Page 1

SERVICE MANUAL

HALF-SIZE

CONVECTION OVENS

ELECTRIC AND GAS

MODEL ML

ELECTRIC

GCO2D Shown

This Manual is prepared for the use of train ed Vulcan Service

Technicians and should not be used by those not properly

qualif ied. If you have att ended a Vu lcan Service School for this

product, you may be qualified to perform all the procedures

described in this man ual.

Thi s manu al i s no t i nten ded to be al l en comp assi ng . I f you have

not attende d a Vulcan Servic e School f or this produc t, you should

read, in its entirety, the repair procedure you wish to perform to

determine if you have the necessary tools, instruments and skills

required to perform the procedure. Procedures for which you do

not have th e necessary t oo ls, in strument s and skills should be

performed b y a trained Vu lcan Service Technician .

ECO2D 114570

ECO2C 114572

GAS

GCO2D 114569

GCO2C 114571

- NOTICE -

Reproduction or other use of this Manual, without the express

written consent of Vulcan-Hart, is prohibited.

A product of VULCAN-HART LOUISVILLE , KY 40201-0696

Form 24575 ( 12/96)

Page 2

HALF-SIZE CONVECTION OVENS

TABLE OF CONTENTS

GENERAL............................................................................. 3

Introduction ....................................................................... 3

Specifications ..................................................................... 3

Gas Ovens................................................................ 3

Electric Ovens ............................................................. 3

Tools............................................................................ 3

REMOVAL AND REPLACEMENT OF PARTS ................................................. 4

Covers and Panels ................................................................. 4

Control Panel Components ........................................................... 5

Blower And/or Blower Motor........................................................... 6

Oven Door........................................................................ 7

Door Switch....................................................................... 8

Heat Exchanger (Gas Ovens) ......................................................... 8

Burner (Gas Ovens)................................................................. 9

Gas Valve (Gas Ovens).............................................................. 9

Heating Elements (Electric Ovens) .................................................... 10

SERVICE PROCEDURES AND ADJUSTMENTS .............................................. 11

Temperat ure Probe Test (Al l Models) .................................................. 11

Verification of Spark at Spark Probe ................................................... 11

Gas Pressure Adjustment ........................................................... 12

Spark Ignition Control Test .......................................................... 12

Electronic Control ................................................................. 13

Solid State Control Test............................................................. 14

Solid State Control Calibration........................................................ 14

Door Switch Adjustment............................................................. 15

Door Reversal .................................................................... 16

Door Adjustment .................................................................. 17

Blower Adjustment................................................................. 17

Element Test..................................................................... 17

ELECTRICAL OPERATION .............................................................. 18

Component Func tion ............................................................... 18

Component Locat ion ............................................................... 19

Sequence of O per ation ............................................................. 20

Ignition Module ............................................................ 20

Gas Oven................................................................ 20

Electric Oven ............................................................. 23

Schematics Gas Ovens............................................................. 26

GCO2D ................................................................. 26

GCO2C ................................................................. 27

Wiring Diagram - Gas Ovens......................................................... 28

GCO2D ................................................................. 28

GCO2C ................................................................. 30

Schematic-Electric Ovens ........................................................... 32

ECO2D ................................................................. 32

ECO2C ................................................................. 33

Wiring Diagram Electric Ovens ....................................................... 34

ECO2D ................................................................. 34

ECO2C ................................................................. 36

TROUBLESHOOTING .................................................................. 38

Electric Ovens.................................................................... 38

Gas Ovens ...................................................................... 39

© VULCAN 1996

2

Page 3

HALF-SIZE CONVECTION OVENS - GENERAL

GENERAL

INTRODUCTION

General

This manual will cover half-s ize ele ctric and gas convection ovens that use either a solid state control or an electronic

control.

Procedures in this manual are applicable t o both gas and electric ovens unless specified.

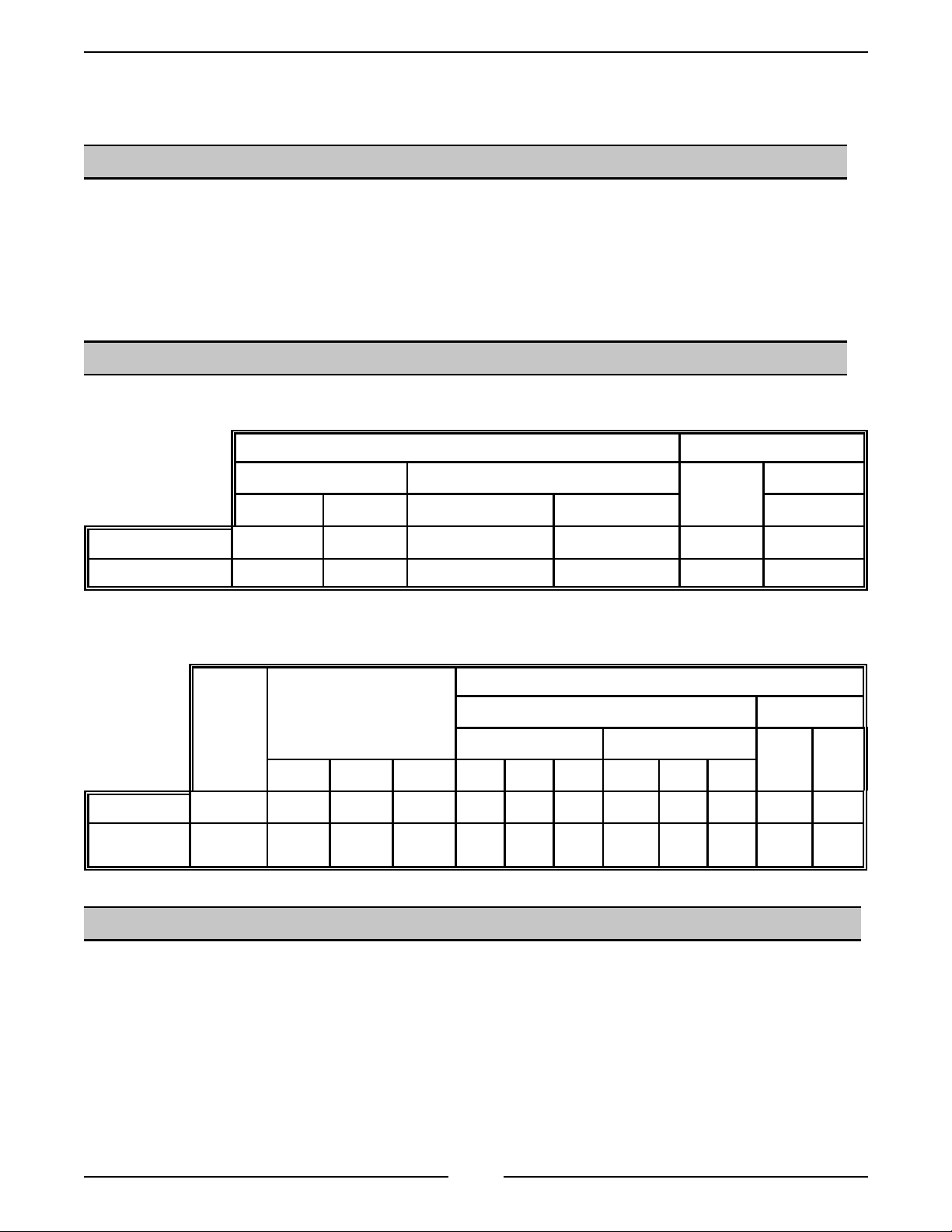

SPECIFICATIONS

GAS OVENS

GAS DATA ELECTRICAL DATA

INPUT BTU/HR MANIFOLD PRESSURE LOAD

Natural Propane Natural Propane 120V

Single Oven 2500 2500 3.5" W.C. 10"W.C. 950 8

Stacked Oven 5000 5000 3.5" W.C 10"W.C. 1900 16

ELECTRIC OVENS

NOMINAL AMPS PER LINE WIRE

3-PHASE LOADING

TOTAL

KW

Single O ven 5.5 2.5 0 3.0 22.9 10.4 12.5 19.9 9.0 10.9 26.5 23.0

Stacked

Ovens

11.0 5.0 0 6.0 45.8 20.8 25.0 39.7 18.0 21.7 52.9 45.9

(KW PER PHASE)

208V 240V 208V 240V

L1-L2 L2-L3 L1-L3 L1 L2 L3 L1 L2 L3

3 PHASE 1 PHASE

(Watts)

AMP/LINE

TOOLS

• Standard set of hand tools

• VOM with AC c ur r ent tester (Any VO M wi th a sensitivity of at least 20, 000 ohms per volt can be used.)

• Temperat ure tester

• Manometer (Gas Ov ens)

