Page 1

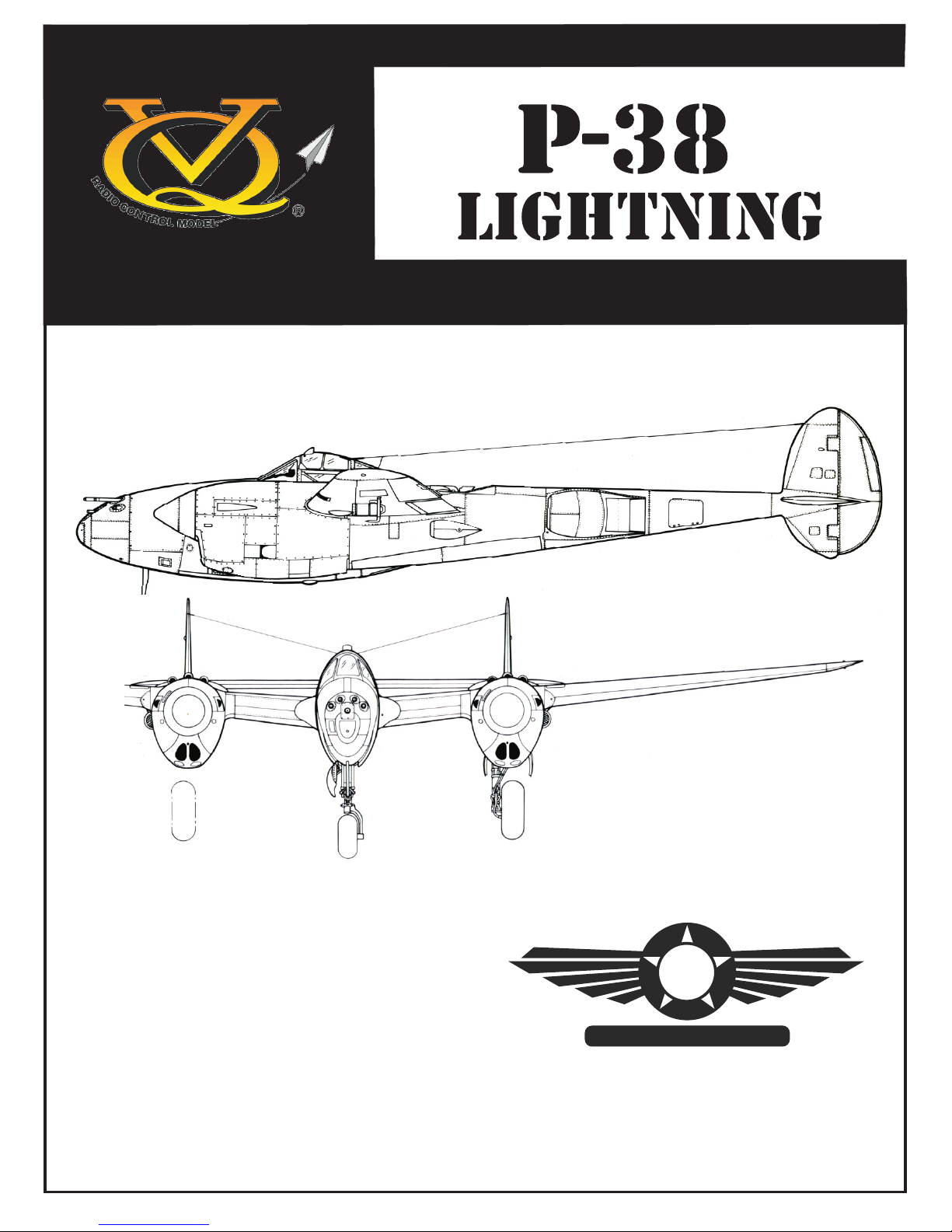

Radio control model

Wingspan approx. 83 in.

Fuselage length approx. 57.5 in.

Glow Engine 7.45cc 2T /11.5cc 4T (x2)

Electric Motor 870 Watt Brushless motor x2

Radio 6 Channel / 10 Servos

INSTRUCTION MANUAL

WARNING! This radio controlled model is NOT a toy. If modified or flown carelessly it could go out of control and

cause serious human injury or property damage. Before flying your airplane, ensure the air field is spacious enough.

Always fly it outdoors in safe areas and seek professional advice if you are unexperienced.

