VQ FOCKE-WULF FOCKE-WULF, FOCKE-WULF FW-190A Instruction Manual

45 Class

70 Class

2-cycle engine

4-cycle engine

INSTRUCTION MANUAL

Wingspan approx. 59 in.

(1500mm)

Fuselage length approx 43 in.

(1090mm)

6 lb.

(2700g)

46~50

(7.45cc)

60~70

(11.5cc)

5~6

FW - 190A

FOCKE-WULF

VQA0450L

VQA044G/Y

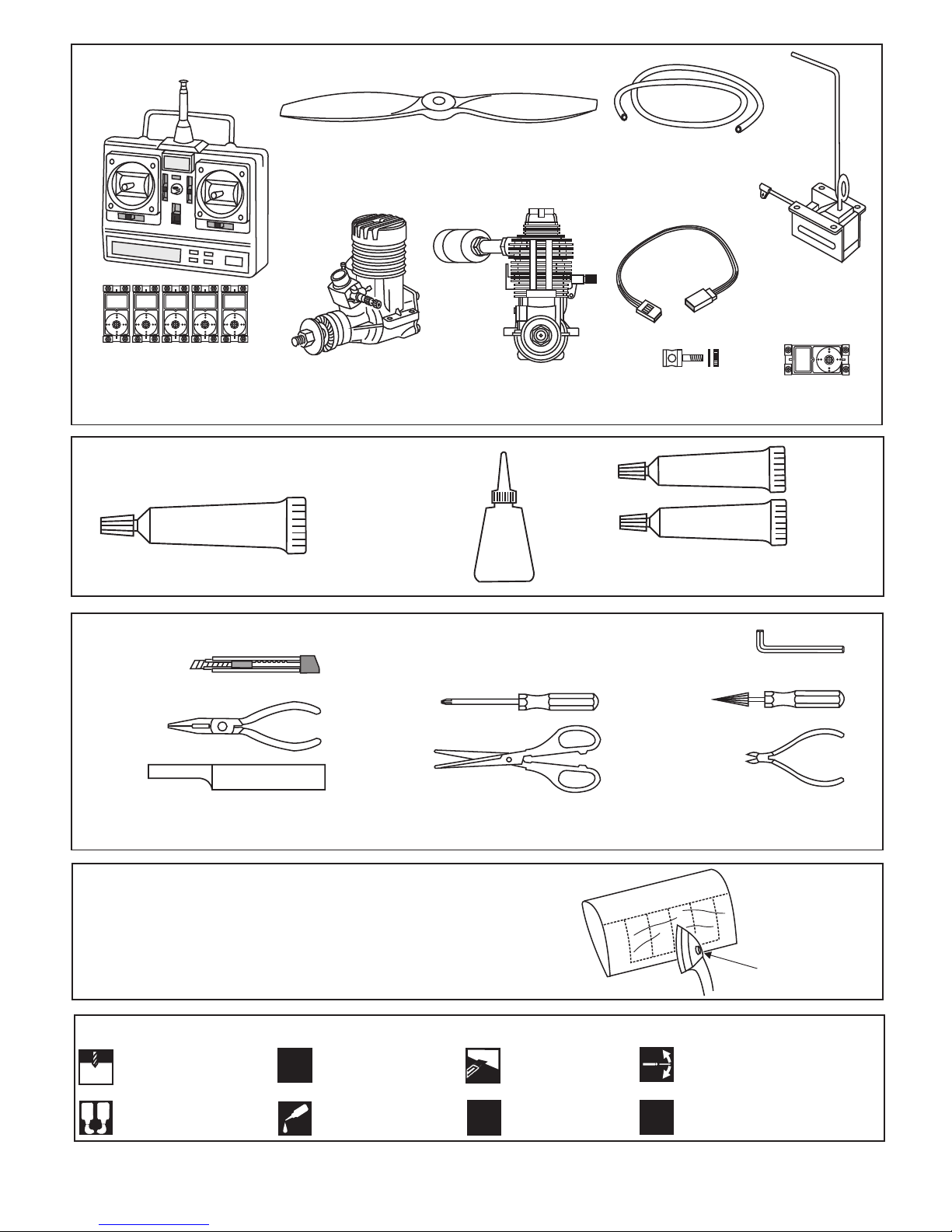

Warning: This radio control model is not a toy. If modified or flow carelessly it could go out of control and cause

serious bodily injury or property damage.

