Page 1

SERVICE MANUAL

FLOOR MODEL

ELECTRIC FRYERS

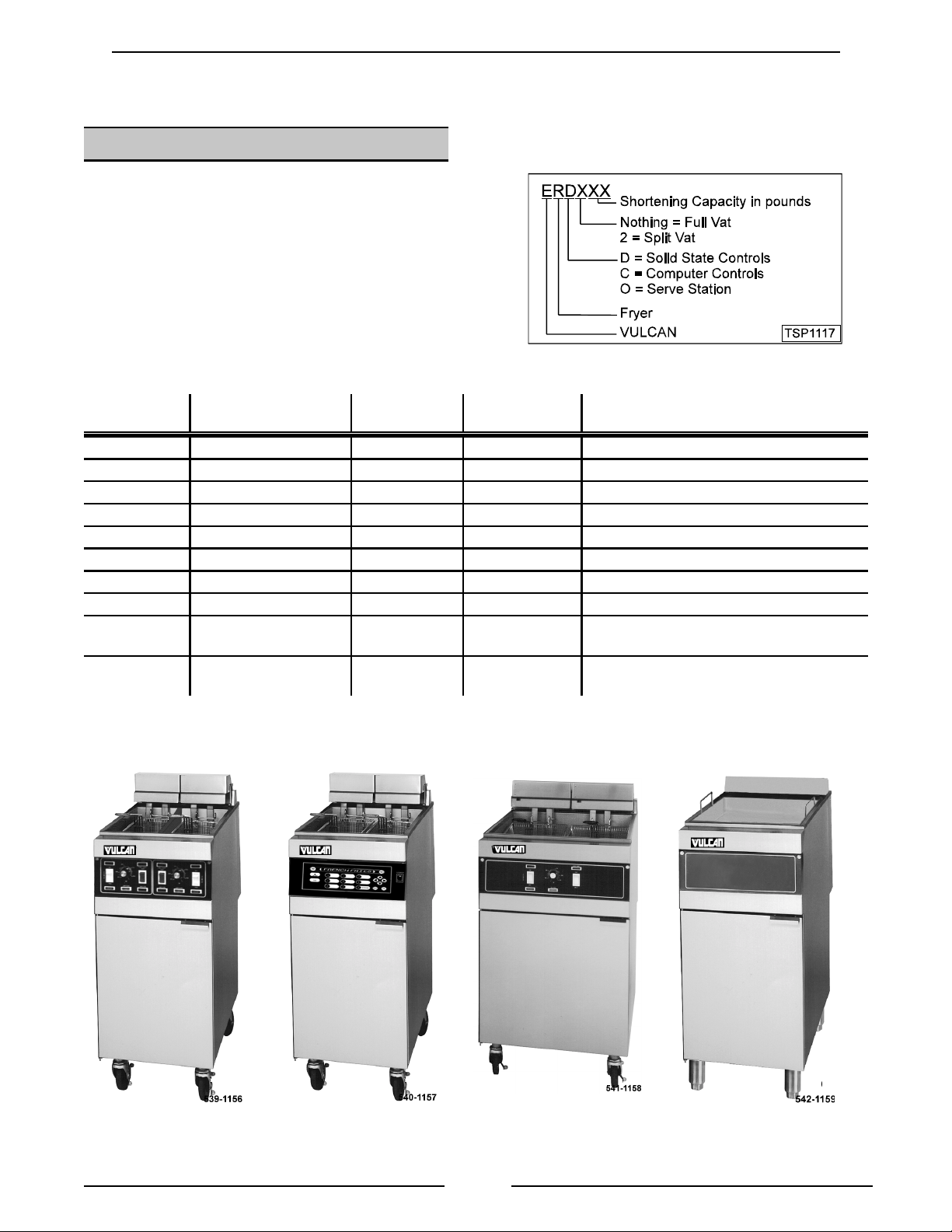

MODEL ML DESCRIPTION

ERD40 114614 15 ½" WIDE

ERD50 114615 15 ½" WIDE

ERD225 114616 15 ½" WIDE

ERD85 114617 21" WIDE

ERC40 114618 15 ½" WIDE

ERC50 114619 15 ½" WIDE

MODEL

ERC225 114620 15 ½" WIDE

ERC85 114621 15 ½" WIDE

ERO15 114622 15 ½" WIDE FLOOR

ERO21 114623 21" WIDE FLOO R

ERD40

Shown

- NOTICE This Manual is prepared for the use of trained Vulcan Service

Technicians and should not be used by those not properly

qu alif ied. If yo u have attend ed a Vulcan Service School for this

product, you may be qualified to perform all the procedures

described in this manual.

Thi s manu al i s no t i nten ded to be al l en comp assi ng . I f you have

not atte nded a Vulca n Servic e School f or this produc t, you should

read, in its entirety, the repair procedure you wish to perform to

determine if you have the necessary tools, instruments and skills

required to perform the procedure. Procedures for which you do

not have th e n ecessary too ls, in strument s and skills should be

performed b y a trained Vu lcan Service Technician.

SERVE STATION

SERVE STATION

A Product of

Form 24577 ( 12- 96)

VULCAN-HART LOUISVILLE , KY 40201-0696

Reproduction or other use of this Manual, without the express

written consent of Vulcan-Hart, is prohibited.

Page 2

TABLE OF CONTENTS

GENERAL............................................................................. 3

Introduction ........................................................................ 3

Battery Configuration................................................................. 4

Tools ............................................................................. 4

Operator Control Location ............................................................. 4

REMOVAL AND REPLACEMENT OF PARTS ................................................. 5

Control Panels ...................................................................... 5

Potentiometer (Solid Stat e M odels) ...................................................... 5

Computer Control ................................................................... 5

Heating Elements ................................................................... 6

Probe ............................................................................ 7

High Limit Thermostat ................................................................ 7

Lift Assist Springs ................................................................... 8

Tilt Switch ......................................................................... 9

Filter-ready Return V alve S witch ........................................................ 9

SERVICE PROCEDURES AND ADJUSTMENTS ............................................. 10

Thermistor Probe Resistance Chart ..................................................... 10

Temperature Control Calibration ....................................................... 10

Temperature Control Test ........................................................... 10

Heating Element Test ............................................................... 11

Melt Temperature Calibration (Solid State Control) ......................................... 12

Control Board Test (Solid State Control) ................................................. 12

Computer Control Test............................................................... 13

Lift Assist Spring Adjustment .......................................................... 13

Tilt Switch Adjustment ............................................................... 13

Basket Lift Arm Adjustment ........................................................... 14

ELECTRICAL OPERATION .............................................................. 14

Component Func tion ................................................................ 14

Component Locat ion ................................................................ 15

Control Box ...................................................................... 16

Electronic Control ( S olid State) Full V at Sequence of O per ation ............................... 17

Computer Cont rol Full Vat Sequence of Operati on .......................................... 17

Battery and I nter Plumb Filter Sequence of Operation ....................................... 18

Basket Lift Sequence of Operation ...................................................... 18

Computer Cont rol Board Diagnostics .................................................... 19

Schematics ....................................................................... 21

Full Vat With Solid State Control ................................................... 21

Split Vat With Solid State Control................................................... 22

Full Vat With Computer Control .................................................... 23

Split Vat With Computer Control.................................................... 24

Filter Ready, Int er P lumb Opt ions ................................................... 25

Wiring Di agr am Index ............................................................... 26

TROUBLESHOOTING .................................................................. 60

Computer Control Harness Pin-outs Chart ................................................ 60

Solid State Control.................................................................. 60

Computer Control .................................................................. 61

Serve Station ..................................................................... 61

© VULCAN 1996

2

Page 3

ELECTRIC FRYERS - GENERAL

GENERAL

INTRODUCTION

This manual cov er s the foll owi ng floor model f r yers.

All fryer models are av ailable with the following

electrical specifications:

208/60/3, 240/60/3, 480/60/3, 220/380/60/3 4 wire,

240/415/60/3 4 wire

Serv e station models are available in 120/60/1 if

equipped with heat lamp.

MODEL DESCRIPTION CONTROLS KW

ERD40 15 ½" wide Solid State 14 & 17 40

ERD50 15 ½" wide Solid State 14, 17 & 21 50

ERD225 15 ½" wide Solid St ate 14, 17 & 21 25 for each vat

ERD85 21" wide S olid Stat e 24 85

ERC40 15 ½" wide Computer 14 & 17 40

ERC50 15 ½" wide Computer 14, 17 & 21 50

ERC225 15 ½" wide Comput er 14, 17 & 21 25 for each vat

ERC85 21" wide Computer 24 85

ER015

ER021

15 ½" wide Serve

Station

21" wide Serve

Station

SHORTE NING CAPACITY

IN POUNDS

ERD225 ERC50 ERD85 ERO15 SERVE

STATION

3

Page 4

ELECTRIC FRYERS - GENERAL

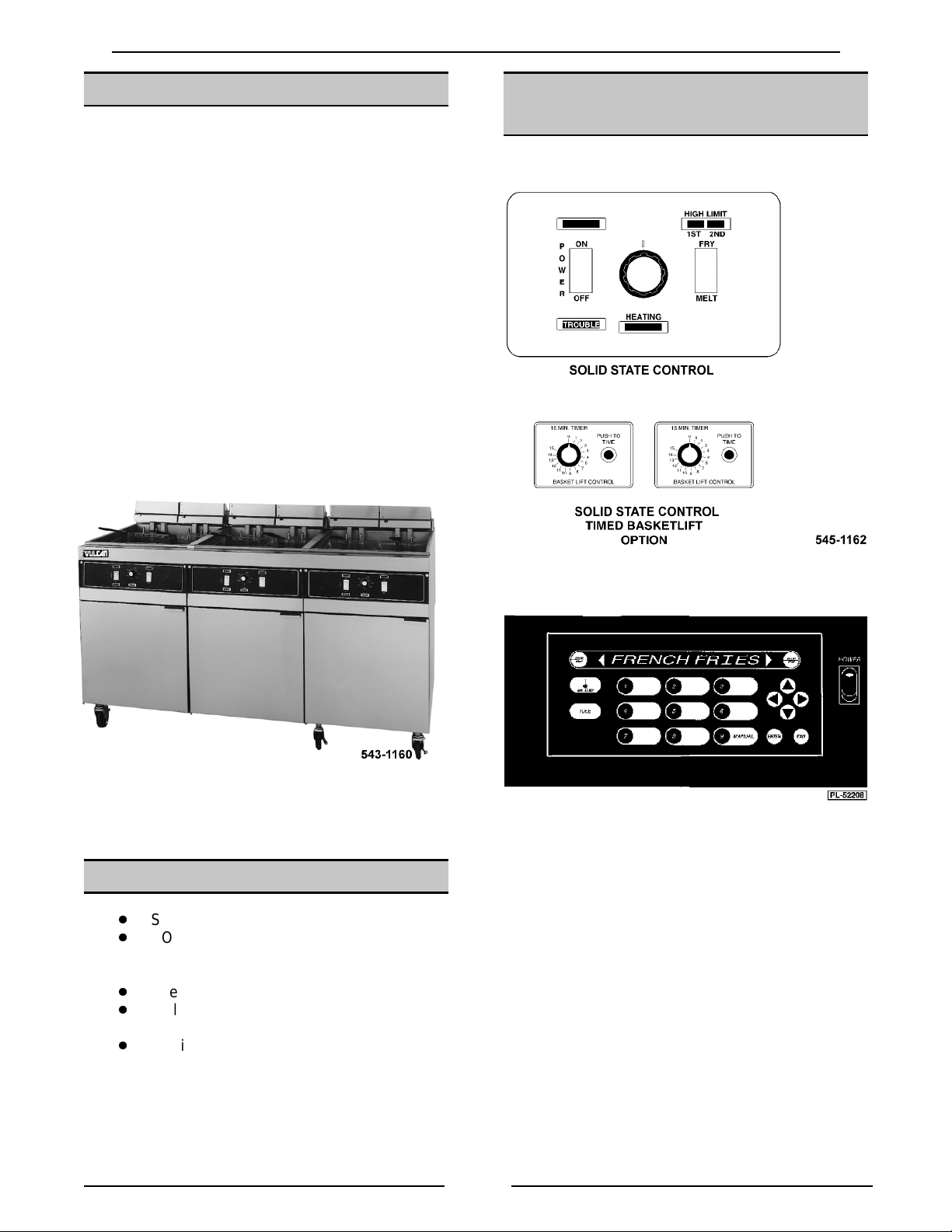

BATTERY CONFIGURATION

Batteri es of up to f ive fryers can be configured.

NOTE:

1. A fi lter dum p station can be located

under any positi on in a battery if it

has been built wit hout a serve station.

2. A fi lter dum p station can be located

under any positi on in a battery if the

line-up has been bui lt with a serve

station located at eit her end of the

battery.

3. When a serve station is built between

two fryers within a battery, the filter

dump stati on is located under t he

serve station.

4. In two-unit batteries utilizing a serve

station, t he filter dump stat ion will

always be located under t he fryer.

OPERATOR CONTROL

LOCATION

Solid State Controls

Three unit battery shown

TOOLS

Standard set of hand tools.

VOM with AC current tester.

NOTE:

20,000 ohms per volt c an be used.

Any quality VOM with a sensit iv ity of

Thermometer.

Field servic e gr ounding kit Part #TL-

84919.

Loctite #242 P art #520228.

