Workshop Manual

Engine Unit

AQ125A, B

AQ145A, B

C

2(0)

Contents

Safety Precautions ............................................................................................................. 2

General Information ...........................................................................................................5

Repair Instructions ............................................................................................................6

Presentation ....................................................................................................................... 8

Repair Instructions

Disassembling, Overhauling and Inspection

Electrical parts, carburetor ...................................................................................................9

Heating exchanger, exhaust pipe, oil filter.................................................................. 10–11

Oil cooler, sea water pump ............................................................................................... 12

Circulation pump, belt pulley, marking the timing belt ...................................................... 13

Belt tensioner, intermediate pulley, camshaft pulley......................................................... 14

Sealing flange, flywheel cover .......................................................................................... 15

Vibration damper, intermediate shaft ................................................................................ 16

Camshaft........................................................................................................................... 16

Cylinder head valves ..................................................................................................16–18

Valve seats, guides, springs, pushers ........................................................................ 19–22

Flywheel, sealing .............................................................................................................. 22

Lubricating oil pump, pistons, crankshaft.................................................................... 23–24

Cylinders, pistons, connecting rods, crankshaft.......................................................... 25–28

Fuel pump, oil cooler, lubricating oil pump ................................................................. 28–30

Heat exchanger, carburetor, flywheel cover................................................................ 31–33

Assembling

Crankshaft, pistons, lubrication oil pump, flywheel ..................................................... 33–35

Oil sump, cylinder head, camshaft .............................................................................. 36–37

Intermediate shaft, seals, camshaft gear wheel .......................................................... 38–39

Intermediate gear, marking, timing belt ....................................................................... 40–42

Oil pump drive, circulation pump, valve adjustment.................................................... 42–46

Distributor, oil cooler, exhaust pipe, heat exchanger .................................................. 46–48

Lubrication oil filter, sea water pump, expansion tank ................................................ 48–49

Thermostat sea water strainer, alternator.................................................................... 49–50

Starter motor, induction pipe, carburetor ..................................................................... 50–51

Electric wiring diagram ................................................................................................... 52

Fault finding chart ........................................................................................................... 53

Special tools .............................................................................................................. 54–55

Technical data AQ125A, AQ145A............................................................................ 56–60

Valve adjusting kit........................................................................................................... 61

Technical data AQ125B, AQ145B............................................................................ 62–68

1

Safety Precautions

Introduction

This Workshop Manual contains technical data, descriptions and repair instructions for Volvo Penta

products or product versions contained in the contents list. Ensure that the correct workshop literature is being used.

Read the safety information and the Workshop

Manual “General Information” and “Repair Instructions” carefully before starting work.

Important

In this book and on the engine you will find the following special warning symbols.

WARNING! If these instructions are not followed there is a danger of personal injury, extensive damage to the product or serious mechanical malfunction.

IMPORTANT! Used to draw your attention to

something that can cause damage, product

malfunction or damage to property.

NOTE! Used to draw your attention to important infor

mation that will facilitate work or operations.

Check that the warning or information decals

on the product are always clearly visible. Replace decals that have been damaged or painted over.

Never use start spray or similar to start the

engine. The starter element may cause an explosion in the inlet manifold. Danger of personal injury.

Avoid opening the filler cap for engine coolant

system (freshwater cooled engines) when the

engine is still hot. Steam or hot coolant can

spray out. Open the coolant filler cap carefully

and slowly to release pressure before removing the cap completely. Take great care if a

cock, plug or engine coolant line must be removed from a hot engine. It is difficult to anticipate in which direction steam or hot coolant

can spray out.

Below is a summary of the risks and safety precautions you should always observe or carry out when

operating or servicing the engine.

Immobilize the engine by turning off the power

supply to the engine at the main switch

(switches) and lock it (them) in the OFF position before starting work. Set up a warning notice at the engine control point or helm.

Generally, all servicing should be carried out

with the engine switched off. Some work (carrying out certain adjustments for example) requires the engine to be running. Approaching

a running engine is dangerous. Loose clothing

or long hair can fasten in rotating parts and

cause serious personal injury.

If working in proximity to a running engine,

careless movements or a dropped tool can result in personal injury. Avoid burns. Take precautions to avoid hot surfaces (exhausts, turbochargers, charge air pipes and starter

elements etc.) and liquids in supply lines and

hoses when the engine is running or has been

turned off immediately prior to starting work

on it. Reinstall all protective parts removed

during service operations before starting the

engine.

Hot oil can cause burns. Avoid skin contact

with hot oil. Ensure that the lubrication system

is not under pressure before commencing

work on it. Never start or operate the engine

with the oil filler cap removed, otherwise oil

could be ejected.

Stop the engine and close the sea cock before

carrying out operations on the engine cooling

system.

Only start the engine in a well-ventilated area.

If operating the engine in an enclosed space,

ensure that exhaust gases and crankcase

ventilation emissions are ventilated out of the

working area.

Always use protective goggles where there is

a danger of pieces of metal, sparks from

grinding, acid or other chemicals being thrown

into your eyes. Your eyes are very sensitive,

injury can lead to loss of sight!

2

Avoid skin contact with oil. Long-term or repeated contact with oil can remove the natural

oils from your skin. The result can be irritation, dry skin, eczema and other skin problems. Used oil is more dangerous to health

than new oil. Use protective gloves and avoid

using oil-soaked clothes and rags. Wash regularly, especially before meals. Use the correct

barrier cream to prevent dry skin and to make

cleaning your skin easier.

Most chemicals used in products (engine and

transmission oils, glycol, petrol and diesel oil)

and workshop chemicals (solvents and paints)

are hazardous to health Read the instructions

on the product packaging carefully! Always

follow safety instructions (using breathing

apparatus, protective goggles and gloves for

example). Ensure that other personnel are not

unwittingly exposed to hazardous substances

(by breathing them in for example). Ensure

that ventilation is good. Handle used and excess chemicals according to instructions.

All fuels and many chemicals are inflammable.

Ensure that a naked flame or sparks cannot

ignite fuel or chemicals. Combined with air in

certain ratios, petrol, some solvents and hydrogen from batteries are easily inflammable

and explosive. Smoking is prohibited! Ensure

that ventilation is good and that the necessary

safety precautions have been taken before

carrying out welding or grinding work. Always

have a fire extinguisher to hand in the workplace.

Store oil and fuel-soaked rags and fuel and oil

filters safely. In certain conditions oil-soaked

rags can spontaneously ignite. Used fuel and

oil filters are environmentally dangerous waste

and must be deposited at an approved site for

destruction together with used lubricating oil,

contaminated fuel, paint remnants, solvent,

degreasing agents and waste from washing

parts.

Never allow a naked flame or electric sparks

near the batteries. Never smoke in proximity

to the batteries. The batteries give off hydrogen gas during charging which when mixed

with air can form an explosive gas – oxyhydrogen. This gas is easily ignited and highly

volatile. Incorrect connection of the battery

can cause a spark which is sufficient to cause

an explosion with resulting damage. Do not

disturb battery connections when starting the

engine (spark risk) and do not lean over batteries.

Never mix up the positive and negative battery terminals when installing. Incorrect installation can result in serious damage to electrical equipment. Refer to wiring diagrams.

Always use protective goggles when charging

and handling batteries. The battery electrolyte

contains extremely corrosive sulfuric acid. If

this comes into contact with the skin, wash

immediately with soap and plenty of water. If

battery acid comes into contact with the eyes,

immediately flush with copious amounts of

water and obtain medical assistance.

Turn off the engine and turn off power at main

switch(es) before carrying out work on the

electrical system.

Use the lifting eyes mounted on the engine/reverse gear when lifting the drive unit.

Always check that lifting equipment is in good

condition and has sufficient load capacity to

lift the engine (engine weight including reverse

gear and any extra equipment installed).

To ensure safe handling and to avoid damaging engine components on top of the engine,

use a lifting beam to raise the engine. All

chains and cables should run parallel to each

other and as perpendicular as possible in relation to the top of the engine.

If extra equipment is installed on the engine

altering its center of gravity, a special lifting

device is required to achieve the correct balance for safe handling.

Never carry out work on an engine suspended

on a hoist.

3

Never remove heavy components alone, even

where secure lifting equipment such as secured blocks are being used. Even where lifting equipment is being used it is best to carry

out the work with two people; one to operate

the lifting equipment and the other to ensure

that components are not trapped and damaged

when being lifted. When working on-board ensure that there is sufficient space to remove

components without danger of injury or damage.

Components in the electrical system, ignition

system (gasoline engines) and fuel system on

Volvo Penta products are designed and constructed to minimize the risk of fire and explosion. The engine must not be run in areas

where there are explosive materials.

Always use fuels recommended by Volvo Penta. Refer to the Instruction Book. The use of

lower quality fuels can damage the engine. On

a diesel engine poor quality fuel can cause the

control rod to seize and the engine to overrev

with the resulting risk of damage to the engine

and personal injury. Poor fuel quality can also

lead to higher maintenance costs.

4

General information

About the workshop manual

This workshop manual contains technical specification, descriptions and instructions for repairing

the standard versions of the following engines

AQ125A, B – AQ145A, B. The workshop manual

displays the operations carried out on any of the

engines above. As a result the illustrations and pictures in the manual that show certain parts on the

engines, do not in some cases apply to all the engines listed above. However the repair and service

operations described are the same in all essential

details. Where they are not the same this is stated

in the manual and where the difference is considerable the operations are described separately. Engine designations and numbers are given on the

number plate. The engine designation and number

should be given in all correspondence about the engine.

This Workshop Manual has been developed primarily for Volvo Penta service workshops and qualified

personnel. Persons using this book are assumed to

have a grounding in marine drive systems and be

able to carry out related mechanical and electrical

work.

Volvo Penta is continuously developing their products. We therefore reserve the right to make changes. All the information contained in this book is

based on product data available at the time of going

to print. Any essential changes or modifications introduced into production or updated or revised service methods introduced after the date of publication will be provided in the form of Service Bulletins.

Replacement parts

Replacement parts for electrical and fuel systems

are subject to statutory requirements (US Coast

Guard Safety Regulations for example). Volvo Penta Genuine parts meet these requirements. Any

type of damage which results from the use of nonoriginal Volvo Penta replacement parts for the product will not be covered under any warranty provided

by Volvo Penta.

5

Repair instructions

The working methods described in the Service Manual apply to work carried out in a workshop. The engine has been removed from the boat and is installed in an engine fixture. Unless otherwise stated

reconditioning work which can be carried out with

the engine in place follows the same working

method.

Warning symbols occurring in the Workshop Manual (for their meaning see

WARNING!

IMPORTANT!

NOTE!

are not in any way comprehensive since it is

impossible to predict every circumstance under

which service work or repairs may be carried out.

For this reason we can only highlight the risks that

can arise when work is carried out incorrectly in a

well-equipped workshop using working methods and

tools developed by us.

All procedures for which there are Volvo Penta special tools in this Workshop Manual are carried out

using these. Special tools are developed to rationalize working methods and make procedures as safe

as possible. It is therefore the responsibility of any

person using tools or working methods other than

the ones recommended by us to ensure that there is

no danger of injury, damage or malfunction resulting

from these.

In some cases there may be special safety precautions and instructions for the use of tools and chemicals contained in this Workshop Manual. These

special instructions should always be followed if

there are no separate instructions in the Workshop

Manual.

Certain elementary precautions and common sense

can prevent most risks arising. A clean workplace

and engine eliminates much of the danger of injury

and malfunction.

It is of the greatest importance that no dirt or foreign particles get into the fuel system, lubrication

system, intake system, turbocharger, bearings and

seals when they are being worked on. The result

can be malfunction or a shorter operational life.

Safety information

)

Our joint responsibility

Each engine consists of many connected systems

and components. If a component deviates from its

technical specification the environmental impact of

an otherwise good engine may be increased significantly. It is therefore vital that wear tolerances are

maintained, that systems that can be adjusted are

adjusted properly and that Volvo Penta Genuine

Parts as used. The engine Maintenance Schedule

must be followed.

Some systems, such as the components in the fuel

system, require special expertise and special testing equipment for service and maintenance. Some

components are sealed at the factory for environmental reasons. No work should be carried out on

sealed components except by authorized personnel.

Bear in mind that most chemicals used on boats are

harmful to the environment if used incorrectly. Volvo Penta recommends the use of biodegradable degreasing agents for cleaning engine components,

unless otherwise stated in a workshop manual.

