Page 1

SERVICE MANUAL

ELECTRIC RESTAURANT

RANGES

E36LC SERIES

E36SLC MODEL SHOWN

- NOTICE This Manual is prepared for the use of trained Vulcan Service

Technicians and should not be used by those not properly qualified.

If you have attended a Vulcan Service School for this product, you

may be qualified to perform all the procedures described in this

manual.

This manual is not intended to be all encompassing. If you have not

attended a Vulcan Service School for this product, you should read,

in its entirety, the repair procedure you wish to perform to

determine if you have the necessary tools, instruments and skills

required to perform the procedure. Procedures for which you do not

have the necessary tools, instruments and skills should be

performed by a trained Vulcan Service Technician.

ML-136624

Reproduction or other use of this Manual, without the express

written consent of Vulcan, is prohibited.

For additional information on Vulcan-Hart Company or to locate an authorized parts

and service provider in your area, visit our website at www.vulcanhart.com.

A product of VULCAN-HART Louisville, KY 40201-0696

Form 25297 (July 2008)

Page 2

E36LC SERIES ELECTRIC RESTAURANT RANGES

TABLE OF CONTENTS

GENERAL ................................................................................3

Introduction ............................................................................ 3

Installation ............................................................................ 3

Operation ............................................................................. 3

Cleaning .............................................................................. 3

Tools................................................................................. 3

Specifications .......................................................................... 3

REMOVAL AND REPLACEMENT OF PARTS .................................................... 4

Covers and Panels ...................................................................... 4

Range Tops ........................................................................... 4

Blower Wheel .......................................................................... 5

Blower Motor .......................................................................... 6

Door ................................................................................. 6

Door Mechanism Components ............................................................. 7

Door Switch ........................................................................... 8

Oven Heating Element ................................................................... 8

French Plate ........................................................................... 9

Hot Top.............................................................................. 10

Griddle Heating Element ................................................................ 11

Oven Thermostat ...................................................................... 12

Griddle and Hot Top Thermostats ......................................................... 13

Infinite Switch ......................................................................... 14

Rocker Switch......................................................................... 14

Indicator Lights ........................................................................ 15

Motor Contactor (480V Only) ............................................................. 15

SERVICE PROCEDURES AND ADJUSTMENTS................................................. 16

Oven Thermostat Calibration ............................................................. 16

Griddle Thermostat Calibration............................................................ 17

Hot Top Thermostat Calibration ........................................................... 17

3 Heat Switch Test (480V) ............................................................... 18

Infinite Switch Test (208, 240V) ........................................................... 18

Door Adjustment....................................................................... 18

Heating Element Test ................................................................... 19

ELECTRICAL OPERATION .................................................................. 20

Component Function ................................................................... 20

Oven Sequence of Operation ............................................................. 21

Wiring Diagrams ....................................................................... 22

TROUBLESHOOTING ...................................................................... 28

© VULCAN 2008

F25297 (July 2008) Page 2 of 28

Page 3

E36LC SERIES ELECTRIC RESTAURANT RANGES - GENERAL

GENERAL

INTRODUCTION

This manual is for the Vulcan Restaurant Series

Electric Range equipped with convection oven.

Procedures in this manual will apply to all models

unless specified. Pictures and illustrations will be of

model E36SLC unless otherwise noted.

All of the information, illustrations and specifications

contained in this manual are based on the latest

product information available at the time of printing.

INSTALLATION

Refer to the Instruction Manual for detailed

installation instructions.

OPERATION

Refer to the Instruction Manual for specific operating

instructions.

SPECIFICATIONS

CLEANING

Refer to the Instruction Manual for specific cleaning

instructions.

TOOLS

Standard

• Standard set of hand tools.

• VOM with A.C. current tester (Any quality VOM

with a sensitivity of at least 20,000 ohms per

volt can be used).

Special

• Temperature tester (thermocouple type) with

surface mount probe.

• Clamp on amp meter.

• Wheel puller, for blower wheel removal.

• Sealant, for thermostat calibration screw.

Model

No.