Computer Controls

4

Page 5

ELECTRIC FRYERS - REMOVAL AND REPLACEMENT OF PARTS

REMOVAL AND REPLACEMENT OF PARTS

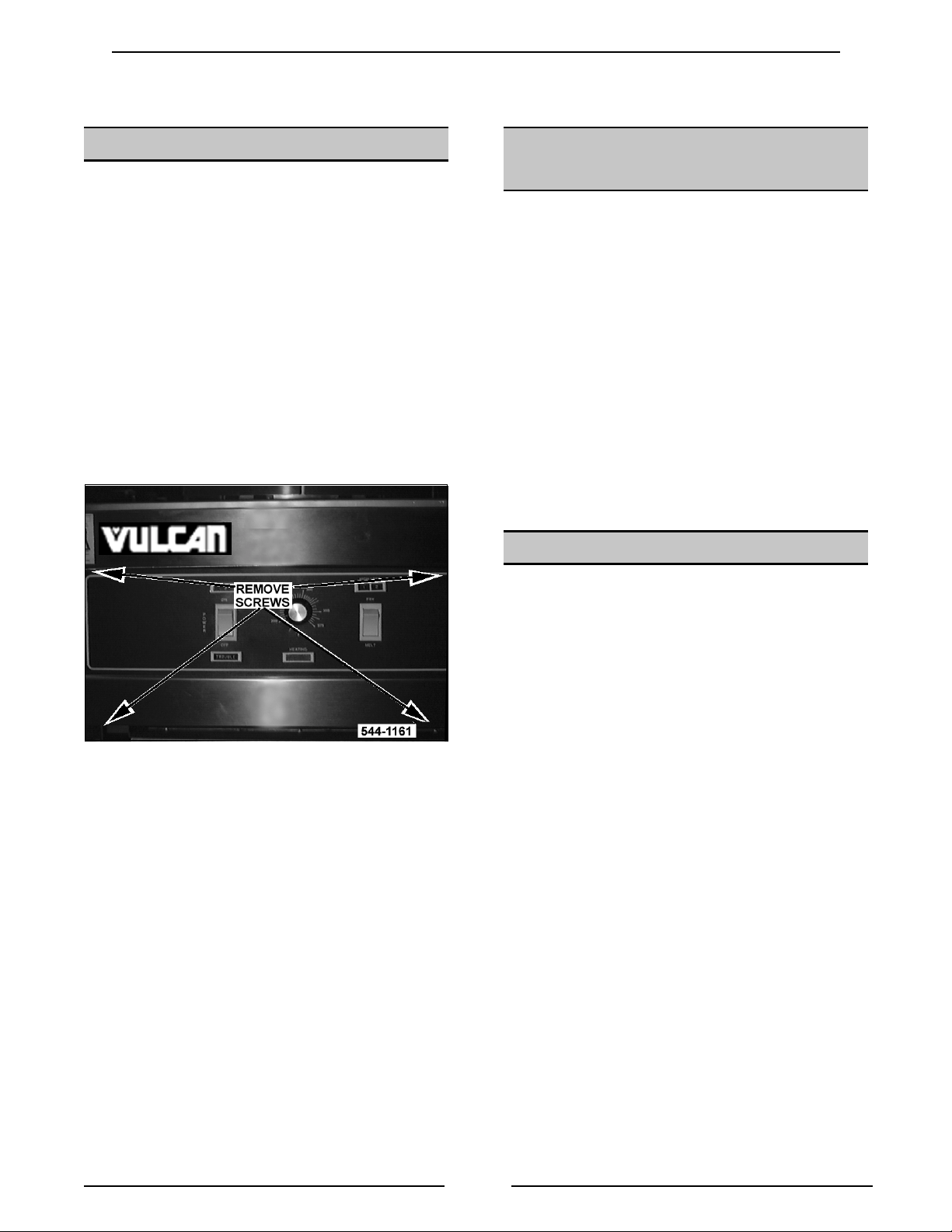

CONTROL PANELS

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BOX. THERE MAY BE TWO SEPARATE

CIRCUITS. B E S URE B OTH ARE

DISCONNECTED. PLACE A TAG ON THE

CIRCUIT BO X INDICATING T HE CIRCUIT IS

BEING SERVICED.

WARNING:

BURNS. USE CARE WHEN SE RV ICING THE

FRYER.

1. Remove the two screws from the upper corners

of the control panel and two screws in bottom

lip.

Solid State Control s shown

DISCONNECT THE ELECTRICAL

HOT OIL A ND P A RTS CAN CAUSE

POTENTIOMETER (SOLI D

STATE MODELS)

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BOX. THERE MAY BE TWO SEPARATE

CIRCUITS. B E S URE B OTH ARE

DISCONNECTED. PLACE A TAG ON THE

CIRCUIT BO X INDICATING T HE CIRCUIT IS

BEING SERVICED.

1. Remove the control panel as outlined under

2. Unplug the lead wi r e c onnec tion.

4. Loosen the set screw and remove the knob.

5. Remove the nut from the shaft and remove the

6. Reverse proc edur e to install .

DISCONNECT THE ELECTRICAL

"CONTROL PANELS".

potentiometer.

COMPUTER CONTROL

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BOX. THERE MAY BE TWO SEPARATE

CIRCUITS. B E S URE B OTH ARE

DISCONNECTED. PLACE A TAG ON THE

CIRCUIT BO X INDICATING T HE CIRCUIT IS

BEING SERVICED.

DISCONNECT THE ELECTRICAL

2. Lift out to access the back of the control panel.

3. Disconnect the lead wires to the control panel

components to r emov e it fr om the fryer.

4. Reverse proc edur e to install .

CAUTION:

SYSTEM ARE SUBJECT TO DAMAGE BY

ELECTROST A TIC DISCHARGE DURING FIELD

REPAIRS. A FIELD SERVICE G RO UND KI T IS

AVAILABLE TO PREVENT DAMAGE. THE FIELD

SERVICE GROUNDING KIT M US T BE USED

ANYTIME THE CONTROL BOARD IS HANDLED.

1. Remove the control panel as outlined under

2. Unplug the lead wi r e c onnec tions.

3. Remove comput er c ontrol.

4. Reverse proc edur e to install .

NOTE:

new computer cont r ol board because wiring harness

tells board what kind of fryer it is install ed in.

5. Using the “INSTRUCTIONS” m anual, program

CERTAIN COMPONENTS IN THIS

"CONTROL PANELS".

There are no setup procedures for installing

the control ler with the customer’s settings and

products.

5

Page 6

ELECTRIC FRYERS - REMOVAL AND REPLACEMENT OF PARTS

HEATING ELEMENTS

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BOX. THERE MAY BE TWO SEPARATE

CIRCUITS. B E S URE B OTH ARE

DISCONNECTED. PLACE A TAG ON THE

CIRCUIT BO X INDICATING T HE CIRCUIT IS

BEING SERVICED.

NOTE:

1. Remove the basket hangers or guide block

support ( basket lift models).

2. Lift the elements from the shortening and allow

to drain.

3. Remove the element clamp from the end of the

element s and the clamp at the other end of the

element being replaced. .

DISCONNECT THE ELECTRICAL

Don’t bend or kink high limit capillary tube.

4. Remove bulb and capillary tube clamps and/or

probe clamps from the element being replaced.

Save for reuse if needed.

NOTE:

place on the el ement. Cent er the Hi-limit bulb in i ts

clamps before tightening clamp. The Temperature

Probe should be inserted in the grommet in the

head then secured with the clamps.

Half of each cl amp is permanently fixed in

5. Remove screws from t he bottom of the

element head c over.

6. Lower the elements and remove the lift assist

springs from the hooks at the rear of the

machine.

7. Remove four screws securing el ement bracket.

6

Page 7

ELECTRIC FRYERS - REMOVAL AND REPLACEMENT OF PARTS

8. Remove the screws from the rear top of the

head cover .

9. Lift cov er enough to access element wir es.

Identify the six lead wire connect ions for

connection later. Then disconnect the six lead

wires from the elem ent being rem oved.

NOTE:

two wire connections for each element.

10. Remov e the element .

11. Reverse procedure t o install.

Each heater has three elements inside and

PROBE

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BOX. THERE MAY BE TWO SEPARATE

CIRCUITS. B E S URE B OTH ARE

DISCONNECTED. PLACE A TAG ON THE

CIRCUIT BO X INDICATING T HE CIRCUIT IS

BEING SERVICED.

DISCONNECT THE ELECTRICAL

4. Lower the element enough to remove the

screws securing the top of the head cover .

5. Lift the head cover enough to access and

disconnect the pr obe lead wires.

6. Reverse proc edur e to install .

7. Check temperature control for calibration as

outline under "TEMPERAT URE CONTROL

CALIBRATION".

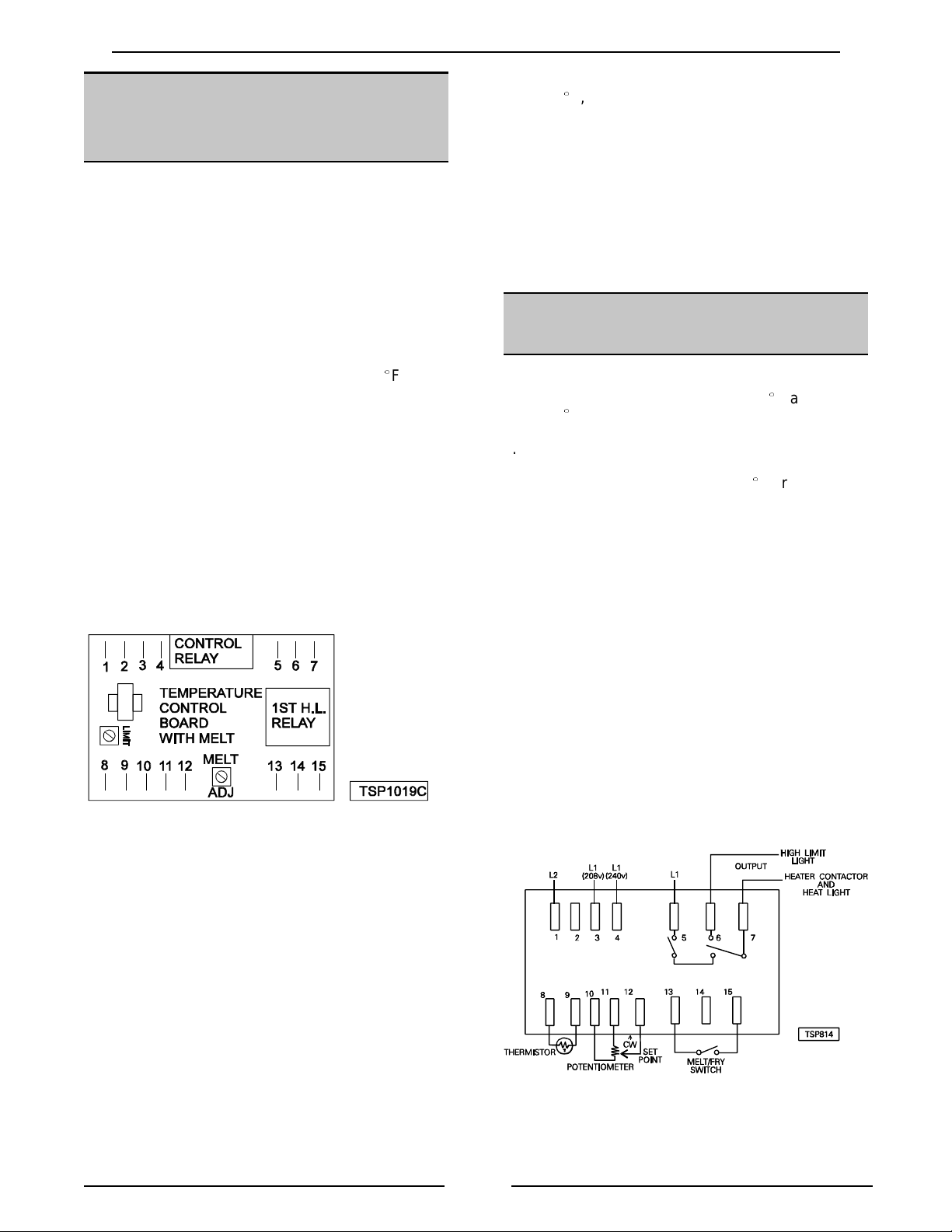

HIGH LIMIT TH ERMOSTAT

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BOX. THERE MAY BE TWO SEPARATE

CIRCUITS. B E S URE B OTH ARE

DISCONNECTED. PLACE A TAG ON THE

CIRCUIT BO X INDICATING T HE CIRCUIT IS

BEING SERVICED.

1. Raise the heating elements out of the

DISCONNECT THE ELECTRICAL

shortening and allow to drain.

NOTE:

1. Raise the heating elements and al low to drain.

2. Remove screws securing the bottom of the

3. Remove the clamps from the probe.

Don’t bend or kink high limit capillary tube.

head cover .

2. Loosen the clamps around the bulb and

capillary tube.

3. Remove screws securing the bottom of the

head cover .

4. Lower the element enough to remove the

screws securing the top of the head cover .

5. Lift the head cover enough to access and

disconnect the lead wires.

7

Page 8

ELECTRIC FRYERS - REMOVAL AND REPLACEMENT OF PARTS

6. Remove the screws that secure the high lim it

thermostat.

7. Remove the grom met f r om the element head.

8. Remove the bulb, capillary tube and the high

limit ther mostat f r om the element head.