Take special care when working on-board, that oil

and waste is taken for destruction and is not accidentally pumped into the environment with bilge water.

Tightening torques

Tightening torques for vital joints that must be

tightened with a torque wrench are listed in workshop manual “Technical Data”: “Tightening Torques”

and are contained in work descriptions in this Manual. All torques apply for cleaned threads, screw

heads and mating surfaces. Torques apply for lightly oiled or dry threads. If lubricants, locking fluid or

sealing compound are required for a screwed joint

this information will be contained in the work description and in “Tightening Torques” Where no

tightening torque is stated for a joint use the general

tightening torques according to the tables below.

The tightening torques stated are a guide and the

joint does not have to be tightened using a torque

wrench.

Dimension Tightening Torques

Nm lbt.ft

M5 6 4.4

M6 10 7.4

M8 25 18.4

M10 50 36.9

M12 80 59.0

M14 140 103.3

6

Tightening torques-protractor (angle)

tightening

Tightening using both a torque setting and a protractor angle requires

that first the recommended torque is

applied using a torque wrench and

then the recommended angle is added according to the protractor scale.

Example: a 90° protractor tightening

means that the joint is tightened a

further 1/4 turn in one operation after the stated tightening torque has

been applied.

Locknuts

Do not re-use lock nuts that have been removed

during dismantling as they have reduced service life

when re-used - use new nuts when assembling or

reinstalling. For lock nuts with a plastic insert such

as Nylock® the tightening torque stated in the table

is reduced if the Nylock® nut has the same head

height as a standard hexagonal nut without plastic

insert. Reduce the tightening torque by 25% for bolt

size 8 mm or larger. Where Nylock® nuts are higher, or of the same height as a standard hexagonal

nut, the tightening torques given in the table apply.

Tolerance classes

In this Volvo Penta Service Manual the user will find

that each section where these agents are applied in

production states which type was used on the engine.

During service operations use the same agent or an

alternative from a different manufacturer.

Make sure that mating surfaces are dry and free

from oil, grease, paint and anti-corrosion agent before applying sealant or locking fluid. Always follow

the manufacturer’s instructions for use regarding;

temperature range, curing time and any other instructions for the product.

Two different basic types of agent are used on the

engine and these are:

RTV agent (Room temperature vulcanizing). Use for

gaskets, sealing gasket joints or coating gaskets.

RTV agent is clearly visible when a component has

been dismantled; old RTV must be removed before

the joint is resealed. Old sealant can be removed

using methylated spirits in all cases.

Anaerobic agents. These agents cure in an absence

of air. They are used when two solid parts, for example cast components, are installed face-to-face

without a gasket. They are also commonly used to

secure plugs, threads in stud bolts, cocks, oil pressure switches and so on. The cured material is

glass-like and it is therefore colored to make it visible. Cured anaerobic agents are extremely resistant to solvents and the old agent cannot be removed. When reinstalling the part is carefully

degreased and then new sealant is applied.

Screws and nuts are divided into different strength

classes, the class is indicated by the number on the

bolt head. A high number indicates stronger material, for example a bolt marked 10-9 indicates a higher tolerance than one marked 8-8. It is therefore important that bolts removed during the disassembly

of a bolted joint must be reinstalled in their original

position when assembling the joint. If a bolt must be

replaced check in the replacement parts catalogue

to make sure the correct bolt is used.

Sealants

A number of sealants and locking liquids are used

on the engines. The agents have varying properties

and are used for different types of jointing trengths,

operating temperature ranges, resistance to oil and

other chemicals and for the different materials and

gap sizes in the engines.

To ensure service work is correctly carried out it is

important that the correct sealant and locking fluid

type is used on the joint where the agents are required.

7

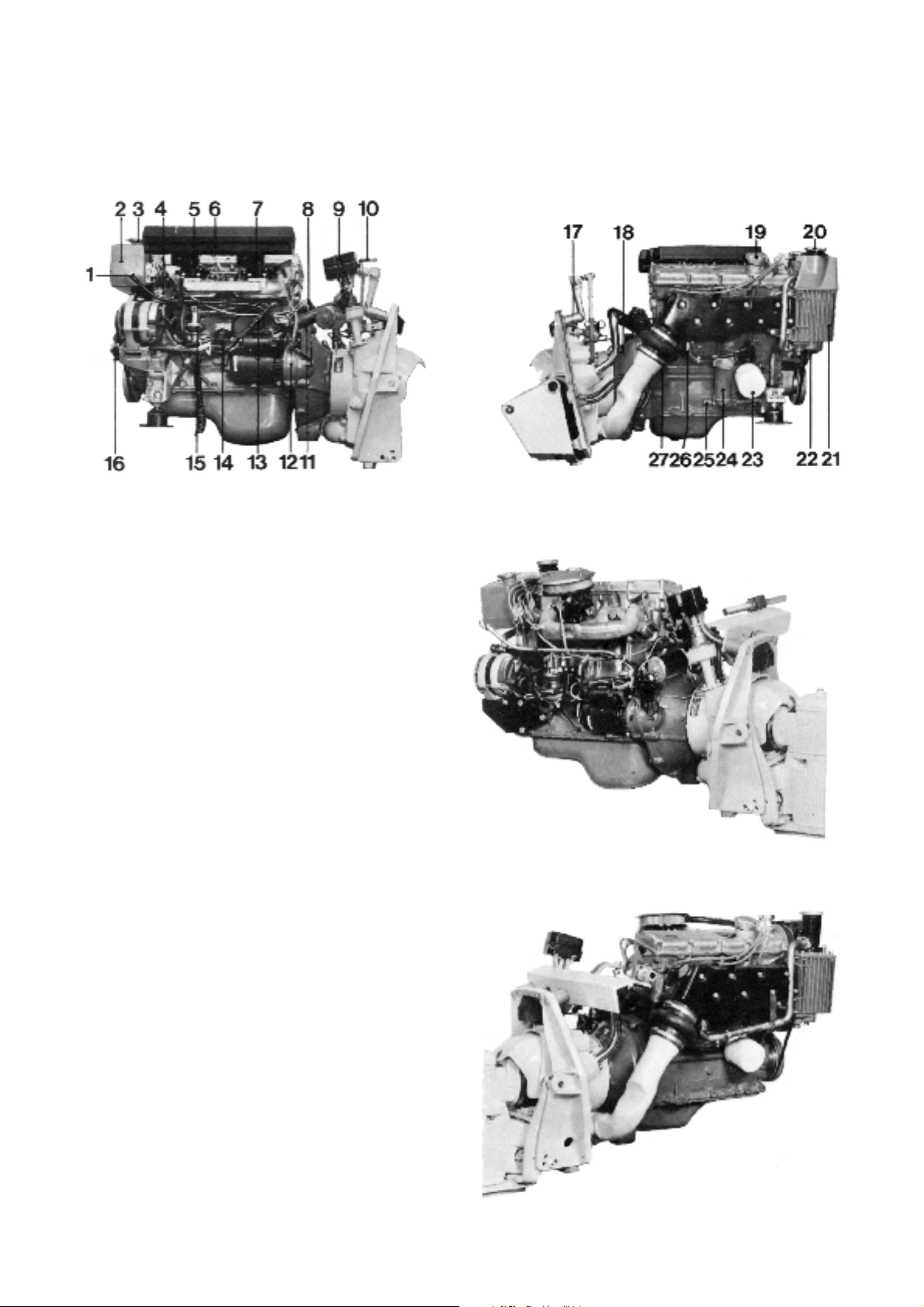

Presentation

AQ145A

1. Oil dipstick

2. Fresh water tank

3. Filler cap, checking, fresh water

4. Distributor

5. Carburettor, front (AQ125 has only one)

6. Intake air silencer

7. Carburettor, rear

8. Ignition coil

9. Electro-mechanical lift device

10. Steering arm

11. Fuse box (exec. USA)

12. Serial number

13. Fuse (exec. USA)

14. Fuse (not USA)

15. Fuel pump

16. Sea water pump

17. Grease joint, upper steering shaft journal

18. Grease joint, drive shaft journal

19. Oil filler cap engine

20. Water filter

21. Heat exchanger

22. Draining, sea water

23. Luboil filter

24. Oil cooler (only AQ145A)

25. Draining, sea water

26. Draining, sea water

27. Draining, fresh water

AQ145A

AQ125

AQ125

8

Repair Instructions

1. AQ145. Remove the four screws and pull the in-

duction silencer to one side so that it comes free

from the evacuation tube (1). AQ125. Remove the

cover.

3. Remove the alternator, drive belt, cable harness,

ignition coil, main fuse, starter motor, ignition

cables and distributor. NOTE! Mark the cables

before they are removed.

2. Remove the air filters (1), the fuel pipe (2) between the feed pump and the carburetors and

unscrew the carburetors from the induction pipe.

AQ125 has only one carburetor.

4. Remove the cooling water pipe (1), and the

bracket for the ignition coil (2). Remove the screw

(3) and draw up the dip stick with its tube (4).

Then remove the feed pump (5) and the induction

pipe (6). NOTE! There are double gaskets plus an

intermediate washer on the feeder pump. There is

a lifting eye in the induction pipes rear screws.

There are no washers under the lifting eye.

9

5. Remove the thermostat housing and lift out the

thermostat.

NOTE! The forward lifting eye is screwed onto the

thermostat housing.

7. Remove the cap and lift out the strainer (1) from

the heat exchanger. Then pull up the rubber ring’s

tongue (2). The tongue is marked “UP”. The cover

(3) is now loose and can be lifted up. (Not on

AQ125.)

6. Remove and discard the O-ring (1) in the heat exchanger and if necessary, unscrew the holder (2)

for the ignition cables. The holder is fixed with two

guide pins.

8. Pull the heat exchanger’s fresh water section to

one side. The fresh water section is mounted on a

rubber bushing (1) and the water pipe (2), which

seals against an O-ring.

10

9. AQ145. Remove the cooling water pipes between

the seawater pump and the heat exchanger and

between the heat exchanger and the oil cooler.

(Between the heat exchanger and the exhaust

pipe on AQ125.)

11. Remove the cooling water pipe between the oil

cooler and the exhaust pipe. Not on AQ125. Then

remove the exhaust pipe.

10. Remove the remaining three screws (X) on the

heat exchanger and draw it to one side from the

circulation pump.

12. Unscrew the oil filter. Use tool 999 2903 or push a

screwdriver through the filter and work it loose.

NOTE! Be careful not to spill oil.

11

13. Remove the nut (1) and remove the oil cooler.

Only AQ145. Spanner width = 28 mm. Remove

the oil pressure

15. Remove the saltwater pump and the generator’s

tensioning bracket. The spanner width for the

saltwater pump is 10 mm. The other screws

which hold the cover have a spanner width of 8

mm. Check the impeller, the key and the packing

on the pump’s front side plus the sealing ring on

the pump’s rear side. Clean the pump and replace damaged parts.

14. AQ145. If the oil cooler’s channels are to be

cleaned when the exhaust pipe is fitted on the

engine the cooling water pipes (1) and (2) must

be removed. Undo the oil cooler’s screw (3) and

remove the lower cover.

The oil filter is then removed and the centre nut

(4) is loosened so that the oil cooler can be turned

to a horizontal position.

After this the insert’s channels can be cleaned.

16. Undo the cover’s two hexagonal socket screws

(6 mm key) and hexagonal screw (spanner width

10 mm). NOTE! The cover’s upper fixture is fitted

with a guide which means that the cover must be

withdrawn a few millimetres before it is free.

