Page 1

SERVICE MANUAL

ENDURANCE / CHALLENGER

MODULAR SERIES GAS

RANGES

VULCAN

WOLF

This Manual is prepared for the use of trained Vulcan Service

Technicians and should not be used by those not properly

qualified.

12

24S

36S, 36C

48C, 48S, 48SS

60SS, 60SC, 60CS

72SS, 72SC, 72CC, 72CS

C12,

C24S

C36S, C36C

C48S, C48SS, C48C

C60SS, C60SC, C60CS

C72SS, C72SC, C72CC, C72CS

This manual is not intended to be all encompassing. If you have

not attended a Vulcan Service School for this product, you should

read, in its entirety, the repair procedure you wish to perform to

determine if you have the necessary tools, instruments and skills

required to perform the procedure. Procedures for which you

do not have the necessary tools, instruments and skills should

be performed by a trained Vulcan Service Technician.

The reproduction, transfer, sale or other use of this Manual,

without the express written consent of Vulcan, is prohibited.

This manual has been provided to you by ITW Food Equipment

Group LLC (“ITW FEG”) without charge and remains the property

of ITW FEG, and by accepting this manual you agree that you will

return it to ITW FEG promptly upon its request for such return

at any time in the future.

For additional information on Vulcan-Hart Company or to locate an authorized

parts and service provider in your area, visit our website at www.vulcanequipment.com

VULCAN-HART

DIVISION OF ITW FOOD EQUIPMENT GROUP, LLC

www.vulcanequipment.com

BALTIMORE, MD 21222

F454A (0615)

Page 2

ENDURANCE / CHALLENGER MODULAR SERIES GAS RANGES

TABLE OF CONTENTS

SERVICE UPDATES ....................................................................................... 4

SERVICE UPDATES ................................................................................... 4

GENERAL .................................................................................................. 5

INTRODUCTION ....................................................................................... 5

INSTALLATION, OPERATION AND CLEANING ......................................................... 5

LUBRICATION ......................................................................................... 5

TOOLS ................................................................................................. 5

SPECIFICATIONS ...................................................................................... 5

REMOVAL AND REPLACEMENT OF PARTS ............................................................... 6

MANIFOLD COVER .................................................................................... 6

CONTROL BRACKET COVER .......................................................................... 6

CONTROL PANEL (30" OVENS) ........................................................................ 6

KICK PANEL (24" & 30" OVENS) ....................................................................... 6

BULL NOSE ............................................................................................ 7

CONTROL BRACKET .................................................................................. 7

STANDARD OVEN PILOT ASSEMBLY AND THERMOCOUPLE ......................................... 8

STANDARD OVEN BURNER ........................................................................... 8

STANDARD OVEN THERMOSTAT (24" OVEN) ......................................................... 9

STANDARD OVEN THERMOSTAT (30" OVEN) ........................................................ 10

CONVECTION OVEN PILOT ASSEMBLY AND THERMOCOUPLE ..................................... 11

CONVECTION OVEN BURNER ....................................................................... 12

CONVECTION OVEN THERMOSTAT-COMBO VALVE ................................................ 12

CONVECTION OVEN BLOWER AND MOTOR ......................................................... 13

BURNER ORIFICE HOOD (STANDARD AND CONVECTION OVENS) ................................. 14

GAS SAFETY VALVE (STANDARD AND CONVECTION OVENS) ...................................... 14

TOP BURNER PILOT VALVE .......................................................................... 15

TOP BURNER ASSEMBLY ............................................................................ 16

TOP BURNER CONTROL VALVE ..................................................................... 16

TOP BURNER ORIFICE HOOD ....................................................................... 17

OVEN DOOR ......................................................................................... 17

GAS PRESSURE REGULATOR ....................................................................... 18

CONVECTION OVEN DOOR SWITCH ................................................................. 19

CONVECTION OVEN SOLENOID ..................................................................... 19

GRIDDLE THERMOSTAT-COMBO VALVE ............................................................ 20

GRIDDLE GAS SAFETY VALVE ....................................................................... 22

GRIDDLE PILOT ASSEMBLY AND THERMOCOUPLE ................................................. 22

GRIDDLE BURNER ORIFICE HOOD .................................................................. 23

CHARBROILER BURNER ............................................................................. 23

CHARBROILER PILOT ................................................................................ 25

SERVICE PROCEDURES AND ADJUSTMENTS ........................................................... 27

OVEN PILOT FLAME HEIGHT ......................................................................... 27

OVEN PILOT ADJUSTMENT ...................................................................... 27

OPEN TOP PILOT ADJUSTMENT ................................................................. 27

BURNER AIR SHUTTER ADJUSTMENT ............................................................... 27

REGULATOR ADJUSTMENT .......................................................................... 28

BURNER NOZZLE CHECK ............................................................................ 29

STANDARD OVEN THERMOSTAT BY-PASS FLAME ADJUSTMENT .................................. 29

STANDARD OVEN THERMOSTAT TEMPERATURE ADJUSTMENT ................................... 30

CONVECTION OVEN THERMOSTAT-COMBO VALVE ADJUSTMENT ................................. 30

OPERATION ...................................................................................... 30

ADJUSTMENT .................................................................................... 30

GRIDDLE THERMOSTAT-COMBO VALVE ADJUSTMENT ............................................. 31

OPERATION ...................................................................................... 31

ADJUSTMENT .................................................................................... 31

F45471 Rev. A (0615) Page 2 of 38

Page 3

ENDURANCE / CHALLENGER MODULAR SERIES GAS RANGES

THERMOCOUPLE TEST .............................................................................. 32

OPERATION ...................................................................................... 32

PILOT CHECKS ................................................................................... 32

THERMOCOUPLE CHECKS ...................................................................... 32

CHARBROILER PILOT ADJUSTMENT ................................................................ 33

ELECTRICAL OPERATION ................................................................................ 34

COMPONENT FUNCTION ............................................................................ 34

SEQUENCE OF OPERATION - CONVECTION OVEN ................................................. 34

SCHEMATIC DIAGRAM - CONVECTION OVENS ...................................................... 35

WIRING DIAGRAM - CONVECTION OVENS .......................................................... 36

TROUBLESHOOTING ..................................................................................... 37

TROUBLESHOOTING ................................................................................. 37

© HOBART SERVICE 2015

Page 3 of 38 F45471 Rev. A (0615)

Page 4

ENDURANCE / CHALLENGER MODULAR SERIES GAS RANGES - SERVICE UPDATES

SERVICE UPDATES

SERVICE UPDATES

This section lists the service updates to the

information in the manual.

June 2015

Added

• CHARBROILER BURNER removal.

• CHARBROILER PILOT removal.

• CHARBROILER PILOT ADJUSTMENT .

• CHARBROILER BURNER AIR SHUTTER

picture under BURNER AIR SHUTTER

ADJUSTMENT.

F45471 Rev. A (0615) Page 4 of 38

Page 5

ENDURANCE / CHALLENGER MODULAR SERIES GAS RANGES - GENERAL

GENERAL

INTRODUCTION

This manual is for the Endurance / Challenger

XL™ Modular Series Gas Ranges. Procedures in this

manual will apply to all models unless specified.

Pictures and illustrations will be of model 60SC unless

otherwise noted.

All of the information, illustrations and specifications

contained in this manual are based on the latest

product information available at the time of printing.

INSTALLATION, OPERATION AND

CLEANING

Refer to F38201 VULCAN ENDURANCE / WOLF

CHALLENGER Modular Series Gas Restaurant

Ranges I/O Manual for detailed installation, operation

and cleaning instructions.

LUBRICATION

Anderson and Forrester (or comparable) valve grease

for top burner gas valves, top burner pilot valves, and

pressure tap plugs. Apply light coat to valve/plug

threads. Valve grease must be insoluble in propane

and natural gas.

• A non perminate type sealer (preferably fast

drying) such as nail polish or equivelant for

sealing thermostat adjustment screw. If using

Loctite 242, it begins to set in approximately 10

minutes and fully cures in 24 hours according to

manufacturer.

• 3/4" pipe tee and hose barb assembly for

temporarily checking manifold pressure when a

pressure tap is not available in the gas manifold

on some models.

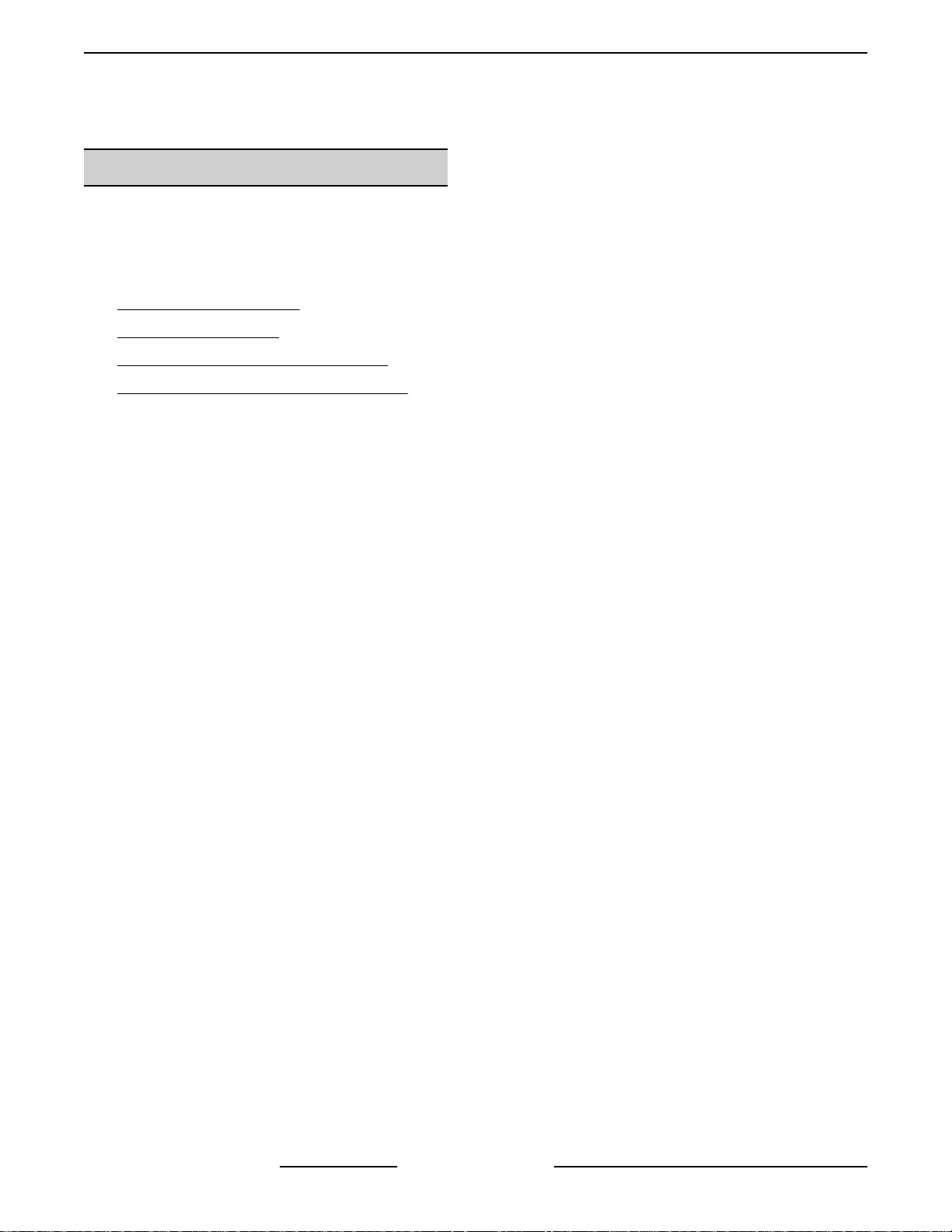

• Adaptor to test thermocouple closed circuit DC

voltages (purchase locally). Adaptors vary

between manufacturers. An example of one

adaptor type is pictured below.

