Page 1

Workshop Manual

EGC Diagnostics

4.3GXi-F(F), 4.3OSi-F(F)

5.0GXi-F(F), 5.0OSi-F(F)

5.7Gi-F(F), 5.7GXi-G(F)

5.7OSi-E(F), 5.7OSXi-E(F)

8.1Gi-G(F), 8.1GXi-F(F), 8.1OSi-C(F)

C

2(0)

Page 2

Copyright © 2006 Volvo Penta of the Americas, Inc. All rights reserved. This manual may not be copied, photocopied, reproduced, or converted to any electronic or machine-readable form in whole or in part without the express

written consent from Volvo Penta of the Americas, Inc.

Page 3

General Information . . . . . . . . . . . . . . . . . . . 1

System Description . . . . . . . . . . . . . . . . . . 29

Volvo Penta Diagnostic Scan Tool . . . . . . 35

Symptoms . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . 76

ECM Limits . . . . . . . . . . . . . . . . . . . . . . . . 305

Vodia Index by Number . . . . . . . . . . . . . . 310

VPA 7746872 English 2006-10

Page 4

VPA 7746872 English 2006-10

Page 5

Section 1: General Information

Intake Manifold Vacuum Testing . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Gasoline Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Gasoline Containing Alcohol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Crankcase Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Off-Season Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Prepare a storage mixture . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Change Motor Oil and Oil Filter . . . . . . . . . . . . . . . . . . . . . . . . 13

Change Sterndrive Lubricant . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Drain Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Preparation for Boating After Storage . . . . . . . . . . . . . . . . . . . . 15

Engine Break-in . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Submerged Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

General Information

20-Hour Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Belt Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Positive Closed-Type Ventilation System . . . . . . . . . . . . . . . . . . 19

5.0L and 5.7L engines only . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Troubleshooting - System Isolation . . . . . . . . . . . . . . . . . . . . . . 20

Engine Troubleshooting Guides . . . . . . . . . . . . . . . . . . . . . . . . . 21

Engine Will Not Crank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Engine Cranks, But Will Not Start . . . . . . . . . . . . . . . . . . . . . . 22

Hard Starting - Cold Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Hard Starting - Hot Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Engine Runs Rough . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Engine Noises and Vibrations . . . . . . . . . . . . . . . . . . . . . . . . . 24

Engine Overheats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Engine Dies Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Engine Won’t Reach Operating RPM . . . . . . . . . . . . . . . . . . . 25

Defective Engine Lubricating System . . . . . . . . . . . . . . . . . . . 26

Low Battery Voltage After Short Storage . . . . . . . . . . . . . . . . 26

Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

This service manual is divided into sections concerning various systems and assemblies. Refer to the Contents to locate the section covering the system or assembly requiring service. Each section title page

has an additional listing that will describe the sections contents in

more detail. Be sure to read the Safety Section at the end of this man-

ual, and pay special attention to all safety warnings as they appear

throughout the text. Since models are subject to change at any time,

some photos may not depict actual product.

VPA 7746872 English 2006-10 1

Page 6

General Information

Good Service Practice Service required for the engine and sterndrive is generally one of three

kinds:

• Normal care and maintenance - which includes putting a new

engine and stern drive into operation, storing, lubrication, and

care under special operating conditions such as salt water and

cold weather.

• Operating malfunctions - due to improper engine or drive

mounting, propeller condition or size, boat condition, or the malfunction of some part of the engine. This includes engine servicing procedures to keep the engine in prime operating condition.

• Complete disassembly and overhaul - such as major service

or rebuilding a unit.

It is important to determine before disassembly just what the trouble is

and how to correct it quickly, with minimum expense to the owner.

When repairing an assembly, the most reliable way to ensure a good

job is to do a complete overhaul on that assembly, rather than just to

replace the bad part. Wear not readily apparent on other parts could

cause malfunction soon after the repair job. Repair kits and seal kits

contain all the parts needed to ensure a complete repair, to eliminate

guesswork, and to save time.

Repair time can also be minimized by the use of special tools. Volvo

Penta special tools are designed to perform service procedures

unique to the product that cannot be completed using tools from other

sources. They also speed repair work to help achieve service flat rate

times. In some cases, the use of substitute tools can damage the part.

Preparation for Service Proper preparation is extremely helpful for efficient service work. A

clean work area at the start of each job will minimize tools and parts

becoming misplaced. Clean an engine that is excessively dirty before

work starts. Cleaning will occasionally uncover trouble sources. Obtain

tools, instruments and parts needed for the job before work is started.

Interrupting a job to locate special tools or repair kits is a needless

delay.

Caution!

Use proper lifting and handling equipment. Working on

stern drives without proper equipment can cause damage

and personal injury.

Always use clean fresh fuel when testing engines. Troubles can often

be traced to the use of old or dirty fuel.

Service Policy It is a Volvo Penta policy to provide dealers with service knowledge so

they can give professional service demanded by today’s consumer.

The Volvo Penta Training Centers, frequent mailing of Service Bulletins, Letters and Promotions, Special Tools, Partner Network, and this

Service Manual represent the latest effort to assist dealers in giving

consumers the best and most prompt service possible. If a service

question does not appear to be answered in this manual, you are

invited to contact the Volvo Penta Service Department by calling or

through Partner Network for additional help. Always be sure to give

complete information, including engine model number and serial number.

2 VPA 7746872 English 2006-10

Page 7

General Information

Replacement Parts Warning!

When replacement parts are required, always use genuine

Volvo Penta parts, or parts with equivalent characteristics, including type, strength, and material. Failure to do

so may result in product malfunction and possible injury

to the operator and/or passengers.

Parts Catalogs Parts Catalogs and the electronic parts catalog (EPC) contain

exploded views showing the correct assembly of all parts, as well as a

complete listing of the parts for replacement. These catalogs are helpful as a reference during disassembly and reassembly, and are available from Partner Network and Volvo Penta Parts.

Special Service Tools Volvo Penta has specially designed tools to simplify some of the disas-

sembly and assembly operations. These tools are illustrated in this

Service Manual, in many cases in actual use. All special tools can be

ordered from Volvo Penta Parts. Individual purchasers of Service

Manuals must order Special Tools through an authorized dealer.

Product References, Illustrations &

Specifications

Volvo Penta reserves the right to make changes at anytime, without

notice, in specifications and models and also to discontinue models.

The right is also reserved to change any specifications or parts at any

time without incurring any obligation to equip same on models manufactured prior to date of such change. All information, illustrations and

specifications contained in this manual are based on the latest product

information available at the time of printing. The right is reserved to

make changes at anytime without notice.

All photographs and illustrations used in this manual may not depict

actual models or equipment, but are intended as representative views

for reference only. The continuing accuracy of this manual cannot be

guaranteed.

The purpose of an engine tune-up is to restore power and performance that has been lost through wear, corrosion or deterioration of

one or more parts or components. In the normal operation of an

engine, these changes can take place gradually at a number of points,

so that it is seldom advisable to attempt an improvement in performance by correction of one or two items only. Time will be saved and

more lasting results will be obtained by following a definite and thorough procedure of analysis and correction of all items affecting power

and performance.

Economical, trouble-free operation can better be ensured if a complete

tune-up is performed once every year, preferably in the spring. Components that affect power and performance can be divided into three

groups:

• Components affecting compression

• Components affecting ignition

• Components affecting fuel system

Tuning the Engine Tune-up procedures should cover these groups in the order given.

While the items affecting compression and ignition may be handled

according to personal preference, correction of items in the fuel system group should not be attempted until all items affecting compres-

VPA 7746872 English 2006-10 3

Page 8

General Information

Engine Compression Testing During all work done around the engine, while the engine is running or

sion and ignition have been satisfactorily corrected. Most of the

procedures for performing a complete engine tune-up will be covered

in greater detail in this manual. This section will deal mainly with the

order of procedures involved in tuning the engine.

being cranked, use extreme care to avoid getting fingers or clothing

caught in any belts, pulleys, or other moving parts.

2. Visually inspect stern drive unit for leaks, missing parts or other

obvious defects. Replace deteriorated parts.

3. Compression check: Proper compression is essential for good

engine performance. An engine with low or uneven compression

cannot be properly tuned.

• Operate engine to normal operating temperature.

Caution!

Engine must not be started and run without water for cooling.

• Remove any foreign matter from around spark plugs by blowing

out with compressed air.

• Remove and inspect all spark plugs. Install thread-type compression gauge in spark plug hole.

• Set the Volvo Penta Scan tool to “ECM TESTS” and select

“COMPRESSION TEST” before cranking the engine.

Caution!

This test commands the ECM to disable all spark and fuel

injector outputs. The test must be properly exited from the

Scan Tool to re-enable normal spark and fuel operation.

DO NOT perfrom this test in open water. Always perform

this test dockside or on a trailer. The engine will be disabled until the test is properly exited.

If the scan tool is disconnected during the COMPRESSION TEST, the engine will remain disabled until the scan

tool is reconnected and the COMPRESSION TEST mode is

exited properly. Refer to the documentation that comes

with the Scan tool for further information on Scan tool

operation.

Test Conclusion The indicated compression pressures are considered normal if the

lowest reading cylinder is within 75% of the highest.

Example:

If the highest pressure reading was 140 PSI, 75% of 140 is 105.

Therefore, any cylinder reading less than 105 PSI indicates an improperly seated valve, worn valve guides, piston, cylinder, or worn or broken piston rings. Any cylinder reading 105 PSI or greater is within

specifications, and compression is considered normal.