12

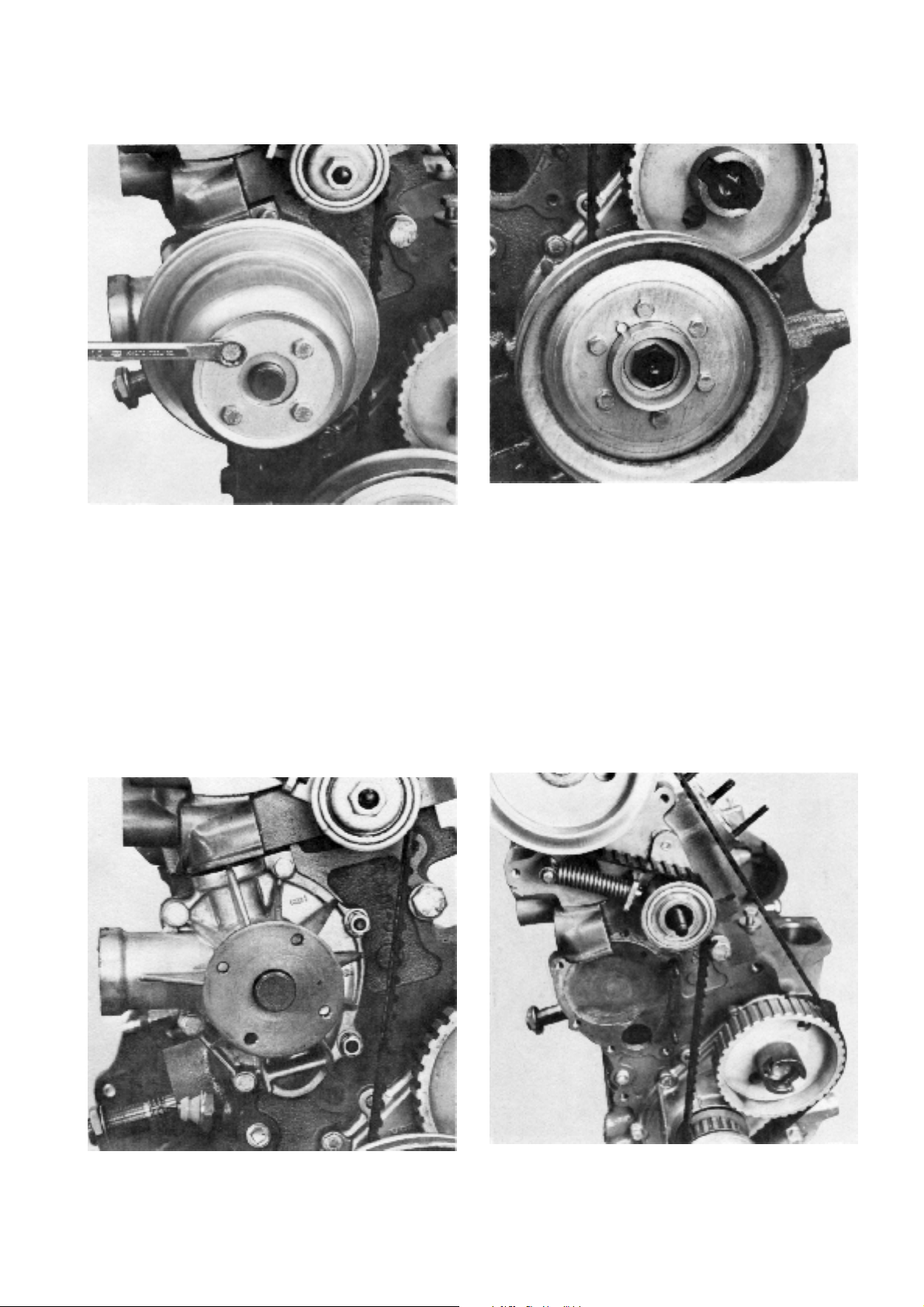

17. Remove the circulation pump’s pulley. The spanner width is 10 mm.

19. Remove the crankshaft pulley. Six screws. The

spanner width is 10 mm.

18. Remove the circulation pump. The spanner width

is 10 mm. There are four screws and two nuts

with washers. Discard the plain packing and the

rubber seal. NOTE! The pump is to be changed

as a complete unit if it has been damaged.

20. If the belt’s markings have disappeared the belt is

to be marked before it is removed. The marking of

the belt is carried out as follows: Make a mark by

the camshaft’s pulley marking. Make a mark by

the intermediate gear’s marking and two marks

on the crankshaft pulley’s marking. Undo and remove the nut and washer for the belt tensioner.

13

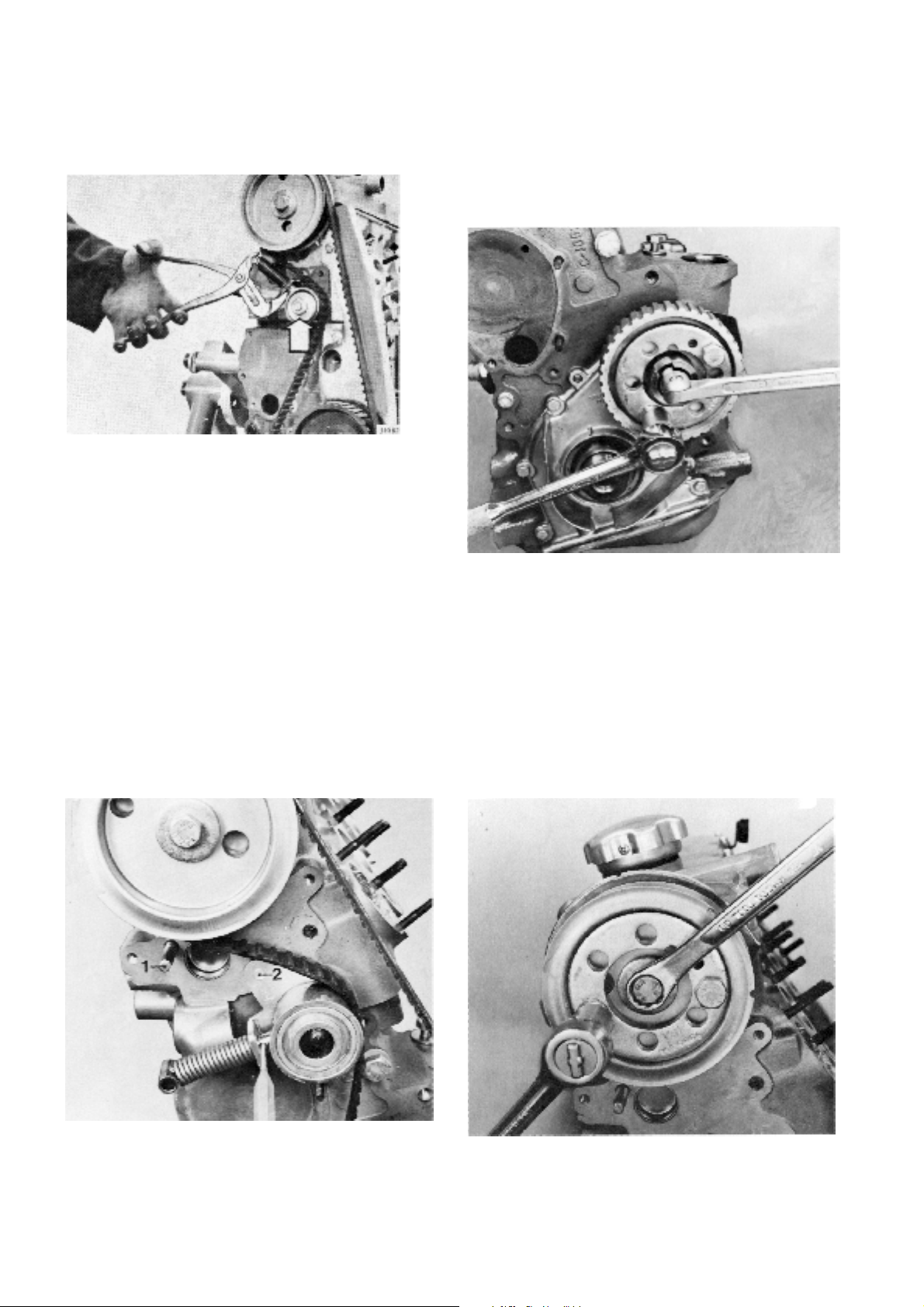

21. Slacken the belt by depressing the roller against

the spring pressure. Lock the spring by inserting a

3 mm (0.118") pin (e.g. a drill) in the hole on the

pressure pin.

23. Remove the cross piece from the intermediate

gear wheel. Check that cross piece is not damaged. Then remove the screw from the carrier.

Use counterforce 999 5034. Remove the carrier

and the pulley. Then remove the carrier from the

pulley. Mild force from the rear with a wooden

shaft or similar tool may be necessary.

22. Remove the belt tensioner from the shaft (1). The

belt tensioner’s guide pin 2 is now free after

which the belt tensioner is twisted and removed.

Then remove the belt. The shaft (1) can be replaced by unscrewing it from the cylinder head.

The timing belt is to be changed if the cord

re-inforcement and the rubber are beginning to

separate or if the tread on the timing belt is worn.

The timing belt is to be changed every five hundred hours.

24. Remove the pulley from the camshaft. Use counterforce 999 5034. Remove the pulley by hand.

Check that the outer and the inner guide plate’s

edges are not damaged so that these in turn can

damage the belt.

14

25. Remove the centre screw and pull off the carrier

and outer guide plate from the crankshaft.

27. Remove the screws from the sealing flange. The

flange is also tightened with two of the screws in

the oil sump. Remove the flange plate and remove the seals. Use tool 999 5025 for the small

seal and tool 999 5024 for the large seal.

26. Remove the key and pull off the pulley and the

inner guideplate from the crankshaft.

28. Unscrew the flywheel cover’s four screws and the

three screws which hold the protective plate on

the underside between the cover and the cylinder

block.

15

29. Remove the vibration damper’s six screws. Spanner width 13 mm. Carefully remove the vibration

damper from the three guide pins.

31. Pull out the intermediate shaft. Use the impact

tool 999 4030 where necessary. NOTE! Be careful to make sure that the intermediate shaft’s

gearwheel does not damage the bushes in the

cylinder block’s bearings.

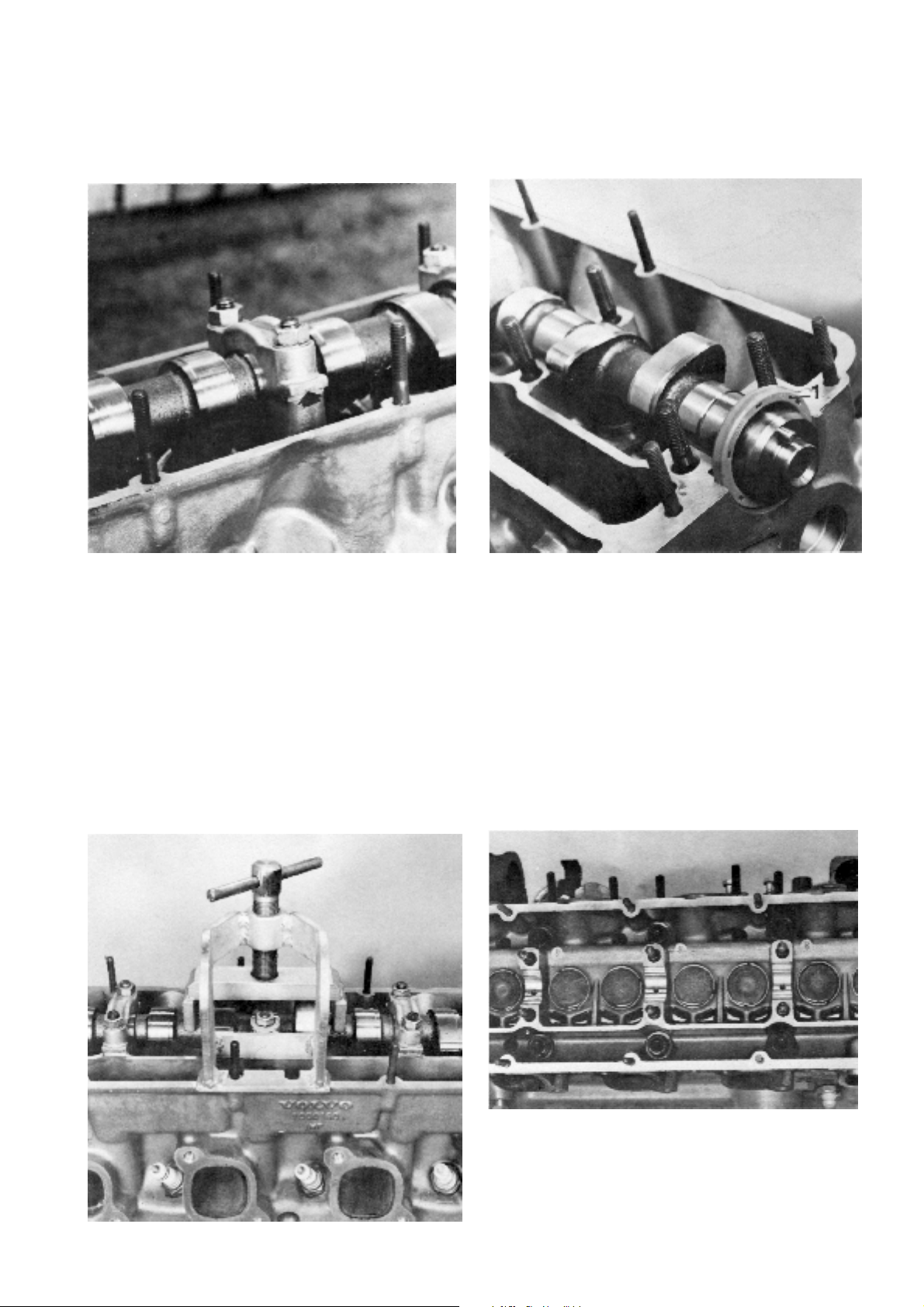

30. Remove the cover and the bracket for the oil

pump drive. Then lift up the oil pump drive.