Fig. 1

SPECIFICATIONS

TOOLS

Standard

• Standard set of hand tools.

• VOM with A.C. current tester (Any quality VOM

with a sensitivity of at least 20,000 ohms per volt

can be used).

Special

• Temperature tester (K type thermocouple

preferred).

• Manometer.

• Long reach phillips screwdriver #2 for installing

or removing motor assembly through the

convection oven cavity.

• Two standard 1/4"- 20 x 1" bolts (allen head

recommended). The bolts are used to relieve

spring tension on the door hinge during door

removal and installation.

• Loctite® 246™ for use on the door handle

mounting screws.

Gas Pressures

• Manifold/Operating Pressure

Natural: 5 in. W.C.

Propane: 10 in. W.C.

• Inlet Supply Pressure

Natural - Recomended 7 in. W.C. ; Minimum

5 in. W.C.

Propane - Recomended 11 in. W.C. ;

Minimum 11 in. W.C.

Maximum 14 in. W.C. (0.5 PSI) (Natural or

Propane)

Orifice Size Requirements

• See Orifice Chart in Parts Catalog F43260

ENDURANCE/CHALLENGER MODULAR

SERIES GAS RANGES.

Page 5 of 38 F45471 Rev. A (0615)

Page 6

ENDURANCE / CHALLENGER MODULAR SERIES GAS RANGES - REMOVAL AND REPLACEMENT OF PARTS

REMOVAL AND REPLACEMENT OF PARTS

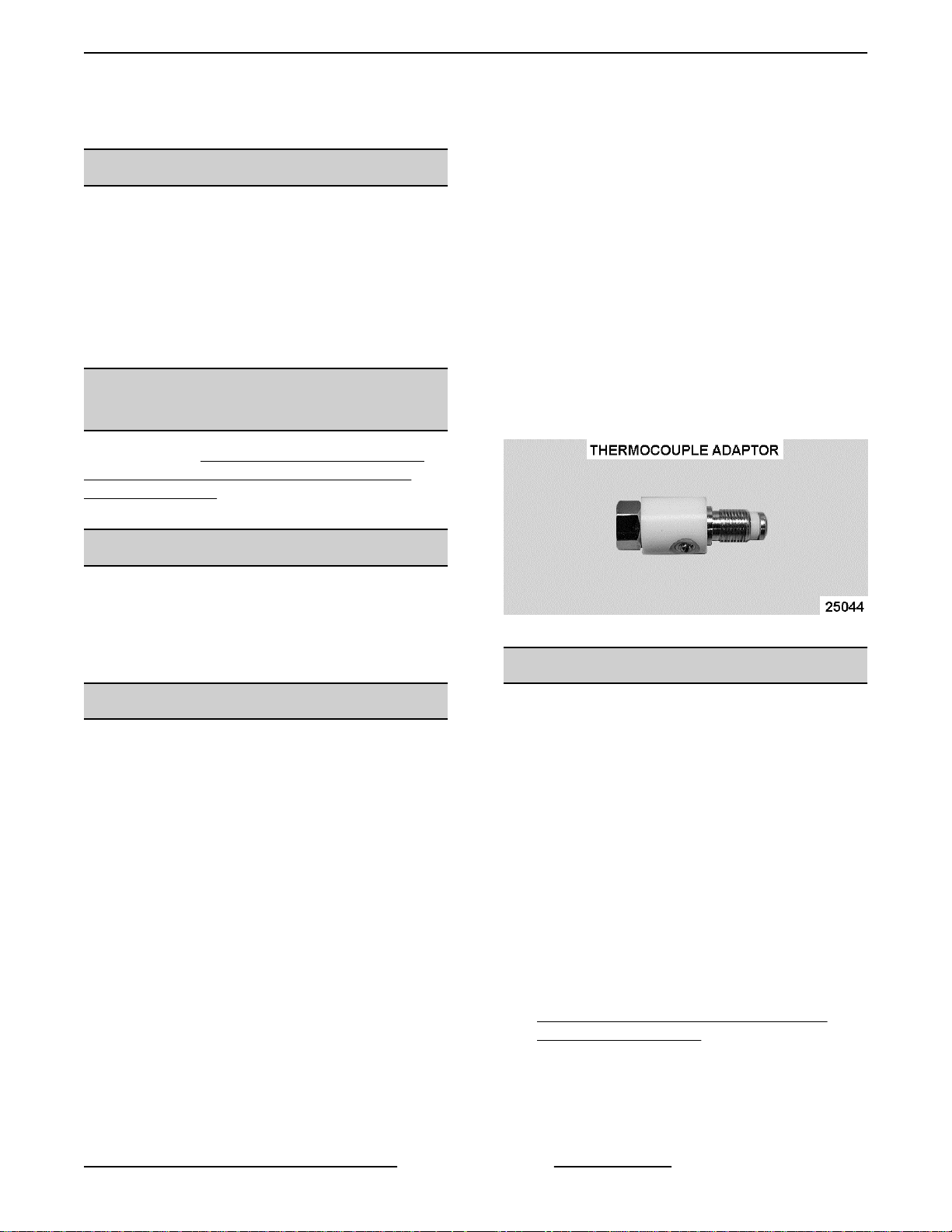

MANIFOLD COVER

Shut off the gas before servicing the

unit.

1. Pull crumb tray out.

2. Loosen set screw in the open top burner control

knobs and remove knobs.

3. Remove screws that secure manifold cover and

remove cover.

4. Reverse procedure to install.

Fig. 2

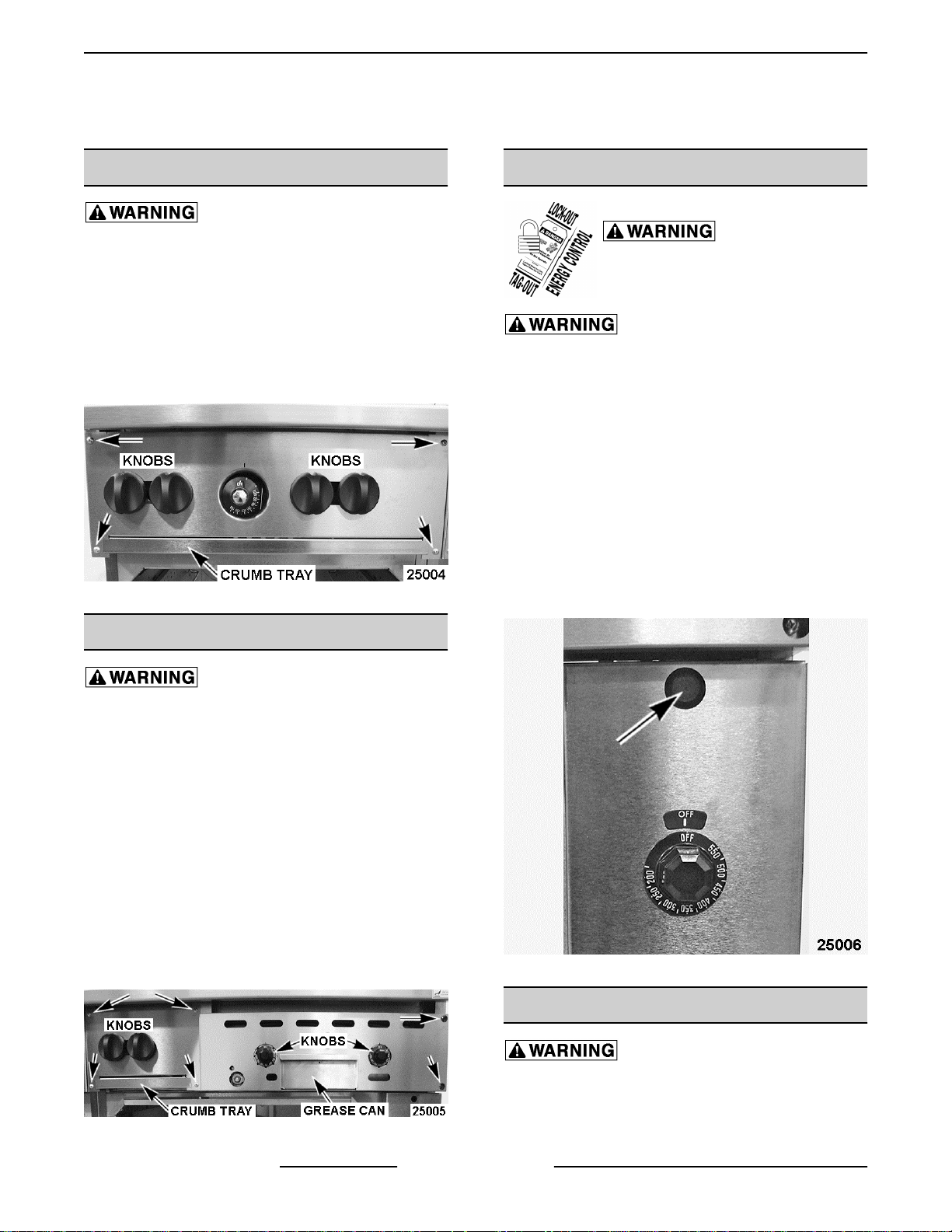

CONTROL PANEL (30" OVENS)

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Shut off the gas before servicing the

unit.

NOTE: Electrical power disconnect warning applies

to convection ovens.

NOTE: Removal procedure applies to standard and

convection 30" ovens.

1. Pull knob from thermostat.

2. Remove hole plug at top of control panel.

3. Remove screw and lift off control panel.

4. On convection ovens only, note lead wire

locations and disconnect from power switch.

5. Reverse procedure to install.

CONTROL BRACKET COVER

Shut off the gas before servicing the

unit.

1. Pull grease can out.

2. Pull knobs from thermostats.

3. If removing control bracket cover from oven with

a 12" open top burner module and 24" griddle top

module:

A. Pull crumb tray out of 12" section if installed.

B. Loosen set screw in the open top burner

control knobs and remove knobs.

4. Remove screws that secure control bracket

cover and remove the bracket.

5. Reverse procedure to install.

Convection Oven Panel Shown

KICK PANEL (24" & 30" OVENS)

Shut off the gas before servicing the

unit.

1. Lift up on kick panel and rotate down 90°.

Fig. 3

F45471 Rev. A (0615) Page 6 of 38

Page 7

ENDURANCE / CHALLENGER MODULAR SERIES GAS RANGES - REMOVAL AND REPLACEMENT OF PARTS

2. Remove screws securing kick panel mounting

brackets (2) to the oven and remove kick panel.