4 VPA 7746872 English 2006-10

Page 9

General Information

If one or more cylinders read low, squirt approximately one tablespoon

of engine oil on top of the pistons in the low reading cylinders. Repeat

compression pressure check on the cylinders.

1. If compression improves considerably, the piston rings are at fault.

2. If compression does not improve, valves are sticking or seating

poorly, or valve guides are worn.

3. If two adjacent cylinders indicate low compression pressures and

squirting oil on the pistons does not increase the compression, the

cause may be a cylinder head gasket leak between the cylinders.

This problem could allow engine oil and/or coolant to enter the cylinders. It is recommended the following quick reference chart be

used when checking cylinder compression pressures. The chart

has been calculated so that the lowest reading number is 75% of

the highest reading.

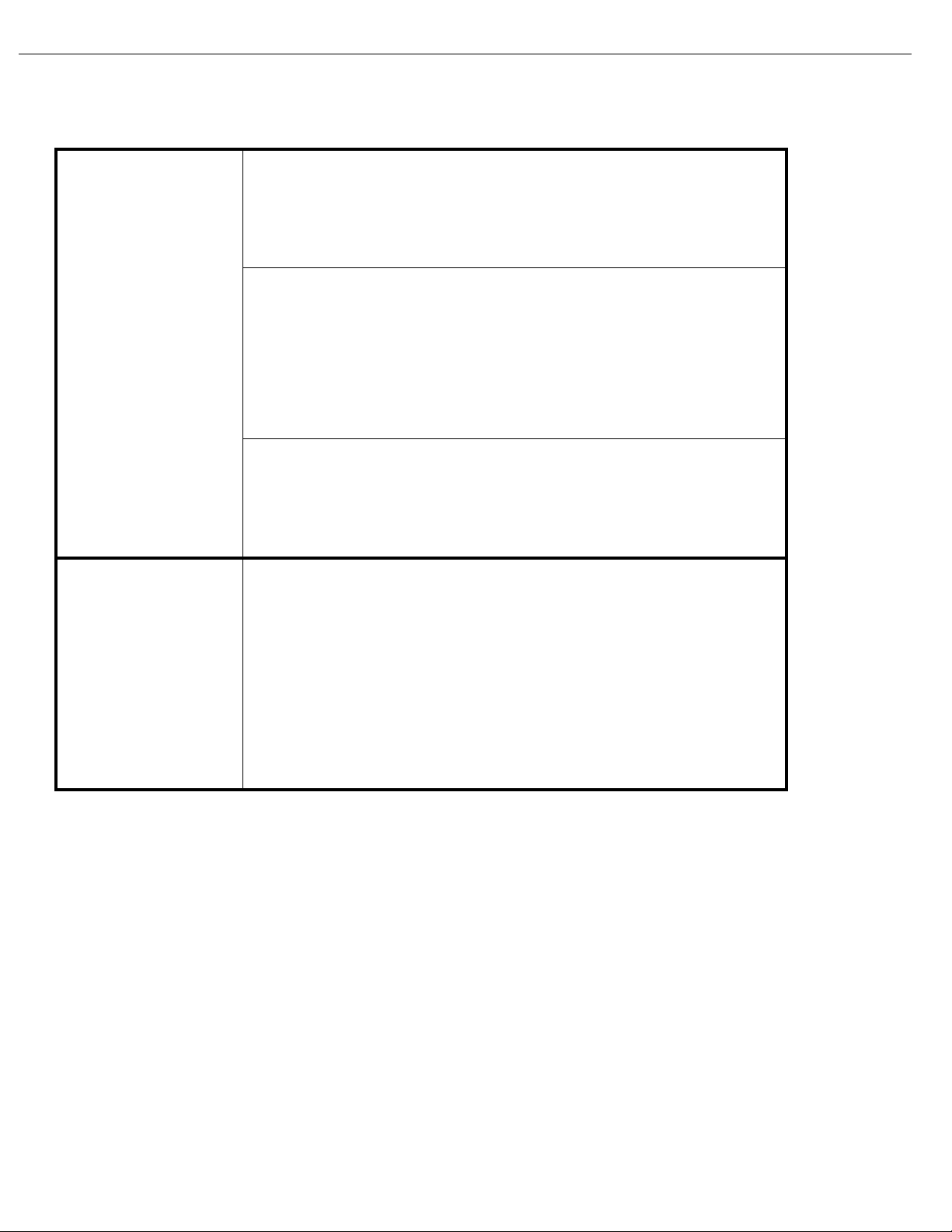

Table 1: Compression Pressure Limit

Max. PSI Min. PSI Max. PSI Min. PSI Max. PSI Min. PSI Max. PSI Min. PSI

134 101 154 115 174 131 194 145

136 102 156 117 176 132 196 147

138 104 158 118 178 133 196 148

140 105 160 120 180 135 200 150

142 107 162 121 182 136 202 151

144 108 164 123 184 138 204 153

146 110 166 124 186 140 206 154

148 111 168 126 188 141 208 156

150 113 170 127 190 142 210 157

152 114 172 129 192 144 212 158

After checking cylinder compression, repairs should be made as necessary. Subsequent adjustments to an engine that does not have

proper compression will not measurably improve performance or correct operational problems. After verifying compression, check ignition

and fuel system components.

Ignition System Components •Spark Plugs

• Spark Plug Leads

• Distributor Cap

• Rotor

• Ignition Coil

• High Tension Lead

• Ignition Switch

• Circuit Wiring and Connectors

Fuel System Components • Fuel Tank Pickup and Screen

VPA 7746872 English 2006-10 5

Page 10

General Information

• Fuel Tank Vent

• Anti-Siphon Valve (if equipped)

• Fuel Octane and Quality

• Boat Fuel Lines and Valves

• External Engine Fuel Filter

• Fuel Pump(s) and Line

• Engine PCV Valve

• Flame Arrestor

All of the above listed components are not necessarily part of an

engine tune-up, but must be considered when attempting to correct

engine/boat performance problems. Repair or replace components

only as required.

Warning!

Do not substitute automotive parts. Volvo Penta marine

components meet U.S. Coast Guard regulations for external ignition proof operation and marine use. Volvo Penta

marine components are specially designed not to cause

ignition of fuel vapors in the bilge or engine compartment.

The use of automotive parts can result in fire and explosion.

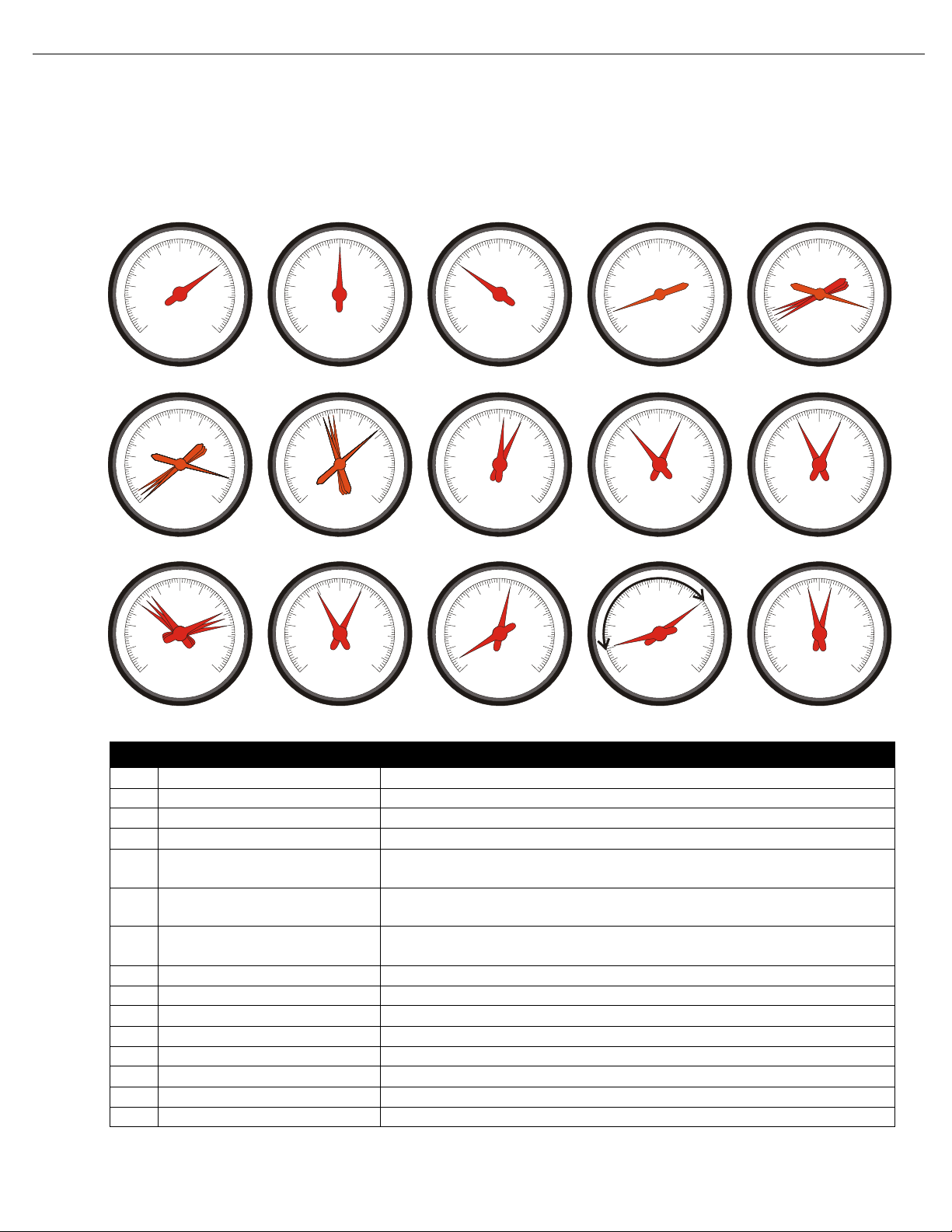

Intake Manifold Vacuum Testing

Test Procedures 1. Install a vacuum gauge to a good intake manifold source (usually