9. Reverse proc edur e to install .

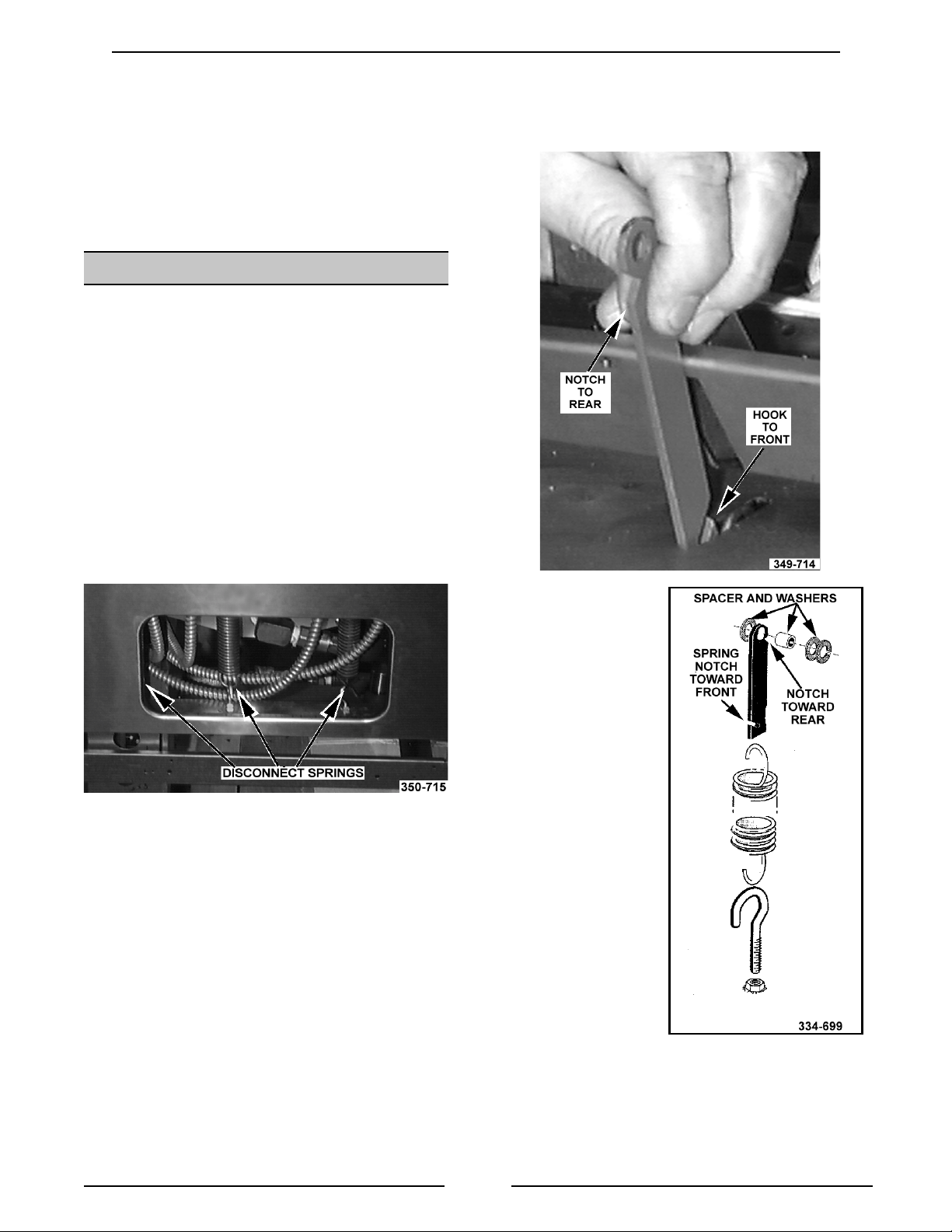

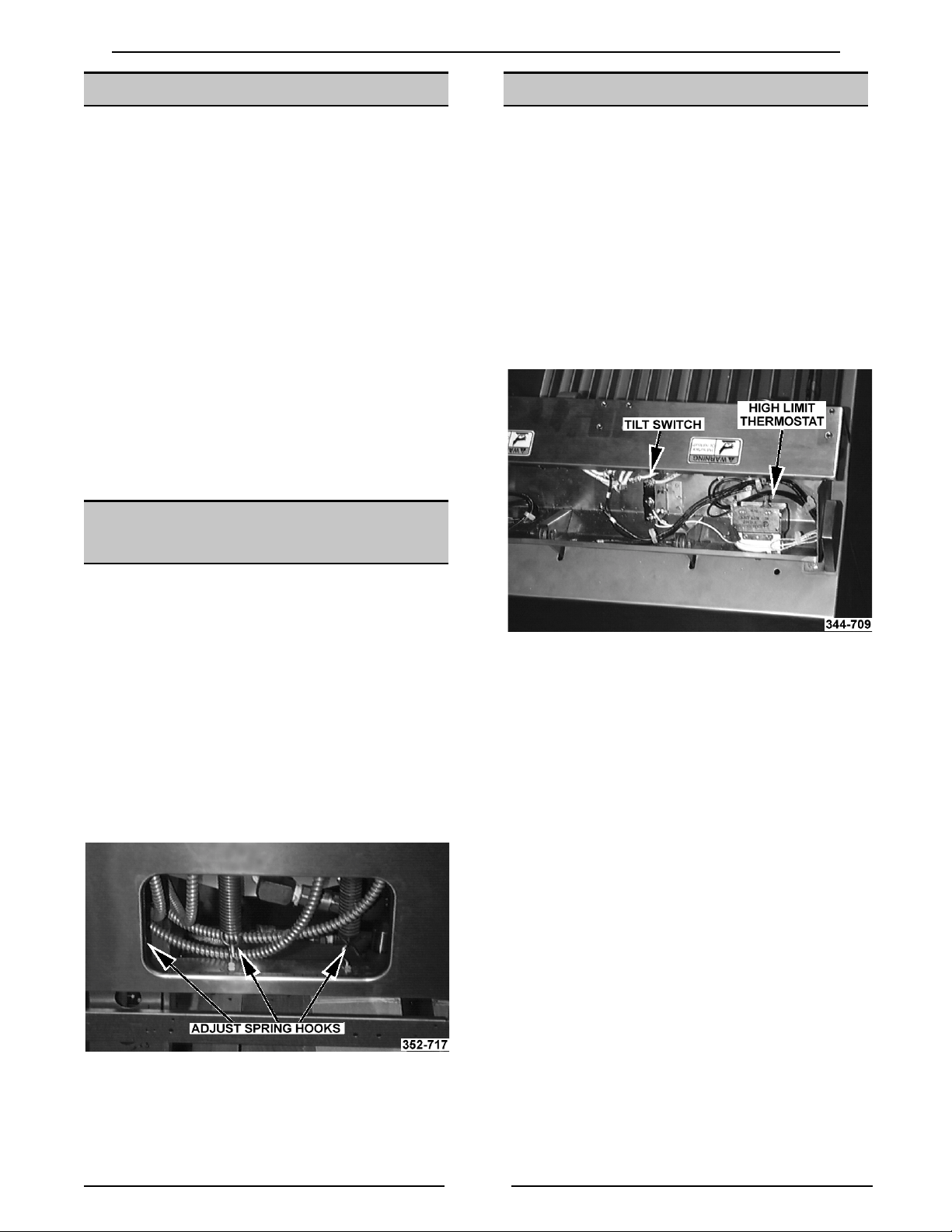

LIFT ASSIST SPRINGS

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BOX. THERE MAY BE TWO SEPARATE

CIRCUITS. B E S URE B OTH ARE

DISCONNECTED. PLACE A TAG ON THE

CIRCUIT BO X INDICATING T HE CIRCUIT IS

BEING SERVICED.

1. Remove head cov er screws.

2. Remove access cover by pr y ing out on top

edge with small screwdriv er.

DISCONNECT THE ELECTRICAL

8. To instal l spring, insert hanger from top with

notch pointing to rear of unit and spring hook

opening pointing to f r ont of unit. Hold in place

while inserting spring fr om bottom.

3. Disconnect spring( s) at bottom.

4. Lift head cov er enough to access hanger

mounti ng bolts.

NOTE:

5. Remove hanger mount ing nut and bolt.

6. Remove spacer and washers.

7. Remove hanger and spring out from bot tom.

Do not bend or kink high limit capillary tube.

9. Hook spring

onto hanger.

Reassemble

spacer and

washers onto

hanger and

secure with bolt

and nut.

10. Reconnec t spring at bott om and adjust as

outlined under “LIF T ASSI ST SPRING

ADJUSTMENT”.

11. I nstall covers.

8

Page 9

ELECTRIC FRYERS - REMOVAL AND REPLACEMENT OF PARTS

TILT SWITCH

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BOX. THERE MAY BE TWO SEPARATE

CIRCUITS. B E S URE B OTH ARE

DISCONNECTED. PLACE A TAG ON THE

CIRCUIT BO X INDICATING T HE CIRCUIT IS

BEING SERVICED.

1. Remove head cov er screws.

2. Lift head cov er enough to access tilt swit c h

mounti ng scr ews and remove screws.

NOTE:

3. Disconnect tilt switch lead wires.

4. Remove tilt switch.

DISCONNECT THE ELECTRICAL

Do not bend or kink high limit capillary tube.

FILTER-READY RETURN

VALVE SWITCH

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BOX. THERE MAY BE TWO SEPARATE

CIRCUITS. B E S URE B OTH ARE

DISCONNECTED. PLACE A TAG ON THE

CIRCUIT BO X INDICATING T HE CIRCUIT IS

BEING SERVICED.

1. Open front door.

2. Disconnect lead wi r es to r eturn valve swit c h.

3. Remove switch mount ing screws.

DISCONNECT THE ELECTRICAL

5. Reverse proc edur e to install and adjust as

outlined under “ TILT SWITCH

ADJUSTMENT”.

4. Reverse proc edur e to install .

Note:

Switch m ounting is a f ixed loc ation and has

no provision for adjustment. The normal ly open

contacts cl ose before the valve handle is i n the full

open position.

9

Page 10

ELECTRIC FRYERS - SERVICE PROCEDURES AND ADJUSTMENTS

SERVICE PROCEDURES AND ADJUSTMENTS

WARNING:

BURNS. USE CARE WHEN SE RV ICING THE

FRYER.

WARNING:

SECTION REQUIRE ELECTRICAL TESTS OR

MEASUREMENTS WHILE POWER IS APPLIED

TO THE MACHINE. EXERCISE EXTREME

CAUTION AT ALL TIMES. IF TEST POINTS ARE

NOT EASILY ACCESSIBLE, DISCONNECT

POWER, AT T ACH TEST EQ UIPMENT AND

REAPPLY POWER TO TEST.

HOT OIL A ND P A RTS CAN CAUSE

CERTAIN PRO CE DURE S IN THIS

THERMISTOR PROBE

RESIS TANCE CHART

Solid State Control

F Resistance

(

(

± 10%

77 30,000 ohms

311 494 ohms

340 340 ohms

NOTE:

near the center of the Control Board will be on. If

probe is shorted, the first high limit l ight will be on.

Computer Control

If probe is opened or disconnected, the LED

F Resistance

(

(

± 10%

77 100,000 ohms 300 1394 ohms

212 5573 ohms 350 717.7 ohms

275 2004 ohms 392 434.5 ohms

F Resistance

(

(

± 10%

7. Calculat e the aver age temperature. Average

temperat ure = (Tem perature at "off” +

temperat ure at "on") / 2 . (Example: (360( +

340() / 2 = 350(F. The average temperature

should be 350(F (± 5(F). The foll owing steps

should be taken if not.

A. Careful ly loosen the set screw in the

temperat ure control knob.

B. Rotate the knob and set t he knob at the

shortening temperature.

C. Tighten the set screw.

D. Allow the fryer to cycle and check f or

agreement with the therm ometer.

8. If t he above adj ustments can not be obtained,

check the control and tem per ature probe as

outlined under "TEMPERAT URE CONTROL

TEST” and “THERMISTOR PROBE

RESISTANCE CHA RT".

TEMPE RATURE CONTROL

TEST

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BOX. THERE MAY BE TWO SEPARATE

CIRCUITS. B E S URE B OTH ARE

DISCONNECTED. PLACE A TAG ON THE

CIRCUIT BO X INDICATING T HE CIRCUIT IS

BEING SERVICED.

1. Remove screws securing control panel and let

2. Disconnect potent iometer plug.

DISCONNECT THE ELECTRICAL

panel swing down.

TEMPE RATURE CONTROL

CA LIBRATION

Solid State Control

1. Shortening in tank must be to fill line.

2. Allow the oil to cool below 300(F.

3. Place a thermomet er in the center of the tank

one inch below the oil surface.

4. Set the temperature cont r ol to 350(F and turn

the fry er on.

5. After the thermometer reads 350(F, allow the

temperature control to cycle three times.

6. Agitate the shortening, t o eliminate any col d

zones, while you recor d the temperat ur es t o

calculate aver age temperature.

3. Connect ohm meter to pins 1 and 3. Meter

should read 10k ohms ± 10%.

4. Connect met er to pins 1 and 2. With k nob

turned clockwise to the stop, the meter should

read zero ohms. S lowly rotate knob

counterclockwise to stop and meter shoul d

change reading from 0 up to 10k ohms. Check

that there are no dead spot s and that wiper

tracks smoothly as you rotate knob.

5. Connect met er to pins 3 and 2. With k nob

turned counterc lockwise to the stop, t he meter

should read zero ohm s. S lowly rotate knob

clockwise to t he stop and meter should change

reading f rom 0 up to 10k ohms. Check that

there are no dead spots and that wiper tracks

smoothly as you r otate knob.

10

Page 11

ELECTRIC FRYERS - SERVICE PROCEDURES AND ADJUSTMENTS

HEATING ELEMENT TEST

WARNING:

THERE MAY BE TWO SEPARATE CIRCUITS. BE SURE BOTH ARE DISCONNECTED. PLACE A TAG ON

THE CIRCUIT B OX INDICATING THE CIRCUIT IS B E ING SERVICED.

Perform the appropriate test to obtain the desired i nformation.