3. Reverse procedure to install.

Fig. 5

BULL NOSE

CONTROL BRACKET

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Shut off the gas before servicing the

unit.

All gas joints disturbed during

servicing must be checked for leaks. Check with a

soap and water solution (bubbles). Do not use an open

flame.

1. Remove BULL NOSE.

2. Remove CONTROL BRACKET COVER.

3. If installed, remove compression nut on the

flexible tubing gas line that supplies gas to the

manifold on the adjacent open top burner

section.

1. Turn top burners and griddle off.

2. Remove front row of top burner grates on ranges

with open top burners.

3. Remove all screws securing bull nose to range.

The total number of screws depend on the width

of the range.

4. Lift bull nose off range.

Fig. 6

5. Reverse procedure to install.

Fig. 7

4. Loosen the recessed screws (4) through the

access holes on the two manifold cover brackets

(L & R) that secure the control bracket to the

oven. The bracket mounting holes are keyed for

removal of the control bracket.

Page 7 of 38 F45471 Rev. A (0615)

Page 8

ENDURANCE / CHALLENGER MODULAR SERIES GAS RANGES - REMOVAL AND REPLACEMENT OF PARTS

2. Remove cavity bottom by lifting up and sliding

out.

3. Remove screws securing oven pilot assembly to

burner carrier.

Fig. 8

5. Lift the control bracket up and tilt forward to

remove bracket from mounting screws.

6. Partially install the grease drawer leaving enough

of the drawer extended to support the control

bracket while servicing.

4. Lower the KICK PANEL (24" & 30" OVENS).

Fig. 10

Fig. 9

7. Griddle controls are now accessible for removal.

A. If replacing control bracket, remove screws

securing griddle controls to bracket.

B. Remove manifold cover brackets (L & R)

from each end of the control bracket as

necessary (2 screws for each bracket).

8. Reverse procedure to install and check for proper

operation.

STANDARD OVEN PILOT

ASSEMBLY AND THERMOCOUPLE

5. Pull oven pilot assembly out through opening in

lower oven frame.

6. If replacing thermocouple only, remove

thermocouple from oven pilot assembly and gas

safety valve. Continue to last step.

When installing, do not bend and kink the

capillary tube or damage to the component may occur.

7. If replacing oven pilot assembly, remove pilot

tubing and thermocouple from oven pilot

assembly.

8. Reverse procedure to install and check for proper

operation.

STANDARD OVEN BURNER

Shut off the gas before servicing the

unit.

All gas joints disturbed during

servicing must be checked for leaks. Check with a

soap and water solution (bubbles). Do not use an open

flame.

Shut off the gas before servicing the

unit.

All gas joints disturbed during

servicing must be checked for leaks. Check with a

soap and water solution (bubbles). Do not use an open

flame.

1. Remove bottom oven rack(s) and rack guides.

F45471 Rev. A (0615) Page 8 of 38

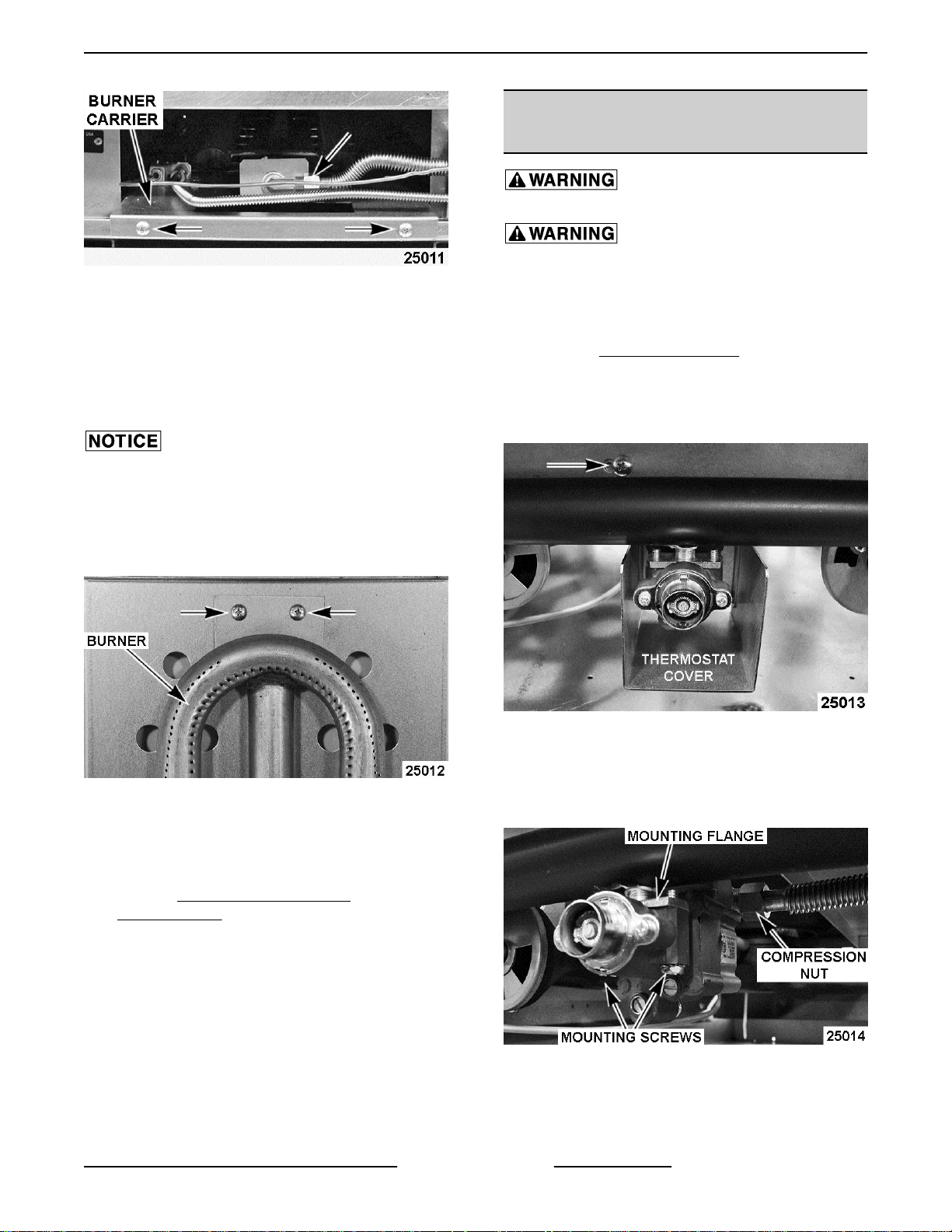

1. Lower the KICK PANEL (24" & 30" OVENS).

2. Hold the tab on burner carrier with plyers to

3. Remove screws securing burner carrier to oven

support it then remove compression nut from

burner elbow fitting to disconnect gas supply

tubing.

frame.

Page 9

ENDURANCE / CHALLENGER MODULAR SERIES GAS RANGES - REMOVAL AND REPLACEMENT OF PARTS

STANDARD OVEN THERMOSTAT

(24" OVEN)

Shut off the gas before servicing the

unit.

All gas joints disturbed during

servicing must be checked for leaks. Check with a

Fig. 11

4. Pull burner carrier out through opening in lower

oven frame enough to access the oven pilot

assembly.

5. Remove screws securring oven pilot assembly to

burner carrier. Move oven pilot assembly away

from burner.

Do not bend and kink the capillary tube or

damage to the control may occur.

6. Pull burner carrier with burner attached out from

oven.

soap and water solution (bubbles). Do not use an open

flame.

1. Pull out crumb tray.

2. Remove MANIFOLD COVER.

3. Remove oven thermostat knob.

4. Remove screw securing thermostat cover to

oven frame.

7. Remove screws securring burner to the burner

carrier.

Fig. 12

8. Slide oven burner off the burner nozzle to

remove.

9. Reverse procedure to install.

10. Perform BURNER AIR SHUTTER

ADJUSTMENT.

Fig. 13

5. Remove compression nut from elbow fitting at

the rear of thermostat.

6. Remove screws securing thermostat to mounting

flange.

Fig. 14

A. Inspect mounting flange and gasket. If okay,

they may be used during installation. If not

okay, remove and install replacement

flange.

Page 9 of 38 F45471 Rev. A (0615)

Page 10

ENDURANCE / CHALLENGER MODULAR SERIES GAS RANGES - REMOVAL AND REPLACEMENT OF PARTS

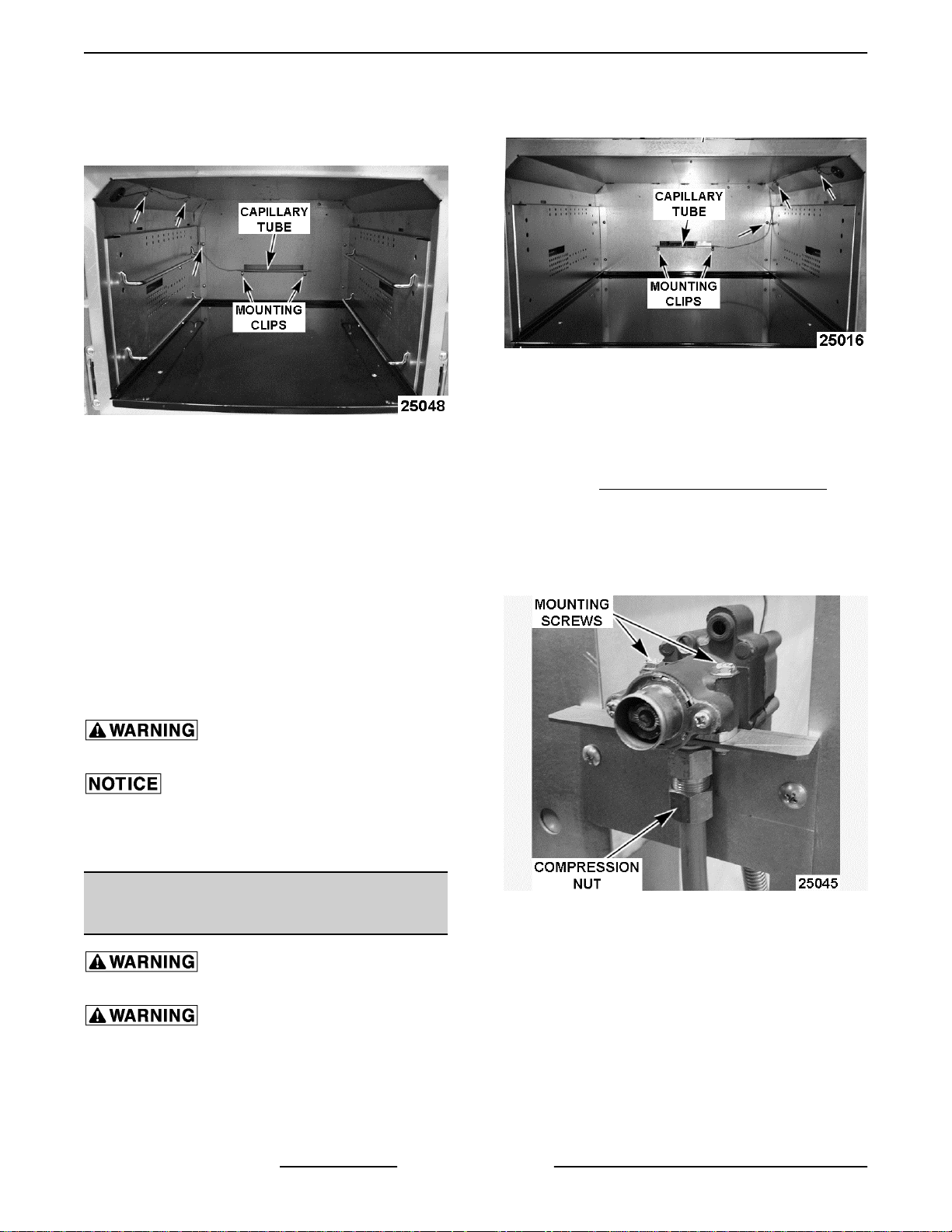

7. Open oven door and remove oven racks.

8. Remove screws securing capillary tube mounting

clips (5) inside the oven cavity.

