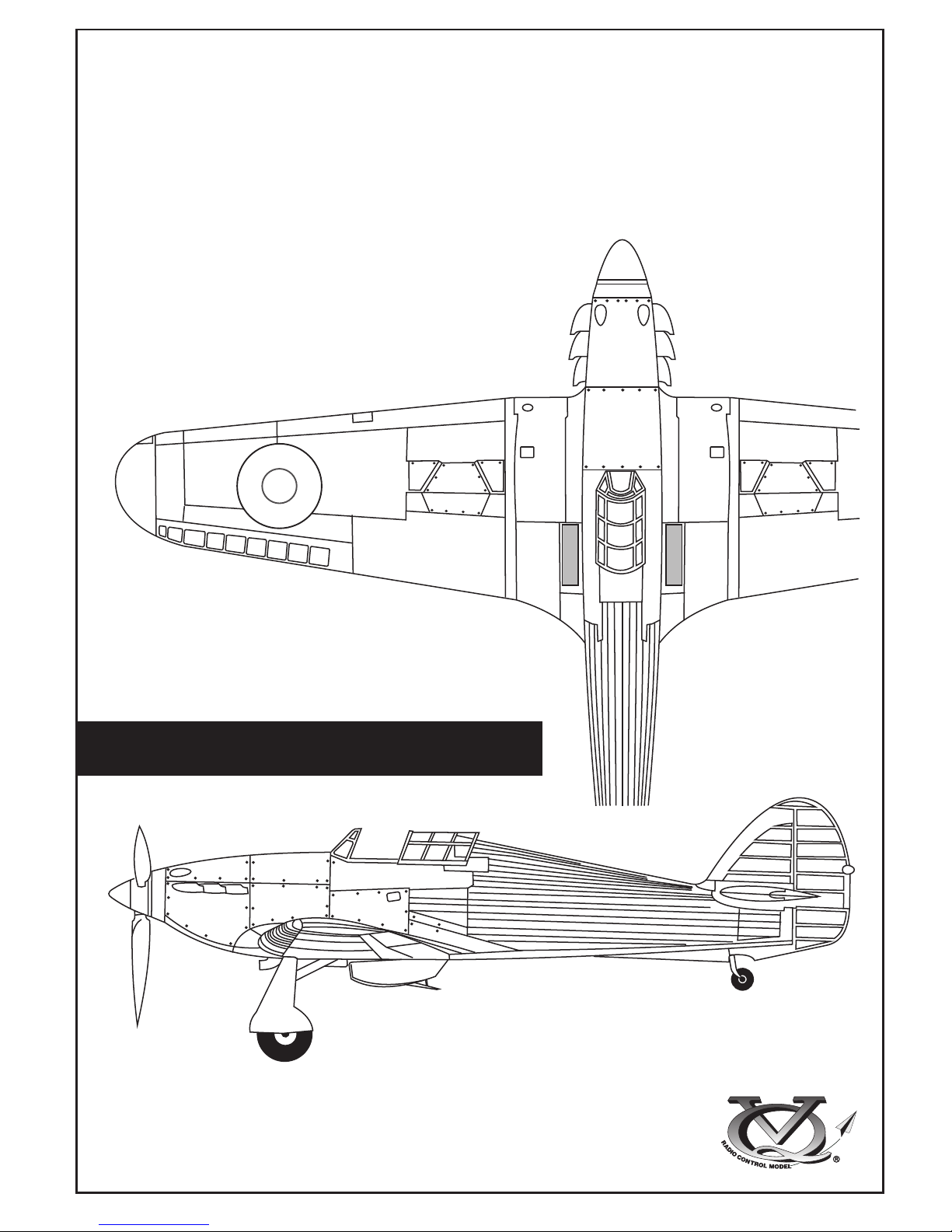

Page 1

RADIO CONTROL MODEL

INSTRUCTION MANUAL

SPECIFICATIONS

Wingspan.......63 in. / 161cm

Length............50 in. / 129cm

Engine.............50~60 2T / 70~90 4T

Or Electric equivalent.

WARNING!

This radio control model is not a toy. If modified or flow carelessly it could go out of control

and cause serious bodily injury or property damage.