LEGEND MODELS

L

Page 2

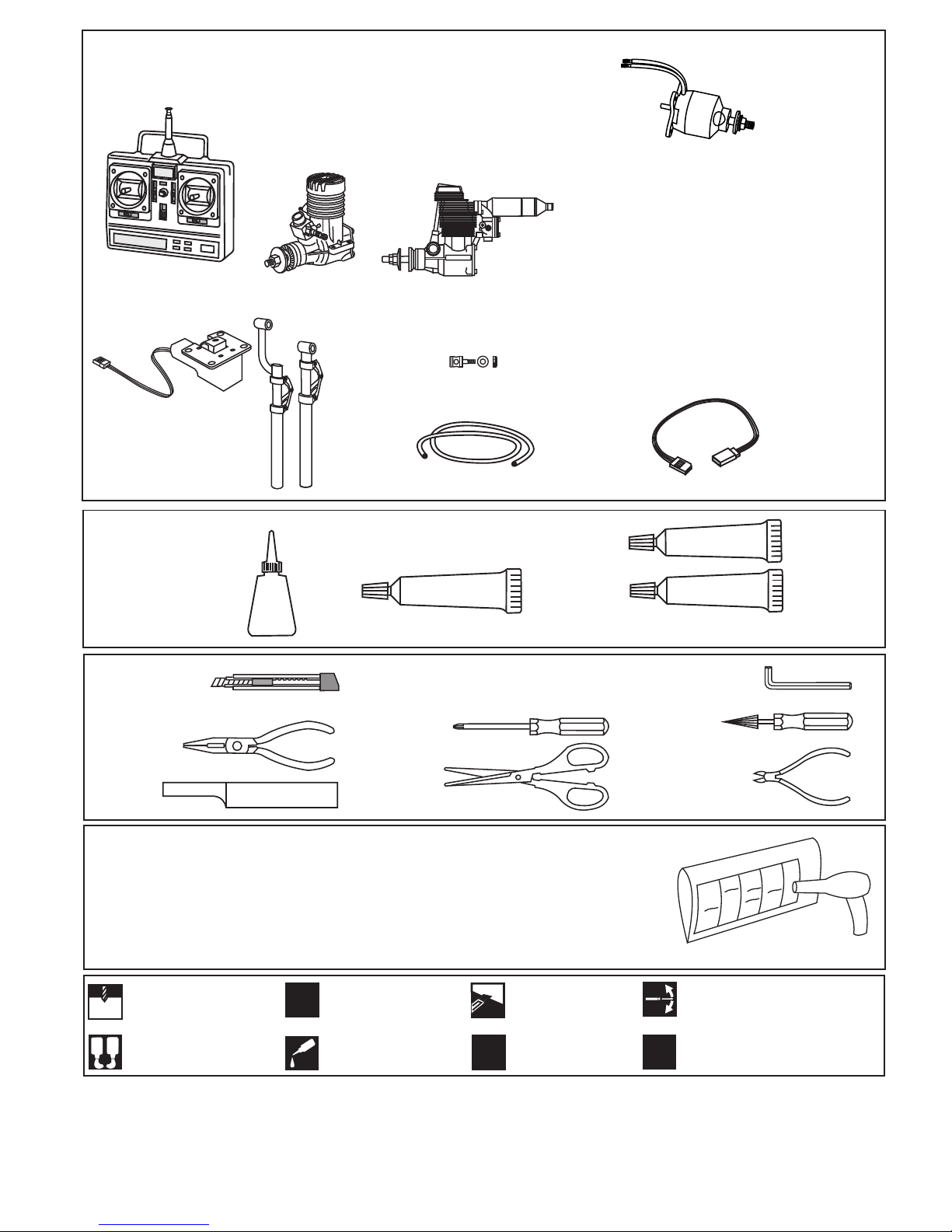

Silicone tube

.46 - .50 cu.in.(x2)

7.45cc (x2)

.60 - .70 cu.in (x2)

10cc - 11.5cc (x2)

SILICON

EPOXY A

EPOXY B

CA

GLUE

Silicon Glue

Epoxy ( 5min-Typ)

Cyanoacrylate Glue

Needle nose Pliers

Awl

Scissors

Wire Cutters

Hex Wrench

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

Sander

Hobby knife

Phillip screw driver

REQUIRED ITEMS

Minimum 6 channel radio

for airplane / 8-10 servos.

1.5mm

A

B

!

CA

L/R

Assemble left and right

sides the same way.

X

Drill holes using the stated

size of drill

(in this case 1.5 mm Ø)

Use epoxy glue

Take particular care here

Hatched-in areas:

remove covering

film carefully

Not included.

These parts must be

purchased separately

Check during assembly that these

parts move freely, without binding

Apply cyano glue

Connector

If exposed to direct sunlight and / or heat, wrinkles can appear. Storing the model in

a coll place will let the wrinkles disappear. Otherwise, remove wrinkles in covering

film with a hairdryer, starting with low temperature. You can fix the corners by using

a hot iron.

Read through the manual before you begin, so you will have an overall idea of what to do.

