of the appliance. It is

recommended that the flue gases be ventilated to the outside of the building through a ventilation system installed by qualified

personnel.

6 For an appliance equipped with casters, (1) the installation shall be made with a connector that complies with the Standard for

Connectors for Movable Gas Appliances, ANSI Z21. 69 (latest edition), and Addenda, Z21.69a (latest edition), and a quickdisconnect device that complies with the Standard for Quick-Disconnect Devices for Use With Gas Fuel, ANSI Z21. 41 (latest

edition), and Addenda, Z21. 41 a (latest edition) and Z21. 41 b (latest edition) and (2) adequate means must be provided to limit

the movement of the appliance without depending on the connector and the quick-disconnect device or its associated piping to

limit the appliance movement If disconnection of the restraint is necessary, reconnect this restraint after the appliance has been

returned to its originally installed position.

7 The appliance and its individual shutoff valve must be disconnected from the gas supply piping system during any pressure

testing of that system at test pressures in excess of 1/2 psig (3.45 k Pa)

8 The appliance must be isolated from the gas suppiy system by closing its individual manual shutoff valve during any pressure

testing of the gas supply system at test pressures equal to or less than 1/2 psig (3 45 k Pa)

CAUTIONS

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS

IN THE VICINITY OF THIS EQUIPMENT OR ANY OTHER APPLIANCE.

1. KEEP THE APPLIANCE FREE AND CLEAR FROM ALL COMBUSTIBLE SUBSTANCES.

2. IN THE EVENT A GAS ODOR IS DETECTED, SHUT UNIT(S) DOWN AT THE MAIN

SHUTOFF VALVE AND CONTACT THE LOCAL GAS COMPANY OR GAS SUPPLIER

FOR SERVICE.

3. POST IN A PROMINENT LOCATION, INSTRUCTIONS TO BE FOLLOWED IN THE EVENT

THE SMELL OF GAS IS DETECTED. THIS INFORMATION MAY BE OBTAINED FROM A

LOCAL GAS SUPPLIER.

Page 4

INSTALLATION, SERVICE & PARTS MANUAL FOR

ET-4 ELECTRIC HALF SIZE CONVECTION OVEN INDEX

All Vulcan equipment is produced with the best possible

workmanship. Proper usage and maintenance will result in

many years of satisfactory performance.

DESCRIPTION PAGE

The manufacturer suggests that this entire manual be

thoroughly read and all instructions provided within be carefully

followed.

DEFINITIONS OF PERSONNEL (Installation, Service & Parts)

and SHIPPING DAMAGE CLAIM PROCEDURES

IMPORTANT NOTES 116021-1

INDEX 116021 - 2

CAUTIONS 116021-2

INSTALLATION INSTRUCTIONS 116021-3

GENERAL THEORY OF OPERATION 116021-3

OPERATING INSTRUCTIONS 116021-4

PREHEATING, LOADING, UNLOADING & CLEANING 116021-5

COOKING CHART 116021-5 & 6

OPERATORS TROUBLE SHOOTING 116021-7

SERVICE PERSONNEL TROUBLE SHOOTING 116021-8 & 9

PARTS DESCRIPTION AND REPLACEMENT 116021 - 9 thru -11

REPLACEMENT PARTS LIST & PHOTOGRAPHS 116021 - 12 thru -17

REVISION PAGE (Inside Back Cover)

(Inside Front Cover)

CAUTIONS AND NOTATIONS

NOTE:

A complete set of wiring diagrams are packaged in a separate envelope and sent out with the unit. A wiring diagram decal may also

be found on the back of the unit next to the electrical supply line.

OPENING OVEN DOOR:

Opening oven door will automatically cut "off" fan and heating elements. However, hot air gathered within the oven cavity may be

thrusted outwards when the door is opened.

CAUTION:

DO NOT stand directly in front of oven while opening door.

When opening door, operator should pull handle outward while simultaneously stepping back away from the front of the unit.

Load oven as quickly as possible to conserve heat. Center pans on racks.

NOTE:

All Vulcan electric convection ovens are equipped with an electrical rating plate indicating unit model number, serial number, unit

voltage, motor volts, motor amps, unit phase and heater kilowatts. The rating plate may be found mounted on the cover of the

terminal box located to the lower right hand corner of body back when facing unit from the front.

116021-2

Page 5

INSTALLATION INSTRUCTIONS

116021

-3

Vulcan electric convection ovens are U.L. listed under file

number E75870 and are manufactured for use on electrical

service of the characteristics specified on the rating plate. For

proper installation procedures in the United States of America,

refer to: National Electrical code (ANSI/ N F P A No. 70 (latest

edition) Information on the construction and installation of

ventilating hoods may be obtained from the "Standard For The

Vapors From Commercial Cooking Equipment", N. F. P. A. No

96 (latest edition) available from The National Fire Protection

Association “Attention Publication Services", Battery March

Park, Quincy, MA 02269

NOTE: This equipment is design certified by a nationally

recognized testing laboratory to the appropriate national

standards as indicated on the equipment rating plate. Any

modification made without written permission of Vulcan-Hart

Corporation voids the certification and warranty of this unit.