Before flying your airplane, ensure the air field is spacious enough.

Always fly it outdoors in safe areas with no debris or obstacles.

Almost ready to fly

HURRICANE

VQAA040G

VQAA040B

RC Functions:

Motor - Rudder - Aileron - elevator

Flap - Retract landing gear

Page 2

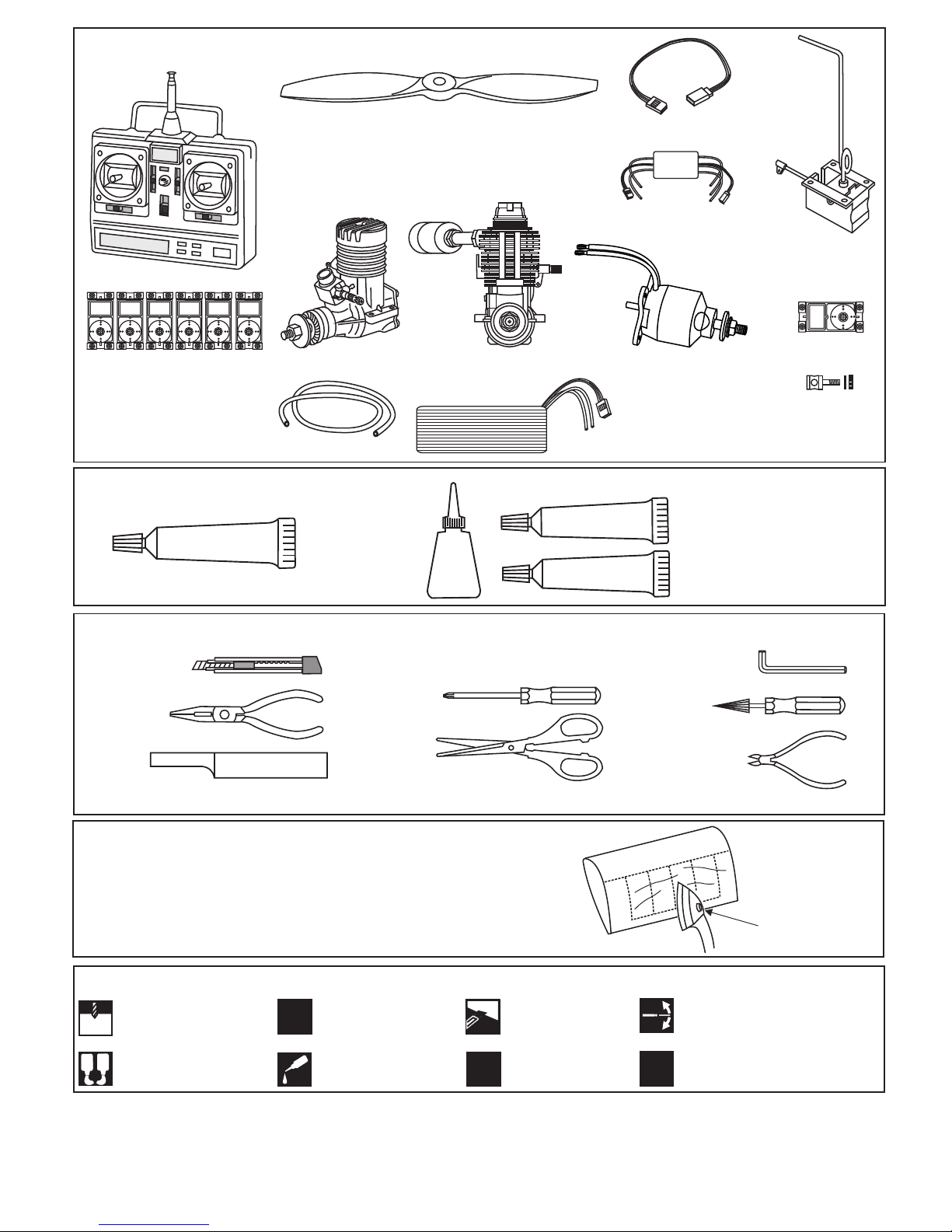

1.5mm

A

B

!

