Page 1

SERVICE MANUAL

SUPPLEMENT

KLEENSCREEN SERIES ELECTRI C

FRYER BATTERY

MODEL ML

ERD40F 126905

ERD50F 126906

ERD225F 126907

ERD85F 126908

ERC40F 126909

ERC50F 126910

ERC225F 126911

ERC85F 126912

2ERD40F SHOWN

This Service Manual Supplement should be used

in addition to F24577 "FLOOR MODEL ELECTRIC

FRYERS" for Service Information related to the

Fryer and F24599 "MOBILE FILT E RS " f or Service

Information related to the pump.

- NOTICE This Manual is prepared for th e use of trained Vulcan Service

Technicians and should not be used by those not properly

qu alif ied. If yo u have attend ed a Vulcan Service School for this

product, you may be qualified to perform all the procedures

described in this man ual.

Thi s manu al i s no t i nten ded to be al l en co mpassi ng . I f you have

not attende d a Vulcan S ervic e School for this produ ct , you should

read, in i ts en ti rety, t he re p a i r p r oced ure yo u w ish to perfo rm to

determine if you have the necessary tools, instruments and skills

required to perform the procedure. Procedures for which you do

not have th e necessary tools, instruments and skills should be

performed b y a trained Vu lcan Service Technician .

Reproduction or other use of this Manual, without the express

written consent of Vulcan, is prohibited.

A product of VULCAN-HART LOUISVILLE , KY 40201-0696

F24696 (May 2001)

Page 2

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT

TABLE OF CONTENTS

GENERAL............................................................................. 3

Introduction ........................................................................ 3

Description..................................................................... 3

Model Designations .............................................................. 3

Kleenscreen Filteri ng S y stem ....................................................... 4

Information Sources.............................................................. 4

Installation......................................................................... 4

Operation.......................................................................... 4

Cleaning .......................................................................... 4

Maintenance ....................................................................... 4

Specifications ...................................................................... 5

Electrical ...................................................................... 5

REMOVAL AND REPLACEMENT OF PARTS ................................................. 6

Covers and Panels ................................................................... 6

Pump and Motor .................................................................... 6

Filter Valve and Discard Val ve Switches .................................................. 7

Heater Contactors ................................................................... 7

SERVICE PROCEDURES AND ADJUSTMENTS ............................................... 8

Computer Cont rol Board Diagnostics ..................................................... 8

ELECTRICAL OPERATION ............................................................... 9

Sequence of O per ation ............................................................... 9

Solid State Fryer Control, Full Vat ................................................... 9

Computer Control, Full Vat........................................................ 11

Kleenscreen Filteri ng S y stem ...................................................... 12

Discard of Used Oil ............................................................. 13

Component Func tion ................................................................ 14

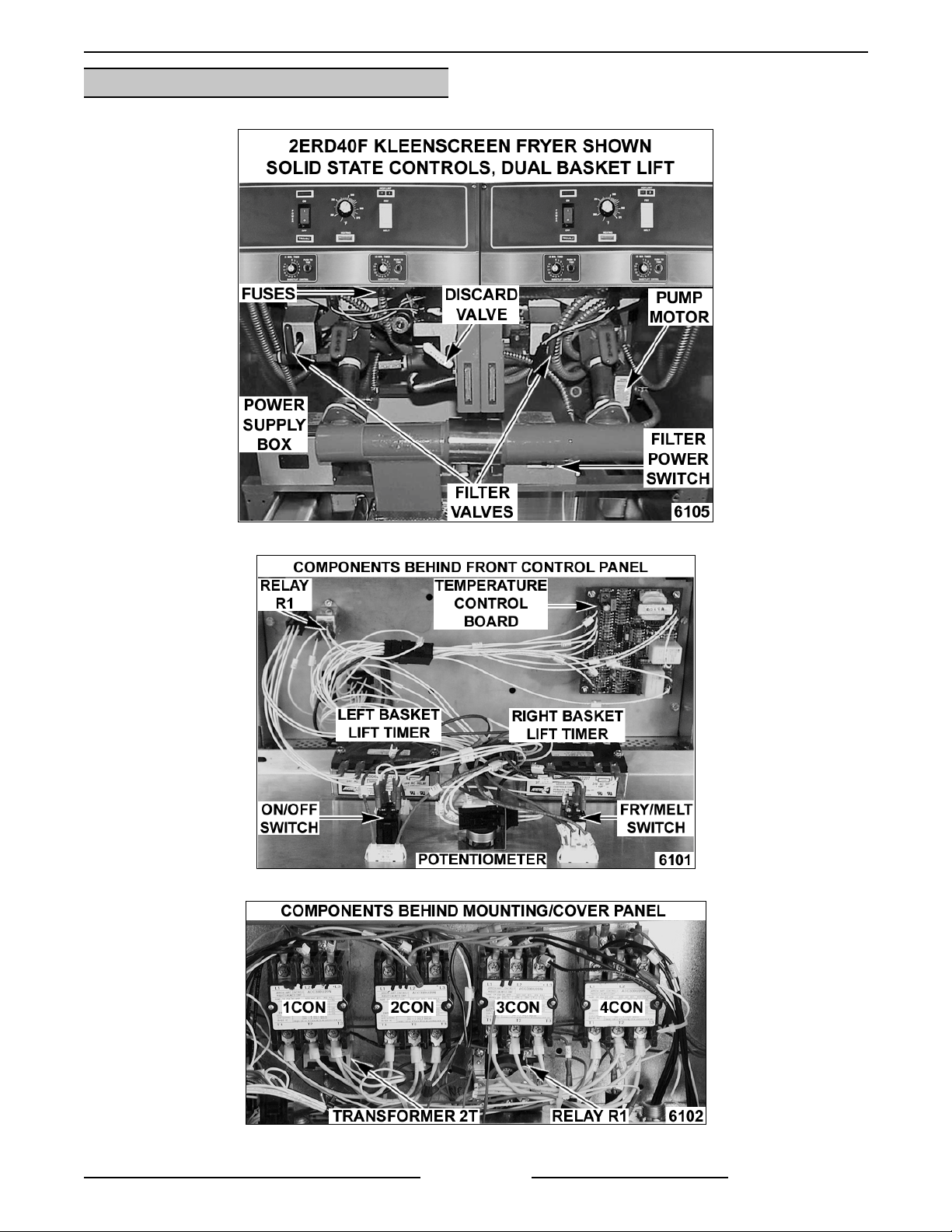

Component Locat ion ................................................................ 15

Schematic Diagrams ................................................................ 16

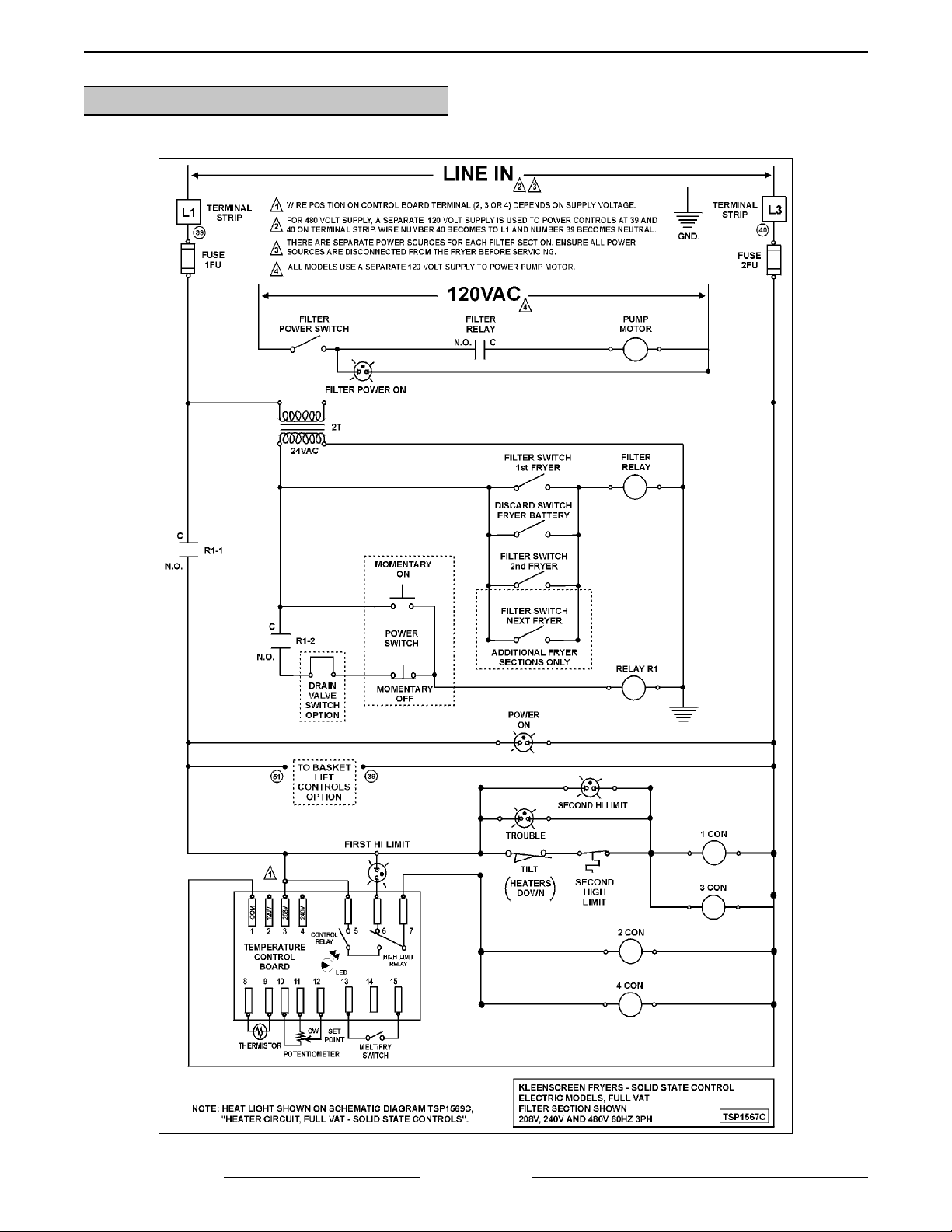

Solid State Control and K leenscreen Filter, Full Vat ..................................... 16

Computer Control, Full Vat........................................................ 18

Computer Control, Split Vat ....................................................... 19

Kleenscreen Filteri ng S y stem, Computer Control ....................................... 20

Heater Circuit, Solid State Controls, Full Vat .......................................... 21