Cylinder head

32. Remove the valve cover, the gasket and the cres-

cent shaped rubber seal and check the marking

on the camshaft bearing caps.

16

33. Remove the centre camshaft bearing cap. Spanner width 1/2". There are spring washers under

the nuts. When necessary use a chisel or similar

tool against the lug as shown by the arrow.

35. Remove the seal (1) from the camshaft. Then

undo the tool spindle and release the camshaft.

Remove the tool and lift out the camshaft.

34. Fit tool 999 5021 on the camshaft. Use the bearing cap’s nuts. The camshaft is held in position

with the tool. Undo the other four camshaft bearing caps.

36. Remove the screws in the cylinder head. Use

hexagonal socket key 10 mm. Lift away the cylinder head and remove the gasket. Remove the

spark plugs.

17

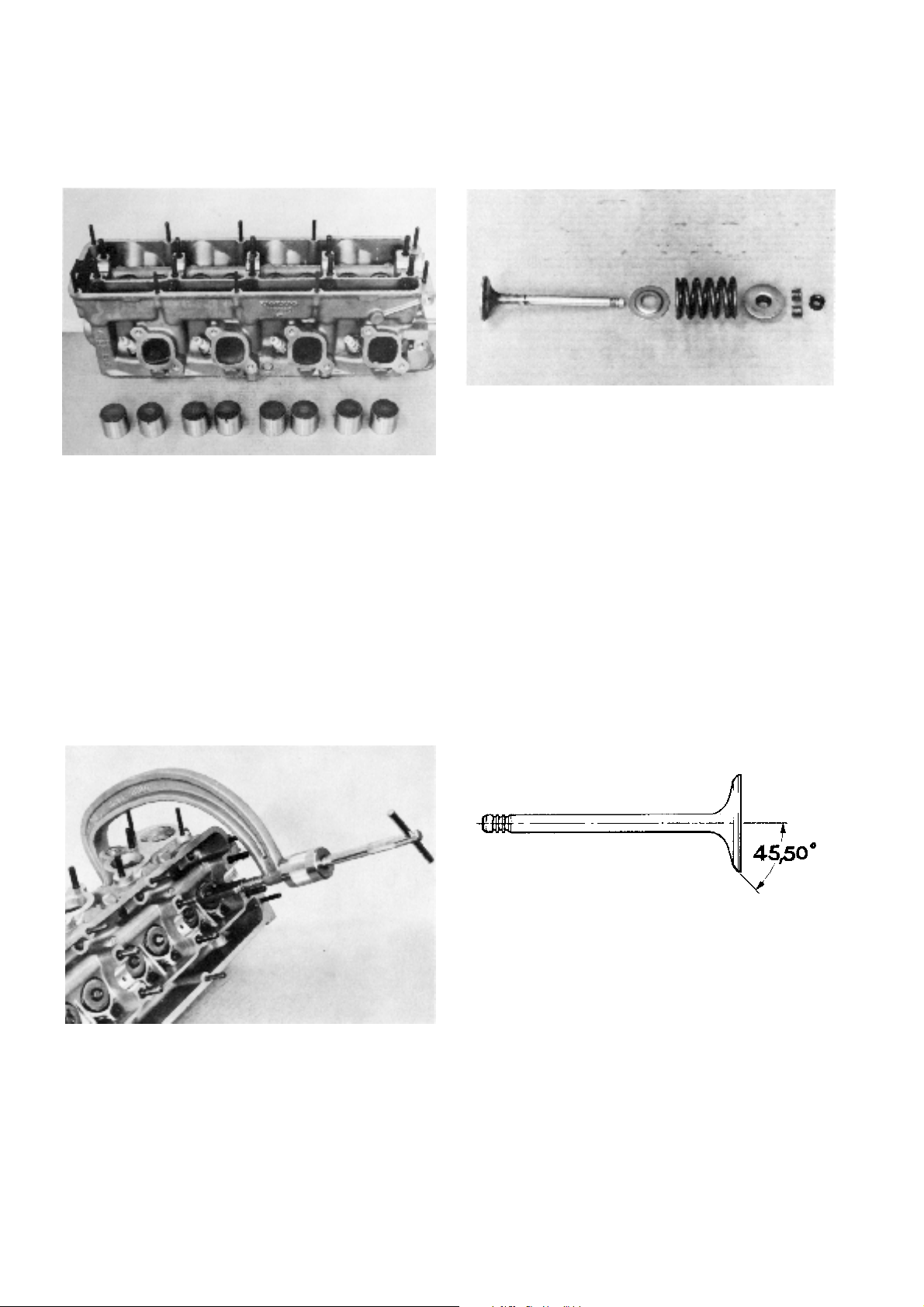

37. Lift up the valve pushers and place them in the

same order as they fit in the cylinder head.

39. Remove the rubber ring, collets, upper washers,

springs, lower washers and valves. Then remove

the valve seals from the inlet valve guides. Clean

all the parts. Remove carbon deposits from the

combustion chamber and the valves.

38. Remove the valves. Use valve spring compressor

884 580.

40. Grind the valves if necessary in a valve grinding

machine. The angle is the same for both the exhaust and the inlet valves.

18

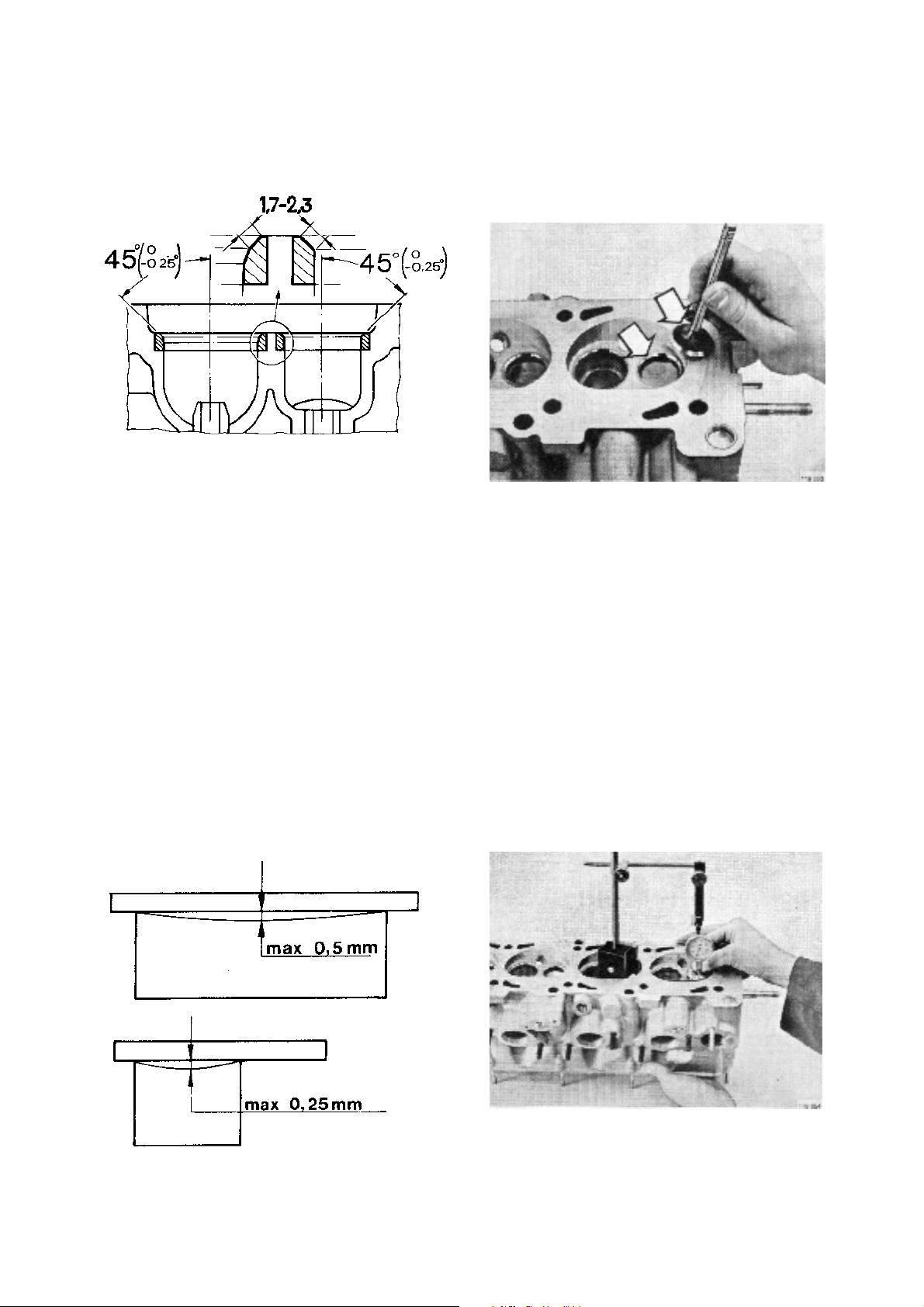

41. Mill or ream the valve seats. The angle is the

same for the exhaust and inlet valve seats.

43. Check that all the valves and the valve seats are

perfectly ground by marking the valve seat face

and turning it against the valve seat with light

pressure. If the marking is not evenly distributed

on the whole of the seat (leaking valve) the valve

is ground further and a new check is carried out

until the result is satisfactory.

42. Check the flatness of the cylinderhead. Use a

steel straight edge.

44. Check the wear of the valve and the valve guides.

The play for the inlet valve is 0.030–0.060 mm

(0.0012–0.0024") and for the exhaust 0.060–

0.090 mm (0.0024–0.0035").

19

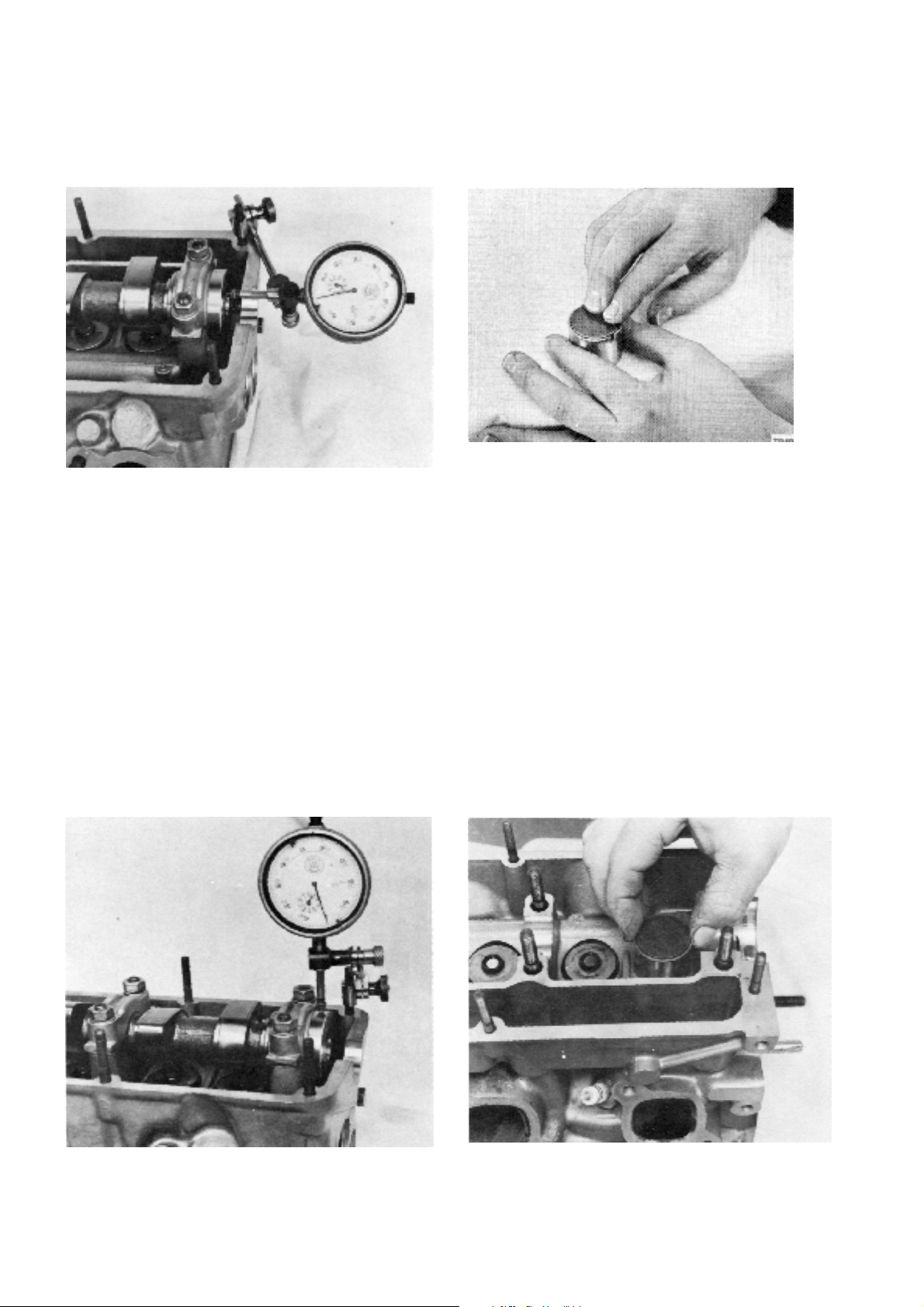

45. Replace the camshaft in the cylinder head and

check the axial play which is 0.1–0.4 mm

(0.004–0.016").