CONVERSION TABLE

1.0mm = 3/64”

1.5mm = 1/16”

2.0mm = 5/64”

2.5mm = 3/32”

3.0mm = 1/8”

4.0mm = 5/32”

5.0mm = 13/64”

6.0mm = 15/64”

10mm = 13/32”

12mm = 15/32”

15mm = 19/32”

20mm = 51/64”

25mm = 1”

30mm = 1-3/16”

45mm = 1-51/64”

Electric Set up 1:

2X Dualsky XM5050EA-7 610Kv motors.

2X Dualsky XC8018BA 80A ESC, 100A burst

2X Dualsky XP45004EX 4S, 35C, 4500mAh Lipo

2X Prop: 14x9 x3-blade Master Airscrew

Approx Weight: 1600grams / 3.6lbs

Electric Setup 2:

2X Dualsky XM5060EA-6 470Kv motors.

2X Castle Creations Edge 100AMP ESC

2X Dualsky XP45005EX 5S, 35C, 4500mAh Lipo

2X Prop: 16x10 x3-blade Master Airscrew

Approx Weight: 2200grams / 4.8 lbs

VQ-ARE18S

Electric Retract:

Extension cord

Nose gear Eretract&Strut

Main gear Eretract&Struts

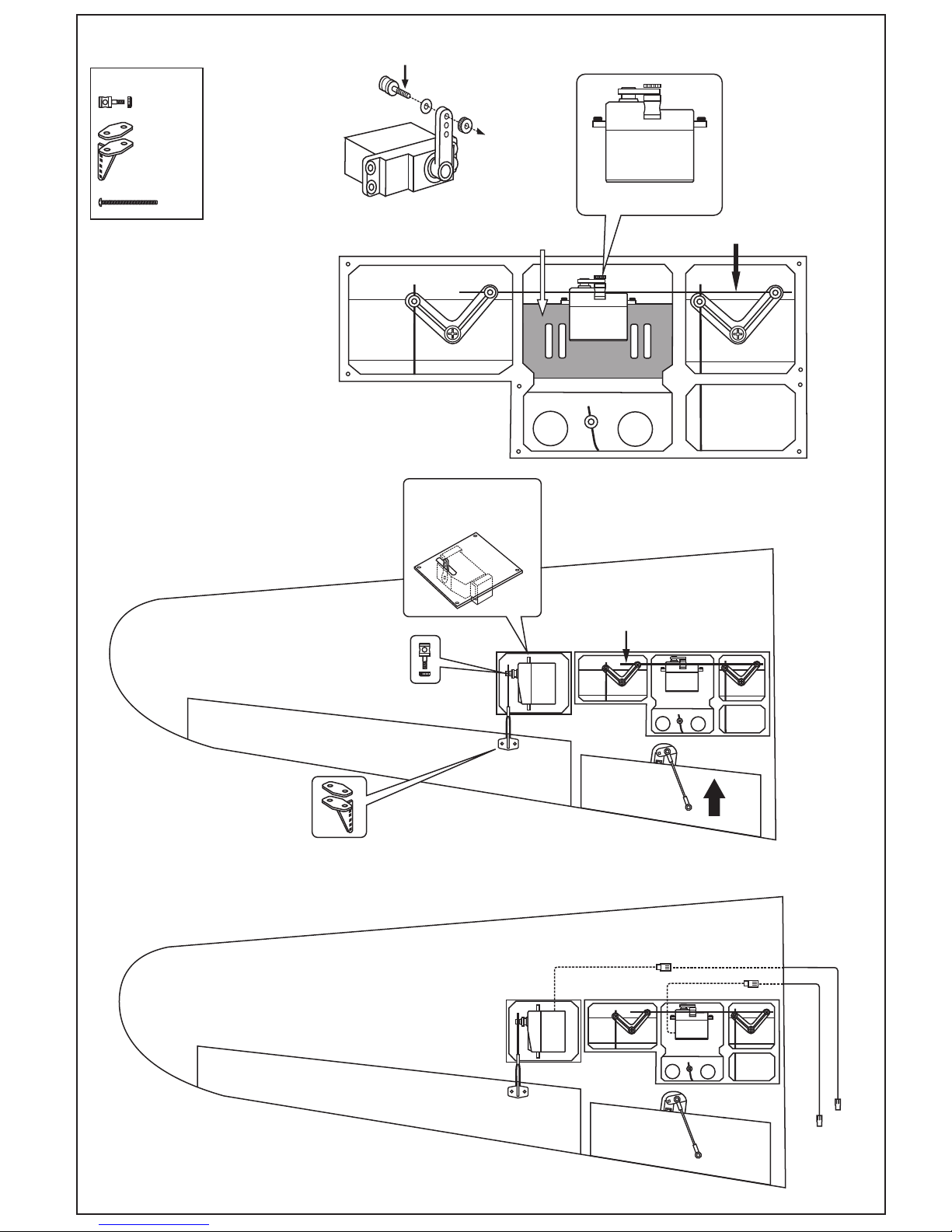

Page 3

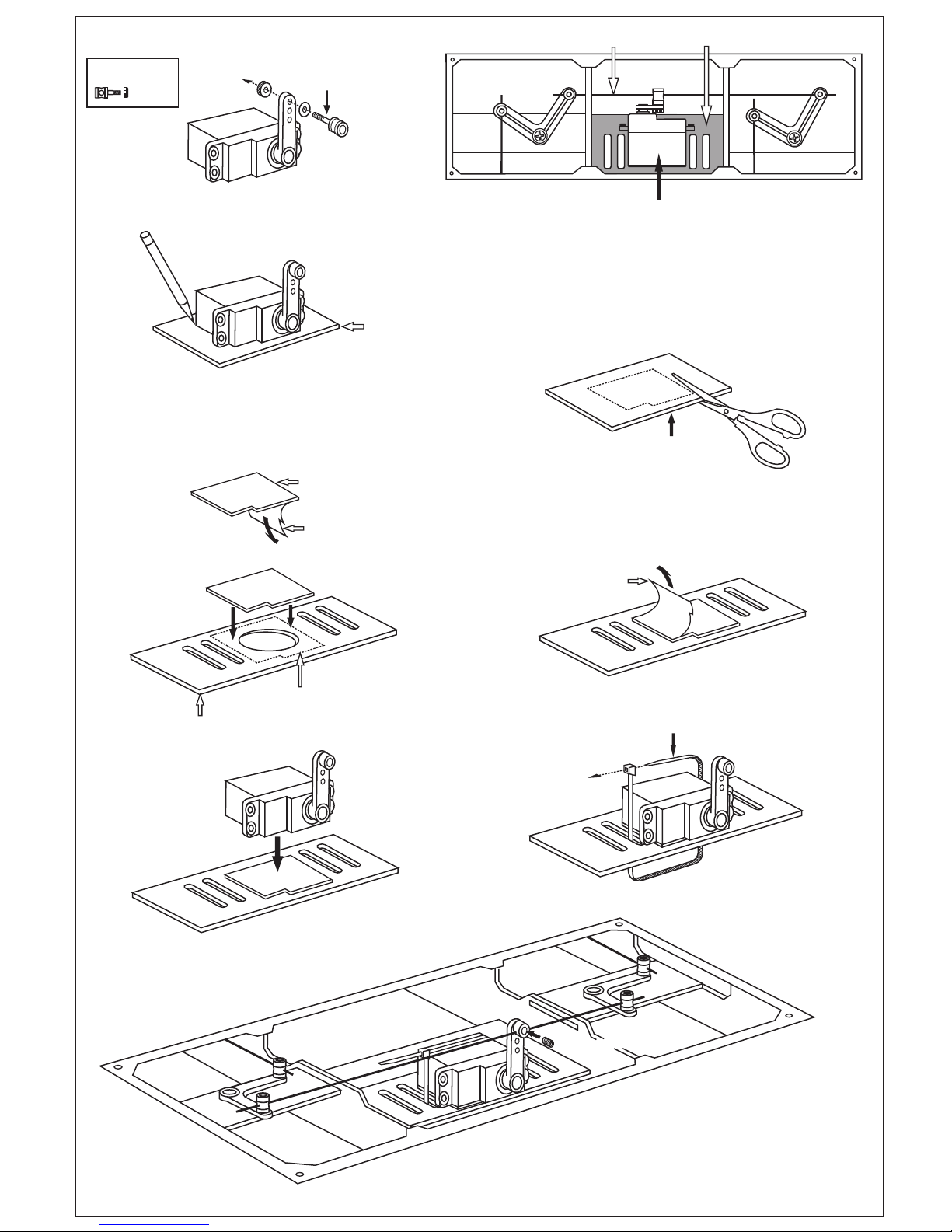

Install the push rod connector onto the

outer-most hole of the flap servo arm.

Move the flap servo arm a few times to make sure it move

freely with out any binding.

Connector

........2

Nylon cable tie

(included)

Servo mount

Flap servo

-Turn the center wing over.

-Turn the four screws and move the hatch out of the wing.

-Place the flap servo onto the servo mount with the flap push rod installed

as shown.

-Using the pencil, trace around the servo, where it meets the servo mount.

Connector (included)

Remove the servo out of the wing.

Place the servo onto the adhesive tap as shown.