2. Observe the vacuum gauge while operating the engine over a

Test Results

1. A steady vacuum reading between 14 and 19in. Hg. (47-64 kPa)

2. A vacuum reading below 14 in. Hg. (47 kPa) at idle, indicates an

3. Possible causes of low intake manifold vacuum are late ignition

4. If the gauge fluctuates at idle, possible causes are sticking or leak-

5. If the gauge fluctuates at idle but smooths out as engine RPM

6. If the gauge fluctuates more with increases engine RPM, check for

7. If the vacuum gauge fluctuates regularly with each engine cycle,

at the PCV valve port), following the gauge manufacturer’s instructions. Start and warm up the engine.

range of engine speeds.

at idle indicates an engine in good mechanical condition.

engine that is not developing enough vacuum. Further testing for

base mechanical problems is needed.

timing, low compression, poor engine sealing, leaks at vacuum

lines and connections or bad MAP sensor.

ing valves, or an ignition miss.

increases, check for bad valves or camshaft.

weak or broken valve springs, bad valves, ignition miss, or a leaking head gasket.

check for a bad valve.

6 VPA 7746872 English 2006-10

Page 11

General Information

10

15

10

15

30

15

30

10

15

25

30

10

10

15

30

15

25

10

25

15

20

30

15

20

30

30

20

25

10

25

30

10

O

8. If the vacuum reading drops steadily as engine RPM increases,

check the exhaust system between the engine and vertical drive

for restrictions.

9. See table and chart below and on the following page for more

information.

15

10

5

0

10

5

0

20

25

30

In./Hg.

15

20

25

30

In./Hg.

15

10

5

0

10

5

0

20

25

30

In./Hg.

15

20

25

30

In./Hg.

15

10

5

0

10

5

0

20

25

30

In./Hg.

15

20

25

30

In./Hg.

15

10

5

0

10

5

0

20

25

30

In./Hg.

15

20

25

30

In./Hg.

FGH I

15

10

5

0

20

25

30

In./Hg.

15

10

5

0

20

25

30

In./Hg.

15

10

5

0

20

25

30

In./Hg.

15

10

5

0

20

25

30

In./Hg.

15

10

5

0

20

25

30

In./Hg.

EABCD

15

10

5

0

20

25

30

In./Hg.

J

15

10

5

0

20

25

30

In./Hg.

K

Pos Condition Reading

A Normal at Idle 14-19 in. Hg. (47-64 kPa)

B Late Ignition Timing 11-17 in. Hg. (37-57 kPa)

C Late Valve Timing 8-15 in. Hg. (27-50 kPa).

L

MN

D Intake Leak Low but steady reading

E Normal Acceleration Drops to 2 then rises to 25 when throttle is rapidly increased and

decreased.

F Worn Rings Drops to 0, then rises to 22 when throttle is rapidly increased and

decreased

G Sticking Valve(s) Normally steady, intermittently flicks downward approx. 4 in. Hg. (13 kPa)

from highest level.

H Leaking Valve Drops 2 in. Hg. (6 kPa) from highest reading.

I Burned or Warped Valve Evenly spaced down-scale flicker approximately 5 in. Hg (17 kPa).

J Worn Valve Oscillates Approximately 4 in. Hg. (13 kPa).

K Weak Valve Springs Violent oscillations as RPM increases.

L Improper Idle Mixture Floats slowly between 13-17 in. Hg. (44-57 kPa)

M Restricted Exhaust Normal when first started. Drops to approx. 0 as RPM increases

N Head Gasket Leak Floats between 5-20 in. Hg. (17-68 kPa)

O Defective Ignition Component Slight float between 14-16 in. Hg. (47-54 kPa)

VPA 7746872 English 2006-10 7

Page 12

General Information

Gasoline Requirements

DANGER!

Gasoline is extremely flammable and highly explosive

under certain conditions. Always stop engine and do not

smoke or allow open flames or sparks near the boat when

refuelling gas tanks. When filling the gas tank, ground the

tank to the source of gasoline by holding the hose nozzle

firmly against the side of the deck filler plate, or ground it

in some other manner. This action prevents static electricity buildup which could cause sparks and ignite fuel

vapors.

USE ONLY UNLEADED FUEL. Use lead-free gasoline with the fol-

lowing minimum or higher octane specification:

Inside the U.S.: (R+M)/2 (AKI) = 87

Outside the U.S.: (RON) = 90

If fuels with 89 AKI pump posted (93 RON) octane number or higher

are used an increase in power can be expected with EFI models.

Premium fuels contain injector cleaners and other additives that protect the fuel system and provide optimum performance.

Gasoline Containing Alcohol

Caution!

Engine damage resulting from the use of gasoline with

octane 86 AKI (89 RON) and lower is considered misuse of

the engine and will void the engine warranty. Vol vo Pe nta

suggests the use of 89 AKI or higher fuels. These fuels

have additives that are beneficial to maximum engine performance and long life of service components.

To prevent gum formation and corrosion in the fuel system, use a

Marine Fuel Stabilizer in the gasoline.

Many brands of gasoline being sold today contain alcohol. Two commonly used alcohol additives are Ethanol (ethyl alcohol) and Methanol

(methyl alcohol).

Caution!

Do not use any gasoline which contains Methanol (methyl

alcohol).

See the boat’s Operators Manual to determine if the boats fuel system

is compatible with alcohol blended fuels. If it is, your engine may use

gasoline blended with no more than 10% Ethanol (ethyl alcohol) meeting the minimum octane specification. Do not use any gasoline which

contains METHANOL (methyl alcohol).

Continued use of METHANOL (methyl alcohol) fuel will cause serious

damage to the fuel system.

If you use gasoline containing alcohol, be aware of the following:

8 VPA 7746872 English 2006-10

Page 13

Crankcase Oil

General Information

• ïThe engine will operate leaner. This may cause engine problems such as vapor lock, low speed stalling, or hard starting.

• ïAlcohol blended fuels attract and hold moisture. Moisture can

cause fuel tank corrosion. Inspect fuel tanks at least annually.

Replace corroded or leaking fuel tanks.

• ïFrequently inspect non-metallic parts of fuel system and

replace if excessively stiff, deteriorated or leaking.

Fuel leakage can contribute to a fire and/or explosion.

Initial factory fill is a high quality motor oil for API Service SJ. During the

break-in period (20 hours), frequently check the oil level. Somewhat

higher oil consumption is normal until piston rings are seated. The oil

level should be maintained in the safe range between the Add and Full

marks on the dipstick. This range represents approximately 1 litre (1

quart). If it is necessary to add or change the motor oil, use a quality oil

with API service category SJ.

At the end of the break-in period (20 hours), change the crankcase oil

and replace the oil filter. Refer to Lubrication and Inspection Chart

for recommended oil change intervals.

Draining and Filling the Engine

Crankcase

NOTE! The use of multi-viscosity oils, such as 10W-30 or 10W-40,

is not recommended.

If using Volvo Penta Premium Synthetic Engine Oil, drain and refill

crankcase every 200 hours of operation or once a year, whichever occurs first.

If using oil other than Volvo Penta Premium Synthetic Engine Oil, drain

and refill crankcase every 100 hours of operation or once a year, whichever occurs first.

DANGER!

To prevent fire and explosion, always make sure engine

compartment is free of gasoline fumes before using any

spark-producing tools such as the electric drill motor

used with oil withdrawal pump kit.

Check the motor oil level frequently with the dipstick. When oil is to be

changed, remove dipstick and withdraw oil from crankcase through

withdrawal/dipstick tube. The oil withdrawal tube is provided so oil does

not have to be drained into the bilge. Withdraw oil with a suction pump.

Fill the crankcase to the specified capacity with a quality motor oil labelled for service category SH. When changing motor oil, select from

the following chart the SAE viscosity that matches the temperature

range in which the boat will be operated. If it is necessary to add motor

VPA 7746872 English 2006-10 9

Page 14

General Information

oil, use motor oil of the same viscosity.