Units designed for 208 or 240 volts will operate satisfactorily

within the voltage range of 197 to 218 and 228 to 252 volt A C

respectively Units designed for 220/380 or 240415 volt AC

require voltage supplies with ground and neutral (3-phase, 4wire, or 1-phase, 3-wire)

Units wired for three(3) phase service may be changed to single

phase or single phase units may be changed to three (3) phase

as shown on the wiring diagram and connection decal (Except

for 3-phase motor construction )

1. Remove crating with care. Remove all wood blocking,

packing, material and accessories.

2. Unit has been factory equipped and electrically connected for

use with the specific electric supply indicated on rating plate.

Check electric supply available. If the two voltages don't

agree, contact your dealer or Vulcan-Hart immediately

without proceeding to the next step.

3. Install unit in final position if this was not done while making

connection.

4. Using a carpenter's level placed on oven rack, adjust the

feet on the bottom of each leg, so that oven is level from

front to back and side to side. (NOTE: Level oven when in

permanent position only )

5. Bring the conduit containing the proper size field supply

wires (select the size and type of the field wires in

accordance with National Electric Code, suitable for carrying

the equipment's rated amps and voltage. For equipment

rated over 100 amps, 75°0 field wires must be used) to back

of the unit through the l13-/32” hole provided in body back

and connect the phase leads (as well as neutral lead in

220/380 or 240 /415 volt A. C. units) to the field terminal

block identified by X, Y Z sections, and connect the green

grounding lead to the labeled ground lug Oven should now

be ready for operation To place the unit in operation, simply

push the master switch to the 'on" position and set the thermostat to the desired position (See operating instructions for

further details )

NOTES: In 220/380 or 240/415 A.C. models, the oven operates

on either 220 or 240 volts between the neutral wire,

independent from the grounding wire which is used to ground

the oven frame for safety reasons, is included in the main

supply leads.

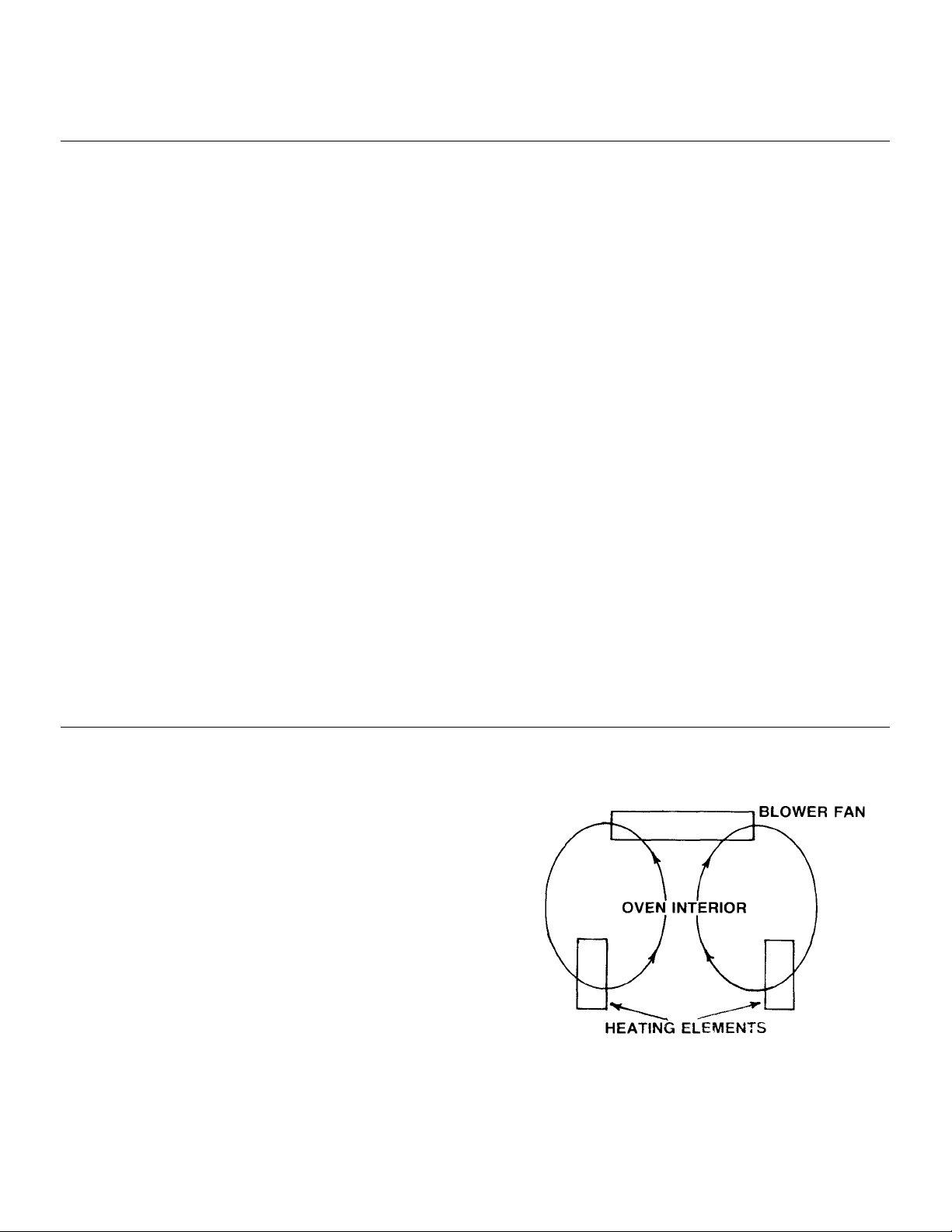

GENERAL THEORY OF OPERATION

Figure 8.0 Air Flow Pattern: Shows the air flow pattern inside

the Vulcan-Hart Half Size Convection Oven The blower pulls

the air from inside the oven cavity and forces it toward the front

and back of the cavity. The forced air is then deflected through

the fan cover, towards the left side of the oven in both the front

and back. The air carries the heat from the heating elements

located behind the fan cover and distributes it throughout the

oven cavity. In general, the blower operates continuously,

while the thermostatically controlled heating elements (3

elements) are energized only when there is a demand for heat

and de-energize when the desired temperature is reached.

