Volvo 240, d20, d24 Service Manual

Service

Manual

Repairs

EngineD20,D24

and

TP

30420/1

maintenance

11.88

240 1979-

19

..

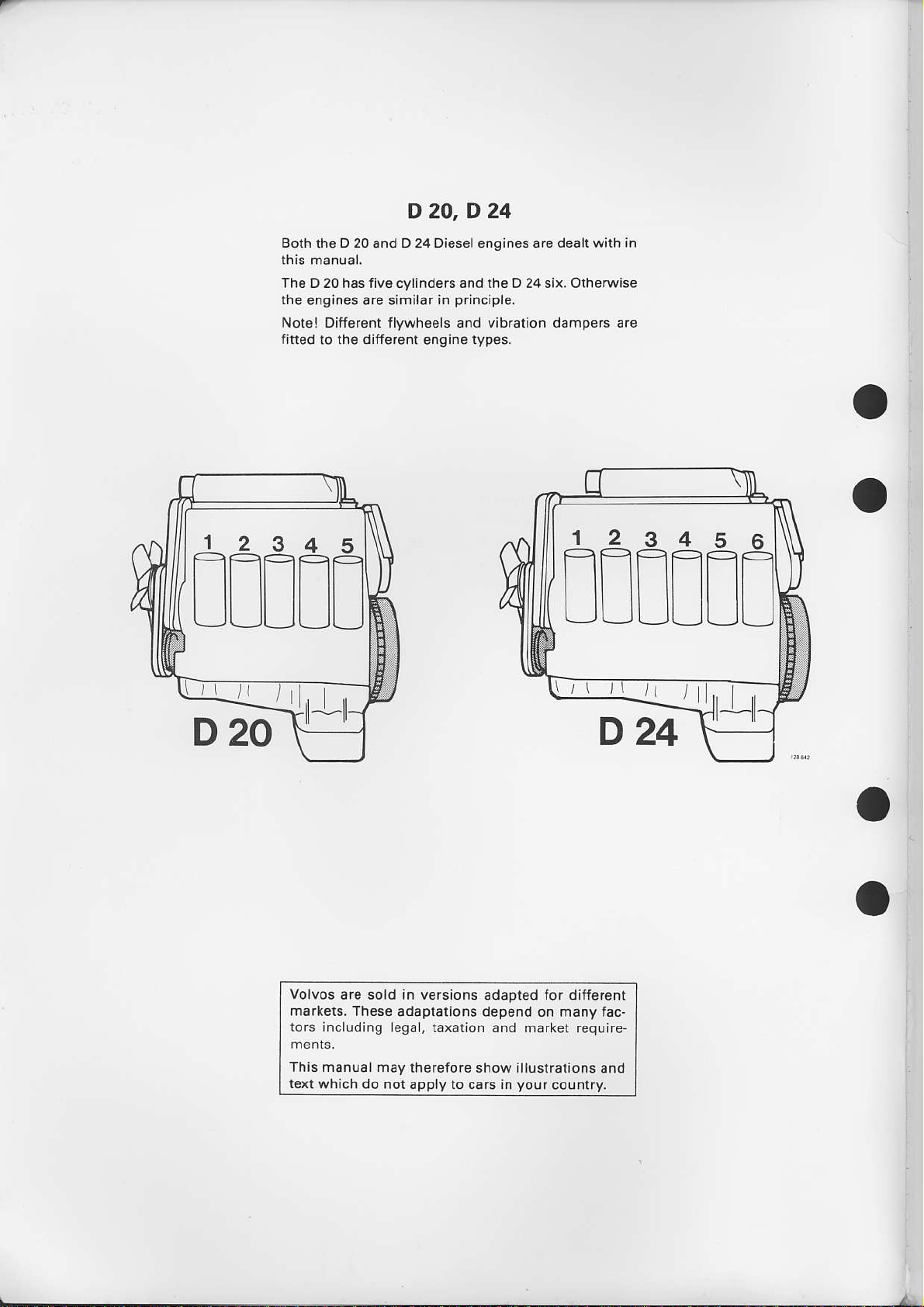

D20,D24

Both

this manual.

The D 20 has five cylinders and the D 24 six. Otherwise

the

Not6l

fitted

D 20

the

engines are similar

Different

to the dilferent engine types.

ancl D 24 Dieselengines are

in

llywheels

iffim

dealtwilh in

principle.

vibration dampers ar€

and

itm!r

Volvos

markets. These

Iors Including

This manual may

lext

are sold in versions

adaptations clepend on many fac-

ega, taxarion and marker reqJi.e

therefore show ill!strations

which do not apply to cars

adapted tor different

and

in

your

country.

:i!r-l-l

Contents

page

f

mportant information ...............................

Specitications ........

Special

tools ................................... 12

Group 21 Engine assembly ...............................................

(Work

wilh engine in-ca., replacernent

of engrnej

Group 22 Lubricating System .........................................

Group 23 FuelSystem .........................................................

Group 25Intake

Group 26

Cooling system ..................................................

and exhaust systems .............. .. .. r60

Group27En9inecontro1s..................................................

Appendix"A"Faulttracing.............................................

Index 178

2

3

16

123

125

i63

175

A1

We

reserye

Reprint

OVOLVO

NORTH

Order No,: TP 30420/1

the right

of'1983 literature

to make alerat

without

AMERICA

CORPORATION

ons

change.

lmportant

information

CLEANLINESS

Diesel injection

and foreign m6tter. A special

therefore be used for insoection ofcomoonents.

systems areoxtremelysensitiveto

workplace should

dirt

PLUGS

Clean fuel Iine connections thoroughly

necting

Plug

removed. Do not remove thess

nent is reconnected.

pipes.

of fusl lines etc as each component is

ends

plugs

before discon-

until the compo'

Tightening torques

Two kinds of tighlening

1. Tighten to 40 Nm

wrench must be used Iortightening.

2. Tightening torque 40 Nm

guidevalug.

Ioroue wrencn.

Tightening need not be donewith a

torques will be found in this

lbs) indicates th6t a torque

{30ft

lbs) indicates a

ft

{30

Specifications

Specifications

.,o

,o

Group

20

General

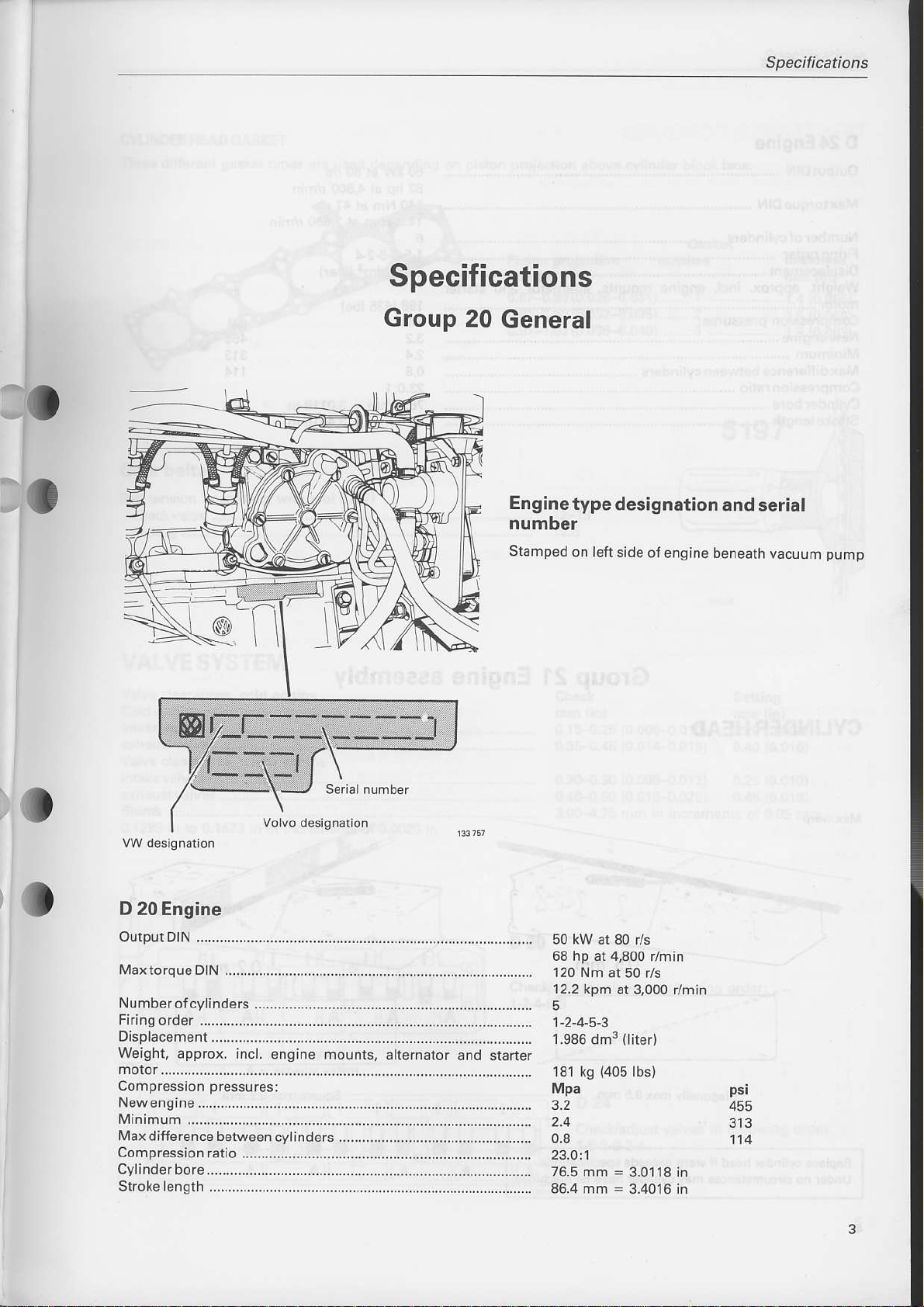

Engine

number

Stamped

type designation

left

on

side

of engine beneath

and

serial

vacuutr,

pump

D

20 Engine

Output DIN

Maxtorque

Number

Displacement.........

Weight,

Compression pressuresi

\ew

iV nirnJn .......................

Maxd;ffe.enceberweencyl

Comp.ess,or ratro .....

Cyl:nder bore..................

Stro\e

..........................

DIN

ofcylinders

........

approx. incl.

en9ine..................

lengr

h

engine mounts, altefnaror

...

nders..........................

and starter

50 kW ar 80 r/s

68 hp at 4,800 r/min

120 Nm at

12.2 kpm

5

1-2-4-5-3

1.986

'181

Mpa

3.2

2.4

0.8

23.0:1

76.5

86.4 mm = 3.4016 in

50 /s

at 3,000 /min

(liter)

dm3

(405lbsl

kg

mm : 3.0118 in

313

114

Specifications

D

24 Engine

OutputDlN

MaxtorqueDlN

Numberof cylinders .......

Firing order ............,,...,...

Disp1acement...,,...,,....,...

Weight, approx. incl,

Compression

pressurss:

engine mounts, alternator

Newongin€.........,,,,,.,......

lvlinimum ................,,......

Maxdiffsr€nce between

cy1inders ...........................

Com p ression ralio .......,,

Cylinder

bore....,.............

Slrokelength

and starter

60 kW al 80 r/s

82 hp at 4,800 r/min

140 Nm

14.3 kpm

47

at

r/s

6t 2,800 r/min

6

1-5-3-6-2-4

2.383 dm3

1S8

{435

{litsr)

lbs)

MP.