With the pencil, trace around the servo, where it

meets the adhesive tape.

Adhesive tape

(included)

Adhesive tape

Servo mount

Pencil line.

Adhesive tape

Peel the bottom cover

Peel the top cover

With the scissors, cut along the pencil line

1A

1B

1C

1D

1E

1F

1G

1H

1I

Flap push rod

3mm screw

Do the same way with the flaps on the left and the right wing

1-Wing

Page 4

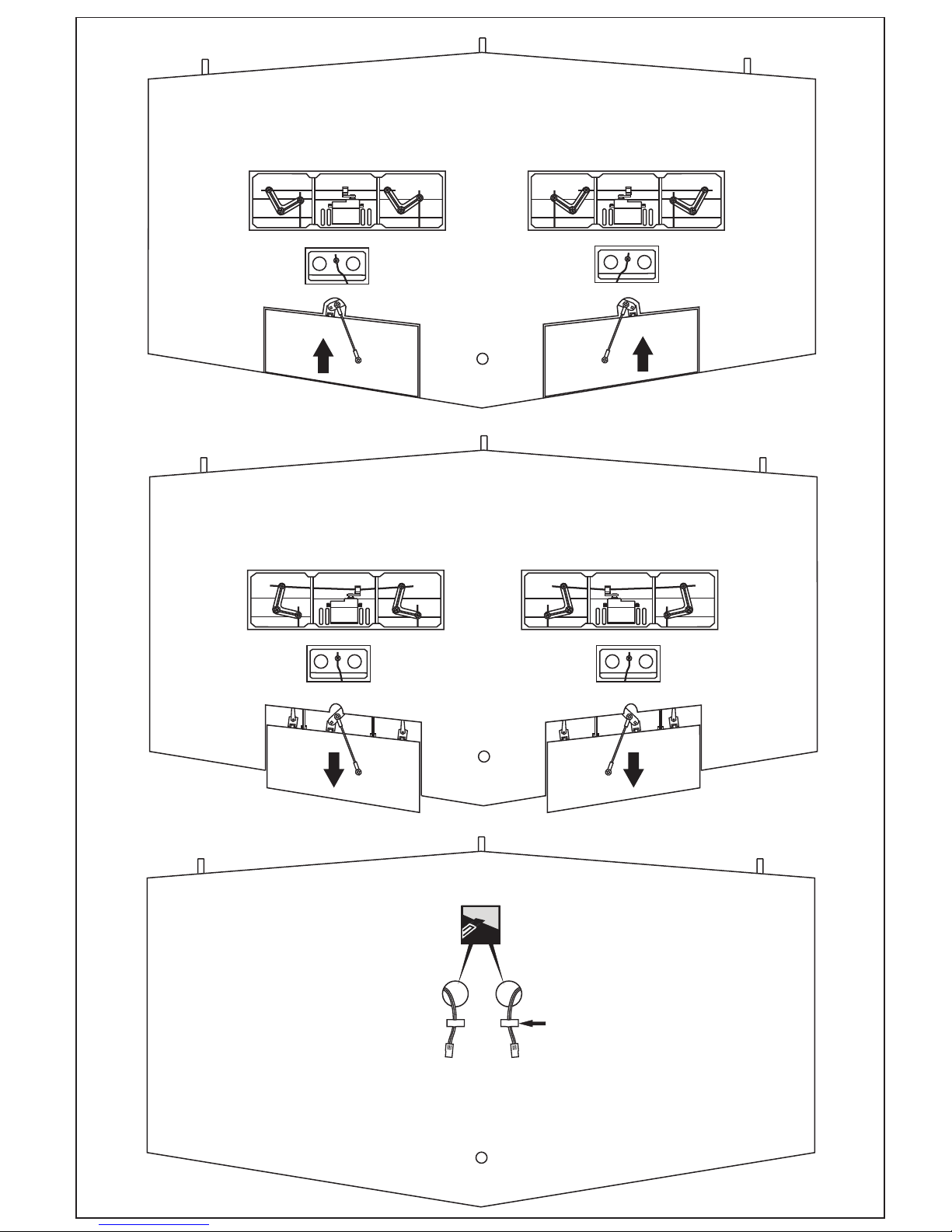

Note: Do not close the hatches in this time

2-Wing

CENTER WING - Top-view

Adhesive tape (keep the

extension in place)

Cut away the covering for

the extension cord exit

CENTER WING

Bottom-view

The center wing with the flaps in closed position.

The center wing with the flaps in opened position.

Page 5

Aileron servo hatch with

servo installed (standard

servo using)

Flap pushrod

RIGHT WING - Bottom-view

Note: Do the same way with the Left wing

700mm

extension

To be connected the extension with the aileron

servo cord before attach the hatch to the wing

Note: the aileron extension must 700mm long

or use two 300mm long.