E36LC

E36SLC

E36FLC

E36XLC

AVAILABLE VOLTAGES - 208 OR 240 VOLT - 1 OR 3-PHASE, 480 VOLT - 3-PHASE

Nominal AMPS Per Line Wire

3-Phase

1-Phase

208V 240V 480V

X Y Z X Y Z X Y Z 208V 240V 480V

38.3 50.0 54.9 33.2 43.3 47.6 16.5 21.6 23.7 82.6 71.6 N/A

38.3 47.5 52.4 33.2 41.1 45.4 16.5 20.8 22.6 79.7 69.1 N/A

38.3 45.0 49.9 33.2 39.0 43.3 16.5 19.7 21.5 76.9 66.6 N/A

35.8 42.5 49.9 31.0 36.8 43.3 N/A N/A N/A 74.0 64.1 N/A

F25297 (July 2008)Page 3 of 28

Page 4

E36LC SERIES ELECTRIC RESTAURANT RANGES - REMOVAL AND REPLACEMENT OF PARTS

REMOVAL AND REPLACEMENT OF PARTS

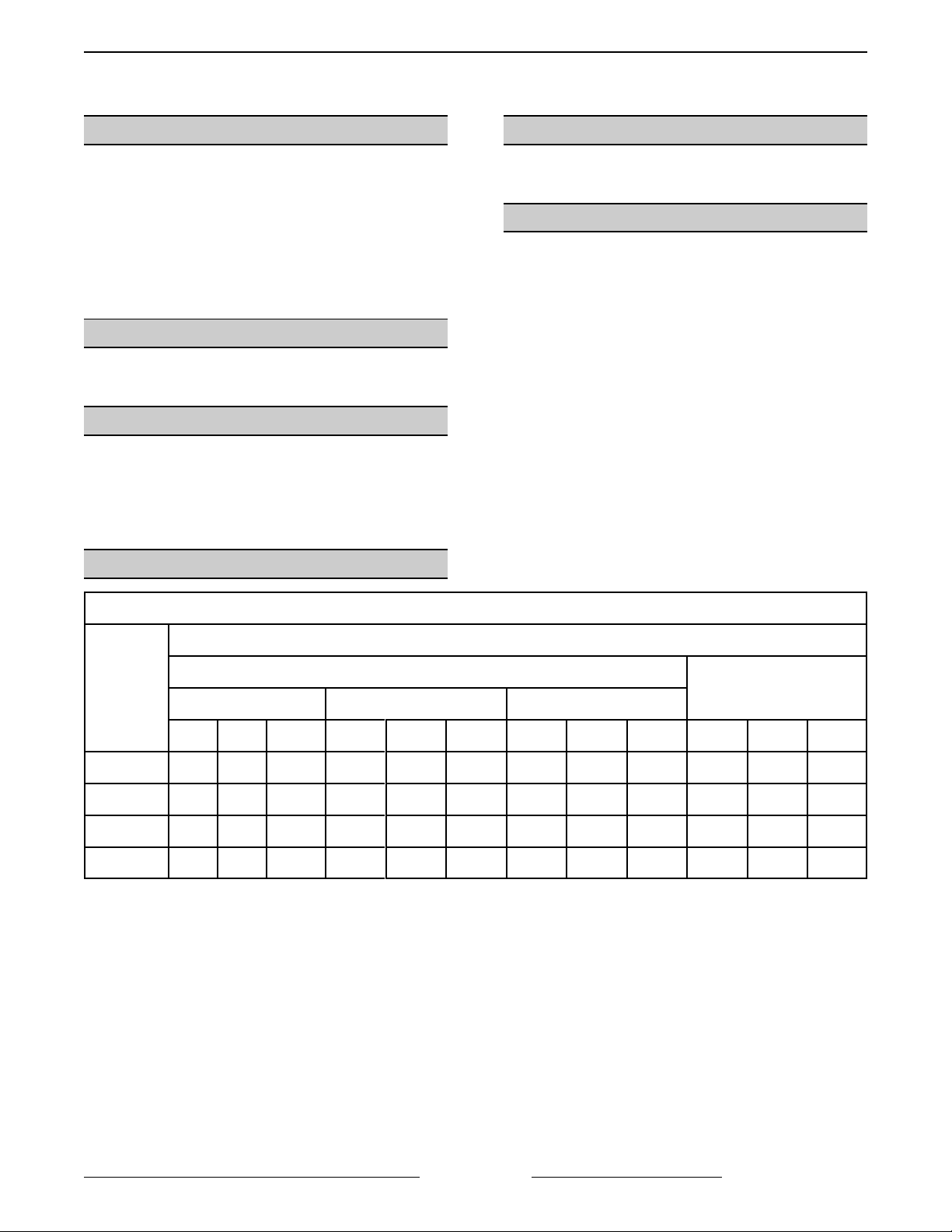

COVERS AND PANELS

Control Panel

1. Pull out or remove crumb tray.

2. Remove screws in top corners of control panel.

NOTE: Control panel is hinged and will open down.

RANGE TOPS

1. Remove screws securing backsplash to frame.

3. Reverse procedure to install.

Kick Panel

1. Open kick panel by lifting, pulling out and

rotating down.

2. Apply outward pressure on one of the ends to

remove.

3. Reverse procedure to install.

2. Lift off backsplash.

3. Open control panel as outlined under COVERS

AND PANELS.

4. Remove retaining screw securing range top

mounting bracket.