3.2

2.4

0,8

23.0r1

76.5 mm

=

3.0118 in

86.4 mm = 3.4016 in

psl

455

313

114

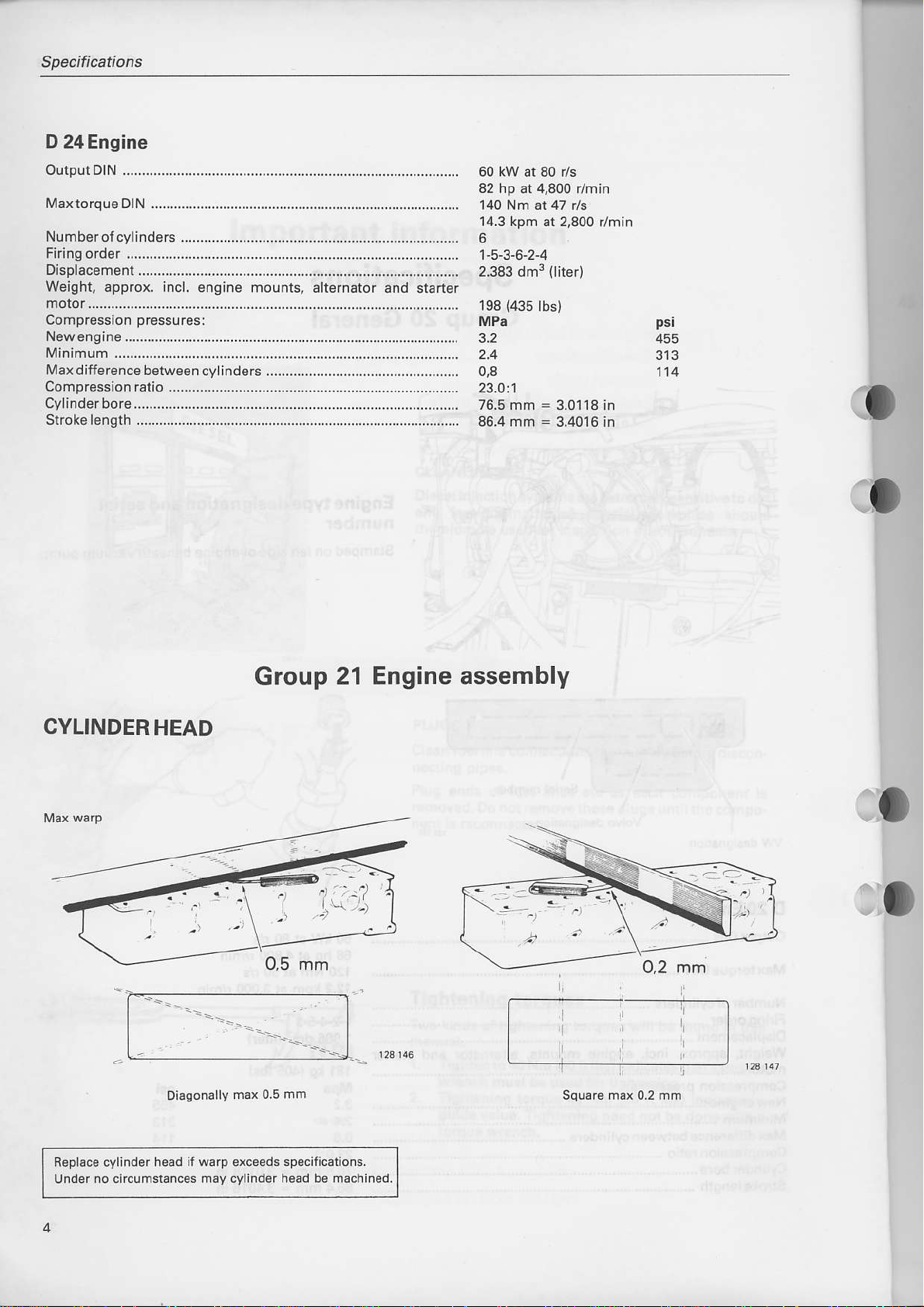

CYLINDERHEAD

Diagonally

Group

max 0.5 mm

21 Engine assembly

.,1

:.'

.,

9-

;

\|

,\

Replace cylinder h€ad

Und€r no circumst.ncos

jfwarp

€xce€ds sp€cificalions.

may cylihder h€ad b€ machinod.

_o

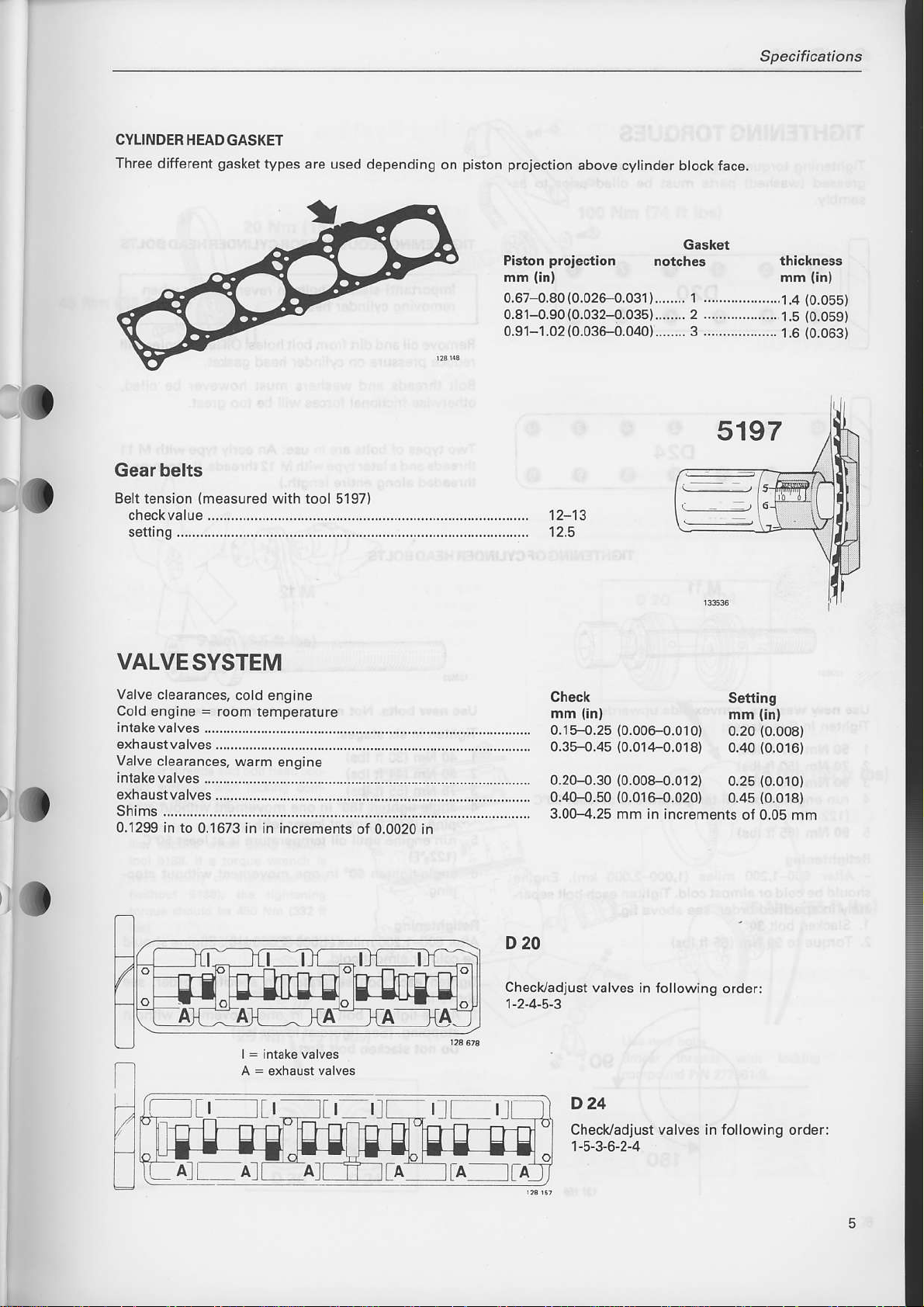

CYLINDEB HEAD GASKET

Thfee different gasket

types are used

depending on

piston projection

Pistonproi€ction notches

mm

0.67-0.80

0.81-0.90(0.032-{1.035)........ 2

0.91-r.02

above cytinder block

linl

(0.026-{.031

(0.036--0.040)........

G.sket

1

)........

3

Specifications

face.

thickness

(in)

mm

....................1.4

...................

...................

{0.0S5)

1.5

{0.059)

(0.063)

1.6

-o

Do

,lo

VALVESYSTEM

Valve clearances,

Cold

engine = room temperature

Valve

clearances, warm

0.1299 in to 0.1673 in

cold engine

engine

in increments

of 0.0020 in

Check

(in)

mm

0.15 {.25

0.35-0.45

0.20-0.30(0.008-0.012)

0.4(F0.50(0.016-0.020)

3.00-4.25 mm in increments

o20

(0.006-{.010)

(0.014-0.01

Setting

mm

0.20

8)

0.40

0.25{0.010)

0.45{0.018)

lin)

{0.008)

(0.016)

of 0-05

mm

a

u

n

!

r-l[ r

Checldadjust

1-2-4-5"3

]

valves

D24

Checuadjust valves in following order:

1-5-3-6-2-4

Specifications

TIGHTENINGTOROUES

Tight€ning

grsased

{washed}

oo

@o

@@o

@@@

torquB apply

parts

,Ot rO

D20

,oo

Mtl

to oiled nuts and bo|Is.

must b€ oiled

prior

to

@@

@@

@

@@@

D24

o

@@)@

NGHIENING

OF

De-

TIGHIENITVG

lmportlntl

removing

Removs oiland

reduc€

Eolt threads

otherwise frictional forces

Two types

threads

lhr@d6d along

CYLINDER HEAD BOLTS

SEOUENCE FOR CYLIIIDER XEAD BOLTS

cylindsr h€ad.

pressure

and washers

ot bolls ars in

and 6 later

slsck6n botts in rev€rsa

dirtfrom bolt holes.

on cylinder head

will b6 too

uset An early type

type with M 12 threads.

entir€ l6ngth.l

Oil

gasket,

must however be

grear.

M12

oder when

left

in hol€s will

oiled,

with M 1 1

typ€ is

{Later

Us6 now

Tlght€n

l50Nm{37ftlbsl

2 ?0 Nm

3 90 Nm

4 run

5 90 Nm

R.lightening

-

Atler

should

atsly in

L

2. Torque

waahera, convex

in fiv€

(50

{65 ft lbs}

6ngin€ until

1122'Fl

Slack€n

(65

600-1.200 miles

be cold

specifi€d

bol 3(r

to 90 lrlm

stages:

ft lbs)

ft lbs)

or almost cotd.

order,

sid6 upwards,

oil temperaturo

(1,000-2.000

Tighten

see abovs fio.:

(65

ft tbs)

is st t€ast

each boltsep6r-

km).

50.C

Engine

Us€ n.u bolb.

Tighten

1 ao

2 60 Ntn

3 75 Nm

4 angle-tightsn

5 run €ngin€ until

6 anglo-tighten 90P in

Nm

ping,

lt22

in

{Se€

"Fl

Not n€ce$ary

six stag6s:

ft lbsl

€0

l4a ft lbsl

ft lbs)

{55

l8f in

figur€ 6t lower lefi}

oil tehperature is

pins.

Rdighl.nlng

After

60F1,200 mil€6

b6

cold or almost cold.

Tighten

€bov€ fig.:

1. Angle-tighten

6ach boll

stopping.

Do not shckon boh

(See

(1,000-2,000

separatoly in spocifi€d

bolt 9|r in

figure

to roplac€ w6shers.

ono movem€nr without

at lerst 50oC

on6 movsment

one movemont without

lower left)

at

firf,

without stop-

km). Engine should

order, se€

stop-

20 Nm

6\1fl

l1s

ft lbs)

100

Nm

(74

Specificalions

ft@lbs)

45 Nm

133

ft lbs)

b0

l'-

I

i!

(6.5

'

D20

ft lbsl

@@'

Smearthreads and bolt head contacl suriaces wilh locking com-

pound (P/N

Tiqhtening lorque

lbs)

tool 5188. lf a torque wrench is

lsed dirscny on the cenler boll

(wiihout

torqle should be 450 Nm

277961-9).

Nn

350

appli6s when using special

5188), the tiqhlening

zb

(258

ro'\

350 Nm

ft

{258

(332

ft

ft lbs)

1rs

tt tu"t

Smear

compound

threads wiih

75 Nm

P/N 277961-9.

Nm

(55

(55

ft lbs)

ft tbs)

Specifications

Gtoup

22

Lubricating

OILCAPACITIES

D20

Litors

Excl.oilfilter

Incl.oillilter

Difference

in volume,

max-min

5.2

6.0

1.0

{US

(5.5)

(6.3)

(1.0)

ENGINEOIL

Oua1ity............,,,,,............

Accord'ng to API .......................................,,..,....,.:::::::::::::,.:::::::

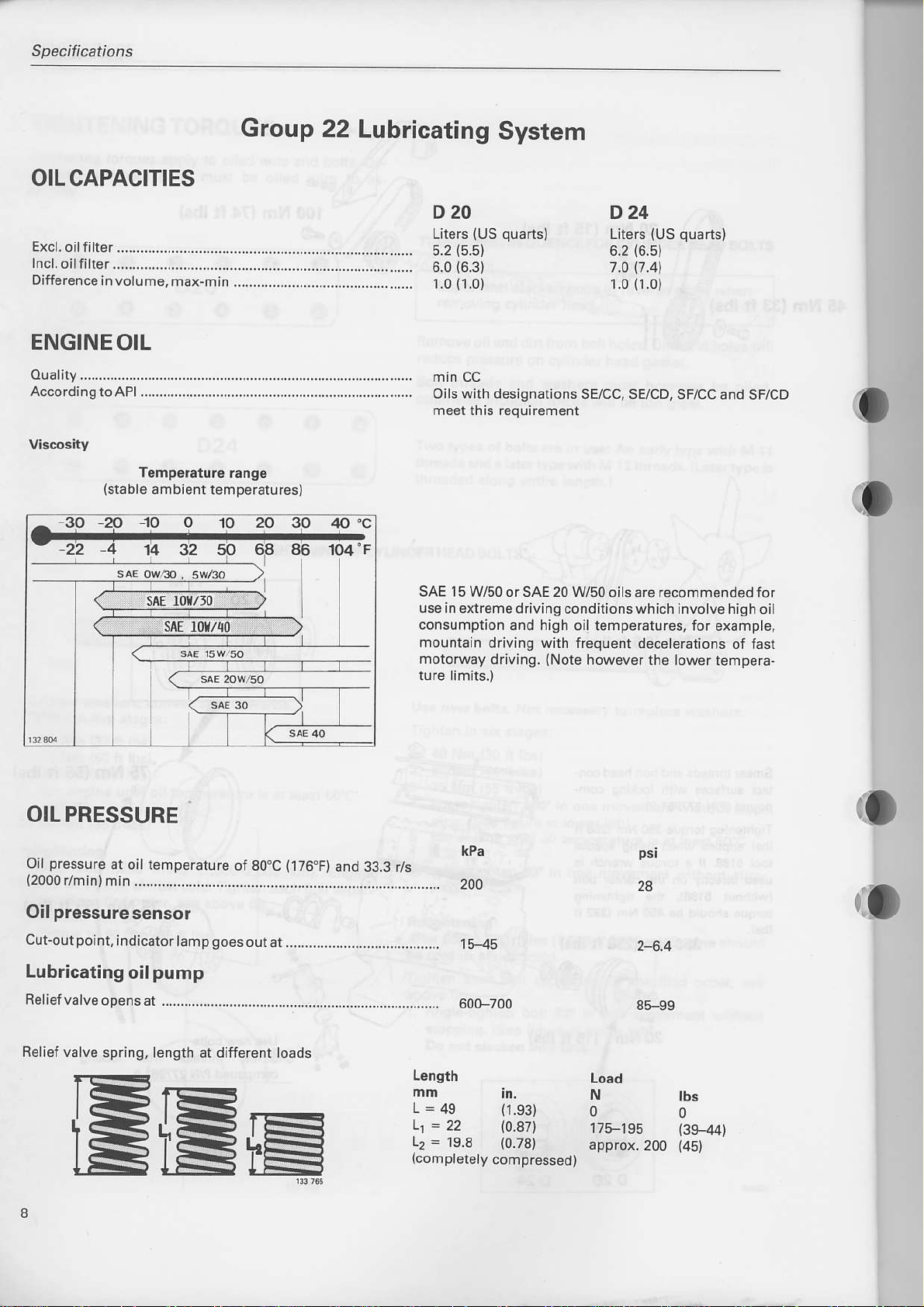

VbGosity

Tomporaturc

(stable

ambisnt temperatures)

rangs

min CC

Oilswith designations SSCC,

meot this r€quirement

System

quarts}

D24

IUS

(6.5)