47. Check that the shims do not have too much play

in the valve pushers. If there are signs of wear on

the plain surface of the shim it should be changed. The play between the shim and the valve

presser is 0.009–0.068 mm (0.0004–0.0027).

46. Check the radial play which is 0.030–0.071 mm

(0.0012–0.0028").

48. Replace the valve pressers in the cylinder head

and check that the play is not too much or that

they do not stick. The play between the valve

pressers and the cylinder head is 0.030–0.075

mm (0.0012–0.0030").

20

49. Check the valve springs.

Length unloaded 45 mm (1.77")

Length loaded with 300±20 N (67.2±4.48 lbf.)

38 mm (1.50")

Length loaded with 760±40 N (170±8.96 lbf.)

27 mm (1.06")

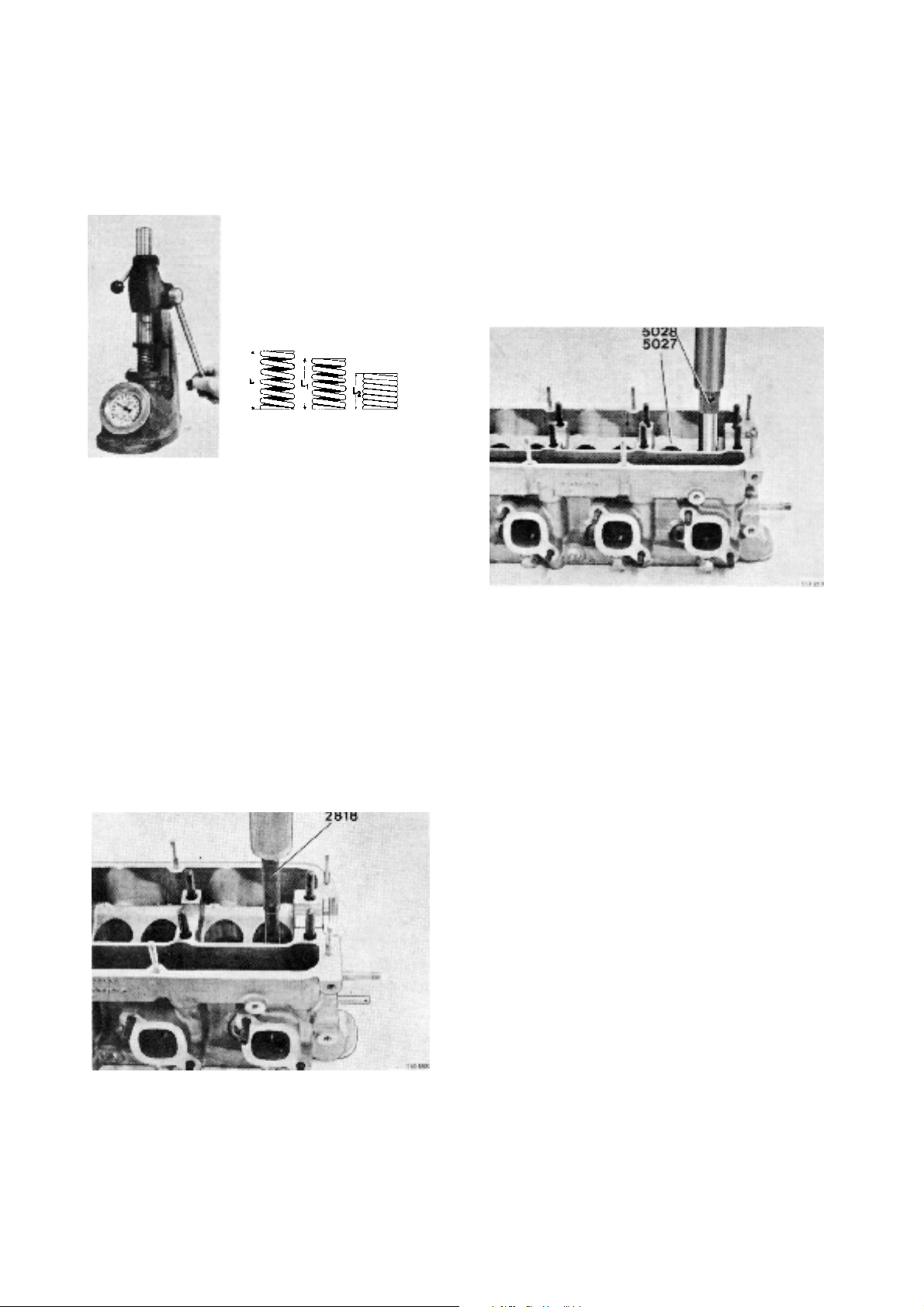

51. Fit the new valve guides. Use tool 999 5027 for

the inlet valves and tool 999 5028 for the exhaust

valves. The cylinder head is to be at room temperature. The pressing force for fitting the valve guides is to be at least 9000 N (900 kp) (2016 lbf). If

this pressing force is not obtained for the guides

the hole is to be reamed and a suitable oversized

valve guide is to be fitted. Press the guide down

until the tool comes up against the cylinder head.

This gives the guide a height above the valves

spring face around the guide of: 15.5±0.1 mm

(0.610±0.004") for the inlet valve and 18.0±0.1

mm (0.708±0.004") for the exhaust valve.

Changing the valve guides

50. Press up the valve guides with tool 999 2818.

Heat the cylinder head in 60°C (140°F) water.

21

52. Refit the valves.

1. Rubber ring

2. Upper valve washer

3. Collets

4. Valve springs

5. Valve stem seal (inlet)

6. Lower valve spring washer

Then refit the spark plugs.

NOTE! Make sure that the spark plug thread

screws in correctly so that the thread in the

aluminium cylinder head is not damaged. The

tightening torque is: 25–30 Nm (2.5–3.0 kpm)

(18.4–22.1 lbf. ft.)

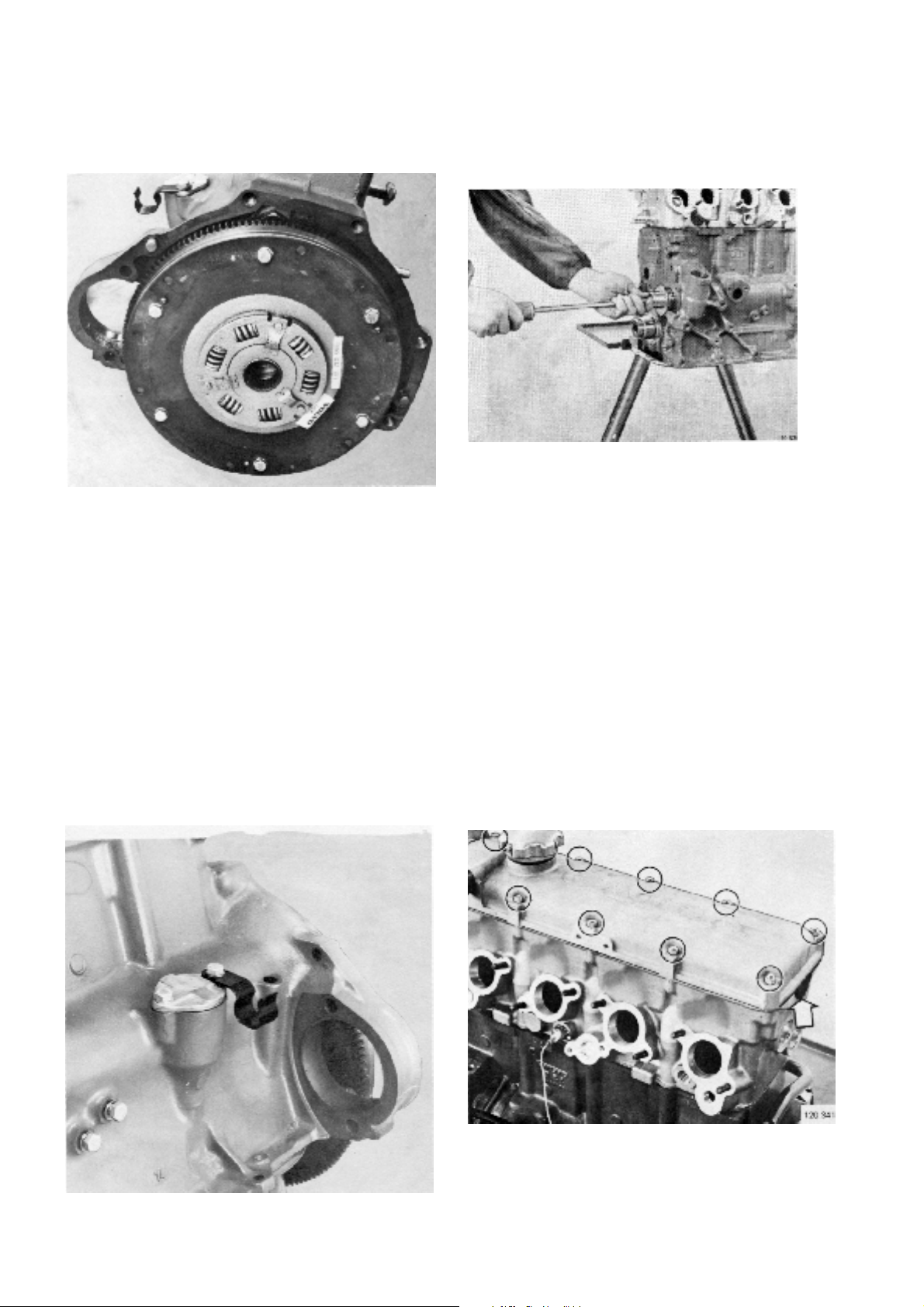

54. Remove the bearing for the input shaft. Use tool

999 4090. Remove the flywheel.

55. Remove the sealing flange. NOTE! Two screws

from the sump must also be removed.

53. Remove the locking ring for the bearing on the input shaft.

22

56. Remove the seal from the sealing flange with tool

999 2817.

57. Undo the screws and remove the oil sump. Then

remove the two screws in the lubricating oil pump

and lift out the pump with the pipe.

59. Note that the crankshaft and the crankshaft bearing caps are numbered. Then remove the bearing

caps and remove the bearing shells.

58. Remove the rubber ring for the oil pipe from the

cylinder block (And from the pipe where necessary).

60. Press out of the pistons from the cylinders. Let

the pistons fall on a soft surface so that they cannot be damaged. Then remove the piston rings.

Use piston ring pliers.

23

61. Remove the locking rings for the gudgeon pins

and press the gudgeon pins out.

63. Lift out the crankshaft and remove the bearing

shells from the block and the bearing caps.

62. Note that there are markings for the main bearing

caps. The bearing caps are marked 1–5 from the

transmission side. Remove the main bearing

caps.