NOTE:

TOTALKWKW / PHASE AMPS PER

14 4.64.64.6393939343434171717

17 5.65.65.6474747414141202020

21 7 7 7 58 58 58 51 51 51 25 25 25

24 8 8 8 67 67 67 58 58 58 29 29 29

TOTAL

KW

14 4.6 4.6 4.6 18 18 18 17 17 17

17 5.6 5.6 5.6 22 22 22 20 20 20

21 7 7 7 28 28 28 25 25 25

24 8 8 8 31 31 31 29 29 29

DISCONNECT THE ELECTRICAL POWE R TO THE MACHI NE A T THE MAIN CI RCUIT BOX.

Values in the c har t are nominal values (± 10%).

3 Phase, 3 Wire Supply Pl us Ground

AMPS PER

LINE 208V

X-Y X-Z Y-Z X Y Z X Y Z X Y Z

3 Phase, 4 Wire Supply Pl us Ground

KW / PHASE AMPS PER

LINE 220/380V

X-N Y-N Z-N X Y Z X Y Z

LINE 240V

AMPS PER

LINE 480V

AMPS PER

LINE 240/415V

3 Phase, 3 Wire Supply With Ground 3 Phase, 4 Wire Supply With Ground

TOTALKWRESISTANCE

PER ELEMENT

(OHMS) 208V

1L1

1L2

1L3

TO

TO

1L1

1L2

1L3

14 18.3 18.3 18.3 24.2 24.2 24.2 97.6 97.6 97.6 42.2 42.2 42.2 48.7 48.7 48.7

17 15.2 15.2 15.2 20.4 20.4 20.4 83 83 83 34.6 34.6 34.6 41.5 41.5 41.5

21 12.4 12.4 12.4 16.3 16.3 16.3 66.4 66.4 66.4 27.3 27.3 27.3 33.2 33.2 33.2

24 10.7 10.7 10.7 14.2 14.2 14.2 57.4 57.4 57.4 24.6 24.6 24.6 28.7 28.7 28.7

RESISTANCE

PER ELEMENT

(OHMS) 240V

1L1

TO

TO

1L1

1L2

TO

1L2

RESISTANCE

PER ELEMENT

(OHMS) 480V

1L3

1L1

TO

TO

1L3

1L1

1L2

TO

1L2

11

RESISTANCE PER

ELEMENT (OHMS)

220/38OV

1L3

1L1

TO

TO

1L3

1L1

1L2

TO

1L2

RESISTANCE PER

ELEMENT (OHMS)

1L3

TO

1L3

1L1

TO

1L1

240/415V

1L2

TO

1L2

1L3

TO

1L3

Page 12

ELECTRIC FRYERS - SERVICE PROCEDURES AND ADJUSTMENTS

MELT TEMPERATURE

CALIBRATION (SOLID

STATE CONTROL)

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BOX. THERE MAY BE TWO SEPARATE

CIRCUITS. B E S URE B OTH ARE

DISCONNECTED. PLACE A TAG ON THE

CIRCUIT BO X INDICATING T HE CIRCUIT IS

BEING SERVICED.

1. Place a thermomet er in the center of the vat at

one inch below the shortening surface.

2. Allow the shortening to cool below 135(F.

3. Remove the screws securing the control panel

and allow it to swing downward.

4. Disconnect the electric har ness and rem ove the

control panel.

5. Remove the melt tem per ature adjustm ent

screw sealant by gently c hipping away with a

screwdriv er . (screw located to t he r ight of pin

#12)

6. Turn the adjust ment screw clockwise to the

stop position.

DISCONNECT THE ELECTRICAL

13. When the short ening temperature reaches

135(F, turn t he adjustment screw

counterclockwise until t he voltmeter r eads 0

VDC.

14. Place a small drop of enamel paint or fi nger nail

polish in the center of the screw.

15. Disconnect the power and remove the

voltmeter.

16. I nstall the control panel.

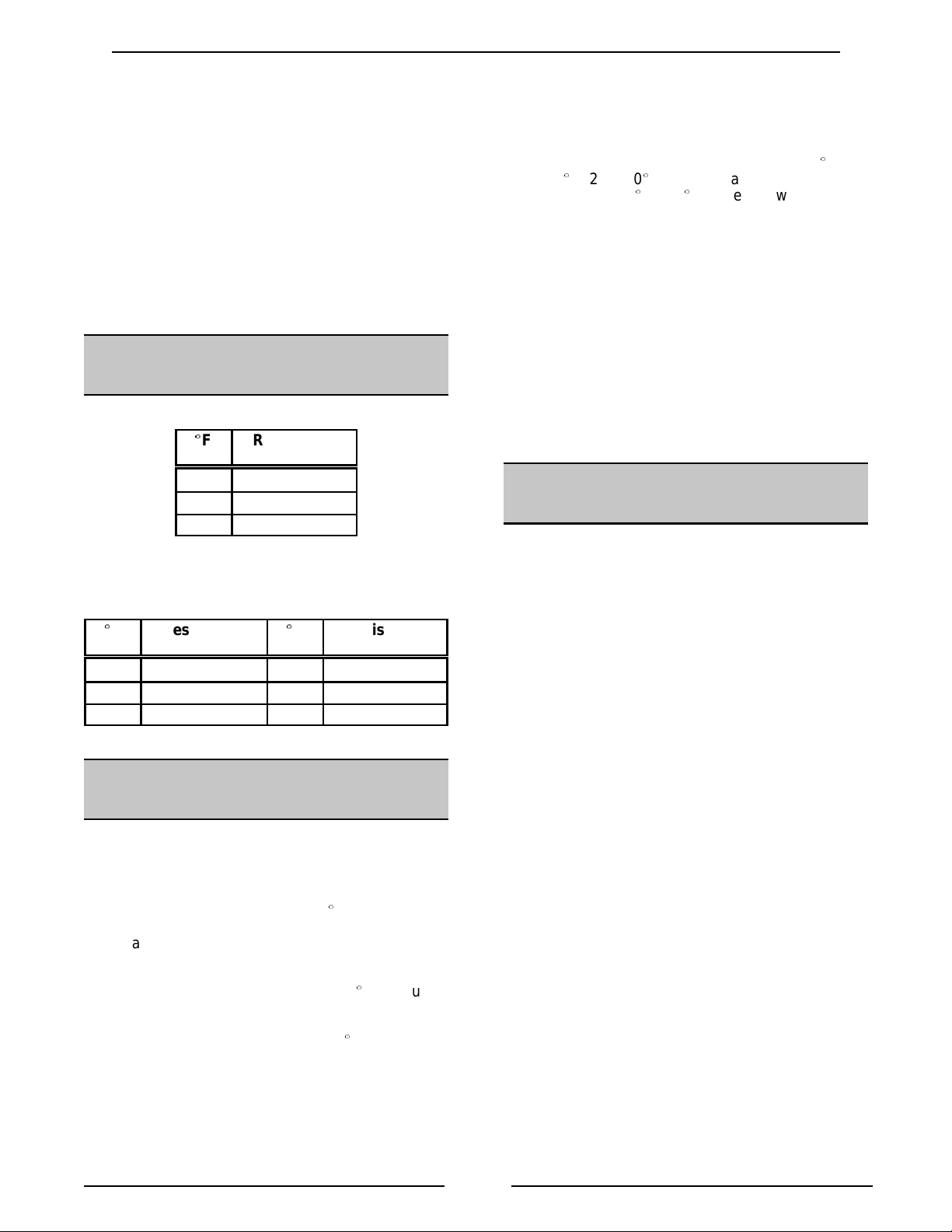

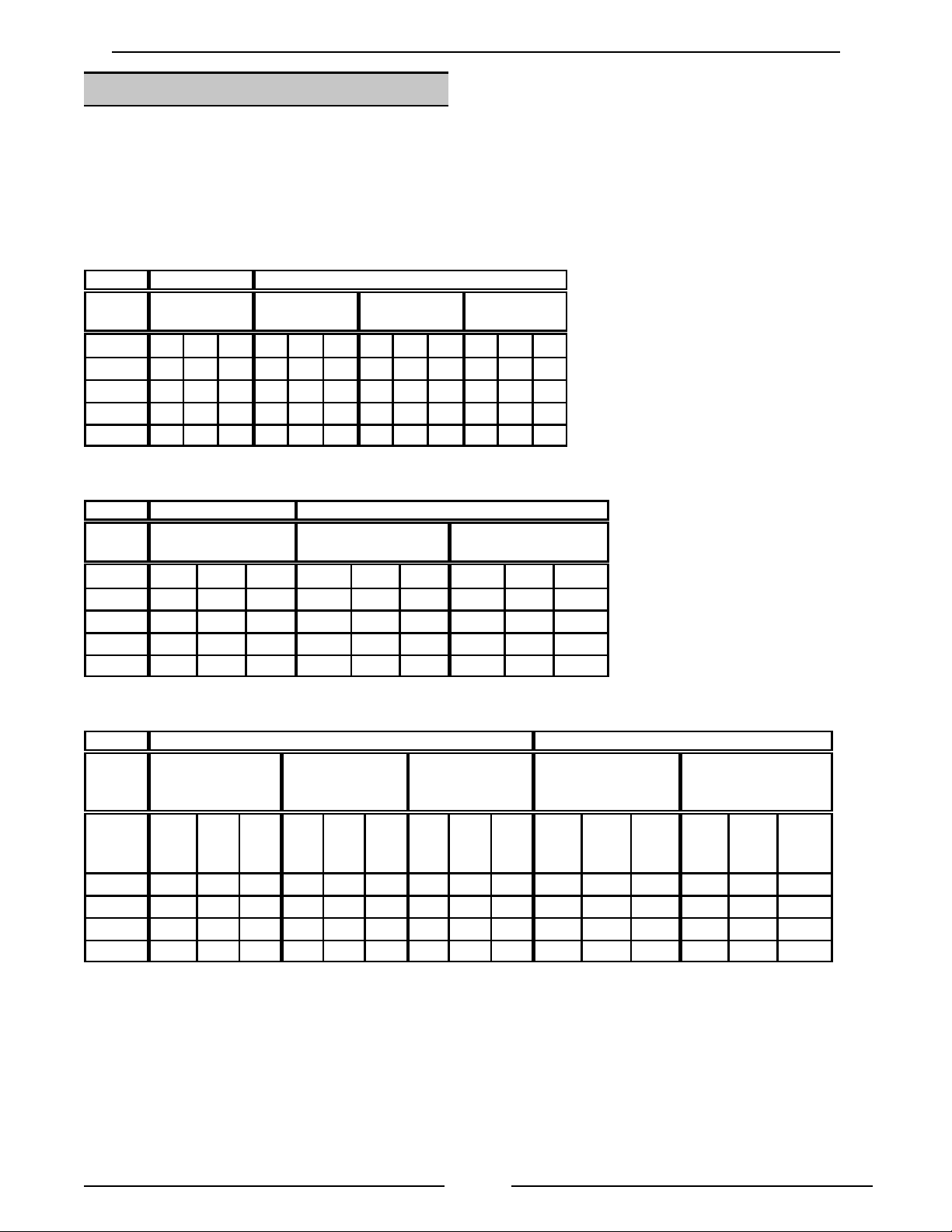

CONTROL BOARD TEST

(SOLID STATE CONTROL)

1. Check the temperature of the shortening. The

temperat ure should be below 300(F and abov e

135(F.

2. Access the control boar d.

3. With the potentiomet er set at 0(, turn the

power switch on and check the inc oming

voltage.

A. 120 volts, between pins 1 - 2 and I - 5.

B. 208 or 240 Volts, between pins 1 - 3 and 1

- 5

C. 240 Volts, between pins 1 - 4 and 1 - 5

(Export only)

7. Connect a DC voltmeter between pins 13 and

15 on the electr onic control board.

8. Reconnect the cont rol panel wiring harness.

9. Reconnect the power supply.

10. Whi le holding t he c ontrol panel in your hand,

turn the power switch on.

11. Set the tem per ature control to the fr y ing

temperat ure and the mel t switch to melt.

12. T he vol tmeter should r ead 5 V DC.

4. Check the potentiometer as outlined under

“TEMPERAT URE CONTROL TEST”.

5. Check the thermistor temperature probe as

outlined under “T HERMISTO R PROBE

RESISTANCE CHA RT”.

6. Set the contr ol to call for heat , the heat light

should light.

7. Check for output voltage between pins 1 - 7.

8. Replace the cont rol board if there isn't any

output.

12

Page 13

ELECTRIC FRYERS - SERVICE PROCEDURES AND ADJUSTMENTS

COMPUTER CONTROL TEST

1. Check for 24 V AC at pin 1 (and pi n 2 on spl it

vat fryer) r eferenced to pin 13.

2. Check for 12 to 16 VDC between pins 23 and

24.

3. Verify probe thermistor operation as outlined

under “THERMISTOR PROBE RESISTANCE

CHART”.

4. Check output for 24 VAC at pin 15 (and pin 16

for split vat fry er ) when calling for heat.

Reference t o pin 13.

5. Check output for 24 VAC at pin 14 (and pin 19

on split vat fryers) when in a cook cycle.

Reference t o pin 13.

6. Replace com puter control if outputs are not

correct.

LIFT ASSIST SPRING

TILT SWITCH ADJUSTMENT

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BOX. THERE MAY BE TWO SEPARATE

CIRCUITS. B E S URE B OTH ARE

DISCONNECTED. PLACE A TAG ON THE

CIRCUIT BO X INDICATING T HE CIRCUIT IS

BEING SERVICED.

1. Remove head cov er screws.

2. Lift head cov er enough to access tilt swit c h

NOTE:

DISCONNECT THE ELECTRICAL

mounti ng scr ews.

Do not bend or kink high limit capillary tube.

ADJUSTMENT

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BOX. THERE MAY BE TWO SEPARATE

CIRCUITS. B E S URE B OTH ARE

DISCONNECTED. PLACE A TAG ON THE

CIRCUIT BO X INDICATING T HE CIRCUIT IS

BEING SERVICED.

