Page 1

Owner’s Manual & Safety Instructions

Save This Manual Keep this manual for the safety warnings and precautions, assembly,

operating, inspection, maintenance and cleaning procedures. Write the product’s serial number in the

back of the manual near the assembly diagram (or month and year of purchase if product has no number).

Keep this manual and the receipt in a safe and dry place for future reference. 19h

Visit our website at: http://www.harborfreight.com

Email our technical support at: productsupport@harborfreight.com

When unpacking, make sure that the product is intact

and undamaged. If any parts are missing or broken,

please call 1-888-380-0318 as soon as possible.

Copyright© 2017 by Harbor Freight Tools®. All rights reserved.

No portion of this manual or any artwork contained herein may be reproduced in

any shape or form without the express written consent of Harbor Freight Tools.

Diagrams within this manual may not be drawn proportionally. Due to continuing

improvements, actual product may differ slightly from the product described herein.

To ol s re q u ir e d fo r as s e mb l y a n d s e r vi c e m a y n o t b e in c l ud e d .

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

Page 2

Table of Contents

Safety ......................................................... 2

Specifications ............................................. 7

SAFETY MAINTENANCEBASIC WELDING WELDING TIPSSETUP

Setup .......................................................... 8

Basic Welding ............................................ 15

Welding Tips .............................................. 23

Maintenance .............................................. 27

Parts List and Diagrams ............................ 30

Warranty .................................................... 32

WARNING SYMBOLS AND DEFINITIONS

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that

follow this symbol to avoid possible injury or death.

Indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

Addresses practices not related to personal injury.

IMPORTANT SAFETY INFORMATION

Read all safety warnings and instructions.

Failure to follow the warnings and instructions may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

General Safety

PROTECT yourself and others. Read and understand this information.

1. Before use, read and understand

manufacturer′s instructions,

Material Safety Data Sheets (MSDS′s),

employer′s safety practices, and ANSI Z49.1.

2. Keep out of reach of children.

Keep children and bystanders away while operating.

3. Place the welder on a stable location before use.

If it falls while plugged in, severe injury,

electric shock, or fire may result.

4. Do not overreach.

Keep proper footing and balance at all times.

5. Stay alert, watch what you are doing and use

common sense when operating a welder.

Do not use a welder while you are tired or under

the influence of drugs, alcohol or medication.

A moment of inattention while operating welders

may result in serious personal injury.

6. Avoid unintentional starting. Make sure you are

prepared to begin work before turning on the Welder.

7. Never leave the Welder unattended while

energized. Turn power off if you have to leave.

8. The warnings, precautions, and instructions

discussed in this instruction manual cannot

cover all possible conditions and situations

that may occur. It must be understood by the

operator that common sense and caution are

factors which cannot be built into this product,

but must be supplied by the operator.

Page 2 For technical questions, please call 1-888-380-0318. Item 63617

Page 3

Fume and Gas Safety

Welding and Plasma Cutting Produce toxic fumes.

1. Exposure to welding or cutting exhaust

fumes can increase the risk of developing

certain cancers, such as cancer of the

larynx and lung cancer. Also, some diseases

that may be linked to exposure to welding

or plasma cutting exhaust fumes are:

• Early onset of Parkinson’s Disease

• Heart disease

• Ulcers

• Damage to the reproductive organs

• Inflammation of the small intestine or stomach

• Kidney damage

• Respiratory diseases such as

emphysema, bronchitis, or pneumonia

Use natural or forced air ventilation and wear

a respirator approved by NIOSH to protect

against the fumes produced to reduce the

risk of developing the above illnesses.

2. Do not use near degreasing or

painting operations.

INHALATION HAZARD:

3. Keep head out of fumes.

Do not breathe exhaust fumes.

4. Use enough ventilation, exhaust at arc, or

both, to keep fumes and gases from breathing

zone and general area. If engineering controls

are not feasible, use an approved respirator.

5. Work in a confined area only if it

is well-ventilated, or while wearing

an air-supplied respirator.

6. Have a recognized specialist in

Industrial Hygiene or Environmental Services

check the operation and air quality

and make recommendations

for the specific welding situation.

Follow OSHA guidelines for

Permissible Exposure Limits (PEL’s) and

the American Conference of Governmental

Industrial Hygienists recommendations for

Threshold Limit Values (TLV’s) for fumes and gases.

SAFETYMAINTENANCE BASIC WELDINGWELDING TIPS SETUP

Arc Ray Safety

ARC RAYS can injure eyes and burn skin.

1. Wear ANSI-approved welding eye protection

featuring at least a number 10 shade lens rating.

2. Wear leather leggings, fire resistant shoes

or boots during use. Do not wear pants with

cuffs, shirts with open pockets, or any clothing

that can catch and hold molten metal or sparks.

3. Keep clothing free of grease, oil,

solvents, or any flammable substances.

Wear dry, insulating gloves and protective clothing.

4. Wear an approved head covering to protect

the head and neck. Use aprons, cape, sleeves,

shoulder covers, and bibs designed and

approved for welding and cutting procedures.

5. When welding/cutting overhead or in confined

spaces, wear flame resistant ear plugs or

ear muffs to keep sparks out of ears.

Page 3For technical questions, please call 1-888-380-0318.Item 63617

Page 4

Electrical Safety

ELECTRIC SHOCK can KILL.

1. Turn off, disconnect power, and

SAFETY MAINTENANCEBASIC WELDING WELDING TIPSSETUP

discharge electrode to ground before setting

down torch/electrode holder and before service.

2. Do not touch energized electrical parts.

Wear dry, insulating gloves. Do not touch electrode

holder, electrode, welding torch, or welding wire with

bare hand. Do not wear wet or damaged gloves.

3. Connect to grounded, GFCI-protected

power supply only.

4. Do not use near water or damp objects.

5. People with pacemakers should consult their

physician(s) before use. Electromagnetic fields

in close proximity to heart pacemaker could cause

pacemaker interference or pacemaker failure.

6. Do not expose welders to rain or wet conditions.

Water entering a welder will increase

the risk of electric shock.

7. Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the welder.

Keep cord away from heat, oil, sharp edges

or moving parts. Damaged or entangled

cords increase the risk of electric shock.

8. Do not use outdoors.

9. Insulate yourself from the workpiece and

ground. Use nonflammable, dry insulating

material if possible, or use dry rubber mats,

dry wood or plywood, or other dry insulating

material large enough to cover your full

area of contact with the work or ground.

Fire Safety

ARC AND HOT SLAG can cause fire.

1. Clear away or protect flammable objects.

Remove or make safe all combustible materials for a

radius of 35 feet (10 meters) around the work area.

Use a fire resistant material to cover

or block all open doorways, windows,

cracks, and other openings.

2. Keep ABC-type fire extinguisher near

work area and know how to use it.

3. Maintain a safe working environment.

Keep the work area well lit.

Make sure there is adequate

surrounding workspace. Keep the work area free

of obstructions, grease, oil, trash, and other debris.

4. Do not operate welders in atmospheres

containing dangerously reactive or

flammable liquids, gases, vapors, or dust.

Provide adequate ventilation in work areas

to prevent accumulation of such substances.

Welders create sparks which may ignite flammable

substances or make reactive fumes toxic.

5. If working on a metal wall, ceiling, etc.,

prevent ignition of combustibles on the

other side by moving the combustibles to a

safe location. If relocation of combustibles is

not possible, designate someone to serve as

a fire watch, equipped with a fire extinguisher,

during the cutting process and for at least one

half hour after the cutting is completed.

6. Do not weld or cut on materials having

a combustible coating or combustible

internal structure, as in walls or ceilings, without

an approved method for eliminating the hazard.

7. Do not dispose of hot slag in containers

holding combustible materials.

8. After welding, make a thorough examination

for evidence of fire. Be aware that easily

visible smoke or flame may not be present

for some time after the fire has started.

9. Do not apply heat to a container that has held

an unknown substance or a combustible

material whose contents, when heated,

can produce flammable or explosive vapors.

Clean and purge containers before applying heat.

Vent closed containers, including castings,

before preheating, welding, or cutting.

Page 4 For technical questions, please call 1-888-380-0318. Item 63617

Page 5

Welder Use and Care

1. Do not use the welder if the switch does not turn

it on and off. Any welder that cannot be controlled

with the switch is dangerous and must be repaired.

2. Disconnect the plug from the power

source before making any adjustments,

changing accessories, or storing welders.

Such preventive safety measures reduce the

risk of starting the welder accidentally.