CLEANING AND INSPECTION

64. Clean and carefully inspect the cylinder block.

The plugs for channels are to be removed before

cleaning. Re-fit the plugs after cleaning has been

completed. Tightening torque:

1/4 NPTF – 20 Nm (2 kpm) (14.7 lbf. ft.)

3/8 NPTF – 30 Nm (3 kpm) (22.1 lbf ft.)

24

65. Measure the cylinder liners with a special dial indicator. The measurement for greatest wear is

carried out immediately below top dead centre

and transverse to the engine. The measurement

for minimum wear is carried out at bottom dead

centre.

Standard cylinder diameter. AQ145

(C-marked): 96.00–96.01 mm (3.7795–3.7799 in.)

(D-marked). 96.01–96.02 mm (3.7799–3.7503 in.)

(E-marked): 96.02–96.03 mm (3.7803–3.7807 in.)

Oversize I

Standard cylinder diameter. AQ125

(D-marked): 92.01–92.02 mm (3.6224–3.6228 in.)

(G-marked): 92.03–92.04 mm (3.6232–3.6236 in.)

Oversize I: 92.500 mm (3.6417 in.)

: 96.300 mm (3.7973 in.)

II: 96.600 mm (3.8031 in.)

II: 93.000 mm (3.6614 in.)

Pistons

67. Measure the pistons with a micrometer at right

angles to the gudgeon pin hole and 6 mm (0.25")

from the lower edge.

Piston diameter standard. AQ145

(C-marked): 95.940–95.950 mm (3.7776–3.7780 in.)

(D-marked): 95.950–95.960 mm (3.7787–3.7791 in.)

(E-marked): 95.960–95.970 mm (3.7780–3.7783 in.)

(G-marked): 95.980–95.990 mm (3.7787–3.7791 in.)

Oversize I: (0.3–96.245): 96.237–96.252

(0.0118–3.7892): 3.7889–3.7894"

II: (0.6–96.545): 96.537–96.552

(0.0236–3.8010): 3.8007–3.8013"

Piston diameter standard. AQ125

(D-marked). 91.990–92.000 mm (3.6216–3.6220 m.)

(G-marked). 92.020–92.030 mm (3.6228–3.6232 in.)

Oversize I: (0.5–92.480): 92.474–92.492

(0.0196–3.6409): 3.6407–3.6414 in.)

II: (1.0–92.980): 92.977–92.992

(0.394–3.6606): 3.6605–3.6611 in.)

Classification marking

66. Each cylinder liner has a letter which indicates its

and pistons class.

Oversizes indicated by nominal diameter meas-

urement.

25

68. Piston play in cylinder: 0.05–0.07 mm (0.0020–

0.0028").

a. Piston diameter (A) is measured as stated

above.

b. The cylinder diameter is measuredat several

places crosswise to the engine and 30 mm

(1.2") (B) from block face and downwards to

bottom dead centre (C).

c. Calculate the piston’s maximum and minimum

clearances. (Deduct piston diameter to get cylinder liner’s maximum and minimum diameters).

70. Measure the piston ring gap with a feeler gauge.

Increase the gap with a special file where necessary.

The gap for AQ145 is to be:

Compression rings: 0.40–0.65 mm (0.0157–0.0256 in.)

Oil scraper ring: 0.30–0.60 mm (0.0118–0.0236 in.)

The gap for AQ125 is to be:

Compression rings: 0.35–0.55 mm (0.0138–0.0217")

Oil scraper ring: 0.25–0.40 mm (0.0098–0.0157")

Piston rings

69. Insert piston rings, one after the other, in the liner.

Use an inverted piston to fit the ring in the correct

position.

NOTE! When fitting in a worn cylinder liner, the

rings must be tested at bottom dead centre since

the cylinder liner diameter is at a minimum there.

71. Measure the piston ring gap by rolling the piston

rings in the groove. Check the play at several

points with a feeler gauge. The play is:

Compression rings: 0.040–0.072 mm (0.0016–0.0028")

Oil scraper ring: 0.030–0.062 mm (0.0012–0.0024")

26

72. Check the play of the gudgeon pin in the piston.

The play is correct when the gudgeon pin can be

pushed through with light hand pressure.

(Accurate running fit).

The gudgeon pins are available oversized 0.05

mm (0.0019"). If the gudgeon pin hole in the piston is worn so that an oversize gudgeon pin is

needed the hole is reamed to the correct dimension. Use a reamer with a guide ring and make

small cuts at a time.

74. Press in the new bushing with tool 999 5017.

75. The gudgeon pin is to slide through the hole with

light thumb pressure without any appreciable

looseness. (Sliding fit). The bush is machined if

necessary.

73. Press out the small end bush with tool 999 5017.

76. Check the connecting rods for straightness, tor-

sion and possible s-bends. Use a connecting rod

straightener. Nuts and screws are to be replaced

when overhauling.

27

Crankshaft

77. Check the big end bearings and main bearing.

Measurement with a micrometer is carried out at

several points around the circumference and

lengthwise. The ovality of the main bearing journals must not exceed 0.07 mm (0.0028") and on

the connecting rod journals 0.05 mm (0.0019").

The conicity should not be greater than 0.05 mm

(0.0019") for any of the journals. If the dimensions

lie in the vicinity of or exceed the stated values for

wear the crankshaft should be re-ground to the

nearest undersize. Suitable bearing shells are

available for two undersizes. See the technical

data.

Overhauling the oil cooler (AQ145)

78. Remove the centre screw (1) and remove the end

cover (2) and (3). Remove the O-rings (4) which

remain on the insert. Then press out the insert (5)

and be careful not to spill oil. Clean and blow through the insert with compressed air. Check that

there is free flow in the drain tap (6). Re-fit the insert in the housing and slide on the O-rings. (Replace O-rings where necessary). Re-fit the end

cover and tighten them with the centre screw. Replace the O-ring (7) if it is damaged. Check and

replace the O-ring (8) where necessary.

Overhauling the lubrication oil pump

79. Remove the pipe from the pump, remove the lock-

ing clamp and remove the strainer. NOTE! The

strainer cannot be disassembled on the later model.

28

80. Remove the four screws and remove the cover.

82. Check the spring for the pressure release valve.

Test data:

Length unloaded 47.6 mm (1.8740")

Length loaded with

44±4 N (4.4±0.4 kp)

(32.43±2.95 lbf.ft.) 32.0 mm (1.260")

Length loaded with

61±6 N (6.1±0.6kp)

(44.96±4.42 lbf.ft.) 26.0 mm (1.024")

81. Remove the spring, ball and gears. Clean all

parts and replace those damaged or worn.

83. Refit the gear wheels and check the gear flank

clearance which is 0.15–0.35 mm (0.0060–

0.014").

29

84. Check the axial clearance.

The axial clearance is 0.02–0.12 mm

(0.008–0.0047").

86. Refit the strainer and the locking clamp. (Applies

only to the earlier model).

85. Lay the ball and the spring in position and refit the

cover.

87. Fit new sealing rings and press the pipe into position in the pump.

30

Overhauling the heat exchanger.

88. Remove the two screws (1) and remove the strai-

ner housing (2) from the heat exchanger housing

(3). Discard the sealing rings (4) and (5). Then remove the four screws in the heat exchanger’s cover. Pull out the insert (6) and cover (7) from the

heat exchanger housing. Put the spacer ring (8) in

a safe place. Remove the cover from the insert.

NOTE! Remove the support ring (9) which can remain in the bottom of the housing. Remove the

bottom screw (10) on the insert. Discard the copper seal, the O-ring on the insert, the plain packing and the other sealing rings. Wash and rinse all

parts including the expansion tank. Check that the

insert’s channels are free from contamination. Use

compressed air. Change damaged parts. Assemble the heat exchanger in the opposite order,

see the picture. Use new sealing rings, a new

packing, a new copper washer, support ring and

O-rings.

NOTE! The cover for the seawater strainer is to be

lubricated on the inside. Remove the rubber

washer A and the sealing disc B. Distribute grease evenly with a brush on the inside of the cover.

Then replace the sealing disc and the rubber

washer and screw the cover in position.

Overhaul and inspection of carburetor

89. Remove the 4 screws (1) and lift off the upper part

of the carburetor.

31

90. Remove the gasket (1) and disassemble the

needle valve (2). Check that the needle valve

does not bind or is worn (does not seal). Replace

if necessary.

92. Disassemble the idling jet (1) and holder (2) for

the main jet. Unscrew the jet from the holder.

Blow the jets clean and replace if necessary.

Unscrew the mixing screw (3) and blow clean the

duct. Screw (4) locks tight the air cone (5).

91. Lift out the float tube and check that it is tight. If

the float is not tight the float level will be wrong.

Unscrew the emulsifying jet (1) and the acceleration jet (2). NOTE! The gasket. Check and clean

with compressed air. Replace worn or damaged

parts if necessary.

93. Rotate the throttle shaft (1) and press out the push

rod (2) from the lever (3). Then rotate the push rod

downwards and disassemble the check valve (4).

Blow the check valve clean and the strainer.

Clean and blow the carburetor and its ducts. Then

re-fit the check valve and strainer. NOTE! Do not

forget the copper washer. Rotate the throttle shaft

somewhat and press the push rod into the lever.

32

Assembling

94. Fit the idling jet (1), main jet (2)and mixing screw

(3). NOTE! Copper washer on the main jet. Then

fit the emulsifying jet (4), acceleration jet (5) and

gasket (6). Place the float in the float housing and

put on a new gasket (8) and screw on the upper

part of the carburetor housing. Loosen the nut (9)

and remove the levers. The spring can then be replaced.

Adjusting the idling screws:

AQ145A. Screw in the screw until it comes into

contact with the carburetor. Then screw it in a

further 3/4 turn.

AQ125A. 1 1/4 turn.

Adjusting the venting screws:

AQ145A. Screw the venting screw right in. Then

screw it out 1 turn.

AQ125A. 1 turn.

Overhauling the flywheel cover

95. Remove the sealing ring (1) in the flywheel cover.

Check the primary shaft (2) and the bearing (3). If

either one is damaged the lock rings (4) are to be

undone and the shaft with bearings is to be

pressed out. Remove the sealing ring (5) and remove the lock ring (6). Replace the damaged

parts and then fit the lock ring (6) on the primary

shaft and the sealing ring (5). Then press the

bearing brackets (3) on the primary shaft (2).

Press the shaft with bearing in the flywheel cover.

Fit the lock rings (4) and the sealing ring (1).

NOTE! Carefully lubricate the sealing rings before

they are fitted. Press grease into the lubricating

channel (7).

Assembling

96. Put the main bearing shells in position in the

block and the caps. If a spacer tube which has

been removed is to be refitted, it is to be reversed.

33

97. Fit the main bearing caps. NOTE! The main bearing caps are numbered 1–5 counted from the

transmission end. Oil the screws’ threads. Tighten

with a torque wrench. The tightening torque is

110 Nm (11 kpm), (80 ft.lbf.)

99. Refit the pistons and the connecting rods so that

the marks on the pistons point forward in the engine when the figure marking on the connecting

rods is turned towards the crankcase’s starboard

side (oil filter side). Fit the lock rings.

100. Fit the piston rings with piston ring pliers. The piston rings are to be fitted as shown in the picture.

The upper ring is chromium-plated. The lower

compression ring is marked “TOP”. Turn the piston ring so that the gaps are at an angle of 120°

from each other.

98. Check the axial clearance which is 0.037–0.147

mm (0.0014–0.0058").

101. Fit the bearing shells in the connecting rods and

the bearing caps. Oil the cylinder liners, pistons

and big end bearings. Check that the markings on

the pistons are directed towards the transmission

cover when the piston is fitted in the cylinder. Use

piston ring compressor.

34

102. Fit the big end bearings so that the markings on

the cap agree with markings on the connecting

rods. Oil the threads and tighten with a torque

wrench. The tightening torque is: 63 Nm (6.3

kpm). (46.4 lbf. ft.). NOTE! When fitting new

screws the tightening torque is 70 Nm (7.0 kpm).

(51.6 lbf. ft.). Then check that the crankshaft can

be turned.

104. Fit a new sealing ring in the rear sealing flange.

Use tool 999 2817. The sealing ring is to be

pressed in sufficiently so that a new wear surface

is obtained against the crankshaft. Then fit the sealing flange with a new seal against the engine.

Lubricate the seal’s rubber lip and the opposite

surface on the crankshaft before fitting. Great care

must be exercised so that the rubber lip is not

damaged by the edge of the crankshaft or turned

inside-out so that the spring jumps out of position.

