Page 1

SERVICE MANUAL

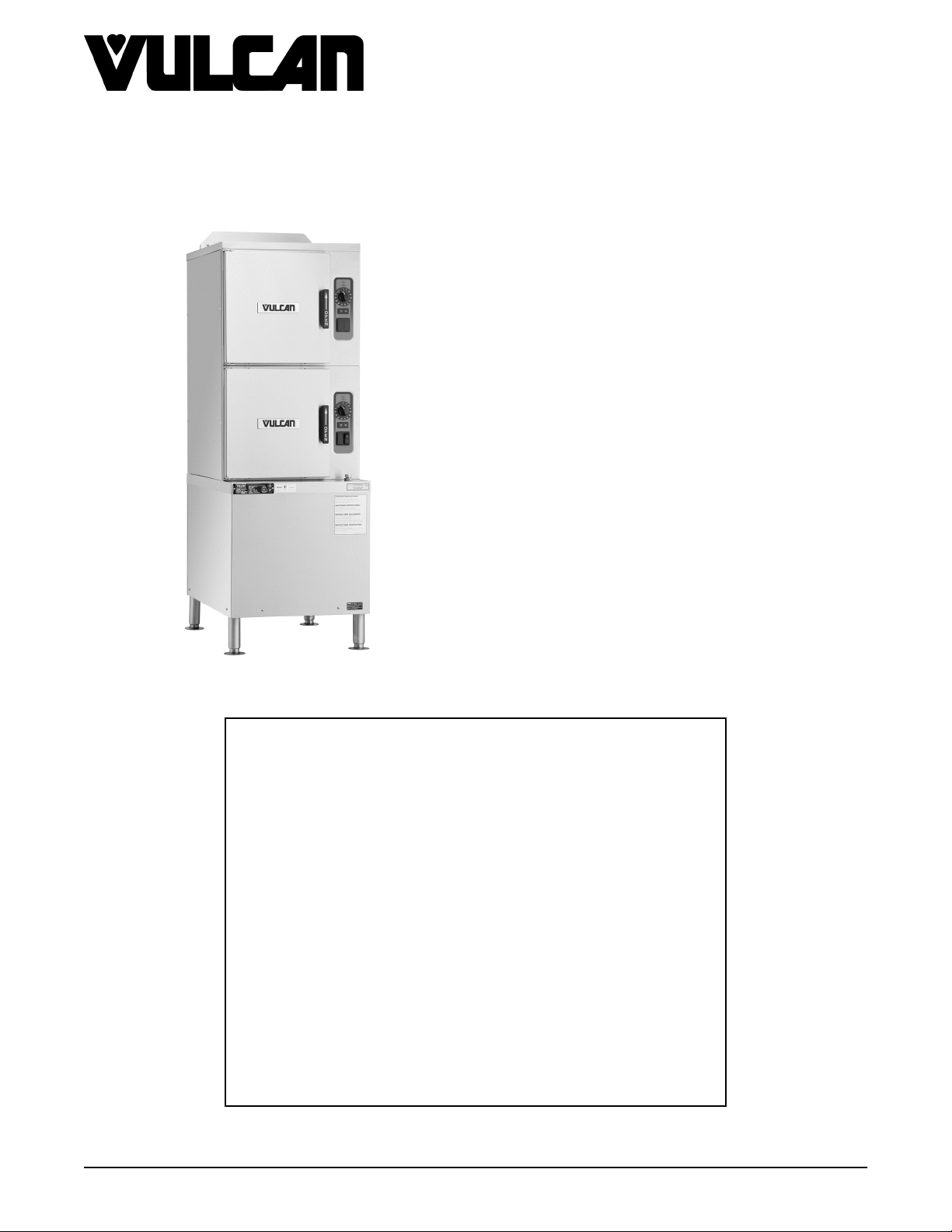

C24GA AND C24DA SERIES

CONVECTION STEAMER

C24GA6 ML-136021

ML-136056

ML-136085

C24GA10 ML-136022

ML-136057

ML-136085

C24DA6 ML-152022

C24DA10 ML-152023

- NOTICE -

This Manual is prepared for the use of trained Hobart Service

Technicians and should not be used by those not properly

qualified.

This manual is not intended to be all encompassing. If you have

not attended a Hobart Service School for this product, you should

read, in its entirety, the repair procedure you wish to perform to

determine if you have the necessary tools, instruments and skills

required to perform the procedure. Procedures for which you do

not have the necessary tools, instruments and skills should be

performed by a trained Hobart Service Technician.

The reproduction, transfer, sale or other use of this manual,

without the express written consent of Hobart, is prohibited.

This manual has been provided to you by ITW Food Equipment

Group LLC ("ITW FEG") without charge and remains the property

of ITW FEG, and by accepting this manual you agree that you will

return it to ITW FEG promptly upon its request for such return at

any time in the future.

A product of Vulcan-Hart 3600 North Point Blvd Baltimore, MD 21222

F35425 Rev. E (0119)

Page 2

C24GA AND C24DA SERIES CONVECTION STEAMER

TABLE OF CONTENTS

SERVICE UPDATES ....................................................................................... 4

SERVICE UPDATES - C24GA .......................................................................... 4

TIS DOCUMENT LIST - C24GA SERIES ................................................................ 4

GENERAL .................................................................................................. 7

INSTALLATION, OPERATION AND CLEANING ......................................................... 7

INTRODUCTION ....................................................................................... 7

GENERAL .......................................................................................... 7

STEAM COOKING ................................................................................. 7

WATER QUALITY STATEMENT ........................................................................ 7

SPECIFICATIONS ...................................................................................... 8

ELECTRIC ......................................................................................... 8

GAS PRESSURES ................................................................................. 8

TOOLS ................................................................................................. 8

REMOVAL AND REPLACEMENT OF PARTS .............................................................. 10

COVERS AND PANELS ............................................................................... 10

COOKING COMPARTMENT SIDE PANELS ....................................................... 10

COOKING COMPARTMENT FLUE WRAP ......................................................... 10

CABINET BASE RIGHT SIDE PANEL .............................................................. 10

CABINET BASE LEFT SIDE PANEL ............................................................... 10

CABINET BASE FRONT PANEL ................................................................... 11

CABINET BASE REAR PANEL .................................................................... 11

COMPARTMENT CONTROLS-OLD ................................................................... 11

COOKING COMPARTMENT DOOR ................................................................... 12

MAIN BURNER ....................................................................................... 15

GAS COMBINATION CONTROL VALVE ............................................................... 16

GENERATOR ASSEMBLY ............................................................................ 17

FILL AND COLD WATER SOLENOID VALVES ........................................................ 19

PILOT/SPARK PROBE FLAME SENSOR (ONLY UNITS WITH ADJUSTABLE PILOT) .................. 20

BLOWER CONTROL RELAY (K3) ..................................................................... 21

SERVICE PROCEDURES AND ADJUSTMENTS ........................................................... 22

BLOWER AIR PRESSURE ADJUSTMENT (ONLY UNITS WITH ADJUSTABLE PILOT) ................. 22

SOLARONICS BURNER ADJUSTMENT (STARTING AT SERIAL NUMBER 463024850) ................ 24

AIR PRESSURE SWITCH ADJUSTMENT (ONLY UNITS WITH ADJUSTABLE PILOT) .................. 26

PILOT BURNER ADJUSTMENT (ONLY UNITS WITH ADJUSTABLE PILOT) ........................... 27

AUTOMATIC IGNITION SYSTEMS .................................................................... 34

IGNITION TEST ....................................................................................... 37

MANIFOLD PRESSURE ADJUSTMENT (ONLY UNITS WITH ADJUSTABLE PILOT) ................... 37

COOKING COMPARTMENT .......................................................................... 39

DOOR ................................................................................................ 39

LATCH ADJUSTMENT ............................................................................ 39

STRIKER ADJUSTMENT .......................................................................... 40

DELIME GENERATOR ................................................................................ 40

COOKING CYCLE TEST .............................................................................. 41

GENERAL ........................................................................................ 41

PROBE INSPECTION ................................................................................. 42

MAINTANENCE CHECKS ............................................................................. 42

ELECTRICAL OPERATION ................................................................................ 44

WATER LEVEL CONTROLS .......................................................................... 44

LOW LEVEL CUT-OFF AND DIFFERENTIAL CONTROL ........................................... 44

SEQUENCE OF OPERATION ......................................................................... 44

SOLARONICS BURNER SEQUENCE OF OPERATION ................................................ 47

COMPONENT FUNCTION - COMPARTMENT ......................................................... 49

COMPONENT FUNCTION - STEAM GENERATOR .................................................... 50

F35425 Rev. E (0119) Page 2 of 65

Page 3

C24GA AND C24DA SERIES CONVECTION STEAMER

COMPONENT LOCATION ............................................................................. 51

SCHEMATICS AND DIAGRAMS ....................................................................... 54

TROUBLESHOOTING ..................................................................................... 59

TROUBLESHOOTING (ADJUSTABLE PILOTS ONLY) ................................................. 59

GENERAL ........................................................................................ 59

WATER NOT BEING SUPPLIED TO GENERATOR ................................................ 59

PILOT OR MAIN BURNER WILL NOT LIGHT ...................................................... 59

DRAIN SOLENOID VALVE DOES NOT DRAIN .................................................... 59

WATER ACCUMULATING IN COMPARTMENT .................................................... 59

COOKING CYCLE CANNOT BE ACTIVATED ...................................................... 59

STEAMER ACHIEVES PRESSURE SLOWER THAN NORMAL .................................... 59

TROUBLESHOOTING SEQUENCE OF OPERATION .................................................. 60

TROUBLESHOOTING CHART ........................................................................ 61

LED DIAGNOSTIC FLASH CODES (SOLARONICS BURNER SYSTEM WITH

FENWAL IGNITION MODULE UNITS ONLY) ...................................................... 65

© VULCAN 2019

Page 3 of 65 F35425 Rev. E (0119)

Page 4

C24GA AND C24DA SERIES CONVECTION STEAMER - SERVICE UPDATES

SERVICE UPDATES

SERVICE UPDATES - C24GA

January, 2019

• Add swtich step to SOLARONICS BURNER ADJUSTMENT (STARTING AT SERIAL NUMBER

463024850).

December, 2018

• Add C24DA Schematic and Models to service manual.

November, 2018

• Added SOLARONICS BURNER ADJUSTMENT (STARTING AT SERIAL NUMBER 463024850).

• Added BLOWER CONTROL RELAY (K3).

• TROUBLESHOOTING CHART

• Added SOLARONICS BURNER SEQUENCE OF OPERATION.

• Miscellaneous updates per product support.

November, 2014

• This Service Manual was completely revised to include the Professional Model. This revsion was released in

November, 2014. No updates presently apply.

TIS DOCUMENT LIST - C24GA Series

SERVICE TAB

Document Title Document Type

C24GA Convection Steamer Service Manual Service Manual

#00-858726 Burner Assembly Replacement Service Kit Instructions (SKI)

C24GA 6 & 10 Gas Floor Steamers - Pressure Switch Not

Maintaining Setpoint

Substitute Ignition Module C24GA steamers Part No.

00-857207-00002

SERVICE TAB (Multimedia)

Document Title Document Type

All Stainless Steel with Automatic Timers & Manual

Boilers Direct Steam - ST. STL. LEG

Electric Boiler Owners Manual Instructions

Repair Flood-Damaged Food Equipment Misc

C24GA6 & C24GA10 Gas Convection Steamers I/O

Manual

C24GA6 & C24GA10 Nason Relay Instructions Service Instructions

Deliming Instructions C24GA6/10 Series Steamers Service Instructions

Fundamentals of Steam Service Instructions

Temporary Service Instructions (TSI)

Temporary Service Instructions (TSI)

Instructions

Operator

F35425 Rev. E (0119) Page 4 of 65

Page 5

C24GA AND C24DA SERIES CONVECTION STEAMER - SERVICE UPDATES

SERVICE TAB (Multimedia)

Fundamentals of Gas Service Instructions

Hobart Water Filter Replacement Cross Reference Sheet Service Instructions

Pilot & Burner Problems on Units Without Powered

Burners Service Information

ScaleStick Twin System, Part No. 01-234301-51200 Service Instructions

Water Level Pressure Switches Information Service Instructions

Rating Plate Locations on Current Vulcan-Hart/Wolf

Range Equipment

SB630 Gas Range Thermocouples Technical Service Bulletin (TSB)

SB760 Vulcan Steam Temporary Service Instruction /

Inspect All Warrick Water Level

SB780 Vulcan C24GA Series Steamers - Enhancements

& Additional Service

SB790 Vulcan C24GA - Elimination of Hold Thermostat Technical Service Bulletin (TSB)

SB800 Vulcan Steam Equipment - Enhanced Ignition

Modules

SB820 C24GA Series Steamers - Pilot Air Assembly

Change & Pressure Regulator

SB860 Atmospheric Steamer Door Switch Actuator Rod Technical Service Bulletin (TSB)

TSB 1374 Water Level Control Part No. 844069-1

Changes

TSB 1393 Steam Cooking Equipment - Prevention,

Detection and Treatment of Corrosion on Stainless Steel

TSB 1037A Hobart to Vulcan "Common" Model Cross

Reference List

TSB 1270 C24GA (Vulcan) - Elimination of Hold

Thermostat

TSB 1281 C24GA(Vulcan) Series Enhancements &

Additional Service Information

TSB 1298A Atmospheric Steamer Door Switch Actuator

Rod

TSB 1300B Vulcan Steam Equipment - Enhanced

Ignition Modules

TSB 1301 Onwatch Quicklook 72 for Gas Cooking

Equipment

TSB 1308 C24GA (Vulcan) Series Steamers - Pilot Air

Assembly Change and Pressure Regulator Addition

TSB 1339 Vulcan High Efficiency Gas Steamers - Burner

Noise

TSB 1360 C24GA Series Gas Steamers - Worm Gear

Hose Clamps Replacement with Constant Tension Hose

Clamps

TSB 1385 C24GA Series Gas Steamers - Universal

Generator Kit Part No. 857684-1

Service Instructions

Technical Service Bulletin (TSB)

Technical Service Bulletin (TSB)

Technical Service Bulletin (TSB)

Technical Service Bulletin (TSB)

Technical Service Bulletin (TSB)

Technical Service Bulletin (TSB)

Technical Service Bulletin (TSB)

Technical Service Bulletin (TSB)

Technical Service Bulletin (TSB)

Technical Service Bulletin (TSB)

Technical Service Bulletin (TSB)

Technical Service Bulletin (TSB)

Technical Service Bulletin (TSB)

Technical Service Bulletin (TSB)

Technical Service Bulletin (TSB)

Technical Service Bulletin (TSB)

Temporary Service Instructions (TSI)

Page 5 of 65 F35425 Rev. E (0119)

Page 6

C24GA AND C24DA SERIES CONVECTION STEAMER - SERVICE UPDATES

SERVICE TAB (Multimedia)

C24GA Series Gas Steamers - Blower Air Pressure

Adjustment Procedure Change

Hobart & Vulcan Steamers/Kettles with Warrick Water

Level Control Boards

Steamers - Main Transformer Primary Tap on Electric

Machines

Steamers Wire Insulation Pinched Under Screw Lug on

Terminal Block & Contractors

PARTS TAB

Document Title Document Type

Part Catalog for C24GA 6 & 10 Parts Catalog

Temporary Service Instructions (TSI)

Temporary Service Instructions (TSI)

Temporary Service Instructions (TSI)

Temporary Service Instructions (TSI)

F35425 Rev. E (0119) Page 6 of 65

Page 7

C24GA AND C24DA SERIES CONVECTION STEAMER - GENERAL

GENERAL

INSTALLATION, OPERATION AND

CLEANING

Refer to the F35423 - C24GA6/10 Series Gas

Convection Steamers Installation & Operation

Manual and F35439 -Deliming Instructions

C24GA6/10 Series Steamers for specific instructions.