3. Prevent unintentional starting.

Ensure the switch is in the offposition before connecting to power

source or moving the welder. Carrying

or energizing welders that have the

switch on invites accidents.

Maintenance

1. Maintain welders. Check for misalignment or

binding of moving parts, breakage of parts

and any other condition that may affect the

welder’s operation. If damaged, have the

welder repaired before use. Many accidents

are caused by poorly maintained welders.

2. Have your welder serviced by a qualified

repair person using only identical

replacement parts. This will ensure that

the safety of the welder is maintained.

4. Store idle welders out of the reach of

children and do not allow persons unfamiliar

with the welder or these instructions to

operate the welder. Welders are dangerous

in the hands of untrained users.

5. Use the welder and accessories in

accordance with these instructions, taking

into account the working conditions and

the work to be performed. Use of the welder

for operations different from those intended

could result in a hazardous situation.

6. Do not use the welder for pipe thawing.

3. Maintain labels and nameplates on the Welder.

These carry important information.

If unreadable or missing, contact

Harbor Freight Tools for a replacement.

4. Unplug before maintenance. Unplug the Welder

from its electrical outlet before any inspection,

maintenance, or cleaning procedures.

SAFETYMAINTENANCE BASIC WELDINGWELDING TIPS SETUP

Gas Shielded Welding – Cylinder Safety

Cylinders can explode when damaged.

1. Never weld on a pressurized or a closed cylinder.

2. Never allow an electrode holder,

electrode, welding torch, or welding

wire to touch the cylinder.

3. Keep cylinders away from any electrical circuits,

including welding circuits.

4. Keep protective cap in place over the valve

except when the cylinder is in use.

5. Use only correct gas shielding equipment

designed specifically for the type of welding

you will do. Maintain this equipment properly.

6. Protect gas cylinders from heat, being struck,

physical damage, slag, flames, sparks, and arcs.

7. Always use proper procedures

to move cylinders.

SAVE THESE INSTRUCTIONS.

Page 5For technical questions, please call 1-888-380-0318.Item 63617

Page 6

Grounding

SAFETY MAINTENANCEBASIC WELDING WELDING TIPSSETUP

TO PREVENT ELECTRIC SHOCK AND DEATH

FROM INCORRECT GROUNDING WIRE CONNECTION:

Check with a qualified electrician if you are in doubt as to whether the outlet is

properly grounded.

Do not use the Welder if the power cord or plug is damaged. If damaged, have it repaired by a service

facility before use. If the plug will not fit the outlet, have a proper outlet installed by a qualified electrician,

do not use adapter plugs.

1. The green wire inside the cord is connected to

the grounding system in the Welder. The green

wire in the cord must be the only wire connected

to the Welder’s grounding system and must

never be attached to an electrically “live” terminal.

Never leave the grounding wire disconnected

or modify the Power Cord Plug in any way.

2. Make sure the tool is connected to an outlet having

the same configuration as the plug. If the tool must

be reconnected for use on a different type of electric

circuit, the reconnection should be made by qualified

service personnel; and after reconnection, the tool

should comply with all local codes and ordinances.

Extension Cords

Do not use an extension cord on this Welder.

Replacement Cords

1. Use only one of the supplied power cords for

this Welder or an identical replacement cord.

2. Do not install a thinner or longer

cord on this Welder.

3. Do not patch cords of any length

together for this item. Patches may allow

moisture to penetrate the insulation,

resulting in electric shock.

Page 6 For technical questions, please call 1-888-380-0318. Item 63617

Page 7

Symbology

VAC

A

OCV

KVA

Wire Feed (Speed)

Workpiece Ground Cable

Torch Cable

Overheat Shutdown Indicator

Cooling Fan

Housing Ground Point

Volts Alternating Current

Amperes

Open Circuit Voltage

Kilovolt Amperes

(Volts / 1000 * Amperes)

IPM

AWG

Inches Per Minute

American Wire Gauge

SAFETYMAINTENANCE BASIC WELDINGWELDING TIPS SETUP

Electric Shock Hazard.

Do not touch energized parts.

Inhalation Hazard.

Keep head out of fumes

and use proper ventilation.

Read manual before

setup and/or use.

Fire Hazard.

Keep flammable materials

away during welding. Spatter

can cause accidental fires.

Arc Ray Hazard.

Wear welding helmet with

properly rated filter lens.

Pacemaker Hazard.

Welding processes may

interfere with pacemakers.

Consult doctor before use.

Specifications

Power Input 120 VAC / 60 Hz 240 VAC / 60 Hz

Current Input at Output

Welding Current Range 30 –140 A 30 –220 A

Rated Duty Cycles

Open Circuit Voltage 78 VDC 78 VDC

Welding Wire Capacity

Wire Speed 50 – 500 IPM

Wire Spool Capacity Up to 12 lb spool

15 A: 20.7 A at 100 A

20 A: 24.3 A at 115 A

40% @ 100 A

15 A:

100% @ 75 A

30% @ 115 A

20 A:

100% @ 75 A

Flux Cored: 0.030" / 0.035" / 0.045"

24.8 A at 200 A

25% @ 200 A

100% @ 115 A

Solid Core: 0.025" / 0.030" / 0.035"

Page 7For technical questions, please call 1-888-380-0318.Item 63617

Page 8

Setup

Read the ENTIRE IMPORTANT SAFETY INFORMATION section at the beginning of this manual

SAFETY MAINTENANCEBASIC WELDING WELDING TIPSSETUP

Note: Remove the protective foam and cardboard from the Welder before setup.

including all text under subheadings therein before set up or use of this product.

TO PREVENT SERIOUS INJURY FROM ACCIDENTAL OPERATION:

Turn the Power Switch off and unplug the Welder before setup.

Wire Spool Installation / Wire Setup

1. Turn the Power Switch OFF and unplug

the Welder before proceeding.

Power

Switch

2. Pull up on the Door Latch,

then open the Door.

3. 2 Pound Wire Spool Installation:

Remove the Wingnut and Spacer. If

replacing a Spool, remove the old Spool

and all remaining wire from the liners.

4. Place the new Wire Spool over the Spool Spindle

and against the Spool Brake Pad as illustrated.

To prevent wire feed problems, set the

Spool so that it will unwind clockwise.

5. Replace the Spacer over the

Spool Spindle and secure Spool

in place with the Wingnut.

Notice: If Wire Spool can spin freely, Wingnut is too

loose. This will cause the welding wire to unravel and

unspool which can cause tangling and feeding problems.

Door

Door

Latch

Wingnut

Spacer

Spool

Spindle

2 lb

Wire Spool

Spool

Brake Pad

Welder

Wall

2 lb Spool Loading

Page 8 For technical questions, please call 1-888-380-0318. Item 63617

Page 9

6. 10-12 Pound Wire Spool Installation:

Remove the Wingnut and Spacer. If

replacing a Spool, remove the old Spool

and all remaining wire from the liners.

Spool Knob

Wingnut

7. Place the Spool Adapter over the Spool Spindle

and against the Spool Brake Pad as illustrated.

8. Place the new Wire Spool over the Adapter and

line up pin on Adapter with hole in Spool.

To prevent wire feed problems, set the

Spool so that it will unwind clockwise.

9. Replace the Spacer over the Spool Spindle

and secure Spool in place with the Wingnut.

Notice: If Wire Spool can spin freely, Wingnut

is too loose. This will cause the welding

wire to unravel and unspool which can

cause tangling and feeding problems.