Cut off protruding parts on the seal.

Oil pump

103. Fit a new sealing ring on the pipe for the oilpump.

Where necessary also change the sealing ring at

the other end of the pipe. Fit the pump. Make sure

that the seals are not damaged. The pump is to

mate properly with the crankcase before the

screws are tightened.

105. Protect the inside of the flywheel with Tectyl or

similar fluid and refit the flywheel. The tightening

torque is 70 Nm (7 kpm) (51.6 lbf. ft.). Fit the bearing for the ingoing shaft with tool 999 1426 and

then refit the washer and the lock ring for the

bearing.

35

106. Fit a new gasket for the sump on the crankcase.

Then replace the sump. Tighten all the screws

except the four nearest the front sealing flange.

The tightening force is 11 Nm (1.1 kpm) (8.1 lbf.

ft.). Carefully protect the primary shaft in the flywheel cover against rust. Then refit the vibration

damper and the flywheel cover and the protective

plate on the flywheel cover’s underside.

108. Lubricate the cylinder head screw threads and the

washers then fit and tighten the screws. The tightening force is 90 Nm (9 kpm) (66 lbf. ft.). The tightening is to be carried out in two stages.

1. 60 Nm (6 kpm) (44.2 lbf. ft.)

2. 90 Nm (9 kpm) (66 lbf. ft.).

The screws are to be re-torqued after the engine

has been warmed up and allowed to cool for 30

minutes. When retorquing, screws must first be

loosened sufficiently so that they turn when being

re-torqued. (Static friction must be overcome).

109. Oil the positions for the bearings on the camshaft.

Lay the camshaft in position in the cylinder head.

The pin (1) for the pulley is to be directed upwards.

Cylinder head

107. Clean the cylinder head surface carefully and fit a

new cylinder head gasket. Then refit the cylinder

head.

36

110. Oil and lay the bearing caps in position at the rear

end (guide bearings).

111. Fit tool 999 5021 and depress the camshaft.

112. Lubricate the camshaft seal’s rubber lip and fit it

on the camshaft. Be careful so that the rubber lip

is not damaged by the sharp edge when fitting it.

Fit the sealing ring so that a new wear surface

against the camshaft is obtained.

113. Oil and lay the other three bearing caps in position and fit the nuts for the four bearing caps.

Tighten them somewhat NOTE! The forward

bearing cap’s surface against the cylinder head

is to be painted with sealing fluid before it is

fitted. Make sure that the seals fit correctly before

the front bearing cap is tightened. Then remove

the tool.

114. Oil and fit the last bearing cap. Then tighten all

the nuts with a torque wrench. The tightening torque is 20 Nm (2.0 kpm) (14.7 lbf. ft.).

37

Transmission

115. Oil the intermediate shaft bearings.

117. Fit the front sealing flange (and positioning plate)

with a new gasket. The tightening torque is 10

Nm (1.0 kpm) (8.0 lbf. ft.). Then torque tighten the

screws for the sump. The tightening torque is 10

Nm (1.0 kpm) (8.0 lbf.ft.).

Then check the intermediate shaft’s axial clearance. The clearance is 0.20–0.46 mm (0.0079–

0.0181 in.).

116. Push the intermediate shaft in carefully in the

crankcase so that the intermediate shaft’s gear

wheel does not damage the bushings in the

block. Use tool 999 4030.

118. Fit the crankshaft seal with tool 999 5024. Lubricate the seal’s rubber lip before fitting. If the spacer tube on the crankshaft has not been removed

the position for the sealing ring is to be changed

so that a new contact surface against the tube is

obtained. Be careful when fitting the seal so that

the rubber lip is not damaged and that the spring

does not jump out of position.

38

119. Fit the intermediate shaft seal with tool 999 5025.

NOTE! Lubricate the seal’s rubber lip before fitting. Alter the sealing ring’s position in relation to

its earlier position so that a new contact surface

against the shaft is obtained. Be careful when fitting the seal.

121. Fit the screw, the guide plate and the washer and

tighten it with a torque wrench. Use tool 999 5034

as a counterforce. The tightening torque is 50 Nm

(5.0 kpm). (36.9 lbf. ft.).

120. Paint mineral grease or similar grease in the

flywheel’s hub and replace the flywheel and the

guide plate on the camshaft. The flywheel’s

groove is to be fixed on the guide pin on the

camshaft. NOTE! The guide plate’s bend is to

point backwards (against the seal).

122. Paint mineral grease or similar lubricant in the

pulley’s hub and fit it in position on the intermediate shaft. Fit the screw and tighten it with a torque

wrench.

The tightening torque is 50 Nm (5.0 kpm) (36.9

lbf. ft.). Use tool 999 5034 as a counterforce. Then

refit the cross piece.

39

123. Paint mineral grease or similar lubricant in the

hub on the crankshaft’s pulley. Position the guide

plate (turn the bend towards the seal) and fit the

pulley on the crankshaft. Then refit the outer plate

and the carrier and fit the screws. The tightening

torque is 165 Nm (16.5 kpm) (122 lbf. ft.). Use a

suitable counterforce.

125. Turn the intermediate shaft into position after

marking.

124. Turn the crankshaft into position after marking.

Nick on the inner guide plate.

126. Place the valve cover in position without the gasket. Check that the camshaft’s pulley’s marking

agrees with the marking on the valve cover.

Then check that the timing belt is in good condition. NOTE! Oil or grease must not be used on the

belt. Coloured marks (stripes) are on the belt so

that the adjustment can be checked. Line up the

mark with two stripes against the crankshaft

pulley’s marking and then the marking with one

stripe against the intermediate shaft pulley’s

marking and finally the marking with one stripe

against the camshaft pulley’s marking.

40

127. Then fit the belt tensioner carefully so that the belt

is not damaged. Turn the belt tensioner so that

the spring rod (1) can be pushed onto its shaft

and the guide pin (2) can be pushed into the hole.

Use no tools otherwise the belt can be damaged.

Fit a washer and tighten the nut.

129. Turn the crankshaft clockwise a few degrees.

This is to take up the backlash between the pulleys. NOTE! Do not turn the crankshaft

anti-clockwise otherwise the belt can hop over

teeth and alter the adjustment.

130. Loosen the nut on the belt tensioner againso that

the spring tensions the belt. Check that the belt

tensioner can move around its shaft. Then tighten

the nut again. The tightening torque is 50 Nm (5.0

kpm) (36.9 lbf. ft.). Then rotate until the marking

agrees for the crankshaft and check the marking

for the intermediate shaft and the camshaft. The

belt is to be tensioned once every season and to

be changed every 500 hours.

128. Compress the spring with a polygrip or similar

tool and then remove the pin which has held the

spring in the compressed position. Undo the nut

so that the spring tensions the belt. Then tighten

the nut.

41

131. Refit the crankshaft pulley on the carrier.

133. Fit a new O-ring on the cover for the oil pump

drive.

132. Fit the oil pump drive. It is possible that the

crankshaft (intermediate shaft) may need to be

turned somewhat so that the oil pump drive engages.

134. Fit the cover and the brackets for the cooling water pipe. NOTE! Check first that the cover’s pressure surface (which presses against the oil pump

drive) is not worn.

42

135. Fit a new rubber ring and gasket on the circulation pump. Fit the pump to the engine. Press the

pump upwards against the cylinder head and

tighten the screws and nuts.

Valve adjustment

137. Lift off the valve cover. Turn the camshaft to the

position for firing on No. 1 cylinder. Both the cams

for No. 1 cylinder point obliquely upward at equal

angles. The timing pulley’s timing position is 0°.

NOTE! Always turn on the crankshaft’s centre

screw.

136. Fit the cover (with the firing position marking).

138. Measure the valve clearance with a feeler gauge

for No. 1 cylinder.

Clearance when checking:

Cold engine: 0.25–0.45 mm (0.010–0.018 in.)

Hot engine: 0.30–0.50 mm (0.012–0.020 in.)

adjustment not necessary

Clearance when adjusting:

Cold engine: 0.35–0.40 mm (0.014–0.016 in.)

Hot engine: 0.40–0.45 mm (0.016–0.018 in.)

The clearance is the same for inlet and exhaust

valves.

43

139. If the clearance is incorrect the adjustment shims

are to be changed as follows: Turn the valve

pusher so that the groove is at right angles to the

camshaft’s length.

141. Remove the shim with pliers 999 5026.

140. Fit tool 999 5022 and depress the valve pressers.

Screw the tool spindle down and adjust its length

so that the presser’s groove lies over the edge

and is accessible with the pliers.

142. Measure the thickness of the shim with a micrometer. Calculate the thickness of the shim which

gives the right clearance.

Ex: Measured clearance: 0.30 mm, (0.012 in.),

correct clearance: 0.40 mm (0.016 in).

Clearance difference: –0.10 mm (0.004 in.).

Measured thickness on the existing shim:

3.80 mm (0.150 in.).

Correct thickness of the new shim:

3.80–0.10 = 3.70 mm. (0.150–0.004 = 0.146 in.).

44

143. The shims are available in different thickness between 3.55–4.20 mm (0.140–0.166 in.) at intervals

of 0.05 mm (0.02 in.).

NOTE! The shims are to be fitted with the marking

downwards. Complete valve adjustment set. Part

No. 884 516. (See page 61).

145. Remove tool 999 5022. Turn the cam position in

the position for firing on cylinder No. 3. Measure

the clearance with a feeler gauge and rectify

where necessary according to the instructions

above. Repeat the operations on cylinders No. 4

and 2 in the stated order.

144. Oil the new shim and lay it in position.

146. Check the clearance for all the valves. NOTE!

Turn the camshaft a few times before checking.

45

147. Place the gasket and crescent-shaped rubber

seal in position and fit the valve cover.

149. Remove the distributor cap.

Distributor

148. Turn the crankshaft to the firing position for No. 1

cylinder. Check this by unscrewing the oil filler

cap and seeing how the camshaft’s cams are positioned and by checking the marking on the pulley. See also point 138.

150. Turn the rotor so that the line on it is at 60° from

the line on the distributor.

46

151. Press the distributor into position in the crankcase

and check that the line on the rotor and the line on

the distributor housing are opposite each other.

Tighten the distributor in this position.

Replacing contact breakers

153. Remove the distributor cover (1), rotor(2) and the

washer (3). Then undo the screw (4) and the tab

connection (5) and then remove the contact

breakers. Fit a new breaker set. The contact breaking gap is 0.40 mm (0.016 in.). Change the condenser (6) at the time by undoing the screw (7).

Tighten a new condenser and connect the tab

connection and replace the washer. Press the rotor in position and refit the distributor cap.

NOTE! The cam angle is checked and adjusted

during test running. See “Technical Data”

152. Fit the distributor cover.

154. Fit the oil pressure sender (1). The tightening tor-

que is 12 Nm (1.2 kpm) (8.9 lbf. ft.). Lay a new

O-ring in the oil cooler’s groove and fit the oil cooler to the engine. Do not tighten the nut before the

cooling water pipe has been fitted. Only AQ145.

47

155. Place the screws in the exhaust pipe and hang

the gasket in position. NOTE! The marking “UT” is

turned outwards. Then fit the pipe to the engine. A

lifting eye is fixed with one of the screws.

157. AQ145. Fit the cooling water pipes (1) and (2) between the oil cooler and the exhaust pipe and

heat exchanger respectively. The cooling water

pipe for AQ125 is connected from the exhaust

pipe to the heat exchanger. It may be necessary

to undo the centre screw (3) in the oil cooler’s cover in order to align the cooling water pipes. Then

tighten all the screws. Tighten nut No. 4 as well.

Fit the engine mountings. Make sure that the rubber bush 5 on the cooling water pipe comes into

the right position.

156. Lay a sealing ring on the heat exchanger’s pipe

(1) and press the pipe into the circulation pump

and screw the heat exchanger to the exhaust

pipe.

158. Oil the lubricating oil filter’s rubber packing and

screw the filter in sufficiently so that the rubber

packing just comes into contact with the engine

body. Then screw it another half turn by hand.

Check the oil pressure and for leakage around

the oil filter during the first test run.

48

159. Fit the pulley on the circulation pump and then

the seawater pump.

161. Fit a spacer ring and two sealing rings on the expansion tank’s outgoing water pipe (1) and press

in the tank’s guide pin and pipes in the heat exchanger. The guide pin (2) is made of rubber. At

the same time check that the support screw (3)

has a plastic sleeve.