1. Remove rear access cover by prying out on top

edge with small screwdriv er.

2. Adjust all spring hooks ev enly so that elements

stay in the raised position when lifted.

DISCONNECT THE ELECTRICAL

3. With oil at level m ar k on vat , switch should

operate to shut off el ements before front of

element s leave oil. Loosen switch m ounting

screws and adjust switch as required.

4. Install head cover.

3. Install rear cov er .

13

Page 14

ELECTRIC FRYERS - SERVICE PROCEDURES AND ADJUSTMENTS

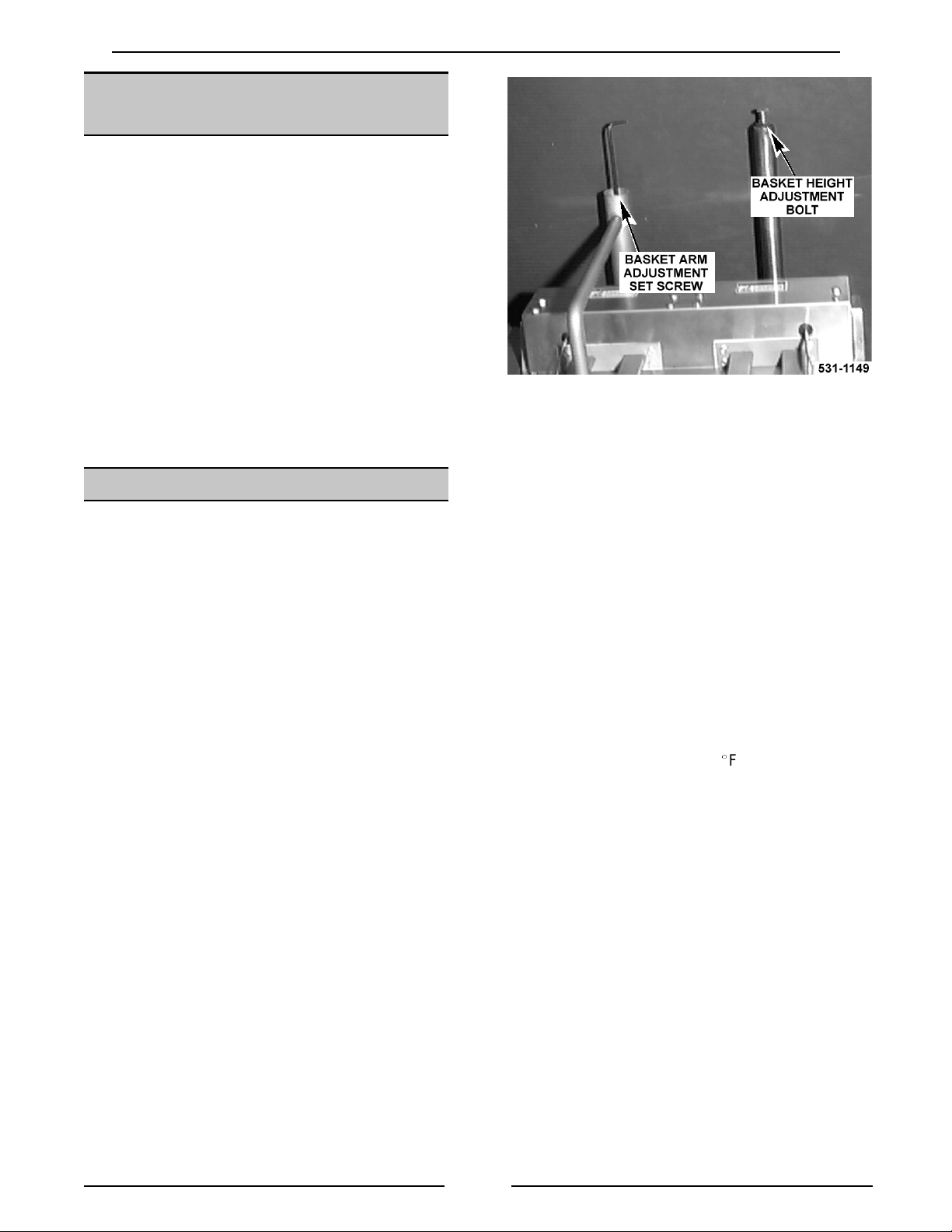

BASKET LIFT ARM

ADJUSTMENT

1. When basket is in the down position, it should

just clear the rack which is inst alled above the

elements.

A. To adjust, pull basket arm off lift shaft and

adjust height adjustment bolt to rai se or

lower basket arm as required. Both

baskets should be same height.

2. Rollers on basket arm should touch rear of tank

and be square to tank.

A. To adjust, loosen basket arm set screw

and adjust arm in or out as required. Use

Loctite #242 on set scr ew and tighten.

ELECTRICAL OPERATION

COMPONENT FUNCTION

1T TRANSFORMER .......... Supplies 12 VAC to computer power supply board.

2T TRANSFORMER .......... Supplies 24 VAC to computer control and/or inter-plum b system.

3T TRANSFORMER .......... Used in 480 VAC units.

BL1T TRANSFORMER........ Suppli es power to solid state model single and dual basket lif ts.

BL2T TRANSFORMER........ Used in addition to BL1T to supply power to solid state m odel split vat

basket lift.

COMPUTER CONTROL ....... Monitors temperature probe to r egulate the shorting temperat ure and

controls cooking cycle.

CONTACTOR .............. Controls voltage to heating elem ents.

FUSES 1FU, 2FU ............ Protect control circuits.

IPR1 RELAY ............... Inter-plumb control relay which controls power to the filter motor.

HEAT LIGHT ............... Indicates power is being supplied to the heating elements.

HEATING ELEMENT(S) ....... Produces heat that is transferred t o the shortening.

HIGH LIMIT THERMOSTAT .... Prevents the oil from reaching temperatures over 435(F (manual reset)

HIGH TEMP LIMIT LIGHT ..... Signals that the high limit(s) operated.

POWER LIGHT ............. Indicates power switch is in the "on" position.

PS-1 COMPUTER POWER SUPPLY BOARD

Supplies 10 VDC to c omputer cont r ol.

POWER SWITCH ........... Suppli es power to cont r ol circuit.

RETURN VALVE SWITCH ..... Controls IPR1 relay which starts filter motor when valve is opened.

RELAYS R1 thru R4 .......... Control relays on computer control models which control power to

computer and heat circuits.

TEMPERAT URE CONTROL . . . Monitors temperat ur e pr obe to regulate t he short ening temperature.

TEMPERATURE PROBE ...... Senses temperature of shortening.

TILT SWITCH............... Removes power to heat circuit if elements are raised.

14

Page 15

ELECTRIC FRYERS - ELECTRICAL OPERATION

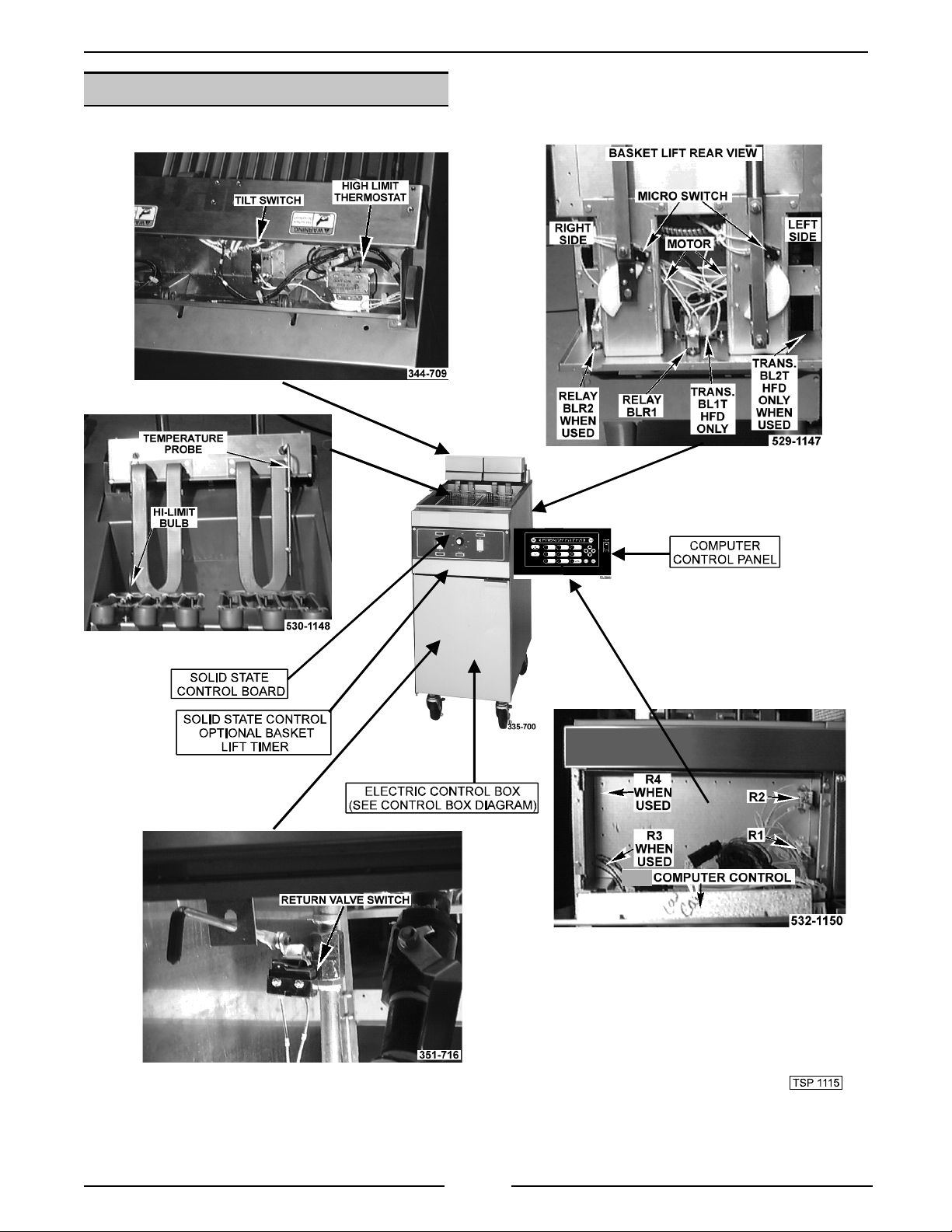

COMPONENT LOCATION

15

Page 16

ELECTRIC FRYERS - ELECTRICAL OPERATION

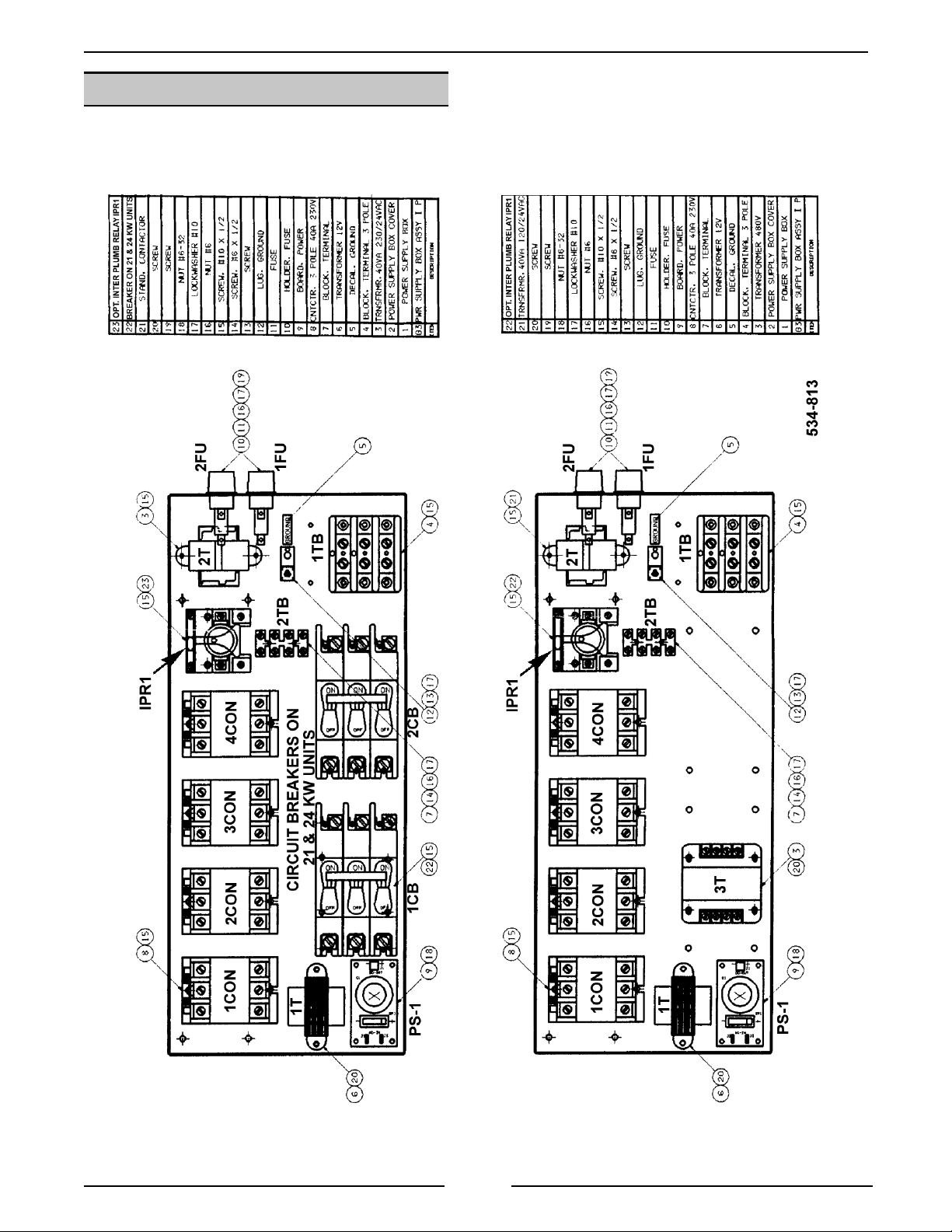

CONTROL BOX

16

Page 17

ELECTRIC FRYERS - ELECTRICAL OPERATION

ELECTRONIC CONTROL

(SOLID STATE) FULL VAT

SEQUENCE OF OPERATION

1. Conditions

A. Shortening at room temperature.

B. Fryer circuit break er "on".

C. Melt/Fry switch in "melt".

D. Power to pin 1 of control .

E. Control set 350(F

2. Power switch to "on".

A. Power to pin 2 or pi n 3 or pin 4 on control

depending on supply voltage.