INTRODUCTION

General

Procedures in this manual will apply to all models

unless specified. Pictures and illustrations can be of

any model unless the picture or illustration needs to

be model specific. All information and specifications

contained in this manual are based on the latest

product information available at the time of printing.

Steam Cooking

Convection steamers offer an efficient way to produce

many foods in either small portions or larger batches.

Convection steam cooking will steam cook fresh foods

or will steam defrost and cook frozen foods providing

the maximum color, flavor and nutritional value with

the least expenditure of energy and labor. The

atmospheric steaming compartment allows the

operator to open and close the door anytime during a

cooking cycle. The generator burner heating will shut

off when the door is opened then re-start when the

door is closed.

equipment will vary depending on the local water

conditions. Your water supply must be within the

general guidelines outlined in the chart below at all

times during use of this machine or service issues not

covered under warranty may result.

Water hardness should be treated by removing the

impurities (water softener with carbon block or

dechlorinator and/or in-line water treatment). Low

water hardness may also require a water treatment

system to reduce potential corrosion. Water treatment

has been shown to reduce costs associated with

machine cleaning, reduce deliming and reduce

corrosion of metallic surfaces.

Daily washing and rinsing of the cavity is required. In

some cases, it may be needed more than once a day

to prevent compounding of contaminants deposited

inside cavity even with acceptable filtration. Failure to

wash and rinse down the cavity daily could result in

damage of the oven cavity and interior parts. A

Reverse Osmosis water treatment system can be

installed to eliminate chlorides or other contaminates

from the water if needed.

NOTE: Failure to properly maintain water quality or

preventative procedures for water can lead to issues

not covered under warranty.

Plumbing connections must comply with the

applicable sanitary, safety and plumbing codes.

Model Designations

MODEL CONTROLS

C24GA6-BSC Basic 6

C24GA6-DLX Professional 6

C24GA10-BSC Basic 10

C24GA10-DLX Professional 10

* based on 1 inch pan depth

PAN

CAPACITY*

WATER QUALITY STATEMENT

The fact that a water supply is potable is no guarantee

that it is suitable for steam generation. Proper water

quality can improve the taste of the food prepared in

the oven, reduce scale build-up or corrosion, and

extend equipment life. Local water conditions vary

from one location to another and can change

throughout the year. The recommended water

treatment for effective and efficient use of this

Page 7 of 65 F35425 Rev. E (0119)

WATER SUPPLY GENERAL GUIDELINES

Supply Pressure

(dynamic flow)

Hardness

Silica less than 13 ppm

Chloramines

Chlorides

Total Chlorine

PH range 7-8

Undissolved Solids less than 5 microns

1

Testing of water is always done AFTER water

filter or water treatment used. Water quality does

change with usage and should be checked after

idle times to see if the condition worsens.

2

2

4

30-60 psig

less than 3 grains (17.1

ppm = 1 grain of

hardness)

zero

less than 30 ppm

zero

1

3

Page 8

C24GA AND C24DA SERIES CONVECTION STEAMER - GENERAL

2

A carbon block filter system should always be

used to remove Chlorine and Chloramine. If a

water softener is used, a carbon block is still

required. Check with your local water treatment

specialist for proper sizing and replacement

intervals for the carbon block cartridge.

3

If the Chlorides exceed 30 ppm and the oven is

used more than 8 hours during the day in steam

or combination mode, the cavity will require

rinsing every 8 hours. Failure to do so will result

in corrosion and rusting of the oven cavity and

interior parts. A Reverse Osmosis water treatment

system can be installed to eliminate chlorides

from the water and reduce the hardness.

Preventative washing and rinsing may be needed

more than once a day to prevent compounding of

contaminants inside cavity.

4

Total Chlorine of 4.0 ppm is the max limit for the

building water supply. A carbon block filter must

still be used to remove all Chlorine and

Chloramines from the water. Failure to do so will

result in corrosion and rust in the cooking cavity,

which is not covered under warranty.

SPECIFICATIONS

Burner Pressure**

Hot .4" to .5" WC.

Cold .33" to .35" WC

** The blower air pressure reading will be higher

when the steam generator is hot vs cold. If the

steam generator has been on for 15 minutes or

more, the operating condition is considered hot.

24 volt transformer needs to be disconnected

when checking blower speed settings.

TOOLS

Standard

• Standard set of hand tools.

• VOM with minimum of NFPA-70E CATIII 600V,

UL/CSA/TUV listed. Sensitivity of at least 20,000

ohms per volt and the ability to measure DC

micro amps. Meter leads must also be rated at

CAT III 600V.

• Temperature tester (thermocouple type).

• Manometer.

• Gas leak detection equipment. (Must be resistant

to reaction of propane gas).

Electric

120VAC/60HZ/1 phase (proper ground required).

NOTE: Do not connect this unit to a ground-fault

circuit-interrupter (GFCI) 125-volt, single-phase, 15and 20-ampere receptacle. Electronic burner ignition

systems are prone to nuisance tripping and possible

ignition failure.

Gas Pressures

Gas Supply Pressure*

Natural 7.0" - 10.5" W.C.

Propane 11.0" - 13" W.C.

* Maximum supply pressure can not exceed 14"

W.C. (1/2 psig).

Gas Manifold Pressure

Natural 2.5" W.C.

Propane 10.0" W.C.

Blower Air Pressure

NOTE: Blower settings

are only made on units up

to serial number

463024849, soloranics

burner is not adjustable.

0.35" W.C. - Cold

.45" W. C. - Hot

• Clear silicone sealant.

Special

• Requires U-inclined (Grainger P/N 3T294) or

digital (Grainger P/N 4JZ78) manometer capable

of reading in 0.01" WC increments. Used for

measuring gas manifold pressures and blower

air pressures.

• RTV 109 for securing gasket to door.

• Loctite® 271.

• Screwdriver, 1/8 X 4 cabinet tip.

• Scale Release PN 854893-13 (14 oz).

• SPS620V Red Filter Head (Kit P/N

854306-00013).

• SMF620 Black Head (Kit P/N 857487-00620).

• Combustion analyzer needed for Soloronics

burner assembly set up procedures.

• Pressure Gauge Assembly

• Low Pressure Gauge - 0 to 5 psi.

recommended (Grainger Part No. 2C641).

• Water Hose Coupling - swivel type

(Grainger Part No. 4KG87).

• Reducer Bushing (Grainger Part No.

6MN61).

F35425 Rev. E (0119) Page 8 of 65

Page 9

C24GA AND C24DA SERIES CONVECTION STEAMER - GENERAL

• Pipe thread sealant (as required).

Fig. 1

• Pressure gauge and fittings to check inlet water

pressure for condensate connection.

Page 9 of 65 F35425 Rev. E (0119)

Page 10

C24GA AND C24DA SERIES CONVECTION STEAMER - REMOVAL AND REPLACEMENT OF PARTS

REMOVAL AND REPLACEMENT OF PARTS

COVERS AND PANELS

Disconnect the electrical power to

the machine and follow lockout /

tagout procedures.

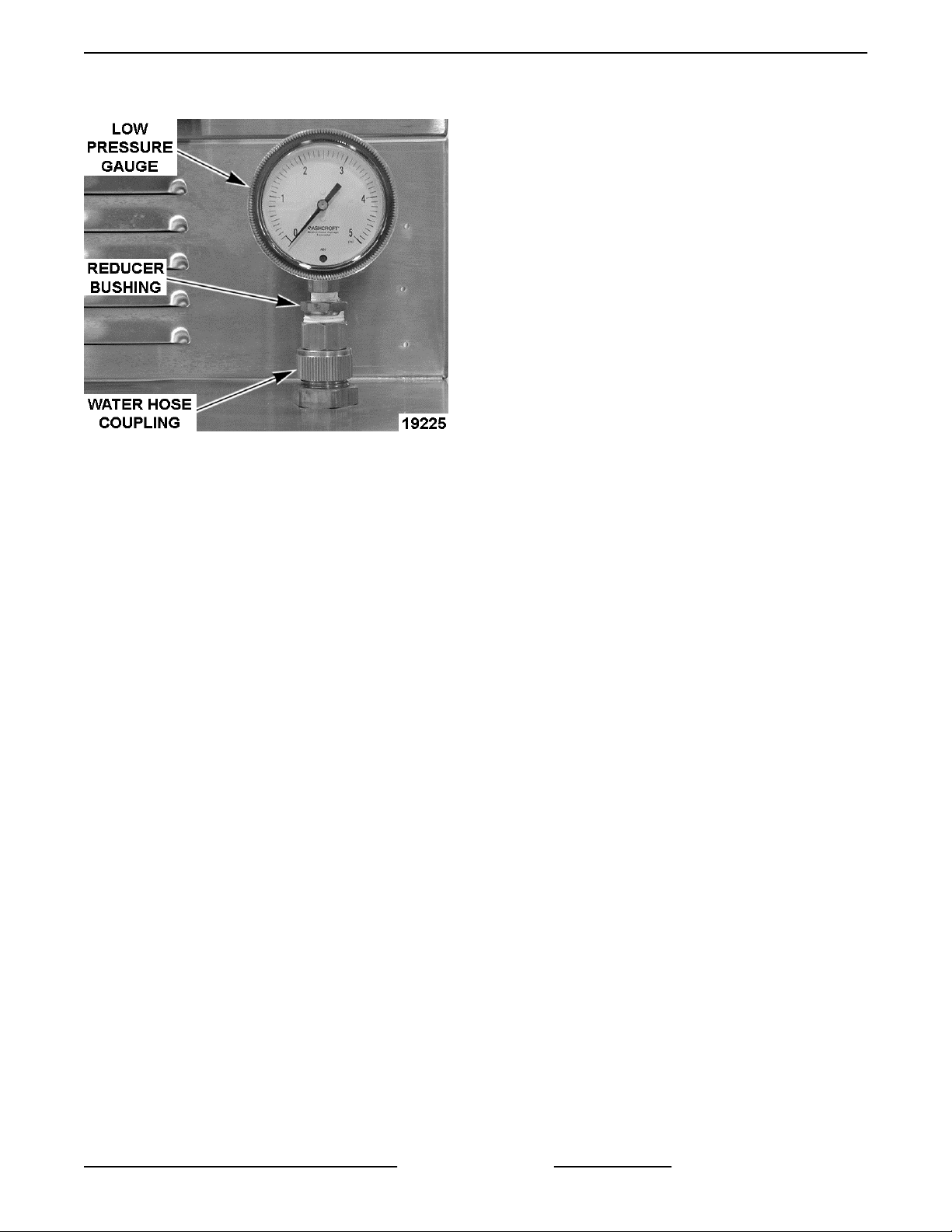

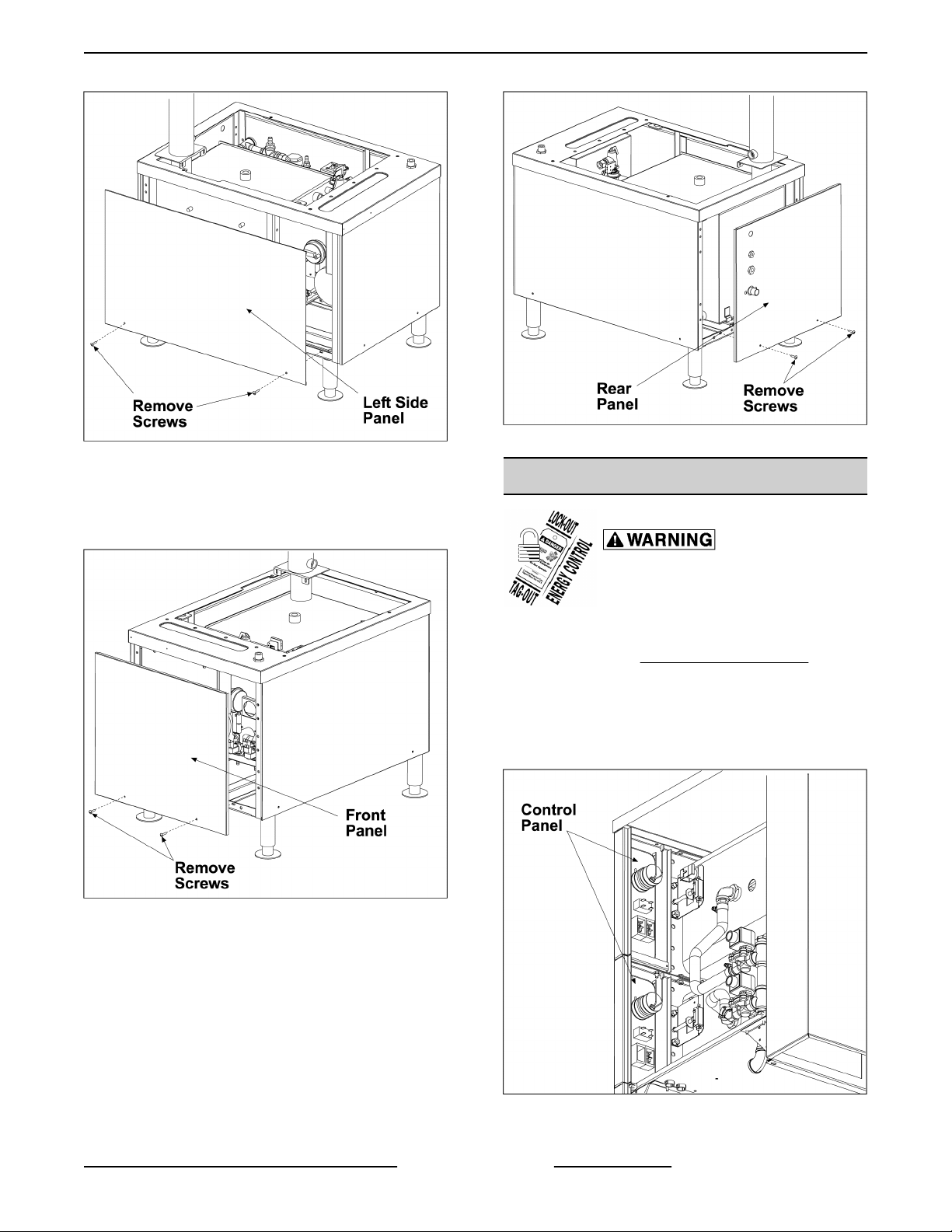

Cooking Compartment Side Panels

NOTE: Removal of left side panel is identical to the

procedure for the right side panel.