3

Page 4

HALF-SIZE CONVECTION OVENS - REMOVAL AND REPLACEMENT OF PARTS

REMOVAL AND REPLACEMENT OF PARTS

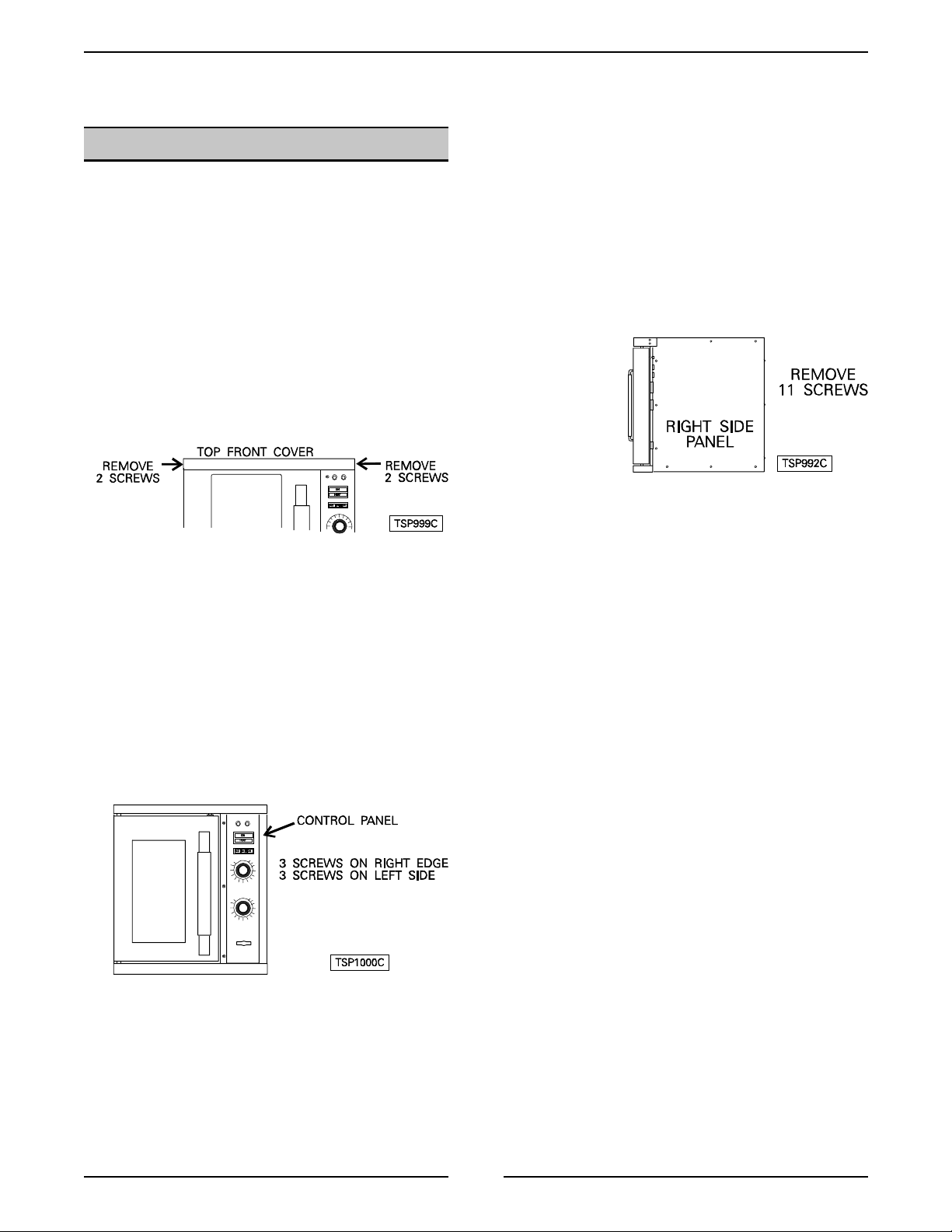

COVERS AND PANELS

WARNING:

POWER TO THE MACHINE AT THE MAIN CIRCUIT

BOX. PLACE A TAG ON THE CIRCUIT BOX

INDICATI NG THE CIRCUIT IS BEING SE RV ICED.

WARNING:

SERVICING THE UNIT. (When appl icable)

Top Front Cover

1. The t op f ront cover is secured with f our screws,

two on each side of cover. Remove these screws

then pull c over off uni t.

2. Reverse the procedure to install.

DISCONNECT THE ELECTRICAL

SHUT OFF THE GAS BEFORE

Right Side Panel

1. Remove the three screws which secure the right

side of the c ontrol panel.

2. Loosen the two screws on the right side of the top

front c over.

3. Remove the remaining eight screws securing the

right side panel.

4. Pul l the right side panel out at t he bottom then

down to remove.

5. Reverse the procedure to install.

Control Panel

1. On gas models, remove the handle from the

manual gas valve.

2. Remove the three screws from the left front and

loosen the three screws on the ri ght side of the

control panel.

3. Pul l the panel away f r om the oven.

4. Unplug the lead wires to the control panel

components and disconnect the temperature

probe leads.

5. Reverse the procedure to install.

4

Page 5

HALF-SIZE CONVECTION OVENS - REMOVAL AND REPLACEMENT OF PARTS

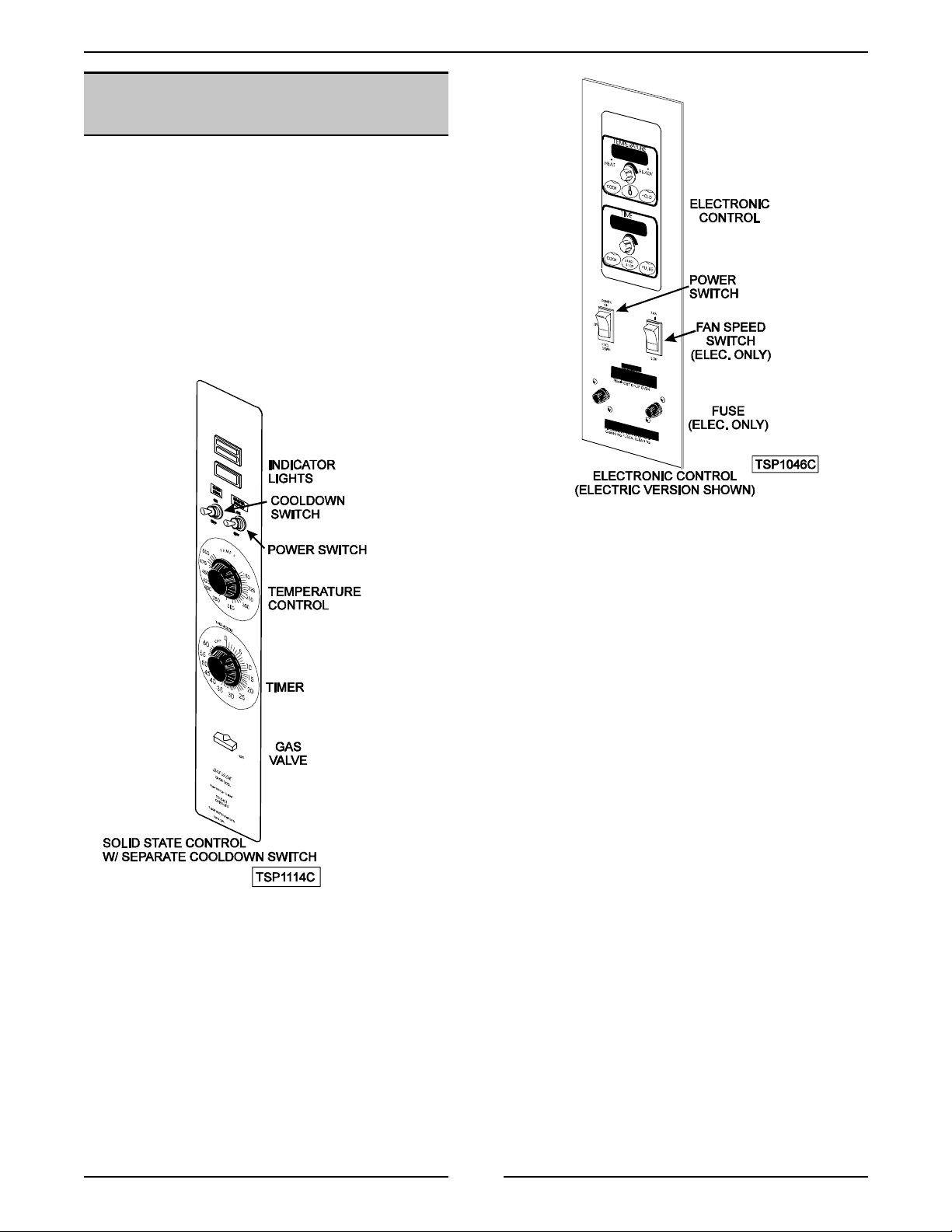

CONTROL PANEL

COMPONENTS

Removable Components

Listed on the illustration.

Procedure

WARNING

1. Remove the control panel as outlined under

: UNPLUG UNIT BEFORE SERVICING.

"COVERS AND PANELS".

2. Disconnect the wire leads at the component to be

replaced.

3. Rem ove the component.

4. Reverse the procedure to install the new

component, then check oven for proper

operation.

5

Page 6

HALF-SIZE CONVECTION OVENS - REMOVAL AND REPLACEMENT OF PARTS

BLOWER AND/OR BLOWER

MOTOR

WARNING

1. Rem ove racks and the r ight rack support.

2. Rem ove baffle panel by lifting up and out.

3. For gas ovens only, remove the heat exchanger

: UNPLUG UNIT BEFORE SERVICING.

as outlined under “HEAT EXCHANGER”.

8. Disconnect the wire leads to the motor.

A. P1 (purpl e) to wire# 11

B. Orange (Low speed) to wire# 12

C. Blue (high speed) to wire# 13

D. Red wires connected together.

9. Rem ove the bolt s that secure the motor to the

motor mounting plate and remove the motor from

the ov en.

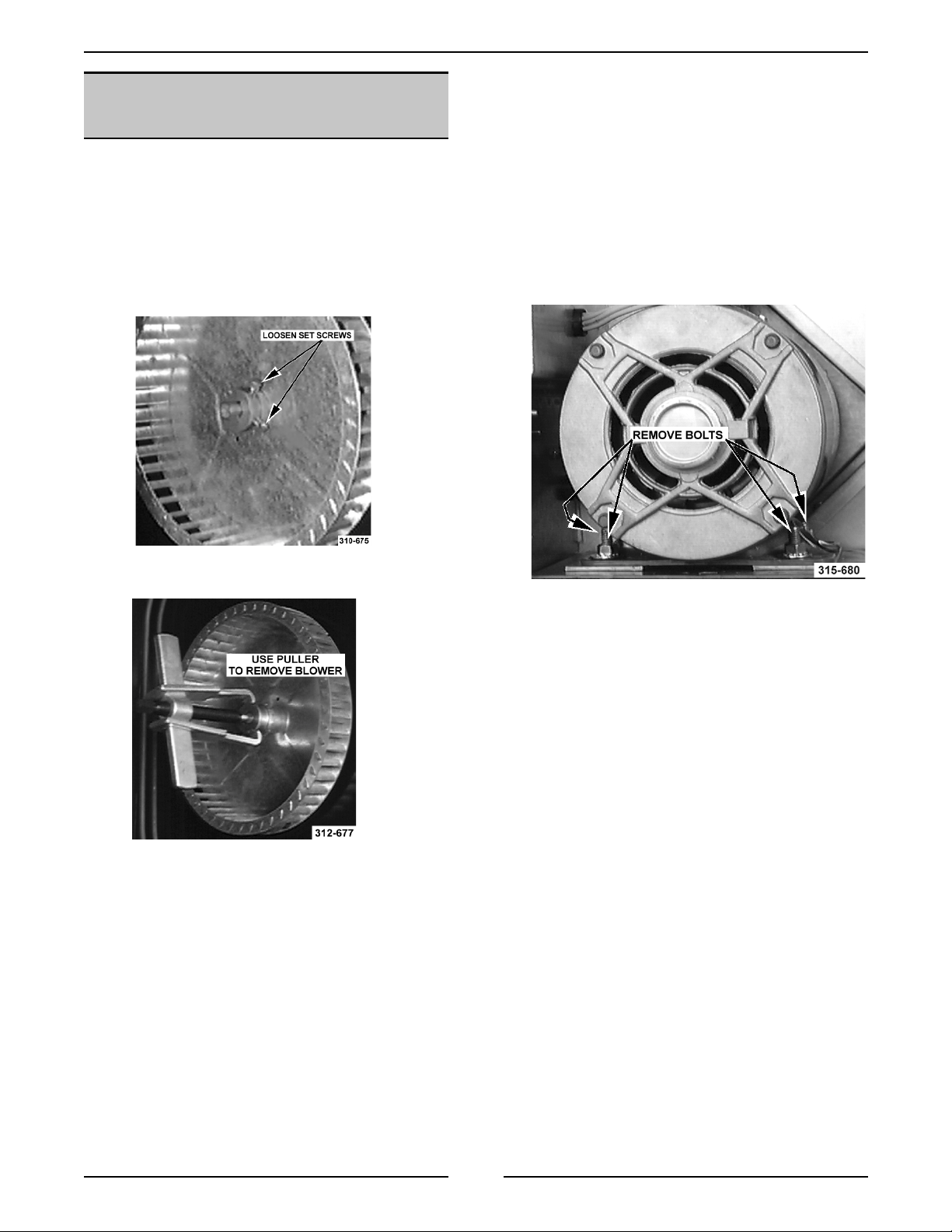

4. Loosen set screws on blower hub.

5. Remove blower from motor shaft. You may have

to use a bearing puller.