A PLunger action door switch, mechanically linked with the door

shuts off both the heat and the blower when the door is opened

and will automatically reset when the door is eluded.

In the parts description and replacement section in the

installation, service and parts manual, the detailed function of

each component is explained.

FIG. NO. 8.0 AIR FLOW

PATTERN

Page 6

OPERATING INSTRUCTIONS

116021

-4

WARNING: The oven is hot. Use care when operating and

cleaning the oven.

GENERAL

The Vulcan method of air circulation and the thermostat make

possible the Vulcan system of controlled convection cooking.

This system lets you adjust the oven for the product result you

desire from your recipes.

AIR CIRCULATION

The ET4 oven cavity shall be direct heated by (3) independent

oven elements rates at 2,000 watts each for a total input of

6,000 watts. Heated air is circulated over the oven elements by

a 9 5/32" diameter airotor. The heated air is then delivered to

the oven cavity via the fan cover and the air flow scoops to the

top and bottom of the oven cavity. After circulating throughout

the oven cavity, the air is drawn through the center opening of

the fan cover and the process is repeated.

CONTROLS

The thermostat controls the temperature that the air in the oven

will reach and cuts the heating elements off when air is at the

thermostat setting.

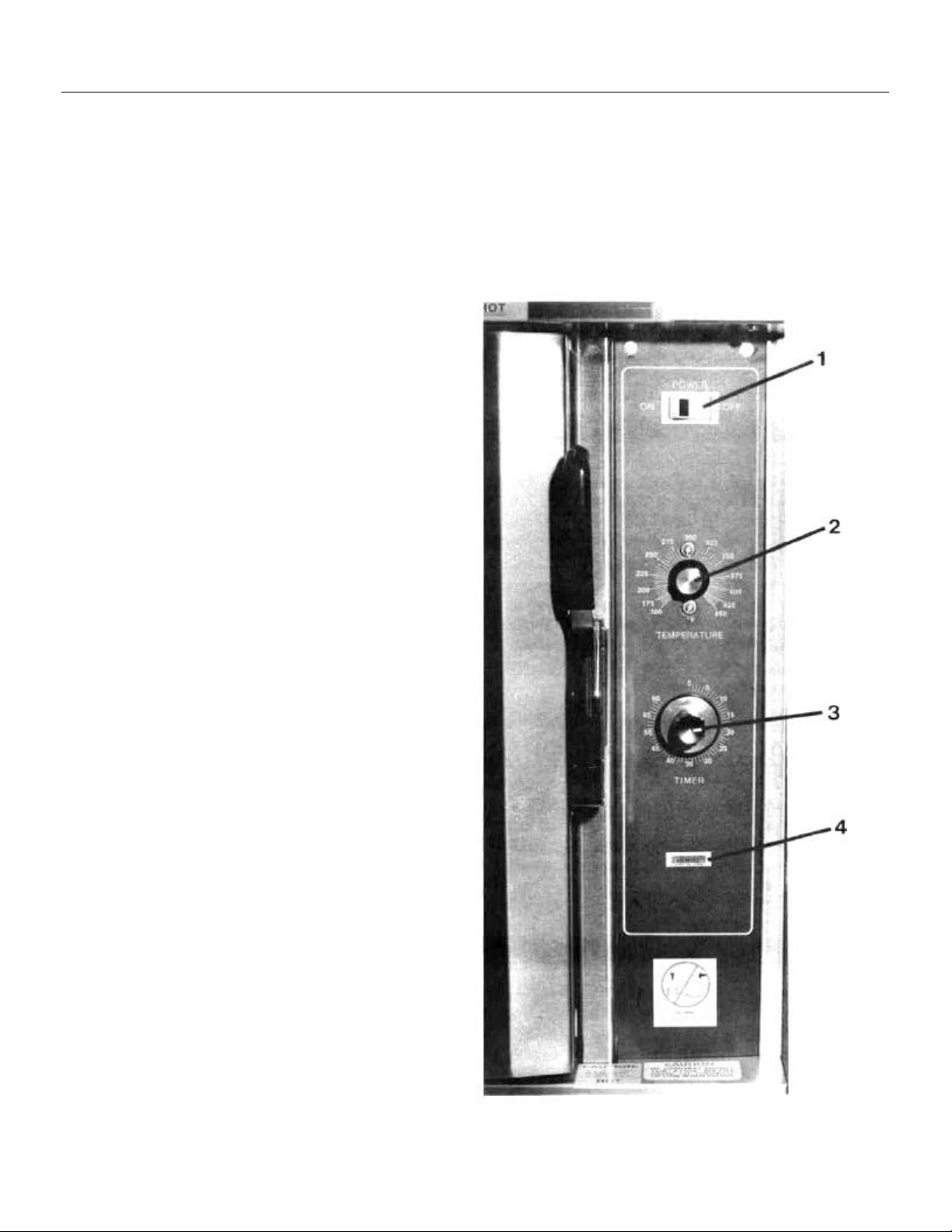

3. Timer - Item 3

The one hour timer is graduated in one minute increments.