10. Screw the Spool Knob into the Spool Adapter.

10-12 lb

Spool

Adapter

Wire

must

unwind

in this

direction

10-12 lb Spool Loading

Spacer

10-12 lb

Wire Spool

Spool Spindle

Spool

Brake Pad

Welder

Wall

SAFETYMAINTENANCE BASIC WELDINGWELDING TIPS SETUP

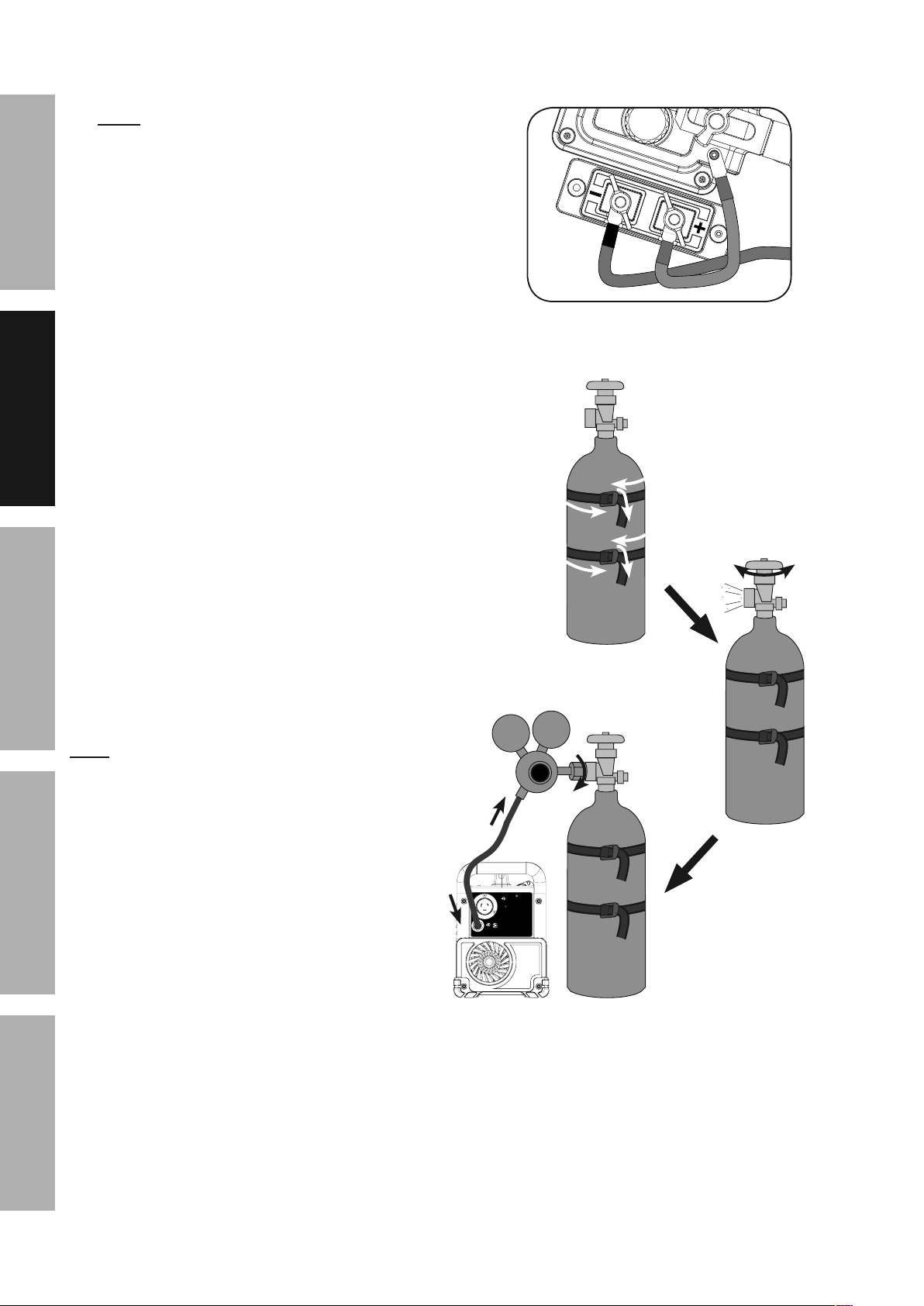

11. DCEN Direct Current Electrode Negative

Wire Setup for Flux-Cored (gasless) welding:

Remove the two Wingnuts securing the cables.

Connect the Black Ground Cable to the positive (+)

Terminal using the Wingnut.

Connect the Red Cable to the negative (–)

Terminal using the other Wingnut.

Make sure the Cable connectors

sit flush in the grooves.

DCEN

Flux-Cored (Gasless) Polarity Setup

Page 9For technical questions, please call 1-888-380-0318.Item 63617

Page 10

Reset

Power Input

Gas Inlet

12. DCEP Direct Current Electrode Positive Wire

SAFETY MAINTENANCEBASIC WELDING WELDING TIPSSETUP

Setup for Solid Core (gas shielded) welding:

a. Remove the two Wingnuts securing the

cables. Connect the Black Ground Cable to the

negative (–) Terminal using the Wingnut.

Connect the Red Cable to the positive (+)

Terminal using the other Wingnut.

Make sure the Cable connectors

sit flush in the grooves.

b. Determine which type of shielding gas

would be appropriate for the welding

you will do. Refer to the Settings Chart

on the inside of the Welder door.

DCEP

Solid Core (Gas Shielded) Polarity Setup

c. With assistance, set the cylinder (not included)

onto a cabinet or cart near the Welder

and secure the cylinder in place with two

straps (not included) to prevent tipping.

d. Remove the cylinder’s cap. Stand to the

side of the valve opening, then open the

valve briefly to blow dust and dirt from the

valve opening. Close the cylinder valve.

e. Locate the Regulator (included) and close its

valve until it is loose, then thread Regulator

onto cylinder and wrench tighten connection.

Note: When using C100 shielding gas, connect the

enclosed CGA 580/320 adapter to the inlet connection

of the Regulator and wrench tighten. Thread the

adapter onto the gas cylinder and wrench tighten.

f. Attach the Gas Hose (included) to the

Regulator’s outlet and the Welder’s gas

inlet. Wrench-tighten both connections.

c

Briefly open valve

d

to clean,

then close

valve.

f

e

Page 10 For technical questions, please call 1-888-380-0318. Item 63617

Page 11

13. Turn the Feed Tensioner knob counterclockwise to

loosen it enough to pull it down to remove tension.

The spring-loaded Idler Arm will move up as shown.

Feed Tensioner

Idler Arm

SAFETYMAINTENANCE BASIC WELDINGWELDING TIPS SETUP

14. Feed Roller Instructions:

Check that the Feed Roller is correct for the

type of wire being used (solid core or fluxcored) and that it is turned to properly match

the wire size marked on the Wire Spool:

a. Unscrew the Feed Roller Knob counterclockwise.

b. Remove the Feed Roller Knob to

expose the Feed Roller.

Feed Roller

Knob

Solid Core

V-Groove

groove

0.030 / 0.035

0.025

groove

A

Feed

Roller

B

c. Flip or replace the Feed Roller as needed and

confirm that it is the correct Roller for the type of

wire being used and that the number showing

is the same as the wire diameter on the Spool.

d. Screw the Feed Roller Knob back into

place to secure the Feed Roller.

0.045

groove

0.030 / 0.035

Flux-Cored

Knurled Groove

C

groove

D

Page 11For technical questions, please call 1-888-380-0318.Item 63617

Page 12

Wire Feed

Mechanism

15. Loosen the Knob on the Wire Feed

SAFETY MAINTENANCEBASIC WELDING WELDING TIPSSETUP

mechanism, then insert the Gun Cable

Connector through the hole on the Welder

front and into the socket on the Wire Feed.

16. Ensure that the Gun Cable Connector

is fully inserted into the socket on

the Wire Feed mechanism as shown,

then tighten the Knob securely.

If Connector is not fully inserted, the gas

connection will leak, preventing shielding

gas from reaching the welding arc.

NOTICE: To prevent damage, do

not overtighten the Knob.

Gun Cable

Connector

Knob

Incorrect – Connector not fully inserted

Wire

Feed

Control

Cable

17. Connect the Wire Feed Control Cable to the

Wire Feed Control Socket located on the front

of the machine and tighten the lock ring on the

Cable plug. Note that the plug on the Cable fits

into the Socket in one specific orientation only.

Securely hold onto the end of the welding wire and keep

tension on it during the following steps.

If this is not done, the welding wire will unravel and unspool

which can cause tangling and feeding problems.

18. Cut off all bent and crimped wire.

The cut end must have no burrs or

sharp edges; cut again if needed.

IMPORTANT

Welding

Wire

Correct – Connector fully inserted

HOLD WIRE

SECURELY

Feed

Guide

19. Keep tension on the wire and guide at

least 12 inches of wire into the Wire

Inlet Liner and Feed Guide.

Page 12 For technical questions, please call 1-888-380-0318. Item 63617

Wire

Spool

Wire Inlet

Liner

Page 13

20. Make sure the welding wire is resting in the groove

Reset

Power Input

Gas Inlet

of the Feed Roller, then push the wire Idler Arm

down, and swing the Feed Tensioner up to latch it

across the tip of the arm.

After the wire is held by the Tensioner,

you may release it.

Note: The tension should be 3 – 5 for solid wire and

2 – 3 for flux-cored wire. Too much force on flux-cored

wire will crush it and may cause feeding issues.

