VQ T-34 Mentor Instruction Manaul

SPECIFICATIONS

Wingspan:.........................1560mm (61.4in)

Length:................................1170mm (46 in)

Electric Motor:.....................See next pager

Glow Engine:.................... .46 2-T / .70 4-T

RTF Weight: 3.2Kg / 7.05lbs (Will vary with

Equipment Used).

Radio:......................6 Channel / 6-7 Servos

Function: Ailerons-Elevator-Rudder-Throttle

Flaps-Optional Retractable Landing Gear.

WARNING! This radio controlled model is NOT a toy. If modified or flown carelessly it could go out of controll and

cause serious human injury or property damage. Before flying your airplane, ensure the air field is spacious enough.

Always fly it outdoors in safe areas and seek professional advice if you are unexperienced.

ACHTUNG! Dieses ferngesteuerte Modell ist KEIN Spielzeug! Es ist für fortgeschrittene Modellflugpiloten bestimmt,

die ausreichende Erfahrung im Umgang mit derartigen Modellen besitzen. Bei unsachgemässer Verwendung kann

hoher Personen- und/oder Sachschaden entstehen. Fragen Sie in einem Modellbauverein in Ihrer Nähe um

professionelle Unterstätzung, wenn Sie Hilfe im Bau und Betrieb benötigen. Der Zusammenbau dieses Modells ist

durch die vielen Abbildungen selbsterklärend und ist für fortgeschrittene, erfahrene Modellbauer bestimmt.

Radio control model / Flugmodel

ALL BALSA, PLYWOOD CONSTRUCTION AND ALMOST READY TO FLY

BEECHCRAFT

MILITARY TRAINER

Instruction manual / Montageanleitung

TECHNISCHE DATEN

Spannweite:...................................1560mm

Lange:............................................1170mm

Elektroantrieb.............(siehe nächste Seite)

Verbrennerantrieb:...............7.45cc - 11.5cc

Fluggewicht:.......................................3.2Kg

Fernsteuerung.............6 Kanal / 6-7 Servos

VQ No: VQA095

1.5mm

A

B

!

CA

L/R

Assemble left and right

sides the same way.

X

Drill holes using the stated

size of drill

(in this case 1.5 mm ÿ)

Use epoxy glue

Take particular care here

Hatched-in areas:

remove covering

film carefully

Not included.