Fig. 15

NOTE: Capillary tube is permanently attached to

thermostat-combo valve.

9. Remove all mounting clips from capillary tube

and retain for reuse.

10. Pull capillary tube through the hole in oven

sidewall and remove thermostat from oven.

A. Remove insulation sleeve from capillary

tube for installation on replacement

thermostat capillary tube.

2. Remove screws securing capillary tube mounting

clips (5) inside the oven cavity.

Standard 30" oven

NOTE: Capillary tube is permanently attached to

thermostat.

3. Remove all mounting clips from capillary tube

and retain for reuse.

4. Remove CONTROL PANEL (30" OVENS).

5. Remove compression nuts from thermostat

fittings (front & rear).

6. Remove screws securing thermostat to mounting

bracket.

B. Note orientation of compression fitting

elbow on valve body and remove for

installation on replacement valve body.

Clean pipe threads and apply thread

sealant that is suitable for use with propane gases.

When installing, do not bend and kink the

capillary tube or damage to the control may occur.

11. Reverse procedure to install and check for proper

operation.

STANDARD OVEN THERMOSTAT

(30" OVEN)

Shut off the gas before servicing the

unit.

All gas joints disturbed during

servicing must be checked for leaks. Check with a

soap and water solution (bubbles). Do not use an open

flame.

1. Open oven door and remove oven racks.

Fig. 17

F45471 Rev. A (0615) Page 10 of 38

Page 11

ENDURANCE / CHALLENGER MODULAR SERIES GAS RANGES - REMOVAL AND REPLACEMENT OF PARTS

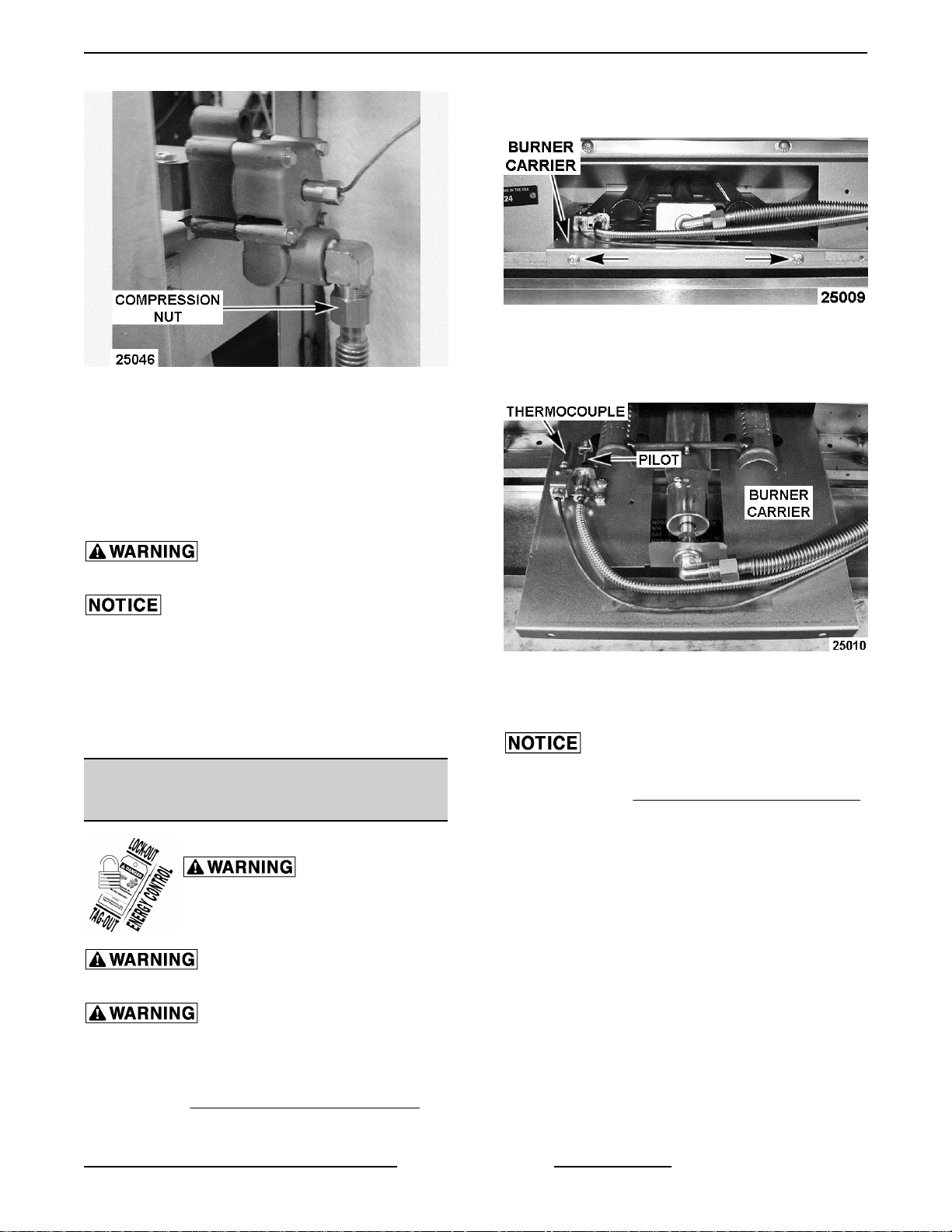

2. Remove screws securing burner carrier to oven

frame.

Fig. 19

3. Pull burner carrier out through opening in lower

Fig. 18

7. Remove gas line tubing from thermostat.

8. Pull capillary tube through the hole in oven

sidewall and remove thermostat from oven.

A. Note orientation of compression fittings on

thermostat body and remove for installation

on replacement valve body.

oven frame enough to access the oven pilot

assembly.

Clean pipe threads and apply thread

sealant that is suitable for use with propane gases.

When installing, do not bend and kink the

capillary tube or damage to the control may occur.

NOTE: When installing thermostat capillary tube,

push any insulation back through grommet and

remove loose insulation from oven cavity.

9. Reverse procedure to install and check for proper

operation.

CONVECTION OVEN PILOT

ASSEMBLY AND THERMOCOUPLE

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Shut off the gas before servicing the

unit.

All gas joints disturbed during

servicing must be checked for leaks. Check with a

soap and water solution (bubbles). Do not use an open

flame.

Fig. 20

4. If replacing thermocouple only, remove

thermocouple from oven pilot assembly.

When installing, do not bend and kink the

capillary tube or damage to the component may occur.

A. Remove CONTROL PANEL (30" OVENS).

B. Remove thermocouple from gas safety

valve and remove thermocouple from oven.

Continue to last step.

5. If replacing oven pilot assembly, remove pilot

tubing and thermocouple from oven pilot

assembly.

6. Remove screws securing oven pilot assembly to

burner carrier.

7. Reverse procedure to install and check for proper

operation.

1. Lower the KICK PANEL (24" & 30" OVENS).

Page 11 of 38 F45471 Rev. A (0615)

Page 12

ENDURANCE / CHALLENGER MODULAR SERIES GAS RANGES - REMOVAL AND REPLACEMENT OF PARTS

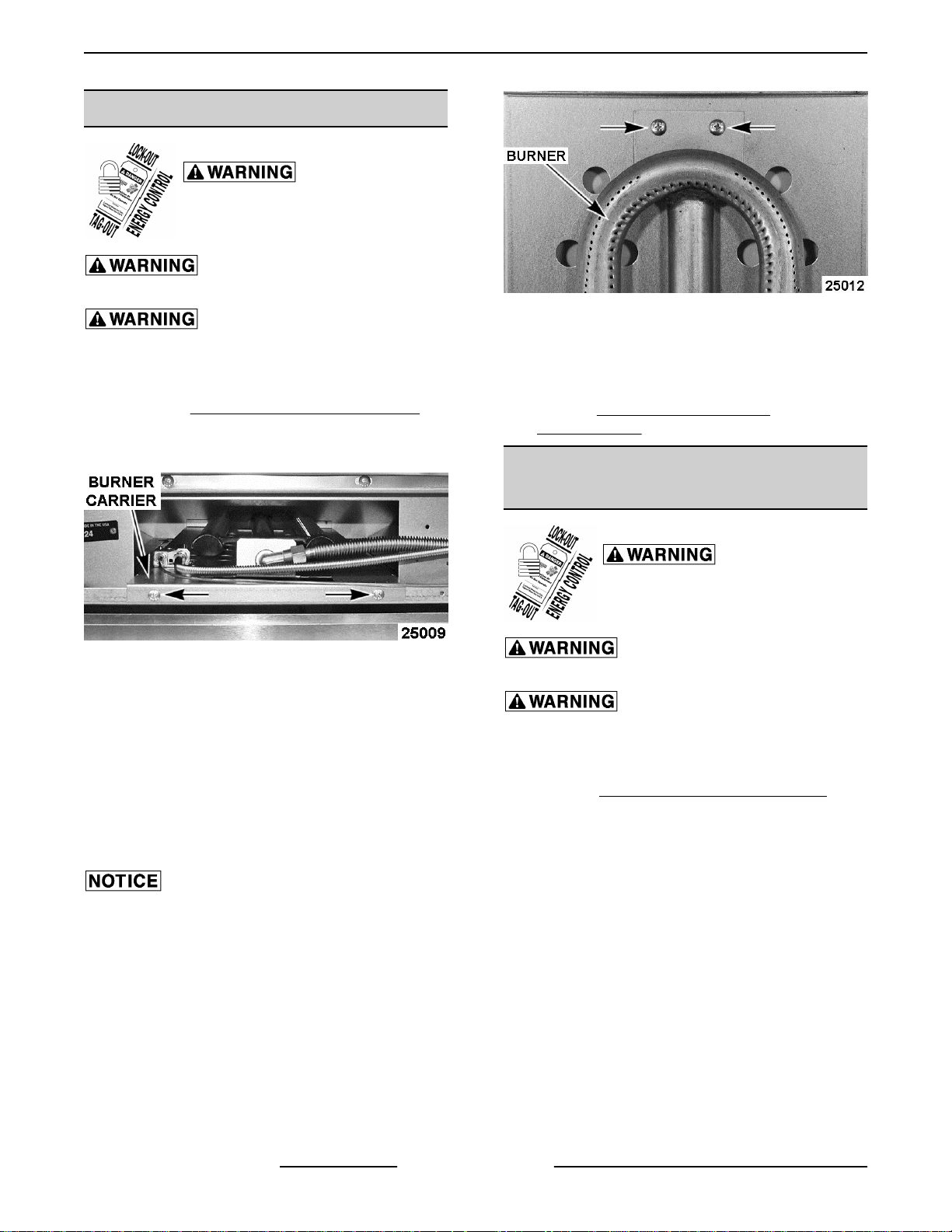

CONVECTION OVEN BURNER

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Shut off the gas before servicing the

unit.