CA

L/R

Assemble left and right

sides the same way.

X

Drill holes using the stated

size of drill

(in this case 1.5 mm Ø)

Use epoxy glue

Take particular care here

Hatched-in areas:

remove covering

film carefully

Not included.

These parts must be

purchased separately

Check during assembly that these

parts move freely, without binding

Apply cyano glue

The pre-covered film on ARF kit may wrinkle due to variations

of temperature. Smooth out as explained right.

* Use an iron or heat gun. Start as low setting. Increase the

setting if necsessary. If it is too high, you may damage the

film

Low setting

SILICON

EPOXY A

EPOXY B

CA

GLUE

Epoxy Glue ( 5 minute type)

Silicon sealer

Cyanoacrylate

Glue

Minimum 6 channel radio

for airplane with 6 servos

.70 ~.90 - 4 cycle

12x6 for .60 - 2 cycle engine

13x6 for .70 - 4 cycle engine

14x6 for .90 - 4 cycle engine

14x8 ~ 15x8 - Brushless Motor

Silicone tube

Extension for aileron

servo, retract servo.

.50 ~ .60 - 2 cycle

REQUIRED FOR OPERATION (Purchase separately)

Linkage Stopper x2

(for retract servo)

Epoxy Glue (30 minute type)

TOLLS REQUIRED

Hobby knife

Needle nose Pliers

Phillip screw driver

Awl

Scissors

Wire Cutters

(Purchase separately)

Hex Wrench

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

Sander

Masking tape - Straight Edged Ruler - Pen or pencil - Rubbing alcohol - Drill and Assorted Drill Bits

Read through the manual before you begin, so you will have an overall idea of what to do.

Symbols used throughout this instruction manual, comprise:

(Purchase separately)

Retract landing

gear

VQAR06

Retract servo

x1

.Motor control x1 .Aileron x2

.Elevator x1 .Rudder x1

-Flap x1

Quantum 4120/07

Brushless Motor

or equivalent.

Brushless

Motor Control

Li-Po Battery.

CONVERSION TABLE

1.0mm = 3/64”

1.5mm = 1/16”

2.0mm = 5/64”

2.5mm = 3/32”

3.0mm = 1/8”

4.0mm = 5/32”

5.0mm = 13/64”

6.0mm = 15/64”

10mm = 13/32”

12mm = 15/32”

15mm = 19/32”

20mm = 51/64”

25mm = 1”

30mm = 1-3/16”

45mm = 1-51/64”