Turn dial clockwise to increase time and counterclockwise to

decrease time.

4. Thermostat Light - Item 4

When the thermostat light is "on" it indicates that the oven is

pre-heating or has not recovered to the dial temperature

setting during a cooking cycle.

RECIPE ADJUSTMENT

The oven does not require special recipes. Excellent results can

be obtained from any good commercial recipe with reduced

cooking times.

TEMPERATURE ADJUSTMENT

The oven will cook or bake full or partial loads at standard

recipe temperatures when the thermostat is properly set. As

with any oven, you may wish to use a temperature of up to 25°

higher or lower than the recipe for the particular product result

that you prefer.

USE OF CONTROLS:

1. Master Switch - Item 1

The main on-off switch connects and disconnects the electric

supply to the unit controls, turning the unit "on and off".

2. Thermostat - Item 2

The thermostat is a snap-acting on-off type control. The

thermostat regulates the oven temperature from 150° through

450°. Turn dial clockwise to increase temperature and

counterclockwise to decrease temperature.

NOTE: All heating elements are under supervision of the

thermostat.

Page 7

PREHEATING, LOADING, UNLOADING & CLEANING

(STANDARD AND ROAST & HOLD OVENS)

Set the timer to the required time (see separate cooking chart).

When the preset time is up, the timer buzzer will sound, turn the

timer pointer to the "hold" position which is to the left of the "0"

minute mark.

Check the product for proper consistency and unload, or set for

additional time as required.

UNLOADING (See Caution Page)

Arrangements should be made so that adequate counter space

is available for the products to be unloaded from the oven

Rapid unloading will conserve heat, and this is essential if you

are reloading for high production. On multiple loading, close the

doors between each load and allow the oven to recover its

preset temperature. Unloading is easier if the racks are pulled

forward for better access to the pans; or if a bakers peal is

used.

CARE AND CLEANING

Stainless steel oven front may be cleaned with a damp cloth.

Stubborn soil may be removed with detergent. (Do Not Use

"Dawn".)

CAUTION: Scouring power should not be used except with

great care. Scouring powder is extremely difficult to remove

completely. It can build up accumulations that will damage the

oven. It will scratch and fog glass and can even damage and

remove corrosion resistant finishes.

Nickel plated racks and rack supports may be removed for

cleaning.

The fan cover is also removable for cleaning. Normally this is

not necessary, but will be helpful if batter or liquid is accidently

spilled into the fan area. It is recommended that fan cover be

removed at least twice yearly in order to remove debris trapped

behind the linings.

After processing some foods at low temperatures, odors may

linger in the oven. These odors may be cleared by setting the

thermostat at 450°F., then allow the oven to operate unloaded

for 30 to 45 minutes.

REQUIRED LUBRICATION

Motor bearings are packless, sealed and lubricated for life.

COOKING CHART

IMPORTANT

Recommended temperatures, times and number of racks are

intended as a guide only. Adjustments must be made to

compensate for variations in recipes, ingredients, preparation

and personal preference in product appearance.

RECOMMENDED TEMPERATURES AND TIMES FOR

ROASTING

Meat roasting is most satisfactory at temperatures of 225° to

325°F for beef, lamb, poultry and ham; 325°F for fresh pork as

recommended by USDA and American meat Institute.

A pan full of water may be placed in the oven bottom. This

water supplies humidity to reduce shrinkage. Water should be

added if necessary during roasting.

Roasting pans should be no deeper than necessary to hold

drippings, usually 2" to 2 1/2".

Cooking time and shrinkage may vary with roasting temperature, cut and grade of meat and degree of doneness.

Smaller cuts will generally show greater time savings than large

cuts at a given temperature.

RECOMMENDED TEMPERATURES & TIMES FOR ROASTING

ROASTING TEMPERATURE CHART

PRODUCT

Standing Rib

Roasts - oven ready

Rolled Rib Roasts

20to22lbs.

Veal Roast-15 Ibs. 300 F 4 hours - medium well

Turkeys-15 to 20 Ibs 300°F 3 hours

Meat Loaf-8to10 Ibs. 350°F 45 to 60 minutes

TEMPERATURE APPROXIMATE TIMES

250°F

275°F 4 hours-medium

3 to 4 hours-rare

4 to 4 1/2 hours-medium

Page 8

COOKING CHART (CONTINUED

BAKING TEMPERATURES CHART FOR STANDARD BAKING PANS 1 x 12 1/2 x 17 1/2

PRODUCT TEMPERATURE APPROX. TIMES RACK POSITION*

Biscuit Products

3 Pan Bake

Biscuit Products

4 Pan Bake

Biscuit Products

5 Pan Bake

Cake Products

3 Pan Bake

Cake Products

4 Pan Bake

Cake Products

5 Pan Bake

*NOTE: Rack positions are counted from bottom to top of oven cavity.

RECOMMENDED TEMPERATURES AND TIMES FOR

BAKING

NOTES ON SPECIAL PROCEDURES FOR BAKING

YEAST BREAD: Cooking starts immediately in the convection

oven. Yeast breads do not usually rise as much in a convection

oven. It is, therefore, usually necessary to allow curing and

rising times of up 2 1/2 to 3 times the increase of volume for

best cooking results.