All gas joints disturbed during

servicing must be checked for leaks. Check with a

soap and water solution (bubbles). Do not use an open

flame.

1. Lower the KICK PANEL (24" & 30" OVENS).

2. Remove screws securing burner carrier to oven

frame.

8. Slide oven burner off the burner nozzle to

remove.

9. Reverse procedure to install.

10. Perform

ADJUSTMENT.

BURNER AIR SHUTTER

Fig. 22

CONVECTION OVEN

THERMOSTAT-COMBO VALVE

Fig. 21

3. Pull burner carrier out through opening in lower

oven frame enough to access the oven pilot

assembly and burner elbow fitting.

4. Hold the tab on burner carrier with plyers to

support then remove compression nut from

burner elbow fitting.

5. Remove screws securing oven pilot assembly to

burner carrier. Move pilot assembly away from

burner.

Do not bend and kink the capillary tube or

damage to the control may occur.

6. Pull burner carrier with burner attached out from

oven.

7. Remove screws securing burner to the burner

carrier.

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Shut off the gas before servicing the

unit.

All gas joints disturbed during

servicing must be checked for leaks. Check with a

soap and water solution (bubbles). Do not use an open

flame.

1. Remove CONTROL PANEL (30" OVENS).

2. Remove compression nuts from thermostatcombo valve fittings.

3. Remove screws securing thermostat-combo

valve to mounting bracket.

F45471 Rev. A (0615) Page 12 of 38

Page 13

ENDURANCE / CHALLENGER MODULAR SERIES GAS RANGES - REMOVAL AND REPLACEMENT OF PARTS

Clean pipe threads and apply thread

sealant that is suitable for use with propane gases.

When installing, do not bend and kink the

capillary tube or damage to the control may occur.

NOTE: When installing thermostat capillary tube,

push any insulation back through grommet and

remove loose insulation from oven cavity.

9. Reverse procedure to install and check for proper

operation.

CONVECTION OVEN BLOWER AND

MOTOR

Fig. 23

4. Remove thermostat-combo valve from gas line

tubing.

5. Remove oven racks.

6. Open oven door and remove screws securing

capillary tube mounting clips (4) at the top of oven

cavity.

Fig. 24

NOTE: Capillary tube is permanently attached to

thermostat-combo valve.

7. Remove all mounting clips from capillary tube

and retain for reuse.

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove cover from electrical junction box at the

rear of range.

2. Disconnect motor wiring at junction box.

3. Loosen screw securing armored cable to junction

box.

4. Remove oven racks and rack guides from oven.

5. Place cardboard over the oven cavity bottom to

protect it during motor removal.

6. Remove screws securing motor mount panel to

the oven. Pull the assembly out from the oven.

8. Pull capillary tube through the hole in oven

sidewall and remove thermostat-combo valve

from oven.

A. Remove insulation sleeve from capillary

tube for installation on replacement

thermostat capillary tube.

B. Note orientation of compression fittings on

valve body and remove for installation on

replacement valve body.

Fig. 25

7. Remove screws (4) securing blower cover to

motor mount panel.

Page 13 of 38 F45471 Rev. A (0615)

Page 14

ENDURANCE / CHALLENGER MODULAR SERIES GAS RANGES - REMOVAL AND REPLACEMENT OF PARTS

BURNER ORIFICE HOOD

(STANDARD AND CONVECTION

OVENS)

1. Access burner for the type of oven being serviced

as outlined under STANDARD OVEN BURNER

or CONVECTION OVEN BURNER.

2. Remove the orifice hood from fitting.

3. Perform BURNER NOZZLE CHECK.

Fig. 26

8. Loosen bolts (2) securing blower to motor shaft

then remove blower.

9. If replacing blower only, proceed to last step. If

replacing motor, continue with procedure.

10. Remove mounting nuts and spacers securing

motor mounting brackets (2) to motor mount

panel.

Fig. 27

A. Remove motor mounting brackets from

motor for reuse.

B. Remove cover from motor junction box,

disconnect wires and remove armored

cable from motor junction box.

4. Reverse procedure to install.

5. Check for proper operation.

GAS SAFETY VALVE (STANDARD

AND CONVECTION OVENS)

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Shut off the gas before servicing the

unit.

All gas joints disturbed during

servicing must be checked for leaks. Check with a

soap and water solution (bubbles). Do not use an open

flame.

1. Remove CONTROL PANEL (30" OVENS) on

standard and convection ovens or lower the

KICK PANEL (24" & 30" OVENS) on standard

24" ovens.

2. Remove pilot tubing and thermocouple from gas

safety valve.

3. Remove inlet and outlet gas lines from gas safety

valve.

C. Inspect the motor insulation located

between the motor mounting brackets and

the motor mount panel. Replace if

damaged.

11. Install motor mounting brackets and armored

cable onto replacement motor.

12. Reverse procedure to install and check for proper

operation.

F45471 Rev. A (0615) Page 14 of 38

Page 15

ENDURANCE / CHALLENGER MODULAR SERIES GAS RANGES - REMOVAL AND REPLACEMENT OF PARTS

TOP BURNER PILOT VALVE

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Shut off the gas before servicing the

unit.

All gas joints disturbed during

servicing must be checked for leaks. Check with a

Gas Safety Valve on Standard 24" Oven

soap and water solution (bubbles). Do not use an open

flame.

1. On the module section being serviced, loosen set

screw on top burner knobs and remove knobs

from manual valve.

2. Remove MANIFOLD COVER.

Gas Safety Valve on 30" Convection Oven

NOTE: Safety valve replacement is identical on 30

inch wide standard ovens.

4. Remove screws securing gas safety valve to

mounting bracket and remove the valve. On 24"

standard ovens, spacers are installed between

the valve and mounting bracket. Retain spacers

for reuse. Spacer locations shown in picture

25022 "Gas Safety Valve on Standard 24"

Oven".

5. Remove compression fittings and tubing from

gas safety valve for installation on replacement

valve.

Clean pipe threads and apply thread

sealant that is suitable for use with propane gases.

3. Remove compression nut securing pilot tube to

pilot valve.

4. Remove pilot valve from the manifold.

Fig. 30

5. Reverse procedure to install.

Clean pipe threads and apply thread

sealant that is suitable for use with propane gases.

Do not over tighten pilot valve or damage

to the threads may ocurr.

6. Check OVEN PILOT FLAME HEIGHT under

Open Top Burner Adjustment.

6. Reverse procedure to install and check for proper

operation.

Page 15 of 38 F45471 Rev. A (0615)

Page 16

ENDURANCE / CHALLENGER MODULAR SERIES GAS RANGES - REMOVAL AND REPLACEMENT OF PARTS

TOP BURNER ASSEMBLY

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Shut off the gas before servicing the

unit.

All gas joints disturbed during

servicing must be checked for leaks. Check with a

soap and water solution (bubbles). Do not use an open

flame.

1. Remove top burner grates (front and rear) from

the module section being serviced.

6. Check for proper operation.

7. Verify BURNER AIR SHUTTER ADJUSTMENT.

Fig. 32

2. Remove pilot from mounting clip on the top

burner assembly. Move pilot away from burner

assembly.

Fig. 31

3. Lift burner heads off the top burner assembly.

4. Lift the top burner assembly at the rear and pull

away from manual valves.

TOP BURNER CONTROL VALVE

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Shut off the gas before servicing the

unit.

All gas joints disturbed during

servicing must be checked for leaks. Check with a

soap and water solution (bubbles). Do not use an open

flame.

A. Remove pilot mounting clip and flash tube

from the top burner assembly for resuse on

replacement burner assembly.

5. Reverse procedure to install.

NOTE: When installing, ensure that each end of the

flash tube is aligned with the ignition ports on the

burner “venturi” casting for proper burner ignition.

F45471 Rev. A (0615) Page 16 of 38

1. Remove MANIFOLD COVER.

2. Remove TOP BURNER ASSEMBLY.

3. Remove TOP BURNER PILOT VALVE.

4. Remove top burner control valve from the

Fig. 33

manifold.

Page 17

ENDURANCE / CHALLENGER MODULAR SERIES GAS RANGES - REMOVAL AND REPLACEMENT OF PARTS

5. Inspect the top control valve for wear and

damage, replace as necessary.

6. Reverse procedure to install.

Clean pipe threads and apply thread

sealant that is suitable for use with propane gases.

NOTE: When installing, ensure top burner control

valve is aligned and centered in the burner assembly

opening. The valve must be perpendicular to the

manifold.

7. Check for proper operation.

TOP BURNER ORIFICE HOOD

1. Access top burner orifice hood as outlined under

TOP BURNER ASSEMBLY.

2. Remove the orifice hood from top burner control

valve.

3. Reverse procedure to install.

4. Check for proper operation.

OVEN DOOR

5. Close door leaving enough space to clear the

oven gas manifold cover during removal. As the

door approaches this position, you should notice

a decrease in the spring tension on the door.

6. Remove door as follows:

A. Hold door at bottom corners then lift the door

up and out to disengage the hinges.

B. The notch on swivel hinge must release

from bottom edge of the door hinge stop to

remove door. As needed, lift up on the

swivel hinges using forefinger to aid in

releasing.

C. The spring-loaded hinge must release from

the roller inside the slot on door hinge stop

to remove door.

7. If replacing door or door spring hinge, position the

door face down. Press down on hinge enough to

relieve spring force then remove bolt from door

hinge slot.

Installation

1. Compress each spring-loaded hinge enough to

insert the bolt into the slot at top of hinge.

Removal

1. Remove CONTROL PANEL (30" OVENS).

NOTE: Removal of control panel is to provide

additional space on the right side of door to ease door

removal and installation.

2. Lower KICK PANEL (24" & 30" OVENS).

3. Fully open the oven door.

4. Insert a 1/4"-20 x 1" bolt (see TOOLS) into each

door hinge slot at the top of the spring loaded

hinge.

2. Hold door at bottom corners while facing the oven

cavity. Place knee on the front of door to help

balance it as necessary during installation.

A. Using index fingers, lift swivel hinges until

they touch the spring-loaded hinges and

hold in place.

B. Tilt the top of door toward the oven so that

the swivel hinge is at a slightly downward

angle to pass between the bar and bottom

edge of door hinge stop.

C. Insert hinges into the slots making sure that

the spring-loaded hinges go above the bar

to catch on the roller and the swivel hinges

go underneath the bar to catch on the

bottom edge of door hinge slot.