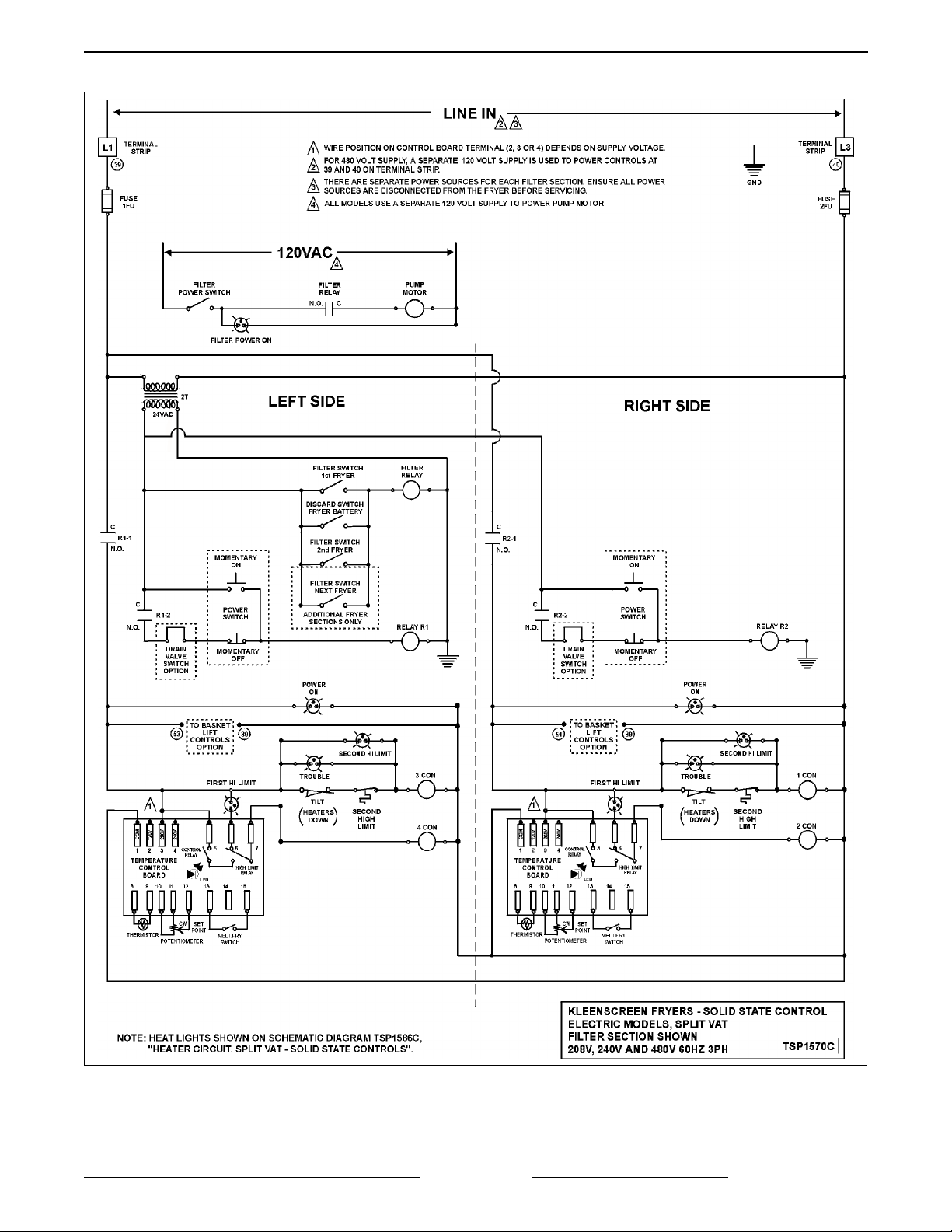

Heater Circuit, Solid State Controls, Split Vat.......................................... 22

Basket Lift Circuit, Solid State Controls .............................................. 23

Wiring Diagrams ................................................................... 24

Kleenscreen Filteri ng S y stem ...................................................... 24

Wiring Diagr am Index ............................................................ 25

TROUBLESHOOTING .................................................................. 50

Solid State Control.................................................................. 50

Computer Control .................................................................. 51

Computer Control Harness Pin-Outs Chart................................................ 52

Kleenscreen Filteri ng S y stem .......................................................... 53

CONDENSED SPARE PARTS LIST ........................................................ 56

© VULCAN 2001

F24696 (May 2001) Page 2 of 56

Page 3

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - GENERAL

INTRODUCTION

GENERAL

Description

This Service Manual Supplem ent cover s specific

servi ce infor mation only related t o the Vulcan

Kleenscreen filter models li sted on the front c over.

The fryer battery utilizes many of the same controls

and components as the Vulcan ERD series (solid

state control ) and ERC series (comput er c ontrol)

fryers.

Kleenscreen fryer batteries are available i n a

minimum of two and a maximum of six fryer

sections. The fryer size of each section is identical.

An ERO series Fry mate (dum p station) can also be

included as one or more of t he sect ions.

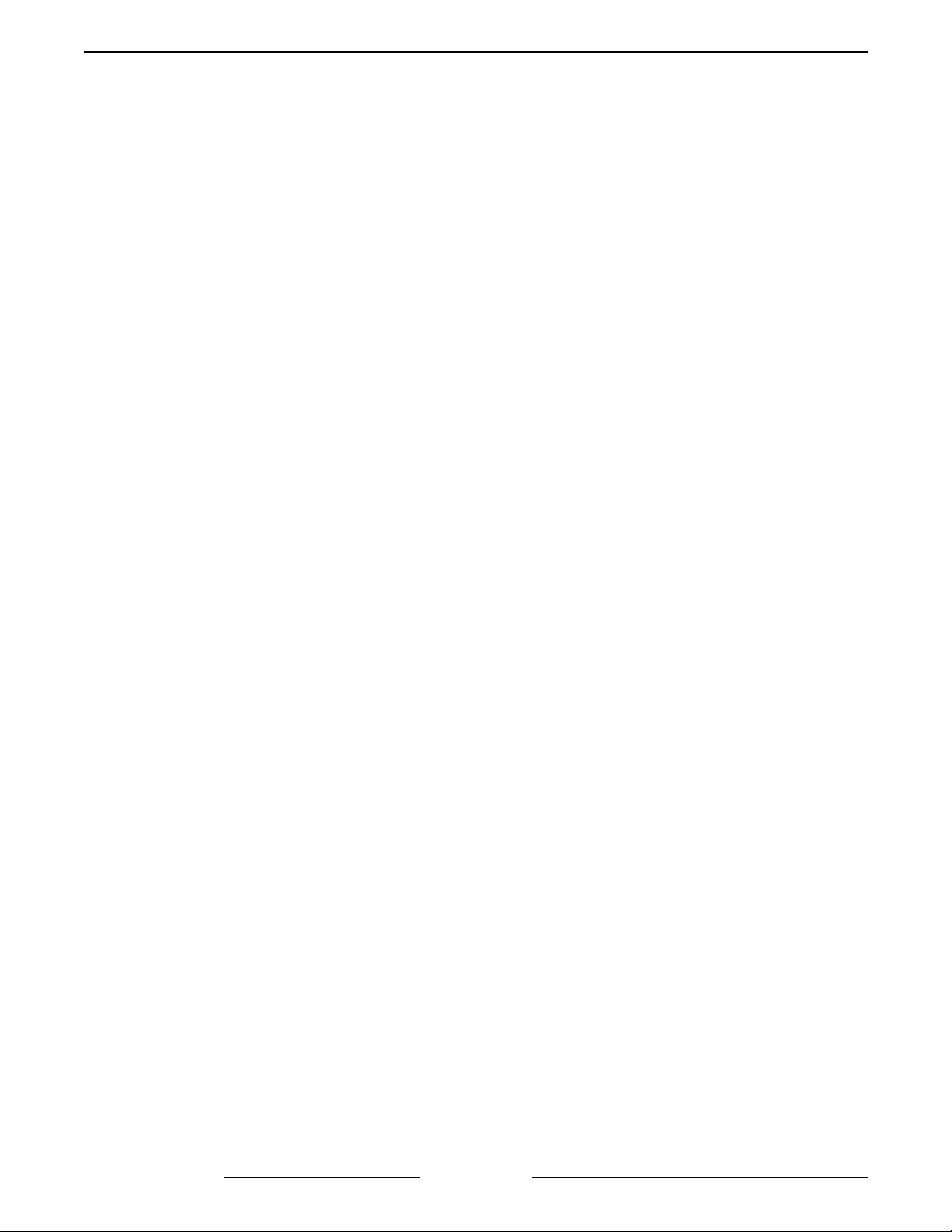

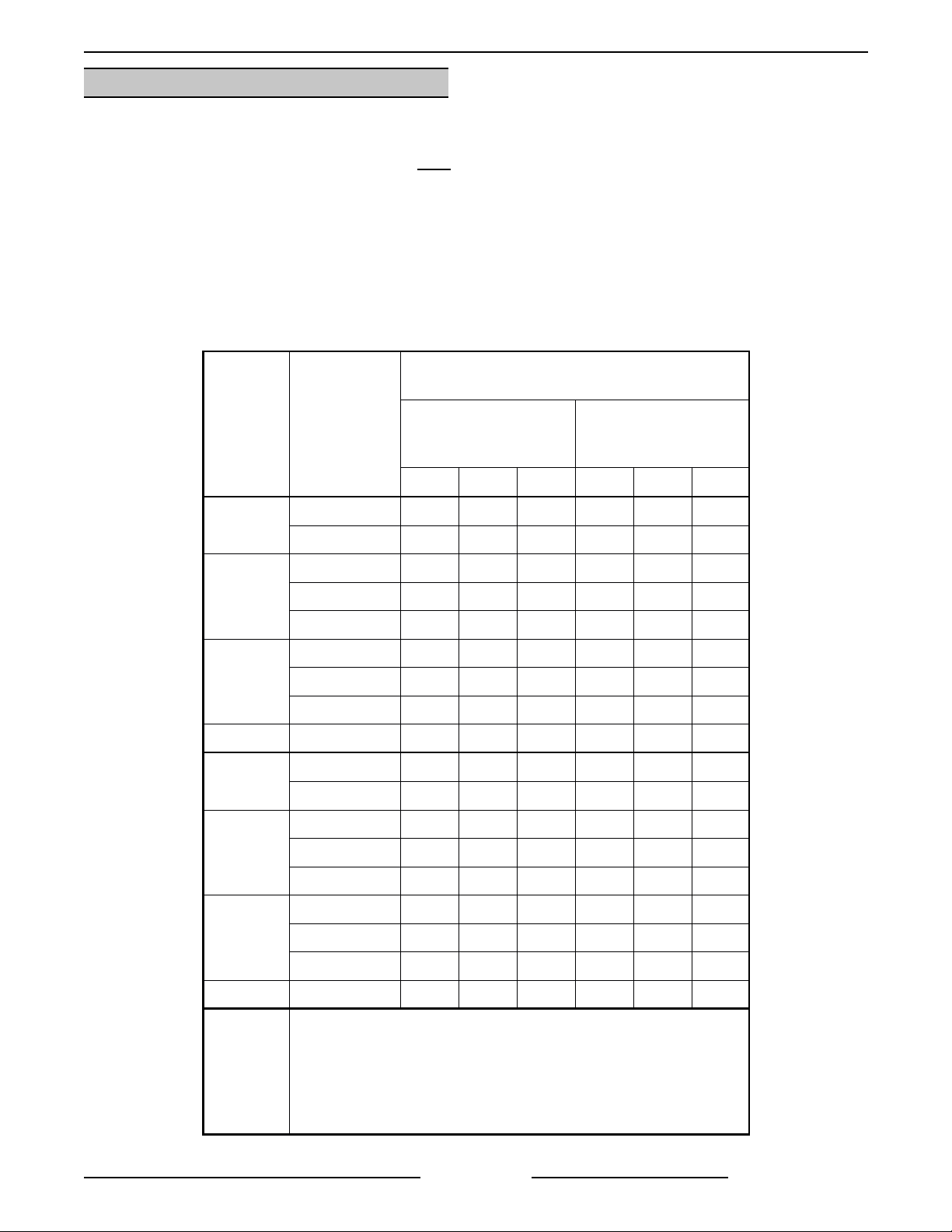

Models, Features and Options

FEATURES OPTIONS

MODEL

2ERD40F

2ERD50F

FRYER

WIDTH

(INCHES)