These parts must be

purchased separately

Check during assembly that these

parts move freely, without binding

Apply cyano glue

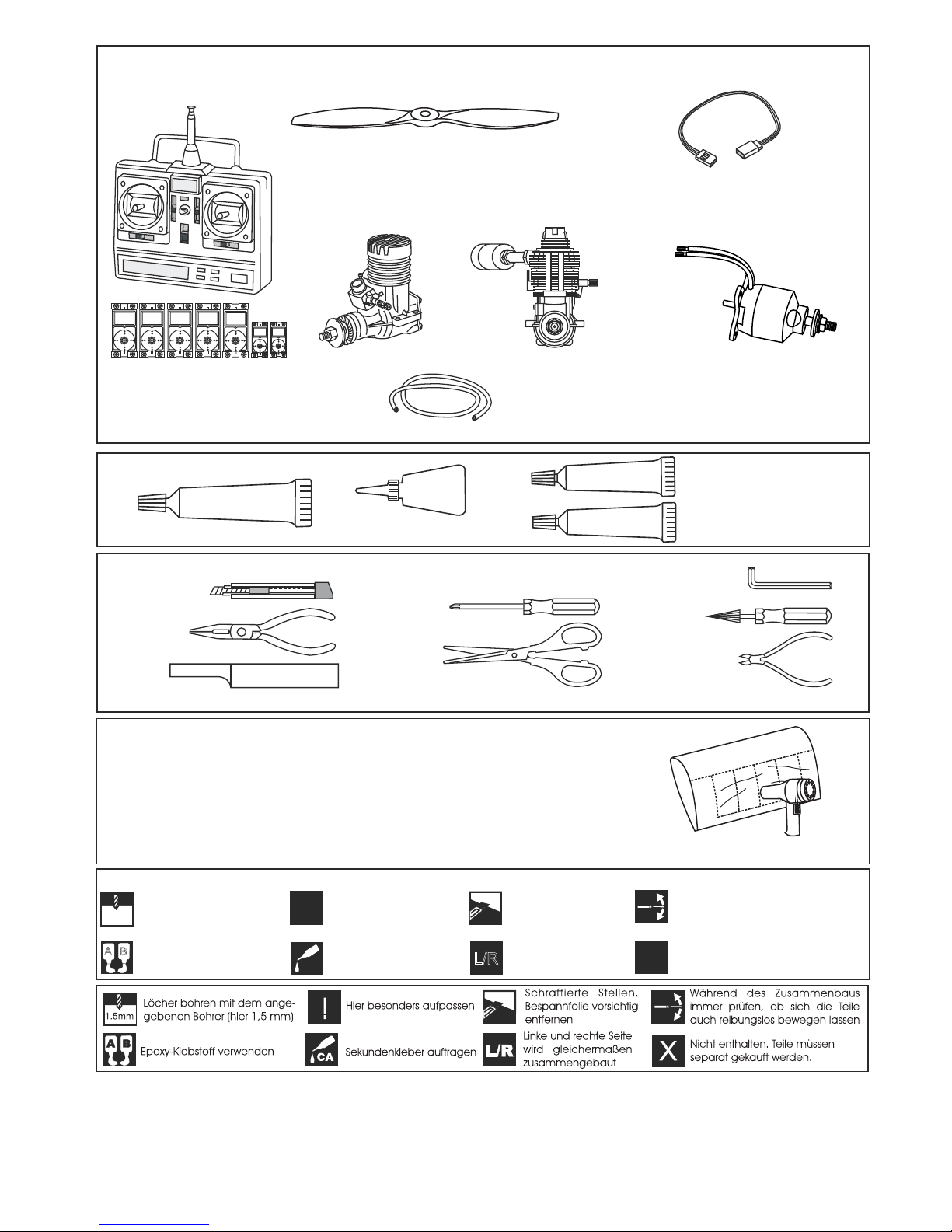

SILICON

EPOXY A

EPOXY B

CA

GLUE

Epoxy Glue ( 5 minute type)

Silicon sealer

Cyanoacrylate Glue

Minimum 6 channel radio

for airplane with 5 (4 for EP) standard servos

and two servo mini.

.60 ~.70 - 4 cycle

10.5x6 for .40 - 2 cycle engine

11x6 for .46 - 2 cycle engine

12x6 for .60 - 4 cycle engine

12x7 for .70 - 4 cycle engine

13x7 - 13x8 for electric motor

Silicone tube

Extension for aileron

servo, retract servo

and Rx battery pack.

.46 ~ .50 - 2 cycle

Epoxy Glue (30 minute type)

TOLLS REQUIRED

Hobby knife

Needle nose Pliers

Phillip screw driver

Awl

Scissors

Wire Cutters

(Purchase separately)

Hex Wrench

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

Sander

Masking tape - Straight Edged Ruler - Pen or pencil - Drill and Assorted Drill Bits

Read through the manual before you begin, so you will have an overall idea of what to do.

Symbols used throughout this instruction manual, comprise:

(Purchase separately)

.Motor control x1(for GP) .Elevator x1

.Rudder x1. Aileron x2. Flapx2 mini servo

CONVERSION TABLE

1.0mm = 3/64”

1.5mm = 1/16”

2.0mm = 5/64”

2.5mm = 3/32”

3.0mm = 1/8”

4.0mm = 5/32”

5.0mm = 13/64”

6.0mm = 15/64”

10mm = 13/32”

12mm = 15/32”

15mm = 19/32”

20mm = 51/64”

25mm = 1”

30mm = 1-3/16”

45mm = 1-51/64”

If exposed to direct sunlight and/or heat, wrinkels can appear. Storing the

model in a cool place will let the wrinkles disappear. Otherwise, remove

wrinkles in covering film with a hair dryer, starting with

low temperature. You can fix the corners by using a hot iron.

Bei Sonneneinstrahlung und/oder Wärme kann die Folie erschlaffen bzw. Falten

entstehen. Verwenden Sie ein Warumluftgebläse (Haartrockner) um evtl. Falten aus der Folie

zu bekommen. Die Kanten können Sie mit einem Bügeleisen behandeln. Nicht zuviel Hitze anwenden !