.............2

.......4

2x30mm screw

Servo mount

Flap push rod

Note: the connector is

turn-down

Note: the connector is

turn-down

Connector

RIGHT WING - Bottom-view

Connector

........2

3-Wing

3A

From Step 3B to Step 3I, follow the

procedure as described in the

1-WING section

3J

3K

Page 6

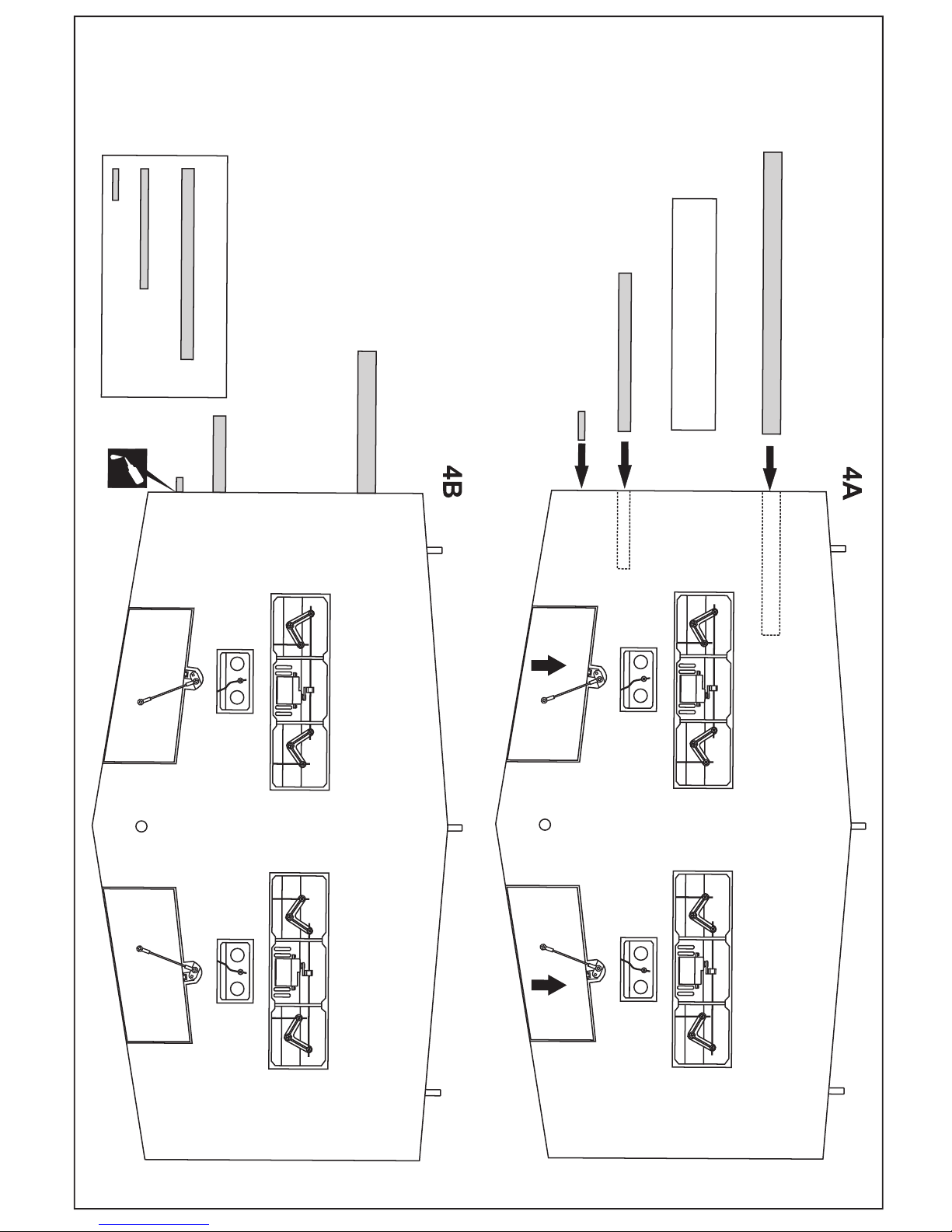

19x317mm aluminum tube

12x182mm aluminum tube

Do the same way with the other side

of the center wing.

Slide the aluminum tube into the left and right

side of the center wing.

19x317mm aluminum tube

12x182mm aluminum tube

......................2

...2

6x12mm wooden dowel

6x12mm wooden dowel

......................2

CA

Glue the dowel only

Bottom-view

CENTER WING

Bottom-view

CENTER WING

4-Wing

Page 7

Carefully, slide the left wing

to meet the center wing

Aileron extension

4x20mm screw

Secure the outer wing in place

using 4x20mm screw

4x20mm screw

.....2

.............2

!Check the ailerons and flaps functions

move in the correct before attach all

hatches to the bottom of the wing.