D. Lower the door and position it as necessary

to engage the swivel hinge slots with the

bottom edge of both door hinge slots.

Fig. 34

Page 17 of 38 F45471 Rev. A (0615)

Page 18

ENDURANCE / CHALLENGER MODULAR SERIES GAS RANGES - REMOVAL AND REPLACEMENT OF PARTS

GAS PRESSURE REGULATOR

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Shut off the gas before servicing the

unit.

All gas joints disturbed during

servicing must be checked for leaks. Check with a

soap and water solution (bubbles). Do not use an open

flame.

Fig. 35

3. Fully open door to check operation. If bottom

edge of door rubs the front edge of cavity bottom

then the swivel hinge is not engaged as

described.

A. To seat the swivel hinge, open door

approximately 30° and pull in the same

direction on the door handle. The hinge

should drop into place.

4. Open door and check operation. If okay, remove

bolts and close door. If not okay, remove door

and repeat installation procedure.

5. On convection ovens, verify door switch is

operating properly.

6. Reinstall oven control panel.

7. Raise kick panel.

Clean pipe threads and apply thread

sealant that is suitable for use with propane gases.

1. Thread regulator onto pipe hand tight with arrow

pointing in direction of gas flow to the range.

Fig. 36

2. Tighten regulator securely in horizontal position

with the regulator adjustment upward as

described on regulator.

NOTE: Regulator will not function properly without

adjustment screw pointing upward.

3. Connect supply gas line to gas pressure

4. Adjust regulator as outlined in REGULATOR

F45471 Rev. A (0615) Page 18 of 38

regulator inlet.

ADJUSTMENT.

Page 19

ENDURANCE / CHALLENGER MODULAR SERIES GAS RANGES - REMOVAL AND REPLACEMENT OF PARTS

CONVECTION OVEN DOOR

SWITCH

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

NOTE: Door switch is installed on Convection Ovens

only.

1. Remove

2. Remove single mounting nut securing door

switch bracket to safety valve mounting bracket.

3. Remove screws securing door switch bracket to

oven frame and remove bracket from control

area.

CONTROL PANEL (30" OVENS).

Fig. 38

7. Reverse procedure to install and check door

switch for proper operation.

CONVECTION OVEN SOLENOID

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Shut off the gas before servicing the

unit.

All gas joints disturbed during

servicing must be checked for leaks. Check with a

soap and water solution (bubbles). Do not use an open

flame.

Fig. 37

4. Open door to unoperate the switch.

5. Note lead wire locations and disconnect from

door switch.

6. Remove screws and mounting nuts securing

door switch to door switch bracket.

1. Remove door switch bracket as outlined under

CONVECTION OVEN DOOR SWITCH. Allow

bracket to rest at the bottom of control area.

2. Remove screws securing the mounting bracket

that holds the safety valve, oven thermostat and

the oven solenoid to the oven frame.

Page 19 of 38 F45471 Rev. A (0615)

Page 20

ENDURANCE / CHALLENGER MODULAR SERIES GAS RANGES - REMOVAL AND REPLACEMENT OF PARTS

GRIDDLE THERMOSTAT-COMBO

VALVE

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Shut off the gas before servicing the

unit.

All gas joints disturbed during

servicing must be checked for leaks. Check with a

soap and water solution (bubbles). Do not use an open

flame.

1. Remove BULL NOSE.

Fig. 39

3. Remove compression nuts on the inlet and outlet

of solenoid.

4. Remove screws and mounting nuts securing

solenoid to bracket.

5. Disconnect lead wires from solenoid.

2. Raise griddle plate from the front and support

using 4x4 blocks.

3. Pull thermostat bulb out of the holder for the

thermostat-combo valve being replaced.

NOTE: Capillary tube is permanently attached to

thermostat-combo valve.

Fig. 41

4. Remove CONTROL BRACKET COVER.

5. If installed, remove compression nut on the

Fig. 40

6. Remove fittings from solenoid for reuse on

replacement valve.

Clean pipe threads and apply thread

sealant that is suitable for use with propane gases.

7. Reverse procedure to install and check for proper

operation.

F45471 Rev. A (0615) Page 20 of 38

flexible tubing gas line that supplies gas to the

manifold on the adjacent open top burner

section.

Page 21

ENDURANCE / CHALLENGER MODULAR SERIES GAS RANGES - REMOVAL AND REPLACEMENT OF PARTS

9. Remove compression nuts from thermostatcombo valve fittings for the thermostat being

replaced.

Fig. 42

6. Loosen the recessed screws (4) through the

access holes on the two manifold cover brackets

(L & R) that secure the control bracket to the

oven. The bracket mounting holes are keyed for

removal of the control bracket.

10. Remove screws (3) securing thermostat-combo

valve to the control bracket and remove the

thermostat-combo valve.

Fig. 45

Fig. 43

7. Lift up control bracket and tilt forward to access

griddle thermostat-combo valves.

8. Partially install the grease drawer leaving enough

of the drawer extended to support the control

bracket while servicing.

Fig. 44

Page 21 of 38 F45471 Rev. A (0615)

Fig. 46

A. Note orientation of compression fittings on

the thermostat-combo valve and remove for

installation on replacement valve.

B. Remove insulation sleeve from capillary

tube for installation on replacement

thermostat capillary tube.

Clean pipe threads and apply thread

sealant that is suitable for use with propane gases.

When installing, do not bend and kink the

capillary tubes or damage to the controls may occur.

Ensure capillary tubes are routed properely through

mounting slots before lowering the griddle or damage

to the controls may occur.

NOTE: When installing, ensure orifice hood is aligned

and centered in the burner assembly opening. The

griddle orifice bracket must be perpendicular to the

manifold.

Page 22

ENDURANCE / CHALLENGER MODULAR SERIES GAS RANGES - REMOVAL AND REPLACEMENT OF PARTS

11. Reverse procedure to install and check for proper

operation.

GRIDDLE GAS SAFETY VALVE

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Shut off the gas before servicing the

unit.

All gas joints disturbed during

servicing must be checked for leaks. Check with a

soap and water solution (bubbles). Do not use an open

flame.

1. Remove CONTROL BRACKET.

2. Remove pilot tubing and thermocouple from gas

safety valve.

3. Remove compression nuts from gas safety valve

fittings.

Fig. 47

4. Remove screws (2) securing gas safety valve to

the control bracket and remove the valve.

A. Note orientation of compression fittings on

the valve and remove for installation on

replacement valve.

Fig. 48

When installing, do not bend and kink the

capillary tube or damage to the control may occur.

Clean pipe threads and apply pipe joint

compound. Any pipe joint compound used must be

resistant to the reaction of propane gases.

NOTE: When installing, ensure orifice hood is aligned

and centered in the burner assembly opening.

5. Reverse procedure to install and check for proper

operation.

GRIDDLE PILOT ASSEMBLY AND

THERMOCOUPLE

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Shut off the gas before servicing the

unit.

All gas joints disturbed during

servicing must be checked for leaks. Check with a

soap and water solution (bubbles). Do not use an open

flame.

1. Remove CONTROL BRACKET.

2. Remove screws (2) securing pilot assembly

3. If replacing pilot assembly, remove pilot tubing

F45471 Rev. A (0615) Page 22 of 38

mounting bracket to griddle burner box.

A. If replacing thermocouple only, remove

thermocouple from pilot assembly and gas

safety valve. Continue to last step.

and thermocouple from pilot assembly.

Page 23

ENDURANCE / CHALLENGER MODULAR SERIES GAS RANGES - REMOVAL AND REPLACEMENT OF PARTS

NOTE: When installing, ensure orifice hood is aligned

and centered in the burner assembly opening.

CHARBROILER BURNER

Shut off the gas before servicing the

unit.

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Fig. 49

4. Remove screws (2) securing pilot assembly to

mounting bracket.

5. Reverse procedure to install and check for proper

operation.

When installing, do not bend and kink the

capillary tube or damage to the control may occur.

NOTE: When installing, ensure orifice hood is aligned

and centered in the burner assembly opening.

GRIDDLE BURNER ORIFICE HOOD

Shut off the gas before servicing the

unit.

All gas joints disturbed during

servicing must be checked for leaks. Check with a

soap and water solution (bubbles). Do not use an open

flame.

1. Remove CONTROL BRACKET.

2. Remove the orifice hood from fitting.

Fig. 51

Charbroiler Burner Components - Front View

• [1] Grate

• [2] Radiant

• [3] Burner

• [4] Deflector

1. Remove grate [1] from charbroiler.

Fig. 50

3. Reverse procedure to install and check for proper

operation.

Page 23 of 38 F45471 Rev. A (0615)

Page 24

ENDURANCE / CHALLENGER MODULAR SERIES GAS RANGES - REMOVAL AND REPLACEMENT OF PARTS

Fig. 52

2. Remove radiant [1] to access burner.

Fig. 53

3. Remove burner [1] and deflector [2] by lifting at

the rear of burner.

F45471 Rev. A (0615) Page 24 of 38

Page 25

ENDURANCE / CHALLENGER MODULAR SERIES GAS RANGES - REMOVAL AND REPLACEMENT OF PARTS

Fig. 55

5. To Install:

A. Install deflector onto replacement burner.

6. Verify BURNER AIR SHUTTER ADJUSTMENT.

Fig. 54

4. Remove burner rod [1] securing deflector [2] to

burner.

7. Install radiant above the burner.

8. Install grate.

9. Check for proper operation.

CHARBROILER PILOT

Shut off the gas before servicing the

unit.

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove

pilot.

2. Remove crumb trays.

CHARBROILER BURNER to access

Fig. 56

3. Remove knobs from front of range.

Page 25 of 38 F45471 Rev. A (0615)

Page 26

ENDURANCE / CHALLENGER MODULAR SERIES GAS RANGES - REMOVAL AND REPLACEMENT OF PARTS

Fig. 57

4. Remove manifold cover.

Fig. 58

5. Remove compression nut from pilot valve then

remove pilot tube assembly from valve.

Fig. 60

Fig. 59

6. Remove pilot tube assembly from pilot bracket.

Use pliers to separate as needed.

7. Reverse procedure to install.

NOTE: If replacing pilot and tubing, ensure a

compression nut and ferrule are installed on the end

of tubing that connects to pilot valve.

F45471 Rev. A (0615) Page 26 of 38

Page 27

ENDURANCE / CHALLENGER MODULAR SERIES GAS RANGES - SERVICE PROCEDURES AND

ADJUSTMENTS

SERVICE PROCEDURES AND ADJUSTMENTS

OVEN PILOT FLAME HEIGHT

Oven Pilot Adjustment

1. Remove CONTROL PANEL (30" OVENS).

2. Lower the KICK PANEL (24" & 30" OVENS) to

access gas safety valve on 24" standard ovens

and to view pilot flame height on all ovens.

3. Remove pilot adjustment cover screw from gas

safety valve.

panel. You may need to remove a knob depending on

the orientation of the pilot adjustment screw.

1. Locate the pilot adjustment screw located behind

the adjustment access hole in the panel.