Before flying your airplane, ensure the air field is spacious enough.

Always fly it outdoors in safe areas with no debris or obstacles.

RADIO CONTROL MODEL

Or Electric equivalent

TOLLS REQUIRED

Hobby knife

Needle nose Pliers

Phillip screw driver

Awl

Scissors

Wire Cutters

(Purchase separately)

Hex Wrench

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

Sander

1.5mm

A

B

!

CA

L/R

Assemble left and right

sides the same way.

X

Drill holes using the stated

size of drill

(in this case 1.5 mm Ø)

Use epoxy glue

Take particular care here

Hatched-in areas:

remove covering

film carefully

Not included.

These parts must be

purchased separately

Check during assembly that these

parts move freely, without binding

Apply cyano glue

The pre-covered film on ARF kit may wrinkle due to variations

of temperature. Smooth out as explained right.

* Use an iron or heat gun. Start as low setting. Increase the

setting if necsessary. If it is too high, you may damage the

film

Low setting

SILICON

EPOXY A

EPOXY B

CA

GLUE

Epoxy Glue ( 5 minute type)

Silicon sealer

Cyanoacrylate

Glue

Minimum 5 channel radio

for airplane with 5 servos

.60 ~.70 - 4 cycle

10.5x6 for .40 - 2 cycle engine

11x6 for .46 - 2 cycle engine

12x6 for .60 - 4 cycle engine

12x7 for .70 - 4 cycle engine

Silicone tube

Extension for aileron

servo, retract servo

and power pack

.46 ~ .50 - 2 cycle

REQUIRED FOR OPERATION (Purchase separately)

Linkage Stopper x2

(for retract servo)

Epoxy Glue (30 minute type)

Masking tape - Straight Edged Ruler - Pen or pencil - Rubbing alcohol - Drill and Assorted Drill Bits

Read through the manual before you begin, so you will have an overall idea of what to do.

Symbols used throughout this instruction manual, comprise:

(Purchase separately)