PIES: When baking pies in your convection oven place pies on

a sheet or bun pan This procedure helps the bottom crust to

bake, makes handling easier, reduces the possibility of boil over

spoiling and enhances appearance of the pies cooked in the

lower racks.

RECOMMENDED USE OF CONTROLS

TIME REDUCTION

Because of the many variations in recipes, ingredients and

individual tastes, we do not give exact times for different

products.

The cooking charts are intended and should be used as a guide

only. When first cooking a product, check at one half recipe

time, the product may then be done or additional cooking time

may need to be estimated again

116021-6

375°F 10 to 12 Mm 2,5 & 8

375°F 11 to 13 Min 2,4,6 & 8

375°F 13 to 15 Min 1,3,5,7 & 9

315°F 22 to 24 Min 2,5 & 8

315°F 24 to 26 Min 2,4,6 & 8

315°F 26 to 28 Min 1,3,5,7 & 9

IMPORTANT: When established, oven times and temperature

control settings should be noted on your recipe.

In baking, the oven, its design, and proper functioning are of

great importance, but product quality and satisfactory results

are also dependent on the recipe, the ingredients used, and the

accuracy and the care with which the ingredients are measured

and the recipe instructions followed.

Forced air convection cooking is faster than conventional oven

cooking and therefore over cooking is more common. Care

must be taken not to cook products faster than is practical for

the best results. Since forced convection supplies heat to the

surface of the product, the thicker or more massive a product is

for its type, the longer it will take to absorb enough heat to

cook.

POWER OUTAGE NOTE: In case of a power outage, the unit

will automatically shut down. When power is restored to the

lines, the unit will resume its normal cooking function, after the

unit thermostat light indicates that the unit has recovered to its

proper cooking temperature. However, if the unit is left

unattended during a power outage, push the master power

switch to the "off" position. When power is restored to lines,

push power switch to the "on" position, wait for the oven to preheat then resume normal cooking operations.

Page 9

OPERATORS TROUBLE SHOOTING GUIDE

PROBLEM CAUSE REMEDY

UNEVEN BROWNING OR OVER-

COOKING AT EDGE OF PANS.

TEMP. SETTING TOO HIGH, WRONG RACK

POSITIONS USED FOR PRODUCT LOAD.

REDUCE TEMPERATURE CONTROL SETTING.

REDUCE NUMBER OF RACKS BEING USED. (SEE

SEPARATE COOKING CHART.) CHECK RACK

POSITIONS.

PULLING TO THE EDGE OF PAN OR

SPILLING.

OVERBROWNING BEFORE DONE OR

SHRINKING AND OVER BROWNING AT

EDGES.

EXCESSIVE SHRINKAGE.

OVEN OUT OF LEVEL OR WARPED SHEET

PANS.

TEMPERATURE SETTING TOO HIGH.

FORGETTING TO MAINTAIN WATER IN OVEN

OR THE USE OF TOO HIGH A ROASTING

TEMPERATURE.

HAVE OVEN LEVELED, ON THE RACKS, SIDE TO

SIDE AND FRONT TO BACK. THE RACK SHOULD

CHECK DEAD LEVEL SIDE TO SIDE AND FROM

LEVEL TO 1/8“ LOW AT THE FRONT, FROM

FRONT TO BACK. PANS USED FOR BAKING

BATTER PRODUCTS SHOULD BE KEPT

SEPARATED FROM GENERAL PURPOSE PANS. IF

ANY PAN SHOWS A TENDENCY TO WARP, IT

SHOULD BE REMOVED FROM THE BAKING

GROUP.

REDUCE TEMPERATURE CONTROL SETTING,

INCREASE COOKING TIME. (SEE SEPARATE

COOKING CHART.)

PUT A PAN OF WATER IN OVEN OR ADD WATER

TO PAN. LOWER THE ROASTING TEMPERATURE.

Page 10

SERVICE PERSONNEL

TROUBLE SHOOTING GUIDE (ALL ELECTRIC CONVECTION OVENS)

This section provides a guide for trouble shooting and covers

some of the more common problems with the equipment. The

servicing personnel, as with any other equipment, need to

become familiar enough with the circuit and the components in

order to be able to follow a logical sequence of trouble shooting,

and repair malfunctions not mentioned in the following

paragraphs.

THE INSTRUMENTS NECESSARY FOR TROUBLE

SHOOTING WOULD BE:

1. A.C. voltmeter to measure line voltages up to 480 volt

2. A.C.ammeter to measure line currents up to 50 amp for 208

volt, 1-phase model.

3. Accurate thermometer to measure oven temperature up to

500"F.

PROBLEM CORRECTION PROCEDURE

Step A—Measure the voltage between leads 42 and of the master switch.

If 208 volts, measure voltage across 21 and 48.

1. No blower, no heat.

If 208 volts, check for a bad connection to the switch terminal.

If no voltage, check for a tripped 15-amp fuse or a bad connection to the breaker.

Check for proper connections to the door switch on leads number 13 & 14.

In the following paragraphs, the voltmeter is used to measure

the voltage between 2 phases on 208 volt and between one

phase and neutral on 220/380 and 204/415 volt supplies. Do

not measure the voltage to the chassis ground. For the sake of

simplicity, when the measured voltage is referred to as 208 volt,

it is assumed that the supply is 208 volt. When supply is 240 or

220, the measured voltage rating of the oven matches exactly

(within the allowable supply tolerance) that of the field supply

Refer to the appropriate wiring diagram.