21. Pull the Nozzle to remove it.

Idler Arm

Feed Tensioner

SAFETYMAINTENANCE BASIC WELDINGWELDING TIPS SETUP

MIG Gun

22. Unscrew the Contact Tip

counterclockwise and remove.

23. Lay the MIG Gun Cable out in a straight line so

that the welding wire moves through it easily.

Leave the cover open, so that the feed

mechanism can be observed.

Nozzle

Contact

IMPORTANT

Stainless steel wire is less flexible than other welding wire. Therefore, it is

more difficult to feed through the liner and gun. It is especially important

to keep the gun cable straight while feeding stainless steel wire.

DANGER

PARTS MAY BE AT WELDING VOLTAGE

TO PREVENT ELECTRIC SHOCK AND DEATH:

1. Keep hands away from Wire Feed mechanism.

Tip

2. Close door before plugging in, unless using Cold

3. Do not touch Trigger while feeding wire through to gun.

24. Plug either 120 VAC or 240 VAC Power

Cord into Power Input Socket.

Note: Plug will only fit one way.

Wire Feed to feed wire through to gun.

Power

Input

Page 13For technical questions, please call 1-888-380-0318.Item 63617

Page 14

25. Do not touch the Gun’s Trigger. Plug the Power

Cord into a properly grounded, GFCI protected

SAFETY MAINTENANCEBASIC WELDING WELDING TIPSSETUP

120 VAC (20 amp rated) or 240 VAC receptacle that

matches the plug and turn the Power Switch ON.

The circuit must be equipped with delayed

action-type circuit breaker or fuses.

Power

Switch

26. Point the Gun away from

all objects. Press and

hold the Cold Wire Feed

Switch until the wire feeds

through two inches.

The wire liner may come

out with the welding

wire. This is normal,

just push the wire liner

back into the Gun.

If the wire does not feed

properly and the Spool

is stationary, turn OFF

and unplug the Welder

and slightly tighten the

Feed Tensioner clockwise

before retrying.

27. To check the wire’s drive tension, press and hold

Trigger to feed the wire against a piece of wood

from 2 to 3 inches away.

Note: After pressing Trigger, wire will stop

feeding after 3 seconds if there is no arc.

Check tension for less than 3 seconds.

If the wire stops instead of bending, unplug

the Welder, slightly tighten the Feed Tensioner

clockwise, and try again. If the wire bends from

the feed pressure, then the tension is set properly.

Cold Wire

Feed Switch

2"

Welding

Wire

Incrementally

increase tension

until

wire bends.

MIG Gun

2–3"

28. Turn OFF the Power Switch and unplug the

Power Cord from its electrical outlet.

29. Close the Door. Make sure

Door is securely latched.

30. Select a Contact Tip that is compatible with

the welding wire used. Slide the Contact

Tip over the wire and thread it clockwise into

the MIG Gun. Tighten the Contact Tip.

31. Replace the Nozzle and cut the wire

off at 1/2" from tip (1/2" stickout).

Page 14 For technical questions, please call 1-888-380-0318. Item 63617

Nozzle

Contact

Tip

MIG Gun

Page 15

Basic Welding

Read the ENTIRE IMPORTANT SAFETY INFORMATION section at the beginning of this manual

including all text under subheadings therein before welding.

TO PREVENT SERIOUS INJURY:

Protective gear must be worn when using the Welder; minimum shade number 10 full face shield

(or welding mask), ear protection, welding gloves, sleeves and apron, NIOSH-approved respirator, and fire

resistant work clothes without pockets should be worn when welding.

Light from the arc can cause permanent damage to the eyes and skin.

Do not breathe arc fumes.

Flux-cored wire welding is used to weld mild steel

and stainless steel without shielding gas.

MIG welding uses solid wire and shielding gas,

and is used to weld mild steel and stainless steel.

MIG welding can also be used to weld thinner

workpieces than flux-cored welding can.

Aluminum welding can be performed with an

optional Spool Gun (sold separately) using

aluminum wire and shielding gas.

Good welding takes a degree of skill and experience.

Practice a few sample welds on scrap before

welding your first project. Additional practice

periods are recommended whenever you weld:

• a different thickness of material

• a different type of material

• a different type of connection

• using a different process (MIG vs. Flux)

Make practice welds on pieces of scrap to practice

technique before welding anything of value.

SAFETYMAINTENANCE BASIC WELDINGWELDING TIPS SETUP

TO PREVENT SERIOUS INJURY,

FIRE AND BURNS:

Keep welding tip clear of grounded

objects whenever unit is plugged

in and turned on.

Practice your welding

technique on scrap

pieces before welding

anything of value.

Power

On

=

Page 15For technical questions, please call 1-888-380-0318.Item 63617

Page 16

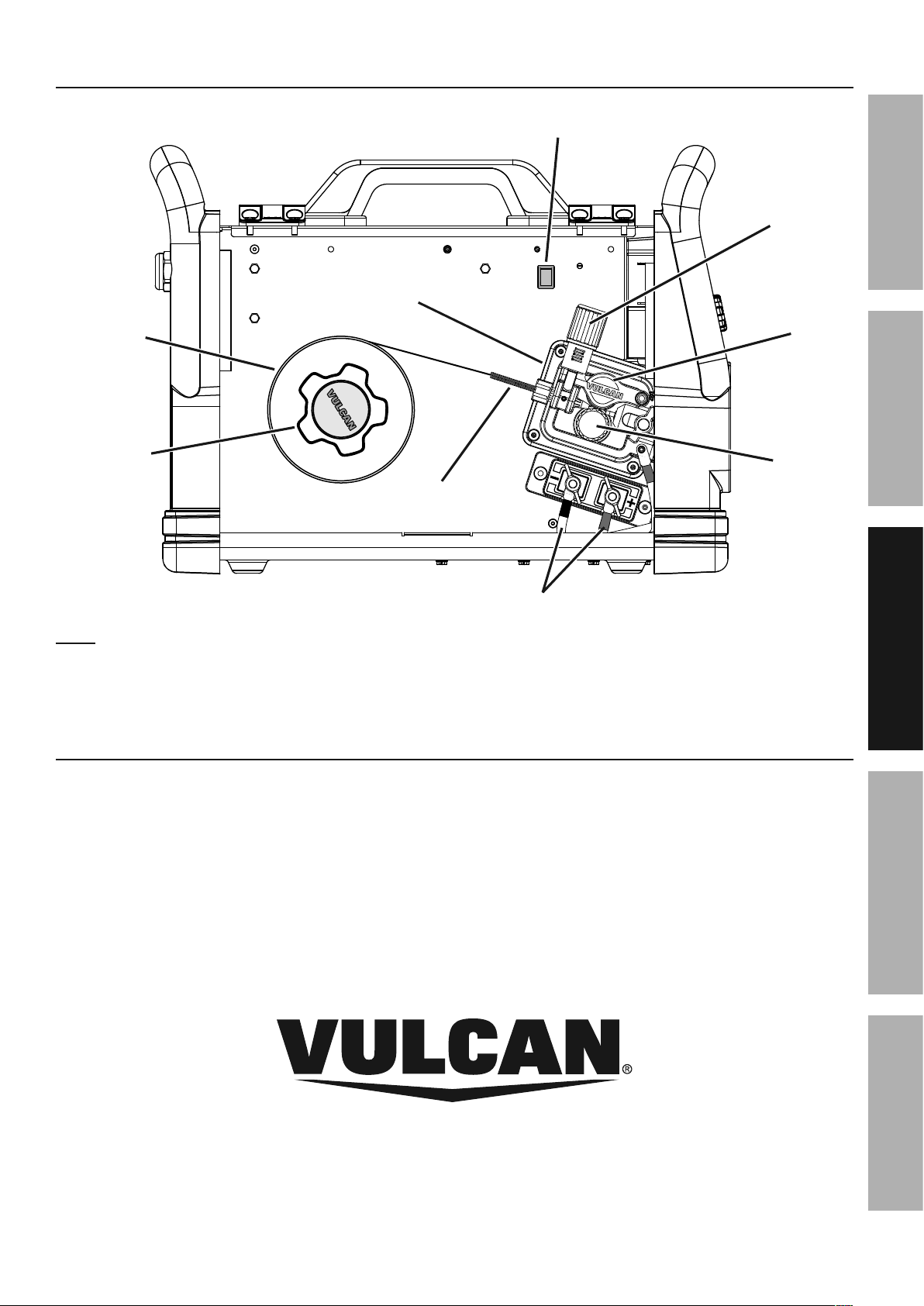

Front Panel Controls

Voltage

Input /

SAFETY MAINTENANCEBASIC WELDING WELDING TIPSSETUP

Thermal

Overload

Indicator

Power ON

Indicator

Material

Thickness /

Voltage Knob

Synergic

Indicator

Power

Switch

Process

Selection Knob

Wire Speed

Knob

MIG Gun /

Spool Gun

Cable Socket

Wire Feed

Control Socket

Ground

Cable

Voltage Input / Thermal Overload Indicator:

Lights up if the input voltage is outside the

machine’s specifications or duty cycle has been

exceeded, resulting in overheating the Welder.