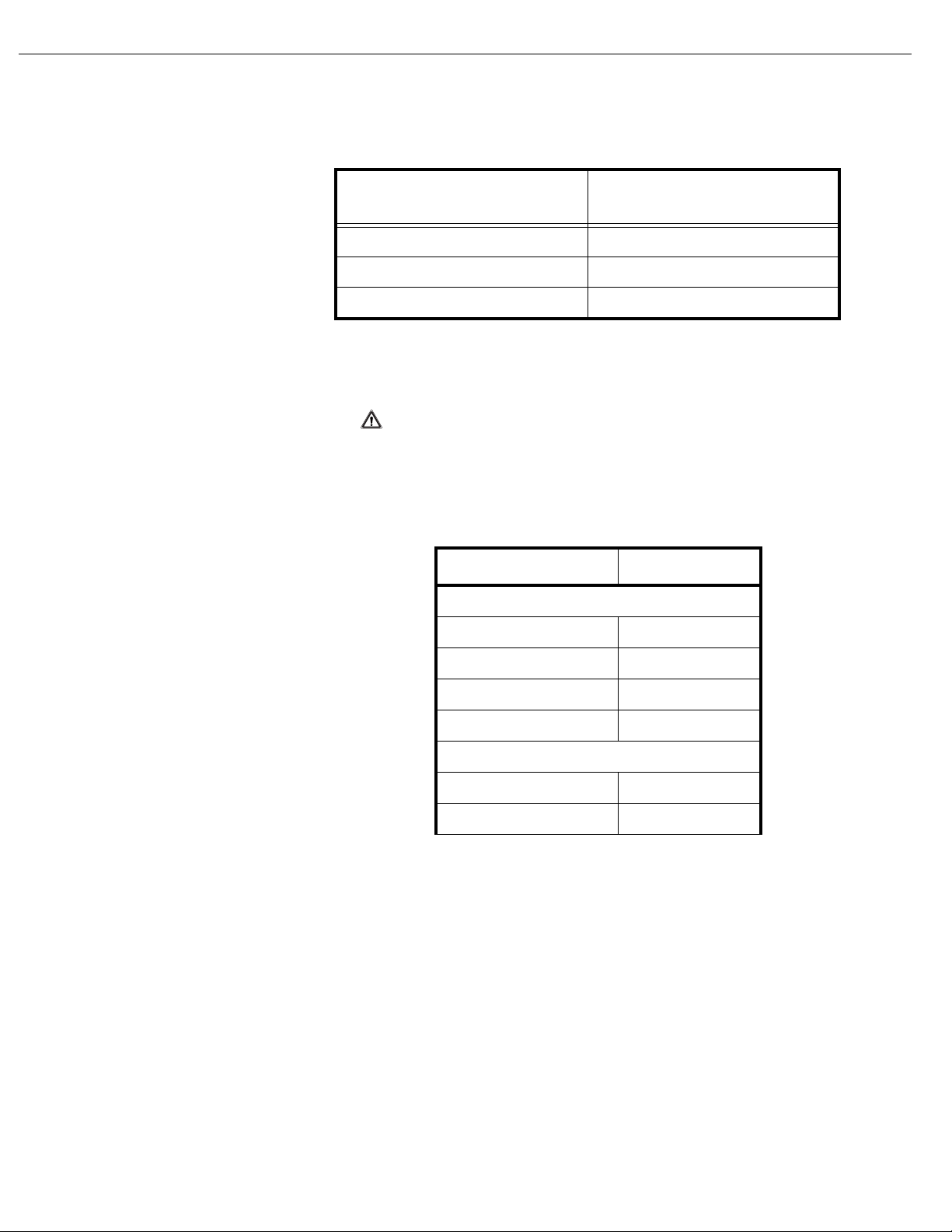

Table 2: Temperature Viscosity Recommendations

If the lowest Anticipated

Temperature is:

32° F (0° C) and above SAE 30

0° F (-18° C) to 32° F (0° C) SAE 20W-20

Below 0° F (-18° C) SAE 10

NOTE! Disregard any reference to multi-viscosity oil printed on

engine. Such reference is intended for automotive use

only and not marine application.

Caution!

Do not fill above full mark. Overfilling results in high operating temperatures, foaming (air in oil), loss of power, and

overall reduced engine life.

Table 3: Crankcase Capacities

Model With Filter

4.3GXi/OSi 5.0 qts. (4.7 liters)

The Following SAE Viscosity

Oils are Recommended

Sterndrive

Off-Season Storage

5.0GXi/OSi 5.5 qts. (5.2 liters)

5.7Gi/GXi/OSi/OSXi 5.5 qts. (5.2 liters)

8.1Gi/GXi 9.0 qts. (8.5 liters)

Inboards

5.7GiI/GXiI 5.5 qts. (5.2 liters)

8.1GiI/GXiI 9.0 qts. (8.5 liters)

Oil Filter Replace the oil filter whenever the motor oil is changed. This filter is a

self-contained, screw-on type. To remove, unscrew filter canister

counterclockwise and discard. When attaching a new filter, be sure the

gasket is lightly lubricated with motor oil. Hand tighten only, run engine

and check for leaks. Do not run engine without supplying cooling

water. See Parts Catalog for model and filter requirements.

Maintain the level with Volvo Penta Power Trim/Tilt & Steering Fluid.

Approved power steering fluids such as GM power steering fluid or

Dexron II automatic transmission fluid can also be used. Do not overfill

the pump reservoir.

There are nine steps that must be completed for Off-Season Storage

Preparation

10 VPA 7746872 English 2006-10

Page 15

General Information

When gasoline engines are removed from service for long periods (2

months or more), it is important that they are correctly stored or protected (internally). Today’s gasoline blends are not as stable as in the

past and consideration must be given if the fuel will not be used within

a short time or if the engine is being placed in storage. Failure to properly stabilize the fuel can damage fuel system components and is not

considered as warrantable.

Boat manufacturers should follow the gasoline storage mixture

section for testing prior to shipment.

Note! Volvo Penta has discontinued the fuel stabilizer #3855832,

a suitable replacement can be purchased locally at most

automotive supply stores.

Limited Use If the vessels fuel within the tank(s) will not be consumed within a 30-

day period from the time of filling, a gasoline fuel stabilizer must be

added as per the manufacturers instructions. This will help prevent the

fuel from breaking down and causing reduced engine performance or

damage from uncontrolled combustion.

Storage If the boat is being placed into storage, a gasoline fuel stabilizer must

be added to the tank(s) as per the manufacturers instructions. The

amount of stabilizer required is determined by the quantity of fuel and

the length of time it will be placed in storage. The maximum period that

fuel can be stabilized is six months due to limitations of the stabilizers

and fuels.

DANGER!

Any fuel leakage should be corrected immediately to prevent possible fire and/or explosion.

Caution!

Do not run engine out of fuel or run the electric fuel

pumps dry more than 10 seconds. Running the electric

fuel pumps dry will cause fuel pump damage.

Prepare a storage mixture In addition to stabilization of the fuel, it is highly desirable to have the

valves and cylinders coated with a light film of oil previously accomplished through fogging. Today’s fuel injection manifolds are designed

with a complex air channel design that will not allow the traditional fogging oils to be injected past the throttle plate while running. The oil will

get stuck in the plenum and never reach the cylinders. Together with

the stabilizer, two-cycle motor oil can be added to a fuel mixture for

stabilization purposes.

• Using an outboard motor six-gallon fuel tank, add two-cycle

motor oil at a ratio of 50:1 (one pint to 6 gallons) and stabilizer

at one ounce per gallon (unless stated otherwise on the manufacturers label). Mix well.

• Disconnect boat fuel line at engine fuel pump. Attach the storage mixture fuel tank.

• Connect a suitable engine flush device if the boat is not in the

water.

VPA 7746872 English 2006-10 11

Page 16

General Information

Electric Fuel Pumps and Fuel Cells Regardless of the ratio of fuel stabilizer to fuel we use, the maximum

• Run the engine on the storage mixture for approximately 5 minutes at 1500 RPM. This will ensure that all fuel system and

internal engine components are thoroughly protected. Do not

operate the engine above 1500 RPM as the water pump

demand may exceed the supply, damaging the pump.

• Reduce the engine speed to idle and stop the engine.

• Reconnect the fuel fitting and check for fuel leaks.

recommended storage time for gasoline, according to STA-BIL, is six

months. During final assembly testing at our Lexington factory, each

engine is run on a fuel mix that is stabilized. Each engine is shut off

without running the fuel pumps dry and the fuel system is sealed to

prevent damage. With the delay in time between the product getting

installed in a boat, shipped to you, sold and finally delivered; the sixmonth time frame can easily be exceeded.

Since delivering a quality, dependable product is one of our highest

goals; we work closely with our suppliers to identify the root cause of

failure on any parts returned for warranty credit. While there are certainly legitimate failures of fuel pumps, the major portion of them are

returned to us due to varnished fuel from long term storage. We would

like to offer some advice on dealing with these issues.

Stuck Pumps If a fuel pump appears stuck and will not operate, you may try briefly

reversing the polarity to the pump to turn it in the opposite direction.

You should disconnect the electrical plug of one pump at a time on the

fuel cell to determine which pump might have a problem.

Noisy Fuel Pumps Electric pumps will often cavitate and become noisy if they are starving

for fuel. On carbureted engines or low-pressure fuel cell pumps, check

the fuel supply, quality of the fuel hose, anti-siphon valve, and filter

before replacing the fuel pump.

A noisy high-pressure pump on a fuel cell may indicate a low fuel level

in the reservoir. Check the fuel supply and low pressure pump operation to be sure the reservoir is receiving the correct volume of fuel. The

same information would apply to engines with the earlier vapor separator tank design.

This information may help prevent the needless replacement of pumps

in many cases and reduce the repair time for the boat owner.

Change Motor Oil and Oil Filter • Engine should first be operated under load until oil is thoroughly

warmed up. If oil is allowed to warm up before draining, a more

complete draining will be accomplished. In addition, accumulated impurities will be held in suspension by the oil and be

removed during draining operation.

• Remove motor oil by siphoning it out of oil withdrawal tube. Follow the procedure under Draining and Filling the Engine

Crankcase.

• Install a new oil filter and fill crankcase with recommended oil.

Caution!