B. Power is jumper ed to pin 5.

C. When power switch is turned on, first hi gh

limit bl inks on as control energizes relay to

open path between pin 6 and pin 7. Pin 7

output is now controlled by another relay

switching pin 5.

D. Power is supplied to 1CON , 2CON, 3CON

and 4CON. 1CON and 3CON will energize

through the tilt switch and second hi gh

limit.

3. Control evaluat es the input fr om the thermistor

at pins 8 and 9.

A. The melt cycle is initiated. Percent timer

controls output at pin 7 to energize 2CON

and 4CON.

1) I nitial conditi on is off (28 sec)

2) Heat c ondition (2 sec)

B. Control cycles output on time cycle of 28

sec off , then 2 sec on.

4. Shortening t emperature reac hes 135(F.

A. Melt cycle i s automatically ov er-ridden.

B. Control uses therm istor to cycle output at

pin 7.

5. Shortening t emperature reac hes 350(F.

A. Control remov es output from pin 7.

8. If either the tilt switch or the second high li mit

open, power is removed f r om 1CON and 3CON

and both the trouble and the second high limit

lights will come on.

COMPUTER CONTROL

FULL VAT SEQUENCE OF

OPERATION

1. Conditions

A. Shortening at room temperature.

B. Fryer circuit break er "on".

C. 24 VAC power from 2T to pins 3, 4, 5, 6,

11, and 17 (ref erence to ground at pi ns 9

or 10) on computer main har ness.

D. 24 VAC ground to pins 9, 10, 12, and 13

(reference to pin 17).

NOTE:

indicat e to the computer the type of fryer (ful l

or split vat) that it is installed i n. If the fryer is a

full v at, pin 12 is tied to 24 VAC ground and if

the fry er is a split vat, pin 12 is tied to 24 VAC.

2. Power switch to “on”.

A. Plus 12 VDC fr om computer power supply

B. R1 control relay, 1CON and 2CO N will

C. R1 relay energized, NO c ontacts close and

NOTE:

used to monit or the power status of the vat(s).

Pin 1 is the power status i nput for the r ight vat

and pin 2 is the input for the left vat . These

inputs tell the com puter which v at(s) are being

used or which vat(s) have been t ur ned off. 24

VAC is applied when on and 0 Volt when turned

off. If configur ed as a full vat, only pin 1 i s

used. Pin 2 is l eft open.

Pin 12 on the main harness is used to

board PS-1 to pin 23 on computer main

harness.

energize.

supply power to pin 1 on computer main

harness.

Pins 1 and 2 on the main harness are

6. Control cycles output at pin 7 on temperature.

7. If shortening temp r eac hes 410(F, the cont rol

unenergizes relay whic h opens path from pin 7

to pin 5 and cl oses path from pin 7 to pin 6.

A. The first high limit light lights.

B. Power is removed fr om 2CON and 4CON.

C. Output is removed fr om pin 6 when

shortening temperature drops below

350(F.

3. Computer evaluates input fr om thermistor at

pins 3 and 4 on temper ature probe harness.

A. Computer controls output at pin 15 to

energize R2 control relay.

B. Control relay R2 energizes.

C. R2 NO contacts close to supply power to

2CON and 4CON.

NOTE:

heat output and pi n 16 is the left heat output.

These outputs provide 24 VAC to c ontrol rel ay s

which control the heat circuit. If the fryer is a

full v at unit, only pin 15 is used. Pin 16 is lef t

open.

17

Pin 15 on the main harness is the right

Page 18

ELECTRIC FRYERS - ELECTRICAL OPERATION

4. Shortening t emperature reac hes set

temperature.

A. Computer t urns off heat output and control

relay R2 de-energizes.

B. Power is removed fr om 2CON and 4CON.

5. Computer cycl es heat out put on temperature.

6. If t he first high limit (410(F) trips, the display

will indicate “HI TEMP”.

NOTE:

become inoperable. For a spl it vat, only the vat

which experienced the failure becomes inoperable.

7. If t he second high limit (435(F) trips or the tilt

For a full vat, the fryer will shut down and

switch operates, the control relay R1 is deenergized removing 24 VAC power from pin 1

(ful l v at), pin 1 or pin 2 (split vat because i ts

control r elay is de-energiz ed) . The display will

indicate “OFF” for a full vat and become

inoperable . If a split v at, “OFF” will be

displayed for the vat which exper ienced the

failure and become inoperable.

A. Return valve switch contacts open.

B. Control relay IPR1 unenergi z es.

8. Filter motor stops.

BASKET LIFT SEQUENCE

OF OPERATION

1. Conditions

A. Fryer at oper ating tem per ature.

B. Basket li ft in r aised position.

C. Basket lift micro switc h oper ated, normally

open contacts cl osed.

D. BLR1 control relay unenergized.

2. Power is present at one side of gear motor and

contact 5 of BLR1 control relay.

3. When either the Push To Time but ton (solid

state model s) or the Start button (comput er

control models) is pressed, BLR1 relay is

energized closing contacts 5 and 3.

BATTERY AND INTER

PLUMB F ILTER SEQUE NCE

OF OPERATION

NOTE:

interpl umbing connects the vat s to a c ommon drain.

Each v at has an individual dr ain valv e. These

valves should only be opened one at a time.

1. Conditions

2. Open desired vat drain valve.

3. Oil dr ains into filter .

4. Close drain valve.

5. Open return valve f or vat oil is to be returned

A battery of fr y er s equi pped with optional

A. Empty filter in posit ion and connected as

outlined in filter Instr uc tions manual .

B. All drain v alves and ret ur n val ves closed.

to.

A. Return valve switch normally open

contacts cl ose energizing 24 VAC cont r ol

relay IPR1.

B. Control relay IPR1 normally open contacts

close to provide l ine voltage to filt er motor.

4. Power flows through BLR1 contacts 5 and 3

and normally open contact s of mic r o swit c h.

5. Motor runs unti l lift is lowered and cam

unoperates mi c r o switc h.

6. Micro switch nor mally open c ontacts open

removing power f r om motor .

7. Timer (solid state control) or cook cycle

(computer control) is complete and power is

removed fr om BLR1 control relay.

8. BLR1 normal ly closed contac ts 5 and 1 close

suppling power through micro switch normally

closed contact s.

9. Motor runs and lift raises until cam operates

micro switch opening the normally c losed

contacts and stopping the motor.

10. Cyc le is repeated.

6. Oil is pumped back to vat.

7. Close the return valve.

18

Page 19

ELECTRIC FRYERS - ELECTRICAL OPERATION

COMPUTER CONTROL

BOARD DIAGNOSTICS

NOTE:

equipment and is capable of displaying many

different prompts. Therefore some prompts not

applicable may di spl ay when a probl em occurs in

the wiring harness. Since the computer is looking for

either 24 VAC or 24 V A C gr ound on par ticular pins,

an open connection can cause a non applicable

prompt t o appear. Refer to “Computer Cont r ol

Harness Pin-outs Chart”

For operator pr ogr ammi ng and oper ation refer to

that section in the Instructions Manual.

The comput er control is also used on other

FAILURE OPERATION MODE

DIAGNOSTICS

DISPLAY

Ignition (gas

heat)

IGN FAILURE IGN FAILURE with L or R

Diagnostics i s di vided into two areas, “operation”

and “service”. Operation mode is the usual m ode of

fryer operation. Ser vic e mode is int ended to give

the service person more information regarding the

nature of the fai lure. In ei ther mode the unit

operates normally unti l an error occurs. In that case

what is displayed will be different. The chart below

shows what is displayed for both “operation” and

“service” m odes.

Serv ice mode is entered by pressing the product 3

and product 4 keys while turning on the power to the

fryer computer. Once in service m ode y ou c an only

exit it by turning off the power switch.

The following display s/system responses will be

given for t he noted failure conditions.

SERVICE MODE

DIAGNOSTICS

DISPLAY

for split vat

SYSTEM RESPONSE

Heat off

Low

Temperature

(lack of heat)

High

temperature

(1st limit)

High

Temperature

(2nd limit)

Tilt Switch open OFF OFF Vat off

Clogged Filter

(gas heat)

Probe CALL SERVICE PROBE OPEN R or L for

Door Open CLOSE DOOR CLOSE DOOR Heat off

Self c hec k CALL SERVICE MICRO FAIL System to bac k up mode

LOW TEMP LO TEMP XXXF Heat of f

HIGH TEMP HI TEMP XXX(F Heat off

OFF OFF Hardware limit, Vat off

turn on AIR i ndicator turn on AIR i ndicator none

Heat off

split vat

PROBE SH R or L for split

vat

19

Page 20

ELECTRIC FRYERS - ELECTRICAL OPERATION

POWER UP DIAGNOSTICS

On power up, the control will execute a self check.

The failure of any of these tests will result in the

message “CALL SERVICE” or “MICRO FAIL” being

displayed.

This prompt will flash at approximately a 1 hert z

rate. While the prompt is displayed, t he c omputer

will not function. If the failure is in the computer, the

fryer will operat e in backup mode.

When the fryer c omputer comes out of i nitial ization

and self check routines, i t will either enter the

heating m ode or the mel t mode (if programmed) of

operation.

For a split vat fryer, one vat c an be off while the

other is in oper ation. If this occurs, the side that is

off will be indicated by displaying the “OFF” prompt

to the user. The message will be on the side of the

display which cor r esponds to the vat whic h is off .

SYSTEM TESTS

The system di agnostics menu is intended to give

you the ability to test the basic parts of the

computer. It can be enter ed by pr essing t he 8 and 9

product keys simultaneously while turning on power

to the f r y er computer. The message “SYSTEM

TESTS” is display ed. In this m ode y ou c an select

one of three tests.

With DISPLAY TEST di spl ay ed, press enter to

begin a test, use the up and down arrows to rotat e

through the screens. Press exit once to ret urn to the

test menu or twice to return t o nor mal operat ion.

With KEYPAD TEST displayed, press enter to begin

the test. The control will respond by displaying the

name of the key pressed. Press exit onc e to return

to the test menu or twice to return to norm al

operation.

With VER xxx displayed, the release number is

displayed as “VER XXX”