1

1

31 40 Full Solid State Single or Dual 7.5 or 15

31 50 Full Solid State Single or Dual 7.5 or 15

FRYING

COMPOUND

PER FRYER

(POUNDS)

Model Desi gnations

VAT

TYPE

CONTROL

TYPE

BASKET LIFTS

AUTOMATIC

TIMERS

(MIN)

2ERD225F

2ERD85F

2ERC40F

2ERC50F

2ERC225F

2ERC85F

1

2

1

1

1

2

ER015 (Frymate)

ER021 (Frymate)

NOTES

:

31

50

(25 each v at)

Split Solid State

Single

(each v at)

42 85 Full Solid State Single or Dual 7.5 or 15

31 40 Full Computer Single or Dual 7.5 or 15

31 50 Full Computer Single or Dual 7.5 or 15

31

50

(25 each v at)

Split Computer

Single

(each v at)

42 85 Full Computer Single or Dual 7.5 or 15

15 1/2

21

1. F or eac h additional fryer section, add 15 1/2 inc hes to the width.

2. F or eac h additional fryer section, add 21 inches to t he width.

F24696 (May 2001)Page 3 of 56

7.5 or 15

7.5 or 15

Page 4

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - GENERAL

Kleenscreen Filtering S ystem

The new "Kleenscreen" filt er ing system has been integr ated into the ER S er ies fryer bat tery. The filt er is housed

in a pull -out drawer assembly at t he base of the fr y er . The filteri ng c omponents in the dr awer i nc lude a stainless

steel filter t ank, crumb- c atch basket and fine mesh screen. With t he fil ter drawer closed, a self-seating retur n oil

line provides the pat h to return the filtered oil t o the fry t ank .

This system is designed to prov ide a thorough and easy met hod for f iltering fryer oil.

Some of the benefits include:

• Self - contained system eliminating the use of external fi lter equipment.

• Paperless filteri ng system.

• Easy to clean and low maintenance.

Information Sources

Refer to the appropriate manual below for related information.

ER SERIES

MANUAL

Service F24577 F24599 Parts F31007 - Installation and

Operation

Filtration Syst em

User’s Guide

F24696 Use the Servic e information found in thi s

ELECTRIC

FRYERS

F30981 - -

- - F31150

Serv ice Manual Supplement. The

Supplement cover s additional S er vic e

Information specific to the Kleenscreen

fryer and fil tering system.

PUMP

INFORMATION

KLEEN

SCREEN

INSTALLATION

Refer to the Installation and Operation Manual for specif ic installation i nstr uc tions.

OPERATION

Refer to the Installation and Operation Manual for specif ic operating instructions.

CLEANING

Refer to the Installation and Operation Manual for specif ic cleani ng instructions.

MAINTENANCE

Refer to the Installation and Operation Manual for specif ic mai ntenance instructions.

F24696 (May 2001) Page 4 of 56

Page 5

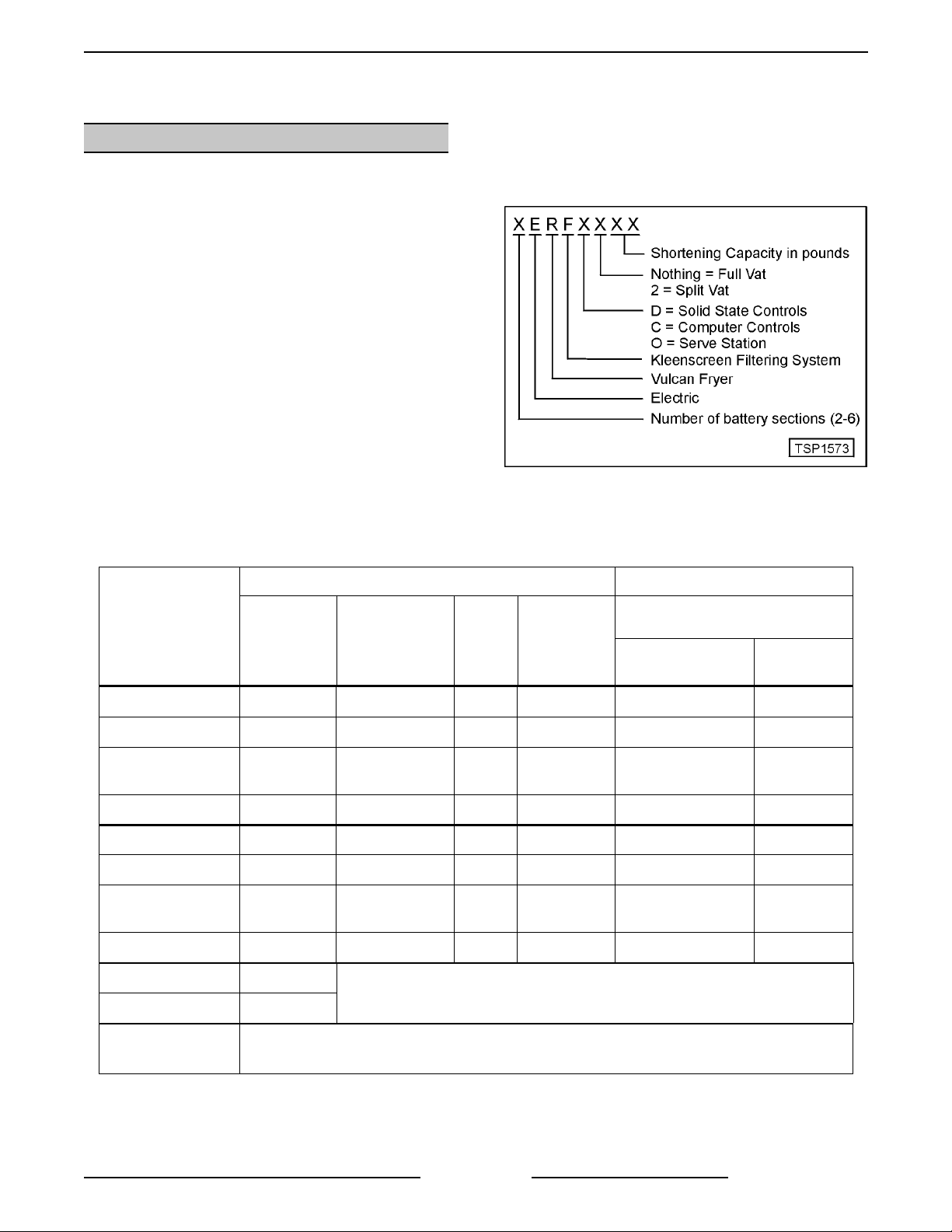

Electrical

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - GENERAL

SPECIFICATIONS

Separate electrical c onnec tions are required for each

section of the battery.

• 208VAC, 240VAC or 480VA C ( 3 phase, 60HZ) to power the heating elements.

• On 208VAC and 240VAC models, step down transformer(s) provide power for the fryer c ontrols, basket lift( s)

if installed, and Kleenscreen filtering controls.

• On 480VAC models, a 120VAC connection is required for each fr y er sect ion.

• All models require a separate 120V A C c onnec tion for the pump motor.

NOTE:

Pump m otor for Kleenscreen filteri ng system draws 5.0 amps.

AMPS - EACH FRYER SECTION

(3 PHASE/ 60HZ)

MODELKWPER FRYER

SECTION

3

PER LINE

1

RECOMMENDED

CIRCUIT

PROTECTION

2

208V 240V 480V 208V 240V 480V

14 39 34 17 50 45 25

ERD40F

17 47 41 20 60 50 30

14 39 34 17 50 45 25

ERD50F

17 47 41 20 60 50 30

ERD225F

ERD85F

ERC40F

ERC50F

ERC225F

ERC85F

NOTES

21 58 51 25 80 70 35

14 39 34 17 50 45 25

17 47 41 20 60 50 30

21 58 51 25 80 70 35

24 67 58 29 90 80 40

14 39 34 17 50 45 25

17 47 41 20 60 50 30

14 39 34 17 50 45 25

17 47 41 20 60 50 30

21 58 51 25 80 70 35

14 39 34 17 50 45 25

17 47 41 20 60 50 30

21 58 51 25 80 70 35

24 67 58 29 90 80 40

1. Amperage values in the table are nomi nal. Tolerance is

:

+5/-10%.

2. Complied in accordance with National Elec tric Code,

ANSI/NFPA 70, latest edition.

3. 14kw is standard on all f r y er s except 85 lb. models which

are 24kw.

F24696 (May 2001)Page 5 of 56

Page 6

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - REMOVAL AND REPLACEMENT OF PARTS