Power ON Indicator: When illuminated

indicates that the Power Switch is on.

Material Thickness / Voltage Knob: This

controls the output voltage of the Welder.

Synergic Indicator: Lights when using Auto Settings

and flashes if chosen settings are incorrect.

Power Switch: Turns on power to the

Welder and internal cooling fan.

MIG Gun / Spool Gun Cable Socket: The MIG Gun

and Spool Gun Cables connect here. The wire,

welding current, and shielding gas (if performing

MIG) feed to the weld through here.

Wire Diameter

Selection Knob

Spool Gun

Gas Outlet

Wire Feed Control Socket: The MIG Gun and

Spool Gun Control Cables connect here.

Ground Cable: This connects to the base

metal to provide a good connection for the

current to travel back to the Welder.

Spool Gun Gas Outlet: When using optional Spool

Gun (sold separately), gas hose connects here.

Wire Diameter Selection Knob: Sets the

diameter of the welding wire to be used.

Wire Speed Knob: Controls the speed that the

welding wire feeds out of the MIG Gun or Spool

Gun and the output amperage of the Welder.

Process Selection Knob: Adjust to select

the welding process to be used.

Page 16 For technical questions, please call 1-888-380-0318. Item 63617

Page 17

Interior Controls

Wire Spool

Wire Feed

Mechanism

Cold Wire

Feed Switch

Feed

Tensioner

Idler

Arm

SAFETYMAINTENANCE BASIC WELDINGWELDING TIPS SETUP

Spool Knob

Wire Inlet

Liner

Polarity Cables

Note: When using an optional Spool Gun (sold separately), connect the Spool Gun gas

hose to the Spool Gun Gas Outlet (see Front Panel Controls on previous page).

Weld Settings

Refer to the Settings Chart on the inside of the Welder door for Flux-Cored and MIG Weld

settings. The chart is only intended to show general guidelines for different wire sizes and for

different thicknesses of material. The initial settings used at the beginning of a weld may need to be

adjusted after stopping and carefully inspecting the weld. Proper welding takes experience.

Feed

Roller Knob

Page 17For technical questions, please call 1-888-380-0318.Item 63617

Page 18

Duty Cycle (Duration of Use)

Avoid damage to the Welder by not welding

for more than the prescribed duty cycle

SAFETY MAINTENANCEBASIC WELDING WELDING TIPSSETUP

time. The Duty Cycle defines the number of

minutes, within a 10 minute period, during

which a given welder can produce a particular

welding current without overheating.

For example, a welder with a 40% duty

cycle at 100 A welding current must be

allowed to rest for at least 6 minutes after

every 4 minutes of continuous welding.

40% Use at 100A

For 10 Continuous Minutes

4

Minutes

Welding

6

Minutes

Resting

Failure to carefully observe duty cycle limitations

can easily over-stress a welder’s power generation

system contributing to premature welder failure.

This Welder has an internal thermal protection

system to help prevent this sort of over-stress.

When the Welder overheats, it automatically

shuts down and the Overload Indicator

lights. The Welder automatically returns to

service after cooling off. Should this occur,

rest the MIG Gun on an electrically nonconductive, heat-proof surface, such as a

concrete slab, well clear of the ground clamp.

Allow the Welder to cool with the Power

Switch on, so that the internal Fan will help

cool the Welder.

When the Overload Indicator is no longer

lit and the Welder can be used again, use

shorter welding periods and longer rest

periods to prevent needless wear.

Overload

Indicator

100% Continuous Use at 75A

25% Use at 200A

For 10 Continuous Minutes

2-1/2

Minutes

Welding

7-1/2

Minutes

Resting

100% Continuous Use at 115A

MIG Gun

Power

Switch

concrete slab

(or other heat-proof,

non-conductive surface)

Page 18 For technical questions, please call 1-888-380-0318. Item 63617

Page 19

Setting Up The Weld

1. Make practice welds on pieces of scrap the

same thickness as your intended workpiece

to practice technique before welding anything

of value. Clean the weld surfaces thoroughly

with a wire brush or angle grinder; there

must be no rust, paint, oil, or other materials

on the weld surfaces, only bare metal.

2. Use clamps (not included) to hold the workpieces

in position so that you can concentrate on

proper welding technique. The distance

(if any) between the two workpieces must be

controlled properly to allow the weld to hold

both sides securely while allowing the weld

to penetrate fully into the joint. The edges of

thicker workpieces may need to be chamfered

(or beveled) to allow proper weld penetration.

Notice: When welding equipment on a vehicle,

disconnect the vehicle battery power from both the

positive connection and the ground before welding.

This prevents damage to some vehicle electrical

systems and electronics due to the high voltage

and high frequency bursts common in welding.

clamps

SAFETYMAINTENANCE BASIC WELDINGWELDING TIPS SETUP

workpieces

Clean

surfaces to

bare metal.

Chamfer thick workpieces.

3. Clamp Ground Cable to bare metal on the

workpiece near the weld area, or to metal work

bench where the workpiece is clamped.

4. Turn the Power Switch to the OFF position,

then plug the Power Cord into a properly

grounded, GFCI protected 120 VAC (20 amp

rated) or 240 VAC receptacle that matches

the plug. The circuit must be equipped with

delayed action-type circuit breaker or fuses.

Ground

Power

Switch

Workpiece

Clean

surface to

bare metal.

Clamp

Page 19For technical questions, please call 1-888-380-0318.Item 63617

Page 20

5. Set MIG Gun down on nonconductive,

SAFETY MAINTENANCEBASIC WELDING WELDING TIPSSETUP

nonflammable surface away from any grounded

objects. Turn the Power Switch ON.

6. Settings - Refer to Label on the

inside of the Welder door.

a. Auto (Synergic) Settings – Synergic

Indicator will light:

• Set Process

• Set Wire Diameter

Note: If using 0.045" flux-cored wire, set Wire

Diameter to MANUAL. In this case, Synergic welding

will be turned off. Refer to Manual Settings below.

• Set Material Thickness – If Synergic

Indicator flashes, Material Thickness

setting is incorrect – refer to Settings

Chart for proper weld settings

b. Manual Settings:

• Set Process

• Set Wire Diameter to MANUAL

• Set Wire Feed Speed according

to Settings Chart

• Set Voltage according to Settings Chart

Note: The initial settings may need to be

adjusted after stopping and carefully inspecting

the weld. Proper welding takes experience.

Power

Switch

DANGER! TO PREVENT DEATH

FROM ASPHYXIATION:

Do not open gas without proper ventilation. Fix

gas leaks immediately.

Shielding gas can displace air and cause rapid loss of

consciousness and death.

Shielding gas without carbon dioxide can be even

more hazardous because asphyxiation can start

without feeling shortness of breath.

7. Gas shielded, solid-core wire only:

a. Open gas cylinder valve all the way.

b. Set Flow Gauge to SCFH value

indicated on Settings Chart.

Page 20 For technical questions, please call 1-888-380-0318. Item 63617

Page 21

Basic Welding Technique

1. Press (and hold) MIG Gun Trigger and contact the

area to be welded with electrode wire to ignite arc.

2. For a narrow weld, you can usually draw the wire in

a steady straight line.

This is called a stringer bead.

For a wider weld, draw the wire back and forth

across the joint.

This is called a weave bead and takes

practice to perform properly.

3. Direct the welding wire straight into the joint.

This gives an angle of 90° (straight up and

down) for butt (end to end) welds, and an

angle of 45° for fillet (T-shaped) welds.

stringer bead weave bead

Weld MIG Gun angles,

viewed from front of weld joint.

45°

SAFETYMAINTENANCE BASIC WELDINGWELDING TIPS SETUP

90°

4. For MIG welding using solid wire and

shielding gas, the end of the MIG Gun should

be tilted so that wire is angled anywhere

in-between straight on and 15° away

from the direction you are welding. The

amount of tilt is called the push angle.