1. Remove the screws then remove the side panel

from the compartment.

Fig. 3

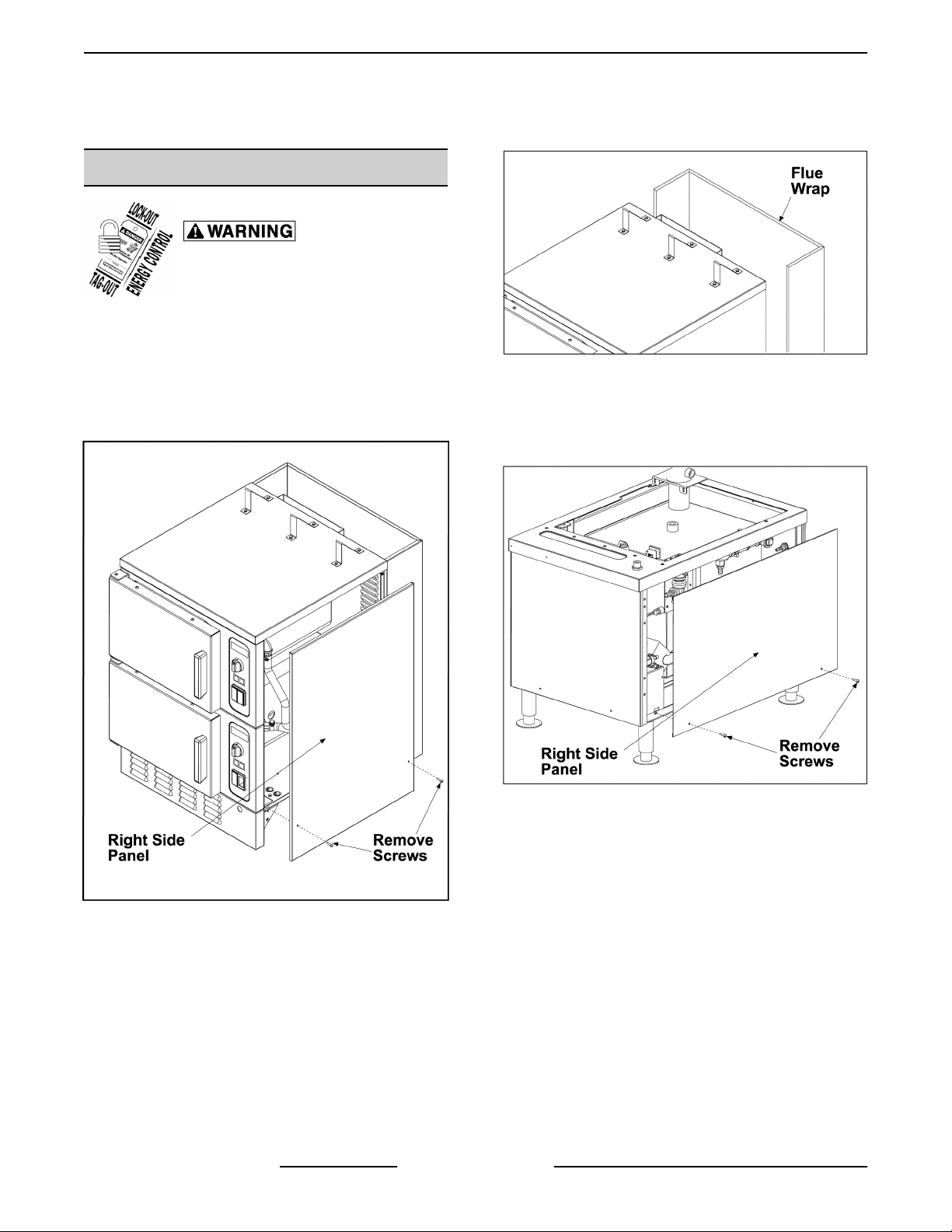

Cabinet Base Right Side Panel

1. Remove the screws then remove the right side

panel from the cabinet base.

Fig. 4

Cabinet Base Left Side Panel

1. Remove the screws then remove the left side

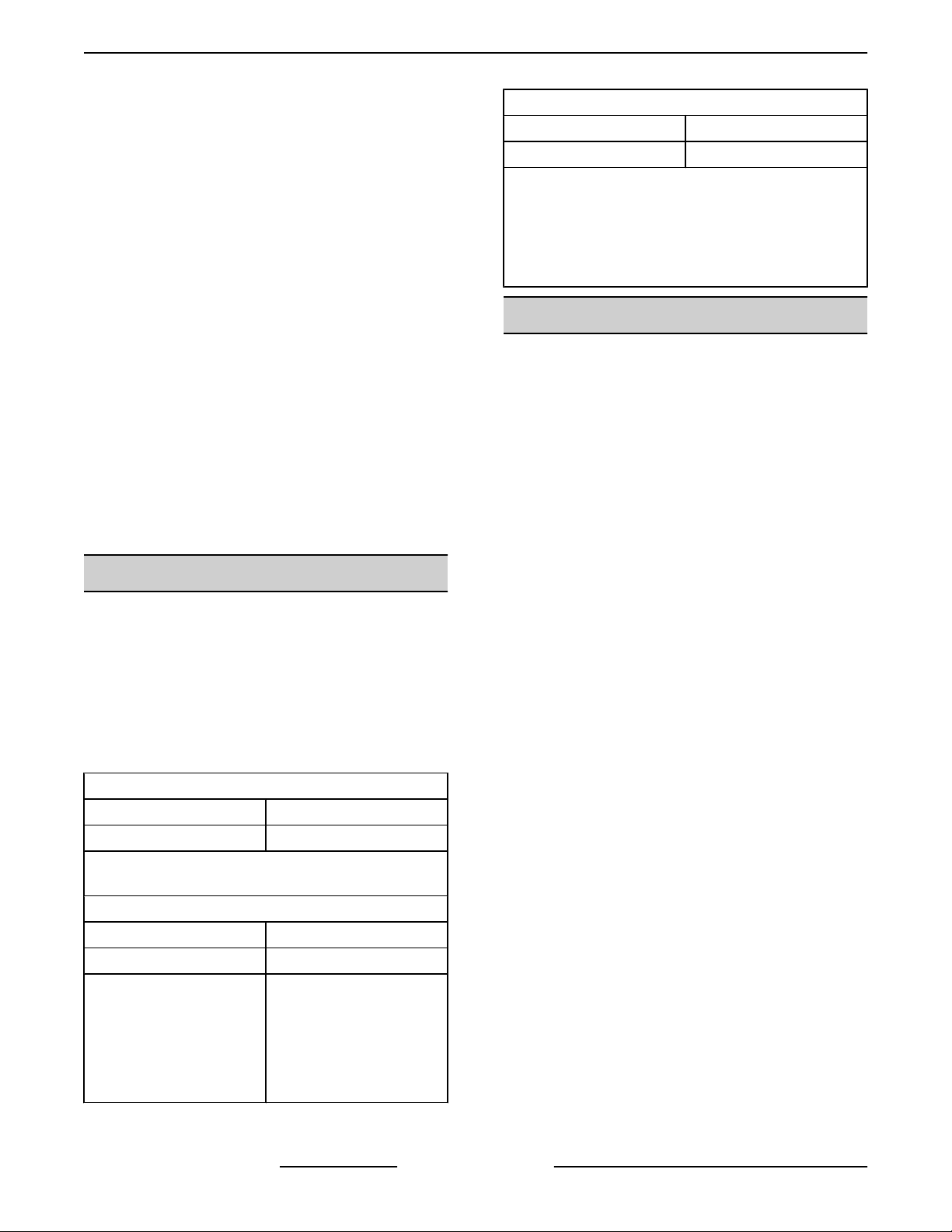

Fig. 2

Cooking Compartment Flue Wrap

1. Remove left and right side panels from

compartment. Remove screws that secure flue

wrap.

F35425 Rev. E (0119) Page 10 of 65

panel from the cabinet base.

Page 11

C24GA AND C24DA SERIES CONVECTION STEAMER - REMOVAL AND REPLACEMENT OF PARTS

Fig. 7

Fig. 5

Cabinet Base Front Panel

COMPARTMENT CONTROLS-OLD

1. Remove the screws then remove the front panel

from the cabinet base.

Fig. 6

Cabinet Base Rear Panel

Disconnect the electrical power to

the machine and follow lockout /

tagout procedures.

1. Remove compartment right side cover as

outlined under COVERS AND PANELS.

2. Remove the component being replaced.

3. Reverse the procedure to install the replacement

component, then check steamer for proper

operation.

NOTE: Electrical components are connected to the

rear panel. Be prepared to note wires and disconnect

when removing rear panel.

1. Remove the screws then remove the rear panel

from the cabinet base.

Page 11 of 65 F35425 Rev. E (0119)

Fig. 8

Page 12

C24GA AND C24DA SERIES CONVECTION STEAMER - REMOVAL AND REPLACEMENT OF PARTS

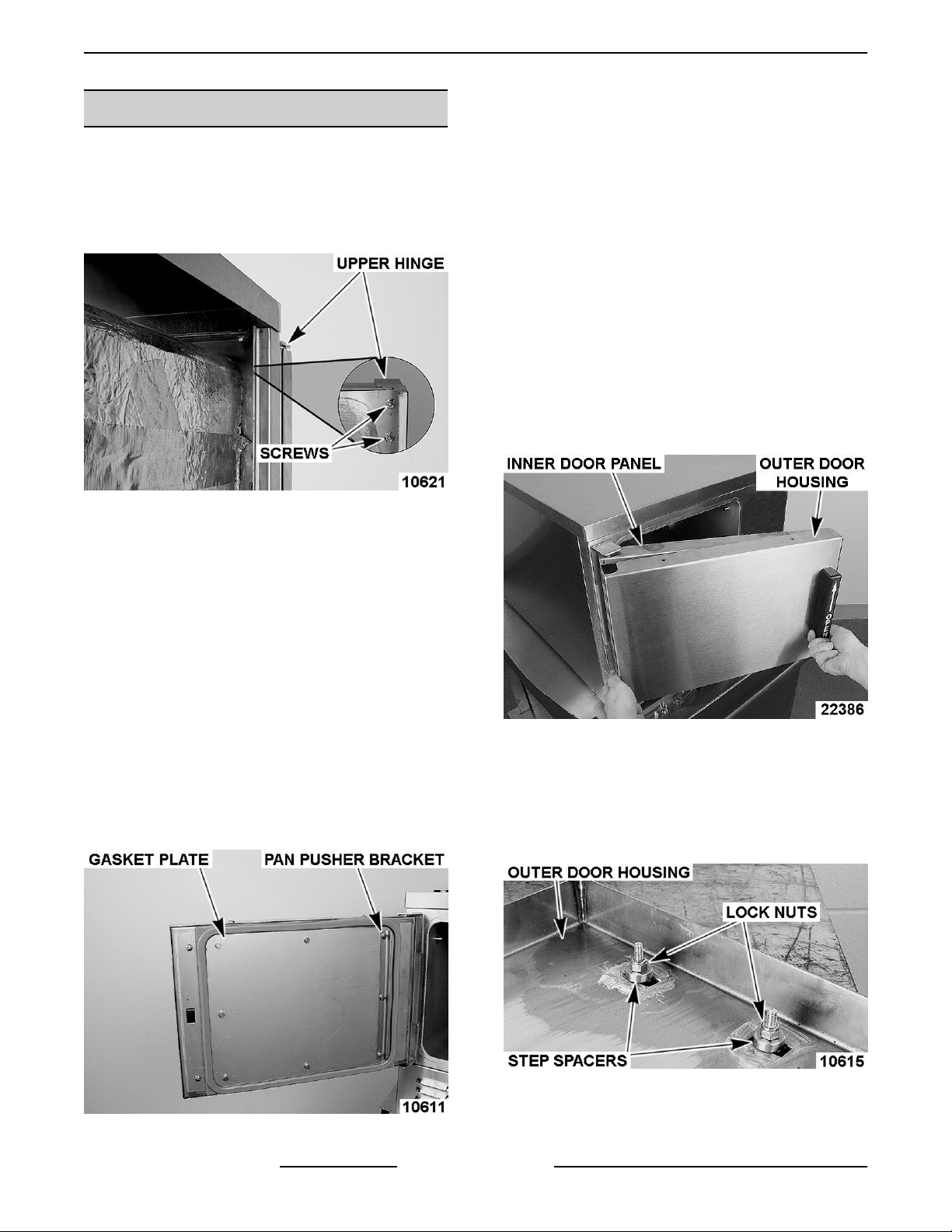

COOKING COMPARTMENT DOOR

Removal

1. Close Door.

2. Remove compartment left SIDE PANEL.

3. Remove nuts from top door support bracket.

Fig. 9

4. Open door slightly, and while holding door, pull

upper hinge away from front panel.