F25297 (July 2008) Page 4 of 28

Page 5

E36LC SERIES ELECTRIC RESTAURANT RANGES - REMOVAL AND REPLACEMENT OF PARTS

4. Pull blower into oven cavity.

5. Lift the range top being removed.

6. Disconnect the electrical connections.

7. Reverse procedure to install.

8. Check range for proper operation.

5. Remove two set scews from blower wheel hub.

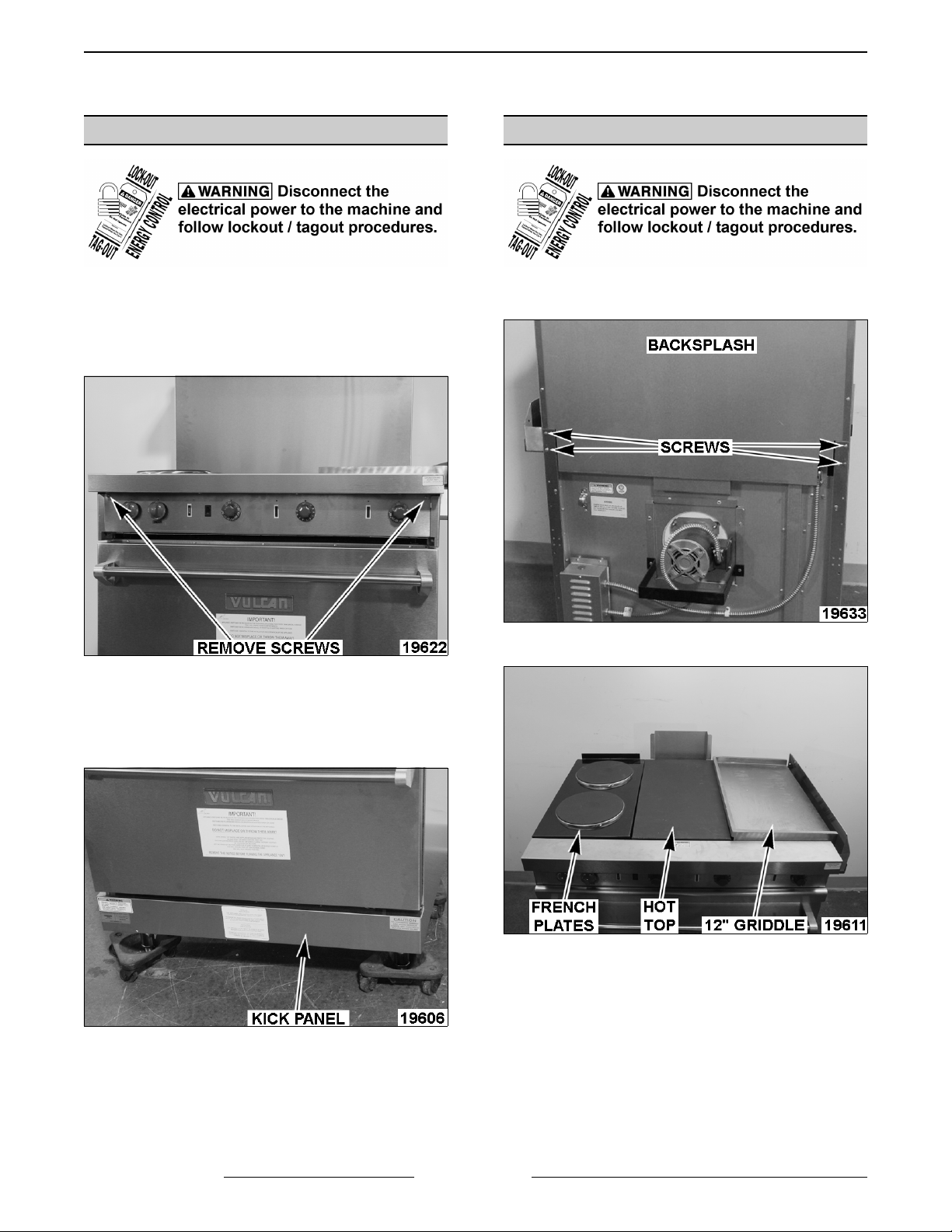

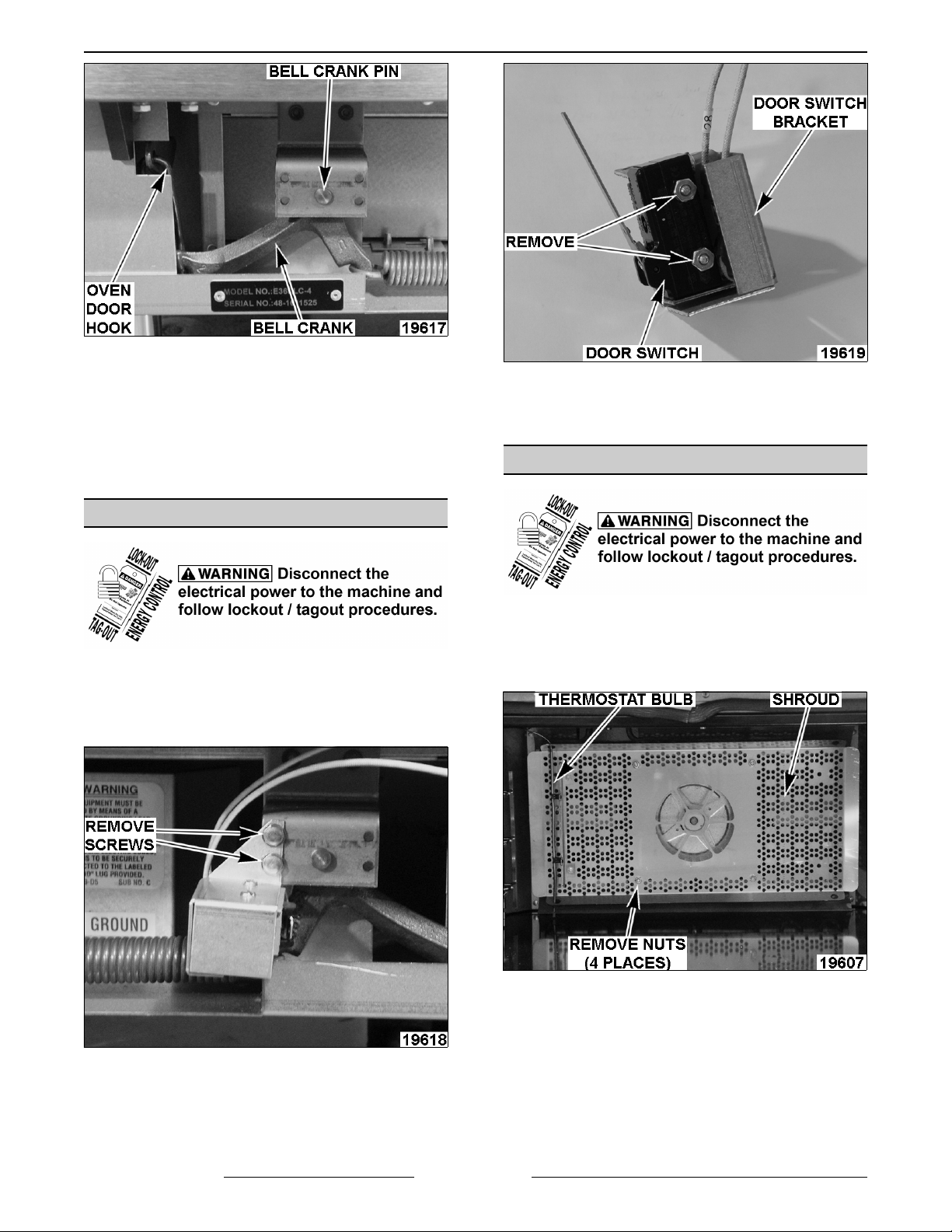

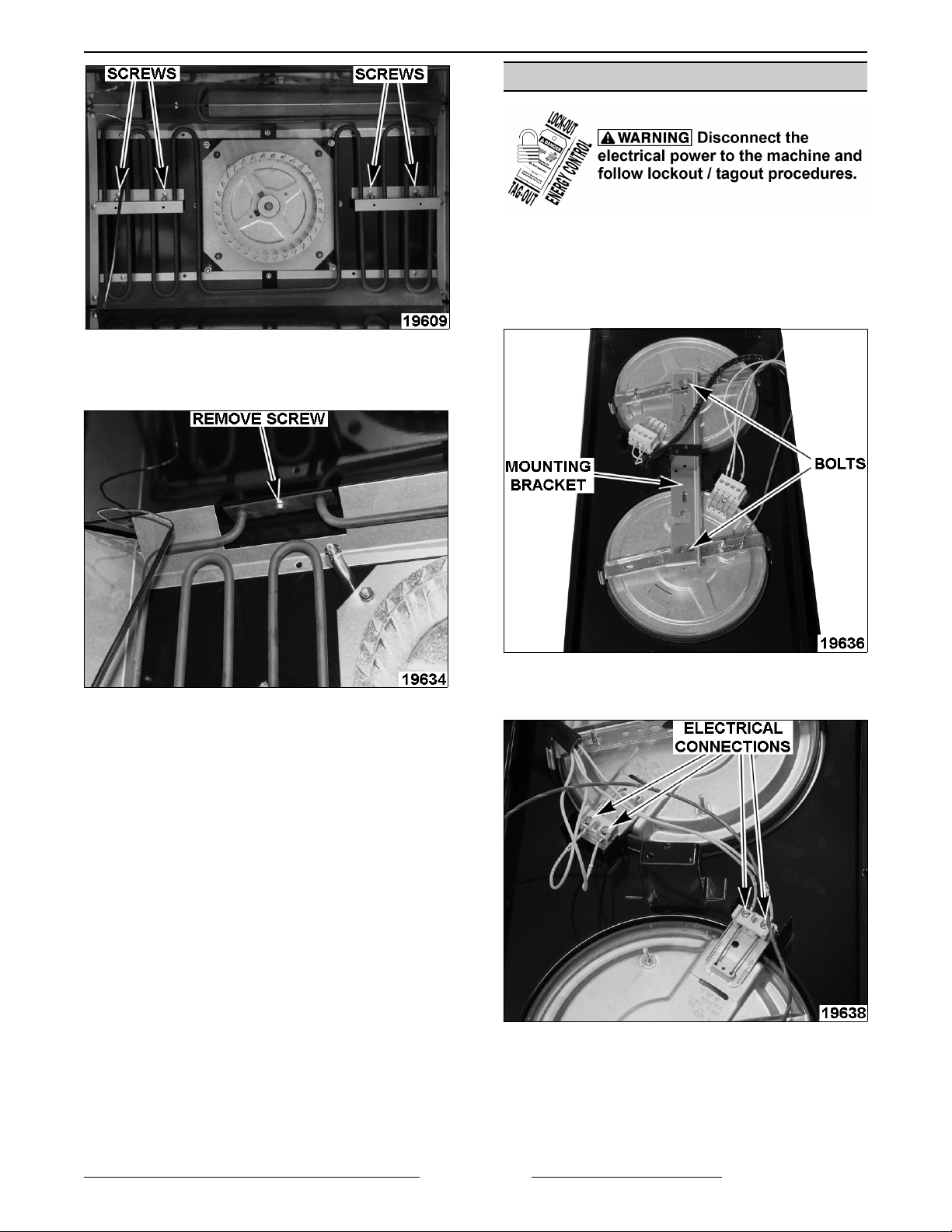

BLOWER WHEEL

1. Remove oven racks.

2. Remove thermostat bulb from heating element

shroud; remove nuts and shroud.

3. Remove four nuts securing blower motor to

mounting bolts.

6. Remove blower wheel.

NOTE: A wheel puller may be necessary to remove

blower wheel from motor shaft.

7. Reverse procedure to install.

8. Check range for proper operation.

F25297 (July 2008)Page 5 of 28

Page 6

E36LC SERIES ELECTRIC RESTAURANT RANGES - REMOVAL AND REPLACEMENT OF PARTS

BLOWER MOTOR