5. When using flux-cored wire without

shielding gas, the end of the MIG Gun

should be tilted so that wire is angled

anywhere in-between straight on and

15° in the direction you are welding. The

amount of tilt is called the drag angle.

fillet weld joint

Push Angle

0-15°

Weld

Direction

Solid Wire with Shielding Gas Flux-Cored Wire without Gas

butt weld joint

Drag Angle

0-15°

Weld

Direction

CTWD

(up to 1/2")

6. The Contact Tip should remain within 1/2"

of the work surface. This distance is called

CTWD - Contact Tip to Work Distance.

Page 21For technical questions, please call 1-888-380-0318.Item 63617

Page 22

Note: If Welder is used too long, the Overload

Indicator lights up and the unit automatically

shuts down. The Welder automatically returns

to service after cooling off. Should this occur,

rest the MIG Gun on an electrically non-

SAFETY MAINTENANCEBASIC WELDING WELDING TIPSSETUP

conductive, heat-proof surface, such as a

concrete slab, away from the ground clamp.

Allow the Welder to cool with the

Power Switch on, so that the internal

Fan will help cool the Welder.

When the Overload Indicator is no longer

lit and the Welder can be used again, use

shorter welding periods and longer rest

periods to help prevent needless wear.

7. After welding the test weld on a piece

of scrap for a few seconds, stop, and

check your progress. Clean, then compare

your weld’s appearance with the diagrams

and descriptions in the Welding Tips section

starting on the next page. After making any

necessary adjustments, continue to weld

while carefully following the DUTY CYCLE

guidelines as explained on page 18.

CAUTION! Weld will be hot, do not touch.

Overload

MIG Gun

Indicator

Power

Switch

concrete slab

(or other heat-proof,

non-conductive surface)

After practice welding for a few seconds,

STOP and examine your weld using the

guidelines starting on the next page.

FOLLOW DUTY CYCLE!

120 VAC

40% Use at 100 A

For 10 Continuous Minutes

4

Minutes

Welding

100% Continuous Use at 75 A

6

Minutes

Resting

For 10 Continuous Minutes

2-1/2

Minutes

Welding

100% Continuous Use at 115 A

240 VAC

25% Use at 200 A

7-1/2

Minutes

Resting

8. When welding is complete, set the MIG

Gun down on a heat-proof, electrically

non-conductive surface.

Turn the Power Switch OFF.

9. Allow Welder to cool down, then

unplug the Power Cord.

10. Remove Ground Clamp from workpiece

or table and disconnect MIG Gun.

11. Respool wire by clipping wire, removing gas

nozzle/contact tip on MIG gun, releasing Idler

Arm on Wire Feed mechanism, and rotating

the Wire Spool counterclockwise. Be sure

to securely hold wire as it is being respooled

because the end of wire has a tendency to

quickly unravel once it clears the wire feeder.

12. MIG ONLY:

Close shielding gas cylinder valve

securely. Remove Regulator and

replace cap. Disconnect Gas Hose from

Welder. Store and secure gas cylinder.

MIG Gun

concrete slab

(or other heat-proof,

non-conductive surface)

Power

Switch

Page 22 For technical questions, please call 1-888-380-0318. Item 63617

Page 23

Welding Tips

A good way to test welding technique is to examine a

weld’s appearance after it has cooled and the slag

has been removed. Then, better welding can be

learned by adjusting your weld technique to remedy

any problems found.

Cleaning the Weld

TO PREVENT SERIOUS INJURY:

Continue to wear ANSI-approved

safety goggles and protective wear

when cleaning a weld.

Sparks or chips may fly when cleaning.

1. A weld from flux-cored wire will be

covered by slag. Use a chipping hammer

to knock this off. Be careful not to

damage the weld or base material.

2. Use a wire brush to further clean the weld

or use an angle grinder (sold separately) to

shape the weld.

A typical flux-cored wire (FCAW) weld

before cleaning.

slag

base metal

A typical solid wire (GMAW) weld

before cleaning.

weld bead

base metal

Chipping

Hammer

weld bead

spatter

SAFETYMAINTENANCE BASIC WELDINGWELDING TIPS SETUP

spatter

Wire Brush

Strike Test

A test weld on a PIECE OF SCRAP can be tested by

using the following procedure.

WEAR ANSI-APPROVED SAFETY GOGGLES

DURING THIS PROCEDURE.

WARNING! This test WILL damage the weld it is

performed on. This test is ONLY an indicator of weld

technique and is not intended to test working welds.

1. After two scraps have been welded together and the

weld has cooled, clamp one scrap in a sturdy vise.

2. Stay clear from underneath while you strike

the opposite scrap with a heavy hammer,

preferably a dead-blow hammer.

3. A GOOD WELD will deform but not break,

as shown on top.

A POOR WELD will be brittle and snap at the weld,

as shown on bottom.

dead-blow hammer

dead-blow hammer

clamp

SCRAP

workpiece

GOOD WELD

bends and is not brittle

clamp

SCRAP

workpiece

POOR WELD

snaps or cracks

Page 23For technical questions, please call 1-888-380-0318.Item 63617

Page 24

Weld Diagnosis

Workpiece Heat Control / Weld Penetration

SAFETY MAINTENANCEBASIC WELDING WELDING TIPSSETUP

Not hot enough Too hotIdeal heat

How to increase workpiece heat

and increase penetration:

(to weld THICKER workpieces properly)

a. Increase weld current

b. Decrease travel speed

c. Use faster wire feed

d. Use shorter CTWD

Example Weld Diagrams

PROPER PENETRATIONINADEQUATE PENETRATION

EXCESS PENETRATION OR

BURN-THROUGH

How to reduce workpiece heat

and limit penetration:

(to weld THINNER workpieces properly)

a. Decrease weld current

b. Increase travel speed

c. Use slower wire feed

d. Use longer CTWD

Good

Weld

Page 24 For technical questions, please call 1-888-380-0318. Item 63617

Voltage

Too Low or

Wire Feed

Too Slow

TO CORRECT:

or

Voltage

Too High or

Wire Feed

Too Fast

TO CORRECT:

or

Travel Speed

Too Fast

TO CORRECT:

travel

slower

Travel Speed

Too Slow

TO CORRECT:

travel

faster

CTWD

Too Long

or

Wrong Polarity

TO CORRECT:

Check Polarity

and

maintain

less

than 1/2"

CTWD

Page 25

Weld Problems

Penetration (Workpiece Heat Control)

EXCESS PENETRATION OR

BURN-THROUGH

Weld droops on top and

underneath, or falls through

entirely, making a hole.

POSSIBLE CAUSES AND SOLUTIONS

1. Workpiece overheating:

Reduce wire feed speed.

Decrease weld current.

2. Travel speed too slow:

Increase travel speed and ensure

that travel speed is kept steady.

3. Excessive material at weld:

Reduce wire feed speed.

Bend at Joint

PROPER PENETRATION

Weld is visible underneath and

bulges slightly on top.

PROFILE VIEWS

POSSIBLE CAUSES AND SOLUTIONS

1. Incorrect welding technique:

Maintain 1/2" or less CTWD.

Keep arc on leading edge of weld puddle.

Hold MIG Gun at proper angles.

2. Insufficient weld heat:

Reduce travel speed.

Increase weld current.

3. Workpieces too thick/close:

Bevel thick workpieces, allow slight

gap, and weld in several passes.

4. Insufficient weld material:

Increase wire feed speed.

INADEQUATE PENETRATION

Weld does not penetrate the

joint fully, just on the surface.

SAFETYMAINTENANCE BASIC WELDINGWELDING TIPS SETUP

PROFILE

VIEW

POSSIBLE CAUSES AND SOLUTIONS

1. Improper clamping:

Clamp workpieces securely.

Make tack welds to hold workpieces.

2. Excessive heat:

Weld a small portion and allow to cool before

proceeding.

Increase travel speed.

Reduce wire feed speed.

Coat of Slag Over Weld

TOP

VIEW

PARTIALLY CHIPPED AWAY TO SHOW WELD

Slag is a necessary part of a flux-cored wire

weld. It shields the weld from impurities.

Clean off the slag with a Chipping Hammer

and Wire Brush after welding.

Gas-shielded MIG welds are protected by the

shielding gas and do not need slag to protect them.

Weld Not Adhering Properly

Gaps present between weld and previous bead or

between weld and workpiece. See areas below.

PROFILE

VIEW

POSSIBLE CAUSES AND SOLUTIONS

1. Incorrect welding technique:

Place stringer bead at correct place in joint.