(1.41

(1.0)

quarts)

Liters

6.2

7.O

1.0

SE/CD, SF/CC and SF/CD

OILPRESSURE

pressurc

Oil

(2000r/min)min

pressuresensot

Oil

Cut-out point,

Lubricating

Reliefvalv€opensat......

at

oil temperature

indicator lamp goes

pump

oil

of 8O.C

out

at

(176.F)

SAE 15 W/50 orSAE 20

use in sxtreme

consumption

mountain

motorway

ture limits.)

and

33,3 r/s

.........................

w/50 oilsare rscommend€d for

d riving conditions which involve hig

and high

driving with frequent

driving.

kPa

200

15-45

600-700

(Note

temperatures.

oil

decel€rations of fast

howover th€ lower

psl

28

2-6.4

85-99

h oil

for example,

tempera-

R€lisf valve

ffiffi8

spring, l€ngth at diffsrent loads

Long1h

mm

L = 49

L1=

22

=

L2

19.8

(completely

compressed)

in.

(1.93)

{0.87}

(0.781

Load

N

0

17F195

approx.

200

lbs

0

{39-.44)

(45)

Specifications

:o

a,o

0i:o

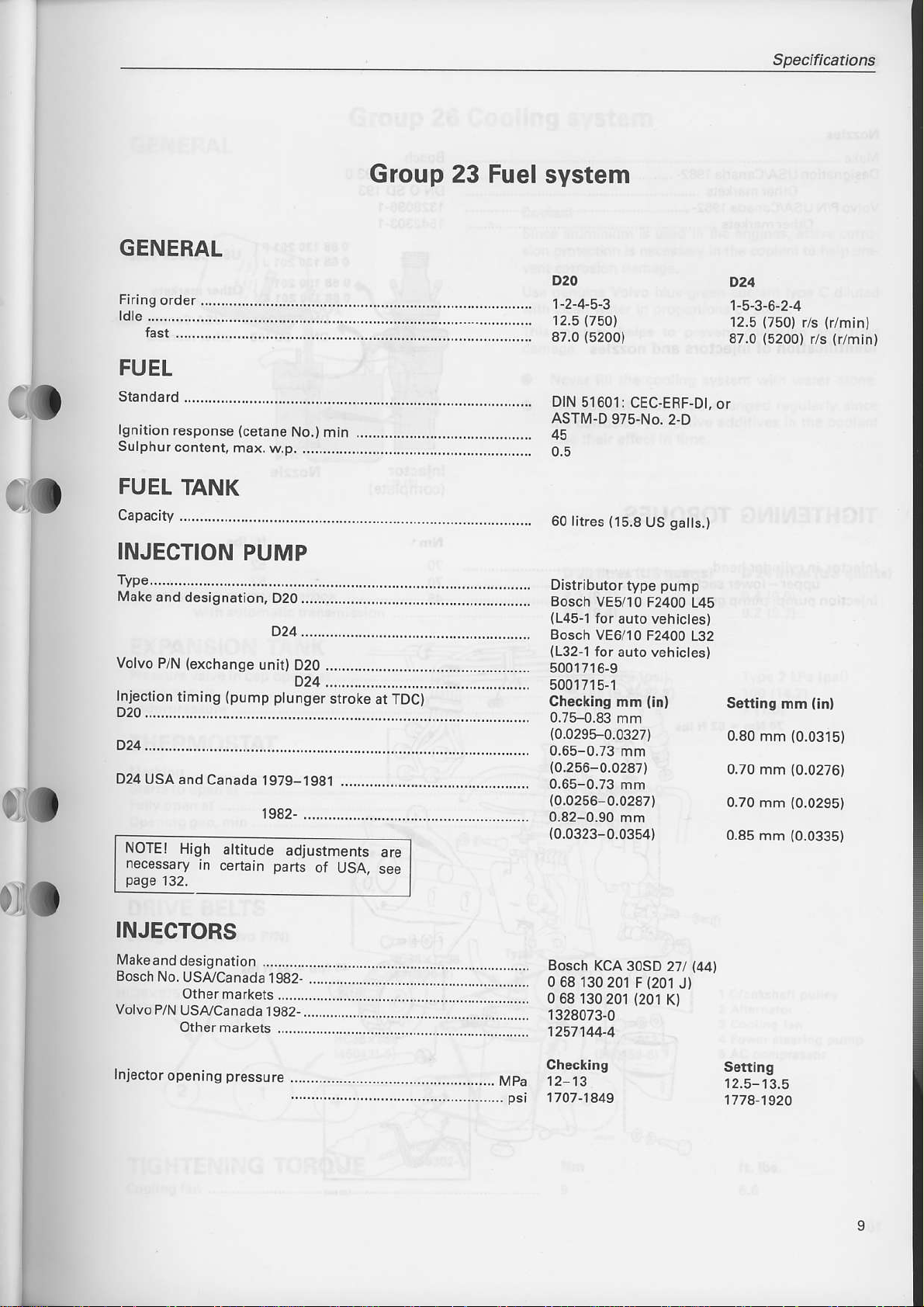

GENERAL

Firins

order.................

ldle

fast

.,.,.....,.,.,.,,.

FUEL

Standard................

Make

and designation,

Volvo P/N

Injeclion

D20.............................

D24

NOTE!

necessary

page

{exchange

timing

USA and

High

In

132.

{purrp

Canada

altitude

certain

INJECTORS

D20

D24

unit) D20

D24

prunger

1979-t98i

1982-

....................

Group 23

slroke at TDC,

Fuel system

D20

'l-2-4-5-3

(750)

12.5

(5200)

87.0

DIN

51601r CEC-ERF-Dl,

ASTIM-D

45

0.5

60litres

Distributor

Bosch

(145'1

Bosch VE6/10

(132-1

500't716-9

5001715-1

Checkins

0.75-0.83

(0.0295-0.0327)

0.65-0.73 mm

10.256-0.O2a7J

0.65-0.73

(0.0256-0.0287)

0.82-0.90 mm

{0.0323-0.0354}

975-No. 2-D

(15.8

rype

VE5/10 F2400

for

auto vehicles)

for auto vehicles)

mm

mm

mm

galls.)

US

pump

F2400

lin)

145

132

D24

1-5-3-6-2

(750)

12.5

(5200)

87.0

or

Settins

0.80 mm

0.70

mm

0.70 mm

0.85 mm

4

(r/min)

r/s

r/s

mm

{in)

(0.0315)

(0.0276)

(0.0295)

{0.0335)

(r/min)

Ir4akeanddesignation

Bosch

No. USA,/Canad€

Other markets...................

Volvo P/N

lnlector

USt"/Canada

opening pressure

1982-

t982-

''''. .

'. . . ...

. . . . ..................................

.",.-

.- . . .

. . . . .....,.-....,.

MPa

psi

Bosch

KCA

30SD 27l

0 68 130 20?

0 68 130

1328073,0

1257

Checkins

1707-1849

201

t44-4

(201

F

(201

(44)

J)

K)

Setting

12.5-',t3.s

1778,1920

Specifications

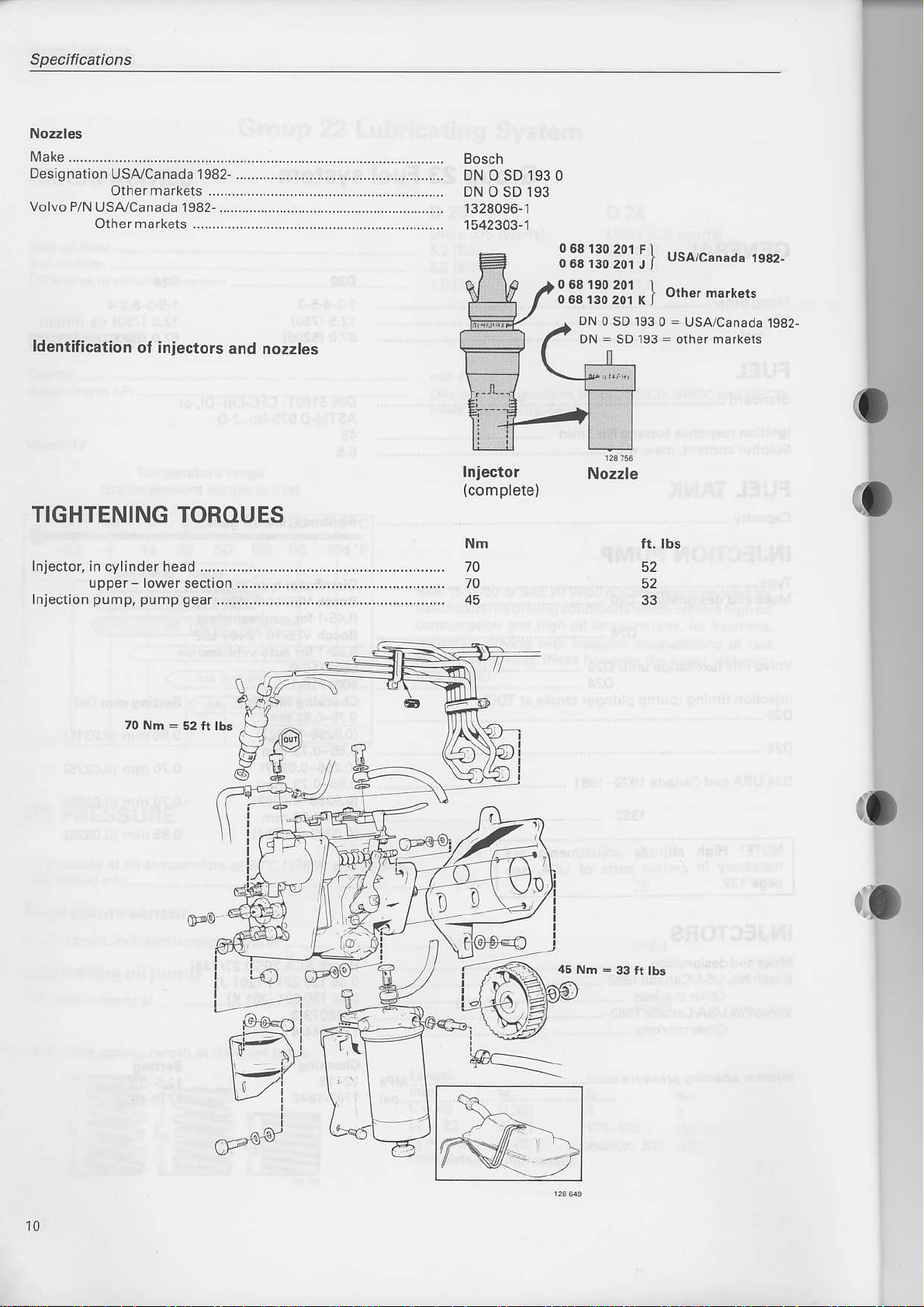

Nozzl6s

Designation

Volvo

USA"/Canada 1982Othermarkets

P/N USA,/Canada 1982'

Bosch

DNOSD1930

DN O SD 193

1328096,1

't542303-1

ldentitication

TIGHTENING

Injector, in cylinder

upper-rowersection...........................::...:.:.:.:.:.:.:::..::

Iniection

ot iniectors

TOROUES

head

pump, pump

g

and

nozzles

Iniector

(complete)

Nm

10

70

45

3::133;3i

068190201

usarcanlda

5l

I ^.

oogrrozolxl

DN

0 5D 193

DN = SD 193 = olher mark€ts

0 = USA/Canads

ft. lbs

52

52

33

,esz.