6. If the blower only is to be replaced, reverse

procedure to install and check blower to be

parallel with the motor mounting plate as outlined

under "BLOW ER A DJUST MENT " i n "SERV ICE

PROCEDURES AND ADJUSTMENTS”. If the

motor is to be replaced, c ontinue to step 7.

10. Place new motor in position on the motor

mounti ng plat e and rout e the wir ing t hrough t he

gromm et in the component panel.

11. Install mounting pads and bolts. DO NOT tighten

mounti ng bolts.

12. Slide the blower onto motor shaft until hub is

flush wit h end of shaft and tighten set screws.

13. Adjust m otor position u nti l blower is parall el to

oven cavity wall with a spacing of ¼" as outlined

under "BLOWER ADJUSTMENT " i n "S ERVI CE

PROCEDURES AND ADJUSTMENTS".

14. Install baffle panel, rack guides and racks.

7. Rem ove the right side panel.

6

Page 7

HALF-SIZE CONVECTION OVENS - REMOVAL AND REPLACEMENT OF PARTS

OVEN DOOR

Removal

WARNING:

1. Remove the top front cover as outlined under

"COVERS AND PANELS".

2. Remove the door switch lever from the door

shaft.

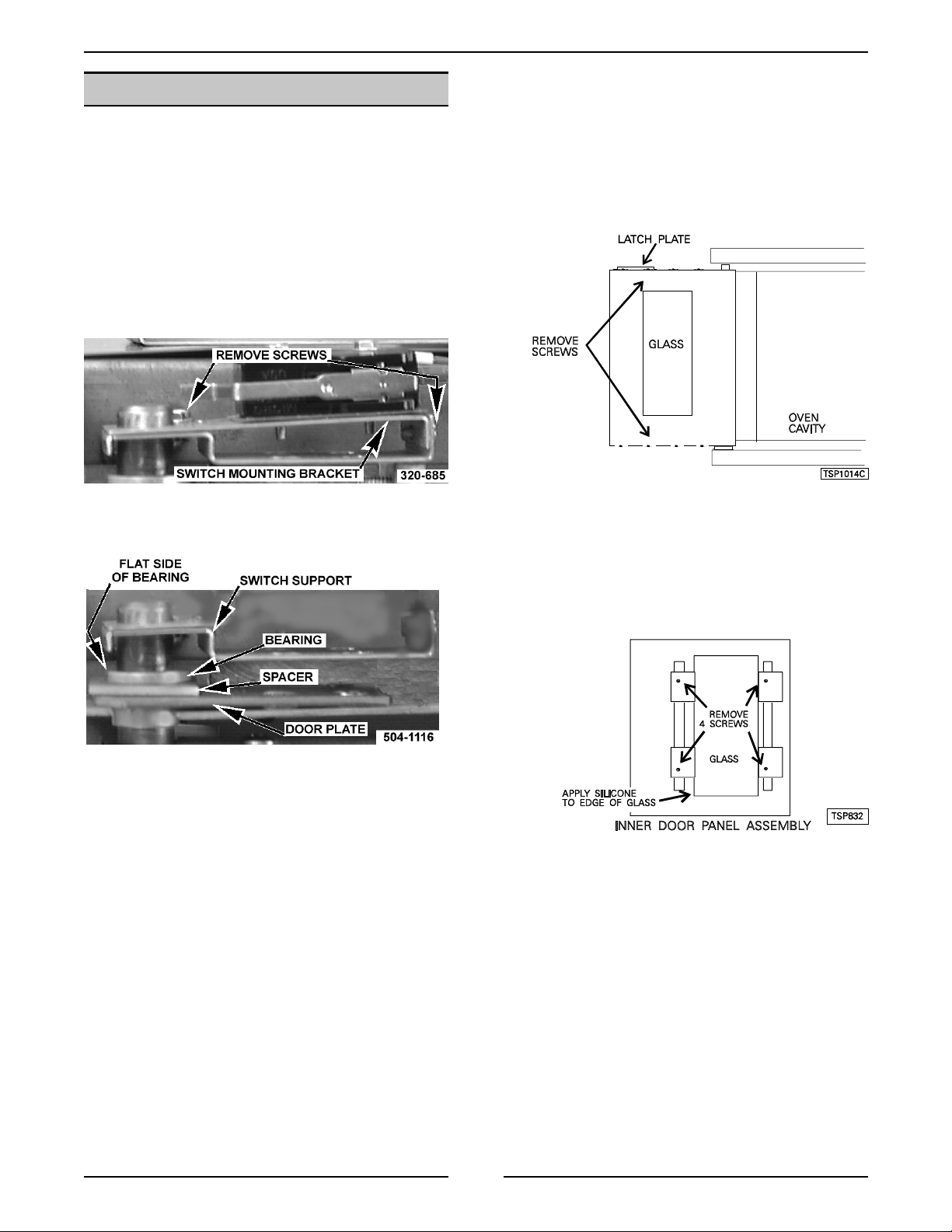

3. Rem ove the door switc h br ac k et.

4. Whil e supporti ng the door, rem ove the beari n g,

door plate and spacer.

UNPLUG UNIT BEFORE SERVICING.

Disassembly

1. Open t he door .

2. Rem ove the door handle and latch plate.

3. Rem ov e t he screws which secure the i nner and

outer door panels to the door frame.

4. Rem ove the inner and outer door panel.

5. Remove the four screws and lift the window

assembly out.

5. Lift the door from the lower bearing.

6. Reverse procedure to i nstall door assembly and

check for proper adjustment as outli ned under

"DOOR ADJUST MENT" and "DOOR S WITCH

ADJUSTMENT" in "SERVICE PROCEDURES

AND ADJUSTMENTS".

NOTE:

the window and the door panel.

6. Reverse the procedure to install the new window

and adjust the door as outlined under “DOOR

ADJUSTMENT”.

Use high temperature silicone between

7

Page 8

WARNING:

HALF-SIZE CONVECTION OVENS - REMOVAL AND REPLACEMENT OF PARTS

DOOR SWITCH

HEAT EXCHANGER (GAS

UNPLUG UNIT BEFORE SERVICING.

OVENS)

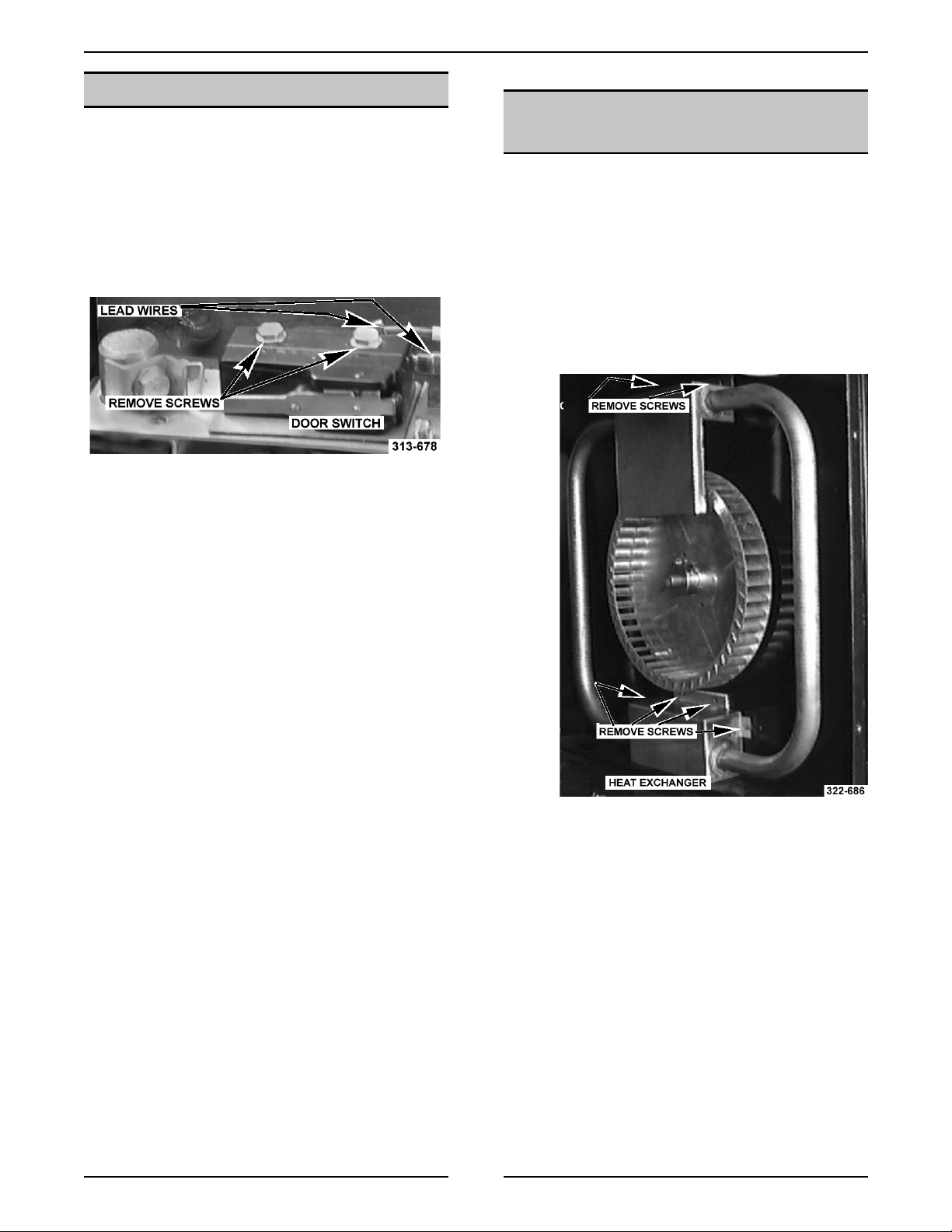

1. Rem ove the t op front cover as outlined under

"COVERS AND PANELS".