Adjust workpiece position or weld angle to permit

proper welding to bottom of piece.

Pause briefly at sides during weave bead.

Keep arc on leading edge of weld puddle.

Hold MIG Gun at proper angles.

2. Insufficient weld heat:

Increase current.

Increase wire feed speed.

3. Dirty workpiece:

Clean workpiece down to bare metal.

4. Insufficient weld material:

Increase wire feed speed.

5. Workpiece gap too narrow:

Widen groove or increase bevel.

Page 25For technical questions, please call 1-888-380-0318.Item 63617

Page 26

Porosity

SAFETY MAINTENANCEBASIC WELDING WELDING TIPSSETUP

Small cavities or holes in the bead.

Excessive Spatter

Fine spatter is normal.

Spatter that is grainy and large is a problem.

TOP

VIEW

POSSIBLE CAUSES AND SOLUTIONS

1. Incorrect polarity:

Check that polarity is set correctly

for type of welding.

2. Insufficient shielding gas (MIG only):

Increase flow of gas.

Clean nozzle.

Maintain proper CTWD.

3. Incorrect shielding gas (MIG only):

Use shielding gas recommended by wire supplier.

4. Dirty workpiece or welding wire:

Clean workpiece down to bare metal.

Make certain that wire is clean and free

from oil, coatings, and other residues.

5. Inconsistent travel speed:

Maintain steady travel speed.

6. CTWD too long:

Reduce CTWD.

TOP

VIEW

POSSIBLE CAUSES AND SOLUTIONS

1. Dirty workpiece or welding wire:

Clean workpiece down to bare metal.

Make certain that wire is clean and free

from oil, coatings, and other residues.

2. Incorrect polarity:

Check that polarity is set correctly

for type of welding.

3. Insufficient shielding gas (MIG only):

Increase flow of gas.

Clean nozzle.

Maintain proper CTWD.

4. Wire feeding too fast:

Reduce wire feed speed.

5. CTWD too long:

Reduce CTWD.

Crooked/Wavy Bead

TOP

VIEW

POSSIBLE CAUSES AND SOLUTIONS

1. Inaccurate welding:

Use two hands or rest hand on steady surface.

2. Inconsistent travel speed:

Maintain steady travel speed.

3. CTWD too long:

Reduce CTWD.

Page 26 For technical questions, please call 1-888-380-0318. Item 63617

Burn-Through

Base material melts away,

leaving a hole in the weld.

TOP

VIEW

POSSIBLE CAUSES AND SOLUTIONS

1. Workpiece overheating:

Reduce current and/or wire feed speed.

2. Travel speed too slow:

Increase travel speed and ensure

that travel speed is kept steady.

3. Excessive material at weld:

Reduce wire feed speed.

Page 27

Maintenance

TO PREVENT SERIOUS INJURY, FIRE AND BURNS:

Unplug the Welder, rest the MIG Gun on a heat-proof, electrically non-conductive surface, and

allow all parts of the Welder to cool thoroughly before service.

SAFETYMAINTENANCE BASIC WELDINGWELDING TIPS SETUP

1. BEFORE EACH USE, inspect the general

condition of the Welder. Check for:

• loose hardware

• misalignment or binding of moving parts

• damaged cord / electrical wiring

• frayed or damaged cables

• cracked or broken parts

• any other condition that may

affect its safe operation.

2. Periodically, have a qualified

technician remove the Rear Panel

and use compressed air to blow

out all dust from the interior.

3. Store in a clean and dry location.

4. For optimal weld quality, clean and

inspect the Contact Tip and Nozzle

before each use, as explained below.

Nozzle and Contact Tip Inspection and Cleaning

1. Make sure that the entire MIG Gun is completely

cool and that the Power Cord is unplugged

from the electrical outlet before proceeding.

2. Pull the Nozzle to remove it.

3. Scrub the interior of the Nozzle

clean with a wire brush.

MIG Gun

4. Examine the end of the Nozzle. The end should be

flat and even. If the end is uneven, chipped, melted,

cracked, or otherwise damaged, the Nozzle will

adversely effect the weld and should be replaced.

5. Unscrew the Contact Tip counterclockwise

and slide it off the welding wire to remove.

6. Scrub the outside of the Tip clean with a wire brush.

Clean out the inside of the tip with a tip

cleaner (sold separately). Check that the Tip

is the proper type for the wire size used.

7. Examine the shape of the hole at the end of

the Contact Tip. It should be an even circle; it

should not be oblong or have any bulges in it.

8. If any problems are noted, replace the

Contact Tip. Select a new Tip of the

correct size for the welding wire used.

9. Reinstall the Tip and securely

reinstall the Nozzle as well.

Nozzle

Contact

Tip

Page 27For technical questions, please call 1-888-380-0318.Item 63617

Page 28

Troubleshooting

IMPORTANT!

SAFETY MAINTENANCEBASIC WELDING WELDING TIPSSETUP

Be CERTAIN to shut off the Welder, disconnect it from power, and discharge the MIG Gun to

ground before adjusting, cleaning, or repairing the unit.

Problem Possible Causes Likely Solutions

1. Insufficient wire feed pressure.

2. Incorrect wire feed roll size.

Wire feed motor

runs but wire does

not feed properly

Wire creates a bird’s

nest during operation

Wire stops

during welding

Welding arc

not stable

Weak arc strength

3. Damaged MIG Gun, cable, or liner assembly.

4. Feed Tensioner is too tight.

1. Excess wire feed pressure.

2. Incorrect Contact Tip size.

3. MIG Gun Cable Connector not fully

inserted into Wire Feed mechanism.

4. Damaged liner.

1. Gun cable is severely bent and Wire

Feed mechanism cannot feed wire.

2. Gun liner is clogged or worn.

3. Gun liner is too small for welding

wire being used.

4. Wire is tangled on the spool.

5. Wire is not making contact with Feed Rollers.

6. Feed Roller is not making enough contact

with wire or is crushing flux-cored wire.

1. Wire not feeding properly.

2. Incorrect Contact Tip or liner

size or excessive wear.

3. Incorrect wire feed speed.

4. Loose MIG Gun cable or ground cable.

5. Damaged MIG Gun or loose

connection within Gun.

6. Incorrect polarity for process being run.

7. Gas coverage may be insufficient or too high.

8. Poor connection with workpiece.

1. Incorrect line voltage.

2. Improper gauge or length of cord.

3. Not enough current.

1. Increase wire feed pressure properly.

Follow step 27 on page 14.

2. Flip roll to correct size. Follow the Wire Spool

Installation instructions on page 8.

3. Have a qualified technician inspect these

parts and replace as necessary.

4. Loosen Feed Tensioner so it applies only

enough pressure to prevent continued

spinning after the Gun Trigger is released.

1. Adjust wire feed pressure properly.

Follow step 27 on page 14.

2. Replace with the proper tip for wire used.

3. Insert Gun Cable Connector properly. Follow

steps 15 and 16 on page 12.

4. Have a qualified technician inspect and

repair/replace as necessary.

1. Straighten Gun cable.

2. Check gun liner for obstruction. Replace if necessary.

3. Check that gun liner is correct size for wire.

4. Check wire for cross winding or tangled spool.

5. Check Feed Rollers and ensure correct

groove for wire diameter is being used.

6. Check Feed Tensioner and ensure it is set properly.

1. See first Troubleshooting section above.

2. Replace with the proper tip or liner size for wire used.

3. Adjust wire feed speed to achieve a more stable arc.

4. Check to ensure that all connections are tight.

5. Have a qualified technician inspect and

repair/replace as necessary.

6. Ensure polarity is correct for operation:

DCEP for MIG welding and DCEN for

Flux-Cored self-shielded welding.

7. Ensure gas flow rate is set according to Settings Chart.

Make sure MIG Gun Cable Connector is fully inserted

into Wire Feed mechanism with no O-Rings exposed.

8. Check the ground clamp connection to

the workpiece and machine. Ensure

the MIG Gun is properly secured.

1. Check the line voltage and, if insufficient, have

a licensed electrician remedy the situation.

2. Do not use an extension cord on this Welder.

Use only one of the supplied power cords for

this Welder or an identical replacement cord.

3. Switch current to proper setting for metal thickness.

Follow all safety precautions whenever diagnosing or servicing the equipment.

Page 28 For technical questions, please call 1-888-380-0318. Item 63617

Page 29

Troubleshooting (continued)

IMPORTANT!