3. Remove the gasket plate.

4. Remove gasket from inner door panel.

5. Remove RTV from bottom part of inner door

panel. Apply new RTV 109 to bottom of door

where shown when assembling gasket to door.

6. Place a small amount of RTV109 into the inner

door panel gasket screw holes before assembly.

7. Position the new gasket on gasket plate and

reverse procedure to install

NOTE: Damage to the gasket sealing surface, such

as nicks or cuts, will cause steam leakage.

Handle Removal

1. Open the door.

2. Remove screws from the top and bottom of the

door.

5. Pull upper hinge out of upper door hinge bushing.

6. Lift door assembly up and off lower door hinge.

7. Reverse the procedure to install and check for

proper operation.

8. Reinstall parts removed in reverse order of

removal.

9. Check door for fit and proper sealing of gasket.

Gasket

1. Open the door.

2. Remove the shoulder screws and pan pusher

bracket from gasket plate.

Fig. 11

3. Pull outer door housing away from inner door

panel starting at the hinge side of door to

separate the door halves.

4. Remove lock nuts and stepped spacers from

threaded studs of door handle.

Fig. 10

F35425 Rev. E (0119) Page 12 of 65

Fig. 12

Page 13

C24GA AND C24DA SERIES CONVECTION STEAMER - REMOVAL AND REPLACEMENT OF PARTS

5. Reverse procedure to install. When installing the

spacers, the smaller diameter fits into the slot in

the door and the latch. Use Loctite 271 to secure

fasteners.

Handle Installation

1. Apply Lubriplate 630AA around slots of outer

door housing where step spacers contact

housing.

2. Install door handle into outer door housing such

that hinge side of door housing is to the left and

arrow on handle is pointed upward.

3. Install step spacer with smaller radius toward

handle and door housing. Smaller radius is a slip

fit with outer door housing slot.

8. Apply Loctite 7471 Primer N and Loctite 242 to

threads of screws before assembling.

9. Install screws to secure door halves together.

10. Check opening and closing operation of door.

Latch Assembly and Removal

1. Separate outer door housing assembly from

inner door panel as outlined under DOOR

HANDLE REMOVAL.

2. Remove screws securing latch assembly to inner

door panel and remove latch mechanism.

Fig. 13

4. Install lock nuts and tighten until no gap exists

between handle, step spacer and lock nut. Do not

over-tighten lock nuts.

5. Close inner door panel so that latch mechanism

engages striker on front panel.

6. Install outer door housing onto inner door panel.

7. Align the top and bottom screw holes of outer

door housing with inner door panel.

Fig. 15

3. Remove E-clip from latch assembly pins and pull

pins from latch mechanism.

Fig. 16

4. Remove retaining pin from spring pin.

5. Separate sliding bracket from stationary bracket.

Fig. 14

Page 13 of 65 F35425 Rev. E (0119)

Page 14

C24GA AND C24DA SERIES CONVECTION STEAMER - REMOVAL AND REPLACEMENT OF PARTS

A. Apply Loctite 271 to threads of screws

before assembly and secure latch assembly

to inner door panel.

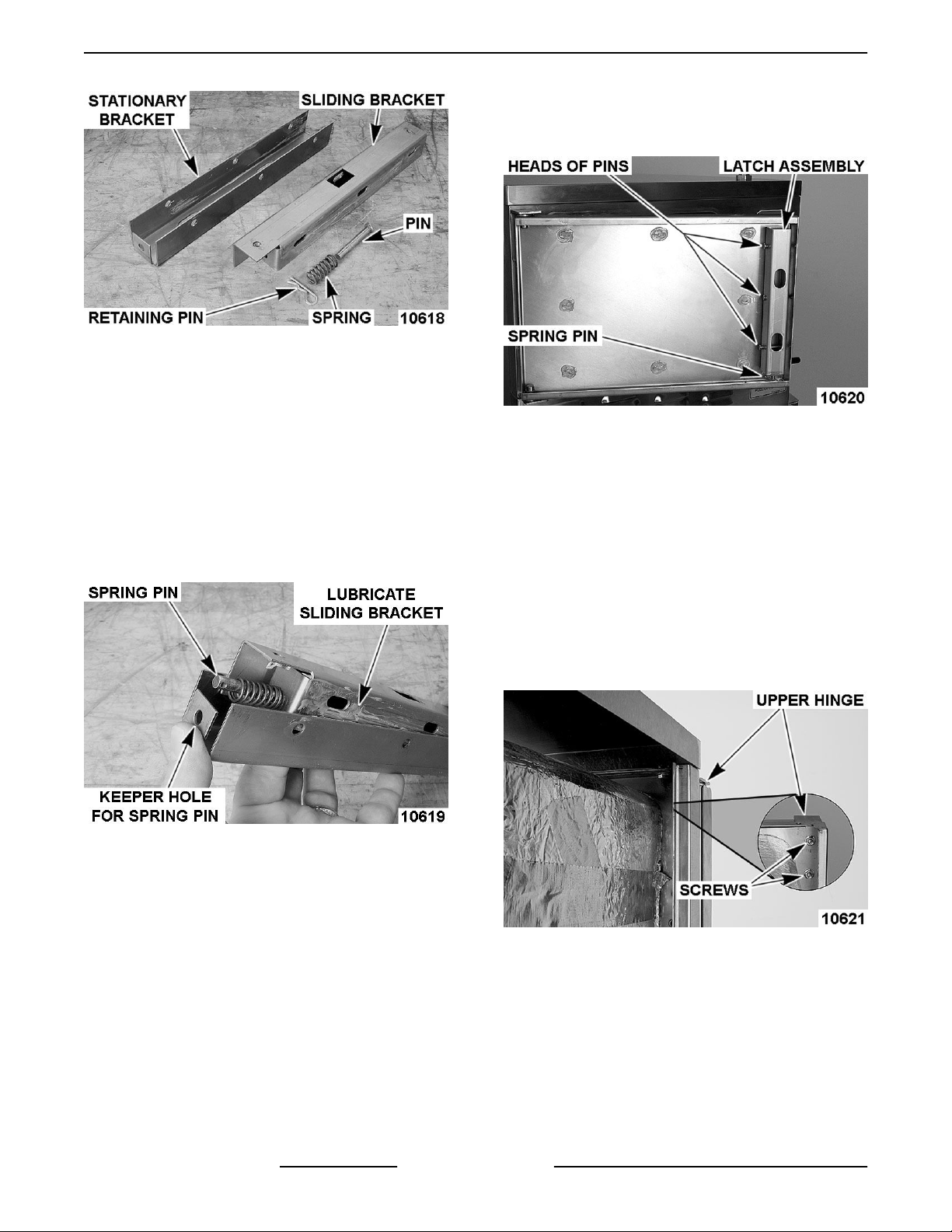

Fig. 17

Latch Assembly

1. Apply Lubriplate 630AA to sides of sliding

bracket.

2. Insert spring pin into bottom of sliding bracket.

A. Place spring over spring pin.

3. Assemble sliding bracket into stationary bracket.

4. While holding head of spring pin against bottom

of sliding bracket, insert spring pin into keeper

hole in bottom of stationary bracket.

2. Install outer door housing assembly as outlined

in DOOR HANDLE INSTALLATION.

3. Check opening and closing operation of door.

4. Check steamer for proper operation and leaks

around door seal

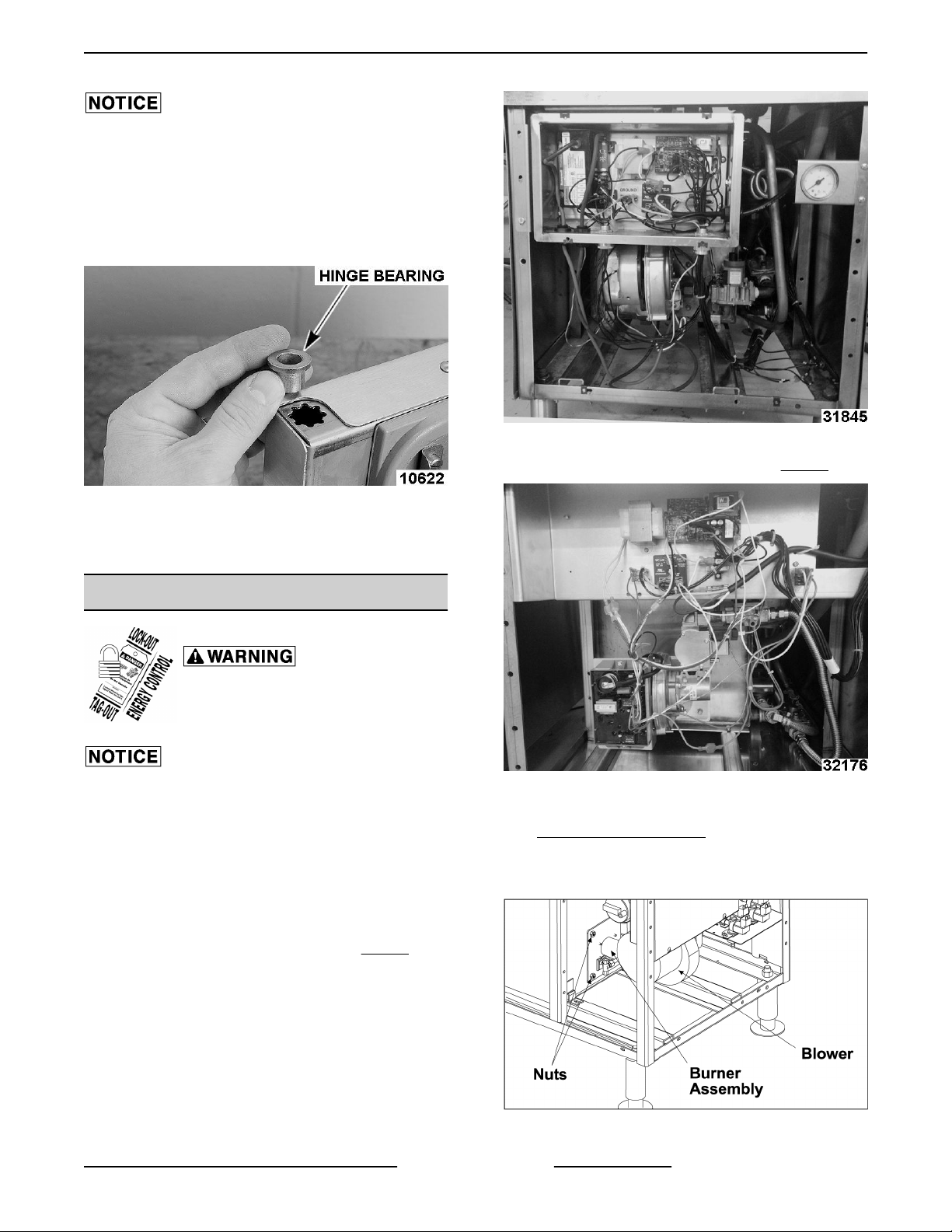

Hinge Bearings

Fig. 19

Fig. 18

A. Secure spring pin in place with retaining pin.

NOTE: Install pins such that heads of pins will be

facing inward toward hinge side of inner door panel

when latch assembly is installed.

5. Install pins to assemble stationary and sliding

brackets together.

A. Secure pins into position with E-clip.

Latch Installation

1. Install latch assembly onto inner door panel with

spring pin toward bottom of door panel.

1. Close door.

2. Remove left SIDE PANEL.

3. Remove nuts from upper hinge located inside

front panel.

Fig. 20

4. Open door slightly, and while holding door, pull

upper hinge away from front panel.

5. Pull upper hinge out of upper door hinge bearing.

6. Lift door assembly up and off lower door hinge.

7. Pry hinge bearing out from door assembly.

8. Remove outer door housing.

F35425 Rev. E (0119) Page 14 of 65

Page 15

C24GA AND C24DA SERIES CONVECTION STEAMER - REMOVAL AND REPLACEMENT OF PARTS

Do not drive bearing into place. The inner door panel

could be damaged. Press bearing into position.

NOTE: When replacing door hinge bearings, replace

both hinge bearings.

9. Position replacement hinge bearing over hinge

opening in door assembly.