2. Disconnect the leads to the door switc h.

3. Rem ove the switch whic h is secured by two

screws.

4. Reverse the procedure to install t he new

switch.

5. Adj ust the door switch as outlined under

"DOOR SWITCH ADJUSTMENT" in

"SERVICE PROCEDURES AND

ADJUSTMENTS".

WARNING:

WARNING:

SERVICING THE UNIT.

1. Rem ove racks and the r ight rack support.

2. Rem ove baffle panel by lifting up and out.

3. Rem ove the screws that secure the heat

exchanger and remove it fr om the oven.

UNPLUG UNIT BEFORE SERVICING.

SHUT OFF THE GAS BEFORE

4. Reverse procedure to i nstall.

8

Page 9

HALF-SIZE CONVECTION OVENS - REMOVAL AND REPLACEMENT OF PARTS

BURNER (GAS OVENS)

WARNING:

WARNING:

SERVICING THE UNIT.

1. Rem ove racks and the r ight rack support.

2. Rem ove baffle panel by lifting up and out.

3. Rem ove the right side panel as outlined under

“COVERS AND PANELS”.

4. Disconnect the lead wires to the electrode

assembly.

5. Rem ove the heat exchanger as outlined under

“HEAT EXCHANGER”.

6. Rem ove the screws from the burner brack et

and pull the bur ner into the oven cavity.

7. Rem ove the screws that secure the electrodes

to the burner brac k et.

UNPLUG UNIT BEFORE SERVICING.

SHUT OFF THE GAS BEFORE

GAS VALVE (GAS OVENS)

WARNING:

WARNING:

SERVICING THE UNIT.

WARNING:

DURING SERVI CING MUST BE CHECK E D FOR

LEAKS. CHECK WITH A SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

A. CHECK ALL JOINTS PRIOR TO THE

B. CHECK ALL JOINTS BEYOND GAS

1. Rem ove the right side panel and control panel

as outlined under “COVERS AND PANELS”.

2. Disconnect the lead wires at the gas valve.

3. Disconnect the gas line fitting going to the

burner at the top of the gas valve.

UNPLUG UNIT BEFORE SERVICING.

SHUT OFF THE GAS BEFORE

ALL GAS JOINTS DISTURBED

GAS VALVE BEFORE LIGHTING UNIT.

VALVE AFTER UNIT IS LIT.

8. Reverse procedure to i nstall.

NOTE:

positioned toward t he front of the oven.

When installed, the electrodes are

4. Rem ove the gas valve from the nipple between

the it and t he manual gas valve.

5. Reverse procedure to i nstall.

6. Adj ust the gas valve as outlined under “GAS

PRESSURE ADJUSTMENT”.

9

Page 10

HALF-SIZE CONVECTION OVENS - REMOVAL AND REPLACEMENT OF PARTS

HEATING ELEMENTS

(ELECTRIC OVE NS)

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Rem ove racks and the r ight rack support.

2. Rem ove baffle panel by lifting up and out.

3. Rem ove the right side panel as outlined under

“COVERS AND PANELS”.

4. Disconnect the lead wires to the heating

elements.

5. Rem ove the screws from the clamps that

secure the heating element assembly.

DISCONNECT THE ELECTRICAL

TEMPERATURE PROBE

Procedure

WARNING

1. Rem ove the control panel as outlined under

2. Disconnect the probe leads at the temperature

3. Rem ove probe from the pr obe guar d and push

NOTE:

the probe should be insert ed into the probe guard.

: UNPLUG UNIT BEFORE SERVICING.

"COVERS AND PANELS".

control.

it thru the oven wall into the control panel ar ea.

When installing, only the metal surface of

6. Pul l the top of the heating element assembl y

into the oven cavity until the ends of the

element s are inside the oven cav ity. Li ft up and

remove the lower clamp f r om between the side

wall and the bottom of the oven cavity.

NOTE:

angle. The hole in the inside oven cavit y wal l may

not line up straight with t he oven cavity outer shell.

4. Reverse the procedure to install t he new probe.

5. Adj ust the temperat ur e c ontrol as outlined

The probe may have to be inserted at an

under "TEMPER A TURE CONTROL

CALIBRATI ON" in "SERVICE PROCEDURES

AND ADJUSTMENTS".

7. Rem ove the clamps fr om the heati ng element

assembly and repl ac e the element ( s).

8. Reverse procedure to i nstall.

10

Page 11

HALF-SIZE GAS CONVECTION OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

SERVICE PROCEDURES AND ADJUSTMENTS

WARNING:

MEASUREMENTS WHILE POWER IS APPLIED TO THE MACHINE. EXERCISE EXTREME CAUTION AT ALL

TIMES. IF TEST POI NT S ARE NOT EASI LY ACCESSIBLE, DISCONNECT POWER, ATTACH TEST

EQUIPMENT AND REAPPLY POWER TO TEST .

WARNING:

1. Rem ove the right side panel as outlined under

"COVERS AND PANELS".

2. Rem ove the probe lead wires from the

electronic control .

3. Test t he pr obe with an ohmmeter.

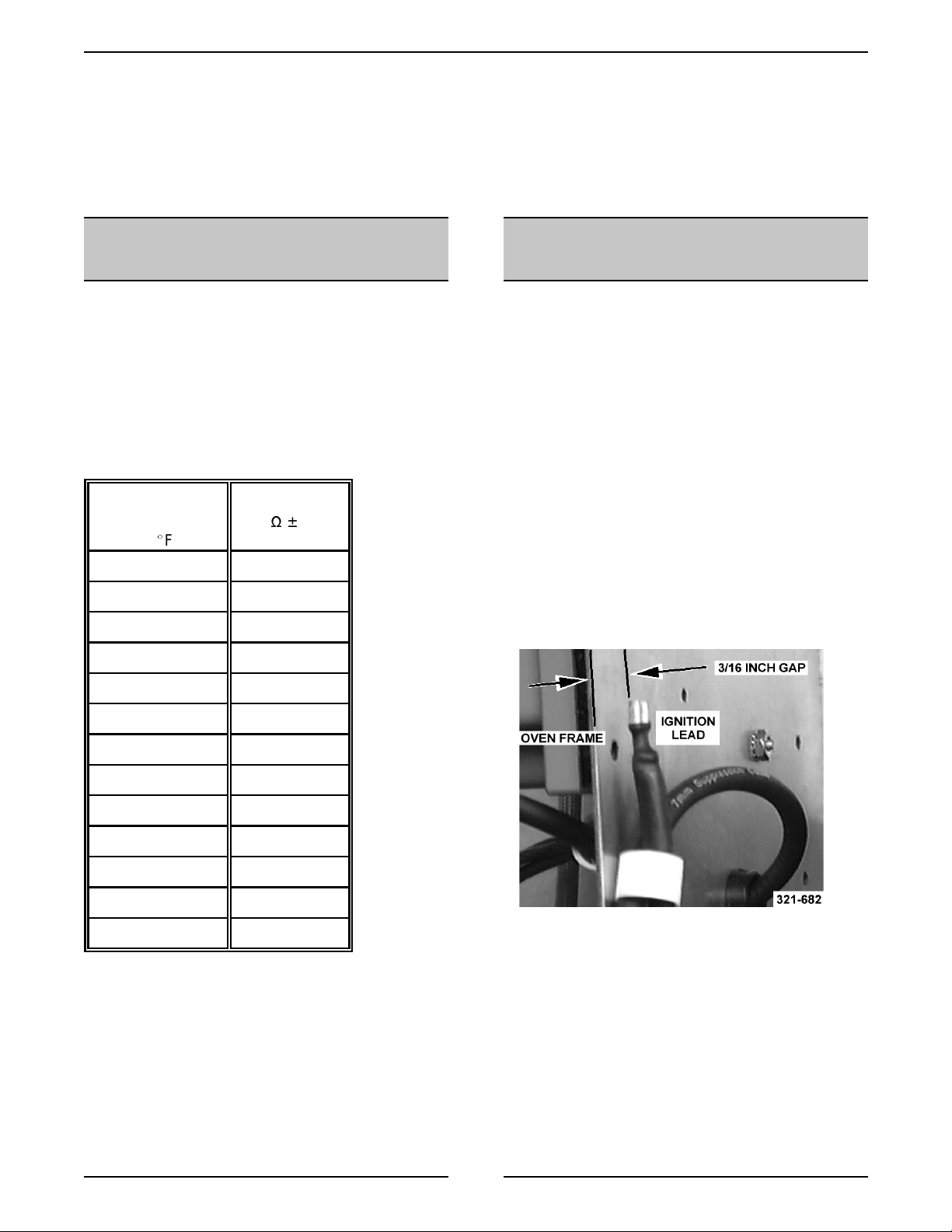

TEMPERA-

TURE

CERTAIN PROCEDURES IN THIS SECTION REQUIRE ELECTRICAL TEST OR

TEMPERATURE PROBE

TEST (ALL MODELS)

UNPLUG UNIT BEFORE SERVICING.

RESISTANCE

in ±10%

in (F

77 90000

240 4077

260 3016

VERIFICATION OF SPARK

AT SPARK PROBE

WARNING:

WARNING:

SERVICING THE UNIT.

1. Rem ove the right side panel and control panel

as outlined under “COVERS AND PANELS”.

2. Disconnect the high voltage lead from the

electrode.

WARNING:

YOUR HANDS FO R THIS TEST. THE MANUAL

GAS VALVE MUST BE CLOSED.

3. Clamp the wire in such a manner that the end

of the wire is 3/16" fr om the f r ame of t he oven.

NOTE:

from the ov en or spark ing may not oc c ur even

though the probe ci rcuits are functioni ng pr oper ly.

UNPLUG UNIT BEFORE SERVICING.

SHUT OFF THE GAS BEFORE

DO NOT HOLD THE W IRE WITH

It is critical that the wire be held 3/16" away

280 2266

300 1726

320 1332

340 1041

360 822

380 656

400 529

425 424

450 334

475 266

WARNING:

POW E R TO BE APPLIED TO THE UNI T DURING

THE TEST. USE EXTREME CAUTION AT ALL

TIMES.

4. Pl ug the unit in and set the temperat ur e

controller to the maximum setting.

5. Turn the power switch on.

6. Sparking should occur after a 15 second purge

tim e. Arcing from the lead wire to the oven

frame should be observed at this time.