1982-

70 Nm

=

52ft lbs

=

45

Nm

33 ft

lbs

ti

10

Specifications

c,il

co

GENERAL

Group 26

Cooling system

Coohnt

Since aluminium is used in the

protection

sion

vent corrosion damage.

genuine

Use

with clean water in

This mixture helps

Never

a

The

a

the corrosion

lose thoir ef{ect in time.

is

necessary in the coolant to help

Volvo blue-green

lill the cooling system with

coolant should be changed

prolective

proponions

to

coolant type C diluted

pr€venl

6dditives

engines, active corro-

pre

of 50/50.

corrosion and frost

water alone.

regularly since

in

the coolant

)ijo

tt:o

Capacity,

with manual

with auiomatic

EXPANSION

Pressure valve

in cap

gearbox

transmission .....,,...

TANK

opens al ,,.,.,.,,,,.,,,.,..,....,.....

THERMOSTAT

Markin9.........................

Starts

to open at ,....,,.,..

Fully

open al

Openins

DRIVE

Deslgndion

HC38x975

(958354-3)

gap.

min .........

BELTS

(Volvo

P/Nl

HC38xl238

(960296-2)

HC38x888

{460431

s)

D 20litros

(8.7)

8.2

(8.4)

8.0

Type 1 kPa

(9.2-12.1)

65-85

7

{1.01

87'C

87'C

{189'Fl

102'C

l216.Fl

(0.3

8 mm

IUS

(psi)

in)

qlrrts)

D 24lirres

9.4

9.2

Type

r00

7

{1.0)

3 Cooling ran

4 Power steo.ing

{9.9}

{9.7)

2 kPa

{14.2)

IUS

{psi)

quarts)

pump

TIGHTENING TOROUE

Cooling fan

Hc38x800

(958302-1)

Ir. lbs.

9

6.6

1l

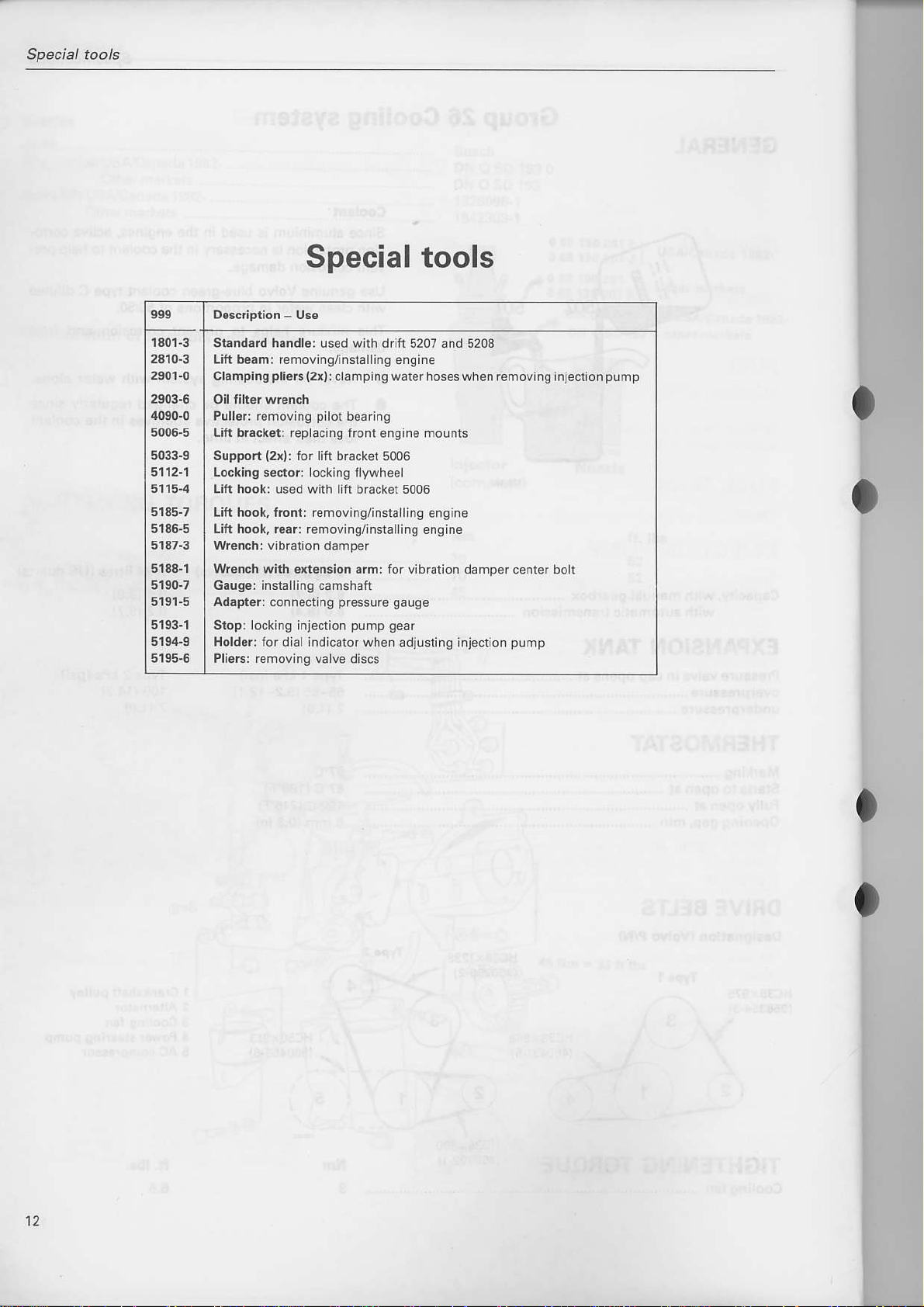

Special tools

Special tools

999

18Ol-3

261G3

2901-0

2903.6

4090-0

5006-5 | Lifi br.ckst: r€placing

5033-9 | Support

5112.1 | Loc*ing

51154

5185-7

5186.5 | Lift hoo*, lsar: ,€movins,4nstaltins

5147.3

5188.'l

5190-7 | Giuse: instslling camshaft

5191-5 | Adapter:

51$n

5194.9 | Holder: for dial indicalor when

5195.5 | PlisB:

lDdcription-U.s

Stand.rd h.ndle: lsed with drift 5207 and 5208

|

Lift be.m: rcmovingfinslalling

|

lC16mpinsplisrc{2x):clampinswat€rhoseswhenremovinsintecrionpump

| Oiltlltor wl6Dch

Pullet: removing

|

{2xl:

6sdo.:

| Lift hook: used with ltft bracket 5006

Lift hoolr lronr: removing/inslallins

|

I Wronchr vibration dEmoer

Wr6nch with oxt nsion arm: lor vibralion

I

connoctins

lockihs

Siop:

I

rcmovins valve discs

pilol

bearins

tronl €nsine mounts

for lilt bracl€t

locking

pr6ssur6

injecrion

5006

flywheel

punp

engin€

€nsin€

ensine

ssuse

sear

adjueins

damper center bolt

inj€ction

pump

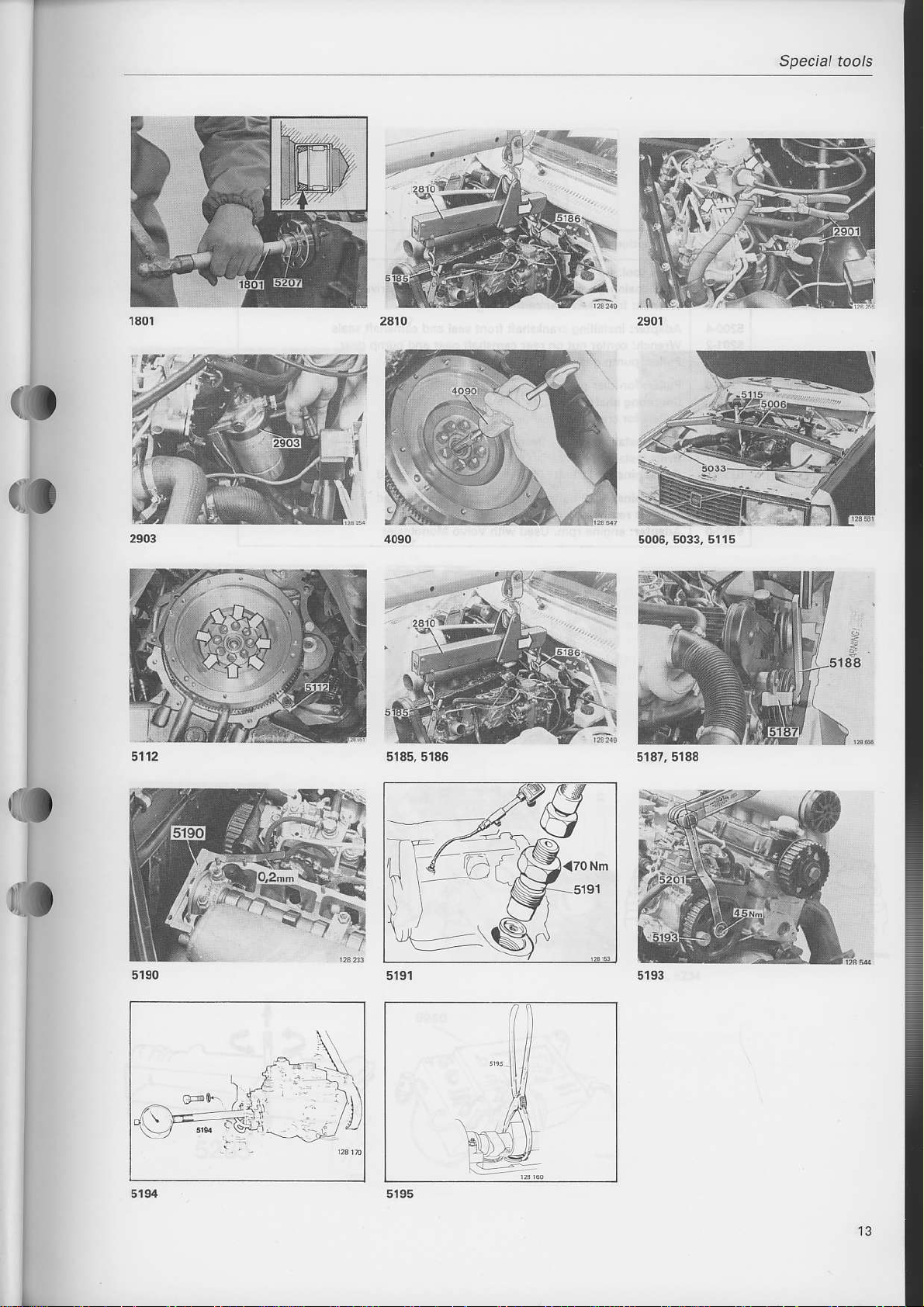

Specialtools

5006,5033,5115

5185,5186 5187,5188

5194 5t95

't3

Special

tools

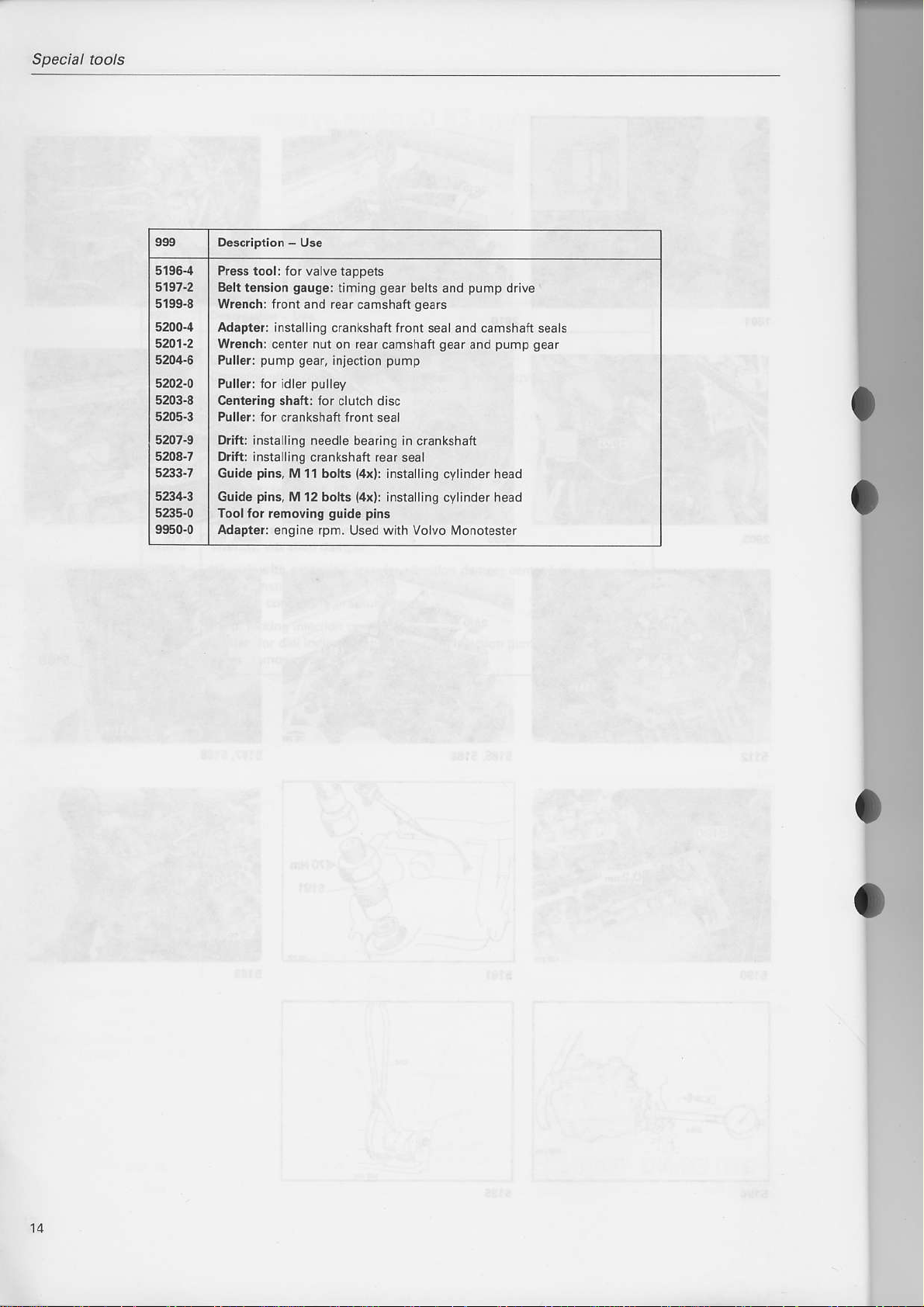

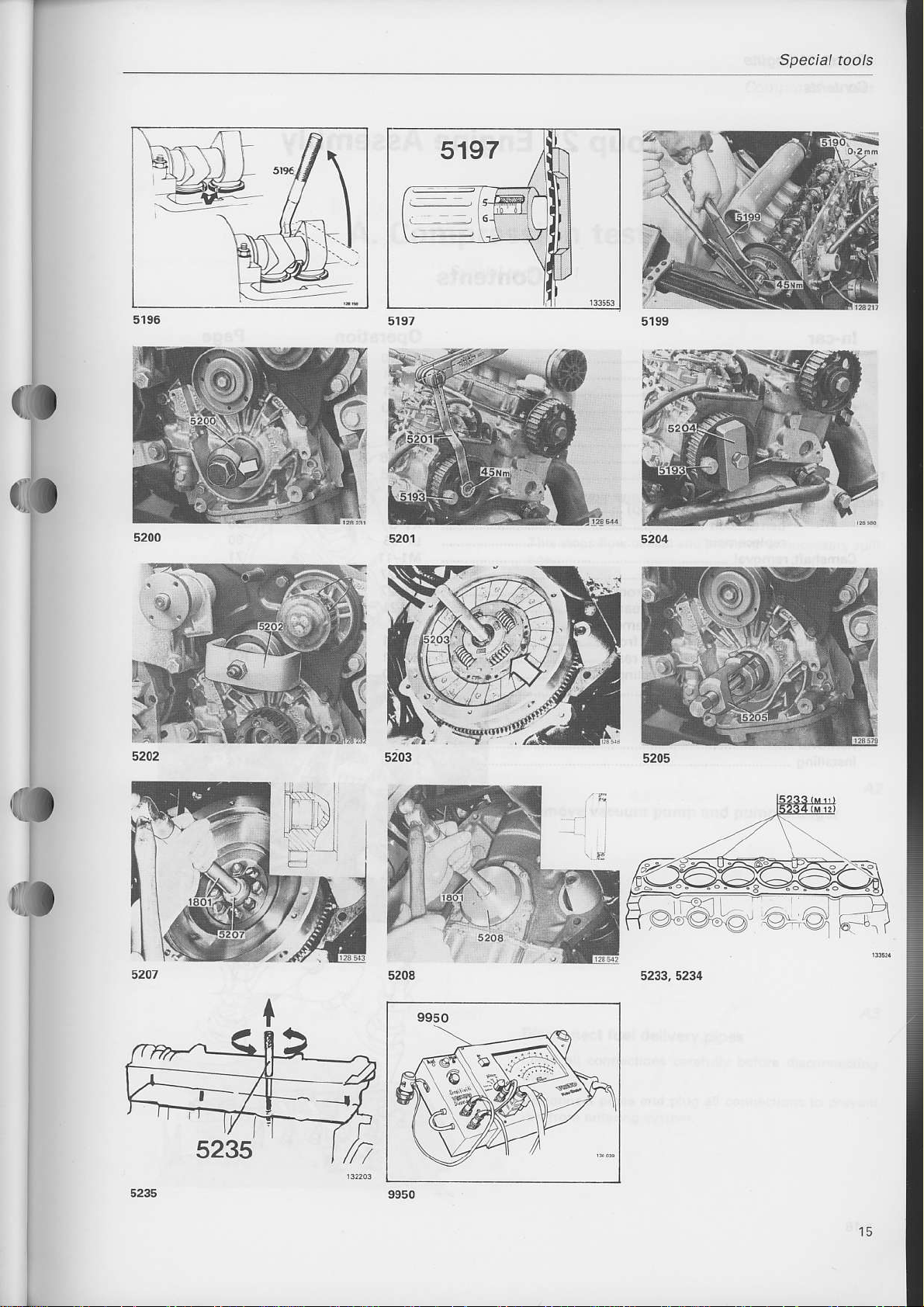

999

5196.4

5197"2

5199-8

52004

5201"2

520/t-6

5202-0

5203-8

5205€

l'207-t

5204-7

5233-7

523/t3

5235-0

9950-0

P.B3 roolj for valve

Balt tonsion

Wr3nch:

Adapter: installing cEnkshaft front

Wr6mh: center nut on rear

Pullor:

P0llor; for

Centerins sh.ft: for

P{ller: for

Drift: installing nsedlg

Drift: installing

Guida

Guide

Tool lor

Adapter:

g.uqo:

front and rear camshafi

pump

idl€r

crankshaft front s€sl

piB,

M t l bolts

piB,

M t2 bolG

removing

gnsine

tappets

ge8r

timing

gear,

inj€ction

pull6y

clutch disc

b€arjns in crankshaft

crankshaft rear seal

{4x):

{4x)r

suide

lpm. Used wirh Volvo Monot€stBr

belts and

gears

camshafl

pump

installing

installins cylind6r h6ad

ping

pump

drive

seal and camshaft s€als

g6ar

cylinder

pump gear

and

h6ad

't4

Specialtools

9950

5233,5234

9950

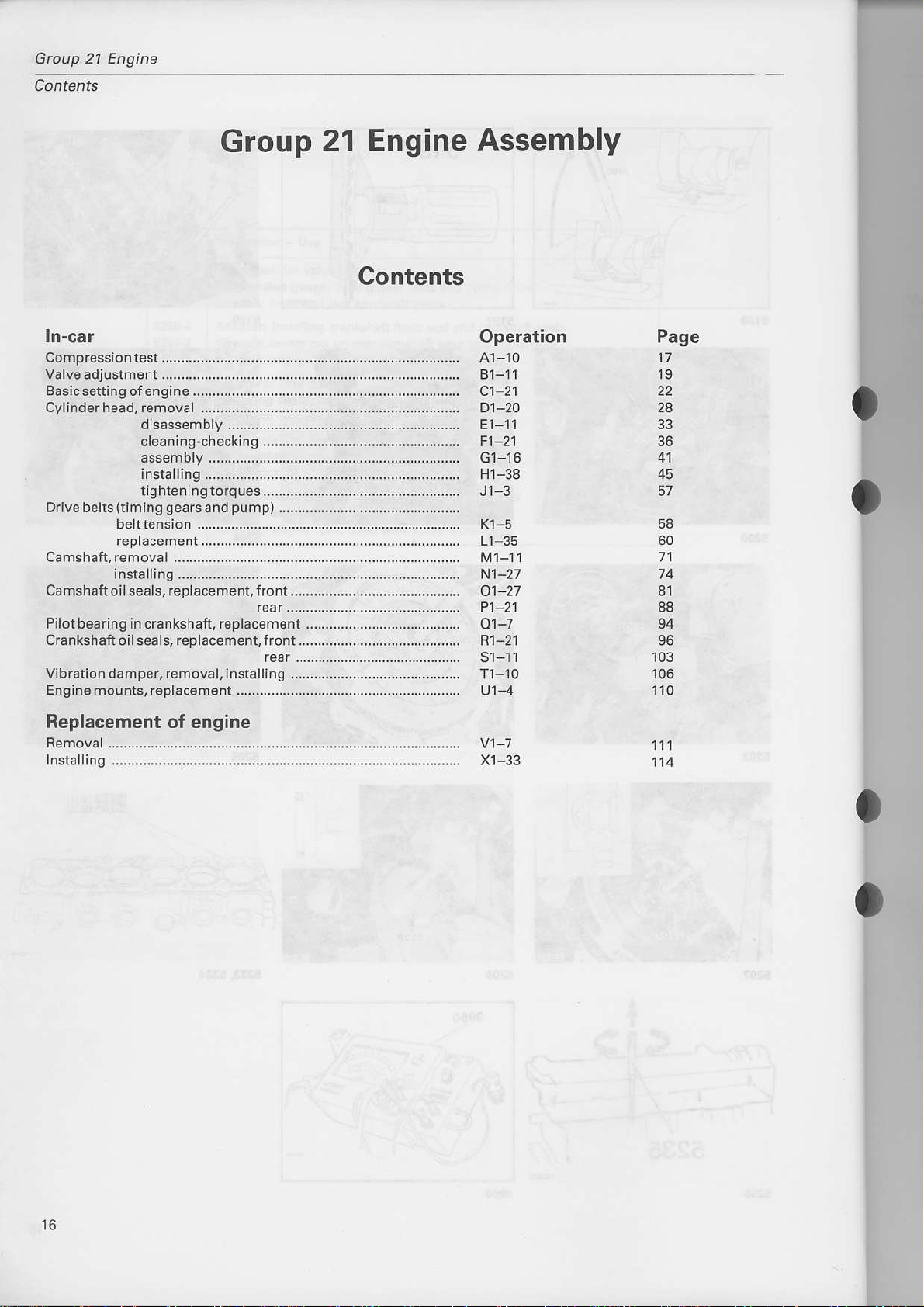

Group 21 Engine

Contents

Group

21 Engine

Contents

In-car

Valveadjustment.,,..,.....

Basicsettingof sngine...

Cylinder head,

Drive beltsltiming

Camshaft, r€moval

Camshaft oil sea ls,

Pilotbearing incrankhaft, replacement .......,....,.,..

Crankshaftoil seals,

Vibration damper, removal, insta11in9,,..........,.......

Engine mounts, rep1acement,,,.,,,.,,....,,...,,...,,...,,...,

removaI

disEssembly ...................

cleaning-chscking ..........

asssmory ........................

insta11ing.........................

tightening torquss,....,,...

gearsand pump)

belttension ....,,,,,,.,.......,,

rep1acement....................

insra11ing.........................

replacemenl,

replacement, front,,..,,...,,...,,..

........................

Iront .,,,...,,..,,...,,,.

Assembly

Operation

A1-10

B1-11

c1-21

D1-20

E1-11

G1-16

H1-38

K1-5

Ll-35

t\41-11

N 1-27

o1-21

P1-21

o1-7

R1-21

s1-11

T1-10

u1-4

Page

17

19

22

28

33

36

41

45

57

58

60

71

74

81

88

94

96

103

106

110

Replacement of engine

Removal .,...,,.......,...,....,.

Insta11in9 ........................

x1-33

'r

11

'114

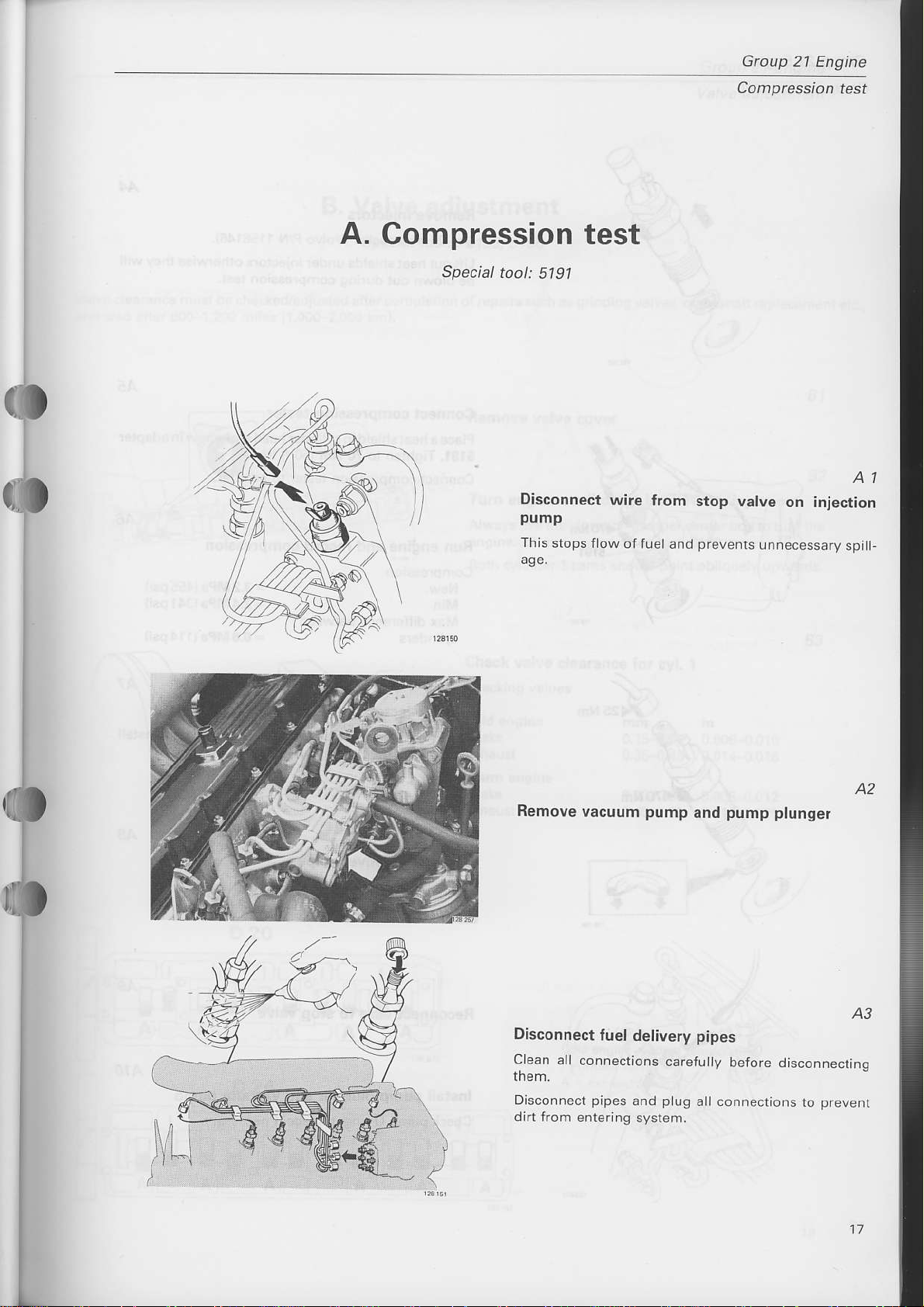

A.