1. Remove blower wheel as outlined under

BLOWER WHEEL.

2. Remove nuts securing mounting plate to motor.

3. Loosen nuts while holding "J" hooks from

rotating.

NOTE: One nut will be right hand threaded and the

other will be left hand threaded.

3. Remove mounting plate from motor.

4. Disconnect lead wires from motor.

5. Reverse procedure to install.

6. Check range for proper operation.

DOOR

Removal

1. Remove kick panel as outlined under COVERS

AND PANELS.

2. Pinch a rag in the door to prevent the door from

falling open during procedure.

4. Rotate turnbuckle to relieve most of the spring

tension.

5. Pry up left bell crank and remove oven door

hook.

6. Repeat with right bell crank.

F25297 (July 2008) Page 6 of 28

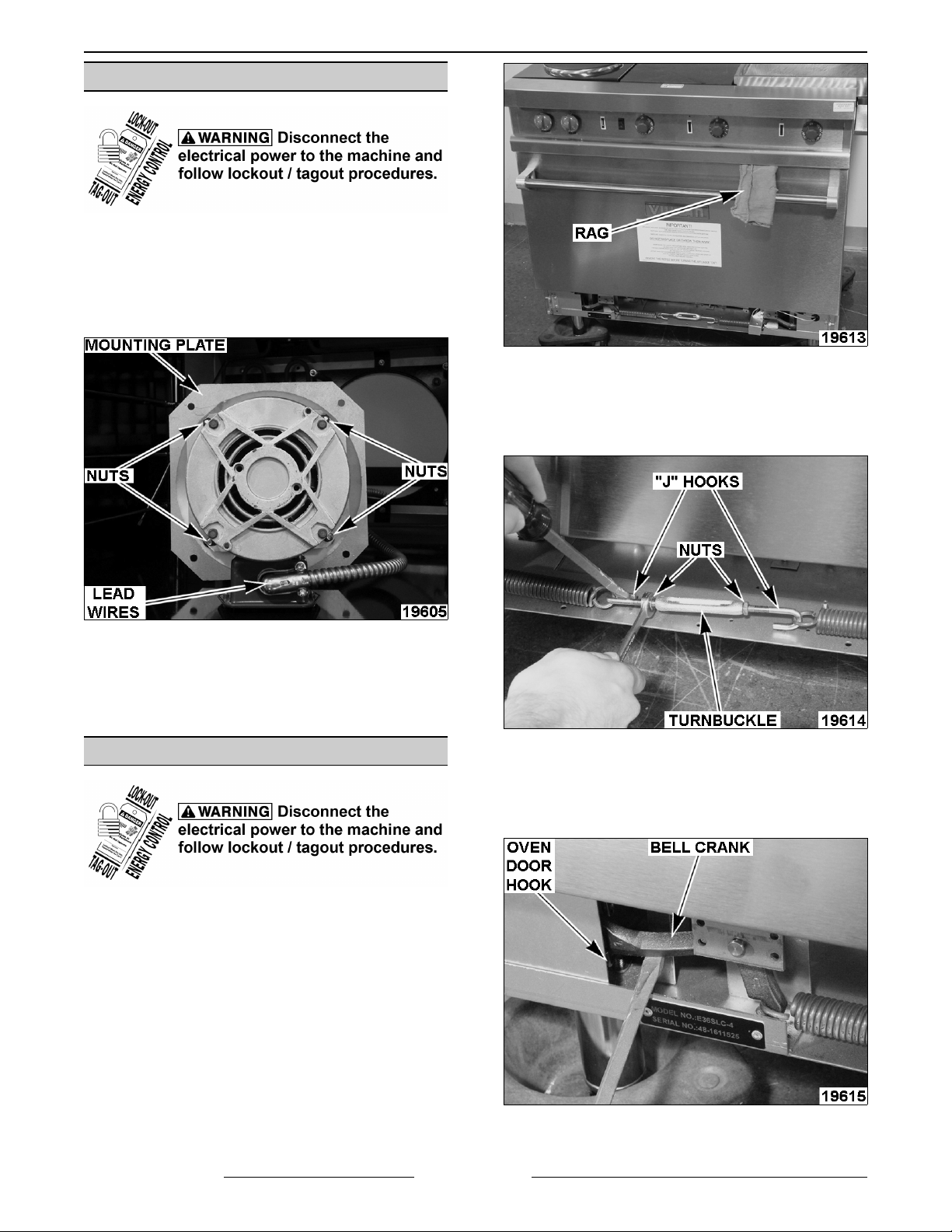

Page 7

E36LC SERIES ELECTRIC RESTAURANT RANGES - REMOVAL AND REPLACEMENT OF PARTS

7. Remove inside door bolts.

8. Loosen outside door screws, then slide to inside

of door slot to disengage pins from door

mounts.