Fig. 22

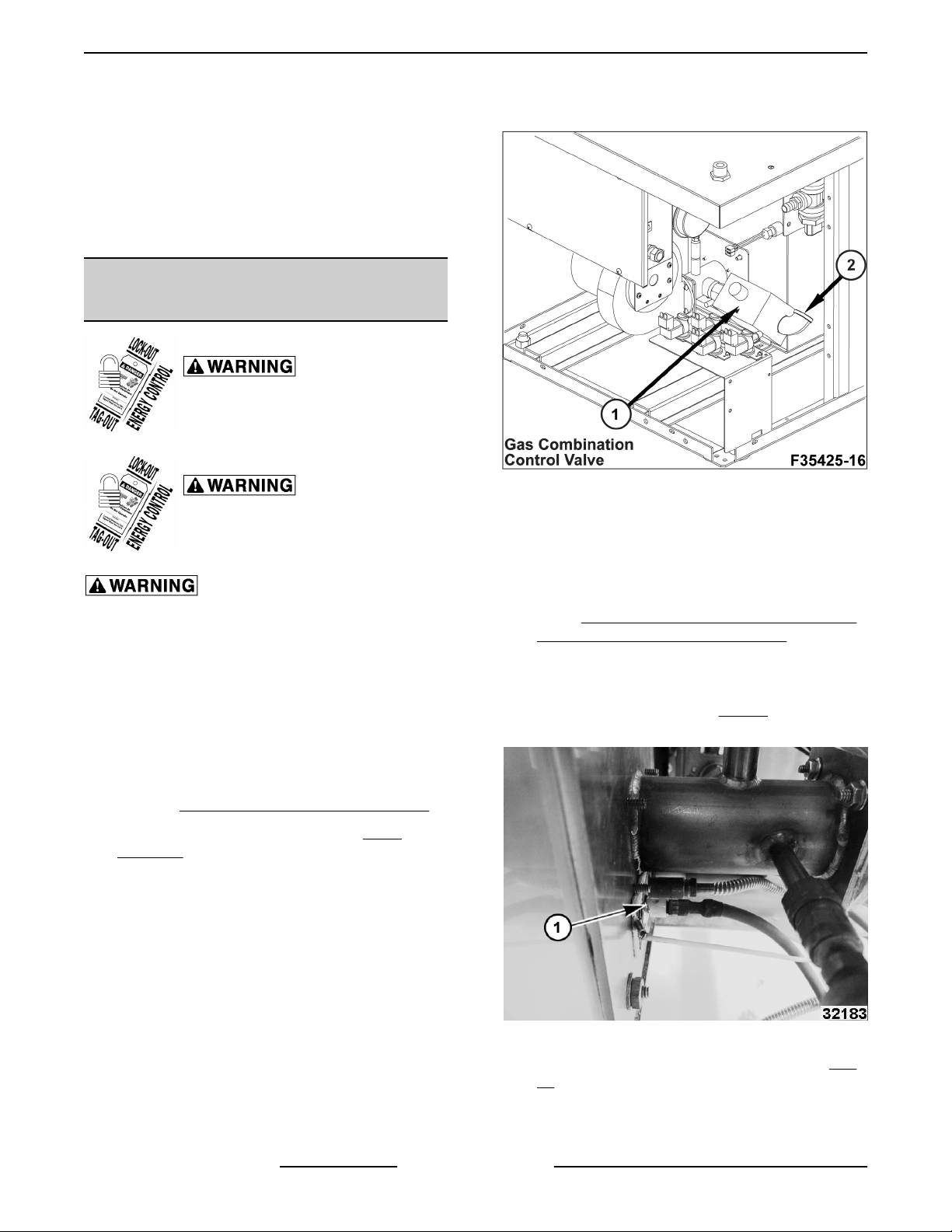

CURRENT PRODUCTION SHOWN IN Fig. 23

Fig. 21

10. Reassemble parts removed in reverse order.

11. Check door for fit and proper door gasket sealing.

MAIN BURNER

Disconnect the electrical power to

the machine and follow lockout /

tagout procedures.

In the previous production (up to serial number

463024849) blower assembly components were

separate (gas valve, air pressure switch, blower, and

ignition module). Current production blower assembly

(starting at serial number 463024850) is one unit and

the air pressure switch is not required. The ignition

module has changed locations and the wire harness

is different. NOTE and VERIFY all wire connections.

PREVIOUS PRODUCTION SHOWN IN Fig. 22

Fig. 23

1. Remove front and side covers as outlined under

COVERS AND PANELS.

2. Disconnect the gas line at gas combination

control valve.

Fig. 24

Page 15 of 65 F35425 Rev. E (0119)

Page 16

C24GA AND C24DA SERIES CONVECTION STEAMER - REMOVAL AND REPLACEMENT OF PARTS

3. Disconnect wires to burner assembly.

4. Remove the nuts securing burner to tank.

5. Drop blower end of burner assembly slightly

down to clear control box and push all interfering

wires out of the way so that burner can be pulled

out of tank.

6. Reverse procedure to install burner assembly.

GAS COMBINATION CONTROL

VALVE

Disconnect the electrical power to

the machine and follow lockout /

tagout procedures.

Fig. 25

Shut off the gas before servicing the

unit and follow lockout / tagout

procedures.

All gas joints disturbed during servicing must be

checked for leaks. Check with a soap and water

solution (bubbles). Do not use an open flame.

A. CHECK ALL JOINTS PRIOR TO THE GAS

VALVE (SOLENOID) BEFORE LIGHTING THE

UNIT.

B. CHECK ALL JOINTS BEYOND GAS VALVE

(SOLENOID) AFTER UNIT IS LIT.

1. Remove FRONT AND RIGHT SIDE PANELS.

2. Remove main burner as outlined in MAIN

BURNER.

3. Disconnect electrical supply wires running to gas

combination control valve.

4. Disconnect pilot gas supply tube from control.

5. Disconnect pipe connections on each side of gas

combination control valve.

6. Reverse procedure to install.

7. Verify PILOT BURNER ADJUSTMENT (ONLY

UNITS WITH ADJUSTABLE PILOT).

NOTE: No pilot burner adjustment needed if unit has

Solaronics burner assembly.

ADJUSTABLE PILOT (1, Fig. 26) BURNER

SHOWN

F35425 Rev. E (0119) Page 16 of 65

Fig. 26

SOLARONICS BURNER ASSEMBLY (1, Fig.

27) NON-ADJUSTABLE PILOT

Page 17

C24GA AND C24DA SERIES CONVECTION STEAMER - REMOVAL AND REPLACEMENT OF PARTS

Fig. 27

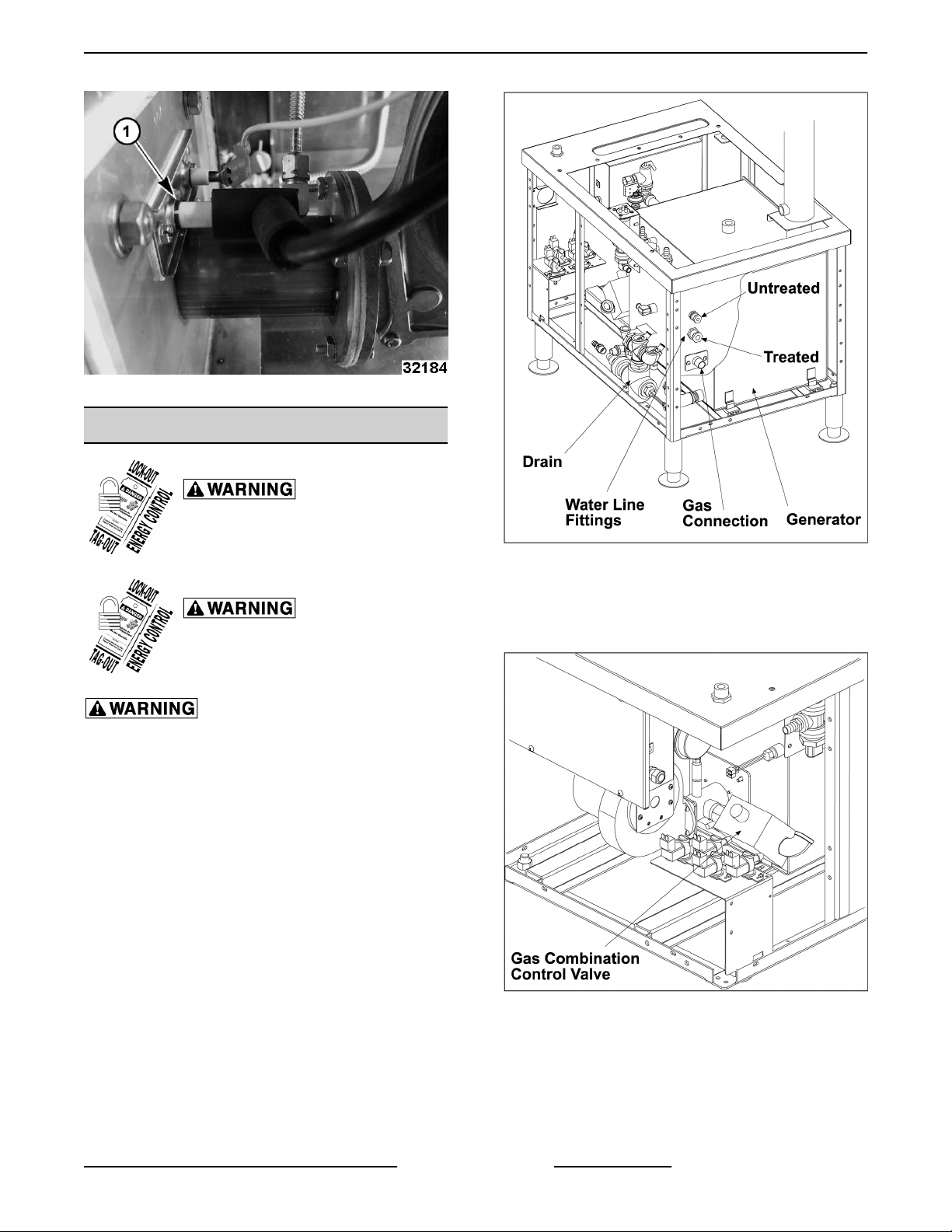

GENERATOR ASSEMBLY

Disconnect the electrical power to

the machine and follow lockout /

tagout procedures.

Shut off the gas before servicing the

unit and follow lockout / tagout

procedures.

All gas joints disturbed during servicing must be

checked for leaks. Check with a soap and water

solution (bubbles). Do not use an open flame.

A. CHECK ALL JOINTS PRIOR TO THE GAS

VALVE (SOLENOID) BEFORE LIGHTING THE

UNIT.

B. CHECK ALL JOINTS BEYOND GAS VALVE

(SOLENOID) AFTER UNIT IS LIT.

1. Drain the generator and allow steamer to cool, if

necessary.

Fig. 28

2. Remove rear and side panels.

3. Disconnect gas line at gas combination control

valve.

Fig. 29

NOTE: Earlier production units show in graphics.

Page 17 of 65 F35425 Rev. E (0119)

Page 18

C24GA AND C24DA SERIES CONVECTION STEAMER - REMOVAL AND REPLACEMENT OF PARTS

Fig. 30

4. Disconnect wires to burner assembly.

5. Disconnect wires from gas combination control

valve.

6. Remove the nuts securing the burner to

generator.

7. Drop blower end of burner assembly slightly

down to clear control box and push all wires out

of the way so that burner can be pulled out of

tank.

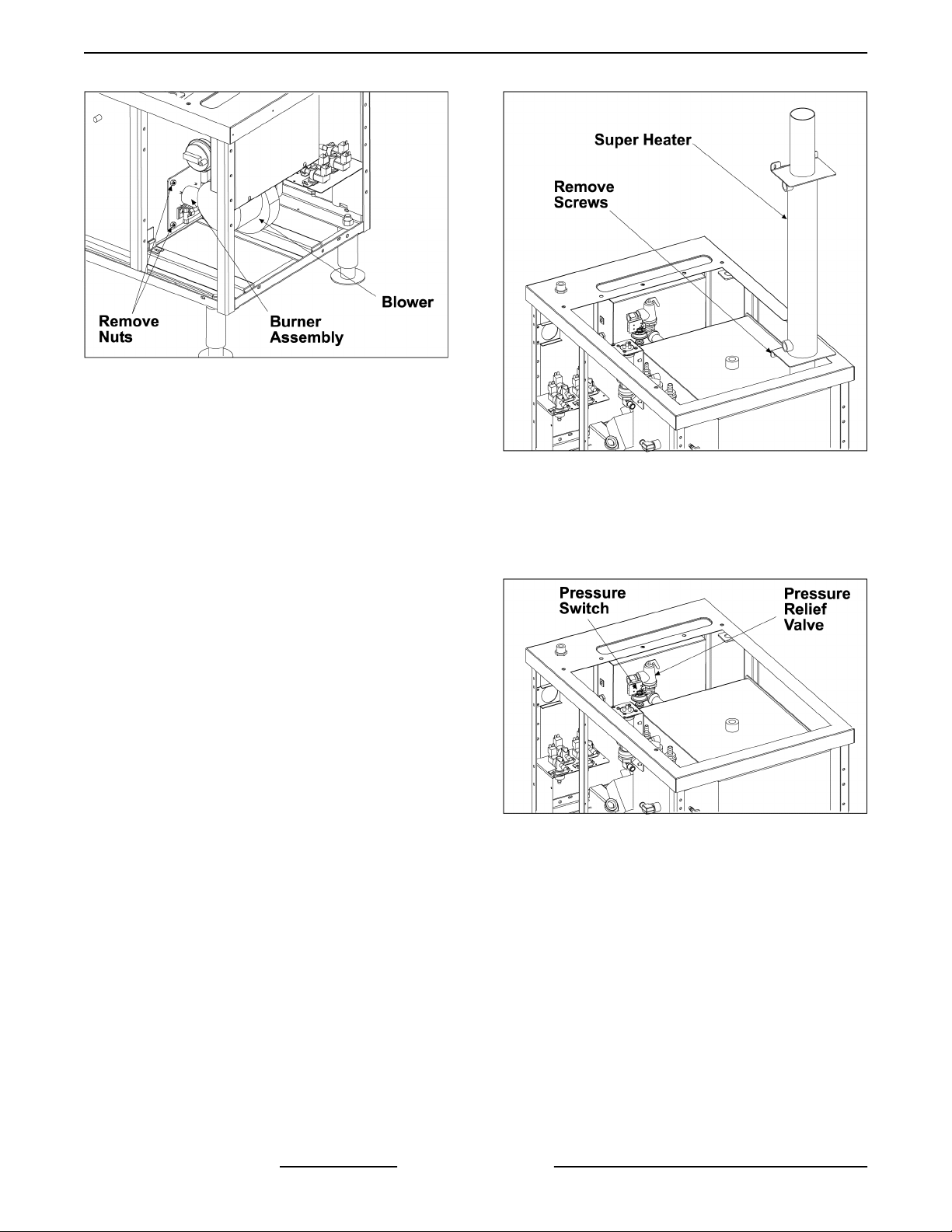

17. Rotate pressure relief valve coupling to allow

pressure relief valve to be rotated about 90° so

that valve is below generator top level.

18. Remove pressure switch from generator.

Fig. 31

8. Disconnect wires from the operating pressure

switch.