5-Wing

Page 8

!

5.5mm

L/R

Align the mark on both

mounts with the center

mark on the balk head.

! Engine thrust on balk head

is already adjust at factory

................8

Blind-nut

A

A

B

B=B’

B’

Align the mark on both

mounts with the center

mark on the balk head.

L/R

3x25...(8)

Washer....(8)

Nut 3mm..(8)

Secure the engine to the engine

mount using four 3x25mm screws

Insert the Z-bend into the hole on the throttle

lever of engine.

Note: It may be easier to temporarily remove

the control arm from the carburetor to insert the

Z- bend

C

C= 132 ~ 134mm

4x30mm screw

..8

.............8

B

B’

132~134mm

SIDE-VIEW

TOP

BOTTOM

6-Engine mounts

7-Engine

6A

6B

Page 9

X

Filler tube

Rubber

stopper

To engine

Aluminum stopper

Aluminum

cap

To muffler

TOP

BOTTOM

Using a aluminum motor mounting plate as a template,

mark the plywood motor mounting plate where the four

holes are to be drilled.

Remove the aluminum motor mounting plate and drill a 1/8”(3mm) hole through the

plywood at each of the four marks marked .

Note: The aluminum motor mounting included with electric motor set.

5x70mm..8

5mm nut..24

washer...32

5mm

3mm

Align the mark on the motor

mounting plate with the

center mark on the balk head.

X

Firewall

132~134mm

B’

B

B=B’

SIDE-VIEW

L/R

L/R

8-Electric Motor

9-Fuel tank

FDP

FDP

CA

CA

Installing the Lipo Battery Stand

Lipo Battery stand

FUSELAGE - Top view

FUSELAGE - Top view

8A

8B

8C

9A

9B

9C

(In case of electric motor using)

9D

Page 10

Throttle servo tray

Rudder servo

Elevator servo

Note: Turn the throttle servo tray for

other engine if needed.

Throttle servo

Rudder servo

Elevator servo

RIGHT FUSELAGE - Top view

Elevator Pushrod

Connecting rod

...............6

L/R

Throttle pushrod

Rudder pushrod

2 mm

RIGHT FUSELAGE - Top view

10-Hatch

Rudder Pushrod

11-Servos

L/R

FUSELAGE - Bottom view

Bottom hatch

Bottom hatch

30x4mm nylon bolt

............4

Secure the Bottom hatch in place

using the 30x4mm nylon bolt.

Cut away only

the covering

CA

11A

11B

11C

Page 11

15mm

2 mm

CA

L/R

2mm

3x20mm screw

.............2

.......4

2x30mm screw

Main landing gear

Gear mount

3x12m

Nylon gear

strap

2mm

3x15mm

Ply gear

mount flat

Square

plastic

2mm

4.7mm collar

.........4

Ply gear mount

plate x 2

Gear mount x 2

3x20mm screw

..........8

3x12mm screw

......16

Nylon gear strap

.......4

Square plastic x 2

Main landing gear

3x15mm screw

..........8

L/R

12-Rudder

13-Fixed gear

13A

13B

13C

13D

Page 12

X

Must be purchased separately

FUSELAGE - Bottom view

L/R

4.7mm nose gear

Nose gear base (plastic)

Nose gear arm

Nose gear push rod

Nose gear control

arm

3mm

3x20mm...4

Washer.....4

Nut 3mm...4

MAIN FUSELAGE - Bottom view

?

Cut the opening

Nose gear mount

Nose gear arm

X

14-Nose gear

15-Main gear

(Electric retract)

16-Nose gear

(Electric retract)

Page 13

Cut away onlly the covering

ABS “balance”

HORIZONTAL STABILIZER

2 mm

ABS “balance”

.............2

.......4

2x30mm screw

CA

Top-view

17-Horizontal Stabilizer

Horizontal stabilizer

LEFT FUSELAGE

RIGHT FUSELAGE

19-Horizontal Stabilizer

RIGHT FUSE.

LEFT FUSE.

6x60mm wooden dowel

................4

12x108mm aluminum tube

....2

L/R

Secure the aluminum

tube and wooden dowel

in place using Thin CA glue

Aluminum tube

Wooden dowel

6x60mm

CA

12x108mm

Wooden dowel

6x60mm

18-Horizontal Stabilizer

A=8mm

A

A

B=60mm

B

A=8mm

A

A

B=60mm

B

Page 14

Horizontal stabilizer

3x15mm screw

3x15mm screw

WING

6x40 Nylon bolt

TOP

RIGHT / LEFT FUSELAGE (TAIL BOOM)

L/R

6x40 Nylon bolt

.....4

L/R

RIGHT / LEFT WING SHIELD

Trial fit the fuselage-top

shield onto the wing, If

necessary, sand the

edge of the fuselage-top

shield until this is

achieved.