With the main power on oven circuit breakers "on' the master

switch turned to 'on' position and the oven door closed:

2. The blower is "on.

3. The oven heats up slowly with

no food in it.

4. The oven heats up properly

when empty, but as soon as the

food is put in it the temperature

drops and the oven never

recovers.

Turn the thermostat knob to about 350°F. If the oven indicator light is lit, follow step A.

Step A — Check for defective thermostat.

Step B — See if the heater contactor is energized (Listen for clicking sound or look at the

contactor’s plunger movement).

If contactor is operating, follow A, if not, follow B.

A Measure the voltage between the phases on the load side of the contactor If 208 volts look for

defective heating elements or connecting leads If no voltage, check the voltage on the supply

side of the contactor If 208 volts, the contactor is defective If no voltage, check the main

circuit breakers and supply voltage connections.

B Check the voltage on the contactor coil terminals. If 208 volts, but the contactor does not pull

in, the contactor is defective. If no voltage, check the voltage across terminals 7 and 8 of the

temperature control. If 208 volts, look for a bad connection on leads 60 and 7. If no voltage,

check for defective temperature controller.

Check for tripped breakers; supply voltage, defective contactor or heating elements. Compare the

amp reading on each phase lead with the expected nominal. They should match closely.

Meals containing excessive moisture can cause the temperature drop. Also, excess load can

cause temperature drop. The K. W. rating of the oven may not be adequate to properly handle the

type of quantity of the food in the oven.

5 The oven temperature does not

correspond with the thermostat

setting.

116021-8

Place a temperature measuring device on the center rack Allow the thermostat to cycle at least 3

times If the thermostat setting and thermometer reading do not correspond with the allowable

tolerance, recalibrate the thermostat.

Page 11

check for clockwise rotation of shaft, for any binding on the shaft of the blower

SERVICE PERSONNEL TROUBLE SHOOTING GUIDE

(ALL ELECTRIC CONVECTION OVENS) Continued

PROBLEM CORRECTION PROCEDURE

6 The oven temperature keeps

increasing beyond the setting of

the thermostat.

7 With master switch "off", the

oven heats up.

8 The motor turns off and

automatically comes back on after

a few minutes.

If the thermostat indicator light cycles on and off, check for a defective contactor (contacts

weldings). If the thermostat light remains "on", check for a defective thermostat (contacts

welding).

Check for defective contactor (contacts welded shut) or for shorted heating elements to ground

(the short could either be internally within the element or externally through the connecting leads

of the elements).

The internal thermal protector of the motor is sensing.

A High current-

wheel (the wheel should rotate freely by hand touch ) If none of the above, the motor may be

defective.

B. High ambient-check for hot air leakage from inside the oven to the side through the element

seal or motor housings. Check to see if hot air is blowing on the motor from the adjacent

equipment. Check for proper ventilation in the area.

NOTE: Occasionally the over current affects the fuse circuit (15 amp breaker) before it does the

thermal protector, and the circuit fuse will keep blowing out.

Page 12

PARTS DESCRIPTION & REPLACEMENT

116021

-9

WARNING: Disconnect the electrical power at the disconnect

switch and place a tag on the disconnect switch before

beginning any service, cleaning or maintenance procedures.

A. Switch Panel

In order to replace the components on the switch panel, it

should be taken out by removing the two screws at both top

corners.

1 Master Switch: The main on-off S. P. S. T. (single pole,

single throw) switch, providing the supply voltage to the

controls. To replace the switch, compress the spring clips

on the top and bottom of the switch while forcing it out the

front of the switch panel.

2 Oven Indicator Light: Light "on" indicates that the oven

has not reached the thermostat dial setting and is calling

for heat. Light "off" indicates that the set temperature has

been reached and that the heating elements are deenergized.

To replace, follow item 1 procedure.

3 Temperature Control: S. P. S. T. (single pole, single-

throw) relay controls the temperature of the oven from

150°F to 450°F. The normally opened contacts of the

thermostat provide power to the coil of the heating

element contactor as long as the heat is needed. Once

the set temperature is reached, the contacts open, deenergizing the contactor coil.

To replace the temperature control, disconnect all wires

from the contactor. Remove the knob and the two

mounting screws and pull the thermostat off the back of

the panel.

a For a calibration check, use a calibrated potentiometer

with the thermocouple located in the center of the center

rack. Set the dial to a mid-range temperature and allow

the oven to cycle at least three times.

b Allow the oven temperature to stabilize

c. After the stabilizing period, the instant the contactor

actuates (as noted by the thermostat "on" light turning

on), the oven temperature should be plus or minus 10°F

(6°C ) of the thermostat setting.

d. If it is within ± 10°F (6°C ) you are finished calibrating. If

not, follow steps E through H for recalibration.

e Loosen the set screw in the temperature control knob

Rotate knob without moving shaft and set the knob to

match the potentiometer reading.

f. Retighten the set screw. CAUTION: Do not over-tighten

g Turn the dial to the desired temperature.

h. Repeat steps A through C.