THE FOLLOWI NG ST EPS REQUIRE

11

Page 12

HALF-SIZE GAS CONVECTION OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

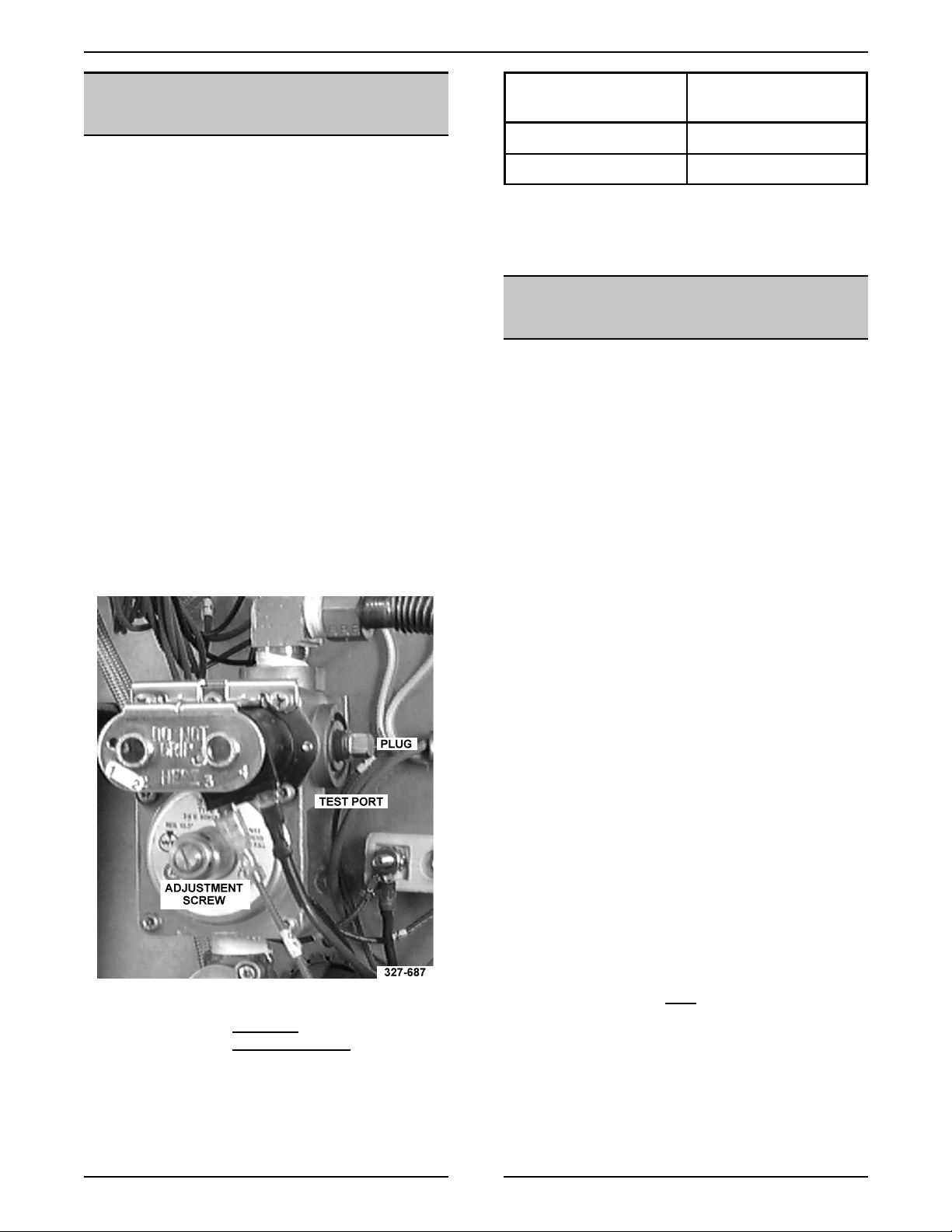

GAS PRESSURE

ADJUSTMENT

WARNING:

WARNING:

SERVICING THE UNIT.

1. Rem ove the right side panel and control panel

as outlined under “COVERS AND PANELS”.

2. Rem ove the plug from the test port and install

the manometer.

WARNING:

POW E R TO BE APPLIED TO THE UNI T DURING

THE TEST. USE EXTREME CAUTION AT ALL

TIMES.

3. Pl ug in the unit and turn on the gas.

4. Set the temperat ur e c ontrol to the highest

setting and turn the power switch on. The

burner must be lit while adjusting the pressure.

5. Turn the adjustment screw to obt ain the proper

gas pressure.

UNPLUG UNIT BEFORE SERVICING.

SHUT OFF THE GAS BEFORE

THE FOLLOWI NG ST EPS REQUIRE

GAS TYPE SETTING AT OUTPUT

OF GAS VALVE

Natural 3.5 inches W.C.

Propane 10 inches W.C.

NOTE:

10.5 (Propane) inches W. C., the desired output

cannot be obtained and the oven will overate at a

lower BTU.

If input pressure is below 4.0 (Natural) or

SPARK IGNITION CONTROL

TEST

WARNING:

NOTE:

to the oven ground.

No Gas Ignition & No Sparking

1. Rem ove the right side panel as outlined under

“COVERS AND PANELS”.

2. Pl ug in the unit and set the temperat ur e

controller to 350°.

3. Turn the power switch on.

UNPLUG UNIT BEFORE SERVICING.

Verify that the ground terminal is connected

• Turn screw clockwise

• Turn screw countercloc k wise

pressure.

to increase pressure.

to decrease

4. Check for 24 VAC between the power terminal

and ground terminal.

A. If 24 V A C is present, replace t he spark

ignition control.

B. If 24 V A C is not present, check t he

transformer, temperature contr oller, and

switches.

No gas ignition - sparking occurs

1. Rem ove the right side panel as outlined under

“COVERS AND PANELS”.

2. Pl ug in the unit and set the temperat ur e

controller to 350°.

3. Turn the power switch on.

4. Check for 24 VAC between the gas valve

terminal and the ground terminal. The voltage

should be present after

and during the 10 second i gnition period.

A. If 24 V A C is present, check the gas valve

and gas supply.

B. If 24 V A C is not present, replac e the spark

ignition control.

the 15 second purge

12

Page 13

HALF-SIZE GAS CONVECTION OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

ELECTRONIC CONTROL

SPECIAL KEY FUNCTIO NS

functions press the specifi ed k ey s whil e turning the

oven on. Y ou c an not toggle between functions.

Each function has to be entered from the off

position.

NOTE:

See diagram foll owi ng the table.

CALIBRATE OVEN

1. Pl ac e a thermocoupl e near the geometric

2. Cycle oven until the cavity temperature stabiliz-

3. Turn the oven off.

4. Enter the calibration mode.

There are f our hidden keys on the contr ol.

HOLD KEYS 1 & 3 4 & 9 6 & 8

FUNCTION Calibration Mode Change between (C & (F Display test

- Perfor m Calibration at 350(F

center of the oven cavity.

es. (usually 3 cycles)

- To activate these

5. Com par e the set temperat ur e to the measured

temperature.

6. Adj ust the temperat ur e on the display to match

the measured temperature.

7. Press key 3 to store the calibration information.

DISPLAY TEST

continuous test unt il the oven is turned off. Each

segment of the displays will be lit in sequence, each

LED in order and then eac h digit will light.

ERROR CODES

- The control will cycle through a

CODES CONDITIONS

E-01 High Limit Error - Check open probe.

E-02 Low Limit Error - check for 6 VAC from tr ansformer.

Check control pins 1-2 for 12 V A C & pins 2-3.

E-03 Control compartm ent ambient temperature is above 215(F

E-04 Control compartm ent ambient temperature is below 32(F

13

Page 14

HALF-SIZE GAS CONVECTION OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

SOLID STATE CONTROL

TEST

NOTE:

1. Rem ove the screws from the control panel and

2. Pl ac e a thermocoupl e in the geomet r ic center

3. Set the temperat ur e to the maximum setting.

4. Turn the power switch to ON.

Ov en temperature must be below 450(F.

pull the c ontrol panel away from the oven to

access the control wir ing.

of the oven cavity.

SOLID STATE CONTROL

CA LIBRATION

1. Pl ac e a thermocoupl e in the geomet r ic center

of the oven cavity.

2. Set the On-Off-Cool Down switch to ON.

3. Set the temperat ur e c ontrol to 350 degrees F.

4. Allow the oven to cycle until the oven

temperature stabilizes. (cycle at least three

times)

5. Record t he temperature at which the HEAT

LIGHT goes of f and on.

A. Check f or at least two com plete heating

cycles.

6. Calc ulate the differ ential by subtrac ting the

temperat ure indicat ed when the heat light

comes on from the temperature i ndicated when

the heat light goes out.

5. Check for supply voltage acr oss:

200-240 volts - pin 10 to pin 6

120 volts - pin 9 to pi n 6

A. If c orrect, proceed to step 7.

B. If incorrect, go to step 6.

6. Check for supply voltage acr oss:

200-240 volts - pin 7 to pin 10 and pin 8 to pi n

10

120 volt - pin 7 to pin 9 and pin 8 to pi n 9

A. If c orrect, proceed to step 7.

B. If incorrect, problem is not with the

temperat ure control. Return to Troubl eshooting Guide.

7. Turn the temperat ur e c ontrol to the minimum

setting.

NOTE:

8. Check for zero (O) Volts across:

Ov en temperature must be abov e 300(F.

200-240 volts - pin 6 to pin 10

120 volt - pin 6 to pin 9

A. If c orrect the problem is not wit h the

temperat ure control. Return to Troubl eshooting Guide.

Differenti al = Heat l ight OFF - Heat light ON.

Exam ple: 360 (light out) - 340 (light on) = 20( F

differential.

A. The differential calculated should be

less than 20 degrees F.

(1) If t he differential is more than 20

degrees F, check t emperature

probe and temperature control

board as outlined under

"TEMPERATURE PROBE

TEST" and " S OLID STATE

CONTROL TE S T".

7. Calc ulate the average tem per ature by adding

the temper ature indic ated when the heat light

goes out to the temperature indicated when the

heat light comes on and dividi ng this answer by

2.

[Temp.(light off) + Temp. ( light on)] ÷ 2 = Average

Temperature

Exam ple: (360 + 340) ÷ 2 = 700 ÷ 2 = 350( F

average temperature

B. If incorrect, replace the t emperature

control.

14

Page 15

HALF-SIZE GAS CONVECTION OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

8. If the average temper ature dif fers more t han 10

degrees F from the dial settings:

A. Pencil mark t he k nob pointer position as a

reference point on the control panel next

to the dial plate.

B. Remove the temperature control knob.

C. Loosen the two dial plate mounting screws

and the temper ature control mounting nut .

Loosen only enough to turn the dial pl ate.