9. Open door partly and remove.

Installation

1. Reverse removal procedure to install.

NOTE: Make sure that pins inside door engage

holes in door mounts.

DOOR MECHANISM

COMPONENTS

1. Remove kick panel as outlined under COVERS

AND PANELS.

2. Pinch a rag in the door to prevent the door from

falling open during procedure.

NOTE: Red oven door hook goes on the right side

and blue hook on the left.

2. Rotate turnbuckle to tension springs until door

closes on its own when held open 5 inches.

Door should bounce once or not at all.

3. Check range for proper operation.

3. Loosen nuts while holding "J" hooks from

rotating.

NOTE: One nut will be right hand threaded and the

other will be left hand threaded.

4. Rotate turnbuckle to relieve most of the spring

tension.

5. Remove springs, turnbuckle assembly, and

door hooks.

6. Remove cotter pins from bell crank pins (behind

bracket).

F25297 (July 2008)Page 7 of 28

Page 8

E36LC SERIES ELECTRIC RESTAURANT RANGES - REMOVAL AND REPLACEMENT OF PARTS

7. Remove bell crank pins and bell cranks.

8. Reverse procedure to install.

9. Check range for proper operation.

NOTE: Tension springs until door closes on its own

when held open 5 inches. Door should bounce once

or not at all.

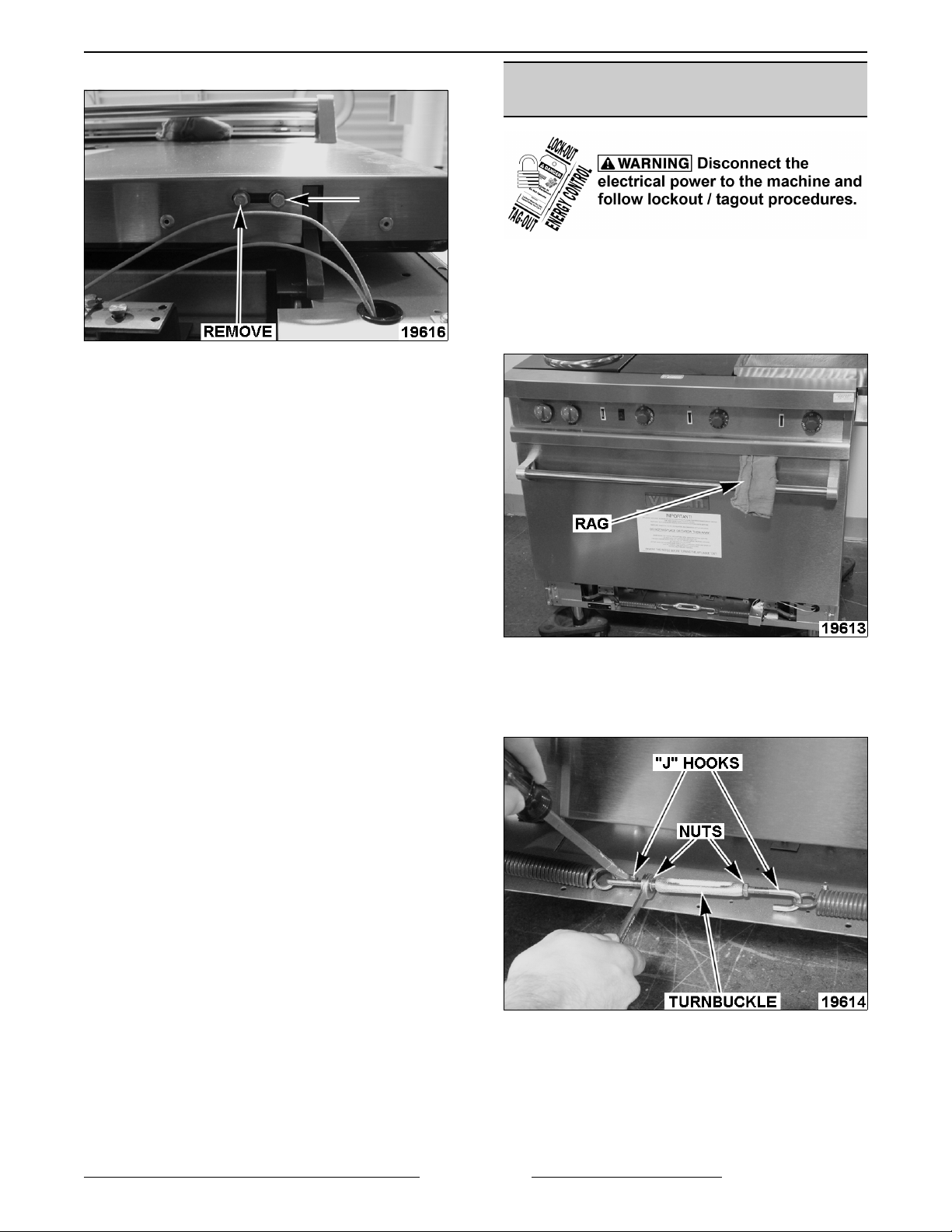

DOOR SWITCH

1. Open kick panel as outlined under COVERS

AND PANELS.

2. Remove door switch bracket mounting screws.

4. Disconnect electrical wiring from switch.

5. Reverse procedure to install.

6. Check range for proper operation.

OVEN HEATING ELEMENT

1. Remove oven racks.

2. Remove thermostat bulb from heating element

shroud.

3. Remove heating element shroud.

4. Remove screws mounting heating element

3. Remove nuts securing door switch to door

switch bracket.

F25297 (July 2008) Page 8 of 28

brackets to oven back wall.