REQUIRED FOR OPERATION (Purchase separately)

More info: www.pichler-modellbau.de

Low seting

G-46 HP Motor

5 cell 4500mAh LiPo battery

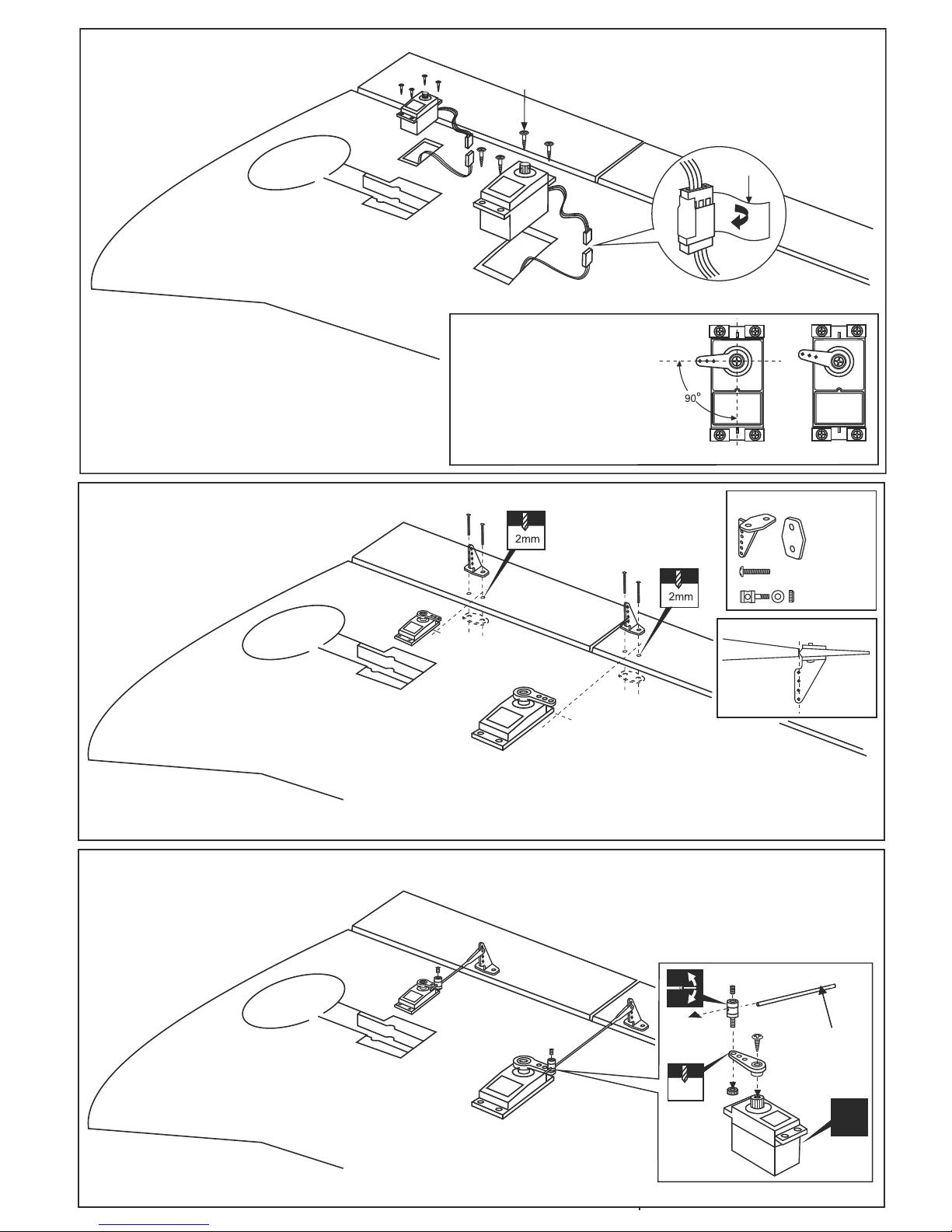

1-Cut away the covering of the wing bottom

where the aileron servo goes.

2-Connect the aileron servo cord to the aileron

extension cord.

3-Install the aileron servo on the servo mount.

-Switch on the radio (trims centered)

then mount the ailerons servo horn

in neutral position.

-The servo horn should be

perpendicular to the servo

YES

NO

1-Depending on the position of the linkage, determine the location of aileron control horn.

The horn holes must be perfectly aligned with the axis of articulation.

2-Mark the position of the “foot” of the horn on the aileron. Then, with the drill, make the 2

holes.

3-Install the aileron control horn as shown.

Included with the

radio set.

Adhesive

tape

Plastic control horn

..........4

2x30mm....8

..........4

Control horn Alignment

Do the same way with second

wing half.

Do the same way with second

wing half.

Do the same way with second

wing half.