RIGHT / LEFT FUSELAGE (TAIL BOOM)

WING

2.mm

3x15mm screw

2.mm drill bit

Aluminum tube

20A

Drill through both the balsa

block and aluminum tube

Balsa block

TOP

Note: The holes on the bottom of the Horizontal stabilizer

are pre-drilled at factory

20-Horizontal Stabilizer

21-Installing the wing

22-Installing the wing shield

Secure the wing shield in place using 2.2x12mm screws

20B

Page 15

WING

FIBER GLASS MAIN FUSELAGE

FIBER GLASS

COCKPIT

2mm

10mm

FIBER GLASS MAIN FUSELAGE

6x50mm plastic bolt

....1

23-Installing the main fuselage

24-Installing the cockpit

Secure the cockpit in place

using 2x8mm screws

25-Cowling

Secure the cowl in place using

2.5x12mm screws

2.5x12mm screw

...........8

L R

Note: The “L” Cowl for LEFT fuselage and

“R” Cowl for RIGHT fuselage (looking from

REAR to FRONT and TOP view).

COWL

BOTTOM VIEW

COWL

BOTTOM VIEW

Gear door

CA

Hinge

26-Gear door

26A

26B

Page 16

Gear door

ALL GEAR DOORS

IN CLOSED POSITION

Fuselage

Fuselage

Cotton thread

(not include)

Spring (not include)

ALL GEAR DOORS

IN OPENED POSITION

(RETRACT LANDING GEAR IN RETRACTED POSITION)

(RETRACT LANDING GEAR IN EXTENDED POSITION)

Spring (not include)

Cotton thread

(not include)

Gear door

Cotton thread

(not include)

Note: you can find the

same spring in old

ball-point pen

Fuselage

Fuselage

Gear door

GEAR DOOR

IN OPENED

POSITION

CA

Frame

Hinge

Frame

CA

CA

Gear door

27-Gear door

27A

27B

Page 17

Gear door

(main fuselage)

Cotton thread

(not include)

Spring (not include)

Gear door

Bottom-view

Balsa block

(not include)

CA

CA

CA

CA

28-Gear door

28A

28B

28C

28D

Page 18

2x8mm screw

2x8mm screw

1.2mm

1.2mm

...................6

Cotton thread

(not include)

GEAR DOOR IN CLOSED POSITION

(NOSE RETRACT LANDING GEAR

IN RETRACTED POSITION)

GEAR DOOR IN OPENED

POSITION

(RETRACT LANDING GEAR IN

EXTENDED POSITION)

Hinge

Fuselage

side

Gear door

CA

GEAR DOOR

IN OPENED

POSITION

Cotton thread

30-Canopy

Putt Putt Maru version

Note: Cut out the stickers and apply them in the proper area. Do not peel the backing paper off all at once.

Peel off one corner of the backing and cut off with scissors. Arrange sticker on model and when satisfied adhere the corner without

backing.

Carefully peel back the rest of the backing while at the same time adhering the rest of the sticker.

Try not to make air bubbles, if there are some, carefully puncture sticker (center of bubble) but not model surface with the tip of the knife

or sharp pin and

squeeze out the air. At curves stretch sticker and apply a little heat so that no ceases occur. Cut off the excess that is produced.

U

R

A

M

T

T

U

P

T

T

U

P

T

T

U

P

T

T

U

P

U

R

A

M

“Putt Maru” decal is

only for one side

Kill-mark only

for one side

31-Decal

29-Gear door

Page 19

1,2,3,4

Fuel cap sticker (for all versions)

“Skidoo”decal is

only for one side

L/R

Kill-mark only

for one side

32-Decal

Skidoo version

IMPORTANT:

Please do not clean your model with pure alcohol, gasoline or strong sloven, only use

kerosene or liquid soap with water or use glass cleaner to clean on surface of your model

to keep the colour not fade.

Page 20

CA

33-Installing the guns

115 ~ 120mm

The ideal C.G. position is 115 ~ 120mm

behind the leading edge.

115~120mm

WING ROOT

8~10mm

8~10mm

30~35mm

10~12mm

10~12mm

25~30mm

AILERON

FLAP

ELEVATOR

RUDDER

25~30mm

Position for

right diagram.

Position for right diagram.

WARNING:

Never fly before checking

the Cg’s required position.

34-Balance

35-Control ranges

Loading...

Loading...