Page 3

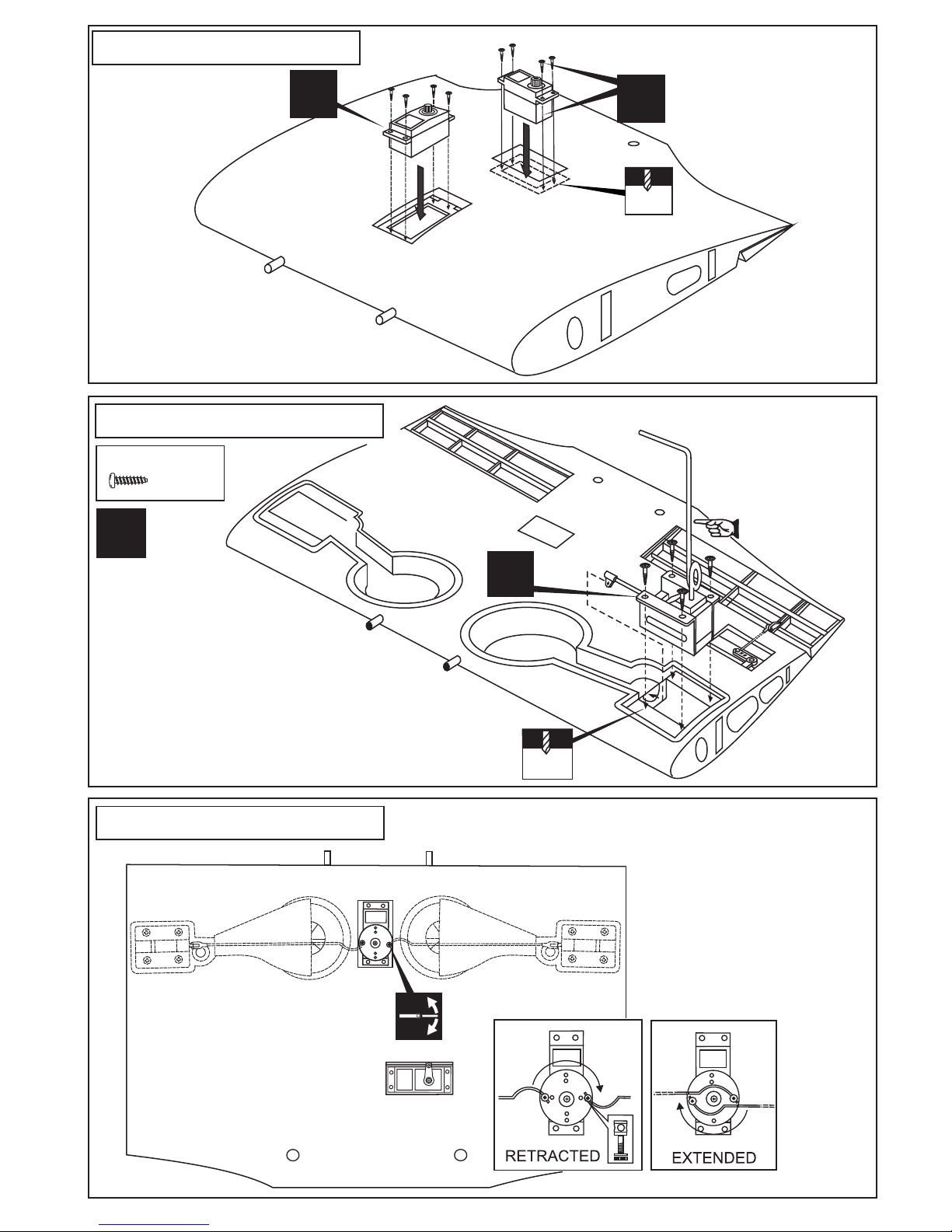

1- Retract / Flap servo

5/64

Flap servo

X

Retract servo

X

CENTER WING - TOP VIEW

3- Retract landing gear

L/R

3x12mm screw

..........8

X

2- Retract landing gear

CENTER WING - BOTTOM VIEW

Bend wire for

smooth retracting

CENTER WING - TOP VIEW

5/64

Ensure smooth

non-binding movement

Trial fit the push rod into

the wing. Join the pushrod to

the retract gear arm and trial fit

the retract into the wing.

Pull and push the retract push rod by hand

to be sure to adjust the stroke so that the landing

gear locks in both up and down position.

After checking that the retract works smoothly with the

servos, fix the retract on the wing with 3x12mm screws

Link the servo and retract gear

arm with push rod.

Be sure to adjust the stroke so

that the landing gear locks in

both up and down position.

Included with the radio set.