Retract landing

gear

VQAR04 - 160224

Retract servo

x1

.Motor control x1 .Aileron x2

.Elevator x1 .Rudder x1

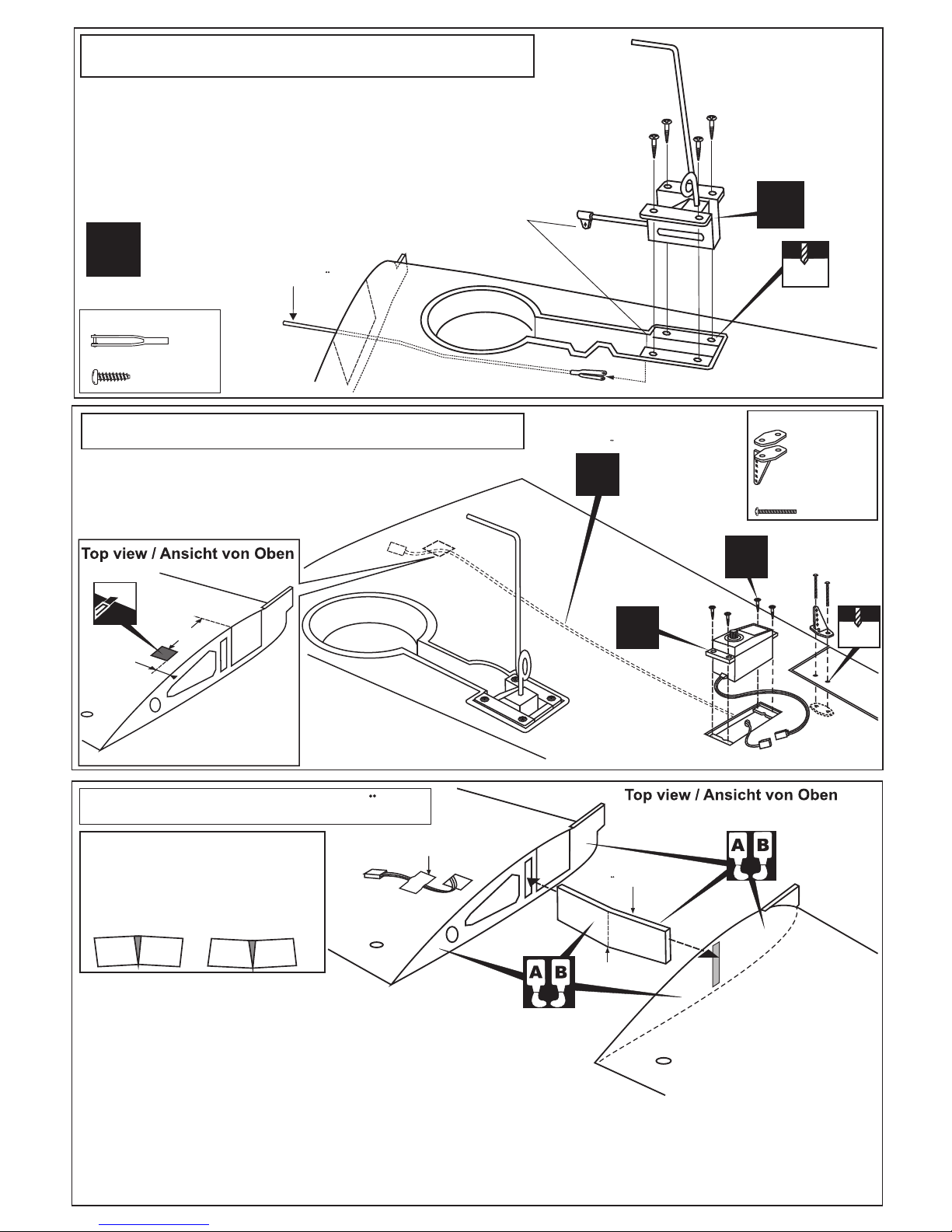

L/R

2mm

3x12mm screw

Trial fit the push rod into the wing. Join the pushrod to the retract

gear arm and trial fit the retract into the wing.

After checking that the retract works smoothly, fix the retract on the

wing with 3x12mm screws

1- Using a pencil, mark the center of the brace.

2- Trial fit the wing joiner into one of the wing panels. It should

insert smoothly up to the center line marked above.

3- Slide the other wing half onto the dihedral brace until

the wing panel meet. If the fit is over tight, it may be

necessary to lightly sand the dihedral brace.

4- Check for the correct dihedral angle.

5- Mix approximately 30 minute epoxy and apply a generous amount of epoxy into the wing joiner cavity of one wing half.

6- Coat one half of the dihedral brace with epoxy up to the center line. Install the epoxy-coated side of the dihedral brace

into the wing joiner cavity up to the center line, marking sure that the “V” of the dihedral brace is positioned correctly

7- Do the same way with the other wing half.

8- Carefully slide the wing halves together, ensuring that they are accurately aligned. Firmly press the two halves

together, allowing the excess epoxy to run out. Clear off the excess epoxy.

Center line

X

Aileron servo

X

Included with the

radio set

Plastic control horn

....................2

2x20mm screw

...............4

2mm

Aileron extension cord

X

Secure one end of the aileron

extension cord with adhesive tape

Querruder servo

Nehmen Sie Epoxykleber, um die

Tragflachen fest miteinander zu Verbinden

und streifen Sie den herausquellenden

Kleber nach dem Verbinden mit einem

fusselfreien Tuch SOFORT ab!