Page 9

E36LC SERIES ELECTRIC RESTAURANT RANGES - REMOVAL AND REPLACEMENT OF PARTS

FRENCH PLATE

1. Remove french plates as outlined under

RANGE TOPS.

2. Remove bolts holding mounting bracket to the

french plate assemblies.

5. Remove screw securing heating element and

pull element out to expose lead wire

connections.

6. Disconnect the lead wires.

7. Reverse procedure to install.

8. Check range for proper operation.

3. Remove electrical connections noting their

location.

4. Remove the nut, spring washer, and locking

bracket.

NOTE: Support the french plate from underneath.

F25297 (July 2008)Page 9 of 28

Page 10

E36LC SERIES ELECTRIC RESTAURANT RANGES - REMOVAL AND REPLACEMENT OF PARTS

5. Remove french plate.

6. Reverse procedure to install.

7. Check range for proper operation.

5. Bend hooks in slightly, then remove electrical

connections.

HOT TOP

1. Remove hot top as outlined under RANGE

TOPS.

2. Remove nuts holding thermostat bulb clamp to

the plate assembly.

3. Remove thermostat bulb clamp and thermostat

bulb from hot top.

4. Remove inside screws from electrical

connections.

6. Remove hot top.

7. Reverse procedure to install.

8. Check range for proper operation.

F25297 (July 2008) Page 10 of 28

Page 11

E36LC SERIES ELECTRIC RESTAURANT RANGES - REMOVAL AND REPLACEMENT OF PARTS

GRIDDLE HEATING ELEMENT

NOTE: 12" griddle shown.

1. Remove griddle as outlined under RANGE

TOPS.

2. Remove nuts and washers to disconnect

element wiring.

6. Remove nuts securing griddle element holding

clamps.

3. Remove nuts securing griddle base cover.

4. Remove griddle base cover.

5. Loosen screws to remove thermostat bulb and

clamp.

7. Remove holding clamps.

8. Remove griddle element.

9. Reverse procedure to install.

10. Check range for proper operation.

F25297 (July 2008)Page 11 of 28

Page 12

E36LC SERIES ELECTRIC RESTAURANT RANGES - REMOVAL AND REPLACEMENT OF PARTS

OVEN THERMOSTAT

1. Remove thermostat knob.

2. Remove thermostat mounting screws.

6. Remove left range top as outlined under

RANGE TOPS.

7. Pull capillary tube and thermostat bulb through

roof of oven cavity.

3. Open the control panel as outlined under

COVERS AND PANELS.

4. Disconnect the lead wires from the thermostat

noting their locations.

5. Remove thermostat bulb from heating element

shroud.

8. Remove thermostat.

NOTE: Do not kink capillary tube.

9. Reverse procedure to install.

NOTE: Route capillary tube so it does not contact

any electrical component.

10. Perform OVEN THERMOSTAT CALIBRATION

as outlined under SERVICE PROCEDURES

AND ADJUSTMENTS.

11. Check range for proper operation.

F25297 (July 2008) Page 12 of 28

Page 13

E36LC SERIES ELECTRIC RESTAURANT RANGES - REMOVAL AND REPLACEMENT OF PARTS

GRIDDLE AND HOT TOP

THERMOSTATS

1. Remove thermostat knob.

2. Remove thermostat mounting screws.

HOT TOP SHOWN

NOTE: See GRIDDLE HEATING ELEMENT to

access griddle thermostat bulb.

7. Remove thermostat bulb from clamp.

8. Remove thermostat.

NOTE: Do not kink capillary tube.

3. Open the control panel as outlined under

COVERS AND PANELS.

4. Disconnect the lead wires from the thermostat

noting their locations.

9. Reverse procedure to install.

NOTE: Route capillary tube so it does not contact

any electrical component.

10. Perform HOT TOP or GRIDDLE THERMOSTAT

CALIBRATION as outlined under SERVICE

PROCEDURES AND ADJUSTMENTS.

11. Check range for proper operation.

5. Access underside of range top as outlined

under RANGE TOPS.

6. Remove fasteners from thermostat bulb clamp.

F25297 (July 2008)Page 13 of 28

Page 14

E36LC SERIES ELECTRIC RESTAURANT RANGES - REMOVAL AND REPLACEMENT OF PARTS

INFINITE SWITCH

1. Pull off infinite switch knob.

2. Remove washer nut from applicable infinite

switch stem.

ROCKER SWITCH

1. Open control panel as outlined under COVERS

AND PANELS.

2. Disconnect rocker switch electrical connections

noting their locations.

3. Open control panel as outlined under COVERS

AND PANELS.

4. Remove infinite switch wire connections from

switch being replaced. Note wire locations.

5. Remove infinite switch.

6. Reverse procedure to install.

3. Squeeze in on the tabs at the ends of the rocker

switch and push through the control panel.

4. Reverse procedure to install.

5. Check range for proper operation.

7. Check range for proper operation.

F25297 (July 2008) Page 14 of 28

Page 15

E36LC SERIES ELECTRIC RESTAURANT RANGES - REMOVAL AND REPLACEMENT OF PARTS

INDICATOR LIGHTS

1. Open control panel as outlined under COVERS

AND PANELS.

2. Disconnect indicator light electrical connections

noting their locations.

MOTOR CONTACTOR

(480V ONLY)

1. Remove contactor box cover.

2. Disconnect all electrical connections to the

contactor noting their locations.

3. Loosen contactor screws.

3. Squeeze in on the tabs at the ends of the

indicator light and push through the control

panel.

4. Reverse procedure to install.

5. Check range for proper operation.

4. Lift and remove contactor.

5. Reverse procedure to install.

6. Check range for proper operation.

F25297 (July 2008)Page 15 of 28

Page 16

E36LC SERIES ELECTRIC RESTAURANT RANGES - SERVICE PROCEDURES AND ADJUSTMENTS

SERVICE PROCEDURES AND ADJUSTMENTS

Certain procedures in this section require electrical test or measurements while power is

applied to the machine. Exercise extreme caution at all times. If test points are not easily accessible,

disconnect power and follow lockout / tagout procedures, attach test equipment and reapply power to

test.

OVEN THERMOSTAT

CALIBRATION

1. Place a temperature tester probe in the

geometric center of the oven.

2. Set the thermostat to 350°F.

3. Allow the thermostat to cycle three times.

4. Note the tester reading when the oven indicator

light turns ON and OFF.