Page 4

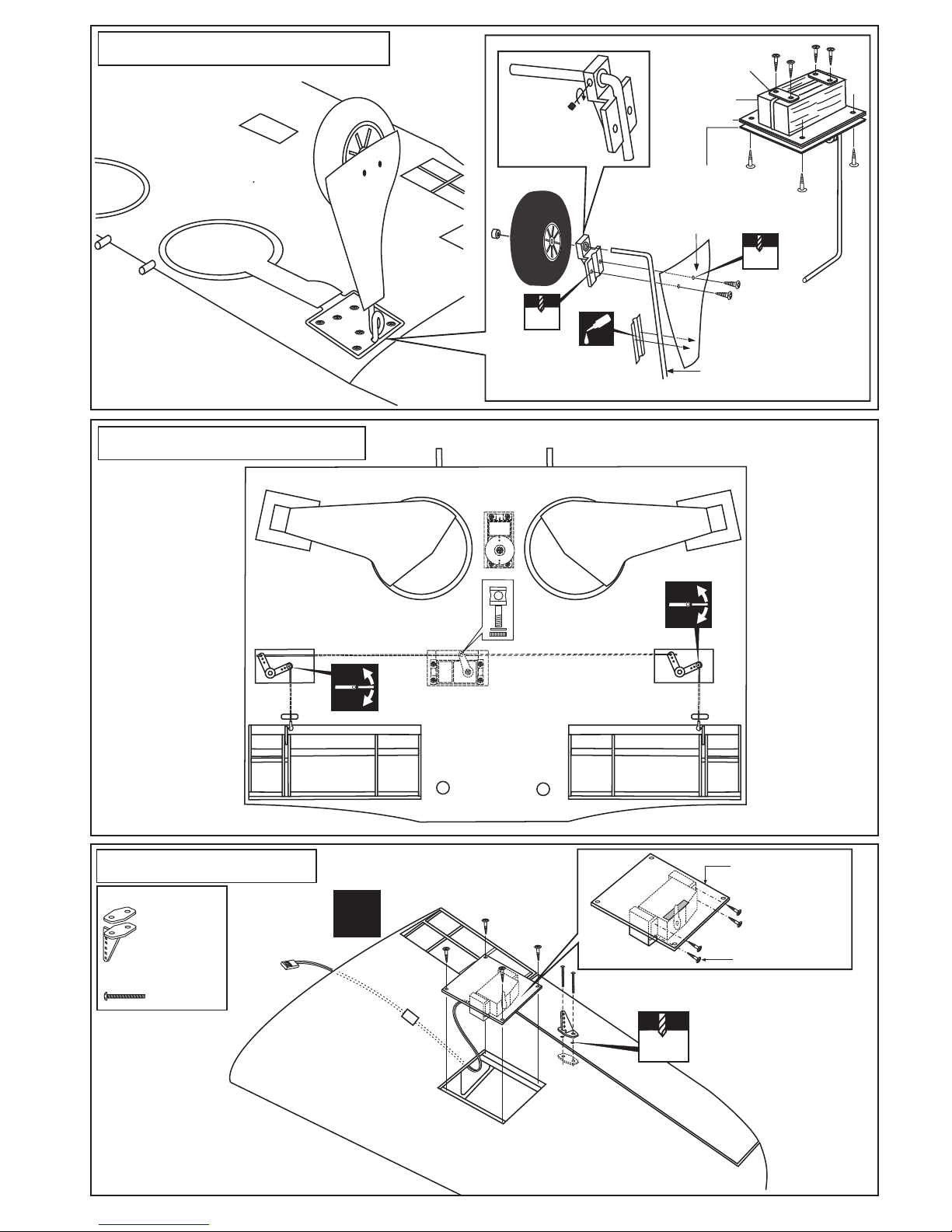

CA

ABS gear cover

ABS gear strap

2x3mm screw

Plastic strap

Main landing gear

Gear mount

(hard wood)

Ply gear mount

plate

Square plastic

3x10mm

3x10mm

2x12mm

4-Center wing - Fix gear

Main landing gear

FIX GEAR INSTALLATION

5- Center wing - Flap

CENTER WING - BOTTOM VIEW

6- Aileron servo

X

Plastic control horn

....................2

2x30mm screw

...............4

5/64

Included with the

radio set

Aileron servo

hatch (ply 3mm)

Aileron servo

extension

cord

CENTER WING - BOTTOM VIEW

Ensure smooth non-binding

movement

1/16

5/64

5/64(2x10mm)

screw

5/64(2x20mm)

screw

Page 5

7- Aileron servo

WING - BOTTOM VIEW

L/R

Assemble left and right wings

the same way

LEFT- WING

CENTER-WING

Dowel

Dowel

CA

8- Joining the wing

A

B

Metal rod, D=5/64 in. (2mm) do not glue here

A

B

WING - TOP VIEW

!Securely glue together, If coming

off during flights, you lose control

of your airplane which leads to

accidents !

1- Trial fit the wing joiner, into one of the wing panels. It should insert smoothly up to the center line marked. Next,

slide the other wing half onto the dihedral brace until the wing panels meet. If the fit is overly tight, it may be

necessary to lightly sand the dihedral brace.