1- Retract landing gear / Fahwerk

2- Aileron servo / Querruder servo

3- Joining the wing / Flache

Use epoxy glue to bury the opening

Retract pushrod

3x12mm schraube

Servoverlangerungskabel

Ansicht von unten

Bottom view

Ansicht von unten

Bottom view /

3x12mm screw

................8

Steel clevis

.........2

40mm

15mm

Fahrwerkanlenkgestange

Wing joiner

Tragflachenverbinde

X

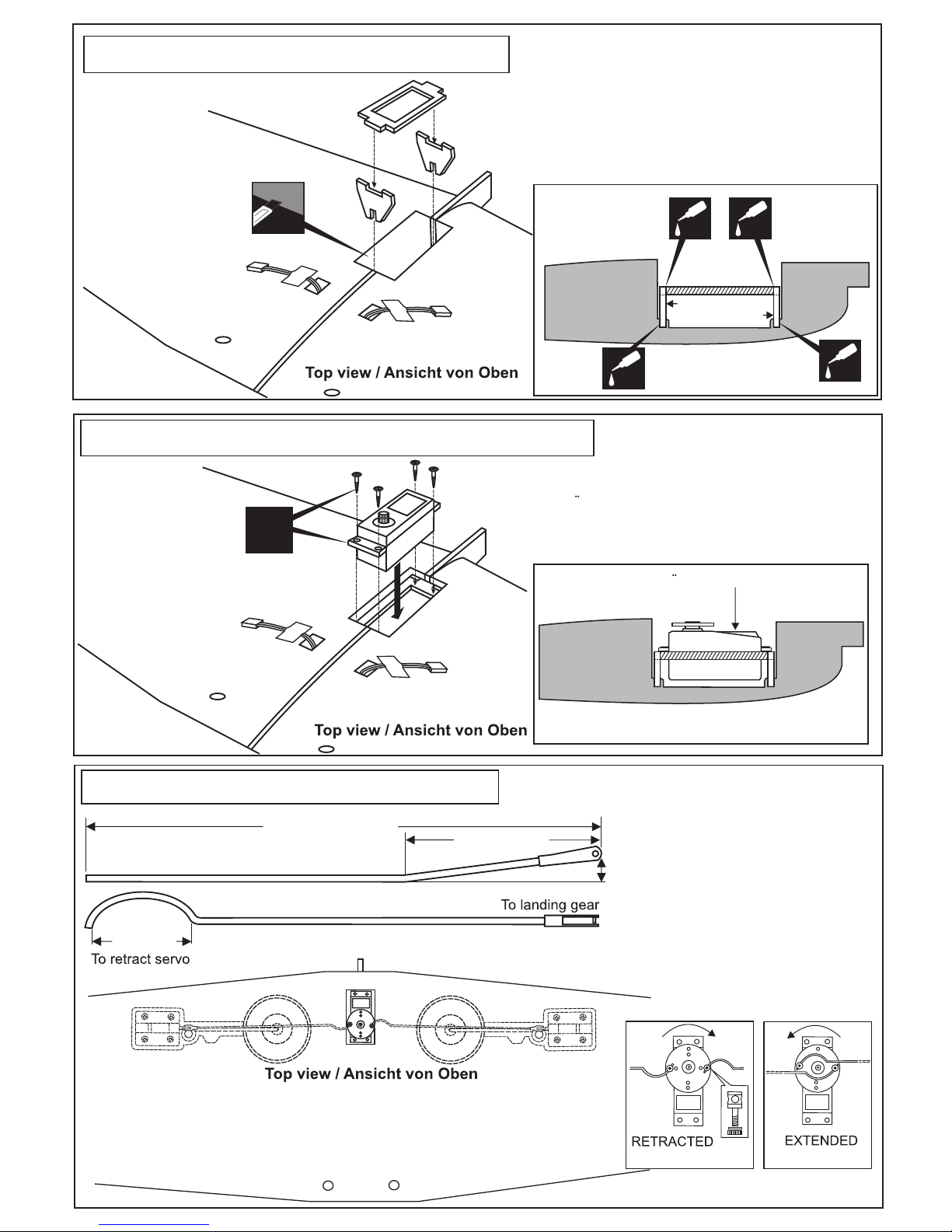

5- Retract servo / Einziehfahrwerk servo

CENTER

WING

SECTION

BOTTOM

Retract servo

/ Retract servo

X

Link the servo and retract gear arm with push rod. Be sure to adjust the stroke so

that the landing gear locks in both up and down position.

2” (~50mm)

1”(25mm)

19/64”

(7.5mm)

8-5/16”(~210mm)

RETRACT PUSHROD (SIDE VIEW)

With the retract and retract servo in the retracted position, mark the position where

each of the pushrod will attach to the servo arm, a small piece of masking tape

works well for this. Cut off the excess length each rod.

(TOP VIEW)

Cut away only

the covering

4- Servo mount / Servohalterung

A

FWU2

FWU1

A

CENTER

WING

SECTION

CA

CA

CA

CA

BOTTOM

Retract servo mount (plywood A,B,C)

Install the retract servo onto the retract

servo mount and secure it in place with

four screw (included with radio set).

Einbau des Servos fur

das Einziehfahrwerk

Instruction how to build in the retracting landing gear

(This Gearis OPTIONAL )

Einbauhilfe bei Anbringen eines

Einziehfahrwerks (Optional

bestellbar; nicht im Baukasten

enthalten!)

Einbau des Servos fur

das Einziehfahrwerk

6- Linkages / Ruderanlenkung

Fahrwerkanlenkgestänge

EINGEFAHREN

AUSGEFAHREN

Einziehfahrwerk servohalterung

Schneiden Sie etwas

Folie weg

FWU2

FWU1

Loading...

Loading...