NOTE: If the difference between the ON and OFF

temperature is greater than 25°F, replace the

thermostat.

5. Add these two temperatures together, then

divide the sum by 2 to obtain an average

temperature.

A. If the average temperature is within 10°F of

the set temperature, the thermostat is

calibrated.

B. If the average temperature is not within

10°F of the set temperature:

1) Remove thermostat knob.

2) Insert a flathead screwdriver into

thermostat dial stem until it reaches

the calibration screw.

3) Turn adjustment screw CW to

increase and CCW to decrease

temperature.

NOTE: A 1/4 turn equals 35°F change.

6. Replace knob and repeat steps 3 to 5 until

average temperature is within 10°F of set

temperature.

7. Reseal adjustment screw to prevent movement.

8. If thermostat cannot be calibrated, replace

thermostat as outlined under OVEN

THERMOSTAT in REMOVAL AND

REPLACEMENT OF PARTS.

F25297 (July 2008) Page 16 of 28

Page 17

E36LC SERIES ELECTRIC RESTAURANT RANGES - SERVICE PROCEDURES AND ADJUSTMENTS

GRIDDLE THERMOSTAT

CALIBRATION

1. Clean the temperature test site, then place

temperature tester surface mount probe there.

See table for proper testing locations according

to griddle size.

NOTE: This procedure will need to be performed for

each testing location on the 24" and 36" griddles.

Griddle Size Distance(s)

From Left Edge of Griddle

12"

24"

36"

1. All readings taken 12" from front of griddle.

2. Set the thermostat to a temperature above

300°F.

3. Allow the thermostat to cycle three times.

4. Note the tester reading when the indicator light

turns ON and OFF.

NOTE: If the difference between the ON and OFF

temperatures is greater than 25°F, replace the

thermostat.

5. Add these two temperatures together, then

divide the sum by 2 to obtain an average

temperature.

A. If the average temperature is within 10°F of

the set temperature, the thermostat is

calibrated.

B. If the average temperature is not within

10°F of the set temperature:

1) Remove thermostat knob.

2) Insert a flathead screwdriver into

thermostat dial stem until it reaches

the calibration screw.

6"

6", 18"

6", 18", 30"

3) Turn adjustment screw CW to

increase and CCW to decrease

temperature.

NOTE: A 1/4 turn equals 35°F change.

6. Replace knob and repeat steps 3 and 5 until

average temperature is within 10°F of set

temperature.

7. Reseal adjustment screw to prevent movement.

8. If thermostat cannot be calibrated, replace

thermostat as outlined under GRIDDLE & HOT

TOP THERMOSTATS in REMOVAL AND

REPLACEMENT OF PARTS.

HOT TOP THERMOSTAT

CALIBRATION

1. Set the control to position 3 (approx. 460°F).

2. Allow the thermostat to cycle three times.

3. When the hot top indicator light goes out, place

the temperature tester surface mount probe

directly in the middle of the hot top.

4. Note the tester reading when the indicator light

turns ON and OFF.

NOTE: If the difference between the ON and OFF

temperatures is greater than 25°F, replace the

thermostat.

5. Add these two temperatures together, then

divide the sum by 2 to obtain an average

temperature.

A. If the average temperature is within 10°F of

the set temperature, the thermostat is

calibrated.

B. If the average temperature is not within

10°F of the set temperature:

1) Remove thermostat knob.

2) Insert a flathead screwdriver into

thermostat dial stem until it reaches

the calibration screw.

F25297 (July 2008)Page 17 of 28

Page 18

E36LC SERIES ELECTRIC RESTAURANT RANGES - SERVICE PROCEDURES AND ADJUSTMENTS

3) Turn adjustment screw CW to

increase and CCW to decrease

temperature.

NOTE: A 1/4 turn equals 35°F change.

6. Replace knob and repeat steps 4 and 5 until

average temperature is within 10°F of set

temperature.

7. Reseal adjustment screw to prevent movement.

8. If thermostat cannot be calibrated, replace

thermostat as outlined under GRIDDLE & HOT

TOP THERMOSTATS in REMOVAL AND

REPLACEMENT OF PARTS.

3 HEAT SWITCH TEST (480V)

1. Open the control panel as outlined under

COVERS AND PANELS in REMOVAL AND

REPLACEMENT OF PARTS.

2. Check input voltage at L3 and L2.

NOTE: See AI 2207 in WIRING DIAGRAMS.

3. Check for correct output voltage at output pins

for all positions of the switch.

DOOR ADJUSTMENT

NOTE: Door is in adjustment when it closes on its

own when held open 5 inches and comes to rest

after 1 or 0 bounces.

1. Remove the kick panel as outlined under

COVERS AND PANELS in REMOVAL AND

REPLACEMENT OF PARTS.

2. Loosen nuts while holding "J" hooks from

rotating.

NOTE: One nut will be right hand threaded and the

other will be left hand threaded.

Position

High 1 & 3 2

Med 1 2

Low 1 3

L3 Input-Output

at Pin(s)

L2 Input-Output

at Pin(s)

INFINITE SWITCH TEST

(208, 240V)

1. Open the control panel as outlined under

COVERS AND PANELS in REMOVAL AND

REPLACEMENT OF PARTS.

2. Connect a voltmeter (set on 300VAC range) to

the output terminals H1 and H2.

3. Compare the percentage of ON time to OFF

time.

NOTE: ±7.5% tolerance allowable.

Dial

Setting

Hi 100 ALL 0

Med. 48 15 15

Low 37 8 14

Med. Low 28 7 24

Very Low 7 3 33

% on

Time

SecondsonSeconds

off

3. Rotate turnbuckle to either increase or decrease

spring tension.

NOTE: "J" hooks cannot rotate while rotating

turnbuckle in order to adjust tension.

4. Once desired spring tension is acquired, tighten

nuts.

5. Install kick panel.

F25297 (July 2008) Page 18 of 28

Page 19

E36LC SERIES ELECTRIC RESTAURANT RANGES - SERVICE PROCEDURES AND ADJUSTMENTS

HEATING ELEMENT TEST

1. Turn power ON and set temperature control to

the highest setting.

2. Measure the voltage at the heating element

terminals and verify it against the data plate

voltage.

A. If voltage is incorrect

problem. If voltage is correct

draw (amps) through the heating element

lead wires.

NOTE: This method is preferred over a resistance

check when a clamp on type amp meter is available.