160. Fit the ingoing and outgoing cooling water pipes

to the salt water pump and press the ingoing pipe

into the bracket (1).

162. Place an O-ring (1) on the expansion tank and fit

the thermostat (2). When necessary the opening

temperature of the thermostat is checked by

lowering it in hot water. At a temperature of 82°C

(180°F) it must begin to open and must be fully

open at 92°C (198°F). Check that the rubber seal

(3) is not damaged when the thermostat is fitted.

NOTE! The forward lifting eye is fitted on the thermostat housing.

49

163. Connect the cables to the spark plugs.

165. Fit the fuel pump. Use new gaskets. Fit the tensio-

ning bar and the engine mounting with the

bracket for the alternator. Then tighten the alternator in position and fit and tension the belt so that it

can be depressed approximately 5 mm (0.2 in)

with normal thumb pressure.

164. AQ145. Lay the cover (1) on the heat exchanger

and slide over the rubber ring (2) so that the cover

is held in position. NOTE! The rubber ring is to be

turned with the marking “UP” upwards. Place the

strainer (3) properly cleaned as shown in the picture. Screw on the cover. NOTE! If the strainer is

incorrectly fitted the cover cannot be screwed in

position.

166. Fit the starter motor. The main fuse (1) is on the

starter motor’s front bracket. The picture below

shows the USA version.

50

167. Fit the oil dipstick sleeve in the crankcase.

NOTE! The bracket for the ignition coil is to be fitted on the flywheel cover’s upper side in the existing screw holes. (Screw diameter 5/16 UNC

length 19 mm) (3/4"). Then fit the ignition coil and

the cable loom. Connect all the cables and clamp

the cable loom in position.

168. Lay the gaskets for the induction pipe in position.

Fit the induction pipe with the lifting eye on the

rear studs. Tighten the nuts with a torque of 20

Nm (2 kpm) (14.8 lbf. ft.). Fit the oil dipstick sleeve

in the induction pipe.

170. Fit the fuel pipe between fuel pump and the carburetor. Make sure that all sealing washers are

fitted.

171. AQ145. Fit the rubber rings and place the air filter

on the carburetors and also fit the induction silencer.

AQ125. Fit the rubber ring, the air filter and the

cover on the carburetor. Connect the hose (1)

between the fuel pump and the carburetor. Even

AQ145.

169. AQ145. Fit the carburetors to the induction pipe.

Fit the throttle rod between the carburetors. Use

new gaskets.

AQ125. Fit the carburettor to the induction pipe.

Use new gasket. NOTE! On engines having main

jet (165) and venturi jet (190) installed, a spacer

washer with a gasket on each side must be installed between the carburetor and the inlet manifold.

172. Close all drain cocks. Replenish the oil and the

water in the engine. See the instruction book for

oil quality and viscosity.

Test run the engine and carry out all the necessary checks which are stated for delivery service

in the warranty certificate.

51

ELECTRIC WIRING DIAGRAM

Cable marking

INSTRUMENT PANEL ENGINE

Position list

1. Key switch with start

button

2. Switch for instrument

lighting

3. Temperature gauge

4. Oil pressure warning lamp

5. Tachometer

6. Charging warning light

7. Switch (extra)

8. Junction box

9. Battery

10. Main switch

11. Starter motor

12. Charging regulator

13. Alternator

14. Fuse

15. Oil pressure sender

16. Temperature sender

17. Ignition coil

18. Distributor

USA-Execution

Design. AWG Colour mm

A 9 Ivory 6

B 15 Black 1.5

B' 19 Black 0.6

C 9 Red 6

C' 13 Red 2.5

C'' 1 R ed 35

D 13 Green 2.5

D' 15 Green 1.5

D'' 19 Green 0.6

E 15 Grey 1.5

F 15 Yellow 1.5

G 15 Brown 1.5

H 15 Blue 1.5

H' 11 Blue 4

2

52

Cable marking

USA-Execution see page 53

Fault finding chart

Engines

does not

start

X

X

X

X

X

Engine

stops

X

X

X

X

Engine does not

reach correct

speed at full

throttle or engine

knocking

X

X

Engine runs

unevenly or

vibrates

abnormally

X

X

X

Engine

becomes

abnormally

hot

CAUSE

Main switch not connected; discharged

battery, break in electrical cables or main

switch.

Empty fuel tank fuel cock closed, blocked

fuel filter.

Water or contamination in the fuel.

Defective spark plugs.

Burnt contact breakers, moisture in the

distributor and ignition cables.

Idling speed not correctly adjusted.

Defective tachometer.

Cable Colour Code

Marking Colour mm

A Red 10.6

A' Red 5.3

B Light blue 1.3

C Orange 5.3

D Light brown 1.3

E Black 5.3

E' Black 1.3

F Yellow/red 5.3

stripes

G Dark red 1.3

H Grey 1.3

I Light yellow 1.3

J Dark blue 1.3

K Black 42.4

L R ed 42.4

X

X

X

X

X

2

SW, Ignition switch: I = IGN, B = BAT, S = SOL

Bosch, Ignition switch: I = 15, 75, B = 30 S = 50

1) Hour meter or fuel gauge

2) Fuses

Boat abnormally loaded.

Weed growth on the boat hull and on the

outboard drive.

Damaged propeller.

Blockage in the cooling water intake, oil

cooler (AQ145), cooling jackets, heat exchanger. Defect impeller or thermostat fluid level too low in the expansion tank.

The fuel quality is not corresponding to the

ignition setting.

53

Special tools

884580 Valve spring compressor.

9991426 Drift for fitting ball bearing in flywheel.

9992817 Drift for fitting crankshaft oil seal on

engine rear end.

9992818 Drift for removing valve guide.

9994090 Puller for ball bearing in flywheel.

9995017 Drift for removing and fitting bushing in

connecting rod.

9995021 Press tool for removing and fitting

crankshaft.

9995022 Tool for pressing down valve lifters.

54

9995023 Fixture for stand.

9995024 Drift for fitting crankshaft oil seal.

9995025 Drift for fitting intermediary shaft oil seal

9995026 Tool for adjusting spacer.

9995027 Drift for fitting valve guide (intake).

9995028 Drift for fitting valve guide (exhaust).

9995034 Counterhold for camshaft and inter-

mediary

55

Technical Data

AQ145A, AQ125A

General

Type designation .................................................................. AQ145A AQ125A

Type of operation .................................................................. 4 stroke overhead

Max. effekt

Max. speed........................................................................... 91.7 r/s (5500 r/m) 80 r/s (4800 r/m)

Max. cruising speed.............................................................. 5–8 r/s (300–500 r/m)

Compression ratio................................................................. 9.7:1 9.3:1

Compression pressure at starter motor speed ...................... 10–12 kp/cm

No. of cylinders..................................................................... 4 in line

Bore ................................................................................... 96 mm (3,7795 in.) 92 mm (3,622 in.)

Stroke................................................................................... 80 mm (3.150 in.)

Displacement........................................................................ 2.315 dm

Weight incl. drive without oil and water, approx. .................... 245 kg (529 lb.)

Idling speed .......................................................................... 15 r/s (900 r/m)

CYLINDER BLOCK

Material ................................................................................. Cast iron

Bore, standard ...................................................................... 96.00–96.03 mm 92.01–92.02 mm

Bore, oversize 1 ................................................................... 96.300 mm (3.7913 in.) 92.500 mm (3.6417 in.)

Bore, oversize 2 ................................................................... 96.600 mm (3.8031 in.) 93.000 mm (3.6614 in.)

1)

kW.................................................................... 99 (135 hp) 84 (115 hp)

(below max. speed reached)

2

(146–174 lbf./in.2)

3

(141.271 cu.in.) (129.798 cu.in.)

2)

2.127 dm

240 (529 lb.)

(3.7795–3.7897") 3.6224–3.6228 in.)

3

2)

PISTONS

Material ................................................................................. Light alloy

Height total............................................................................ 80.4 mm (3.165 in.) 71.0 mm (2.795 in.)

Height from gudgeon pin centre to piston top ........................ 46.4 mm (1.8268 in.) 46.0 (1.811 in.)

Piston clearance ................................................................... 0.05–0.07 mm 0.01–0.03 mm

(0.0020–0.0028 in.) (0.0004–0.0012 in.)

Piston, standard size ............................................................ 95.940–95.990 mm 91.991–92.000 mm

(3.7772–3.7791 in.)

3)

(3.6217–3.6220 in.)

Piston, oversize 1 ................................................................. 96.237–96.252 mm 92.472–92.487 mm

(3.7889–3.7894 in.) (3.6406–3.6412 in.)

Piston oversize 2 .................................................................. 96.537–96.552 mm 92.972–92.978 mm

(3.8007–3.8013 in.) (3.6603–3.6605 in.)

PISTON RINGS

Piston ring gap measures in the opening of the ring (oil rings) 0.30–0.60 mm 0.25–0.40 mm

'' (compression ring) 0.40–0.65 mm 0.35–0.55 mm

Piston ring oversize 1 ........................................................... 0.3 mm (0.0118 in.) 0.5 mm (0.0197 in.)

Piston ring oversize 2 ........................................................... 0.6 mm (0.0236 in.) 1.0 mm (0.0394 in.)

Compression rings

Top ring chromed. Lower ring marked “TOP”

Number on each piston ......................................................... 2

Height upper ......................................................................... 1.728–1.740 mm 1.978–1.990 mm

Height lower.......................................................................... 1.978–1.990 mm 1.978–1.990 mm

Piston ring clearance in groove, upper .................................. 0.060–0.092 mm 0.040–0.072 mm

Piston ring clearance in groove, lower................................... 0.040–0.072 mm 0.040–0.072 mm

(0.0118–0.0236 in.) (0.0098–0.0157 in.)

(0.0157–0.0256 in.) (0.0138–0.0217 in.)

(0.0680–0.0685 in.) (0.0779–0.0783 in.)

(0.0779–0.0783 in.) (0.0779–0.0783 in.)

(0.0024–0.0036 in.) (0.0016–0.0028 in.)

(0.0016–0.0028 in.) (0.0016–0.0028 in.)

4)

1)

Max. flywheel output acc. to SAE J-607.

2)

With Power Trim, 275 (606).

3)

See parts catalogue AQ145.

4)

See parts catalogue AQ125.

56

AQ145A AQ125A

Oil rings

Number on each piston ......................................................... 1

Height ................................................................................... 3.975–3.990 mm 3.978–3.990 mm

Piston ring clearance in groove ............................................. 0.030–0.065 mm 0.030–0.062 mm

(0.1565–0.1571 in.) (0.1566–0.1571 in.)

(0.0012–0.0026 in.) (0.0012–0.0024 in.)

GUDGEON PINS

Fully floating. Circlips at both ends in piston

Fit. Connecting rod................................................................ Push fit

Fit. In piston .......................................................................... Close running fit

Diameter, standard ............................................................... 24.0 mm (0.9449 in.)

Dimension oversize .............................................................. 24.05 mm (0.9469 in.)

CRANKSHAFT

Crankshaft end float.............................................................. 0.037–0.147 mm (0.0015–0.0058 in.)

Main bearings, radial clearance............................................. 0.028–0.083 mm (0.0011–0.0033 in.)

Big-end bearings, radial clearance ........................................ 0.024–0.070 mm (0.0009–0.0028 in.)

MAIN BEARINGS

Main bearing journals

Diameter, standard ............................................................... 63.45–63.46 mm (2.4980–2.4984 in.)

0.25 mm (0.0100 in.) undersize ............................................. 63.20–63.21 mm (2.4882–2.4886 in.)

0.50 mm (0.0200 in.) undersize ............................................. 62.95–62.96 mm (2.4783–2.4787 in.)

Main bearings

Diameter, standard ............................................................... 63.49–63.52 mm (2.4996–2.5008 in.)

0.25 mm (0.0100 in.) undersize ............................................. 63.24–63.27 mm (2.4898–2.4909 in.)

0.50 mm (0.0200 in.) undersize ............................................. 62.99–63.02 mm (2.4799–2.4811 in.)

BIG-END BEARINGS

Big-end bearing journals

Width of bearing recess ........................................................ 24.75–24.85 mm (0.9744–0.9783 in.)

Diameter, standard ............................................................... 53.99–54.00 mm (2.1255–2.1260 in.)

0.25 mm (0.0100 in.) undersize ............................................. 53.74–53.75 mm (2.1157–2.1161 in.)