DOOR SWITCH

ADJUSTMENT

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Rem ove the upper front cover as outlined

under "COVERS A ND P A NE LS " .

2. The door switc h ac tuator should be operated by

the switch lever when the door is about ½" from

being closed.

3. If adjustm ent is necessary, use the following

procedures.

A. Loosen the two switch mount ing screws.

B. Adjust t he switc h br ac k et to obtain t he

DISCONNECT THE ELECTRICAL

correct sett ing as outlined in step 2.

D. Rotate the dial plate until the temper ature

calculated in step 7 is in line with the

pencil mark.

E. If the above adjustment cannot be

obtained, chec k temperat ur e pr obe and

temperat ure control board as outlined

under "TEST ING TEMPERATURE

CONTROL BO A RD" .

C. Tighten the two switch bracket mounti ng

screws.

D. If the adjustment can not be obt ained by

moving the switch, you can bend the tab

of the actuator lever.

4. Install the upper front cover.

15

Page 16

HALF-SIZE GAS CONVECTION OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

DOOR REVERSAL

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Rem ove the door as outlined under “OVEN

DOOR”.

A. Remove the door strike plate from t he top

B. Rotate the door 180 °. The top of the door

C. Install the door strike on the new top of the

2. Rem ove the bot tom door bushing and antirotation plate.

DISCONNECT THE ELECTRICAL

of the door.

is now the bottom .

door. Use the screws removed to instal l

the strike plate to fill the holes on the

bottom of the door.

7. Rem ove the door switc h from the switch

mounti ng bracket.

A. Use the other set of holes in the mounting

bracket to mount the switch.

B. Place the switch insulation pad on the

mounti ng bracket.

3. Remove the knockout from the lower sill cover.

4. Install the plug button in the old door bushing

hole in the lower sill cover.

5. Install the bott om door bushing and anti rotation plate.

6. Rem ove the catch assembly from the oven.

A. Move the door catch to the opposite side

of the door c atch channel.

B. Install the door catch assembly to the

opposite side of the top sill.

C. Install the switch ont o the mounti ng

bracket.

8. Install the door i n the lower door bushing.

9. Install the top door bushi ng and door switch

mounti ng plate to the new position on the upper

sill.

10. Adjust the door as outlined under “DOOR

ADJUSTMENT”.

11. Adjust the door switc h as outlined under

“DOOR SWITCH ADJUSTMENT”.

12. Replace the t op front cover and check the oven

for proper operation.

16

Page 17

HALF-SIZE GAS CONVECTION OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

DOOR ADJUSTMENT

WARNING:

1. The door shoul d be par allel wit h the face of the

oven cavity.

2. If adjustm ent is needed:

A. Remove the top front cover as outlined

B. Loosen the screws that secure the door

UNPLUG UNIT BEFORE SERVICING.

under “COVERS AND PANELS” in

“REMOVAL AND REPLACEMENT OF

PARTS”.

support and move the door in the slot unti l

it is parallel wit h the face of the oven

cavity.

BLOWER ADJUSTMENT

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Rem ove rack and r ac k support s.

2. Rem ove baffle panel by lifting up and out.

3. Check t he blower. It should be ¼" away from

and parallel to the oven wall. If not, proceed to

step 4.

4. Rem ove the right side panel as outlined under

“COVERS AND PANELS”.

5. To adjust the blower at the sides (front and rear

of oven cavity), loosen the motor mounting

bolts and move the motor until the ¼" gap is

obtained.

6. To adjust the blower at the t op and bottom,

place shims between the motor mounting

bracket and the mounting base.

DISCONNECT THE ELECTRICAL

C. Tighten the screws and install the top front

cover.

7. Reverse the procedure to install.

HEATING ELEMENT TEST

Test each rod in the element assembly.

Values in the table are nominal (± 10%).

VOLTAGE WATTS AMPS RESISTANCE

208 2500 12 17.33

240 2500 10.4 23.1

17

Page 18

HALF-SIZE CONVECTION OVENS - ELECTRICAL OPERATION

ELECTRICAL OPERATION

COMPONENT FUNCTION

POWER SWITCH.............Controls power to oven.

COOLDOWN SWITCH ......... Prevents heaters from operating and allows fan to run. (On some sol id state

control models, this switch is combined with the power switch)

FAN SPEED SWITCH .......... Controls speed of oven cavity blower motor. ( E lectric ovens)

SOLID STATE CONTROL.......Controls oven temperature.

TIMER .....................Signals end of timed baking. Does not shut heater or bur ner off. (Solid state

control)

ELECTRONIC CONTROL.......Controls oven temperature, cook and hold mode, pulse mode and time.

BLOWER MOTOR ............Circulates air inside oven cavity. (Contains centrifugal switch for gas ovens)

(2 speed electric ovens)

DOOR SWITCH ..............Allows heating of oven, only when the doors are closed.

TEMPERATURE PROBE ....... Senses temperature of oven cavity for the solid state control and elect r onic

control.

SOLID STATE RELAY .........Controls power to blower motor. (Electronic Control)

TRANSFORMER..............Provides 12 and 6 VAC power. (E lectronic Control)

TRANSFORMER..............Provides 24 VAC power to the spark ignition control if the centrifugal switch

(part of blower motor) is closed. (Gas Ovens)

GAS VALVE ................. Allows gas to flow to burner. (Gas ovens)

SPARK MODULE .............Generates spark for burner ignit ion, monitors fl ame, controls 15 second

purge time and 10 second ignition time and power to gas valve. (Gas ovens)

POWER LIGHT............... Lit whenev er the power switch is ON. (Solid state contr ol)

HEAT LIGHT.................Lit whenever burner or heater s are operating. (Solid state cont r ol)

NO IGNITION LIGHT ..........Lit when sensor fails to detect flame. (Solid state control - Gas ov en)

CONTACTOR ................Powers heater elements. (E lectric ovens)

FUSE ..................... Protects control circuit. (Electric ovens)

18

Page 19

HALF-SIZE CONVECTION OVENS - ELECTRICAL OPERATION

COMPONENT LOCATION

19

Page 20

HALF-SIZE CONVECTION OVENS - ELECTRICAL OPERATION

SEQUENCE OF OPERATION

Ignition Module

1. 24VAC supplied to ignit ion module as described

under oven sequence of operation

A. 15 second prepurge period

1) No-i gnition light is on

2) Cavit y blower motor removes any

residual gas from combustion chamber

B. 10 second spark period

1) Gas valv e energized

2) No-i gnition light is off

2. The flam e is monitored by a DC voltage of at least 5

microamps passing from the ignitor probe through

the flame to ground.

A. If the flam e is detected before 10 seconds:

1) Sparki ng is terminated

2) G as val ve held open

3) Monit or ing of flam e conti nues

B. If a flame is not established after the 10

second spark period

1) a second 15 second prepurge period

2) A second 10 second spark period

C. If a f lame is not establis hed after the second

10 second spark period

1) a t hi r d 15 second prepurge period

2) A thi r d 10 second spark period

D. If a f lame is not establi shed aft er the thir d 10

second spark period, the module will go into

lock out

1) No ignition light on

Gas Oven

NOTE:

A combinati on of terminal numbers and wire

numbers will be used to describe the circuit paths. The

complete path will be described when a component is

energized.

Solid S t ate Control ( Gas)

NOTE:

Use GCO2D Schematic

1. Conditions

A. Supply voltage to unit

1) L1 t o power switch: wir e #1; J1-1; wire #1

2) L2 t o power switch: wir e #2; J1-2; wire #2

3) G ood chassi s gr ound f or :

a. Ignit ion module: GND

b. No ignit i on light: wire #48; GND;

wire #6; J1-6; wire #6; GND

c. Gas valve: wire #48; GND;

d. Ignit ion transformer: GND

B. Power switch off

C. Oven at room temperature

D. Temperatur e control off

E. Manual gas valve open

F. Door swit ch cl osed

G. Cooldown switch off

H. T imer of f

2. Power switch turned "on" (voltage at terminals of

power switch)

A. Power On lamp lights: wire #34/J1; wire

#41/37

B. Control powered: wire #34; wire #33/3; J1-3;

wire #3; door switch; wir e #27/4; J1- 4; wi r e

#4/36/35; terminal 8; terminal 9 (120 VAC) or

terminal 10 ( 200- 240 VAC); wi r e #39/37

C. Blower m ot or energized: wire #34; wire #33/3;

J1-3; wire #3; door switch; wi r e #27/4; J1- 4;

wire #4/11; J1-11; wire #11; wir e #13/7; J1- 7;

wire #7/37

1) Blower m otor reaches operating speed,

blower motor centrif ugal swi t ch closes

3. To reset the ignition module perform one of the

following

A. Turn power switch off; then on

B. Open and close the door

C. Turn t he temperatur e control all the way off

then back to the set temperature

4. If a f l ame is established then is extinguished before

the temperature control is sat i sf ied, the no ignition

light will be on and the ignition module will attempt

to light t he burner in the sequence described above.

3. Control set to cook t em perature, contacts 6/7 close

A. Ignition t r ansformer primary powered: terminal

6; wire #9; J1-9; wire #9; BK/BL wire; WH/BK

wire; wire #7; J1-7; wire #7/37

B. Heating lamp l i ght s: terminal 6; wire #43; wire

#42/37

4. 24 VAC from ignition tr ansf or mer secondary to

ignition module: transformer secondary wire #52;

centrifugal switch; wire #54; terminal 24V of control

module; GND

5. Ignit ion module operates (see ignition module

sequence of operation)

20

Page 21

HALF-SIZE CONVECTION OVENS - ELECTRICAL OPERATION

6. Temperature is sati sf ied and control contacts 6/7

open

A. Heat light goes out.

B. Power removed from ignit ion transformer.

7. Ignit ion module de-energized

A. Gas valve de-energized, gas supply to burner

off.

8. Oven cycles on solid state control unt il power switch

is moved from the "on" position or the door is

opened.

NOTE:

The blower motor, heat lamp and gas valve

are de-energized when the door is opened during

the heat mode.

Solid S t ate Timer (Gas)

NOTE:

Use GCO2D Schematic

NOTE:

The timer is not connected to the heating circui t

and will not prevent the oven from heating when time

expires.

1. Power switch on

2. Time dialed into tim er, cont act s 1/ 3 cl ose.

A. Timer motor energized: wire #34/64; tim er

contacts 1/3; wht wi r e; wire #37

3. Time expires.

A. Contacts 1/3 open

1) Timer motor de-energized

B. Contacts 1/4 close

4. Buzzer sounds: wire #34/64; timer contacts 1/4; wire

#66; wire #65/37

Electronic Control ( Gas)

NOTE:

Use GCO2C Schematic

NOTE:

A combinati on of terminal numbers and wire

numbers will be used to describe the circuit paths. The

complete path will be described when a component is

energized.