2- Check for the correct dihedral angle

3- Apply a generous amount of epoxy into the wing joiner cavity of one wing half. Next, Coat one half of the dihedral

brace with epoxy up to the center line. Install the epoxy-coated side of the dihedral brace into the wing joiner cavity

up to the center line.

4- Do the same way with the other wing half. Carefully slide the wing halves together, ensuring that they are accurately

aligned. Firmly press the two halves together, allowing the excess epoxy to run out. Clean off the excess epoxy.

5- Apply masking tape at the wing joint to hold the wing together securely while the epoxy cures.

Aileron servo

extension (N.I)

L/R

Assemble left and right wings

the same way

Flap servo

Flap push-rod

Retract servo

Aileron servo

Aileron push-rod

9- Linkages

WING - BOTTOM VIEW

Flap push-rod

IMPORTANT:

Please do not clean off the excess epoxy on the wing with strong solvent or pure alcohol, only use

kerosene to keep the colour of your model not fade.

Page 6

10- Tail wheel

1

2

3x15mm screw

...............4

...................1

2mm tail gear horn

Tail gear mount

................1

Four nuts are installed at factory.

3

4

5

NOTE: Insert the tail gear

pushrod into the tail gear

horn before insert the tail

gear horn on to the tail

gear mount (step 2)

!Securely glue together. If coming

off during flight, you lose control

of your air plane.

-Trial fit each part before gluing . Be certain that there are no gaps.

If the parts will join, but with a gaps, sand or trim the parts a little

at a time until the parts meet exactly with no gaps.

-When joining the stabilizer it is extremely important to use plenty of epoxy (30 minutes) or CA

glue (thin type).

-Carefully slide the stabilizer into the fin, ensuring that they are accurately aligned, using rubbing

alcohol and paper towel, clean off the excess epoxy.

A

B

Cut away only the film

(top and bottom)

A = A’

B = B’

A

A’

11- Vertical / Horizontal Tail

Plastic control horn

....................3

2x25mm screw

...............6

C = C’

B

B’

C

C’

5/64(2x25mm)

screw

Hinge

Petroleum

jelly

STABILIZER

A

B

Apply 5 min.

Epoxy both the

top and bottom.

3/8 in. (9.5mm)

Apply a thin layer of machine oil or petroleum jelly to only the pivot point of the hinges on

the elevator, then push the elevator and its hinges into the hinge slots in the trailing edge

of the horizontal stabilizer.

There should be a minimal hinge gap.

When satisfied with the and alignment, hinge the elevator to the horizontal stabilizer using

5 minute epoxy. Make sure to apply a thin layer of epoxy to the top and bottom of both hinges

and to inside the hinge slots. Repeat the previous procedures to hinge the second elevator to

the other side of the horizontal stabilizer.

A

B

A

B

5mn epoxy

5mn epoxy

30mn epoxy

Page 7

12- Servo installation

Throttle servo

Rudder servo

Elevator servo

X

X

X

BOTTOM VIEW

NOTE: Place of throttle servos may be change depend

of engine (Four-stoke or two-stroke engine)

Throttle servo

Throttle

pushrod

13- Push rod

Elevator / Rudder servo

Elevator pushrod

Connector

Connector

Connector

............2

............2

Elevator push rod

Elevator push rod

Rudder push rod

Tail wheel push rod

Rudder servo

Elevator servo

Throttle servo

BOTTOM VIEW

5/64(2mm) screw

5/64

5/64(2mm) screw

5/64

Page 8

14- Engine mounts

1

2

3

3mm ply wood (A)

Engine thrust on balk head is

already adjust at factory

4

Attach the plywood (A) to the plywood template(B)

Secure them together with one 3x10mm screw, ensure

that these parts move freely.

Insert the plywood template into the fire wall and

drill four 13/64”(5mm) holes through the fire wall

13/64

5mm

13/64

5mm

Plywood template(B)

........4

................4

4x25mm screw

Blind-nut

! Engine thrust on balk head is already adjust at factory.

15- Engine mounts / Engine

1

2

(140 - 142mm)

5.51 ~ 5.59in.

In case of 2 stroke engine

with hang silencer.

In case of 4 stroke engine.