Page 13

PARTS DESCRIPTION & REPLACEMENT (Continued)

A. Switch Panel (Continued)

4. Timer (one-hour model) The normally open and common

contacts of the electric timer are connected together

energizing the timer motor when the knob is set to the

desired position. Once the timer completes its set interval

(returns to the zero mark) the

common terminal disconnects from the timer motor

(shuts the motor off) and connects with the buzzer

The buzzer will continue to sound until the knob is

manually turned to "hold' position where all

contacts are opened (timer motor and buzzer

turned off) (Figure No 16 rear view component)

FIG. NO. 16.0 REAR VIEW SCHEMATIC

B. Blower Motor

The blower motor has internal thermal protection, and its

sealed bearings do not require any lubrication. The

mounting of the blower assembly is as follows.

Remove fan cover by loosening (2) 10-24 screws in front of

fan cover. Loosen and remove (1)10-24 screw and nut from

thermistor probe, letting probe rest on cavity bottom.

Remove fan cover from oven cavity.

Loosen setscrew on the airotor with an allen wrench. Pull

airotor forward off the motor shaft with a wheel puller.

Remove switch panel as described in section A" on page

116021 –19. Remove the panel in the outer right body side

by accessing (2) 10-24 screws through control compartment

in top and bottom flanges of the outer right body side panel.

Remove the four nuts holding the motor mounting plate from

inside control compartment.

Pull the motor assembly forward and out of the control

compartment. Remove the junction box cover and the

supply leads.

NOTE: The motor is suitable for connection of two different

voltage supplies. Check the connection instruction inside the

motor junction box cover to assure proper connection for the

available voltage supply.

The direction of rotation is clockwise as viewed from in front

of the fan cover. The 1-phase motors are internally designed

for C W (clockwise) rotation On 3-

COMPONENT

phase motors, interchange any two supply leads to convert

counterclockwise to clockwise rotation.

C. Oven Heating Elements

The three heating elements are mounted on the right cavity

side behind the fan cover and can be serviced as follows:

Remove the two screws holding the fan cover. Slide fan

cover forward then slightly outward into the oven cavity.

Loosen & remove (1) 10-24 screw, nut and washer from

thermistor probe, letting probe rest on cavity bottom. Pull

the fan cover forward and out of the oven cavity. Remove

switch panel by removing (2) screws at both top corners

Remove the panel in the outer right body side by accessing

(2) 10-24 screws through the control compartment in top and

bottom flanges of the outer right body side panel. From

inside control compartment, remove (2) #10-32 nuts and

washers from appropriate element to be removed. Next,

from inside the oven cavity, remove (2) 10-24 screws holding

the element brackets of the appropriate element to be

removed. From inside the oven cavity, remove the element

from the right cavity side. Replace element.

NOTE: Make sure foil gasket is positioned between the

element bracket and the right cavity side when reinstalling

element.

116021-10

Page 14

PARTS DESCRIPTION & REPLACEMENT (Continued)

D. Door Switch

With the oven door closed, the normally open contact of the

door switch is closed providing power to the element and

motor controls. When the door opens, the normally open

contact is de-energized and the element contactor and the

blower are turned off.

Remove switch panel as described in section "A".

To adjust or replace the door switch, remove the two #8

mounting screws on left side of control compartment and

remove micro switch cover. This will expose (2) 2 3/8" dia.

holes in right inner body side. The micro switch is accessed

through bottom 2%" dia. hole.

To replace door switch, remove nut on micro switch shank

which protrudes through the front frame. This will allow

removal of defective micro switch and replacement of new

one through lower 2%" dia. access hole.

REPLACEMENT PARTS LIST AND PHOTOGRAPHS FOR

ELECTRIC CONVECTION OVENS WARNING ALL SERVICE

PERSONNEL

When servicing this equipment, use only certified controls duplicating those originally supplied on this

equipment by Vulcan-Hart Corporation.

DO NOT SUBSTITUTE Components with different model numbers.

DO NOT SUBSTITUTE Components with different manufacturing names.

NOTE: In order for proper door switch actuation, the relative

location of spacer washers behind front frame should be

noted on defective door switch and their position closely

approximated upon new door switch installation.

E. Power Panel Assembly

1. Contactor. The 4-pole (208, 240 volt models) and 3-pole

(220/380 & 240/415 volt models) contactors when

energized by the thermostat and the load control, provide

power to the heating elements.

2. Buzzer. Signaled by the timer, the buzzer sounds when

the pre-set time is completed.

To replace, cut both wires approximately 3" from the

buzzer and strip the ends. Remove the bracket holding

the defective buzzer. Install the new buzzer equipment

with its mounting bracket and lead, and connect the wires

with wire nuts.

DO NOT SUBSTITUTE Components with rebuilt controls without authorization from Vulcan-Hart

Corporation. Any unauthorized substitution of controls as stated above may be safety hazard and will

automatically void the warranty and the certification associated with this equipment.

REPLACEMENT PARTS ORDERS

The following information must accompany a replacement parts order or it cannot be filled.

A. Model and serial number.

B. Type of gas.

C. Unit voltage, amperage and motor phase.

D. Appliance finish — black, gray, stainless steel, etc.

This information may be found on the unit rating plate. Parts may be ordered from your dealer, service

agency, or parts distributor. For further information concerning parts ordering location, contact Vulcan-Hart

Corporation, 3600 North Point Blvd., Baltimore, Maryland 21222.