REMOVAL AND REPLACEMENT OF PARTS

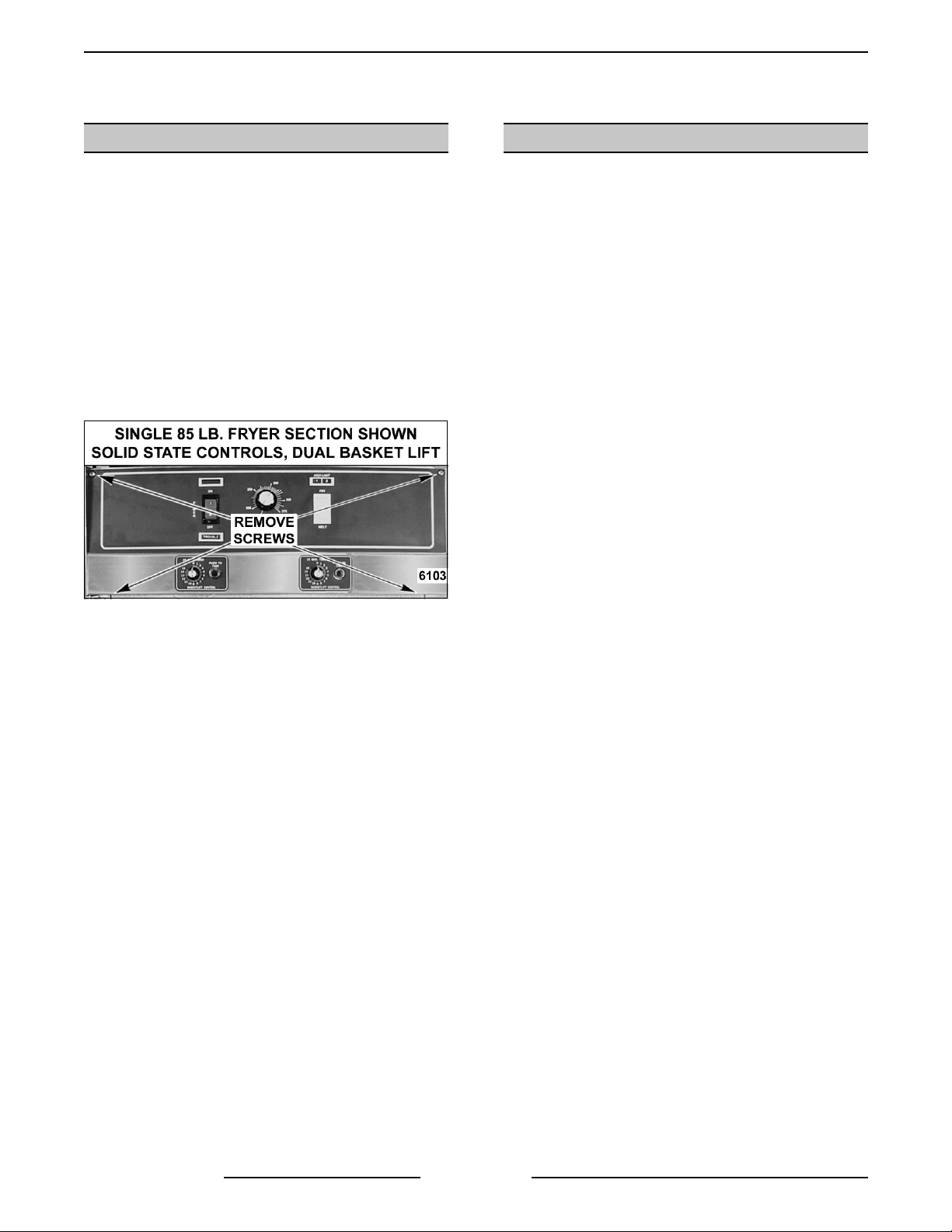

COVERS AND PANELS

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BOX. THERE ARE SEVERAL SEPARATE

CIRCUITS. B E S URE A LL A RE DISCONNECTED.

PLACE A TAG ON THE CIRCUIT B OX(ES)

INDICATI NG THE CIRCUIT IS BEING SE RV ICED.

Front Control Panel

1. O pen the cabinet door t o the fryer section being

serviced.

2. Remove the screws along the bottom lip and

along the top of the of the control panel.

3. Work t he panel loose at each end and lift off.

4. Reverse procedure to install.

Basket lift Co vers

1. Loosen bolt at the top of each basket li ft hanger

and lift the basket hangers from the support r od.

2. Remove the screws that secure the lower cover

at the rear of the fr y er section.

3. Remove the screws along each side of the

cover.

4. Lift t he c over and pl ac e to the side.

5. Reverse procedure to install.

DISCONNECT THE ELECTRICAL

PUMP A ND MOTOR

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BOX. THERE ARE SEVERAL SEPARATE

CIRCUITS. B E S URE A LL A RE DISCONNECTED.

PLACE A TAG ON THE CIRCUIT B OX(ES)

INDICATI NG THE CIRCUIT IS BEING SE RV ICED.

NOTE

locati on of pump motor.

1. O pen the right side cabinet door of the filter

section.

2. Pull the filt er dr awer out , remove the filter tank

assembly and push the tank support ar ms back

underneath the fryer.

3. Disconnect the electrical c onnec tion to the

motor.

NOTE

removal of the pump assembly. If access to the

back of t he fryer is available, i t may be easier t o

remove the pump from the rear.

4. Separ ate the swivel hose connection on the r ight

side (intak e) of the pum p.

5. Separ ate the swivel hose connection on the left

side (discharge) of the pump.

6. Remove the mounti ng bolts from the mot or .

7. Remove the motor, pump and piping assembly.

A. If replacing the pump and motor, remove

8. Reverse procedure to install.

NOTE

gromm ets are install ed under the motor mounting

plate.

DISCONNECT THE ELECTRICAL

: Refer to component location pi cture 6100 for

: The rem aining steps are writt en for f r ont

the exi sting piping assemblies and reuse.

: Ensure the rubber vibration pad or the

F24696 (May 2001) Page 6 of 56

Page 7

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - REMOVAL AND REPLACEMENT OF PARTS

FILTER VALVE AND DISCAR D

VALVE SWITCHES

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BOX. THERE ARE SEVERAL SEPARATE

CIRCUITS. B E S URE A LL A RE DISCONNECTED.

PLACE A TAG ON THE CIRCUIT B OX(ES)

INDICATI NG THE CIRCUIT IS BEING SE RV ICED.

1. O pen the cabinet door t o the fryer section being

serviced.

2. Disconnect lead wire connector from the

appropriate switc h.

3. Remove switc h mounting screws.

4. Reverse procedure to install.

NOTE:

no provision for adjustment.

DISCONNECT THE ELECTRICAL

Switch m ounting is a f ixed loc ation and has

HEATER CONTACTORS

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BOX. THERE ARE SEVERAL SEPARATE

CIRCUITS. B E S URE A LL A RE DISCONNECTED.

PLACE A TAG ON THE CIRCUIT B OX(ES)

INDICATI NG THE CIRCUIT IS BEING SE RV ICED.

1. Remove the front c ontrol panel as outlined under

"FRONT CONTROL PANEL" in "COVERS AND

PANELS".

2. Remove the combination mount ing and cov er

panel fr om the control area.

3. Cont ac tors are now accessible.

NOTE

DISCONNECT THE ELECTRICAL

: Refer to "COMPONENT LOCATION".

4. Reverse procedure to install.

F24696 (May 2001)Page 7 of 56

Page 8

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT- SERVICE PROCEDURES AND ADJUSTMENTS

SERVICE PROCEDURES AND ADJUSTMENTS

COMPUTER CONTROL BOARD

DIAGNOSTICS

The comput er control is used on other equipment and is capable of displaying many dif ferent prompts.

Therefor e, some prompts not applicable

computer is looking for either 24 V A C or 24 V A C gr ound on par ticular pins, an open connection c an c ause a nonapplicabl e prompt to appear. Refer to "COMPUTE R CO NTROL HARNESS PIN-OUTS CHART " under

"TROUBLESHOOTING".

Diagnostics are divided into two areas, "OP E RA TION" and "SE RV ICE". Operation mode is the standard mode of

fryer operation. Ser vic e mode is intended to give the service technic ian more i nformation regarding the nature of

a problem encountered. In either mode t he fryer operat es normally until an error oc curs.