! Align the mark on both mounts

with the mark on the fuselage.

In case of 4 stroke

engine with side

silencer.

Page 9

X

To muffler

Filler tube

To engine

Rubber

stopper

Cap

Stopper

16- Fuel tank installation

Firewall

140~142mm

B’

B

B=B’

SIDE-VIEW

A

A=A’

A’

TOP-VIEW

! Engine thrust on balk head

is already adjust at factory

Using a aluminum motor mounting plate as

a template, mark the plywood motor mounting

plate where the four holes are to be drilled (2).

Remove the aluminum motor mounting

plate and drill a 1/8”(3mm) hole through

the plywood at each of the four marks

marked .

CA

3mm

1

2

Note: The aluminum motor mounting included

with electric motor set.

After confirming the direction . Insert this assembly, clunk end first, into

the fuel tank and tighten and screw the fuel tank cap on firmly.

3x35 mm screw

4mm

2

1

17- Electric Motor mount

Page 10

2.5x10mm.....5

1.5mm

18- Cowling

1~2mm

Board

Adhesive

Board

Attach the board or transparent plastic on the side of

the fuselage with the adhesive as show.

Using a pencil or felt tipped pen trace around the engine

head where it meet the cowl. Cut the opening the board

or transparent plastic for the engine head as marked

before.

Remove the engine and insert the cowl on to the fuselage

so the distance from the fire wall to the front of the cowl is

140 to 142mm (section 14).

Remove the cowl from the fuselage and carefully cut the

opening for the engine head as marked above. Do the

same way with the hole for needle-valve.

Again. Insert the cowl on to the fuselage and secure it in

place with five 2x5mm screws.

123mm

Ruler

CA

ABS cover

ABS cover

ABS cover

2mm screw

19- ABS Cover

2x6mm.......6

Page 11

ABS cover

(clear)

ABS cover

(clear)

A

B

A

B

22- Light

Do not use CA glue to much or it will make the ABS light cover white

5 min.

5 min.

20- Canopy

Sticker

Instrument panel

sticker

2x6mm screw

ABS air scoop

ABS cover

CA

CA

Cut away only the film

Cut away only the film

BOTTOM VIEW

21- Air scoop

Page 12

Wing center section

DO NOT try to fly an out-of-balance model !

23- Balance

(85 ~ 90mm)

Add weight to nose (as show) until the correct balance is achieved.

Stick-on weights are available at your local hobby shop and work

well for this purpose.

Battery pack

3.3 ~ 3.5 in.

To get the correct C.G., Several strips of

lead weight were required in the nose of

this model . To minimize the amount of

weight required, it is desirable to position

the weight as far forward as possible. This

can be done by making a platform form

leftover basswood stick and 3.2mm (1/8”)

ply wood. Using 4x35mm bolts to mount

the engine would also be long enough to

mount the flatform. The lead should be

permanently glued on with epoxy.

IMPORTANT: Recheck the C.G. After the

weight has been installed.

How to add nose-weight

Securely install the nose-weight ensuring it will

not come loose during flights.

!

35 mm

35 mm

8mm

8mm

10mm

10mm

RUDDER STROKE

ELEVATOR STROKE

AILERON STROKE

24- Control Surface

Adjust the travel of the control surfaces to achieve the values stated in the diagrams.

These value will be suitable for average flight requirements. Adjust the values to suit your particular needs.

Securely install the battery pack ensuring it will

not come loose during flights.

!

BEFORE FLYING CHECK EVERYTHING

Before each flight, inspect the airplane for any loose parts. Check the hinges, make sure the pushrods are still firmly

attached, and check the engine mounting bolts. In general, check everything on the plane that might possibly come

loose.

CHECK THE FREQUENCE BEFORE FLYING

DO NOT FLY NEAR A POWER LINE

The power lines cause radio interference, so avoid flying near them.

Basswood stick

Flatform

(3.2mm ply)

Lead should be

permanently glued

on flatform with

epoxy

Battery pack

IMPORTANT:

Please do not clean your model with pure alcohol, only use liquid soap with water or use glass cleaner to

clean on surface of your model to keep the colour not fade.

Loading...

Loading...