Fig. 62

2. Rotate the screw clockwise to decrease and

counterclockwise to increase flame height.

3. Pilot is in adjustment when it will stay on

continually and lights the burners without

delayed ignition.

Gas Safety Valve on 30" Ovens Shown

(Convection & Standard)

4. Rotate pilot adjustment screw clockwise to

decrease and counterclockwise to increase pilot

flame height.

5. Pilot flame is in adjustment when it is

approximately ½" tall and flame surrounds one

third of the thermocouple down from the tip of the

hot junction end.

6. Reverse procedure to install and check for proper

operation.

NOTE: After adjustment, ensure cover screw is reinstalled.

Open Top Pilot Adjustment

To adjust the pilot flame height of the top burners,

locate the pilot adjustment screws found on the front

manifold pipe between the burner control knobs. It is

not necessary to remove the gas manifold cover as

adjustment access holes have been provided in the

BURNER AIR SHUTTER

ADJUSTMENT

The efficiency of the burner depends on a delicate

balance between the air supply and volume of gas.

Whenever this balance is disturbed, poor operating

characteristics and excessive gas consumption may

occur. An air shutter on the front of the burner controls

the gas mixer balance. A yellow streaming flame on

the burner is an indication of insufficient primary air.

To correct this condition, loosen the shutter screw and

rotate the air shutter open until the flame begins to lift

from the burner, then close the shutter slightly and

tighten the shutter screw. A proper flame should be

blue in color, well-defined and seated on the burner

port. A white-blue flame is a result of excessive

primary air.

NOTE: The factory default air shutter positions are

half open natural; full open propane.

Page 27 of 38 F45471 Rev. A (0615)

Page 28

ENDURANCE / CHALLENGER MODULAR SERIES GAS RANGES - SERVICE PROCEDURES AND

ADJUSTMENTS

adjusted as necessary. Make sure the regulator is

mounted in the horizontal position with the arrow

pointing in the direction of gas flow. Clean vent cap

before adjusting. Fig. 66 shows gas flow direction and

vent cap location.

See unit data plate, riveted inside the kick panel, for

manifold pressure setting information. Fig. 67 shows

manifold pressure tap location.

Top Burner Air Shutters

Oven Burner Air Shutter

Charbroiler Burner Air Shutter

REGULATOR ADJUSTMENT

NOTE: Regulators come preset, but should be

checked anytime one is installed. Before adjusting

regulator, check incoming gas line pressure. Incoming

pressure must be 6-14" W.C. for natural gas and

11-14" W.C. for propane gas. If incoming pressure is

not correct, have the gas source checked and

Fig. 66

1. Connect manometer to either of the pressure

taps provided on the range gas piping between

the burner control valve sets. If pressure taps are

not available, install a pipe tee and hose barb

assembly on the outlet of the regulator. See

TOOLS.

Fig. 67

2. Open the valves to turn on approximately half of

the units burners to the full on position and check

manometer reading. The reading should be 5"

W.C. for natural gas and 10" W.C. for propane

gas. Tolerance is ±0.3" W.C.

3. If manifold pressure is not correct, adjust the

regulator as follows:

A. Remove the regulator closing nut.

F45471 Rev. A (0615) Page 28 of 38

Page 29

ENDURANCE / CHALLENGER MODULAR SERIES GAS RANGES - SERVICE PROCEDURES AND

ADJUSTMENTS

OVEN BURNER NOZZLE SHOWN

Fig. 68

STANDARD OVEN THERMOSTAT

B. Insert a flat edge screwdriver into the top of

regulator housing to reach the adjusting

screw. While watching the manometer, turn

the adjusting screw clockwise to increase

pressure and counterclockwise to decrease

pressure until the proper gas pressure is

achieved. See data plate.

C. Install the regulator closing nut.

D. Remove manometer from pressure tap.

E. Apply thread sealant to pressure tap plug

and reinstall. Thread sealant must be

insoluble in propane and natural gas.

BY-PASS FLAME ADJUSTMENT

NOTE: The bypass flame setting has a direct affect

on calibration, and must be verified prior to checking

or adjusting calibration of any "modulating

thermostat". The by-pass flame can be viewed

through the kick panel for adjustment.

1. Turn thermostat knob to 350°F.

2. Wait 15 minutes for oven to heat up.

3. Turn thermostat knob to lowest setting. DO NOT

TURN OFF.

4. Remove thermostat knob.

BURNER NOZZLE CHECK

5. With a small flat edge screwdriver, turn by-pass

The burner nozzle is mounted between the oven gas

supply tubing/mounting bracket and the u-burner

assembly. If burner operation seems poor and other

systems have been checked, access the burner for

the range section being serviced and remove the

burner nozzle.

• Check for blockage or damage.

flame adjustment screw counterclockwise to

increase by-pass flame or clockwise to decrease

flame until both legs of burner have

approximately 1/8" stable flame on each port.

Ports should be set to just above “flickering”.

NOTE: Some flickering of the flame is acceptable,

only in the bend of the burner.

• Verify gas orifice hood is correct for the altitude.

See SPECIFICATIONS for Orifice Size

Requirements.

Page 29 of 38 F45471 Rev. A (0615)

Fig. 70

Page 30

ENDURANCE / CHALLENGER MODULAR SERIES GAS RANGES - SERVICE PROCEDURES AND

ADJUSTMENTS

6. Replace thermostat knob.

A. Turn knob to 350°F and verify increase in

flame height on burner ports.

7. Turn knob back to lowest setting. Verify decrease

in by-pass flame height on burner ports and that

burner remains lit.

STANDARD OVEN THERMOSTAT

TEMPERATURE ADJUSTMENT

NOTE: Calibration on this "modulating thermostat"

version is made using the knob for temperature

adjustments and not the inner screw as on previous

versions.

1. Place a thermocouple type temperature probe

(type K preferred) in center of oven to verify

actual temperatures throughout adjustment.

2. Turn thermostat knob to 350°F. Wait 15 minutes

for oven to heat up.

3. Turn knob to the lowest setting and check the bypass flame for proper adjustment as outlined

under STANDARD OVEN THERMOSTAT BYPASS FLAME ADJUSTMENT.

4. Turn knob back to 350°F and wait for

temperature to stabilize (approximately 30

minutes). When the temperature stabilizes take

a temperature reading. If actual temperature is

more than 15°F from knob setting, calibrate as

follows:

5. Pull off thermostat knob.

6. Loosen two screws on the back of knob.

8. Tighten screws and replace knob.

9. Verify temperature setting at 400°F and 450°F.

Wait 15 minutes for oven to heat up at each

setting. If actual oven temperature is not within

15°F, readjust as outlined in this procedure. If

three consecutive adjustments do not produce

acceptable results, replace thermostat and verify

calibration.

CONVECTION OVEN

THERMOSTAT-COMBO VALVE

ADJUSTMENT

Operation

The "snap action" thermostat-combo valve is selfregulating and the thermostat is internally connected

to the valve. When thermostat dial is set to 350°F and

the oven is below setpoint, the valve opens to allow

gas flow and burner lights. As the oven temperature

rises, the pressure from the sensor bulb in the oven

increases. Fluid in the capillary tube expands with the

temperature increase and presses against a

diaphragm in the thermostat. When the oven

temperature reaches setpoint, the internal valve

closes to stop gas flow to burner.

When the oven temperature decreases below

setpoint, the pressure is reduced in the capillary which

reduces the force on the diaphragm allowing the valve

to open again.

Adjustment

1. Place a thermocouple temperature probe (type K

preferred) in center of oven to verify actual

temperatures throughout adjustment.

2. Turn power switch on.

3. Turn thermostat knob to 350°F and allow oven to

4. Take a temperature reading. If actual

Fig. 71

7. Grasp stem and push it out from knob to clear the

temperature adjustment notches. Move

calibration pointer at base of stem clockwise to

lower temperature or counterclockwise to raise

temperature as close to the desired setpoint as

possible. Each notch equals 10°F.

F45471 Rev. A (0615) Page 30 of 38

than 3/8 turn or damage to the thermostat may occur.

cycle 3 complete times. If the customer has a

preferred temperature setting that they always

operate the oven at such as 325°, 375° or 400°,

you may calibrate to that temperature instead.

temperature is more than 20° from knob setting,

calibrate as follows:

A. Pull off knob. Do not rotate knob during

removal.

Do not turn the adjustment screw more

Page 31

ENDURANCE / CHALLENGER MODULAR SERIES GAS RANGES - SERVICE PROCEDURES AND

ADJUSTMENTS

B. While holding outer shaft in place, turn inner

screw using a small flat edge screwdriver

1/8 turn clockwise to decrease and

counterclockwise to increase. 1/4 turn =

35°F. See Fig. 72 below.

C. Verify temperature at 350°F (or customers

preferred setting). Allow oven to cycle 3

times.

NOTE: You must allow the oven to cycle 3 times to

stabilize oven temperature or the calibration

adjustment may be invalid.

D. Take a temperature reading. If temperature

is within acceptable limits, continue to next

step. If temperature is not within 20°F then

re-adjust as outlined in this procedure. If 3

consecutive adjustments do not produce

acceptable results, replace thermostat and

verify calibration.

E. Apply a small amount of a non permanent

type sealer (preferably fast drying) such as

nail polish or equivalent around the inner

screw head to prevent movement during

outer shaft rotation. Allow sufficient time for

the applied sealer to dry then install knob.

See TOOLS.

F. If calibrating at 350°F, verify temperature at

400°F. If calibrating at a customer preferred

temperature setting, select one temperature

setting above the customer preferred

setting. If the customers temperature setting

is 450F, then calibrate at that temp only.

Allow oven to cycle 3 times at the

temperature setting. If actual oven

temperature is not within 20°F of the setting,

replace thermostat and verify calibration.

GRIDDLE THERMOSTAT-COMBO

VALVE ADJUSTMENT

Operation

The "snap action thermostat-combo" valve is selfregulating and the thermostat is internally connected

to the valve. When thermostat dial is set to 350°F and

the griddle is below setpoint, the valve opens to allow

gas flow and burner lights. As the griddle temperature

rises, the pressure from the sensor bulb secured to

the bottom of the griddle plate increases. Fluid in the

capillary tube expands with the temperature increase

and presses against a diaphragm in the thermostat.

When the griddle temperature reaches setpoint, the

internal valve closes to stop gas flow to burner.

When the griddle temperature decreases below

setpoint, the pressure is reduced in the capillary which

reduces the force on the diaphragm allowing the valve

to open again.

Fig. 72

Adjustment

1. Place a thermocouple type surface temperature

probe (type K preferred) in center of griddle to

verify actual temperatures throughout

adjustment.

2. Turn thermostat knob to 350°F and allow griddle

to cycle 3 complete times. If the customer has a

preferred temperature setting that they always

operate the oven at such as 325°, 375° or 400°,

you may calibrate to that temperature instead.

3. Take a temperature reading. If actual

temperature is more than 20° from knob setting,

calibrate as follows:

A. Pull off knob. Do not rotate knob during

removal.

Do not turn the adjustment screw more

than 3/8 turn or damage to the thermostat may occur.