1) If current draw is correct then heating

element is functioning properly. See

table below for proper values.

2) If current draw is not

power switch OFF and disconnect

the electrical supply to the oven.

a. Replace heating element then

proceed to step 3.

, find the source of the

, check current

correct, turn the

B. If unable to check current draw, a

resistance check may

malfunctioning element.

1) Disconnect electrical supply.

2) Remove lead wires from the heating

element and check resistance (ohms).

See table below for proper values.

3. Check for proper operation.

indicate a

Voltage Element KW per Element AMPS per Element Lead OHMS per Element

5 24.03 8.65

5 24.03 8.65

2 9.61 21.63

3.4 16.34 12.73

5 20.83 11.52

5 20.83 11.52

2 8.33 28.80

3.4 14.16 16.94

5 10.41 17.28

5 10.41 17.28

2 4.16 43.20

3.4 7.08 25.41

208

240

480

NOTES:

Oven

Hot Top

French Plate

Griddle

Oven

Hot Top

French Plate

Griddle

Oven

Hot Top

French Plate

Griddle

1. Values in the table are nominal. Tolerance is +5/-10%.

2. Voltage values are @ 60HZ.

3. Resistance values (ohms) are @ 77° F.

F25297 (July 2008)Page 19 of 28

Page 20

E36LC SERIES ELECTRIC RESTAURANT RANGES - ELECTRICAL OPERATION

ELECTRICAL OPERATION

COMPONENT FUNCTION

Thermostat ................ Regulates temperature of oven cavity, griddle, and hot top.

3 Heat Switch .............. Controls how power is applied to oven heating element assemblies and to the

hot plates on 480V units.

Heating Elements ........... Heats oven cavity and range tops.

Infinite Switch .............. Controls power to hot plate heaters, full power for a specified amount of time

per position of the switch.

Contactors (2) .............. Controls power to convection blower motor. Second contactor controls power

to oven elements. (480V units only)

Door Switch ............... Prevents convection oven from operating with the door open.

Rocker Switch .............. Controls power from contactor to convection oven switch.

Transformer ............... Steps 480V down to 240V.

Fuses (2) .................. Protect convection oven control circuit on 208V and 240V units. (15 amp)

Indicator Light.............. Lights when power is being applied to heating elements.

F25297 (July 2008) Page 20 of 28

Page 21

E36LC SERIES ELECTRIC RESTAURANT RANGES - ELECTRICAL OPERATION

OVEN SEQUENCE OF

OPERATION

208/240V

1. Conditions

A. Unit connected to supply voltage.

B. Thermostat OFF.

C. Rocker switch OFF.

D. Door switch closed.

E. Oven at room temperature.

2. Rocker switch turned ON.

A. Blower motor runs.

3. Thermostat set to desired temperature.

A. Indicator light lights.

B. Power is supplied to heaters.

4. Oven reaches desired temperature.

A. Power is removed from the heaters and

indicator light.

5. Oven temperature drops below set temperature.

A. Steps 4 and 5 cycle until the thermostat or

rocker switch is turned OFF or power is

removed from the oven.

480V

1. Conditions

A. Unit connected to supply voltage.

B. Thermostat OFF.

C. Rocker switch OFF.

D. Door switch closed.

E. Oven at room temperature.

2. Rocker switch turned ON.

A. Motor contactor is energized and blower

motor runs.

3. Thermostat set to desired temperature.

A. Indicator light lights.

B. Heater contactor is energized and power is

supplied to heaters.

4. Oven reaches desired temperature.

A. Power removed from heater contactor,

power is removed from the heaters and

indicator light.

5. Oven temperature drops below set temperature.

A. Thermostat contacts close and steps 4 and

5 cycle until the thermostat or rocker switch

is turned OFF or power is removed from

the oven.

F25297 (July 2008)Page 21 of 28

Page 22

E36LC SERIES ELECTRIC RESTAURANT RANGES - ELECTRICAL OPERATION

WIRING DIAGRAMS

E36LC (208, 240V) Wiring Diagram

F25297 (July 2008) Page 22 of 28

Page 23

E36LC SERIES ELECTRIC RESTAURANT RANGES - ELECTRICAL OPERATION

F25297 (July 2008)Page 23 of 28

Page 24

E36LC SERIES ELECTRIC RESTAURANT RANGES - ELECTRICAL OPERATION

E36LC (480V) Wiring Diagram

F25297 (July 2008) Page 24 of 28

Page 25

E36LC SERIES ELECTRIC RESTAURANT RANGES - ELECTRICAL OPERATION

F25297 (July 2008)Page 25 of 28

Page 26

E36LC SERIES ELECTRIC RESTAURANT RANGES - ELECTRICAL OPERATION

208V & 240V Range Top Wiring Diagrams

F25297 (July 2008) Page 26 of 28

Page 27

E36LC SERIES ELECTRIC RESTAURANT RANGES - ELECTRICAL OPERATION

480V Range Top Wiring Diagrams

F25297 (July 2008)Page 27 of 28

Page 28

E36LC SERIES ELECTRIC RESTAURANT RANGES - TROUBLESHOOTING

TROUBLESHOOTING

Oven

SYMPTOM POSSIBLE CAUSES

No heat, blower inoperative. 1. Main breaker open.

2. Thermostat malfunction.

3. Rocker switch open.

4. Contactors malfunctioning (480V).

5. Oven door switch open.

6. Heaters inoperative.

7. Transformer malfunction (480V).

No heat, blower operative. 1. Heating element contactor malfunction (480V).

2. Heaters inoperative.

Cooking problems. 1. Consult Instruction Manual.

Oven temperature not at set point. 1. Thermostat not calibrated.

2. Thermostat malfunction.

Range Tops

SYMPTOM POSSIBLE CAUSES

Tops do not heat. 1. Main breaker open.

2. Thermostat malfunction (griddle, hot top).

3. 3 heat switch malfunction (french plates 480V).

4. Infinite switch inoperative (french plates 208-240V).

5. Top inoperative.

Hot top or griddle thermostat cycles at a different

temperature than the set temperature.

Cooking problems. 1. Consult Instruction Manual.

Hot top or griddle heats beyond set temperature. 1. Thermostat not calibrated.

1. Thermostat needs calibrated.

2. Thermostat inoperative.

3. Thermostat bulb positioned incorrectly.

2. Thermostat malfunction.

F25297 (July 2008) Printed in U.S.A.

Loading...

Loading...