12 VPA 7746872 English 2006-10

Page 17

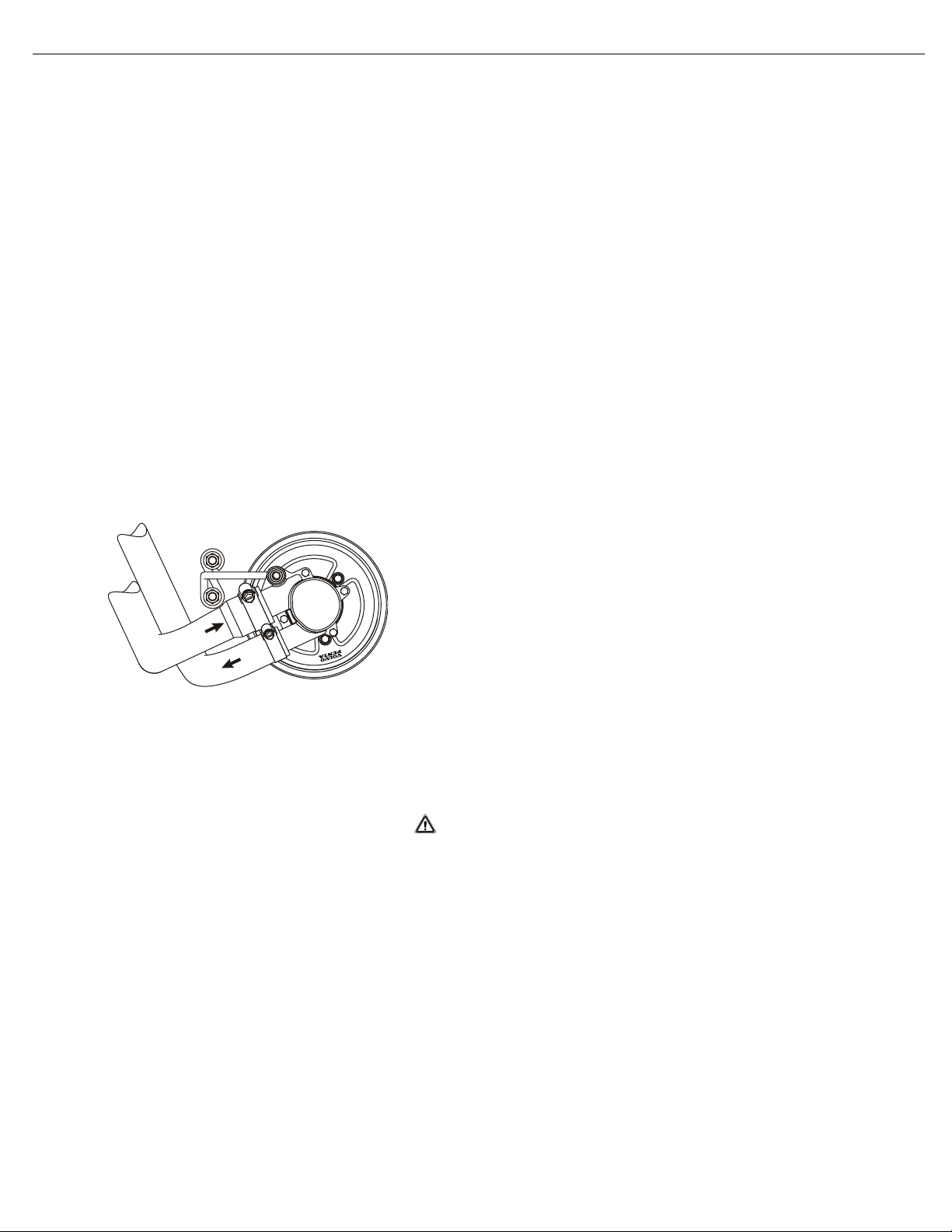

Change Sterndrive Lubricant

Drain Cooling System

D

C

A

B

23681

General Information

Sterndrive must be submerged in water or an accessory

flushing adaptor must be used while operating engine.

When using a flushing adaptor, remove propeller before

starting engine to prevent accidental contact with rotating

propeller.

• With sterndrive in full down position, run engine at a fast idle for

a few minutes to distribute clean oil through engine.

• Shut off engine and check oil level. Check oil filter gasket for

leaks. Add oil if necessary to bring oil level up to, but not over,

the full mark.

Drain and refill with fresh Volvo Penta GL-5 Synthetic Gear Lubricant

or Mobilube 1 SHC Fully Synthetic SAE 75W-90 (meeting or exceeding MIL-L-2105C or D, API GL-4 or 5) gear lubricant. Refer to Vertical

Drive Service Manual.

When draining the cooling system, raise or lower the bow of the boat

to position the engine in a level horizontal plane. This will provide complete drainage of the engine block and manifolds. If the bow is higher

or lower that the stern, some water may be trapped in the engine block

or manifolds.

Improper or incomplete draining may result in freeze damage to the

engine, manifolds, sterndrive, or other components. Freeze damage is

not covered under Volvo Penta’s Limited Warranty.

4.3GXi, 4.3OSi

Front

Port

1. Remove inlet (A) and outlet (B) hoses from raw water pump and

rotate engine with starter 1-2 revolutions. If engine starts to run,

shut off immediately.

Caution!

Do not run engine without water. If engine starts with the

water intake hose disconnected, shut off immediately.

Allowing the engine to run without water will damage the

engine and cooling components.

2. Disconnect the small water by-pass hose at the top of the thermo-

stat housing.

3. Disconnect and drain large hose at the circulation pump.

4. Disconnect the fuel cell water discharge hose. Lower the hose into

the bilge to allow draining. Blow out and remaining water with

compressed air. Reconnect after draining is complete.

5. Remove cylinder block drain plug. Clear hole with small wire to

ensure complete drainage.

6. Remove exhaust manifold drain plug. Clear hole with small wire to

ensure complete drainage.

VPA 7746872 English 2006-10 13

Page 18

General Information

Starboard 7. Remove cylinder block drain plug. Clear hole with small wire to

ensure complete drainage.

8. Remove exhaust manifold drain plug. Clear hole with small wire to

ensure complete drainage.

9. Reinstall drain plugs after draining is complete to keep the threads

of the drain holes from corroding. It will be difficult to install the

drain plugs if the plugs are left out over the winter.

5.0GXi, 5.0OSi, 5.7Gi, 5.7OSi, 5.7GXi, 5.7OSXi, 5.7GiI-F, 5.7GXiI-G

Front

Port

Starboard

1. Remove inlet (A) and outlet (B) hoses from raw water pump and

rotate engine with starter 1-2 revolutions. If engine starts to run,

shut off immediately.

Caution!

Do not run engine without water. If engine starts with the

water intake hose disconnected, shut off immediately.

Allowing the engine to run without water will damage the

engine and cooling components.

2. Disconnect and drain large hose at the circulation pump.

1. Remove cylinder block drain plug. Clear hole with small wire to

ensure complete drainage.

2. Remove exhaust manifold drain plug located at the rear of the

exhaust manifold. Clear hole with small wire to ensure complete

drainage.

1. Remove cylinder block drain plug. Clear hole with small wire to

ensure complete drainage.

2. Remove exhaust manifold drain plug located at the rear of the

exhaust manifold. Clear hole with small wire to ensure complete

drainage.

3. Reinstall drain plugs after draining is complete to keep the threads

of the drain holes from corroding. It will be difficult to install the

drain plugs if the plugs are left out over the winter.

8.1Gi, 8.1GXi, 8.1OSi, 8.1GiI-G, 8.1GXiI-F

Front

1. Remove inlet (A) and outlet (B) hoses from raw water pump and

rotate engine with starter 1-2 revolutions. If engine starts to run,

shut off immediately.

Caution!

Do not run engine without water. If engine starts with

intake hose disconnected, shut off immediately. Allowing

the engine to run without water will damage the engine

and cooling components.

2. Disconnect and drain large hose at the circulation pump.

Port

1. Remove cylinder block drain plug. Clear hole with small wire to

ensure complete drainage.

14 VPA 7746872 English 2006-10

Page 19

General Information

2. Remove exhaust manifold drain plug located at the front of the

port exhaust manifold, behind the power steering pump. Clear

hole with small wire to ensure complete drainage.

Starboard

1. Remove cylinder block drain plug. Clear hole with small wire to

ensure complete drainage.

2. Remove exhaust manifold drain plug located at the rear of the

exhaust manifold. Clear hole with small wire to ensure complete

drainage.

3. Reinstall drain plugs after draining is complete to keep the threads

of the drain holes from corroding. It will be difficult to install the

drain plugs if the plugs are left out over the winter.

Preparation for Boating After Storage

1. Install all drain plugs if they were left out during storage. Install

cooling hoses and clamps. Check condition of hoses, manifold

end caps and clamps. Connect hoses to engine and tighten

clamps securely. Install boat drain plug, if removed.

2. Remove the distributor cap and rotor. Wipe the inside of the dis-

tributor cap dry with a clean cloth and spray with Corrosion Spray.

Replace the rotor and cap.

3. Clean the battery terminals. With the ignition switch in the "OFF"

position, install the battery and attach the battery cables. Spray

terminals with Corrosion Spray.

4. Open the fuel shut-off valve (if so equipped) and check all fuel

line connections for leaks.

5. Check the flame arrestor and clean if necessary. Reinstall, make

sure all parts are in place and tighten nut securely.

Warning!

Do not place fingers in the throttle body on electronic

throttle equipped engines. The throttle plate has a powerful motor that can cause severe injury if the ignition energized.

6. Make a thorough check of the boat and engine for loose or miss-

ing nuts and screws. Pump the bilge dry and air out the engine

compartment.

Danger!

To prevent a possible explosion, operate the blower as

recommended by the boat manufacturer before starting

engine. If the boat is not equipped with a bilge blower,

open engine cover or hatch prior to starting and leave

open until after engine is running.