9. Loosen hose clamp attaching lower flexible water

line at back panel and use a wrench to disconnect

barb fitting from main inlet water connection.

10. Loosen hose clamp attaching upper flexible

water line at back panel and use a wrench to

disconnect barb fitting from main inlet water

connection.

11. Remove water line from generator. Remove

steam hoses from steam trap and supply to super

heater.

12. Disconnect gas tubing from rear panel.

13. Remove steel drain tube at tank.

14. Disconnect union between tank and drain.

15. Loosen cable clamp screws securing electrical

cable at rear panel so that cable is free to move.

16. Remove screws to free super heater and lift

super heater off flue pipe, if applicable.

Fig. 32

19. Remove bolts attaching front of generator to

frame.

F35425 Rev. E (0119) Page 18 of 65

Page 19

C24GA AND C24DA SERIES CONVECTION STEAMER - REMOVAL AND REPLACEMENT OF PARTS

Fig. 33

20. Move any interfering components out of the way,

then push generator slightly forward to

disengage feet and remove generator from rear

of cabinet.

21. Reverse procedure to install generator.

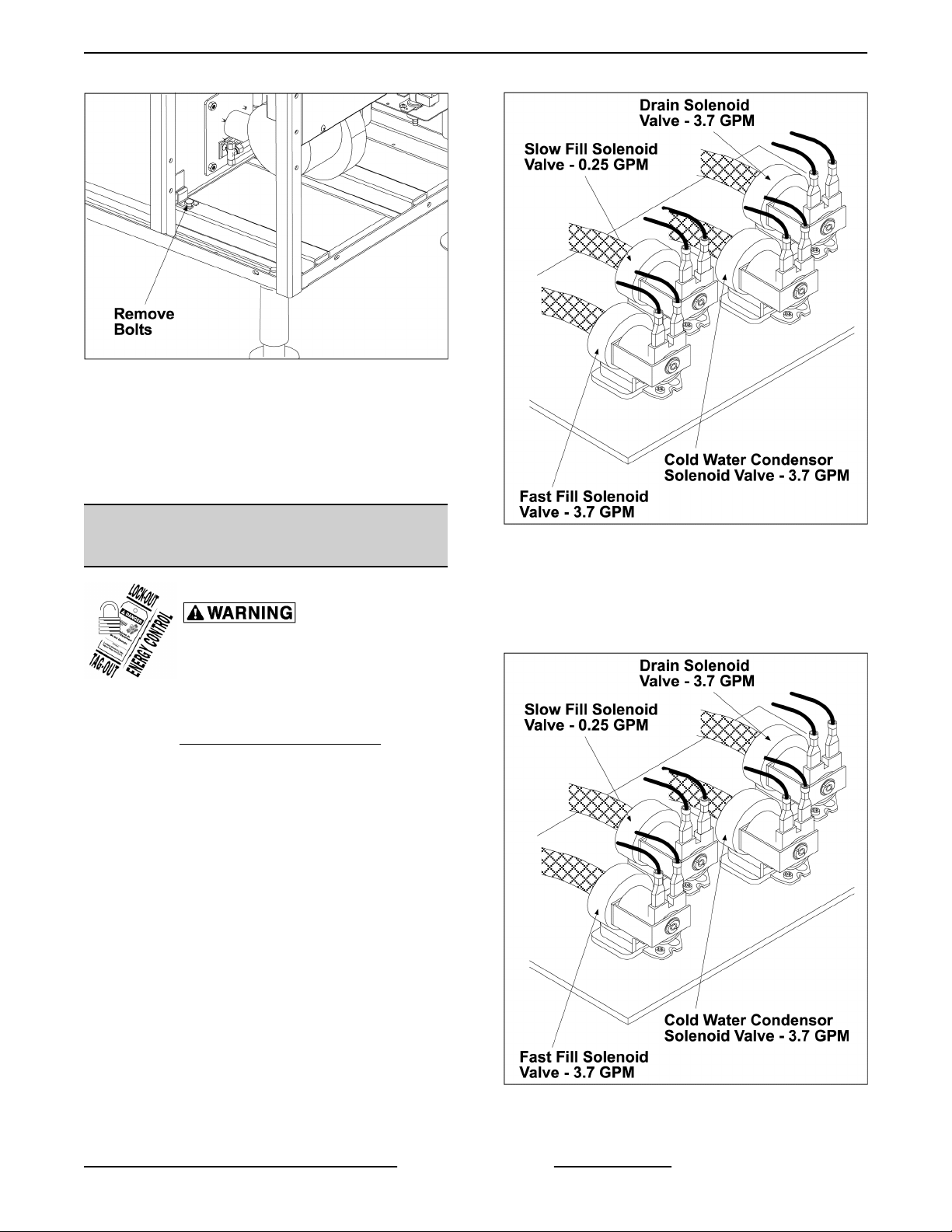

FILL AND COLD WATER SOLENOID

VALVES

Disconnect the electrical power to

the machine and follow lockout /

tagout procedures.

1. Turn off water supply to steamer.

2. Remove FRONT AND SIDE COVERS.

PREVIOUS PRODUCT SHOWN

Fig. 34

3. Pull quick connect power leads off solenoid valve

being serviced.

4. Disconnect water lines to solenoid valve being

serviced and remove solenoid valve from unit.

Fig. 35

CURRENT PRODUCTION SHOWN

Page 19 of 65 F35425 Rev. E (0119)

Page 20

C24GA AND C24DA SERIES CONVECTION STEAMER - REMOVAL AND REPLACEMENT OF PARTS

Fig. 37

SOLARONICS BURNER ASSEMBLY (1) NONADJUSTABLE PILOT

Fig. 36

5. . Reverse procedure to install solenoid valve.

PILOT/SPARK PROBE FLAME

SENSOR (ONLY UNITS WITH

ADJUSTABLE PILOT)

Shut off the gas before servicing the

unit and follow lockout / tagout

procedures.

NOTE: Only for units with adjustable pilot burner.

ADJUSTABLE PILOT BURNER (1)

Fig. 38

1. Remove MAIN BURNER ASSEMBLY.

2. Disconnect gas tube from pilot burner and

remove pilot assembly screws.

F35425 Rev. E (0119) Page 20 of 65

Fig. 39

Page 21

C24GA AND C24DA SERIES CONVECTION STEAMER - REMOVAL AND REPLACEMENT OF PARTS

3. Replace malfunctioning flame sensor or pilot

assembly.

4. Reverse procedure to install a new flame sensor

or pilot assembly.

5. Check for proper operation.

BLOWER CONTROL RELAY (K3)

Shut off the gas before servicing the

unit and follow lockout / tagout

procedures.

Fig. 41

1. Remove CABINET BASE FRONT PANEL.

Disconnect the electrical power to

the machine and follow lockout /

tagout procedures.

NOTE: Starting with production Serial No. 463008610

and higher will have blower control relay (K3) installed.

C24GA 6&10 production gas steamers will begin

using a blower control relay (K3) to carry blower motor

current instead of the operating pressure switch

contacts.

K3 relay must be installed into earlier production units

that are having a Solaronics burner assembly

installed.

NOTE: K3 relay has been used since April 2013 on

units with serial number 463008610 and higher.

ADJUSTABLE PILOT BURNER (1)

2. Locate blower control relay (K3) in front of

steamer base.

3. Note and disconnect lead wires from relay

terminals.

4. Remove (2) mounting screws.

Fig. 40

SOLARONICS BURNER ASSEMBLY (1) NONADJUSTABLE PILOT

Fig. 42

5. Reverse procedure to install and check for proper

operation.

Page 21 of 65 F35425 Rev. E (0119)

Page 22

C24GA AND C24DA SERIES CONVECTION STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

SERVICE PROCEDURES AND ADJUSTMENTS

Certain procedures in this section require electrical test or measurements while power is

applied to the machine. Exercise extreme caution at all times and follow Arc Flash procedures.

If test points are not easily accessible, disconnect power and follow Lockout/Tagout

procedures, attach test equipment and reapply power to test.

BLOWER AIR PRESSURE ADJUSTMENT (ONLY UNITS WITH ADJUSTABLE

PILOT)

NOTE: This adjustment requires a U-inclined or digital manometer capable of reading in 0.01" WC increments to

make the proper blower air pressure adjustments. If the required manometer is not available, do not proceed with

the adjustments.

Shut off the gas before servicing the unit and follow lockout / tagout procedures.

NOTE: Only for units with adjustable pilot burner.

ADJUSTABLE PILOT BURNER (1)

SOLAROINICS BURNER ASSEMBLY (1) NON-

ADJUSTABLE PILOT

F35425 Rev. E (0119) Page 22 of 65

Page 23

C24GA AND C24DA SERIES CONVECTION STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

Blower Air Pressure (COLD)

NOTE: Initial adjustment of blower air pressure should only be made from a cold starting condition.

1. Turn gas supply off.

2. Remove Cabinet Base Front Panel.

3. Remove plug on the outlet side of gas valve and install manometer. Refer to Fig. 45.

Fig. 45

4. Disconnect 24VAC transformer lead wire.

Disconnecting 24 VAC transformer lead wire will prevent ignition sequence from starting when power switch

is on.

5. Verify manometer reading is zero.

NOTE: If ignition module is powered up when checking blower settings it will also affect the blower speed.

6. On Older Machines Only, to access blower speed adjustment screw:

A. Remove 4 screws securing blower shroud to blower.

B. Re-install screws only and continue with next step.

7. Connect power to machine and turn main power switch on.

8. Allow steam generator to fill (approximately 3 to 5 minutes).

NOTE: When water level reaches the low level cut off probe (LLCO) the blower will turn on but ignition module

will not begin sparking to light main burner.

9. Check blower air pressure.

• Reading should be 0.33" to 0.35" WC (cold). If pressure is not correct, adjust blower speed potentiometer

as necessary to achieve correct pressure (clockwise to increase, counterclockwise to decrease).

10. Disconnect power from machine. Leave power switch on to prevent steam generator from draining.

A. Connect 24 VAC transformer lead.

B. Turn gas supply on and connect power to machine (ignition sequence will immediately start). If ignition

module has status LED(s), the ignition sequence can be monitored via LED flash codes.

Page 23 of 65 F35425 Rev. E (0119)

Page 24

C24GA AND C24DA SERIES CONVECTION STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

C. Allow main burner to light. If main burner does not light within 90 seconds, turn power switch off. Wait 5

minutes before re-lighting.

D. Repeat until main burner lights.

If main burner continues not to light, check AIR PRESSURE SWITCH ADJUSTMENT (ONLY UNITS

WITH ADJUSTABLE PILOT). Adjustment of air pressure switch should only be made when machine cold.

11. Verify manifold gas pressure is 2.5" WC (nat) or 10.0" WC (propane). Adjust pressure setting as necessary

(clockwise to increase, counterclockwise to decrease).

If manifold pressure cannot be set correctly, verify gas supply pressure to machine. If machine has pressure

regulator installed in the supply line to gas valve, perform pressure adjustments.

Blower Air Pressure (HOT)

1. Allow steam generator to operate for at least 15 min. (to verify settings when hot & fine tune if necessary).

2. Disconnect power from machine.

3. Leave power switch on to prevent steam generator from draining.

4. Disconnect 24VAC lead wire from ignition module.

5. Verify manometer reading is zero.

6. Connect power to machine. The blower will turn on but ignition module will not begin sparking to light main

burner.

7. Check blower air pressure .

• Reading should be 0.40" to 0.50" WC (hot). If pressure is not correct, adjust the blower speed

potentiometer to achieve 0.45" WC (clockwise to increase, counterclockwise to decrease).

8. Disconnect power from machine. Leave power switch on to prevent steam generator from draining.

9. Connect 24 VAC lead wire to ignition module.

10. Connect power to machine. Ignition sequence will immediately start and main burner will light. If ignition module

has status LED(s), the ignition sequence can be monitored via LED flash codes.

11. Verify manifold gas pressure did not change.

12. Disconnect power and turn gas supply off. Remove manometer and install pipe plug on gas valve manifold

pressure port.

13. Install blower shroud.

14. Reconnect power and turn gas supply on.

15. Steamer is ready for use.

SOLARONICS BURNER

ADJUSTMENT (STARTING AT

SERIAL NUMBER 463024850)

1. Remove RIGHT SIDE PANEL.

2. Check incoming gas pressure to solenoid valve.

A. Loosen screw with flat head screwdriver (1,

Fig. 46) to open pressure tap.

F35425 Rev. E (0119) Page 24 of 65

Page 25

C24GA AND C24DA SERIES CONVECTION STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

Fig. 46

B. Use manometer to measure incoming gas.

• Natural Units- 5" W.C.

• Propane Units - 10" W.C.

C. Turn adjustment screw (1, Fig. 47) all the

way in until it bottoms out.

Fig. 47

D. Back adjustment screw out.

• Natural Units - 6 to 6 ½ Turns.

Fig. 48

4. Analyze combustion.

A. Insert analyzer (1, Fig. 49) into exhaust flue

(2, Fig. 49) as shown.

• Propane Units - 5 to 5 ½ Turns.

3. Check solenoid on/off switch to verify it is in the

ON (Fig. 48) position.

Page 25 of 65 F35425 Rev. E (0119)

Page 26

C24GA AND C24DA SERIES CONVECTION STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

AIR PRESSURE SWITCH

Analyzer wand must be in center of exhaust flue and

at least 2" down into flue.

ADJUSTMENT (ONLY UNITS WITH

ADJUSTABLE PILOT)

Blower air pressure adjustment must be performed

before proceeding with this procedure.

The air pressure switch senses the pressure level

produced by the blower for combustion. When the

pressure is sufficient, the switch closes and supplies

power to the ignition control module. The gas ignition

sequence starts to light the gas pilot and then main

burner. If gas pilot is not lighting (valve not energized),

the ignition control module may not be receiving

power, assuming the minimum water level is satisfied.

Check the air pressure switch operation then adjust if

necessary as outlined in the procedure below.

Fig. 49

B. Verify requirements.

Burner Combustion Requirements

Measure Natural Gas Propane Gas

Supply Pressure

CO2

Percentage

CO (ppm, Air

Free)

C. Turn gas valve adjustment screw clockwise

or counterclockwise to achieve burner

combustion requirements.