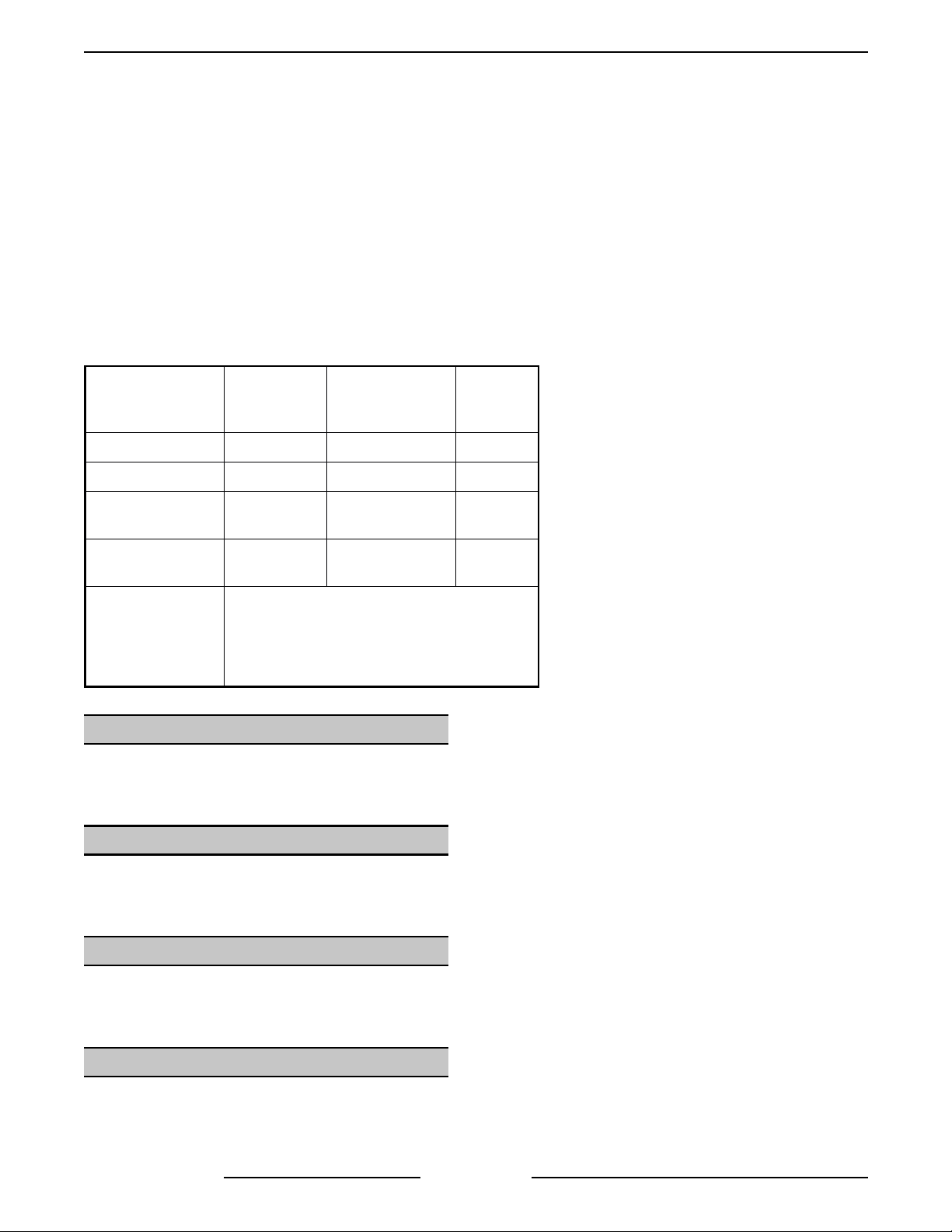

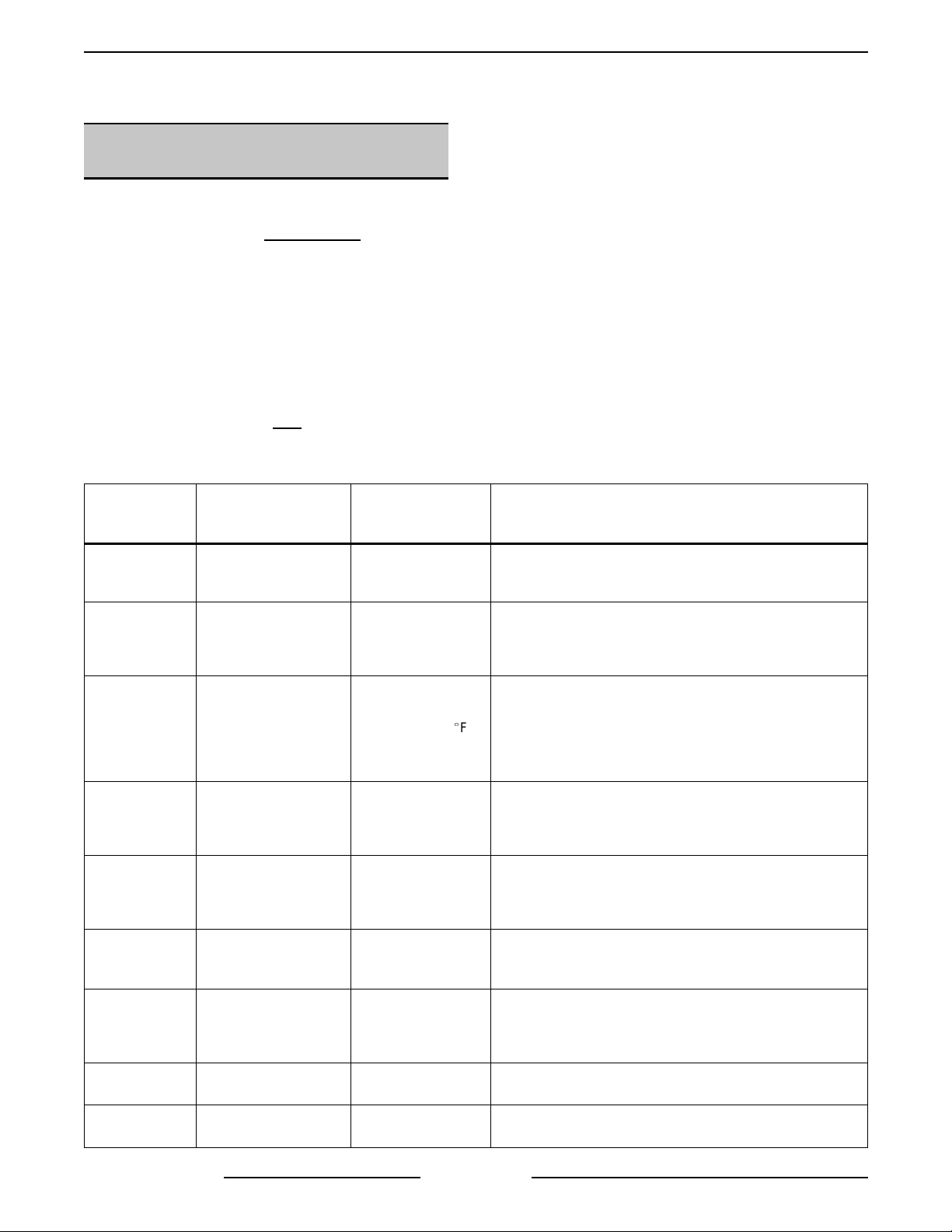

If an error occurs, the information displayed will be different. The chart below shows what is displayed for both

"OPERAT ION" and "SERVI CE " modes.

may display when a problem occur s i n the wiring harness. Sinc e the

The "SERVI CE " mode can only

be entered while an err or is occurring. To enter the service m ode, press and hold

the product 3 and 4 keys and t ur n the power switch ON. To ex it, turn the power switch OFF.

The following display s/c omputer responses will be given for the noted conditions.

CONDITION

No input on

pins

3, 4, 5, or 6

Low

Temperature

(lack of heat)

High

Temperature

Alarm

High

Temperature

(high limit)

Tilt Switch

OPEN

OPERATION MODE

DIAGNOSTICS

DISPLAY

IGN FAILURE

LOW TEMP LO TEMP XXXF

HIGH TEMP HI TEMP XXX(F

OFF OFF

OFF OFF

SERVICE MODE

DIAGNOSTICS

DISPLAY

IGN FAILURE on

left side or right side

for split vat only

COMPUTER RESPONSE

HEAT OFF

HEAT OFF

Temperature is below the lowest operational set point. Refer

to "COMPUTER CONTROL" under

"TROUBLESHOOTING".

HIGH TEMP DISPLAYED

Output at pin 15 and/or 16 (split vat) should already be OFF

unless there is a problem with computer. Vat temperature is

410°F or higher which is well above the highest operational

set point. Refer to "COMPUTER CONTROL" under

"TROUBLESHOOTING".

OFF DISPLAYED

Mechanical high limit is OPEN (435°F), heat OFF and input is

removed from pin 1 and/or pin 2 which indicates to the

computer --- VAT TURNED OFF.

OFF DISPLAYED

Heaters raised or problem with the ti lt switch. Heat is OFF

and input is removed from pin 1 and/or pin 2 which indicates

to the computer --- VAT TURNED OFF.

Drain Valve

Switch

(if installed)

Probe

Open or Short

No input on

pin 11

Not passing

Self Check

DRAIN OPEN DRAIN OPEN

PROBE OPEN R or

CALL SERVICE

CLOSE DOOR CLOSE DOOR HEAT OFF

CALL SERVICE MICRO FAIL System will operate in backup mode

L for split vat

PROBE SH R or L

for split vat

Input is removed from pin 10. Drain valve is OPEN or there is

a problem with switch.

F24696 (May 2001) Page 8 of 56

DRAIN OPEN DISPLAYED

HEAT OFF

, HEAT OFF

Page 9

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - ELECTRICAL OPERATION

Power up Diagnostics

On power up, the control will execute a self check. The failure of any of these tests will result in the message

“CALL SERVICE” or “MICRO FAIL” being displayed.

This prompt will flash at approximately a 1 hert z rate. Whil e the prompt is displayed, the computer will not

function. If the failure is in the computer, the fryer will operate in backup mode.

When the fryer c omputer comes out of i nitial ization and self check rout ines, it will either enter the heating m ode

or the melt mode (if programmed) of operation.

For a split vat fryer, one vat can be OFF while t he other is in operation. If this occurs, the si de that is OFF will be

indicat ed by displaying the OFF prompt to the user. The message will be on the side of the display which

corresponds to the vat which is OF F.

System Tests

The system di agnostics menu is intended to give you the ability to test the basic parts of the computer. It can be

entered by pressing the 8 and 9 produc t keys simultaneously while tur ning on power to the fr y er c omputer. T he

message "SYSTEM TESTS" is di splayed. In this mode you can select one of three tests.

With DISPLAY TEST displayed, press enter to begin a t est, use the up and down arrows to rotate through the

screens. Press exit onc e to return to the test menu or twice to return to normal operation.

With KEYPAD TEST displayed, press enter to begin the test. The control will respond by displayi ng the name of

the key pressed. Press exi t once to return t o the test menu or t wice to return to nor mal operation.

With VER xxx displayed, the release number is displayed as "VER XXX".

ELECTRICAL OPERATION

SEQUENCE OF OPERATION

Solid State Fryer Control, Full Vat

Refer to schematic diagram TSP 1567C for both the

"Fryer Cont r ols" operation and the "Kleenscreen

Filtering system" oper ation.

FRY CYCLE - LIQUID FRYING OIL

: If usi ng solid shortening, r efer to "ME LT

NOTE

CYCLE - SOLID S HORTENING" in this section.

1. Conditions.

A. Fryer connected to corr ec t supply v oltage

(separate connections are required f or

each section of the battery).

1) 208, 240 or 480VAC - power for

heating elements.

2) 208 or 240VAC models - Step down

transformer(s) provide power for the

fryer controls, basket lift(s) if

installed, and the Kleenscreen

filtering controls.

3) 480VAC models - A separate

4) All models require a separate

B. 24VAC transformer ener gized.

C. Fryer properly gr ounded.

D. Internal fryer cir c uit breakers ON.

NOTE

KW only.

E. Power switch to t he fryer section controls

in center NEUTRAL (starting) position.

F. Til t switch contacts CLOSED (N.O. - held

CLOSED with heat ing elements down).

G. Second high limit thermostat CLOSED.

H. F r y ing oil at the proper level in vat and

below 300°F.

120VAC connection is used along

with step down transformer(s) to

provide power for the fryer cont r ols,

basket lift(s) if instal led, and the

Kleenscreen filter ing controls.

120VAC connection for the pump

motor.

: 208 and 240VAC models at 21 and 24

I. Fry/Melt switch in FRY position.

J. T emperature control set to desired frying

temperature.

F24696 (May 2001)Page 9 of 56

Page 10

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - ELECTRICAL OPERATION

2. Press power ON switch.

A. 24VAC i nitial ly energizes relay coil R1

through the m omentary O N power switch

contacts (N.O.).

B. When switch is rel eased, r elay coil R1

remains energized through R1-2 "latching

circuit" contacts (N.O.) and the momentary

OFF power switch cont ac ts (N.C.).

1) R1-1 CLOSED.

2) R1-2 CLOSED.

C. Supply v oltage energizes the foll owing

components:

1) Power ON light (red).

2) Power supplied to basket lif t controls,

if installed.

3) 1CON and 3CON through til t switch

and second high li mit t her mostat.

4) Temperature control board at proper

terminal (2, 3 or 4) for supply voltage

and jumpered to terminal 5.

D. T emperature cont rol board evaluates the

inputs fr om thermistor and set point

potentiometer then energizes the board

relays.

1) The Control relay contacts (N.O.) at

terminal 5 CLOSE.

2) The first high limit relay c ontacts

(N.C.) at terminal 6 change state to

the normally OPEN posi tion and

provide a path to the out put at

terminal 7.

: The f irst high l imit "light " may

NOTE

quickly flash once, unt il the High limit rel ay

is energized.

a. 2CON and 4CON are energized

and heating elements are

powered.

b. Heat light comes ON.

: Refer to "SCHEMATIC

NOTE

TSP1569C" under "S CHE M A TIC

DIAGRAMS".

3. Oil reaches set point temperature.

A. Temperature contr ol de-energizes the

"control r elay" on board, cont ac ts at

terminal 5 OPEN and the output at

terminal 7 is removed.

1) 2CON and 4CON are de-energized

and power is removed from the

heating elements.

2) Heat light goes OFF.

4. Temperature control cycles output to terminal 7

until power switch is turned OFF, heating

element s are r aised or a high li mit condition

occurs.

A. If oil reac hes 410°F ±5, t he temperature

control de- ener gizes "high limit r elay" on

board, contact s revert bac k to the normally

CLOSED position and the output changes

to terminal 6.

1) The first high limit li ght comes ON.

2) 2CON and 4CON are de-energized

and power is removed from the

heating elements.

3) Output is removed fr om term inal 6

when oil temperature drops below set

point temperature and is returned to

terminal 7.

B. If the second high limit OPENS

(435°F ±15) or the tilt switch operat es,

1CON and 3CON are de-energized and

power is removed from the heati ng

element s and heating stops.

1) Trouble "light " and second high limit

"light" come ON.

MELT CYCLE - SOLID SHORTENING

1. Conditions.

A. Sam e as outlined in steps 1A t hr u 1G

under "FRY CYCLE - LIQUID FRYING

OIL".

B. Solid shortening at the proper pounds in

vat and at room temperature.

C. Fry/Melt switch in MELT position.

D. T emperature Contr ol set to desired frying

temperature.

2. Same as outlined in steps 2 thru 2. C. 4) under

"FRY CYCLE - LIQUID FRYING OIL".

3. Temperature control boar d evaluates the inputs

from thermistor then energiz es the boar d

relays.

A. Melt cycle is initiated and the temperat ure

control functions as a percent ON/OFF

timer.