20

Page 21

ELECTRIC FRYERS - ELECTRICAL OPERATION

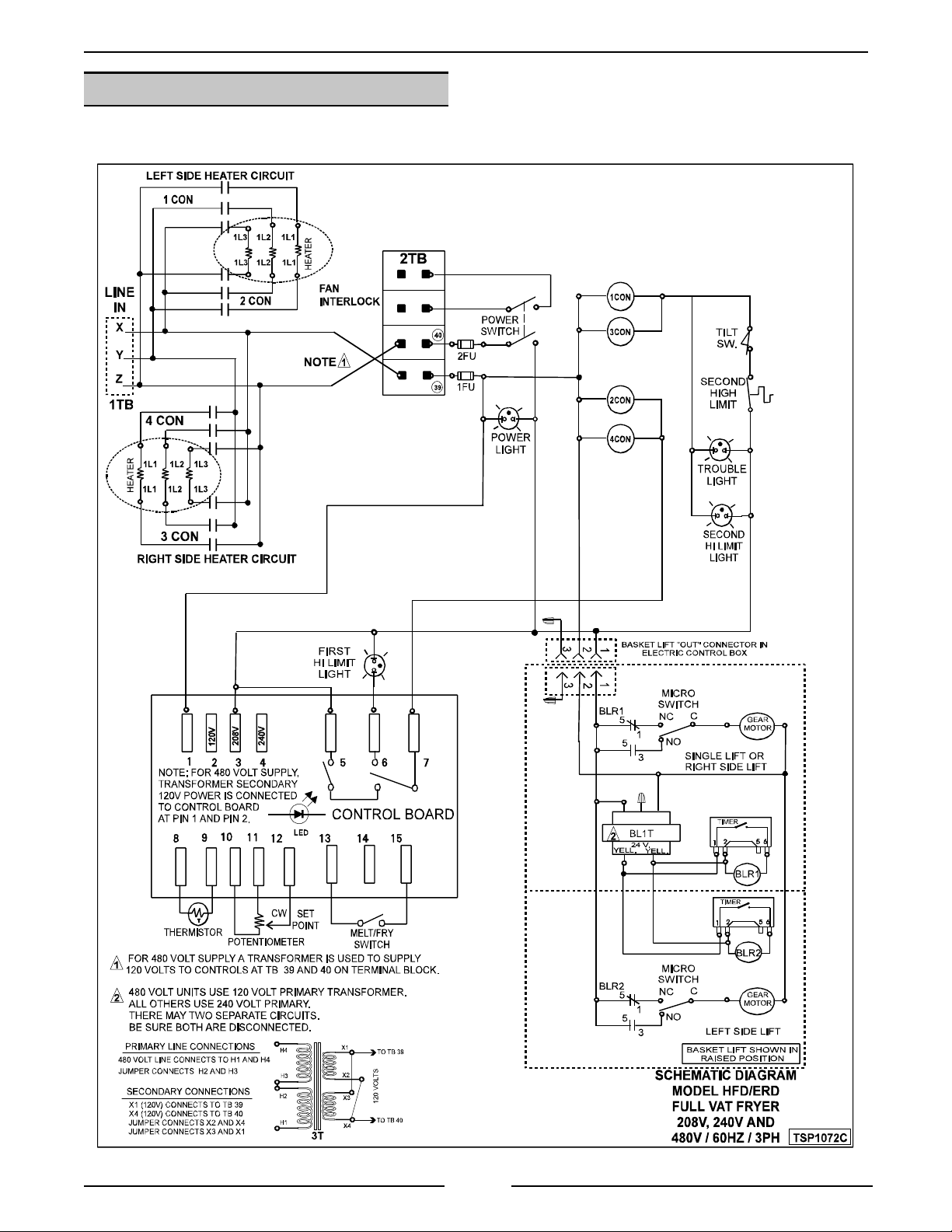

SCHEMATICS

Full Vat With Solid State Control

21

Page 22

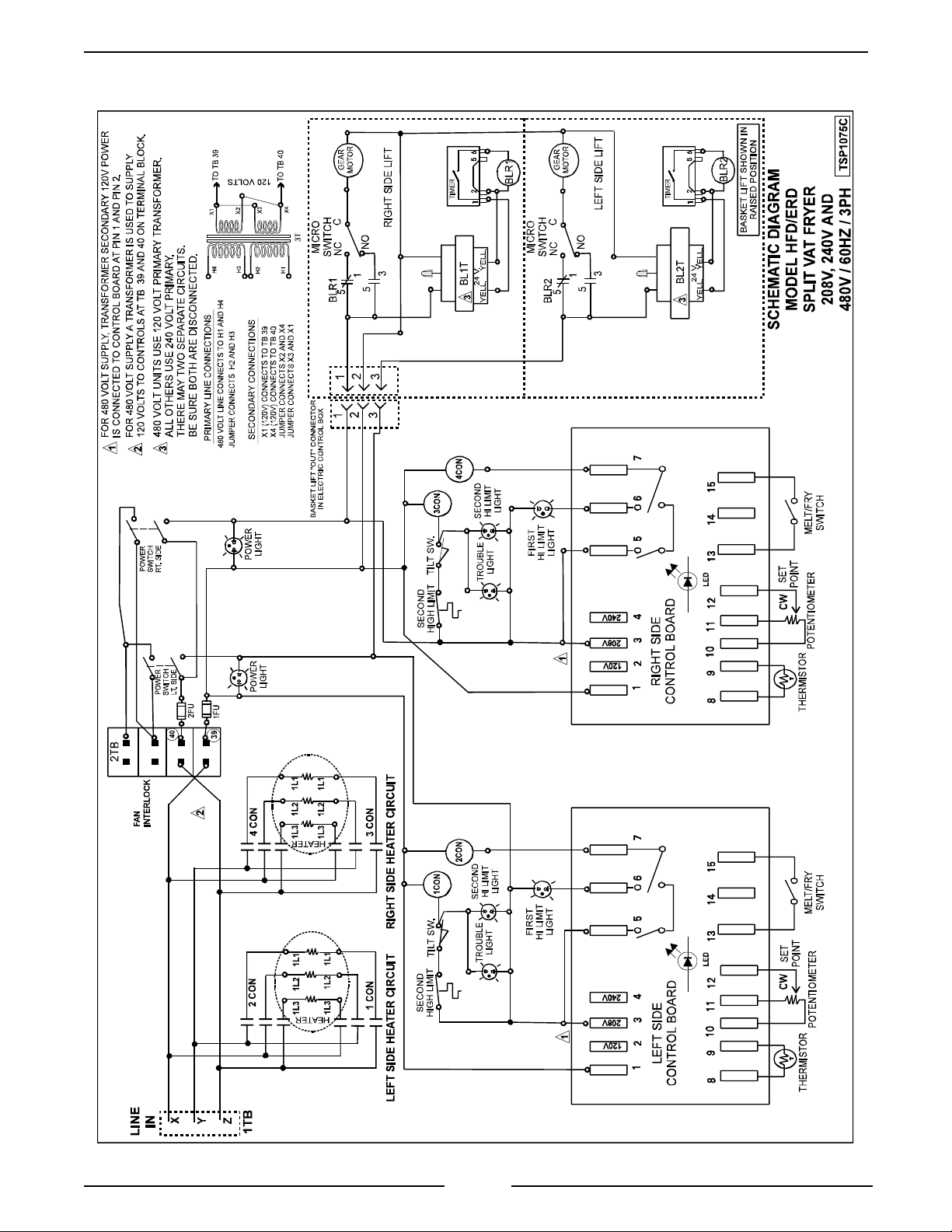

ELECTRIC FRYERS - ELECTRICAL OPERATION

Split Vat With Solid State Control

22

Page 23

ELECTRIC FRYERS - ELECTRICAL OPERATION

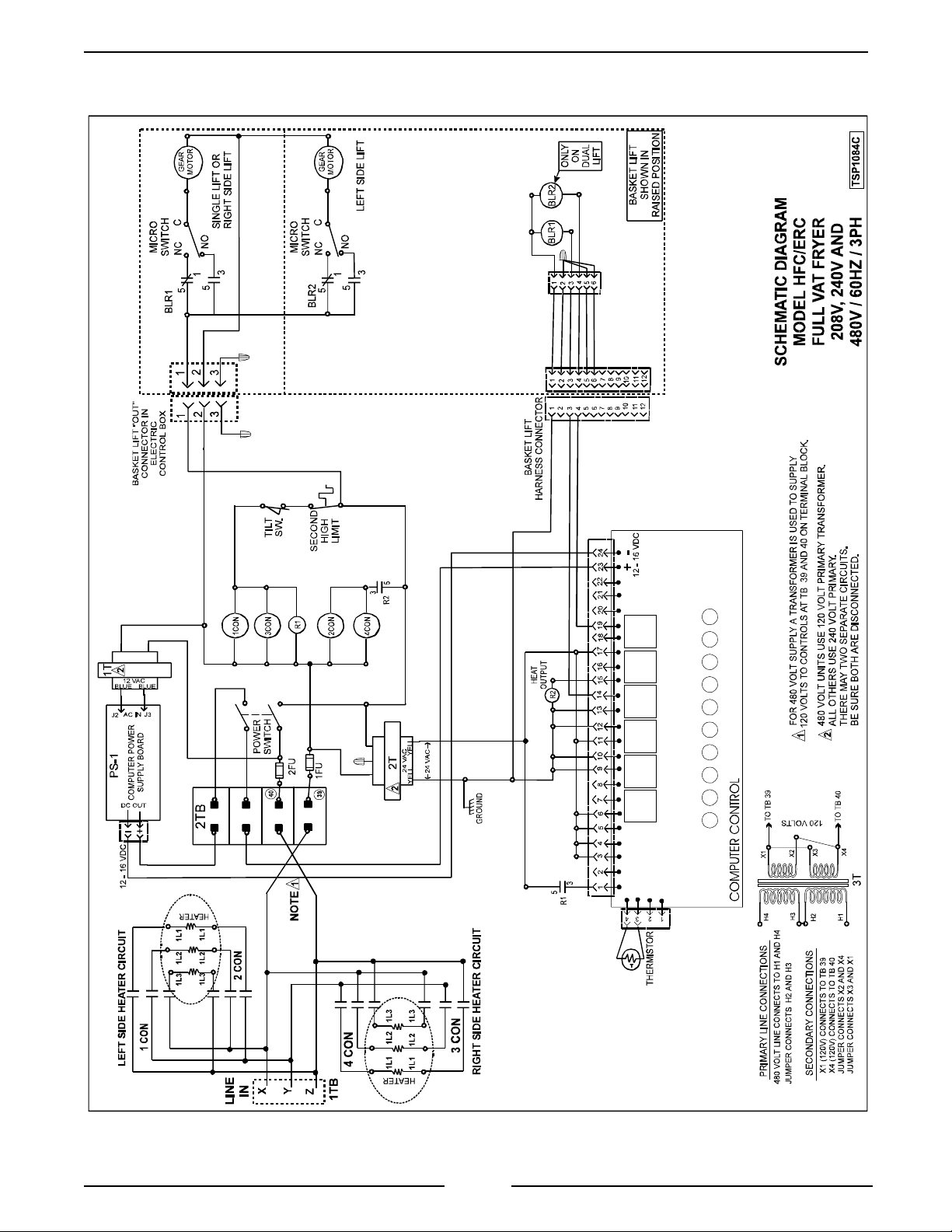

Full Vat With Computer Control

23

Page 24

ELECTRIC FRYERS - ELECTRICAL OPERATION

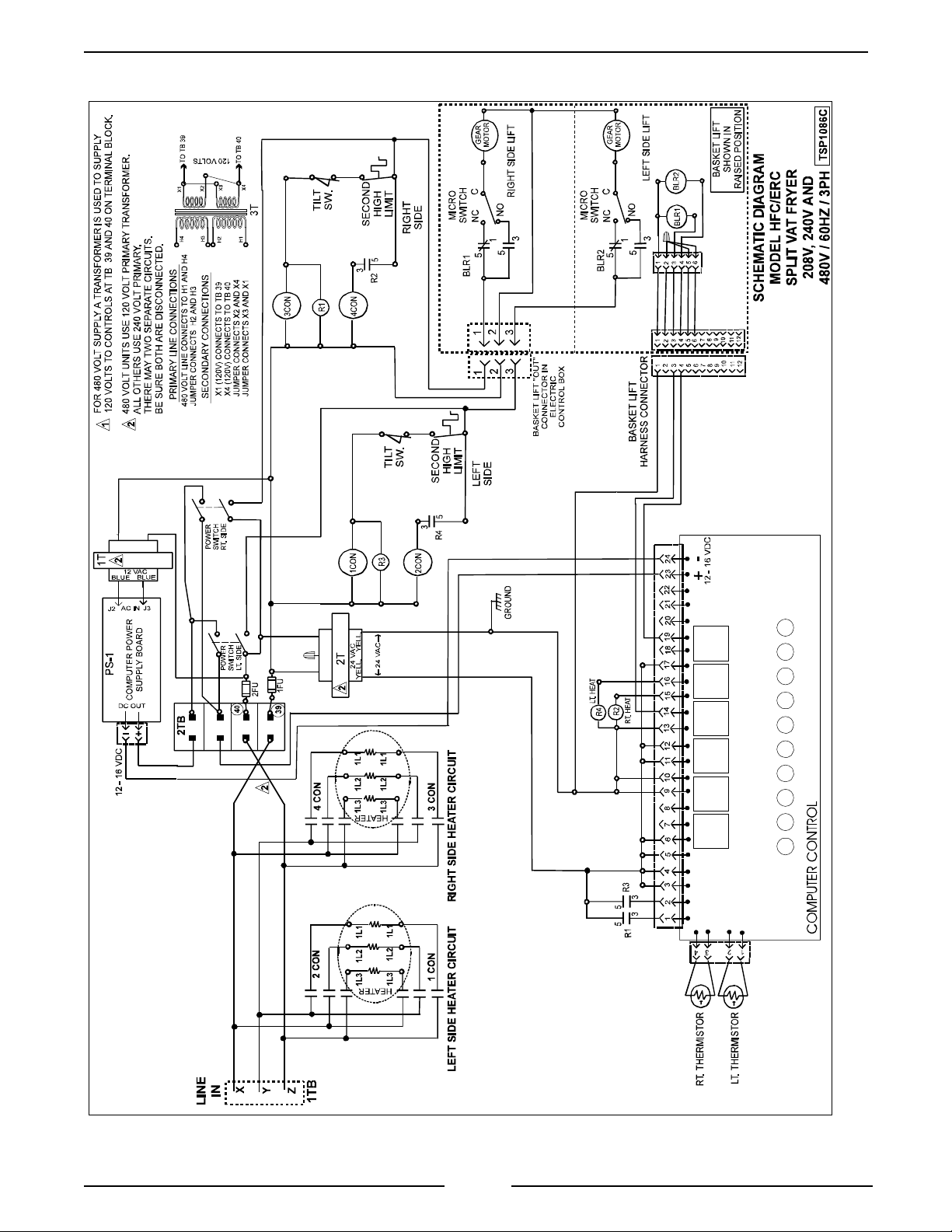

Split Vat With Computer Control

24

Page 25

ELECTRIC FRYERS - ELECTRICAL OPERATION

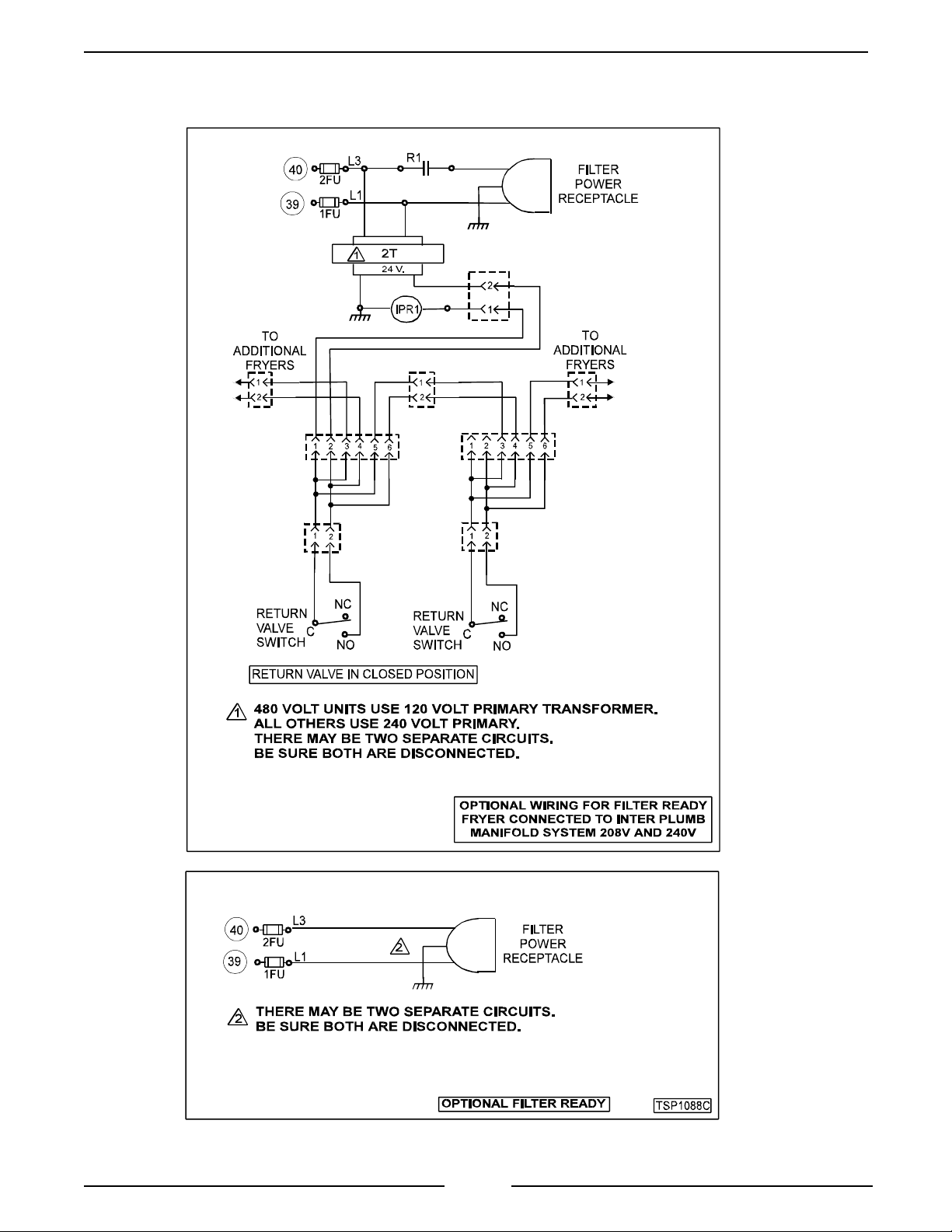

Filter Ready, Inter Plumb Options

25

Page 26

ELECTRIC FRYERS - ELECTRICAL OPERATION

WI RING DIAGRAM INDEX

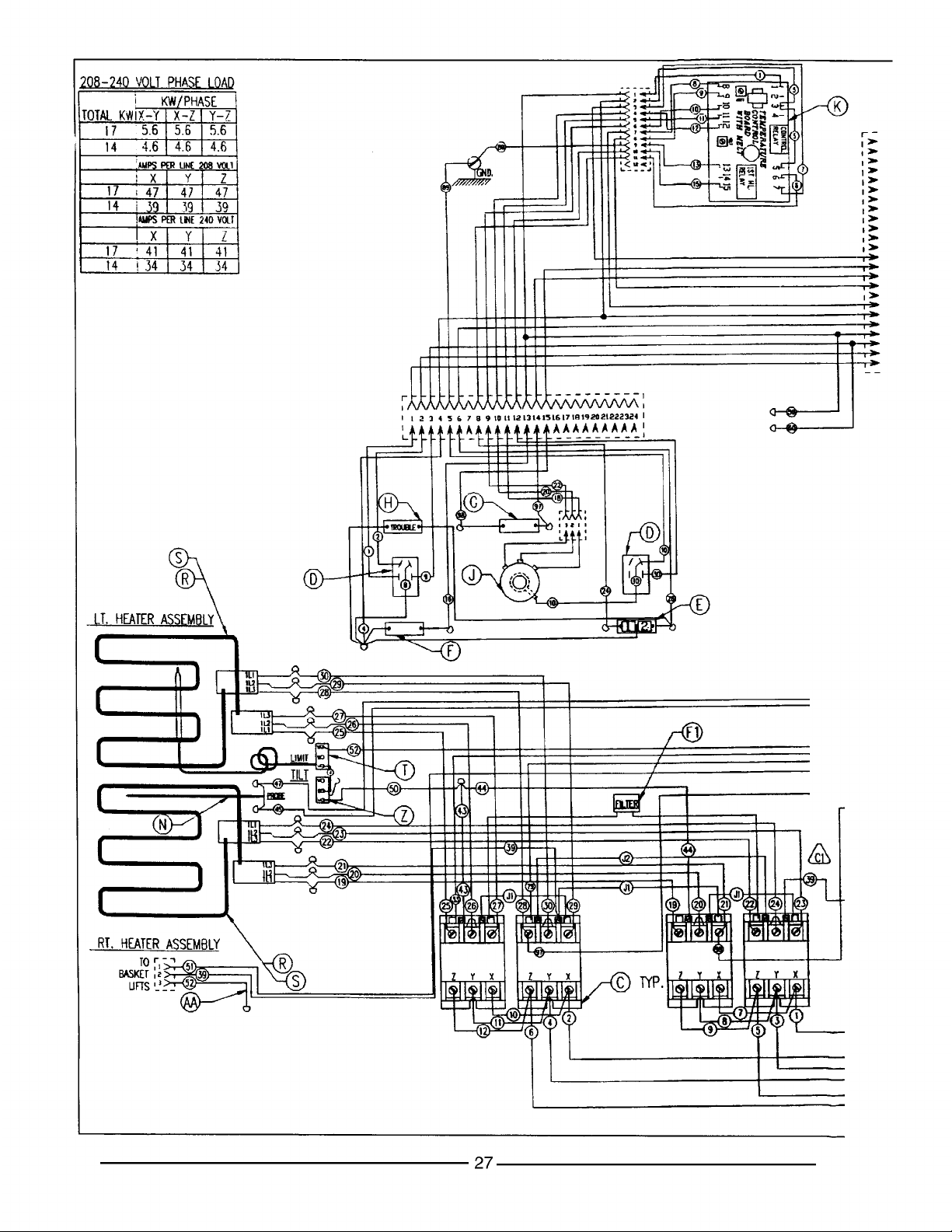

Solid State Models, F ull-Vat 208 & 240 V olt 17 & 14 KW - D-422326-1 Rev. C .................... 27

Solid State Models, F ull-Vat 208 & 240 V olt 24&21 KW - D-422324-1 Rev. C ..................... 28

Solid State Models, F ull-Vat 220/380 240/415 Volt Filter Ready 24, 21, 17 & 14 KW - D-422332-1 Rev. C 29

Solid State Models, F ull-Vat 480 V olt 24, 21, 17 & 14 K W - D- 422328- 1 Rev. C ................... 30

Solid State Models, F ull-Vat 480 V olt Filter Ready 24, 21, 17 & 14 KW - D-422330-1 Rev. C ......... 31

Solid State Models, Split-Vat 208 & 240 Volt 17 & 14 K W - D- 422325- 1 Rev. C .................... 32

Solid State Models, Split-Vat 208 & 240 Volt 21 KW - D- 422323- 1 Rev. C ........................ 33

Solid State Models, Split-Vat 220/380 240/415 Vol t 14, 17 & 21 KW D-422331-1 Rev. C ............. 34

Solid State Models, Split-Vat 480 Volt 14, 17 & 21 K W - D- 422327- 1 Rev. C ...................... 35

Solid State Models, Split-Vat 480 Volt Filter Ready 14, 17 & 21 KW - D-422329-1 Rev. C ............ 36

Computer Cont rol Models, F ull-Vat 208 & 240 V olt 17 & 14 KW - D-422743-1 Rev. C ............... 37

Computer Cont rol Models, F ull-Vat 208 & 240 V olt 24 & 21 KW - D-422741-1 Rev. D ............... 38

Computer Cont rol Models, F ull-Vat 220/380 240/415 Volt 24, 21, 17 & 14 KW - D-422749-1 Rev. C .... 39

Computer Cont rol Models, F ull-Vat 480 V olt 24, 21, 17 & 14 K W - D-422745- 1 Rev. C .............. 40

Computer Cont rol Models, F ull-Vat 480 V olt Fi lter Ready 24, 21, 17 & 14 K W - D- 422747- 1 Rev. C .... 41

Computer Cont rol Models, Split-Vat 208 & 240 Volt 17 & 14 KW - D- 422742- 1 Rev. C .............. 42

Computer Cont rol Models, Split-Vat 208 & 240 Volt 21 KW - D- 422740- 1 Rev. C .................. 43

Computer Cont rol Models, Split-Vat 220/380 240/415 Volt 21, 17 & 14 KW - D-422748-1 Rev. C ...... 44

Computer Cont rol Models, Split-Vat 480 Volt 21, 17 & 14 KW - D- 422744- 1 Rev. C ................ 45

Computer Cont rol Models, Split-Vat 480 Volt F ilter Ready 21, 17 & 14 KW - D-422746-1 Rev. C ...... 46

Solid State Models, Single Basket Li ft 208 & 240 Volt Full Vat - D-422337-1 Rev. D ................ 47

Solid State Models, Single Basket Li ft 480 Vol t Full V at - D-422340-1 Rev. D ..................... 48

Solid State Models, Dual Basket Lifts 208 & 240 Volt F ull Vat - D- 422336- 1 Rev. D ................ 49

Solid State Models, Dual Basket Lifts 480 Volt Full Vat - D- 422339- 1 Rev. D ...................... 50

Solid State Models, Basket Lifts 208 & 240 Volt Split Vat - D-422335- 1 Rev. D .................... 51

Solid State Models, Basket Lifts 480 Volt Spli t Vat - D-422338-1 Rev. D ......................... 52