If operating boat in water, tie boat securely to dock to prevent forward or backward movement.

When using a flushing adaptor, remove the propeller

before starting engine to prevent accidental contact with

rotating propeller.

VPA 7746872 English 2006-10 15

Page 20

General Information

Engine Break-in

7. Test run engine: Launch boat or use a flushing adaptor installed

on Sterndrive.

Caution!

Do not start engine out of water unless using a flushing

adaptor. Always turn water on before starting engine.

Control water pressure as full water pressure may cause

damage to supply pump and engine.

8. With engine compartment open, start the engine. Monitor the volt-

meter, oil pressure and water temperature gauges frequently to be

sure all systems are operating properly. Check for fuel, oil, and

water leaks.

All engines have been run for a short period of time as a final test at

the factory. You must follow the Engine Break-In procedure during the

first 20 hours of operation to ensure maximum performance and longest engine life.

NOTE!

To ensure proper lubrication during the break-in period,

do not remove factory break-in oil until after the 20-hour

break-in is completed.

First Two Hours For the first five to ten minutes of operation, operate engine at a fast

idle (above 1500 RPM). After engine has reached operating temperature, momentarily reduce engine speed, then increase engine speed,

to assist break-in of piston rings and bearings.

During the remaining first two hours of operation, accelerate boat onto

plane quickly and bring throttle back to maintain a planing attitude.

During this period, vary the engine speed frequently by accelerating to

approximately three-fourths throttle for two to three minutes, then back

to minimum planing speed. Maintain planing attitude to avoid excessive engine load.

DO NOT RUN ENGINE AT A CONSTANT RPM FOR PROLONGED

PERIODS OF TIME DURING THE BREAK-IN PERIOD.

Next Eight Hours During next eight hours, continue to operate at approximately three-

fourths throttle or less (minimum planing speed). Occasionally reduce

throttle to idle speed for a cooling period. During this eight hours of

operation it is permissible to operate at full throttle for periods of less

than two minutes.

DO NOT RUN ENGINE AT A CONSTANT RPM FOR PROLONGED

PERIODS OF TIME DURING THE BREAK-IN PERIOD.

Final Ten Hours During the final ten hours of break-in, after warming engine to operat-

ing temperature, it is permissible to operate at full throttle for five to ten

minutes at a time. Momentarily reduce then increase engine speed to

assist break-in of rings and bearings. Occasionally reduce engine

speed to idle to provide cooling periods.

DO NOT RUN ENGINE AT A CONSTANT RPM FOR PROLONGED

PERIODS OF TIME DURING THE BREAK-IN PERIOD.

16 VPA 7746872 English 2006-10

Page 21

General Information

During break-in period, be particularly observant during initial running

of engine, as follows:

1. Check crankcase oil level frequently. Maintain oil level in safe

range, between “add” and “full” marks on dipstick.

NOTE! If you have a problem getting a good oil level reading on

dipstick, rotate dipstick 180° in tube.

2. Watch oil pressure gauge. If indicator fluctuates whenever boat

attitude (i.e. turning, climbing on plane, etc.) is changed, it may be

the oil pickup screen is not covered with oil. Check crankcase dipstick, and add oil to crankcase if required. DO NOT OVERFILL. If

oil level is correct and condition still exists, check for possible

gauge or oil pump malfunction.

NOTE! Oil pressure will rise as RPM increases, and fall as RPM

decreases. In addition, cold oil will generally show higher

oil pressure for any specific RPM than hot oil. Both of

these conditions reflect normal engine operation.

3. Watch engine temperature indicator to be sure there is proper

water circulation.

Caution

Failure to follow the break-in procedure will void the

engine warranty.

At end of break-in period (20 hours), change the motor oil and replace

oil filter. Fill crankcase with recommended motor oil, See “Crankcase

Oil” on page 9.

Operation After Break-in After break-in, the engine can be operated at any RPM from idle to full

throttle. However, cruising at 3600 RPM or less saves fuel, reduces

noise, and prolongs engine life.

When starting a cold engine, always allow engine to warm up gradually. Never run engine at full throttle until engine is thoroughly warmed

up. Be sure to check oil level frequently during the first 50 hours of

operation, since oil consumption will be high until piston rings are

properly seated.

Submerged Engine Remove engine from water as quickly as possible.

It is imperative that all water is removed from the engine and immediately lubricate all internal parts. All electrical devices must also be

dried and inspected for water damage. Delay in completing these

actions may allow extensive engine damage.

Frequently check engine compartment for gasoline fumes and excessive water accumulation; water depth in bilge should be kept well

below flywheel housing.

20-Hour Check

1. Change engine oil and oil filter.

2. Check power trim/tilt reservoir for proper fluid level.

3. Change fuel filter/water separator.

4. Check flame arrestor for proper mounting, cleanliness or damage.

5. Start engine and check complete fuel system for leaks.

VPA 7746872 English 2006-10 17

Page 22

General Information

3

8

6

0

0

9

1

6. Lubricate steering cable ram with Volvo Penta grease. Check

power steering pump reservoir for correct fluid level on models

equipped with power steering. Failure to properly lubricate the

steering system could lead to loss of steering control.

7. Check shift system for proper adjustment and operation.

8. Inspect exhaust system. Tighten all hose clamps, and check for

leaks.

9. Check tension on all drive belts.

10. Check all engine mount screws for tightness.

11. Check for any deficiencies, malfunctions, signs of abuse, etc. Cor-

rection of any problems at this time will prevent the worsening of a

minor problem and help ensure a trouble-free boating season.

12. Check oil level in Sterndrive and add as necessary with GL-5 Syn-

thetic Gear Lubricant or Mobilube 1 SHC Fully Synthetic SAE

75W-90 (meeting or exceeding MIL-L-2105C or D, API GL-4 or 5)

gear lubricant.

13. Make sure engine can achieve maximum rated RPM. See engine

specifications.

Belt Tension

22902 Serpentine belts are tensioned automatically and do not require

adjustment. Replace when the tension indicator lines up with the single line on the housing (A).

The Volvo Penta serpentine belts are for heavy-duty marine use. DO

NOT replace with automotive belts.

A

B

Positive Closed-Type Ventilation System

5.0L and 5.7L engines only A malfunctioning closed crankcase ventilation system may be indi-

cated by loping or rough engine idle. Do not attempt to compensate for

this idle condition by disconnecting the crank-case ventilation system

and making adjustments. The removal of the crankcase ventilation

system from the engine will adversely affect fuel economy and engine

18 VPA 7746872 English 2006-10

Page 23

General Information

ventilation with resultant shortening of engine life. To determine

whether loping or rough idle condition is caused by a malfunctioning

crankcase ventilation system, perform the following tests.

NOTE! 8.1 engines have an internal crankcase ventilation system

and have no serviceable components.

NOTE! 4.3 engines do not have a PCV valve. The crankcase venti-

lation is provided by a fixed orifice located in the port

valve cover and connected by a hose to the intake manifold.

With Engine Idling

With Engine Stopped Remove PCV valve from its mounting and shake it. A metallic clicking

Servicing PCV Valve Caution!

1. Remove PCV valve from its mounting, but leave vacuum inlet side

connected to hose. If the valve is functioning properly and not

plugged, a hissing noise will be heard as air passes through valve.

A strong vacuum will be felt when a finger is placed over valve

inlet. Check for vacuum leaks in hose line and at all connections.

2. Reinstall PCV valve, then remove crankcase air inlet hose at

flame arrestor connection. Loosely hold a small piece of stiff paper

(such as a 3 x 5 memo card or parts tag card) over opening at end

of inlet hose. After a minute or so, (to allow crankcase pressure to

lower) the piece of paper should be sucked against hose opening

with a noticeable force.

noise should be heard, indicating that valve parts are free, and not

sticking.

If ventilation system passes these two tests, it can be considered functionally OK, and no further service is required. If it fails either test,

replace PCV valve and repeat Engine Idling Test.

If system still does not pass test, clean ventilation system hoses and

all passages to induction system in accordance with established procedures.

Do not attempt to clean crankcase ventilation regulator

valve. It should be replaced.

Clean crankcase ventilation system connection(s) on intake manifold

by probing with a flexible wire or bottle brush. Clean hoses, tubes and

associated hardware with a low-volatility, petroleum-base solvent and

dry with compressed air.

Troubleshooting - System Isolation

The following is to help you isolate a malfunction of one or possibly

several systems. After determining which systems are related to the

VPA 7746872 English 2006-10 19

Page 24

General Information

Engine Does not Start

malfunction, refer to the individual system troubleshooting charts to

isolate the specific cause.

Engine should crank at specified RPM. If not, check for

1. Discharged or dead Battery

Cranking System

2. Loose or corroded connections

3. Cranking System Troubleshooting Chart in the Elec-

trical Ignition/ Fuel Service Manual

Ignition System Must have good spark at spark plugs. If not, check the:

1. Distributor Cap

2. Coil and spark plug leads

3. Ignition timing

4. Automatic spark advance

5. Appropriate Ignition Troubleshooting Chart in the

Electrical/Ignition/Fuel Service Manual.

Fuel System

1. Fuel Tank, valves, and lines

2. Fuel pump and filter

3. Boat Fuel System Troubleshooting Chart

4. Engine Fuel System Troubleshooting Chart

Engine Runs Improperly Check the following:

1. Compression

2. Ignition system

3. Fuel and injection system

4. Lubrication system

5. Cooling System

6. Sterndrive and propeller

7. PCV Valve

8. Engine Troubleshooting Guides

Engine Troubleshooting Guides

These guides were written to help you trace the symptoms of the trouble to the source, without having to read through and prove every possibility. Much of the information here will be familiar to well informed

mechanics.