Compression test

Group 21 Engine

Compression

test

Special

tool:5191

Disconnect

pump

This

stops flow

ase.

wire lrom

offue and

stop valve

prevenrs

t]nnecessary

A1

on injection

spi|-

Remove

Disconnect

Cean all

Disconfeci

diri fronr enterlng

vacuum

fuel detivery pipes

connecrions

pipes

and

pump

system.

and

carefu y before

plug

all connedions

pump

A2

plunger

A3

disconnecring

prevenr

ro

11

Gtoup 21 Engina

Compression

test

Remove iniectors

1158146}.

Use 27 mm socket

{Volvo

Lift out h€at shields undsriniectors

be blown out

during compression

Connect compression

heatshield incylind€r head and screwin

Placea

5191. Ighten to 70

connect compression

P/N

tesl.

testel

Nm

{50

ft lbs).

tester to adapter.

otherwise

44

will

they

A5

adapter

Run engine and record

Compression

Min

Max differ€nce between

Install iniectors

to 70

in

Nm

pipes

Nm

new heat shields

Place

injectors. Torque

Reconnect delivery

Tightening

torque 25

compression

=

3.2MPa{455psi}

=

2.4MPa

=

0.8MP.

(s0

it.

ft lbsl.

head,

lbs).

cylinder

(18

A6

(341

psi)

(114

psi)

A7

seefig. Install

A8

18

Reconnect wire to stop

Install

Check

pump plungor

pump

O-ring. replace

and

valve

vacuum

A9

r'.l0

pumP

B.

Valve

adjustment

Group

Valve

21 Engine

adjustment

Valve

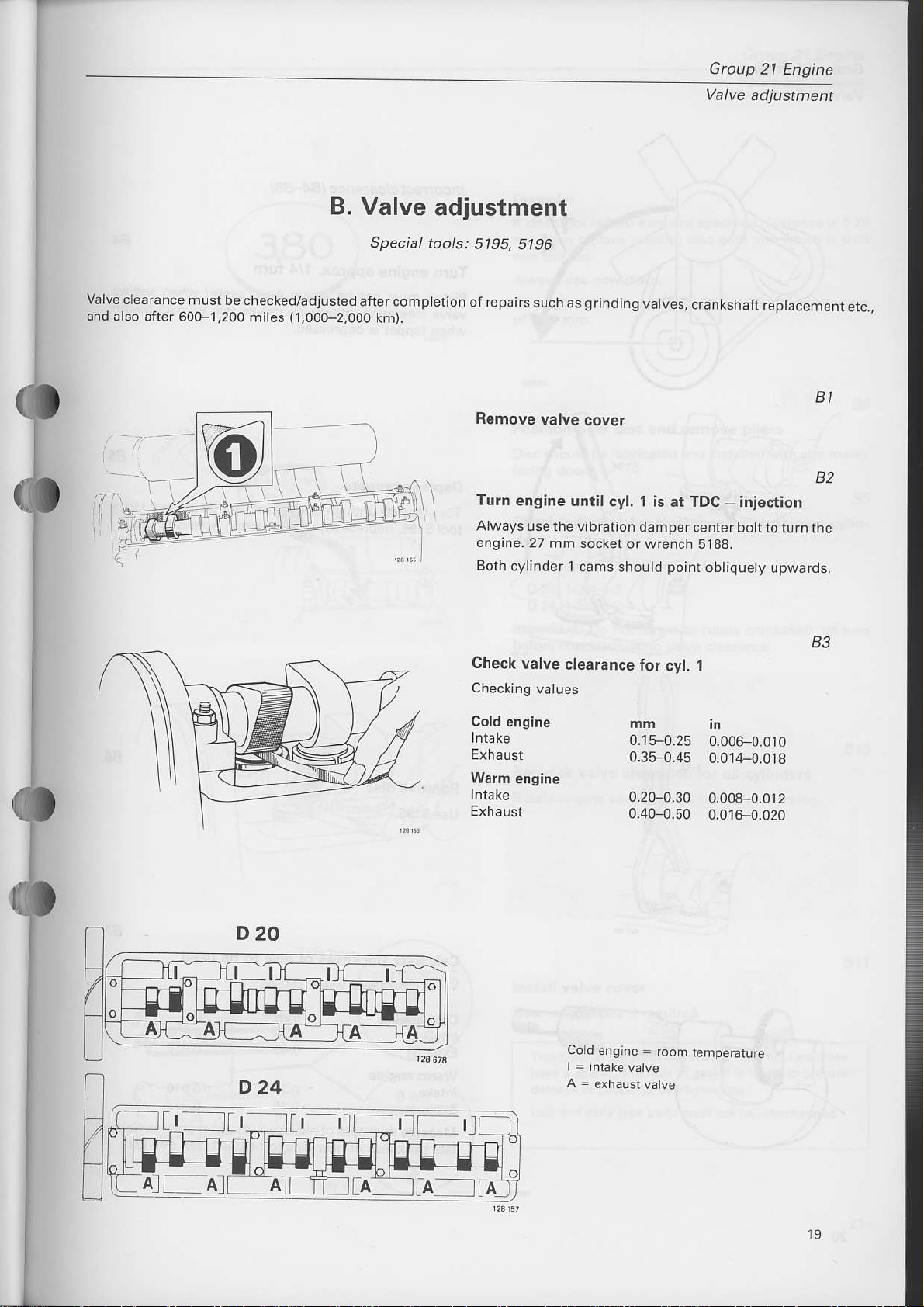

clearance

and also

must be checked/adiusted

after 60G-1,200

miles

Special

(1,00G-2,000

6fier

km).

tools:

5195, 5196

completion of repaifs

Remove

Turn

engine until cyl.

A

ways use the vibration

engine. 27

Both

cylinder 1cams

Check

Checking

valve

such as

values

grinding

valve

cover

mm socket

clearance

vatves,

1 is at TDC - injection

damper

or wrench 5188.

should

lor

crankshafr

center bolt to turn

poinl

obliquely

cyl. 1

reptacement

upwards.

etc.,

B1

B2

the

B3

a

il

a

f r I r

D20

o24

Cold

ensine

Exhaust

Exhaust

Co

d engine

0.15-0.25

0.35

0.45

0.20-0.30

0.40

0.50

=

rooh

temperalure

0.006

0.010

0.01,t-0.018

0.008-0.012

0.016-0.020

!

Alf

Alt

19

Group 21 Engine

Valve adjustment

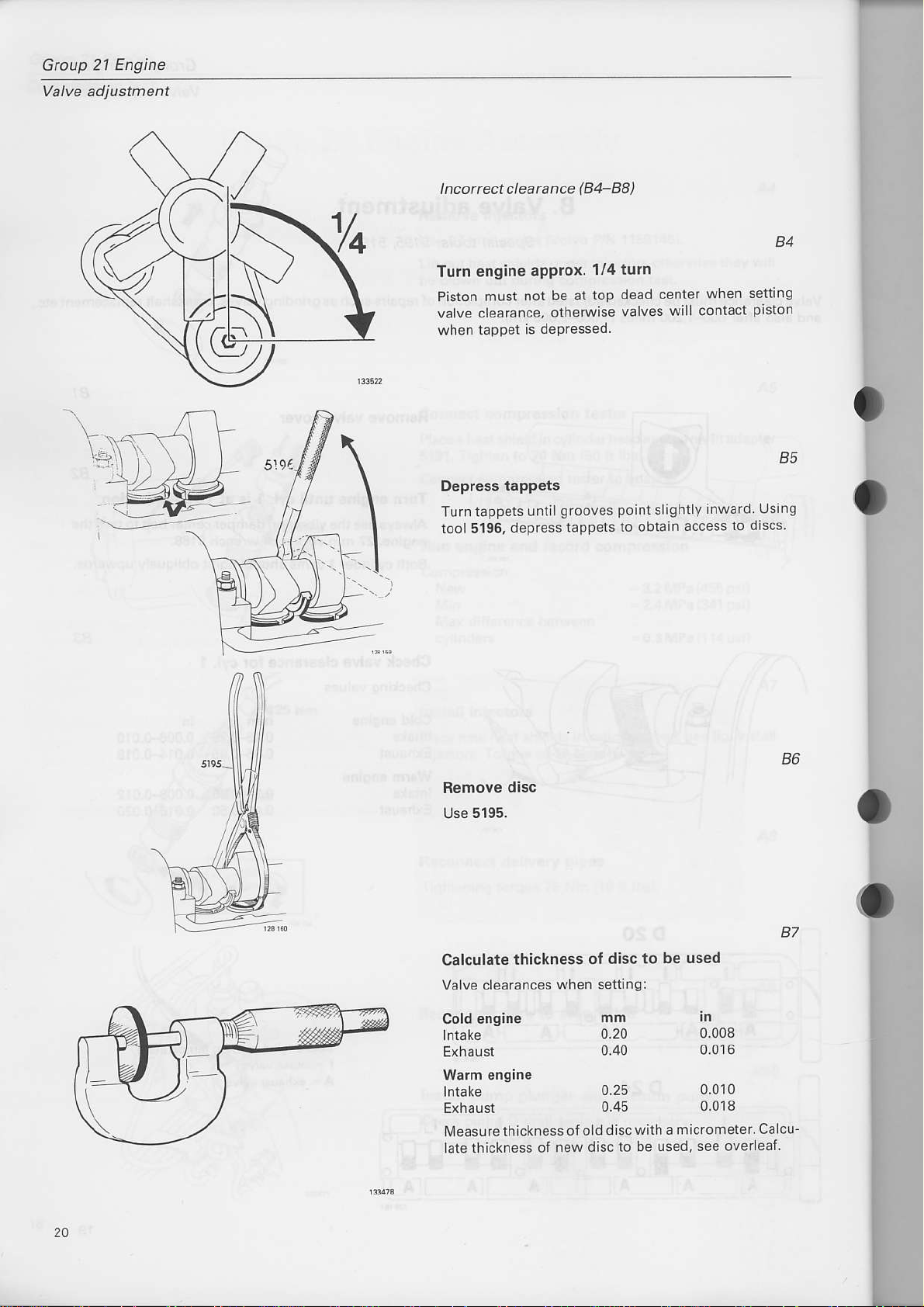

I nco rrect clea ra nce ( BZBS )

Tum engine

not be at

must

Piston

clearance,

valve

when tapp€t

apProx.

deprsssed

is

1/4

top dead

otherwise

Dopress tappets

grooves

Turn tappets

5196, depress

tool

until

tappets

iurn

center

valves

point

will contact

slightly

to obtain

setting

when

inward. using

access to

discs.

B4

piston

B5

Remove

Use

Calculate

Valve cl€arsnces

Cold

Exhaust

Exhaust

Measurethicknessof

late thickness

disc

5195.

thickness ol

when setting:

€ngine

old discwith

of new

disc to be

0.20

0.40

0.25

0.45

disc to be used,

used

a micrometer.

B6

B7

in

0.008

0.016

0.010

0.018

Calcu-

see overleaf.

20

Gtoup

Valve

21 Engine

adjustment

Erample:

lfclearance is 0.20 mm and specified clearance

mm then replace existing

disc with one which

is 0.25

is 0.05

Always use

Discthicknesses 6vailable

new discs,

=

3.0G-4.25 mm 6t

inte als

of 0.05 mm.