Heat

1. Conditions.

A. Supply voltage to unit.

1) L1 t o power/cool down swit ch: wi r e #1;

J1-1; wire #1

2) L2 t o:

a. Motor: wire #2; J1-2; wire #2; J1-7;

wire #7/13

b. Primary of ignit ion transformer: wire

#2; J1-2; wire #2; J1-7; wire #7

c. Primary of control transformer: wire

#2; J1-2; wire #2; J1-7; wir e #7/97

3) G ood chassi s gr ound: ignition module

transformer

a. Ignit ion module: GND

b. Electronic cont r ol : terminal 8 of

control; J2-8; J1-6; wire #6; GND

c. Gas valve: wire #48; GND

d. Ignit ion transformer: GND

B. Power/cooldown “off".

C. Oven at room temperature.

D. Door switch cl osed.

E. Manual gas valve open.

2. Power/cooldown switch turned "on"

A. Control transf or mer primar y powered: wire

#26/4; J1-4; wir e #4/94; wi r e #97/7; J1- 7; wire

#2; J1-2; wire #2; L2

5. Timer turned to off.

A. Contacts 1/4 open

1) buzzer de-energized

Cooldown (Gas/Solid State Control)

NOTE:

Use GCO2D Schematic

1. Conditions

A. Oven tem perature needs to b e lowered.

B. Power swit c h o n

2. Cooldown switch on

A. Blower motor energized: power switch; wire

#34/33/36/11; J1-11; wire #11; wire #13/7; J17; wire #7/37; power switch

3. Control powered from secondary of cont r ol

transformer:

A. 6 VAC - wire #16; J1-16; J2-3; J2-2; J1- 15;

wire #15

B. 12 VAC - wire #14; J1-14; J2-1; J2-2; J1- 15;

wire #15

4. Control set to desired temperatur e

A. Control verifi es heat mode: 16 to 18 VDC

output on J2-11; J1-20; wi r e #20/21;

power/cooldown switch; contacts of swi t ch ar e

open and no return voltage to J2-5

B. Control verifies that door i s closed: 16 to 18

VDC output on J2-11; J1-20; wir e #20/27; door

switch; wire #3; J1-3; J2-4

21

Page 22

HALF-SIZE CONVECTION OVENS - ELECTRICAL OPERATION

5. After verification of heat mode and door closed:

A. Ignition t r ansformer primary powered: wire

#26/43; J2-13; J2-15; J1- 5; wi r e #5; BK/BL

wire; WH/BK wire; wire #7; J1-7; wire #2; J12; W i r e #2; L2

1) 24 VAC from secondary of igniti on

transformer to ignition module: wire #52;

centrifugal switch; wi r e #54; terminal 24V

of control module; GND

B. Solid state relay energized: 16 to 18 VDC

output on J2-11; J1-20; wi r e #20; wir e #19;

J1-19; J2-10

1) Blower motor energized: wire #26/4; J1-4;

wire #4/34; ss relay contacts; wir e #9; J19; wire #11; J1-11; wir e #11; wire #13/7;

J1-7; wire #2; J1-2; Wire #2; L2

a. Blower motor r eaches operating

speed, blower motor centrifugal

switch closes

6. Ignit ion module operates (see ignition module

sequence of operation)

7. Oven cycles on electronic control until

power/cooldown switch is m oved from the "on"

position, a di f ferent mode is selected or the door is

opened.

NOTE:

The blower motor is de-energized and gas

valve closed when the door is opened while the oven

is in the heat mode.

Cook and Hold

1. Conditions

A. Oven in prehea t.

2. A bake temperature and tim e is set.

3. A hold temperatur e and time is set and start key

pressed.

4. Oven cycles at set temperature.

NOTE:

In pulse mode (init iated at the beginning of the

bake cycle), the blower motor is operated in 45 second

cycles, with the first cycl e being off then 45 seconds on.

The pulse time cannot be longer than the bake time.

5. Time expires in cook mode.

A. Buzzer sounds (short beep).

B. Control lowers temperatur e to hol d

temperature.

6. Oven temperature reaches hold temperature.

A. Display counts up time and flashes "hold"

7. Oven continues to cycle at hold t emperatur e unti l

oven is turned off or the hold function is turned off.

NOTE:

The blower motor and gas valve are deenergized when the door is opened while the oven is

in the hold mode.

Cook

1. Conditions

A. Oven in prehea t.

2. Temperature is set.

3. Time is set and start key pressed.

4. Oven cycles at set temperature.

NOTE:

In pulse mode (init iated at the beginning of

the bake cycle), the blower motor is operated in 45

second cycles, with the first cycle being off then 45

seconds on. The pulse time cannot be longer than

the bake time.

5. Time expires.

A. Buzzer sounds continuall y unt il turned off.

6. Oven continues to cycle at set temperature.

NOTE:

The blower motor and gas valve are deenergized when the door is opened while the oven is

in the cook mode.

Cooldown (Gas/Electronic Control)

NOTE:

Use GCO2C Schematic

1. Conditions

A. Cooking completed, oven temperature needs

to be lowered.

B. Power/cooldown switch on

2. Power/cooldown switch to cool down

A. Control transf or mer primar y powered: wire

#26/4; J1-4; wir e #4/94; wi r e #97/7; J1- 7; wire

#2; J1-2; wire #2; L2

3. Control powered from secondary of cont r ol

transformer:

A. 6 VAC - wire #16; J1-16; J2-3; J2-2; J1- 15;

wire #15

B. 12 VAC - wire #14; J1-14; J2-1; J2-2; J1- 15;

wire #15

4. Control verifies cooldown mode: 16 to 18 VDC

output on J2-11; J1-20; wi r e #20/21;

power/cooldown switch; wire #29; J2-5

22

Page 23

HALF-SIZE CONVECTION OVENS - ELECTRICAL OPERATION

5. After verification of cooldown m ode:

A. Solid state relay energized: 16 to 18 VDC

output on J2-11; J1-20; wi r e #20; wir e #19;

J1-19; J2-10

1) Blower motor energized: wire #26/4; J14; wire #4/34; ss relay contacts; ; wi r e # 9;

J1-9; wire #11; J1-11; wir e #11; wir e

#13/7; J1-7; wir e #2; J1-2; wi r e #2; L2

B. Contactor coil will not be energized.

C. The door position signal is not r ead.

Electric Oven

NOTE:

A combinati on of terminal numbers and wire

numbers will be used to describe the circuit paths. The

complete path will be described when a component is

energized.

Solid State Control (Elec)

NOTE:

Use ECO2D Schematic

1. Conditions.

A. Fuses are good.

B. Supply voltage to unit ( t hr ee phase)

B. Control powered: wire #34; wire #33/3; J1-3;

wire #3; door switch; wir e #27/4; J1- 4; wi r e

#4/36/35; terminal 8 and 7; terminal 9 (120

VAC) or terminal 10 ( 200- 240 VAC); wi r e

#39/37

C. Blower m ot or energized: wire #34; wire #33/3;

J1-3; wire #3; door switch; wi r e #27/4; J1- 4;

wire #4; motor speed switch; wir e #11 high or

12 low ); J1-(11 hi gh or 12 low); wire #(11 high

or 12 low); wire #13/7; J1- 7; wi r e #7/37

3. Control set to cook t em perature contacts 6/ 7 cl ose

A. Contactor coil energized: terminal 6; wire

#9; J1-9; wire #9/50; wi r e #52/7; J1- 7;

wire #7/37

B. Heating lamp l i ght s: terminal 6; wire #43;

wire #42/37

4. Heating elements energized

A. L1; wire #61; C1; Wire #70; wire #75; C3; Wire

#64; L3

B. L1; wire #61; C1; Wire #74; wire #71; C2; Wire

#62; L2

5. Oven reaches set temperature and control contacts

6/7 open

1) L1 to power switch: wire #1; J1-1; fuse;

wire #1A and one side of heater contacts

C1: wir e #61

2) L2 t o one side of heater contacts C2: wire

#62

3) L3 to power switch: wire #2; J1-2; fuse;

wire #2A and one side of heater contacts

C31: wire #64

4) G ood chassi s gr ound

C. Po wer s witch "of f"

D. Oven at room temperature

E. Solid state control of f

F. Door swit ch cl osed

G. Fan speed switch in either position

H. Cooldown switch off

J. Timer off

2. Power switch turned "on" (voltage at terminals of

power switch)

A. Power removed from contactor coi l

1) Heating elements de-energized

B. Heating lamp goes out.

6. Oven cycles on solid state control unt il power switch

is moved from the "on" position or the door is

opened.

NOTE:

The blower motor and heating elements are

de-energized when the door is opened and the oven

is in the heat mode.

Solid S t ate Timer (E lec)

NOTE:

Use ECO2D Schematic

NOTE:

The timer is not connected to the heating circui t

and will not prevent the oven from heating when time

expires.

1. Power switch on

2. Time dialed into tim er, cont act s 1/ 3 cl ose.

A. Timer motor energized: wire #34/64; tim er

contacts 1/3; wht wi r e; wire #37

3. Time expires.

A. Power On lamp lights: wire #34/J1; wire

#41/37

A. Contacts 1/3 open

1) Timer motor de-energized

B. Contacts 1/4 close

23

Page 24

HALF-SIZE CONVECTION OVENS - ELECTRICAL OPERATION

4. Buzzer sounds: wire #34/64; timer contacts 1/4; wire

#66; wire #65/37

5. Timer turned to off.

A. Contacts 1/4 open

1) buzzer de-energized

Cooldown (Elec/Solid State Control)

NOTE:

Use ECO2D Schematic

1. Conditions

A. Cooking completed, oven temperature needs

to be lowered.

B. Power swit c h o n

2. Cooldown switch on

A. Blower motor energized: power switch; wire

#34/33/36/ m ot or speed switch; wir e #11 high

or 12 low ); J1-( 11 hi gh or 12 low); wire #(11

high or 12 low); wi r e #13/7; J1- 7; wire #7/37;

power switch

Electronic Control ( E lec)

C. Power/cooldown switch "off "

D. Oven at room temperature

E. Door switch closed

F. Fan speed switch in either position

2. Power/cooldown switch turned "on"

A. Control transf or mer primar y powered: wire

#26/4; J1-4; wir e #4/94; wi r e #97/7; J1- 7; wire

#7/2A; fuse; J1-2; wire #2; L3

3. Control powered from secondary of cont r ol

transformer:

A. 6 VAC - wire #16; J1-16; J2-3; J2-2; J1- 15;

wire #15

B. 12 VAC - wire #14; J1-14; J2-1; J2-2; J1- 15;

wire #15

4. Control set to desired temperatur e

A. Control verifi es heat mode: 16 to 18 VDC

output on J2-11; J1-20; wi r e #20/21; J1-21;

power/cooldown switch; contacts of swi t ch ar e

open and no return voltage to J2-5

B. Control verifies that door i s closed: 16 to 18

VDC output on J2-11; J1-20; wir e #20/27; door

switch; wire #3; J1-3; J2-4

NOTE:

Use ECO2C Schematic

NOTE:

A combinati on of terminal numbers and wire

numbers will be used to describe the circuit paths. The

complete path will be described when a component is

energized.