X

3mm set Screw

2 mm

Aileron pushrod

D=5/64”(2mm)

1-Aileron and Flap servo

2-Aileron/Flap control horn

3-Aileron/Flap linkages

WING - BOTTOM VIEW

WING - BOTTOM VIEW

WING - BOTTOM VIEW

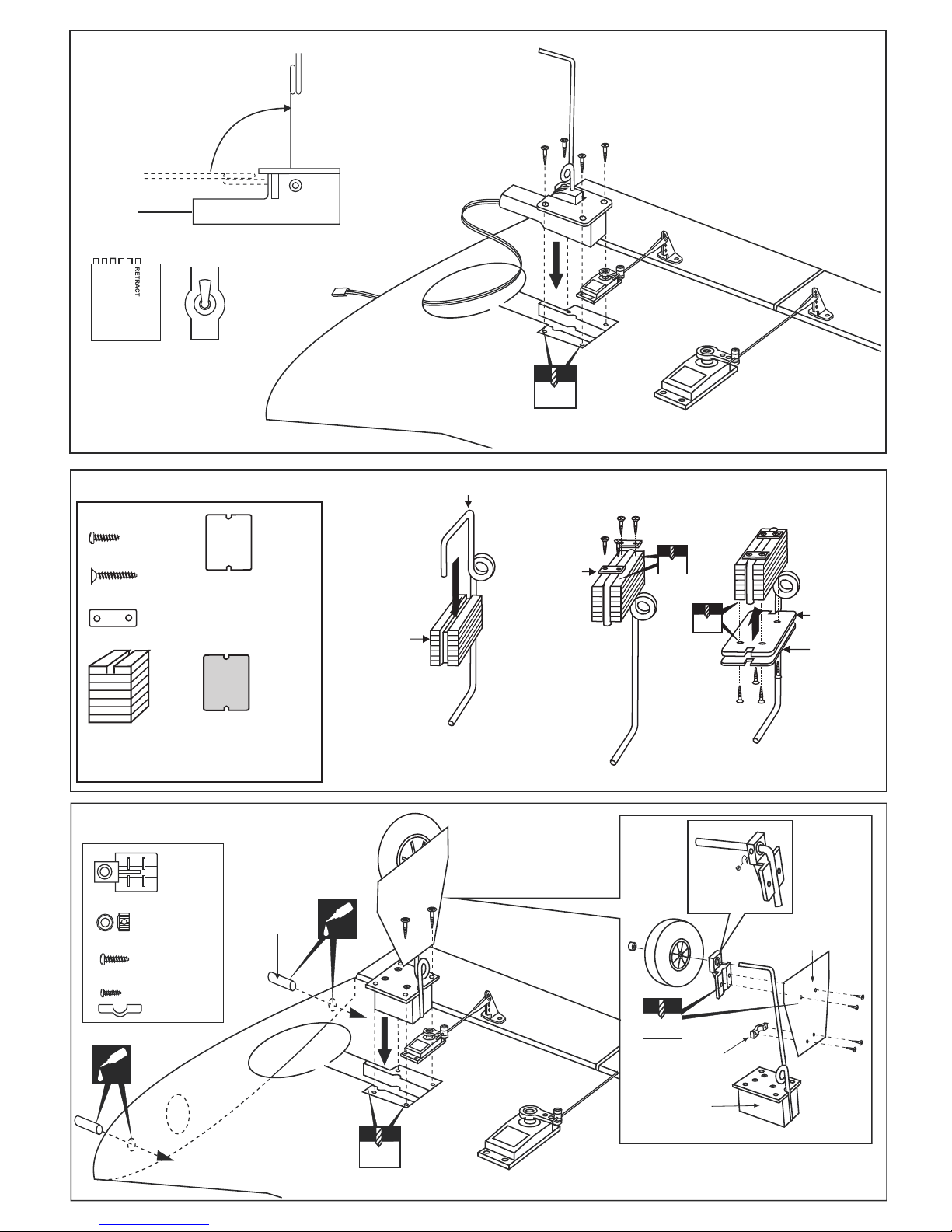

RECEIVER

ELECTRIC RETRACT

LANDING GEAR

ON

OFF

GEAR

EXTENDED POSITION

RETRACTED POSITION

2mm

2mm

1.5mm

gear cover

Gear mount

gear strap

1/16

1/8x13/32”(3x10mm)

5/64x15/64”(2x6mm)

..........8

..........8

5/32”(4mm) collar

..........2

........2

..........2

CA

Thin CA

CA

Thin CA

6x23mm

wooden dowel

4-Electric retract

6-Fixed gear installation

WING - BOTTOM VIEW

Electric retract must be purchase separately

5-Fixed gear

Ply gear mount

plate x 2

Gear mount x 2

Main landing gear

Gear mount

1

3x20mm

Nylon gear

strap

2mm

2

3x20mm

Ply gear

mount flat

Square

plastic

2mm

3

3x20mm screw

..........8

3x12mm screw

......16

Nylon gear strap

.......4

Square plastic x 2

Do the same way with

second wing half.

Loading...

Loading...