B8

Position new disc and

Disc

should

be lubricated

remove

and installed with size marks

Check/adjust valve clearance Ior remaining cylinderc

Checuadjust

D

20. 1-2-4,5-3

in following order:

D 24, 1-5-3-6-2-4

lmportantl Do not forget

before

checUadiusting valve clearance.

to rotate crankshafl 1/4 turn

pliers

B9

iY:'I,l

d.!

Recheck

Rotate engine several

valve clearance for

lnstall valve covet

Use new

gaskets if required.

Twoiypes

have a spacer, and

damage to

L€te

and eary type

stods are available see

ofpin

gaskel

hole in

by ovenightening,

parts

all cylinders

turns before rechecking.

fig.

gasket

is la.ger to

must not be imerchanged.

Laretypes

prevent

810

811

21

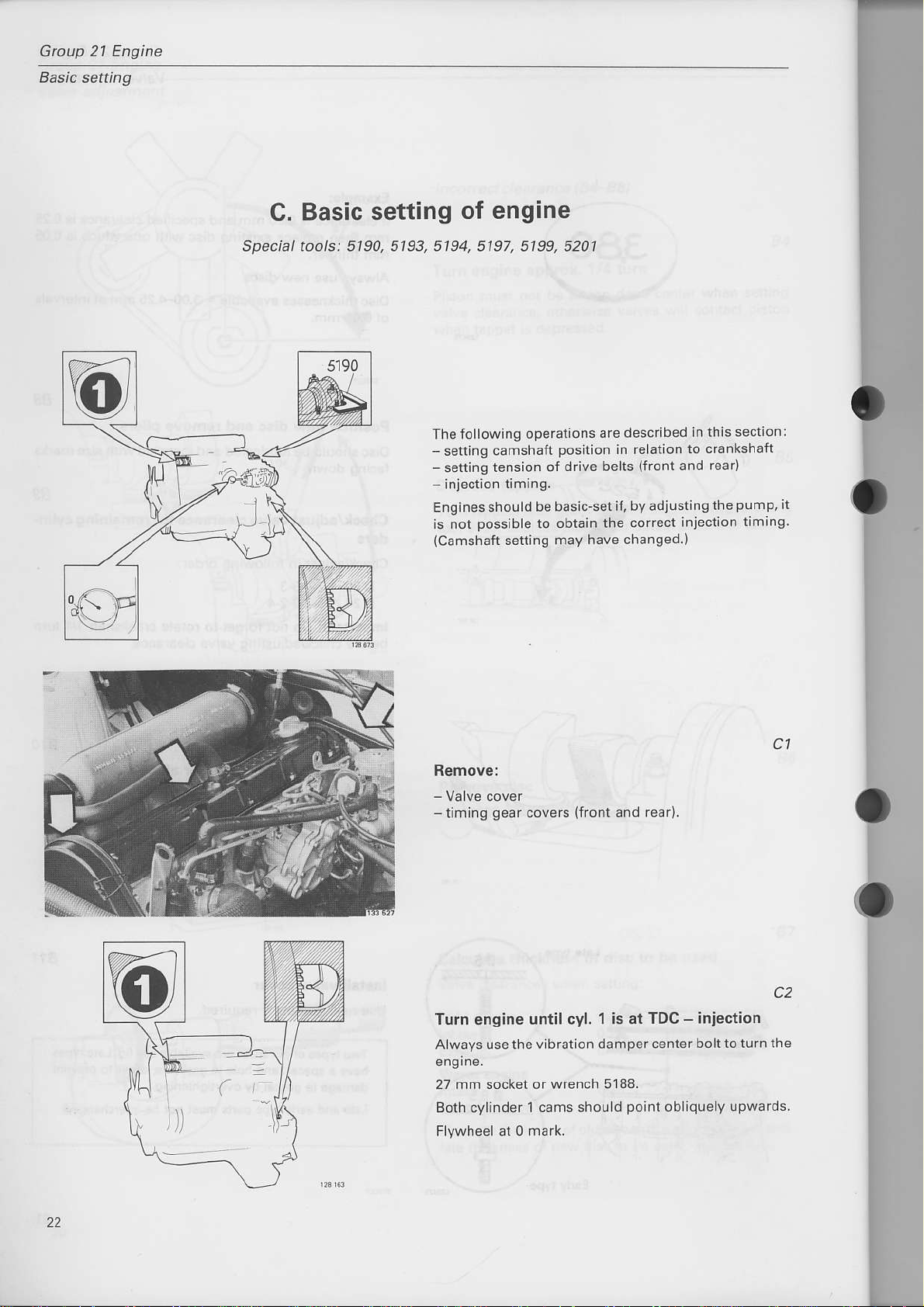

Group 21 Engine

Basic setting

Basic setting

C.

of engine

Special tools: 5190, 5193, 5194, 5197, 5199, 5201

The following

-

setting camshaft

-

setting

-

injection

Engines should

possible

is not

(Camshaft

operations

tension of

timing.

be basic-set

to obtain

sening may

position in rel6tion

drive belts

havs changed

are described

to crankshaft

and

{front

if, by adjusting

the correct

injection

)

in this sectionl

rear)

pump,

the

it

timing.

C1

Remove:

-timing

Turn engine

Always usethevibration

=

engine.

27

Both cylinder

Flywheel at 0

gear

covers

until cyl.

mm socket or wrench 5188.

I cams should

mark.

and rear).

{front

'l

is at

da mper center

point

C2

TDC - iniection

bolt to turn ihe

obliquely upwards.

22

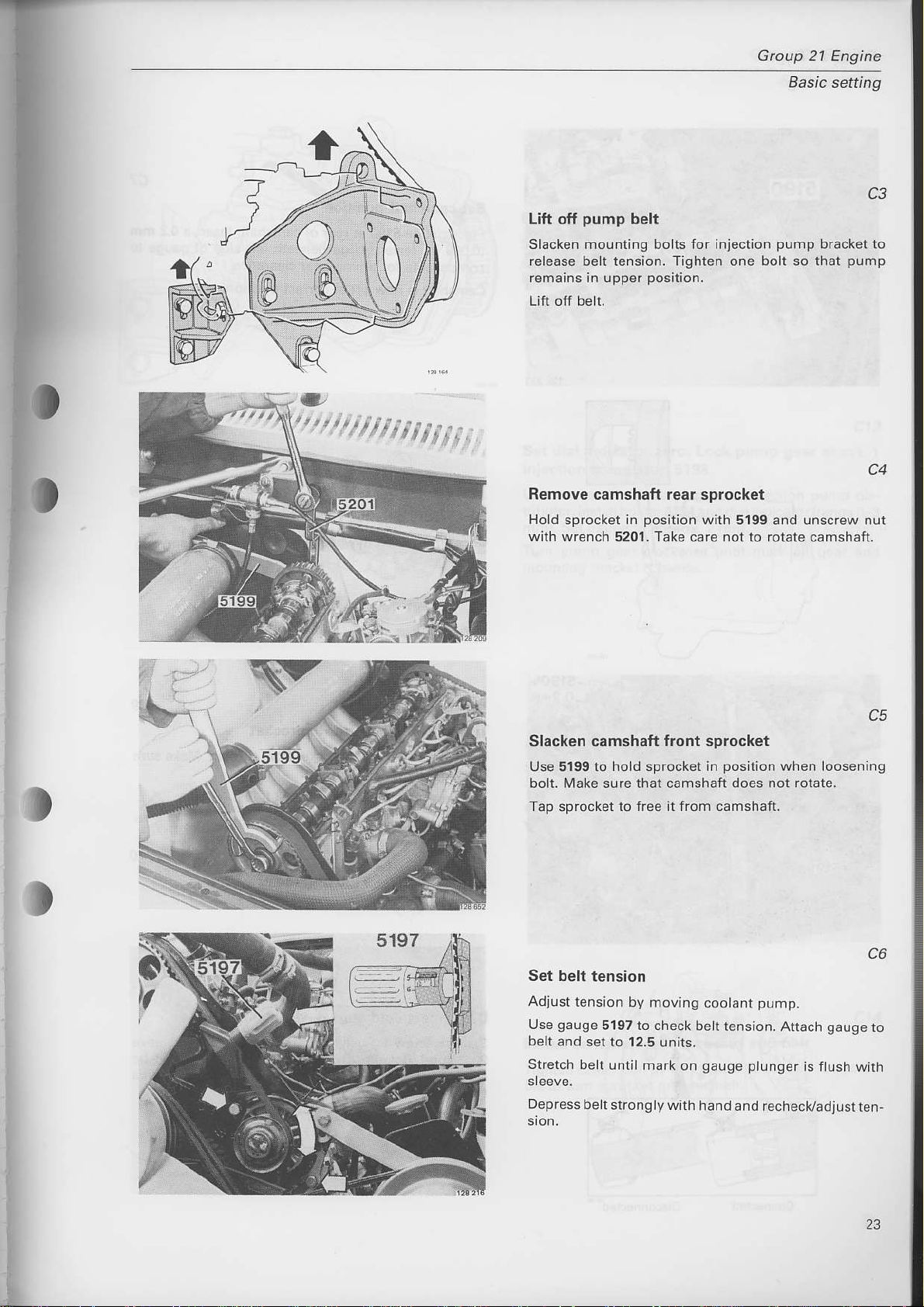

Group 21

Basic setting

Engine

a,

,":'trtiiiiiiiiii

ofi

pump

belt

belt

tension- Tighten one boll so

position.

pump

that

pump

Lift

Slacken mounting bolts for injection

release

remains in upper

Lift off belt.

Remove camshaft rear sprocket

Hold

sprocket in

with wren€h 5201. Take care not to rotate camshaft.

pos;tion

with 5199 and unscrew nut

c4

Slacken camshaft tront sprocket

Use 5199 ro

bolt. Make sure that camshafi does nol rolate.

Tap

sprocket

Set belt

Adjust

gauge

Use

belt

and set to 12.5

Stretch

Depress

hold

sp.ocker

to free it from camshaft.

tension

tension

beli until

by moving

5197 to check

mark on

belt

stronglywith

units.

posinon

in

coolant

belt tension.

gauge ptunger

hand and rechecUadjusl

whe'1 loosening

pump.

Attach

gauge

is ftush

C5

c6

to

with

ten

23

Group 2l

Basic

setting

Engine

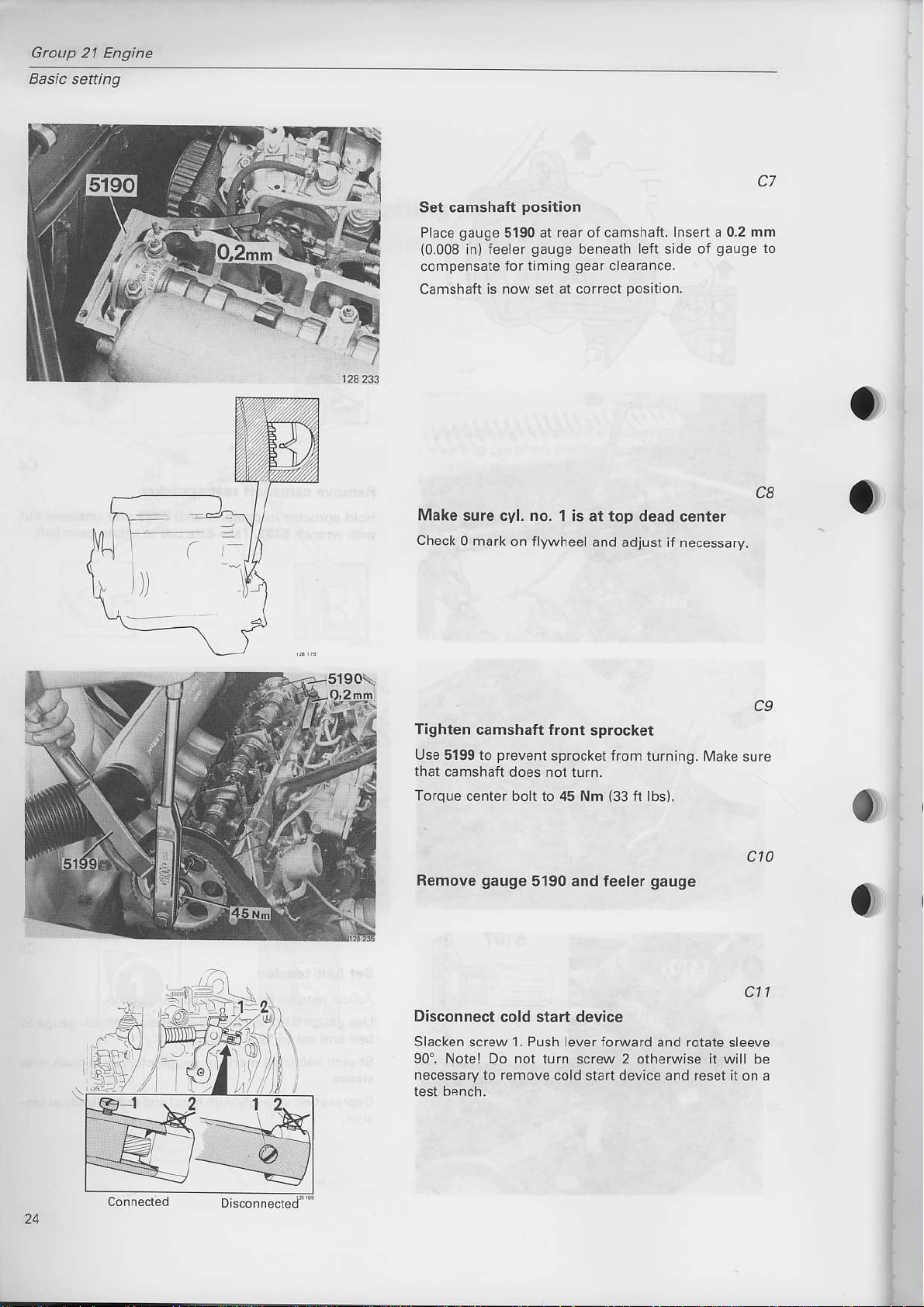

Set camshaft

gaLrge

Place

(0.008

in) ieeler

compensate

Camshafi;s now set at correct

Make sure cyl. no.