1) The control relay contacts (N.O.) at

terminal 5, cycle the output at

terminal 7 to energize 2CON and

4CON and power the heating

elements.

a. Initial condit ion is OFF 45

seconds.

b. Heat condition ON 2 seconds

(heat li ght ON).

F24696 (May 2001) Page 10 of 56

Page 11

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - ELECTRICAL OPERATION

: Refer to "SCHEMATIC

NOTE

TSP1569C" under "S CHE M A TIC

DIAGRAMS".

B. Control cycles output at time interval s of

30 seconds OFF, then 2 seconds ON (heat

light ON).

4. Shortening t emperature reac hes 135(F.

A. Melt cycle is automatically over-ridden.

: The Fry/Melt switch shoul d r emain in

NOTE

the "Melt" position.

B. Control uses thermistor input to cycle the

output at ter minal 7.

5. Shortening r eac hes set poi nt temperat ur e.

A. Control removes output f rom pin 7.

1) 2CON and 4CON are de-energized

and power is removed from the

heating elements.

2) Heat light goes out.

6. Control cycles the output at terminal 7, on the

vat temperature.

4) All models require a separate

120VAC connection for the pump

motor.

B. 24VAC transformer 2T energized.

1) Power to pins 3, 4, 5, 6, 11, and 17

(control system main input) on

computer main harness.

2) 24 VAC ground to pins 9, 12, and 13

(control system main input GND).

NOTE:

Pin 12 on the main harness is used to

indicat e to the comput er the type of fryer ( full

or split vat) the computer is installed in. If the

fryer is a full vat , pin 12 is tied to 24 VAC

ground. If the fry er is a split vat, pin 12 is tied

to 24 VAC.

C. F r y er properly grounded.

D. I nternal f r y er circuit breakers ON.

: 208 and 240VAC models at 21 and 24

NOTE

KW only.

E. Power switch to t he fryer section controls

in the OF F position.

Computer Control, Full Vat

Refer to schematic diagram’s TSP1571C for "Fryer

Controls" operat ion and TSP1587 "Kleenscreen

Filtering system" oper ation.

FRY CYCLE - LIQUID FRYING OIL

: If usi ng solid shortening, the computer

NOTE

control shoul d be pr ogr ammed to use the M E LT

CYCLE. In the M E LT CYCLE, the computer will

"cycle" the heaters ON/ O FF in short intervals to

gradually heat and liquify the short ening until it

reaches a temperature of 135°F.The comput er then

resumes normal operation as described under FRY

CYCLE.

1. Conditions.

A. Fryer connected to corr ec t supply v oltage

(separate connections are required f or

each section of the battery).

1) 208, 240 or 480VAC - power for

heating elements.

2) 208 or 240VAC models - Step down

transformer(s) provide power for the

fryer controls, basket lift(s) if

installed, and the Kleenscreen

filtering controls.

3) 480VAC models - A separate

120VAC connection is used along

with step down transformer(s) to

provide power for the fryer cont r ols,

basket lift(s) if instal led, and the

Kleenscreen filter ing controls.

F. Til t switch contacts CLOSED (N.O. - held

CLOSED with heat ing elements down).

G. Second high limit thermostat CLOSED.

H. F r y ing oil at the proper level in vat and

below 300°F.

I. Computer control is setup properly and

ready to use.

2. Press power ON switch.

A. 12VAC transformer 1T energized.

1) Computer power supply board PS-1 is

energized and a (+ ) 12V DC si gnal is

sent to pin 23 on the computer main

harness.

B. Computer control powers ON, initi alizes

and performs a diagnostic self check.

: If the control passes self c hec k , then

NOTE

the outputs are energized and operation

sequence continues. If control does not

self test then CALL SERVICE or M ICRO FAIL

will display. Refer to "COMPUTER CONTROL

BOARD DIAG NOSTICS" under " S E RV ICE

PROCEDURES AND ADJUSTMENTS".

1) R1 control relay, 1CON and 3CON

will energize.

a. R1 relay energized, NO contacts

CLOSE and supply power to pin

1 on computer main harness.

pass

F24696 (May 2001)Page 11 of 56

Page 12

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - ELECTRICAL OPERATION

NOTE:

Pins 1 and 2 on the main

harness are used to monitor the

power switch "status" of the vat(s).

Pin 1 is the power status i nput on a

full vat or right side split vat and pin 2

is the input for the l eft side split vat

only. These inputs tell the computer

which vat(s) are turned ON or OFF.

3. Computer control evaluates input from

thermistor at pins 3 and 4 (full vat or right side

split vat).

: Pins 1 and 2 (l eft side split v at only) on

NOTE

temperat ure probe harness.

A. Computer control evaluates the input from

thermistor then activates t he 24V A C

output f r om pin 15 and power is applied to

R2 control relay.

1) R2 control relay i s energized and the

N.O. contacts CLOSE.

a. 2CON and 4CON are energized

and heating elements are

powered.

NOTE:

Pin 15 and 16 on the main

computer harness are the heat

outputs. Pin15 is the full v at or right

side split vat output and pin 16 is the

left side output on a split vat only.

4. Oil temperature reaches set temperatur e.

2) R1 contacts OPEN and remove

power from pin 1 (full vat or right si de

split vat). The display will indicate

“OFF”.

: If the second high limit t rips for t he

NOTE

left side split vat onl y, R3 and contactor s 3

and 4 are de-energized. Power is removed

form the left side vat heating elements

only and heati ng st ops. R3 c ontacts OPEN

and remove power from pin 2 ( left side

split vat only). The display will indicate

“OFF” for the left si de vat.

: The f ilter valve handle and t he discard valve

NOTE

handle are connected to a mechani c al valve and

switch assembly to r oute the flow of oil fil tering

system and supply power to the pump motor .

Kleenscreen Filtering S ystem

For Solid State Control, refer to schematic diagram

TSP1567C f or both the "Fryer Controls" operati on

and the "Kleenscreen Filter ing system" operat ion.

For Comput er Control, r efer to schem atic diagrams

TSP1571C f or the "Fryer Cont r ols" operation and

TSP1587C f or the "Kleenscreen Filtering system"

operation.

1. Conditions

A. Fryer connected to corr ec t supply v oltage

(separate connections are required f or

each section of the battery).

A. Computer turns OFF heat output and

control r elay R2 de-energizes.

B. 2CON and 4CON are de-energized and

power is removed from heating elements.

5. Computer cycl es heat out put on oil temperature

until power switch is turned OFF, heating

element s are r aised or a high li mit condition

occurs.

: Steps 5A and 5B discuss OPEN high limits.

NOTE

For additional information on computer control er r or

messages, refer t o " COMPUTER CONT ROL

BOARD DIAG NOSTICS" under " S E RV ICE

PROCEDURES AND ADJUSTMENTS".

A. If the oil r eaches 410(F ±5, the display will

indicate “HI TEMP” as an al ar m to the

operator only .

B. If the second high limit (435(F ±15)

OPENS or the tilt swit c h oper ates, the

control r elay R1 and contactor s 1 thr u 4

are de-energized.

1) Power is removed form the heat ing

element s and heating stops.

B. Fryer properly grounded.

C. Power switch to fryer section controls

turned OFF .

D. F r y ing oil below 300°F.

E. Fi lter drawer assembly installed proper ly.

F. Filter power switch turned O FF.

G. Filter valve handle (red) retr ac ted.

1) Fil ter valve switch N.O. contacts

OPEN.

H. Discard valve handle (white) retrac ted.

1) Discard valve switch N.O. contacts

OPEN.

2. Set tem perature control between 300°F

(minimum) and 350°F (maxim um).

: Oil should not be filtered out side of this

NOTE

temperat ure range. At l ower temperatures the oi l is

thicker whi c h may increase filt er ing time and place a

greater load on the pump. At higher oil

temperat ures, oil seal life is deceased.

3. Turn the power switch ON, to the fry er sect ion

to be filtered.

F24696 (May 2001) Page 12 of 56

Page 13

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - ELECTRICAL OPERATION

A. Allow oil to cycle at set temperature for

approximately 10 minutes.

: If usi ng solid shortening, onc e it has

NOTE

melt ed, stir the oil to eliminate any sold

shortening in c old zone of t he vat. Refer to

"MELT CYCLE - S OLID SHORTENING".

4. Turn the power switch OF F, to the fryer section

to be filtered.

5. Open the manual drain valve to the fryer

section in need of filteri ng and drain the liquid

oil/shortening into filter tank.

: If usi ng solid shortening, allow hot

NOTE

shortening to stand in filter tank for approximately 6

minut es prior to f iltering.

6. Turn filter power switch O N.

A. Switch pilot light comes ON.

7. Extend F ilter valve handle of the same fryer

section.

A. Filter valve switch N.O. contacts CLOSE.

1) Filter rel ay c oil is energi z ed and the

N.O. contacts CLOSE.

a. Power supplied to pump motor.

Discard of u sed oil

1. Conditions

A. Sam e as outlined in steps 1 thr u 4 under

“KLEENSCREEN FILTERING SYSTEM”.

2. Open the manual drain valve to the fryer

section in need of oil discarding and drai n the

oil into the filter.

3. Attach oi l drain hose the male quick c onnec t

fitting on the fryer.

4. Turn filter power switch O N.

A. Switch pilot light comes ON.

5. Place drain hose discharge end into a used oil

holding tank .

6. Extend discard handle.

A. Discard valve switch N.O. contacts

CLOSE.

1) Filter rel ay c oil is energi z ed and the

N.O. contacts CLOSE.

a. Power supplied to pump motor.

B. Oi l begins flowing through drain hose i nto

holding tank until power is removed.

B. Pum p motor circulates oil through f ilter

until power is removed.

8. When the oil filt er ing process is compl eted,

close the manual drain valve to the fryer and

allow the vat to refill.

: No electr ical switching occurs by closing t he

NOTE

manual drain valve unless the optional dr ain valve

switch is installed.

9. When all f iltered oil is retur ned to the fry er ,

retract the filter valve handle.

A. Filter valve switch N.O. contacts OPEN.

1) Filter rel ay c oil is de-energized and

the N.O. contacts OPEN.

a. Power is removed fr om pump

motor.

10. Turn filter power switch OFF.

: If usi ng solid shortening, when all fi ltered oil

NOTE

is returned to the vat and fil ter power switch is OFF,

open the filter drawer approximately one inch. Allow

the remaining shortening in the li ne to drain int o the

filter tank t o prevent possible clogging after the

shortening cool s and solidifies. Close the f ilter

drawer when complete.

7. When all used oil is empti ed from the fryer,

retract the discard valve handle.

A. Discard valve switch N.O. contacts OPEN.

1) Filter rel ay c oil is de-energized and

the N.O. contacts OPEN.

a. Power is removed fr om pump

motor.

8. Close the manual drain valve to the fryer.

: No electr ical switching occurs by closing t he

NOTE

manual drain valve unless the optional dr ain valve

switch is installed.

9. Turn filter power switch O FF.

: If usi ng solid shortening, when all fi ltered oil

NOTE

is returned to the vat and fil ter power switch is OFF,

open the filter drawer approximately one inch. Allow

the remaining shortening in the li ne to drain int o the

filter tank t o prevent possible clogging after the

shortening cool s and solidifies. Close the f ilter

drawer when complete.