Be CERTAIN to shut off the Welder, disconnect it from power, and discharge the MIG Gun to

ground before adjusting, cleaning, or repairing the unit.

Problem Possible Causes Likely Solutions

When switched on,

Power ON Indicator

lights but Welder

does not function

Power ON Indicator

does not light when

Welder is switched on

Wire feeds, but arc

does not ignite

Porosity in the

weld metal

1. Tripped thermal protection device.

2. Faulty or improperly connected Trigger.

3. Machine is in low- or

over-voltage protection.

4. Machine is in the incorrect mode.

1. Unit is not connected to outlet properly.

2. Outlet is unpowered.

3. Circuit supplies insufficient input voltage or

amperage.

4. Plug does not have correct rating.

5. Circuit breaker has tripped due

to high input amperage.

6. Input Power Cord is not seated properly.

1. Improper ground connection.

2. Improperly sized Contact Tip.

3. Excessively worn Contact Tip.

4. Dirty Contact Tip.

1. Shielding gas bottle is empty.

2. Not enough or too much shielding gas.

3. Dirty workpiece.

4. Gun is being used too far away from workpiece.

5. Polarity is incorrect for the application.

6. Dirty welding wire is introducing

contamination into the weld.

1. If the Voltage Input/Thermal Overload Indicator

is illuminated, Welder has overheated and shut

down. Stop and wait with the Power Switch ON

for the Welder to cool. The Welder automatically

returns to service after cooling off. Reduce

duration or frequency of welding periods to

help reduce wear on the Welder. Refer to Duty

Cycle (Duration of Use) on page 18.

2. Ensure the gun connection is properly

seated on machine. Qualified technician

must check and secure/replace Trigger.

3. Check input voltage and ensure it falls within

the specified range. If input voltage is correct,

press Reset Button on back of machine.

4. Ensure the Process Selection Knob is

switched to the correct process.

1. Verify the voltage at the outlet and

the connection to the outlet.

2. Check circuit breaker/GFCI devices; if any are tripped,

determine and remedy cause before resetting.

3. Verify that the circuit is designed to supply the

required input voltage and amperage as detailed on

the Specifications table. If the Voltage Input/Thermal

Overload Indicator is illuminated on machine, check

the input voltage to ensure it is within specified range.

4. Make sure installed plug is correct rating.

See Specifications on page 7.

5. Press Reset Button on back of

machine to reset circuit breaker.

6. Ensure the twist lock input Power

Cord is fully secured.

1. Make certain that the workpiece is contacted

properly by the Ground Clamp and that

the workpiece is properly cleaned near the

ground clamp and the welding location.

2. Verify that Contact Tip is the proper size

for welding wire. If needed, replace

Contact Tip with proper size and type.

3. Check that the hole in the tip is not

deformed or enlarged. If needed, replace

Contact Tip with proper size and type.

4. Properly clean Contact Tip.

1. Check gas bottle and replenish as necessary.

2. Check gas regulator to ensure proper flow.

3. Clean workpiece down to bare metal.

4. Check CTWD (contact tip to work

distance) for the proper procedure.

5. Check the polarity and ensure it is DCEP

for MIG and DCEN for Flux-Cored.

6. Make certain that welding wire is clean

and free of rust and residues.

SAFETYMAINTENANCE BASIC WELDINGWELDING TIPS SETUP

Follow all safety precautions whenever diagnosing or servicing the equipment.

Page 29For technical questions, please call 1-888-380-0318.Item 63617

Page 30

Parts List and Diagrams

Wiring Diagram

SAFETY MAINTENANCEBASIC WELDING WELDING TIPSSETUP

Switch

AC1

AC2

F

Fuse

G

Gas Valve 1 Gas Valve 2

Touch Switch

3

4

1

2

CN6

2

1

〜

+

4

3

〜

-

v

15V

J

2 1

FAN2

FAN2

RECITIFIER

1

2

〜

+

3

4

〜

-

IGBT

34

-t

FAN1

1

2

1

2

LED3

PFC

M3

control panel

CN5

10111213141516171819202122232425262728293031323334

123456789101112131415161718192021222324252627282930313233

LED2

Main Board

34

123456789

VR2

Remote Control Board

20

19

12

11

Gas Valve 1

5

6

CN1

Gas Valve 2

4

CN3

1

2

3

4

7

8

9

10

4

1

CN8

1234567

123

1234567

2

CN3

1

Drawing Wire MotorWire Feed Motor

M

12345

CN4

34

Gun switch

M

123

CN7

Hall Sensor

*

OUT+

OUT-

CN1

123

4

FAN1

VR1

LED1

Parts List

Part Description Qty

1 Right Cover 1

2 Handle Cover 1

3 Handle Base 1

4 Hinge – Right 2

5 Hinge – Left 2

6 Left Cover 1

7 Door Latch 1

8 Middle Panel 1

9 PFC Inductor 1

10 Spool 1

11 Wire Feeder 1

12 Remote Control PCB 1

13 Insulation Block 1

14 Display PCB 1

15 Front Handle Cover Plate 1

16 Ground Clamp Subassembly 1

17 Control Panel 1

18 Knob 2

19 Knob 2

20 Switch 1

21 Front Plate 1

22 Plug Connector 1

23 Bottom Housing 1

24 MIG Welding Torch 1

25 Output Inductor 1

26 Pneumatic Connector 3

27 Solenoid Valve 2

28 Pneumatic Connector 2

K1

K2

Part Description Qty

29 Copper Output Bracket 1

30 Board Insulation Paper 1

31 Main PCB 1

32 Fast Recovery Diode 6

33 Control PCB 1

34 Sheet Metal Air Duct 1

35 Rectifier Heatsink 1

36 Rectifier Heatsink Support Bar 1

37 Transformer 1

38 DC Fan 1

39 IGBT 2

40 Bridge Heatsink 1

41 Bridge Rectifier 2

42 Fast Recovery Diode 2

43 IGBT 4

44 IGBT Heatsink Support Bar 1

45 IGBT Heatsink 1

46 IGBT Heatsink 2

47 DC Fan 1

48 Y-Type Threaded Tee 1

49 Air Fitting 1

50 Overload Protector 1

51 120 Volt Power Cord 1

52 Rear Plate 1

53 Rear Handle Cover Plate 1

54 Power Socket 1

55 Rear Panel 1

56 240 Volt Power Cord 1

Page 30 For technical questions, please call 1-888-380-0318. Item 63617

Page 31

Assembly Diagram

14

15

16

13

12

3 2

11

4

10 9

8

5

6

7

1

55

54

53 52

56

51

50

49

48

47

46

45

SAFETYMAINTENANCE BASIC WELDINGWELDING TIPS SETUP

17

18

19

44

43

42

41

40

39

38

2725

23222120

24

26

28

29

30

32 3331

34

3635

37

Record Serial Number Here:

Note: If product has no serial number, record

month and year of purchase instead.

Note: Some parts are listed and shown for

illustration purposes only, and are not available

individually as replacement parts.

Page 31For technical questions, please call 1-888-380-0318.Item 63617

Page 32

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY DIAGRAM

IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR DISTRIBUTOR

MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE IS

QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS QUALIFIED TO REPLACE

ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY

STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND

LICENSED TECHNICIANS, AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY

ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS

THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

Limited 90 Day Warranty

Harbor Freight Tools Co. makes every effort to assure that its products meet high quality and durability standards,

and warrants to the original purchaser that this product is free from defects in materials and workmanship for the

period of 90 days from the date of purchase. This warranty does not apply to damage due directly or indirectly,

to misuse, abuse, negligence or accidents, repairs or alterations outside our facilities, criminal activity, improper

installation, normal wear and tear, or to lack of maintenance. We shall in no event be liable for death, injuries

to persons or property, or for incidental, contingent, special or consequential damages arising from the use of

our product. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the

above limitation of exclusion may not apply to you. THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS.

To take advantage of this warranty, the product or part must be returned to us with transportation charges

prepaid. Proof of purchase date and an explanation of the complaint must accompany the merchandise.

If our inspection verifies the defect, we will either repair or replace the product at our election or we may

elect to refund the purchase price if we cannot readily and quickly provide you with a replacement. We will

return repaired products at our expense, but if we determine there is no defect, or that the defect resulted

from causes not within the scope of our warranty, then you must bear the cost of returning the product.

This warranty gives you specific legal rights and you may also have other rights which vary from state to state.

26541 Agoura Road • Calabasas, CA 91302 • 1-888-380-0318

Loading...

Loading...