Page 31 of 38 F45471 Rev. A (0615)

Page 32

ENDURANCE / CHALLENGER MODULAR SERIES GAS RANGES - SERVICE PROCEDURES AND

ADJUSTMENTS

B. While holding outer shaft in place, turn inner

screw using a small flat edge screwdriver

1/8 turn clockwise to decrease and

counterclockwise to increase. 1/4 turn =

35°F. See picture Fig. 72 under

CONVECTION OVEN THERMOSTATCOMBO VALVE ADJUSTMENT.

C. Verify temperature setting at 350°F (or

customers preferred setting). Allow griddle

to cycle 3 times.

NOTE: You must allow the griddle to cycle 3 times to

stabilize oven temperature or the calibration

adjustment may be invalid.

D. Take a temperature reading. If temperature

is within acceptable limits, continue to next

step. If temperature is not within 20°F then

readjust as outlined in this procedure. If 3

consecutive adjustments do not produce

acceptable results, replace thermostat and

verify calibration.

E. Apply a small amount of a non permanent

type sealer (preferably fast drying) such as

nail polish or equivalent around the inner

screw head to prevent movement during

outer shaft rotation. Allow sufficient time for

the applied sealer to dry then install knob.

See TOOLS.

F. If calibrating at 350°F, verify temperature at

400°F. If calibrating at a customer preferred

temperature setting, select one temperature

setting above the customer preferred

setting. If the customers temperature setting

is 450F, then calibrate at that temp only.

Allow oven to cycle 3 times at the

temperature setting. If actual oven

temperature is not within 20°F of the setting,

replace thermostat and verify calibration.

THERMOCOUPLE TEST

Operation

The thermocouple supplies a DC millivolt signal (MV)

to the gas safety valve when heated by the pilot flame.

The gas safety valve will shut off gas flow to the pilot

and main burner in case of a pilot outage. When

energized by the thermocouple voltage, the gas safety

valve is held open to permit gas flow to the pilot and

provide gas for the burner when the oven thermostat

calls for heat. The pilot flame height is controlled by

an adjustable needle valve located under a small

cover screw on the gas safety valve.

Visually check pilot flame for the proper contact on

thermocouple and adjust as outlined under OVEN

PILOT FLAME HEIGHT. If adjustment does not result

in a pilot flame of proper height, then gas might not be

flowing properly to the pilot.

Check for:

• A plugged pilot orifice.

• Kinked or plugged pilot gas tubing.

• Low gas supply pressure.

Thermocouple Checks

NOTE: Tubing connection from the thermocouple tip

to gas safety valve is an electrical connection and

must be clean and dry. Do not use any sealing

compound on the threads of thermocouple nut.

Do not overtighten the thermocouple nut

or the insulator could be crushed, shorting the

thermocouple. Finger tighten the nut plus 1/4 turn with

a wrench only.

If pilot flame is correct and there are no excessive air

drafts in the room, then problem is either the

thermocouple output voltage or the gas safety valve.

Visually check the thermocouple tip (hot end) and tube

lead for:

• Loose thermocouple connection (electrical) at

the safety valve.

• Corrosion or debris on the threaded connector or

thermocouple tip causing a poor electrical

connection.

• Kinks or pinches that might cause a short

between the tube and the wire inside.

If thermocouple is loose, tighten mounting nut as

described above in NOTICE. If thermocouple

connection shows signs of corrosion or debris that

cannot be cleaned; or damage as described, replace

it and check pilot operation as outlined under

PILOT FLAME HEIGHT.

Thermocouple Test

Check the thermocouple output voltage (DC millivolts)

with a VOM as outlined in the steps below.

• If thermocouple adaptor (see TOOLS) is

available, check closed circuit voltage as outlined

in the test procedure.

• If thermocouple adaptor is not available, check

open circuit voltage as outlined in the test

procedure.

OVEN

Pilot Checks

If experiencing pilot outages, perform the following:

F45471 Rev. A (0615) Page 32 of 38

Page 33

ENDURANCE / CHALLENGER MODULAR SERIES GAS RANGES - SERVICE PROCEDURES AND

ADJUSTMENTS

• If a VOM is not available, replace the

thermocouple with a new one as outlined under

STANDARD OVEN PILOT ASSEMBLY AND

THERMOCOUPLE or CONVECTION OVEN

PILOT ASSEMBLY AND THERMOCOUPLE or

and check operation GRIDDLE PILOT

ASSEMBLY AND THERMOCOUPLE.

1. Disconnect thermocouple from gas safety valve.

2. Select the test to perform.

3. Closed Circuit.

A. Install thermocouple adaptor at the

threaded connection on gas safety valve.

B. Install thermocouple to the adaptor. Tighten

mounting nut as described above in

NOTICE.

C. Light the pilot. Allow pilot to heat

thermocouple for one to two minutes.

D. Connect one meter lead to the adaptor test

point and the other meter lead to the tube.

Compare reading to the value listed in the

table below.

4. Open Circuit

CHARBROILER PILOT

ADJUSTMENT

Pilot Adjustment

• Turn pilot adjustment screws clockwise to

decrease the flame.

• Turn pilot adjustment screws counter-clockwise

to increase the flame.

• Pilot is in adjustment when it will stay on

continually and lights the burner without delayed

ignition.

Fig. 73

A. Connect one meter lead to the tip of the

threaded end and the other meter lead to the

tube. Compare reading to the values listed

in the table below.

B. Light the pilot and continue to hold red

button down during this test. Allow pilot to

heat thermocouple for one to two minutes.

C. Compare reading to the value listed in the

table below.

THERMOCOUPLE MV READINGS

Closed Circuit Open Circuit

Range 8 to 25 MV 25 to 35 MV

5. If readings are less than the minimum stated

above, replace the thermocouple as outlined

under STANDARD OVEN PILOT ASSEMBLY

AND THERMOCOUPLE or CONVECTION

OVEN PILOT ASSEMBLY AND

THERMOCOUPLE or GRIDDLE PILOT

ASSEMBLY AND THERMOCOUPLE.

6. If pilot is still not functioning properly after

replacing thermocouple, then a problem exists in

the gas safety valve. Install a replacement GAS

SAFETY VALVE (STANDARD AND

CONVECTION OVENS) and check for proper

operation.

Page 33 of 38 F45471 Rev. A (0615)

Page 34

ENDURANCE / CHALLENGER MODULAR SERIES GAS RANGES - ELECTRICAL OPERATION

ELECTRICAL OPERATION

COMPONENT FUNCTION

Power Cord ........... Connects range to power source.

On/Off Switch ......... Provides power for the convection oven motor and solenoid valve.

Solenoid Valve ....... Allows gas flow to the convection oven burner assembly when solenoid is energized by

the door switch (normally closed valve).

Door Switch .......... Removes power from convection motor and solenoid valve when oven door is open (N.O.

- held closed).

Convection Oven

Motor (Single

Phase) ................

Junction Box ......... Connection point for electrical wires.

Circulates heated air inside the oven. The motor electrical power is routed through door

switch.

SEQUENCE OF OPERATION -

CONVECTION OVEN

Refer to AI3549 SCHEMATIC DIAGRAM CONVECTION OVENS.

Oven temperature is below set point of control.

Convection Oven

1. Conditions.

A. 120VAC to oven controls and is properely

grounded.

B. Power switch off.

C. Door switch held-closed (oven door closed).

D. Pilot lit.

E. Thermostat-combo valve is off.

F. Oven at room temperature.

2. Turn power switch on.

3. Set thermostat knob to 350°F.

4. Oven reaches setpoint temperature. Thermostat-

5. Door switch opened (oven door open).

6. Oven door closed. Door switch contacts close

7. Thermostat-combo valve cycles the burner as

B. Power to oven motor (blower circulates air

inside cavity).

A. Thermostat-combo valve calls for heat and

opens internal valve to allow gas flow to

burner.

B. Pilot lights the burner and heating begins.

combo valve closes internal valve to stop gas

flow to burner.

A. Power is removed from oven motor.

and oven motor resumes operation.

required to maintian setpoint temperature untill

thermostat knob is turned to off; or power switch

off.

A. Solenoid is energized allowing gas flow to

thermostat-combo valve.

F45471 Rev. A (0615) Page 34 of 38

Page 35

ENDURANCE / CHALLENGER MODULAR SERIES GAS RANGES - ELECTRICAL OPERATION

SCHEMATIC DIAGRAM - CONVECTION OVENS

Fig. 74

Page 35 of 38 F45471 Rev. A (0615)

Page 36

ENDURANCE / CHALLENGER MODULAR SERIES GAS RANGES - ELECTRICAL OPERATION

WIRING DIAGRAM - CONVECTION OVENS

Fig. 75

F45471 Rev. A (0615) Page 36 of 38

Page 37

ENDURANCE / CHALLENGER MODULAR SERIES GAS RANGES - TROUBLESHOOTING

TROUBLESHOOTING

TROUBLESHOOTING

GENERAL

SYMPTOM POSSIBLE CAUSE

1. Incorrect gas pressure.

2. Pilot burner not adjusted properly.

3. Pilot burner blocked.

Pilot does not remain lit.

Burner flame too yellow

Slow to heat or not hot enough.

Oven temperature too hot.

Low burner flame (all burners).

Low burner flame (individual burner). 1. Air mixture incorrect.

Flame floats on burner.

4. Thermocouple not positioned correctly or

malfunctioning.

5. Gas safety valve malfunction.

6. Incorrect oven pilot orifice.

7. Ventilation issue in room (drafts blowing out pilot).

1. Orifice incorrect size or dirty.

2. Air shutter not adjusted correctly or dirty.

3. Incorrect gas pressure.

4. Incorrect gas type.

5. Orifice misaligned in venturi.

6. Appliance not venting properly.

1. Low gas pressure.

2. Thermostat out of calibration.

1. Thermostat out of calibration.

2. By-pass flame to high.

1. Low gas pressure.

2. Incorrect gas type.

1. Inadequate air supply.

2. Restricted exhaust flue (ovens).

CONVECTION OVENS ONLY

SYMPTOM POSSIBLE CAUSE

Oven temperature too hot. 1. Thermostat out of calibration.

Page 37 of 38 F45471 Rev. A (0615)

Page 38

ENDURANCE / CHALLENGER MODULAR SERIES GAS RANGES - TROUBLESHOOTING

SYMPTOM POSSIBLE CAUSE

Convection motor does not operate.

Convection motor noisy.

CONVECTION OVENS ONLY

1. Main power supply not on.

2. Incorrect voltage.

3. Oven door switch arm not engaging door hinge arm

properely.

4. Oven door switch open or inoperative.

5. Power switch open or inoperative.

6. Convection motor inoperative.

1. Motor mounting bracket or motor mounting plate to

the back of the chassis is loose.

2. Fan shroud is loose or fan is rubbing shroud.

3. Fan loose on motor shaft.

4. Fan excessively dirty or debris stuck in fan.

5. Motor malfunction.

1. Low gas pressure.

Pilot does not remain lit (no gas flow to oven burner).

2. Thermocouple not positioned correctly or

malfunctioning.

3. Solenoid malfunction.

4. Pilot gas flow too low. Adjust on gas safety valve.

F45471 Rev. A (0615) Page 38 of 38

Loading...

Loading...