Heat

1. Conditions

A. Fuses are good.

B. Supply voltage to unit ( t hr ee phase)

1) L1 t o power/cool down swit ch: wi r e #1;

J1-1; fuse; wire #1A/1 and one side of

heater contacts C1: wire #61

2) L2 t o one side of heater contacts C2: wire

#62

3) L3 t o:

a. Motor: wire #2; J1-2; fuse; wire

#2A/7; J1-7; wire #7/13

b. Contactor coi l : wi r e #2; J1-2; f use;

wire #2A/7; J1-7; wire #7/50

c. Primary of control transformer: wire

#2; J1-2; fuse; wire #2A/7; J1-7;

wire #7/97

d. one side of heater contacts C3: wire

#64

4) G ood chassi s gr ound electroni c cont r ol :

terminal 8 of control; J2-8; J1- 6; wi r e #6;

GND

5. After verification of heat mode and door closed,

A. Solid state relay energized: 16 to 18 VDC

output on J2-11; J1-20; wi r e #20; wir e #19;

J1-19; J2-10

1) Blower motor energized: wire #26/4; J14; wire #4/34; ss relay contacts; ; wir e #

(11 high or 12 low ); J1- ( 11 high or 12

low); wire #(11 high or 12 l ow) ; wi r e

#13/7; J1-7; wir e #7/37

B. Contactor coil energized: wire #43; J2-13; J2-

15; J1-5; wire #5; wire #50/7; J1- 7; wi r e

#7/2A; fuse; J1-2; Wire #2; L3

1) Heating el ements energized

a. L1; wire #61; C1; Wire #70; wir e

#75; C3; W ire #64; L3

b. L1; wire #61; C1; Wire #74; wir e

#71; C2; W ire #62; L2

6. Oven reaches set temperature

A. Power removed from contactor coi l

1) Heating elements de-energized

7. Oven cycles on electronic control until

power/cooldown switch is m oved from the "on"

position or t he door is opened.

NOTE:

The blower motor and heating elements are

de-energized when the door is opened and the oven

is in the heat mode.

24

Page 25

HALF-SIZE CONVECTION OVENS - ELECTRICAL OPERATION

Cook

1. Conditions

A. Oven has reached set temperature in heat

mode

2. Time is set and start key pressed.

3. Oven cycles at set temperature.

NOTE:

In pulse mode (init iated at the beginning of

the bake cycle), the blower motor is operated in 45

second cycles, with the first cycle being off then 45

seconds on. The pulse time cannot be longer than

the bake time.

4. Time expires.

A. Buzzer sounds continuall y .

5. Oven continues to cycle at set temperature.

NOTE:

The blower motor and heaters are deenergized when the door is opened and the oven is

in the cook mode.

Cook and Hold

1. Conditions

A. Oven has reached set temperature in heat

mode

2. A bake temperature and tim e is set.

3. A hold temperatur e and time is set and start key

pressed.

4. Oven cycles at set temperature.

NOTE:

In pulse mode (init iated at the beginning of

the bake cycle), the blower motor is operated in 45

second cycles, with the first cycle being off then 45

seconds on. The pulse time cannot be longer than

the bake time.

Cooldown (Elec/Electronic Control)

NOTE:

Use ECO2C Schematic

1. Conditions

A. Cooking completed, oven temperature needs

to be lowered.

B. Power/cooldown switch on

2. Power/cooldown switch to cool down

A. Control transf or mer primar y powered: wire

#26/4; J1-4; wir e #4/94; wi r e #97/7; J1- 7; wire

#7/2A; fuse; J1-2; wire #2; L3

3. Control powered

A. 6 VAC from secondary of control transformer -

wire #16; J1-16; J2-3; J2-2; J1-15; wire #15

B. 12 VAC from secondary of control transformer

- wire #14; J1-14; J2-1; J2- 2; J1-15; wire #15

4. Control verifies cooldown mode: 16 to 18 VDC

output on J2-11; J1-20; wi r e #20/21;

power/cooldown switch; wire #29; J2-5

5. After verification of cooldown m ode:

A. Solid state relay energized: 16 to 18 VDC

output on J2-11; J1-20; wi r e #20; wir e #19;

J1-19; J2-10

1) Blower motor energized: wire #26/4; J14; wire #4/34; ss relay contacts; ; wir e #

(11 high or 12 low ); J1- ( 11 high or 12

low); wire #(11 high or 12 l ow) ; wi r e

#13/7; J1-7; wir e #7/37

B. Contactor coil will not be energized.

C. The door position signal is not r ead.

5. Time expires in cook mode.

A. Buzzer sounds (short beep).

B. Control lowers temperatur e to hol d

temperature.

6. Oven temperature reaches hold temperature.

A. Display counts up time and flashes "hold"

7. Oven continues to cycle at hold t emperatur e unti l

oven is turned off or the hold function is turned off.

NOTE:

The blower motor and heating elements are

de-energized when the door is opened and the oven

is in the hold mode.

25

Page 26

HALF-SIZE CONVECTION OVENS - ELECTRICAL OPERATION

SCHEMATICS GAS OVENS

GCO2D

26

Page 27

GCO2C

HALF-SIZE CONVECTION OVENS - ELECTRICAL OPERATION

27

Page 28

HALF-SIZE CONVECTION OVENS - ELECTRICAL OPERATION

WIRING DIAGRAM - GAS

OVENS

GCO2D - Control Section

28

Page 29

HALF-SIZE CONVECTION OVENS - ELECTRICAL OPERATION

GCO2D - Oven Section

29

Page 30

HALF-SIZE CONVECTION OVENS - ELECTRICAL OPERATION

GCO2C - Control Section

30

Page 31

HALF-SIZE CONVECTION OVENS - ELECTRICAL OPERATION

GCO2C - Oven Section

31

Page 32

HALF-SIZE CONVECTION OVENS - ELECTRICAL OPERATION

SCHEMATIC-ELECTRIC OVENS

ECO2D

32

Page 33

ECO2C

HALF-SIZE CONVECTION OVENS - ELECTRICAL OPERATION

33

Page 34

HALF-SIZE CONVECTION OVENS - ELECTRICAL OPERATION

WIRING DIAGRAM ELECTRIC OVENS

ECO2D - Control Section

34

Page 35

HALF-SIZE CONVECTION OVENS - ELECTRICAL OPERATION

ECO2D - Oven Section

35

Page 36

HALF-SIZE CONVECTION OVENS - ELECTRICAL OPERATION

ECO2C - Control Section

36

Page 37

HALF-SIZE CONVECTION OVENS - ELECTRICAL OPERATION

ECO2C - Oven Section

37

Page 38

HALF-SIZE CONVECTION OVENS - ELECTRICAL OPERATION

TROUBLESHOOTING

ELECTRIC OVENS

SYMPTOM POSSIBLE CAUSES

No power to oven controls. 1. Mai n br eak er open.

2. Control circuit fuses open.

3. 12/6 volt transform er inoperative. (Electronic

control)

No oven operation; power to cont r ols. 1. Door switch open.

2. Temp. control malfunction.

Blower mot or oper ates when oven is heating, but not

in cooldown.

Blower mot or does not oper ate, ov en heats. 1. Door switch open or inoperative.

Ov en is slow to heat or not hot enough. 1. Incor r ec t line voltage.

Ov en temperature is too hot. 1. Thermostat or contr ol not calibrated.

No heat; blower motor operates. 1. Thermostat or contr ol inoperative.

1. Cooldown switch i noper ative (solid state

control).

2. Speed selection switch malfunct ion.

3. Bl ower motor inoperat ive.

4. Sol id state relay malfunction. ( E lectronic

Control)

5. El ec tronic contr ol inoperative. ( E lectroni c

Control)

2. One phase of 3 phase out.

3. Thermostat or contr ol malfuncti on.

4. Bl ower motor inoperat ive.

5. Contactor malfuncti on.

6. Temperature probe malfunc tion.

2. Thermostat or contr ol malfuncti on.

3. Contactor inoperative.

2. Contactor malfuncti on.

3. Heaters open.

Electronic control does not functi on. 1. See "ELECT RONIC CONTROL" in "SERVI CE

PROCEDURES AND ADJUSTMENTS".

Door does not seal or will not shut properly. 1. Doors out of adjustment.

2. Door seals inoper ative.

3. Door cat c h malfunction.

38

Page 39

HALF-SIZ E CONVECTION OVENS - TROUBLESHOOTING

GAS OVENS

SYMPTOM POSSIBLE CAUSES

No power to oven controls. 1. Unit unplugged

2. Power switch inoper ative.

3. 12/6 volt transform er inoperative. (Electronic

control)

No oven operation; power to cont r ols. 1. Door switch open or inoperative.

2. Sol id state relay malfunction. ( E lectronic

control)

3. Bl ower motor malfunction.

4. El ec tronic contr ol malfuncti on.

Gas does not ignit e; no spark. 1. 24 volt t r ansformer not functi oning.

2. Spark igniti on c ontrol inoperative or not

grounded.

3. Sol id state control or probe mal functi on.

4. El ec tronic contr ol or probe inoperat ive.

5. Centrifugal switc h in blower motor inoperati ve.

Ov en is slow to heat or not hot enough. 1. Gas pressure not correc t.

2. Control malfuncti on.(solid state or electronic )

4. Probe inoperative.

5. Bl ower motor malfunction.

6. Check orifi c e.

Gas ignites, but will not maintain flame. 1. Insufficient gas pressure.

2. Flame sensor not positi oned in fl ame.

3. Spark igniti on c ontrol malfunct ion.

4. Check orifi c e.

Sparks but does not ignite. 1. Manual gas valve off.

2. Gas valve mal functi on.

3. Spark igniti on c ontrol inoperative.

Electronic control does not functi on. 1. See "ELECT RONIC CONTROL" in "SERVI CE

PROCEDURES AND ADJUSTMENTS".

Door does not seal or will not shut properly. 1. Doors out of adjustment.

2. Door seals inoper ative.

3. Door l atch malfuncti on.

39

Page 40

Form 24575 ( 12/96) Printed in U.S.A.

Loading...

Loading...