F24696 (May 2001)Page 13 of 56

Page 14

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - ELECTRICAL OPERATION

COMPONENT FUNCTION

NOTE

: For components not li sted her e, refer t o the ER series service manual listed on the front cover and under

"INFORMATION SOURCES" in the "GENERAL" section.

Filter Power Switch

Filter Relay

Transformer 2T

Transformer 1T

Pump Motor

Filter Valve Switch

Discard Valve Switch

Fryer Power Switch

................ Suppli es 120VA C to pump motor through f ilter relay contacts (N.O.) when

............ Suppli es 24VA C to the oil fil ter control c ircuit and fryer power switch.

............ Suppli es 12VA C to the comput er power supply boar d. Transformer is

............... Operates the "pump" to circulate oil through the fil tering system.

.......... Energizes the filter relay coil to supply power to the pump motor through

......... Suppli es 120VA C to pump motor when fil ter relay i s energized.

24VAC coil is energized. Filter power switch must be ON and the filter valve

switch or discard valve switch must be CLOSED (valve handle ext ended) .

Transformer is energiz ed when supply power is connec ted to fry er .

energized when fr y er power switch is turned ON. Computer control models

only.

filter relay contacts (N.O.) when switch i s CLO S E D ( valve handle extended).

When oil f iltering is complete, close the manual drai n valve to t he fryer and

allow the vat to refill. Retract the filter handle when all filtered oil is returned.

....... Energizes the filter relay coil to supply power to the pump motor through

filter relay contacts (N.O.) when switch i s CLO S E D ( valve handle extended).

This allows the oil to be discarded through the discard hose int o a separate

container. When filt er tank is empty, retract the handle to return the discard

switch to norm al operating position.

......... Energizes relay coil R1 and supplies power to fryer c ontrol cir c uit through

relay R1-1 contacts (N.O.). The switch positions are: momentary ON,

momentary OFF wi th a center NEUTRAL ( star ting) position. Soli d state

controls onl y .

Circuit 1 on the switch is the normally CLOSED (N.C.) si de. Press power

OFF to momentar ily OP E N switc h c ontacts and turn the fryer OFF.

Circuit 2 on the switch is the normally OPEN (N.O.) side. Press power ON to

momentarily CLOSE switch contacts and turn the fr y er ON.

Relay R1

Relay R2

F24696 (May 2001) Page 14 of 56

.................. Suppli es power to fryer contr ol circuit and basket li ft ci rcuit (if installed)

through relay R1-1 contacts (N.O.) when 24VAC coil is energized. T he r elay

remains energized through R1-2 cont ac ts (N.C.) and f r y er power switch

contacts until power switch is turned OFF. Ful l vat and split vat fryers, solid

state controls only.

.................. Suppli es power to fryer contr ol circuit and basket li ft ci rcuit (if installed)

through relay R2-1 contacts (N.O.) when 24VAC coil is energized. T he r elay

remains energized through R2-2 cont ac ts (N.C.) and f r y er power switch

contacts until power switch is turned OFF. Split vat fry er s wit h sol id state

controls onl y .

Page 15

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - ELECTRICAL OPERATION

COMPONENT LOCATION

F24696 (May 2001)Page 15 of 56

Page 16

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - ELECTRICAL OPERATION

SCHEMATIC DIAGRAMS

Solid S t ate Control and Kleenscreen Filter, F ull Vat

F24696 (May 2001) Page 16 of 56

Page 17

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - ELECTRICAL OPERATION

Solid S t ate Control and Kleenscreen Filter, Split Vat

F24696 (May 2001)Page 17 of 56

Page 18

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - ELECTRICAL OPERATION

Computer Control, Full Vat

F24696 (May 2001) Page 18 of 56

Page 19

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - ELECTRICAL OPERATION

Computer Control, Split Vat

F24696 (May 2001)Page 19 of 56

Page 20

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - ELECTRICAL OPERATION

Kleenscreen Filtering S yst em, Computer Co ntrol

F24696 (May 2001) Page 20 of 56

Page 21

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - ELECTRICAL OPERATION

Heater Circuit, Solid State Controls, Full Vat

F24696 (May 2001)Page 21 of 56

Page 22

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - ELECTRICAL OPERATION

Heater Circuit, Solid State Controls, Split Vat

F24696 (May 2001) Page 22 of 56

Page 23

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - ELECTRICAL OPERATION

Basket Lift Ci rcuit, Solid State Co ntrols

F24696 (May 2001)Page 23 of 56

Page 24

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - ELECTRICAL OPERATION

WIRING DIAGRAMS

Kleenscreen Filtering S ystem

F24696 (May 2001) Page 24 of 56

Page 25

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - ELECTRICAL OPERATION

Wiring Di agram Index

SOLID STATE CONTROL, KLEENSCREEN

Full-Vat, 208 & 240 Volt 24 & 21 KW ............................................ 26 & 27

Full-Vat, 208 & 240 Volt 17 & 14 KW ............................................ 28 & 29

Full-Vat, 480 Volt 24, 21, 17 & 14 KW ........................................... 30 & 31

Split -Vat, 208 & 240 Volt 17 & 14 KW ........................................... 32 & 33

Split -Vat, 208 & 240 Volt 21 KW ................................................ 34 & 35

Split -Vat, 480 Volt 14, 17 & 21 KW .............................................. 36 & 37

COMPUTER CO NTROL, KLEENSCREE N

Full-Vat, 208 & 240 Volt 17 & 14 ............................................... 38 & 39

Full-Vat, 208 & 240 Volt 24 & 21 KW ............................................ 40 & 41

Full-Vat, 480 Volt 24, 21, 17 & 14 KW ........................................... 42 & 43

Split -Vat, 208 & 240 Volt 17 & 14 KW ........................................... 44 & 45

Split -Vat, 208 & 240 Volt 21 KW ................................................ 46 & 47

Split -Vat, 480 Volt 21, 17 & 14 KW .............................................. 48 & 49

F24696 (May 2001)Page 25 of 56

Page 26

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - ELECTRICAL OPERATION

F24696 (May 2001) Page 26 of 56

Page 27

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - ELECTRICAL OPERATION

F24696 (May 2001)Page 27 of 56

Page 28

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - ELECTRICAL OPERATION

F24696 (May 2001) Page 28 of 56

Page 29

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - ELECTRICAL OPERATION

F24696 (May 2001)Page 29 of 56

Page 30

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - ELECTRICAL OPERATION

F24696 (May 2001) Page 30 of 56

Page 31

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - ELECTRICAL OPERATION

F24696 (May 2001)Page 31 of 56

Page 32

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - ELECTRICAL OPERATION

F24696 (May 2001) Page 32 of 56

Page 33

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - ELECTRICAL OPERATION

F24696 (May 2001)Page 33 of 56

Page 34

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - ELECTRICAL OPERATION

F24696 (May 2001) Page 34 of 56

Page 35

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - ELECTRICAL OPERATION

F24696 (May 2001)Page 35 of 56

Page 36

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - ELECTRICAL OPERATION

F24696 (May 2001) Page 36 of 56

Page 37

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - ELECTRICAL OPERATION

F24696 (May 2001)Page 37 of 56

Page 38

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - ELECTRICAL OPERATION

F24696 (May 2001) Page 38 of 56

Page 39

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - ELECTRICAL OPERATION

F24696 (May 2001)Page 39 of 56

Page 40

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - ELECTRICAL OPERATION

F24696 (May 2001) Page 40 of 56

Page 41

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - ELECTRICAL OPERATION

F24696 (May 2001)Page 41 of 56

Page 42

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - ELECTRICAL OPERATION

F24696 (May 2001) Page 42 of 56

Page 43

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - ELECTRICAL OPERATION

F24696 (May 2001)Page 43 of 56

Page 44

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - ELECTRICAL OPERATION

F24696 (May 2001) Page 44 of 56

Page 45

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - ELECTRICAL OPERATION

F24696 (May 2001)Page 45 of 56

Page 46

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - ELECTRICAL OPERATION

F24696 (May 2001) Page 46 of 56

Page 47

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - ELECTRICAL OPERATION

F24696 (May 2001)Page 47 of 56

Page 48

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - ELECTRICAL OPERATION

F24696 (May 2001) Page 48 of 56

Page 49

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - ELECTRICAL OPERATION

F24696 (May 2001)Page 49 of 56

Page 50

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - TROUBLESHOOTING

TROUBLESHOOTING

SOLID STATE CONTROL

SYMPTOM POSSIBLE CAUSES

Fryer does not heat. 1. Power switch OFF or inoperative.

2. Main circuit br eak er ( s) O FF or the fryers internal circuit

breaker(s), i f appli c able, OFF .

3. Control circuit fuse 1FU or 2FU O P E N .

4. Transformer 2T inoperative.

5. Drain valve switch m alfunction (if installed).

6. Malfunctioning heat control relay R1 (full vat or right side

split vat) or R2 on left side spl it vat only.

Ventil ator OFF, power switch ON, power light

ON.

No heating light, power light ON. 1. Temperat ure control set t oo low or not calibr ated.

No heating light, power light ON, tr ouble light

and fir st and second high limit l ights ON.

Excessive time to melt shortening

(more than 45 minutes).

Fryer shuts down on fi r st high limit and first

high li mit light ON.

1. Ventilator hood ci r c uit breaker OP E N.

2. Interlock wiring O P E N.

3. Power switch inoperative.

2. Heating light inoper ative.

3. Contactor( s) malf unc tion.

4. Control boar d malfunction.

1. Low oil.

2. First high limit i noper ative (control boar d) .

3. Second high limit OPEN or t ilt switch OPEN or tilt switch

malfunction.

4. Contactor( s) malf unc tion.

5. Control boar d malfunction.

1. Melt cycle timing incorrect (control board).

2. Heating elements malfunct ioning.

3. Supply power inc orrect voltage.

1. Low oil.

2. Control not calibrated.

3. Contactor( s) malf unc tion.

4. Control boar d malfunction.

Fryer shuts down on second high li mit, power

light ON, no first high limit light and second

high li mit light ON.

Thermostat out of calibration by more than

25(F.

Light(s) not ON when required. 1. Light inoperative.

F24696 (May 2001) Page 50 of 56

1. Low oil.

2. First high limit "light" inoperative.

3. Second high limit OPEN or t ilt switch OPEN or tilt switch

malfunction.

4. Contactor( s) malf unc tion.

5. Control boar d malfunction.

1. Probe touching element .

2. Probe malfunct ion.

3. Control boar d malfunction.

2. Wiring problem.

Page 51

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - TROUBLESHOOTING

COMPUTER CONTROL

NOTE

: The com puter control is also used in other equipment, therefore it is possible for unr elated error prompts

to appear if a problem occurs in the computer main harness plug.

SYMPTOM POSSIBLE CAUSES

Fryer does not heat. 1. Power switch OFF or inoperative.

2. Main circuit break er(s) OFF or t he fryers int er nal circuit

breaker(s), i f appli c able, OFF .

3. Control c ircuit fuse 1FU or 2FU OP E N.

4. Drain valve switch malfunct ion (if install ed) .

5. Malfunctioning heat control r elay R2 (full vat or right side

split vat) or R4 on left side spl it vat only.