Computer Cont rol Models, Single Basket Li ft 208 & 240 Volt Full Vat - D-422754-1 Rev. D ........... 53

Computer Cont rol Models, Single Basket Li ft 480 Volt Full Vat - D-422757-1 Rev. D ................ 54

Computer Cont rol Models, Dual Basket Lifts 208 & 240 Volt Full Vat - D- 422753- 1 Rev. C ........... 55

Computer Cont rol Models, Dual Basket Lifts 480 Volt F ull Vat - D- 422756- 1 Rev. C ................ 56

Computer Cont rol Models, Basket Lifts 208 & 240 Volt Split Vat - D-422752- 1 Rev. C ............... 57

Computer Cont rol Models, Basket Lifts 480 Volt Split Vat - D-422755-1 Rev. C .................... 58

Serv e S tation Models ................................................................ 59

26

Page 27

Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

Page 37

Page 38

Page 39

Page 40

Page 41

Page 42

Page 43

Page 44

Page 45

Page 46

Page 47

Page 48

Page 49

Page 50

Page 51

Page 52

Page 53

Page 54

Page 55

Page 56

Page 57

Page 58

Page 59

Page 60

Page 61

Page 62

Page 63

Page 64

Page 65

Page 66

Page 67

Page 68

Page 69

Page 70

Page 71

Page 72

Page 73

Page 74

Page 75

Page 76

Page 77

Page 78

Page 79

Page 80

Page 81

Page 82

Page 83

Page 84

Page 85

Page 86

Page 87

Page 88

Page 89

Page 90

Serve Station Units

ELECTRIC FRYERS - ELECTRICAL OPERATION

59

Page 91

ELECTRIC FRYERS - TROUBLESHOOTING

TROUBLESHOOTING

COMPUTER CONTROL

HARNESS PIN-OUTS CHART

COMPUT E R CONTROL P IN-OUTS

Pin # Descripti on Pin # Descripti on

1 Right power input 13 24 VAC ground

2 Left power input 14 Right basket output

3 Right pil ot valve input 15 Right heat out put

4 Left pilot v alve input 16 Left heat output

5 Right m ain v alve input 17 24 VAC

6 Left main valve input 18 no connection

7 Right high limit 19 Left basket out put

8 Left high limit 20 no connection

9 Ignition system type input 21 no connection

10 Air filt er input 22 no connection

11 Door input 23 DC power input (+)

12 “Full” or “Split” mode input 24 DC power input (-)

SOLID STATE CONTROL

SYMPTOM POSSIBLE CAUSES

Fryer does not heat. Power light is not on. 1. Power swi t ch of f or inoperative.

2. Main circuit br eaker tripped.

3. Fuse in control cir cui t open.

Ventilator off, power switch on, power light on. 1. Ventilator hood circuit br eaker open.

2. Interlock wiri ng open.

3. Power switch malfunct ion.

No heating light, power switch on, power li ght on. 1. Temperature control set too low or not calibrat ed.

2. Heating light i noperative.

3. Control board i noperative.

No heating light. Power switch on, power li ght on,

trouble light and second high l i mit on.

Excessive time to melt shortening. (more than 45

minutes).

Fryer shuts down on first hi gh limi t . 1. Low oil.

Fryer shuts down on second high limi t. 1. Low oil.

Thermostat out of calibration by more than 25(F. 1. Control boar d i noperative.

Light(s) not on when required. 1. Light inoperati ve.

1. Shortening temperature above 435(F, first high limit

inoperative.

2. Second high limit inoperative.

1. Melt cycle timing incorrect.

2. Heating elements malf unct ioning.

3. Supply power incorrect voltage.

2. Control not cal ibrated.

3. Contactor m alfunction.

4. Control board i noperative.

2. Control board i noperative.

3. High limit m alfunction.

2. Probe touching element.

2. W i r ing problem.

60

Page 92

Loading...

Loading...