D. Install side panel.

E. Verify operation.

7.0" to 10.5"

W.C.

7.0% (+/- 0.5%) 8.0% (+/-0.5%)

Less than 100

ppm

11.0" to 13.0"

W.C.

Less than 100

ppm

Fig. 50

1. Turn the power switch off.

2. Remove the front panel from the cabinet base.

A. Inspect the air intake to the blower for debris

build up and clogging.

1) If debris is found, clean it away from the

air intake.

B. Turn the power switch on and verify main

burner ignition.

1) If burner ignites no adjustment to the

pressure switch setting is necessary.

2) If burner does not ignite, proceed to

step 3.

3. Turn the main gas valve to off.

4. Adjust the air pressure switch setting as follows:

A. Turn the adjustment screw fully clockwise to

the highest setting.

F35425 Rev. E (0119) Page 26 of 65

Page 27

C24GA AND C24DA SERIES CONVECTION STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

B. Slowly turn the adjustment screw

counterclockwise until main gas valve

energizes then add 1/2 turn to the

adjustment. The screw head should not

extend out past the screw housing.

1) If gas valve energizes, proceed to step

5.

2) If gas valve does not energize, check

the following:

a. Remove the lead wires from the

switch and verify with a meter that

the switch contacts are closing

with the blower on. If necessary,

continue to turn the adjustment

screw several turns

counterclockwise to close the

switch contacts.

b. If the switch contacts are not

closing, turn the power switch off,

remove the pressure switch from

the manifold and check the air

orifice for debris build up and

clogging. If debris is found, clean

it away from the orifice.

5. Restart the ignition sequence by turning the

power switch off, waiting 3 seconds, then back

on. .

A. Listen or use a meter for gas pilot ignition to

verify operation.

1) If gas pilot ignition is successful, listen

for main gas burner ignition to verify

operation.

B. Verify the pilot and main burner both ignite

in succession.

1) Restart the ignition sequence by

rapidly turning the power switch off

then back on. A rapid switching is

needed to keep the generator from

starting automatic blowdown.

C. Listen for main gas burner ignition to verify

operation

PILOT BURNER ADJUSTMENT

(ONLY UNITS WITH ADJUSTABLE

PILOT)

c. Replace the orifice, pressure

switch and connect the lead wires

to the switch. Turn the power

switch on and adjust the pressure

switch again as outlined in steps

4A and 4B. Verify the pilot gas

valve is energizing. d. If the pilot

gas valve is not energizing and

power is available to the pressure

switch, turn the power switch off.

Replace with a new air pressure

switch and adjust the switch as

outlined from step 3 thru the end

of this procedure.

NOTE: Only for units with adjustable pilot burner.

Shut off the gas before servicing the

unit and follow lockout / tagout

procedures.

Page 27 of 65 F35425 Rev. E (0119)

Page 28

C24GA AND C24DA SERIES CONVECTION STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

ADJUSTABLE PILOT BURNER (1)

SOLARONICS BURNER ASSEMBLY (1) NON-

ADJUSTABLE PILOT

F35425 Rev. E (0119) Page 28 of 65

Page 29

C24GA AND C24DA SERIES CONVECTION STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

1. Shut the gas off at combination gas valve.

2. Remove cover from manifold pressure tap.

3. Install a barb fitting and connect manometer.

4. Turn on the steamer, let generator fill.

5. Verify air pressure setting is between 0.35" and 0.4" W.C.

6. Verify air pressure switch adjustment.

Fig. 53

7. Turn off the steamer.

8. Remove pilot assembly from burner.

9. Remove cap from pilot adjustment screw.

10. Using cabinet tip screwdriver turn pilot adjustment screw all the way in.

11. Back out pilot adjustment screw five (5) turns counter clockwise. This will get it close, may need tweaked.

12. Remove the wire from main valve (wire # 35).

13. Turn on the steamer, let generator fill.

14. Turn on combination gas valve.

15. Observe pilot flame; adjust pilot flame length using pilot adjustment screw. Set flame to approx. 2" long (Pilot

flame should be a nice blue flame; with slight touch of yellow permissible at tip.)

Page 29 of 65 F35425 Rev. E (0119)

Page 30

C24GA AND C24DA SERIES CONVECTION STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

Fig. 54

16. Turn off the machine.

17. Re-install pilot, reconnect wire # 35.

18. Turn on the machine, let generator fill

19. Observe proper functioning of gas burner.

Operating Pressure Switch

1. Remove CABINET BASE FRONT PANEL. Pressure switch is located behind control box.

Fig. 55

2. Turn power on and let generator come up to pressure.

3. After ready light comes on, turn one of the cooking compartment timers to exhaust steam from the generator.

F35425 Rev. E (0119) Page 30 of 65

Page 31

C24GA AND C24DA SERIES CONVECTION STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

Fig. 56

4. Observe generator pressure gauge reading for several cycles and verify that the burner is cycling off at 3 psi.

CURRENT PRODUCTION SHOWN (1, Fig. 57)

PREVIOUS PRODUCTION SHOWN (Fig. 58)

Fig. 57

Page 31 of 65 F35425 Rev. E (0119)

Page 32

C24GA AND C24DA SERIES CONVECTION STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

Fig. 58

Thumb Wheel Adjustment

The thumb wheel directly below the microswitch changes both the cut-out (off) and the cut-in (on) points of the

operating Pressure Switch.

Turn the thumb wheel to obtain the proper cut-out (off) setting. Turning thumb wheel clockwise increases the

pressure. The cut-out (off) off setting should be 3 psi.

Fig. 59

F35425 Rev. E (0119) Page 32 of 65

Page 33

C24GA AND C24DA SERIES CONVECTION STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

Fig. 60

Inlet Water/Steam Strainer

1. Unscrew the cap from the body.

Fig. 61

2. Remove the screen and any foreign particles trapped in the opening.

3. Rinse the screen thoroughly to remove accumulated debris and replace the screen in the valve body. If the

screen cannot be thoroughly cleaned, replace it with a new one.

4. Reinstall the cap.

Page 33 of 65 F35425 Rev. E (0119)

Page 34

C24GA AND C24DA SERIES CONVECTION STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

AUTOMATIC IGNITION SYSTEMS

NOTE: Only for units with adjustable pilot burner.

ADJUSTABLE PILOT BURNER (1)

When the main power switch is turned on and the water level is above LLCO, the ignition control module is energized

with 24 volts between terminals five and six. High voltage is sent from terminal nine to the spark electrode and an

output of 24 volts is sent from terminals two and three to the pilot coil in the combination valve, allowing gas to flow

to the pilot. The sparking will continue for 90 seconds or until the flame sensor has confirmed that an adequate pilot

flame is present.

Once the pilot flame is confirmed, a 24 volt output from terminal one will be sent to the gas combination control

valve.

TERMINAL NO. DESCRIPTION

Voltage (24 VAC) will be present on MV terminal #1 with the pilot sensing electrode

1

2 Common MV/PV.

3

4 Ground (burner).

5 Ground (24 VAC Neutral).

6 24 VAC Input.

8 Flame Sensor.

9 Flame Sensor.

PREVIOUS PRODUCTION SHOWN

sensing an adequate pilot flame. This output will remain present as long as the pilot

flame remains adequate.

The Pilot Voltage (24 VAC) will be present on terminal #3 at the instant an input voltage

is supplied to the module. This voltage will remain present on terminal #3 providing an

adequate pilot flame is established within 90 seconds. In the event that an adequate

pilot flame is not established within 90 seconds this output voltage will drop out.

SOLARONICS BURNER ASSEMBLY (1) NON-

ADJUSTABLE PILOT

F35425 Rev. E (0119) Page 34 of 65

Page 35

C24GA AND C24DA SERIES CONVECTION STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

Fig. 64

CURRENT PRODUCTION SHOWN SOLARONICS

Fig. 65

Page 35 of 65 F35425 Rev. E (0119)

Page 36

C24GA AND C24DA SERIES CONVECTION STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

Spark Ignition Control Test

The ignition control module and ignition control module transformer are located in the electronics enclosure behind

the generator base front cover.

PREVIOUS PRODUCTION SHOWN IN Fig. 66

1. Check for earth ground.

PREVIOUS PRODUCTION SHOWN IN Fig. 67

Fig. 66

Fig. 67

2. Check to ensure that all electrical terminal connections on the ignition control module and the igniter are clean

and tight.

3. Verify that the ignition control module and the igniter have good ground wire connections. The igniter mounting

bracket should have good metal to metal contact to its mounting surface.

4. Turn the main power switch on. Make sure LLCO light is on.

5. Check for 24VAC output on the ignition control module transformer.

F35425 Rev. E (0119) Page 36 of 65

Page 37

C24GA AND C24DA SERIES CONVECTION STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

A. If 24VAC is present, then replace ignition control module and retest. It may take up to 3 seconds for the

module to reset if main power is turned off then back on.

B. If 24VAC is not present, then ensure that transformer is receiving 120VAC input. If ignition control module

transformer is receiving proper voltage, then replace ignition control module transformer and retest.

IGNITION TEST

1. The gap between the spark probe and the pilot

burner should be approximately 1/8". If the gap

appears to be excessive or poor sparking is

occurring, remove the electronic ignition pilot and

adjust gap.

PREVIOUS PRODUCTION SHOWN

PREVIOUS PRODUCTION SHOWN

2. Inspect the ceramic flame rod insulator for cracks

or evidence of exposure to extreme heat, which

can permit leakage to ground. If either of these

conditions exist, then replace the pilot igniter

assembly.

3. Check the ignition cable for tightness or

damaged insulation.

4. 4. Check unit for proper operation.

Inspect the pilot burner orifice. This should be

approximately 1/8" in diameter and free of debris.

Fig. 68

MANIFOLD PRESSURE ADJUSTMENT (ONLY UNITS WITH ADJUSTABLE

PILOT)

Page 37 of 65 F35425 Rev. E (0119)

Page 38

C24GA AND C24DA SERIES CONVECTION STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

Disconnect the electrical power to the machine and follow lockout / tagout procedures.

Shut off the steam before servicing the unit and follow lockout / tagout procedures.

All gas joints disturbed during servicing must be checked for leaks. Check with a soap and water solution

(bubbles). Do not use an open flame.

ADJUSTABLE PILOT BURNER (1)

A. CHECK ALL JOINTS PRIOR TO THE GAS VALVE (SOLENOID) BEFORE LIGHTING THE UNIT.

B. CHECK ALL JOINTS BEYOND GAS VALVE (SOLENOID) AFTER UNIT IS LIT.

1. Remove FRONT, RIGHT AND LEFT SIDE

PANELS

2. Turn the gas combination control valve off.

SOLARONICS BURNER ASSEMBLY (1) NON-

ADJUSTABLE PILOT

F35425 Rev. E (0119) Page 38 of 65

Page 39

C24GA AND C24DA SERIES CONVECTION STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

1. For access to compartment controls, remove the

right side panel from the cooking compartment as

outlined under COVERS AND PANELS.

2. Check door switch for proper operation.

Fig. 71

3. To measure the manifold pressure, remove the

1/8" NPT plug (pressure tap) on the outlet side of

the gas combination control valve and attach a

manometer.

4. Turn the gas supply valve and the main power

switch on. Allow generator to fill.

5. Verify burner air pressure is 0.35" to 0.4" W.C.

6. Turn the gas combination control valve on and

wait until main burner lights.

7. Observe the manometer pressure reading and

compare to the pressure chart below.

GAS PRESSURE READINGS (INCHES W.C.)

MANIFOL

D

GAS

TYPE

Natrual 2.5 7.0 5.0 14

Propan

e

* If the incoming line pressure is less than the

minimum stated, then the manifold pressure

cannot be set correctly.

8. Once the correct pressure has been set, turn the

power switch and gas supply off, replace the

adjustment screw cap and 1/8" NPT plug

(pressure tap) on the outlet side of the valve.

10.0 11.0 11.0 14

RECOMMENDED MIN

LINE*

MA

X

3. Check cooking timer function and contact

position. See SCHEMATICS under

ELECTRICAL OPERATION.

4. Check that timer motor operates when

connected to power. If a problem is found in

timer, replace it, do not take timer apart.

5. Check wiring for damaged insulation (no short

circuit).

6. Check that all connections and terminals are

securely fastened (no open circuits).

7. Check that all connections are made according

to compartment control wiring diagram.

Latch Adjustment

If the cabinet door jams and cannot be opened, do not

force or pry the door, as damage will occur.

First, try lifting up on the bottom of the door at the

handle end to disengage the latch. If that does not

work, remove the right side panel from the cooking

compartment as outlined under COVERS AND

PANELS.

The striker that catches on the door latch is located

behind the front face of the cooking cavity. Remove

the nut from the striker to release it from the panel.

Fig. 72

DOOR

COOKING COMPARTMENT

Controls

Page 39 of 65 F35425 Rev. E (0119)

Page 40

C24GA AND C24DA SERIES CONVECTION STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

4. Once the proper slot alignment has been set,

hold the striker close to its base using an open

end wrench, add Loctite to the threads, then

tighten the striker nut. Be careful not to damage

the striker slot when tightening or door may not

latch properly. Do not over tighten as the striker

will begin to turn and change alignment.

5. If door does not open easily, add shims as

necessary between striker and cabinet front.

6. Repeat steps 2 thru 4.

DELIME GENERATOR

READ AND FOLLOW THE INSTRUCTIONS ON THE

DELIMING MATERIAL PACKAGE. AVOID

CONTACT WITH SKIN AND EYES. WEAR PLASTIC

OR RUBBER GLOVES AND SAFETY GOGGLES

Fig. 73

Once the nut and washer have been removed, door

will open freely.

Remove any burrs on the striker that may cause the

latch to stick. Reinstall the striker and adjust so door

will not jam.

Striker Adjustment

1. Reinstall the striker with the slot pointing upwards

and hand tighten nut only.

WHEN HANDLING. WASH THOROUGHLY AFTER

HANDLING. IF DELIMING SOLUTION COMES IN

CONTACT WITH THE SKIN OR EYES, RINSE

THOROUGHLY WITH CLEAN WATER.