116021-11

Page 15

REPLACEMENT PARTS LIST

&

PHOTOGRAPHS

ITEM NO. PART NO. DESCRIPTION QUANTITY

1 115952-G1 Oven Door Handle Assembly (Including Strike Plate) 1

2 115710-G1 Oven Door Assembly 1

3 115689-1 Top Channel Finishing Piece 1

4 115695-G2 Body Top Assembly 1

5 111294-2 Door Window 1

6 115690-1 Bottom Channel Finishing Piece 1

7 115758-D Decal Control Panel Standard 1

8 115747-G1 Control Panel Assembly (NS) 1

9 115704-G2 Body Side, Outer Right Assembly 1

10 115694-2 Body Side, Left (NS) 1

11 115692-G2 Panel, Outer Right Body Side 1

12 103981-2 Hinge Pin (NS) 2

13 104629-2 Hinge Pin Bearing 2

7A 115758-D1 Decal Control Panel, Roto-Digital (NS) 1

14 115778-1 Adjustable Legs (NS) 4

56 116027-1 Silicone Gasket, Door Latch 1

NS = Not Shown By Photo

Page 16

REPLACEMENT PARTS LIST & PHOTOGRAPHS (CONT.)

ITEM NO. PART NO. DESCRIPTION QUANTITY

15 115728-1 Oven Cavity Top 1

16 115729-G1 Oven Cavity Bottom 1

17 115730-G1 Oven Cavity, Right Side 1

18 115732-G1 Oven Cavity, Left Side 1

19 102558-4 Capillary Clip Standard *Different No. For Roto-Digit Probe) 1

20 115682-1 Oven Rack Support, Right Side 2

21 115682-2 Oven Rack Support, Left Side 2

22 113951-1 Clip Rack Support 8

23 115683-1 Oven Rack 5

24 115745-G1 Door Seal Assembly Sides 2

25 115746-G1 Door Seal Assembly, Top & Bottom 2

26 111496-F5 Micro Switch 1

27 115701-G1 Fan Cover Assembly 1

28 115809-1 Cover Piece, Fan 1

29 115780-9 Airoto CC ½” Bore 9 1/8” O.D. 1

30 S06089 Scrulug 1

31 113994-2 Motor 1

32 115823-1 Spacers, Fan Cover Piece 12

33 115727-G1 Oven Cavity Back 1

34 115814-1 Element, Inner 208V 1

34A 115814-2 Element Center, 208V 1

34B 115814-3 Element, Outer 208V Select As Required 1

34C 115814-4 Element, Inner 240V 1

34D 115814-5 Element, Center 240V 1

34 E 115814-6 Element, Outer 240V 1

35 113840-1 Temperature Switch 1

55 114141-5 Thermistor Probe (Standard) 1

55A 116471-2 Thermistor Probe (Rota-Digital) (NS) 1

57 116462-G1 Motor Mounting Plate Assembly 1

58 115844-2 Air Scoop 2

59 115762-1 Door Liner 1

60 115227-2 Gasket, Door Liner 1

61 116286-1 Insulation, Motor Mounting Plate 1

Page 17

REPLACEMENT PARTS LIST & PHOTOGRAPHS (CONT.)

116021

-14

Page 18

REPLACEMENT PARTS LIST & PHOTOGRAPHS (CONT.)

ITEM NO. PART NO. DESCRIPTION QUANTITY

8 115747-G1 Control Panel Assembly 1

36 111496-B4 Power Switch 1

37 116280-1 Thermostats 1

38 114524-1 Thermostat Knob 1

39 111690-2 Timer 1

40 111242-1 Timer Knob 1

41 111496-E4 Heating Light 1

7 115758-D Decal, Control Panel (Standard) 1

7A 115758-D1 Decal, Control Panel (Roto-Digital) 1

42 111496-B3 Rocker Switch (Red) 2

43 116471-1 Roto-Digit Computer Board With Setting Display 1

44 414254-00001 Computer Setting Knob 1

45 111496-E12 On/Ready Light 1

46 111499-1 Buzzer, 230V 1

66 111500-11 Transformer Roto-Digit 220V/10V 1

116021-15

Page 19

REPLACEMENT PARTS LIST & PHOTOGRAPHS (CONT.)

116021

-16

ITEM NO. PART NO. DESCRIPTION QUANTITY

31 113994-2 Motor 1

47 116461-1 Motor Mount Insulation 1

48 417934-G1 Porcelain Block 1

49 111497-D3 Contactor 1

63 115705-G1 Inner Right Body Side Assembly 1

64 115696-G1 Body Bottom Assembly 1

Page 20

REPLACEMENT PARTS LIST & PHOTOGRAPHS (CONT.)

116021

-17

ITEM NO. PART NO. DESCRIPTION QUANTITY

50 115757-G1 Body Back 1

51 115688-1 Cover Plate Terminal Box 1

52 113807-1 Fuse Holder 2

53 113799-2 Fuse(NS) 2

54 110472-8 Terminal Block 1

62 115738-G1 Terminal Box Assembly 1

65 113810-1 Rating Plate 1

Page 21

MANUAL ASSEMBLY: 116021-G1

INSTALLATION, SERVICE & PARTS

ET4 ELECTRIC CONVECTION HALF SIZE OVEN

SIGN

DML 0 116021-1 through-23 06-04-87

DML 1 116021-1 through-18 04-01-89

DML 2 116021-16 12-10-90

MANUAL 116021-G1

SUB NO.

SHEET PART NUMBER

AFFECTED

DATE

116021-18

Loading...

Loading...