6. Contactor( s) malf unc tioning.

7. Computer power supply board or transformer 1T or 2T

inoperative.

8. Open pins 23 or 24 (12 VDC) .

9. Open 24 VAC pi n 1 ( full vat or r ight side spli t vat ) or pin 2

on left side split vat onl y.

10. Open pin 15 right heat output (full vat or right side split

vat ) , or pin 16 left heat output on left side split vat onl y.

11. Computer main harness wiring problem.

12. Malfunct ioning com puter control.

Fryer di spl ay s "HI TEMP" alar m message. 1. Low oil.

2. Fryi ng oil temperature above 410°F, heating elements

turning OFF.

not

A. Malfunct ioning heat cont r ol relay R2 (full vat or r ight

side split vat) or R4 on left si de spl it vat only.

B. Contactor(s) malfunctioning.

3. Malfunctioning computer c ontrol.

A. Pin 15 right heat output (full vat or right side split

vat ) , or pin 16 left heat output on left side split vat

only, not

Fryer heats slowly. 1. Incom ing voltage incorr ec t.

2. Heating element(s) malfunc tion.

Fryer displays "CALL SERVICE" 1. Probe malfunct ion.

2. Failed self-chec k .

3. Malfunctioning computer c ontrol.

Fryer displays "IGN FAI LURE " 1. Pins 3, 4, 5 or 6 not

Fryer displays "DRAIN OPEN" 1. Drain "ball" valve left OPEN.

2. Pin 10 not c onnec ted to 24VAC.

3. Drain valve switch malfunct ion (if install ed) .

Fryer di spl ay s "O FF" 1. Second high limit OPEN or t ilt switch OPEN or tilt switch

malfunction.

turning OFF.

connected to 24VAC.

F24696 (May 2001)Page 51 of 56

Page 52

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - TROUBLESHOOTING

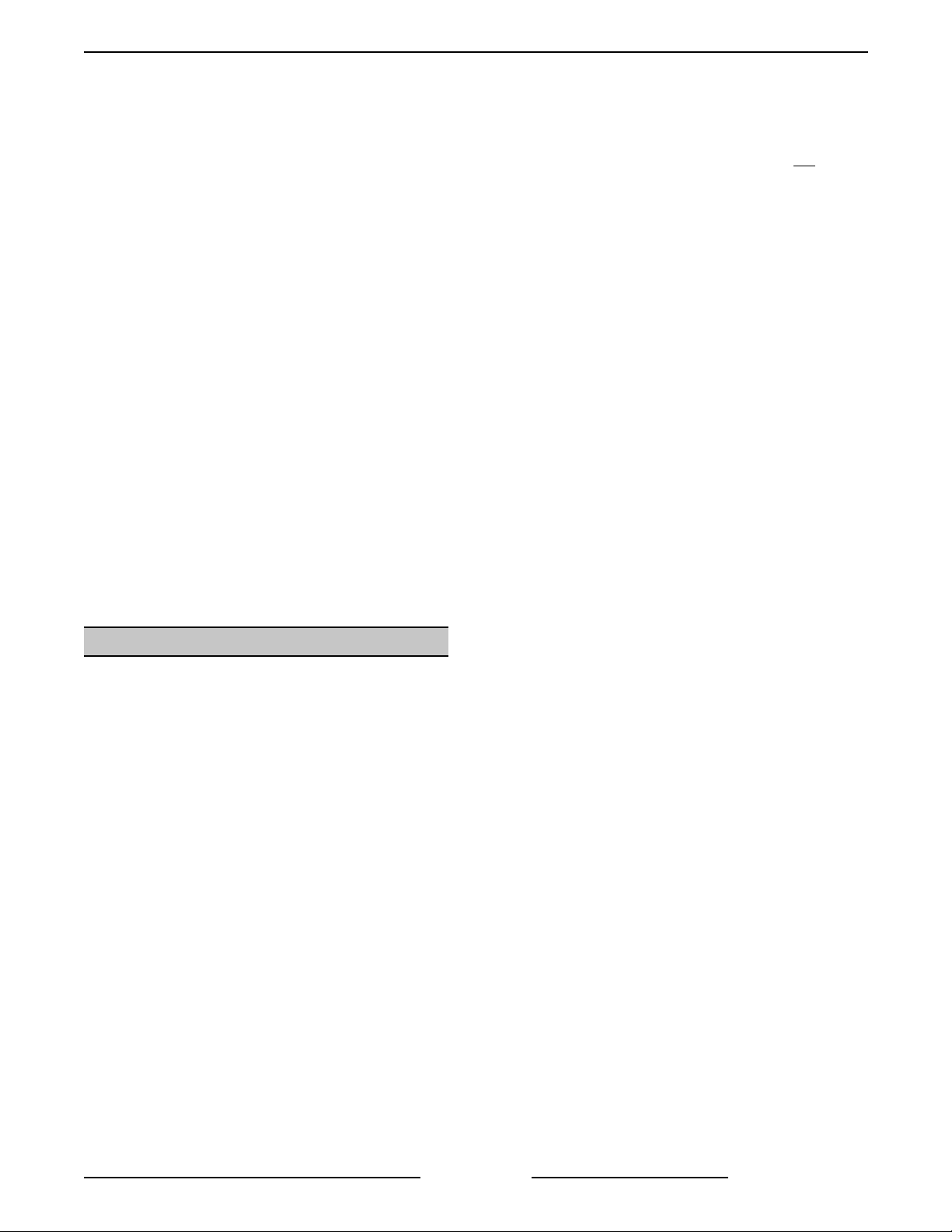

COMPUTER CONTROL

HARNESS PIN-OUTS CHART

NOTE

:

The terms right and left throughout the table below have the following meanings: Right equals Full vat or right

side split vat; Left equals left side, split vat only.

COMPUTER CONTROL PIN-OUTS

PIN # DESCRIPTION PIN # DESCRIPTION

NOTES

3

4

5

6

1

2

1

1

1

1

Right power

input "stat us"

Left power

input "stat us"

Right input 15 Right heat out put

Left input 16 Left heat output

Right input 17

Left input 18 no connection

13

2

24 VAC input gr ound

14 Right basket output

1

24 VAC main input

7 no connection 19 Left basket output

8 no connection 20 no connection

9

2

ground 21 no connection

Drain valve switch(es)

10

(if installed)

22 no connection

input "stat us"

1, 3

11

1, 2

12

1. 24VAC - control system main input to pin 17; jumpered to pins 3, 4, 5, 6, 11 & 12 (split vat only). Input

:

Door switch input " status" 23

Full vat or Split vat

mode Input

24

Computer power i nput

(+) 12 VDC nominal

Computer power i nput

(-) 12 VDC

to jumpered pins must be present or computer control will not function properly.

2. 24VAC ground - control system input to pin 13; jumpered to pins 9 & 12 (full vat only). Input to

jumpered pins must be present or computer control will not function properly.

3. Pin 11 - door switch no longer used on these models. Input must remain or computer will display

"DOOR OPEN".

F24696 (May 2001) Page 52 of 56

Page 53

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT - TROUBLESHOOTING

KLEENSCREEN FILTERING

SYSTEM

SYMPTOM POSSIBLE CAUSES

Oil not filtering, pump motor is ON. 1. Filter screen plugged.

2. Clog in filter system lines.

NOTE

: If usi ng solid shortening, when all fi ltered oil is returned

to the vat and filter power switch is OFF, open the fil ter drawer

approximately one inch. Allow the remai ning shortening in the

line to dr ain into the fil ter tank to prevent possibl e c logging af ter

the shortening cools and solidifies. Close the filter drawer when

complete.

3. Oil/Shortening below 300°F to "thick".

4. Filter valve switch malfunction.

5. Filter valve mec hanical m alfunct ion.

6. Pump is inoperative.

Oil not discarding, pump motor ON. 1. Filter screen plugged.

2. Clog in filter system lines.

NOTE

: If usi ng solid shortening, when all fi ltered oil is returned

to the vat and filter power switch is OFF, open the fil ter drawer

approximately one inch. Allow the remai ning shortening in the

line to dr ain into the fil ter tank to prevent possibl e c logging af ter

the shortening cools and solidifies. Close the filter drawer when

complete.

3. Oil/Shortening below 300°F to "thick".

4. Discard val ve switch malfunc tion.

5. Discard val ve m ec hanical m alfunct ion.

6. Discard hose connection not fully engaged.

7. Pump is inoperative.

Pump m otor is not runni ng. 1. Filter power switch inoperat ive.

2. Filter/ discard handle not extended.

3. Filter/ discard v alve switc h malfunction.

4. Filter relay malfunction.

5. Pump motor inoperative.

F24696 (May 2001)Page 53 of 56

Page 54

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT

- NOTES -

F24696 (May 2001) Page 54 of 56

Page 55

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT

- NOTES -

F24696 (May 2001)Page 55 of 56

Page 56

ER SERIES FRYER SERVICE MANUAL SUPPLEMENT CONDENSED SPARE PARTS LIST

CONDENSED SPARE PARTS LIST

KLEENSCREEN FILTER

PART NUMBER DE S CRIPTIO N NOTES

411496-B4 Lighted Rocker S witch, Filter

417792-1 Pump and Motor Assy, Kleenscreen f ilter

411497-A3 Relay, F ilter Circuit, 24v Coil

ER SERIES ELECTRIC KLEENSCREEN FRYERS

PART NUMBER DESCRI P TION ERD E RC NOTES

411496-F7 " Tilt Limit Switch", "Filter valve switch" and

X

1

"Discard valve switch".

411496-B9 Rocker Switch, Momentary on/off, Center of f X

416535-4 Relay, 24v Coil X

414146-2 Hi-limit Thermostat X

FE-023-55 Fuse, Holder X

FE-019-40 Fuse, 15 Amp X

414142-1 Temperat ur e P r obe, Thermistor X

417876-1 Resistor, Heat Li ght X

415144-12 Temperature Contr ol Board X

415638-G1 Pot entiomet er A ssy. X

411496-B1 Rocker Switch, Fry / Melt X

411497-C3 Contact or , 3 Pole 40 Am p 120v Coil X

411497-C5 Contact or , 3 Pole 40 Am p 240v Coil X

418159-1 Cam Switch, Basket Lift X

418156-1 Gear Motor, B asket Lift X

416741-G5 Element, 208v 14kw, X

416741-G7 Element, 240v, 14kw X

416741-G9 Element, 208v 17kw, X

416741-G11 Element, 240v , 17kw X

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

422737-2 Temperat ur e P r obe, Thermistor X

419574 Power Supply Board, Comput er 12vac-12vdc X

419557-7 Computer Cont r ol X

416535-7 Relay, 240v Coil X

419572-G2 Tr ansformer, 240- 12v X

411500-12 Tr ansformer, 120- 24v X

411500-13 Tr ansformer, 240- 24v X

1

1

X

X

X

X

X

X

X

X

X

X

X

X

X

X

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

1 = COMMO N TO STANDARD ERD SE RIES FRYERS

2 = COMMO N TO STANDARD ERC SE RIES FRYERS

F24696 (May 2001) Printed in U.S.A.

Loading...

Loading...