Also, many factors will seem insignificant but when you think of it, usually the toughest problem to troubleshoot is caused by the smallest

error. The greatest aid to solving a service problem is information.

Start gathering information from the boat operator and write it on his

job card or work ticket. Find out pertinent facts, such as:

• When did this trouble start?

• How was the boat loaded?

• Did the trouble occur suddenly, or start gradually?

Analyze this information and try to match it to similar situations you

have experienced in the past. Keep in mind the fundamental rules:

20 VPA 7746872 English 2006-10

Page 25

General Information

• COMPRESSION - Mixture inducted into cylinder and compressed.

• SPARK - Proper intensity at the proper time.

• FUEL - Proper mixture of air and fuel.

These are very old rules, but necessary for the engine to run. Use

these charts and the service information they refer to. Do not try to

remember tolerances, settings, measurements, etc., as they are written in the service manual. Leave your mind free to analyze the problem.

Following is a list of the troubleshooting guides which may be found on

the pages indicated.

Engine Will Not Crank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 21

Engine Cranks, But Will Not Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 21

Hard Starting - Cold Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 22

Hard Starting - Hot Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 22

Engine Runs Rough . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 23

Engine Will Not Crank

Starter Circuit - Check: • Battery condition: weak, dead, sulfated, bad cells

Engine Noises and Vibrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 23

Engine Overheats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 24

Engine Dies Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 24

Engine Won’t Reach Operating RPM . . . . . . . . . . . . . . . . . . . . . . . . . page 25

Defective Engine Lubricating System . . . . . . . . . . . . . . . . . . . . . . . . . page 25

Low Battery Voltage After Short Storage. . . . . . . . . . . . . . . . . . . . . . . page 26

• Battery cables for loose or corroded connections

• Shorted or open ignition switch

• Starter motor and solenoid for shorts, grounds or open circuits

• Starter assist solenoid/starter relay

• Circuit breakers

• Wiring from battery to ignition switch

•See Electrical/Ignition/Fuel Service Manual

Engine Cranks, But Will Not Start

Ignition Circuit - Check: • Primary circuit wiring from ignition switch to ignition coil/ignition

module

• Secondary circuit wiring from coil to spark plug

• Spark plugs for proper gap, fouling, burned electrodes, cracked

or dirty insulator

•See Electrical/Ignition/Fuel Service Manual

• Low battery voltage

VPA 7746872 English 2006-10 21

Page 26

General Information

Fuel System - Check: • Quantity and condition of fuel in boat tank

Cylinder Compression - Check • Conduct test following procedure in this section, and compare

Hard Starting - Cold Engine

• Operation and flow capacity of boat anti-siphon valve

• Fuel tank vent is unrestricted

• Fuel tank pick-up screen is clean

• Correct diameter/unrestricted boat fuel lines

• Fuel shutoff and multiple tank valves are open and operating

properly

• Fuel pump vent hose for signs of fuel or oil that would indicate a

fuel pump failure.

• Fuel pump/relay/circuit breaker operation

• External fuel filter

• See Electrical/Ignition/Fuel System Service Manual

readings to Compression Limit Chart.

Has Engine Always Done This?

Check:

Was Engine Used For A Long Time?

Check:

Is This A New Condition? Check:

Hard Starting - Hot Engine

Has Engine Always Done This?

Check:

Ask these questions first:

1. Fuel tank antisiphon valve (if equipped)

2. Fuel lines for obstructions

3. For debris inside fuel tank

4. See Electrical/Ignition/Fuel System Service Manual

1. For clean external fuel filters

2. Water in fuel due to condensation

3. Fuel quality deterioration

4. See Electrical/Ignition/Fuel System Service Manual

1. Fuel tank antisiphon valve (if equipped)

2. Fuel system for leaks, dirt, or obstructions

3. Engine and ignition system

4. See Electrical/Ignition/Fuel System Service Manual

Ask these questions first:

1. Fuel tank antisiphon valve (if equipped)

2. See Electrical/Ignition/Fuel System Service Manual

Is This A New Condition? Check:

1. Brand, type or octane of fuel

2. Spark plugs

3. Water in fuel

4. Condition of battery and cables

5. Starter motor for overheat damage

22 VPA 7746872 English 2006-10

Page 27

General Information

Did Engine Refuse To Start After

Being Run? Check:

Ignition coil(s)/ignition module

Engine Runs Rough

If At Slow Speed - Check: 1. Fuel tank antisiphon valve (if equipped)

If At High Speed - Check:

1. Ignition system primary circuit

2. Engine timing

3. Fuel tank antisiphon valve (if equipped)

4. See Electrical/Ignition/Fuel System Service Manual

2. Idle speed

3. Engine timing and spark plugs

4. Fuel pressure

5. Water or contaminants in fuel

6. Manifold vacuum leak

7. See Electrical/Ignition/Fuel System Service Manual

1. Air leak on suction side of fuel system

2. Too low octane fuel

3. Ignition system secondary circuit

4. Engine timing

Engine Noises and Vibrations

Valves - Hydraulic Lifters 1. Rapping only when starting (oil too heavy for prevailing weather,

Ignition System (Ping or Knock)

5. Fuel filter

6. Fuel pump pressure

7. Engine compression

8. Water or contaminants in fuel, water in cylinders

9. See Electrical/Ignition/ Fuel System Service Manual

varnish on lifter, oil needs to be changed)

2. Intermittent rapping (leakage at lifter check ball)

3. Idle noise (excessive leak down rate, faulty check ball seat)

4. Generally noisy (excessive oil in crankcase, stuck lifter plunger)

5. Loud noise at operating temperature (scored lifter plunger, fast

leak down rate, oil viscosity too light for prevailing weather or operating temperatures)

6. See appropriate Engine section

1. Incorrect spark plugs

2. Incorrect spark plug wire routing

3. Use higher octane fuel

4. See Electrical/Ignition/Fuel Service Manual

Cooling System

1. Supply pump

2. Loose belts, pulleys

VPA 7746872 English 2006-10 23

Page 28

General Information

3. See Cooling System section

Crankshaft Balancer or Flywheel

Engine Overheats

Mountings

Alternator

Sterndrive

1. Loose, broken or worn engine mounts

2. Loose lag screws holding mounts to stringer

3. Check engine alignment see Removing and Installing Engine sec-

tion

1. Loose bolt(s)

1. Loose pulley, worn bearings

2. Loose mounting bolts

1. Failed U-joints or gimbal bearing

2. Damaged internal drive components

3. Worn, bent or broken propeller hub or blades

4. Loose, worn or damaged engine coupler

1. Actual engine temperature by verifying with an accurate thermom-

eter

2. Gauge operation and wiring circuit

3. Sending unit operation and wiring circuit

4. Supply pump, circulating pump and belt(s)

5. Water intake screens for blockage

6. Thermostat

7. Water supply hoses

8. Engine timing

9. Water leaks on pressure side of supply pump

10. Air leaks on suction side of supply pump

11. Engine compression

Engine Dies Out

Loss Of, Or Out Of, Fuel - Check: 1. Fuel gauge operation and wiring

2. Fuel level in tank

3. Water or debris in fuel

4. Fuel pickup tube and screen blockage

5. Fuel tank vent blockage

6. Plugged fuel filter

7. Air leak on suction side of fuel system

8. Fuel leak on pressure side of fuel system

9. Inoperative, restricted or incorrectly sized anti-siphon valve

10. Boat fuel lines too small in diameter

11. Fuel pump pressure and suction

24 VPA 7746872 English 2006-10

Page 29

General Information

12. See Electrical/Ignition/Fuel System Service Manual

Loss Of Ignition - Check:

Engine Stops Or Dies Out Due To

Seizure - Check:

1. Primary and secondary ignition circuits

2. Ignition switch

3. Circuit breakers

4. Wiring between engine and dash

5. Main engine harness wiring

6. See Electrical/Ignition/Fuel Service Manual

1. Sterndrive for internal damage

2. Oil pressure gauge

3. Crankcase oil level

4. Water in engine or sterndrive oil

5. Temperature gauge and cooling system operation

6. Internal engine components as required

Engine Won’t Reach Operating RPM

1. Fuel type or octane

2. Propeller pitch or diameter, damaged blades, slipping hub

3. Crankcase oil level

4. Marine growth on hull and drive

5. Wrong Sterndrive gear ratio

6. Operating at high altitude

7. Restricted air intake

8. Restricted exhaust outlets in engine, transom bracket or drive

9. Poor cylinder compression

10. Fuel pump pressure and vacuum

11. Boat overloaded, or load improperly placed

12. Engine overheating

13. Engine timing and ignition system operation

14. Remote control cables and linkage for proper attachment and

travel

Defective Engine Lubricating System

Engine Components - Check: 1. Clogged or incorrect oil filter

2. Worn oil pump gears, cover or shaft

3. Worn or collapsed oil pump relief valve spring, or foreign material

caught on valve seat

4. Oil pump relief valve plunger loose in cover

5. Damaged filter bypass grommet

6. Clogged oil pickup screen, broken tube or housing

7. Plugged crankshaft or blocked oil galleys

VPA 7746872 English 2006-10 25

Page 30

General Information

8. Dirty or defective hydraulic lifters, clogged push rod passages

9. Poor quality, incorrect viscosity or oil level

10. Incorrect hose routing on remote filter systems

11. Water in crankcase oil from condensation, defective head gasket,

oil cooler, or cracked manifold/block water passages

Oil Pressure Warning System -

Check:

1. Oil gauge/warning horn operation and wiring

2. Engine temperature

3. Oil pressure gauge and warning horn sender operation and wiring

Low Battery Voltage After Short Storage

Engine/Boat Components - Check: 1. All electrical accessories including ignition circuit off

2. Disconnect main battery negative cable from battery

3. Connect ammeter or voltmeter in series between negative battery

cable and negative battery post

• Meter reading of “0” indicates no draw, test battery and charging system

• Meter movement no matter how slight indicates draw from battery

4. Disconnect main engine harness 10-Pin Connector

• Meter drops back to “0”, problem caused by boat system, continue to isolate each boat electrical accessory until problem is

found

• Meter does not drop back to “0”, problem caused by engine

electrical system, continue to isolate each engine electrical

accessory until problem is found

5. Repair or replace components as necessary

26 VPA 7746872 English 2006-10

Page 31

Abbreviations

General Information

Table 4: Abbreviations used in this manual

BP

CAN

CKP

CMP

DBW

DTC

DVOM

ECM

ECT

EGC

EGT

EPC

ET

IAC

IAT

IVS

KS

LED

MAP

MIL

PWM

TCP

TPS

OBD

DLC

MEFI

IC

ODM

EEPROM

EI

PFI

ICM

COP

EVC

A/D

T- MA P

AC

Barometric Pressure

Controller Area Network

Crankshaft Position Sensor

Camshaft Position Sensor

Drive-By-Wire

Diagnostic Trouble Code

Digital Voltage and Ohm Meter

Engine Control Module

Engine Coolant Temperature Sensor

Electronic Gas Control System

Exhaust Gas Temperature

Electronic Parts Catalog

Electronic Throttle

Idle Air Control Valve

Intake Air Temperature Sensor

Idle Validation Switch

Knock Sensor

Light Emitting Diode

Manifold Absolute Pressure

Malfunction Indicator Lamp

Pulse Width Modulated

Throttle Control Position Sensor

Throttle Position Sensor

On-board Diagnostics

Data Link Connector

Marine Electronic Fuel Injection

Ignition Control

Output Driver Module

Electrically Erasable Programmable Read-only Memory

Electronic Ignition System

Port Fuel Injection

Ignition Control Module

Internal Micro Processor

Electronic Vessel Control

Analog/Digital

Manifold Absolute Pressure / Manifold Air Temperature sensor

Alternating Current

VPA 7746872 English 2006-10 27

Page 32

General Information

NOTES

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

28 VPA 7746872 English 2006-10

Page 33

Section 2: System Description

Visual / Physical Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Basic Knowledge and Tools Required . . . . . . . . . . . . . . . . . . 29

Electrostatic Discharge Damage . . . . . . . . . . . . . . . . . . . . . . . 29

Engine Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Engine Control Module (ECM) Self-Diagnostics . . . . . . . . . . 30

Malfunction Indicator Lamp (MIL) . . . . . . . . . . . . . . . . . . . . . . 30

Intermittent Malfunction Indicator Lamp (MIL) . . . . . . . . . . . . 30

Reading Diagnostic Trouble Codes (DTC’s) . . . . . . . . . . . . . 31

Service Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Normal Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

On-Board Diagnostic (OBD) System Check . . . . . . . . . . . . . . 32

DLC Scan Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

System Description

Special Tool and Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Visual / Physical Inspection A careful visual and physical inspection must be performed as part of

any diagnostic procedure. This can often lead to fixing a problem without further diagnostics. Inspect all vacuum hoses for correct routing,

pinches, cracks or disconnects. Be sure to inspect hoses that are difficult to see. Inspect all the wires in the engine compartment for proper

connections, burned or chafed spots, pinched wires or contact with

sharp edges or hot manifolds. This visual/physical inspection is very

important. It must be done carefully and thoroughly.

Basic Knowledge and Tools Required To use this manual most effectively, a general understanding of basic

electrical circuits and circuit testing tools is required. You should be

familiar with wiring diagrams, the meaning of voltage, ohms, amps and

the basic theories of electricity. You should also understand what happens if a circuit becomes open, shorted to ground or shorted to voltage.

To perform system diagnostics, several special tools and equipment

are required. Please become acquainted with the tools and their use

before attempting to diagnose the system. Special tools that are

required for system service are illustrated in this section.

Electrostatic Discharge Damage Electronic components used in control systems are often designed to

carry very low voltage, and are very susceptible to damage caused by

electrostatic discharge. It is possible for less than 100 volts of static

electricity to cause damage to some electronic components. By comparison, it takes as much as 4,000 volts for a person to feel the zap of

a static discharge.

There are several ways a person can become statically charged. The

most common methods of charging are by friction and by induction. An

example of charging by friction is a person sliding across a seat, in

which a charge of as much as 25,000 volts can build up. Charging by

induction occurs when a person with well insulated shoes stands near

a highly charged object and momentarily touches ground. Charges of

the same polarity are drained off, leaving the person highly charged

VPA 7746872 English 2006-10 29

Page 34

System Description

with the opposite polarity. Static charges of either type can cause

damage. Therefore, it is important to use care when handling and testing electronic components.

Engine Wiring When it is necessary to move any of the wiring, whether to lift wires

away from their harnesses or move harnesses to reach some component, take care that all wiring is replaced in its original position and all

harnesses are routed correctly. If clips or retainers break, replace

them. Electrical problems can result from wiring or harnesses becoming loose and moving from their original positions, or from being

rerouted.

Engine Control Module (ECM) SelfDiagnostics

Malfunction Indicator Lamp (MIL) The Malfunction Indicator Lamp (MIL) is part of the Diagnostic Trouble

The Engine Control Module (ECM) performs a continuous self-diagnosis on certain control functions. This diagnostic capability is complemented by the diagnostic procedures contained in this manual. The

ECM’s language for communicating the source of a malfunction is a

system of Diagnostic Trouble Codes (DTC’s). The DTC’s are two digit

numbers that can range from 12 to 81. When a malfunction is detected

by the ECM, a DTC is set and the Malfunction Indicator Lamp (MIL) is

illuminated.

Code (DTC) tool, or it can be a dash mounted warning light on some

applications.

• If present, it informs the operator that a problem has occurred

and that the boat should be taken for service as soon as reasonably possible.

• It displays DTC’s stored by the ECM which help the technician

diagnose system problems.

As a bulb and system check, the light will come “ON” with the key

“ON,” engine “OFF.” When the engine is started, the light will turn

“OFF.” If the light remains “ON,” the self-diagnostic system has

detected a problem. If the problem goes away, the light will go out in

most cases after 10 seconds, but a DTC will remain stored in the

ECM.

When the light remains “ON” while the engine is running, or when a

malfunction is suspected due to a driveability problem, the “On-Board

Diagnostic (OBD) System Check” must be performed as the first step.

These checks will expose malfunctions which may not be detected if

other diagnostics are performed prematurely.

Intermittent Malfunction Indicator

Lamp (MIL)

30 VPA 7746872 English 2006-10

In the case of an “intermittent” problem, the Malfunction Indicator

Lamp (MIL) may light for 10 seconds, and then go out. However, the

corresponding DTC will be stored in the memory of the ECM. When

DTC’s are set by an intermittent malfunction, they could be helpful in

diagnosing the system.

If an intermittent DTC is cleared, it may or may not reset. If it is an

intermittent failure, consult the “Diagnostic Aids” on the facing page of

the corresponding DTC table. A physical inspection of the applicable

sub-system most often will resolve the problem.

Page 35

System Description

AiP Q

Pket PCoc

EFM I

Reading Diagnostic Trouble Codes

(DTC’s)

23822

4

8

1

5

Data Link Connector

VODIA Scan Tool The VODIA tool is an advanced flexible diagnostic tool which is com-

VODIA

EDC4

EFMI

EDC1

P ket PCoc

AiP Q

23859

The provision for communicating with the ECM is the Data Link Connector (DLC). It is part of the engine wiring harness, and is a 8-pin connector, which is electrically connected to the ECM. It is used in the

assembly plant to receive information in checking that the engine is

operating properly before it leaves the plant. The DTC(s) stored in the

ECM’s memory can be retrieved with several Diagnostic Trouble Code

(DTC) tools listed below.

patible with all Volvo Penta Gas and Diesel engines with electronic

control systems, including the new EGC Control System. The VODIA

tool is a full-feature scan tool which will read and record all vital engine

parameters, read and reset fault codes, and perform engine tests. The

tool will also allow access to EVC systems and links to the Volvo

Penta Partner Network where updates can be downloaded online for

future expansion.

The VODIA tool may only be ordered through the Volvo Penta Partner

Network. From the home page, select Service/Warranty and then

select VODIA from the menu. Detailed information and pricing may be

found on the VODIA website.

Dealers who currently have a VODIA tool can order the connection

cable for EGC engines (PN 3883170) from our Parts and Accessories

department. The program itself is available for download to all registered users from the VODIA website on the Volvo Penta Partner Network.

Volvo Penta Marine Diagnostic Scan

Tool (P/N 3851228)

YES

NO

PAU SE

SETUP

TEST

23852

Diacom PC Software The Diacom program will provide full access to all vital engine parame-

23854

This full-function scan tool will:

• Provide complete access to all vital engine parameters.

• Read and reset fault codes.

• Perform output tests on EGC Control Systems.

The tool is also compatible with all GM based Volvo Penta EFI engines