THE STEAMER AND ITS PARTS ARE HOT. USE

CARE WHEN OPERATING, CLEANING OR

SERVICING THE STEAMER. THE COOKING

COMPARTMENT CONTAINS LIVE STEAM. STAY

CLEAR WHEN OPENING DOOR.

2. Close the door to center the striker in the oval

mounting hole.

3. Open the door and check the striker’s slot for

horizontal alignment. The slot on the striker must

be kept horizontal in order for the door latch to

catch it properly and latch.

Fig. 74

□ Delime generator weekly. Refer to TOOLS for

Scale Release information.

This procedure is not intended to take the place of a

water treatment program. Use instructions supplied

with Scale blocker PM kit when filter is being replaced.

NOTE: Scale blocker® water treatment system is

used for preventative maintenance and must be

performed according to water hardness. Refer to

schedule chart below. 84 oz of Scale Release is

required to delime generator when no water treatment

is used other than carbon block. 28 oz (2 bags) is

required for C24GA6 & 10.

Hardness (Grains) Deliming Schedule

0 to 5 6 Months

5 to 10 3 Months

10 to 15 Monthly

15 to 20 2 Weeks

20+

Other Water Treatment Is

Required

F35425 Rev. E (0119) Page 40 of 65

Page 41

C24GA AND C24DA SERIES CONVECTION STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

Delime Generator Procedure

Items Required (not provided)

• Deliming material. Refer to TOOLS for scale

release information.

• Funnel.

• Plastic or rubber gloves.

• Safety goggles or face shield.

• Measuring cup.

• 1 gallon container for mixing deliming solution.

• Petrol-Gel Lubricant or equivalent food grade

grease for coating deliming port threads.

NOTE: Deliming solution may cause the surface of

aluminum measuring tools to tarnish or etch.

C24GA (Automatic Drain) 11 US GAL Capacity

Steam Generator.

1. Turn power switch off. Wait 15 minutes for steam

generator to completely drain and the drain valve

to close.

2. Turn cooking timers to off.

8. Turn power switch on. When ready light comes

on, allow steamer to remain on for 45 minutes.

9. After 45 minutes, turn cooking timers on for 5

minutes to delime the steam tubes and nozzles.

10. After 5 minutes, turn power switch off and allow

steam generator to completely drain, 5 minutes.

11. Turn power switch on. When ready light comes

on, turn cooking timers on for 30 seconds to rinse

steam tubes and nozzles.

12. Turn power switch off and allow steam generator

to completely drain.

13. Turn cooking timers to off.

14. Repeat steam generator rinse one time.

15. Clean exterior and interior using a mild solution

of soap and water.

Do not use cleaners containing chlorides or chlorine.

16. Rinse with clean water then dry with a soft cloth.

3. Prepare deliming solution according to the

instructions on deliming material package.

Follow all manufacturers’ instructions.

4. Remove delime port cap on top of unit and insert

funnel into delime port.

Fig. 75

5. Pour deliming solution into steam generator

slowly to avoid spillage.

6. Remove funnel from delime port then rinse port

with clean water.

7. Lightly coat delime port threads with Petrol-Gel

then install delime port cap. Cap must be

installed and tightened securely at all times.

Leave compartment doors open when not in use.

17. The steamer is ready for operation or shutdown.

COOKING CYCLE TEST

General

During a cooking cycle, the gas heating system will

cycle on and off as necessary to maintain steam

pressure in the generator. When the steam pressure

in the steam generator reaches 4 psi for the first time

after machine is switched on, the steam header

pressure relay latches on and supplies power to

compartment controls. Ready light will illuminate

(header pressure relay remains latched until the

machine is switched off).

Test operation of the cooking compartment controls.

1. With both timer knobs at the off position, open the

compartment doors.

2. Observe that no steam has entered the cooking

compartments.

3. Close the doors.

4. Set both timer knobs at 2 minutes.

5. Confirm that the ready lights go off, the cooking

lights come on, and steam begins to enter the

compartments.

6. After one minute, open both doors.

Page 41 of 65 F35425 Rev. E (0119)

Page 42

C24GA AND C24DA SERIES CONVECTION STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

7. Observe that steam has ceased to enter each

compartment, cooking lights go back to ready,

and one minute is remaining on each cook timer.

8. Close the doors.

9. Confirm that steam delivery and cook timing

resume.

10. Observe the floor drain to ensure that live steam

from the compartments is being cooled by cold

water from the cold water condenser solenoid

valve.

11. When the timer knobs reach 0, confirm that the

buzzers sound, steam delivery ceases, cooking

lights go off, and ready lights come on.

12. To silence the buzzers, turn the timer knobs to off

position.

13. Turn the main power switch off to remove power

from the steamer, and confirm that the red light

goes out and generator drains.

PROBE INSPECTION

It is recommended that the generator be thoroughly

inspected for excessive scale and lime build-up on a

quarterly basis. In hard water areas or for units heavily

used, a shorter interval should be used. This

inspection consists of the following:

Drain Plug -

Probe -

Controls -

PREVIOUS PRODUCTION MODELS

Remove clean-out port plug to

check for scale.

A check of lime build-up on the

water level probe assembly.

check of all generator controls,

including the pressure switches.

Fig. 76

CURRENT PRODUCTION MODELS

Periodic Maintanence

F35425 Rev. E (0119) Page 42 of 65

Fig. 77

MAINTANENCE CHECKS

Page 43

C24GA AND C24DA SERIES CONVECTION STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

□ DELIME GENERATOR

□ Change carbon block filter every 6 months or per

filter manufacture’s recommendation.

□ Weekly inspect door seals for cuts, tears, or

leaks. Replace as needed.

□ Weekly check filter system pressure, 20 PSI

minimum while filling, and change cartridge(s) if

less or if they are due for replacement.

Yearly Maintanence

Disconnect the electrical power to

the machine and follow lockout /

tagout procedures.

1. Verify power is removed and locked.

2. Turn off water supply to steamer.

3. Verify hoods system is operating per

manufactures specification and is clean and free

of obstructions and grease build up.

Current Production Models

A. Remove FLUE WRAP.

B. remove the “Y” strainer screen with a

5/8“socket or wrench.

C. Clean the screen.

D. Install screen and flue wrap.

6. Inspect screens.

A. Remove the two water supply hoses and

inspect screens in the valve openings. If

dirty remove the screen by prying it out with

a small screw driver. Clean the screen and

reinsert into the valve opening. Reinstall the

water supply hoses making sure the filtered/

treated water hose is connected to the valve

marked treated or filtered water. Improperly

reconnecting the hoses will result in

excessive scale build up and corrosion.

4. Inspect water level probes.

NOTE: Current production probe housing is welded

to generator tank.

A. Remove

B. Remove and inspect water level probes.

C. Clean water level probes if lime scale is

present.

If probes show signs of corrosion or excessive lime

scale build up, replace probes and have water tested.

D. Apply pipe sealant or teflon tape to threads

on probe.

E. Install water level probes.

5. Inspect steam and drain strainers.

NOTE: Current production generatorsonly have "Y"

type strainers located in middle of steam manifold.

Earlier Production Models

A. Remove pipe plugs located on right side of

steam generator.

RIGHT SIDE COVER .

B. Remove steam and drain strainers.

C. Clean strainers.

D. Install strainers.

E. Apply pipe sealant or teflon tape on plug

threads.

Page 43 of 65 F35425 Rev. E (0119)

Page 44

C24GA AND C24DA SERIES CONVECTION STEAMER - ELECTRICAL OPERATION

ELECTRICAL OPERATION

WATER LEVEL CONTROLS

Low Level Cut-Off and Differential Control

The steamer is equipped with three water level

sensing probes (high, low and low level cut-off) and a

single water level control board. The water level

control board performs two functions:

• Provide low level cut-off protection to shut off the

heat source in case the water level drops below

the low level cut-off (LLCO) probe.

• Perform as a differential level control to maintain

the water level between the low and high water

level probes.

The water level control (WLC) has 120VAC across

terminals L1 and L2 which powers the primary side of

the transformer. On one side of the transformer

secondary, power is provided to the control by a series

path through chassis ground (GND). The other side of

the transformer secondary, 12VAC is attached to the

probe that directs power to the other side of WLC relay

coils (LLCO and HL) and to the inverse latching relay

(ILR) electronic circuit of WLC. As water enters the

steam generator, it becomes part of the WLC circuit.

When the water level in steam generator reaches a

probe, that circuit is completed. The inverse latching

relay contacts of WLC are in their shelf state (ILR-1

NO and ILR-2 NC) until WLC is powered.

through the low level probe (LL) and ILR-1 contacts.

With ILR-2 contacts open, HL relay is de-energized

and HL LED turns off. With HL-1 contacts open, the

slow fill solenoid is de-energized, stopping the flow of

water to the steam generator.

As steam is produced during a cooking cycle, the

water level in the generator recedes. When the water

level drops below the low level (LL) probe, power is

removed from the inverse latching relay, HL relay

energizes through ILR-2 and HL contacts change

state. The slow fill solenoid is energized again through

HL-1 to refill the steam generator and HL LED is lit.

The HL relay and LED will toggle on and off during a

cooking cycle as needed.

Fig. 78

When the main power switch is turned on, power is

supplied to the WLC. The high level (HL) relay is

energized, HL LED illuminates and HL-1 normally

open contacts close. The fast fill solenoid is energized

through LLCO-2 normally closed contacts and steam

generator begins fast fill. Power is not transferred to

the slow fill solenoid until the water level reaches the

LLCO probe and the LLCO relay is energized.

When the water level reaches the low level cut-off

(LLCO) probe, LLCO relay is energized and LLCO

LED is lit. The LLCO-2 contacts open, de-energizing

the fast fill solenoid, and the LLCO-1 normally open

contacts close. With LLCO-1 contacts closed, power

is provided to the heating steamer control circuit to

begin steam generation. With HL-1 contacts closed,

the slow fill solenoid is energized and steam generator

continues to fill at a slower rate.

LLCO relay will remain energized and its LED will stay

lit until the water level in steam generator drops below

LLCO probe or main power switch is turned off.

Water level reaches high level (HL) probe, the inverse

latching relay on WLC is energized and locked

SEQUENCE OF OPERATION

Refer to schematic diagrams AI2947 and 22851 to

explain the steamer electrical sequence of operation.

Initial Fill and Preheat

1. Conditions:

A. Steamer connected to:

1) 120VAC and is properly grounded.

2) Cold water supply with correct water

requirements and valve is on.

3) Steamer Connected to proper gas

supply with correct supply pressures

and valve is on.

B. Power switch off.

C. Cold water thermostat open (drain water

temperature below 140°F for drain cooling).

1) Drain cold water condenser (CWC)

solenoid N.C. is de-energized.

F35425 Rev. E (0119) Page 44 of 65

Page 45

C24GA AND C24DA SERIES CONVECTION STEAMER - ELECTRICAL OPERATION

D. Timer delay output off.

1) Drain solenoid valve N.C. is deenergized.

E. Main gas valve knob in on position.

F. Operating pressure switch (N.C.) is closed.

G. Air pressure switch (N.O.) is open.

H. Steam generator empty.

I. Compartment times off and doors are open.

2. Turn power switch on.

A. Time delay relay de-energized.

B. Power light (amber) on control panel is on.

C. 120VAC to - Terminal 5 on cavity relay K2

(N.O. contacts 5/3 provide power to

compartment controls) and water level

control (WLC) terminal L1.

D. 120VAC applied to compartment controls

after cavity relay K1 is energized (generator

at operating pressure).

3. With water level control (WLC) energized. Refer

to WATER LEVEL CONTROL for complete

operation details.

6. Trial for ignition starts.

A. Ignition module generates spark at ignitor/

direct spark.

1) Sparking will continue until an

adequate pilot flame is sensed

maximum 10 seconds. If pilot flame is

not established within the 10 second

ignition trial time, the output to spark

electrode is shut off (sparking stops)

and the output to enrichment and main

valves is locked out.

B. Sparking stops the main burner lights and

flame sense has been proven.

1) Steam generator begins heating.

7. Water level reaches Low Level (L) probe.

A. Power to terminal L on WLC (no switching

action) (input to board level control circuit

present). WLC internal latching relay ILR-1

contacts are open.

8. Water level reaches High Level (HL) probe

(board level control circuit energized and locked).

A. HL led off. WLC HL (high level) relay de-

energized.

A. HL led lit. WLC HL (high level) relay

energized.

1) WLC HL N.O. contacts close.

B. Fast fill solenoid energized through WLC

LLCO relay N.C. contacts. Steam generator

begins fast fill.

4. Water level reaches Low Level Cut-Off (LLCO)

probe.

A. LLCO LED lit. WLC LLCO relay energized.

1) LLCO N.C. contacts open. Fast fill

solenoid de-energized.

2) WLC LLCO N.O. contacts close. Slow

fill solenoid energized through WLC HL

closed contacts. Steam generator

changes to slow fill.

a. Operating pressure switch N.C

contacts engerizes K3 relay for

blower.

b. K3 relay N.O. contact closes and

blower is powered.

c. Air pressure switch N.O. contacts

close providing 120 volts to

transformer.

5. 24VAC out from transformer secondary.

1) HL N.O. contacts open. Slow fill

solenoid de-energized (generator

filling stops).

9. Steam generator pressure reaches 3 psi.

A. Ready light on (green) (compartment

controls).

1) N.C. contacts open. Power removed

from:

a. Burner system.

b. Burner system de-energized

(heating stops).

2) N.O. contacts close. Cavity relay K2

energized.

a. Relay N.O. contacts 5/3 close and

latch - 120VAC to compartment

controls. Relay remains

energized until power switch is

turned off.

b. Ready light (green) is on.

B. Operating pressure switch contacts change

state.

10. Steamer is ready for operation. Refer to

COMPARTMENT CONTROLS.

Water Re-fill (After Initial Fill)

Page 45 of 65 F35425 Rev. E (0119)

Page 46

C24GA AND C24DA SERIES CONVECTION STEAMER - ELECTRICAL OPERATION