Check

0 mark

position

5190 at rear of camshaft.

sause

for timing

on flywheel

beneath lefi side of

gear

clear;nce.

1 is

at top dead center

and adiust if necessary.

Insert a 0.2 mm

position.

C7

sause

C8

to

)r

Tighten

Use 5199 to

that

Torque

Remove

Disconnect

camshaft front

prevent

camshaft does not

center bolt to 4s Nm

gauge

sprocket from

5190 and leeler

cold start device

sprocket

turn.

Slacken screw 1. Push lever

90". Notel Do not

necessary

to

turn screw 2 otherwise it will be

remove

cold start device and reset it on a

C9

turning. Make sure

(33

ft lbs).

c10

gauge

cl1

forward and rotate sleeve

Group

Basic setting

21 Engine

_--xar-L--.\.-

'

-.l\t'-iHi-

-.t";;

v

-

ilo ,,

.)!\\./.)

-.-

.-

/:)a>- L I

-

Basic-set iniection

S acken

marks

Retighten mo!ntin9

Sel dial indicator

injection using stop

Unscrew and remove

tributor. Install holder5194

mm). Set

Turn

mo'rnting

pump

pump

in

gauge

pump gear

bracket coincide.

pump

mountins bolts

and mounling

bolts.

zero. Lock

5193

plug

and dialindicator

to approx. 2 mm.

clockwise until mark on

(Ailen

key = 6 mm). Align

bracket by turning

pump

from injection

gear

at cyl. 1

pump

(range

gear

c12

pump

c13

dis0-3

and

Then turn

registers

Set indicator to

Turn

mounting bracket coincide. Lock

with

Install

Tighten cenler

b e to turn sprocket

pump gear

on

pump

gear

5193.

srop

camshaft

back slight

dial indicator.

zero.

clockwise !nlilmark on

(lnsert

bo t by hand, but

stop through

rear sprocket

on camshaft.

it

y

until min- reading

gear

gear

in

pump gear

and belt

should stil

and

this

pump

position

possi_

be

into

c14

25

Group 21 Engine

Basic

setting

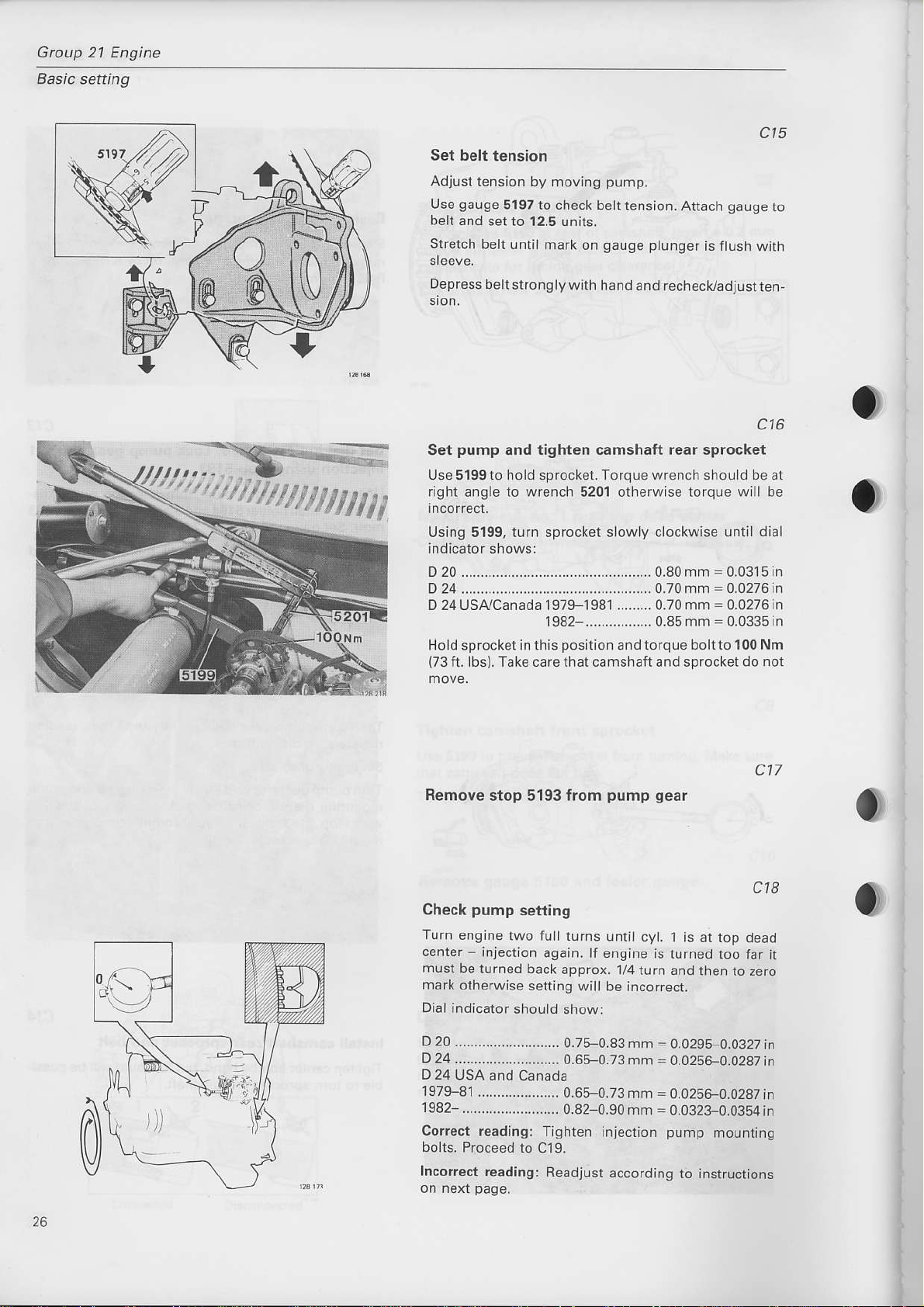

Set belt tension

Adjust tension by

gauge

Use

belt and

Strelch

5197 to check belt

set to 12,5 units.

belt unti mark

moving

on

pump.

tension. Aftach gauge

gauge ptunger

is ftush wirh

c15

ro

Depress beli

slrongly with

hand and .echecUadjusrren

c16

pump

Set

Use 5199 to hold sprocket. Torq!e wrench sho! d rre at

righi angle lo wrench 5201 otherwise torque will be

Using 5199, lurn sprocket s ow y clockwise

D 20 ....-............................................ 0.80 mm : 0.0315 in

D 24 .................................................

D24USA,/Canada1979 1981......... 0.70mm=0.0276in

Ho d sprocket

(73

ft. lbs). Take care that camshafi and sprocket do

and tighten camshaft rear sprocket

unlil dial

0.70 mm = 0.0276 in

1982-................. 0.85 mm: 0.0335 in

position

in

this

and torque boh to 100 Nm

not

Remove

Check

Turn

center - injection

must be

mark

Dia

O20...........................

D 24 .......-..................-

D 24

197F81.....................

1982

Correct

bolls.

rncoftect

stop 5193 trom

pump

engine two

otherwise

indicalor

USA and canada

........-................0.82

Proceed to

setting

full turns

again.

lurned back

setting will

should

reading: Tighren

C19.

reading:

Beadjust

pump gear

unri cyt. 1 is

lf engine is

approx. 1/41urn

be inco(eci.

show:

0.75

0.83mm=0.029F0.0327in

0.6F0.73 mm

0.65-0.73mm=0.0256

0.90 mm

injeciion

according

at lop oedo

turned

and

:

0.0256-0.0287

=

0.0323-0.0354

pump

roo rar r

then to zero

0.0287in

mounting

ro insrructions

c17

ct8

if

in

26

Group 21 Engine

Cylinder head, removal

-trnjE+:

-i;6't;

$tl

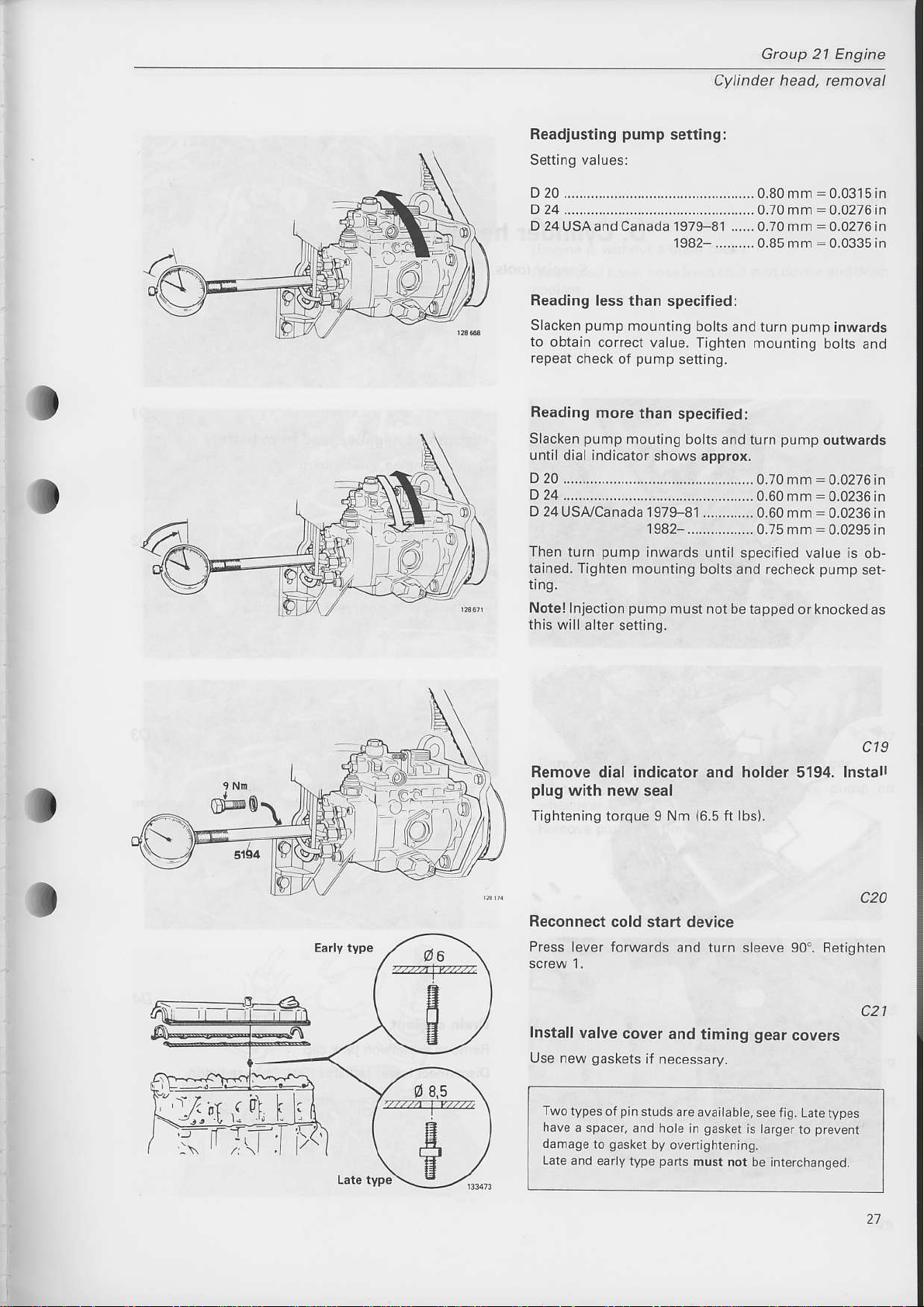

Readlusting

Setting valuesi

D 20 ......-.............-....-....................... 0.80 mm = 0.0315 in

D 24 .....-....-....-........-....-...-...-....-...... 0.70 mm

D24USAandCanada1979

Reading

Slacken

to

obtain corecr value.

repeat

check

Beading

Slacken

until dial indicator

D

20.....................

D 24 ..........................................-...-..

D 24USA,/Canada

Th€n turn

tained. Tighten

ting.

Notel

Injection

this wil

pump

less than specified:

purnp

of

more

pump

pump

alter setting.

setting:

1982- .......... 0.85 mm = 0.0335 in

mounting

pump

than

mouling bolts

l97F81

1S82 .................0.75mm=0.0295in

inwards until

mounting bolts

pump

bolts and lurn

Tighten mounring

setting.

specified:

shows approx.

.....................0.70 mm = 0.0276 in

............. 0.60 mm

must rot be tapped or knocked

=

0-0276

81 ......0.70mm:0.0276in

pump

inwards

bolts and

and turn

pump

outwards

0.60 mm : 0.0236 in

specified va ue is ob-

and recheck

=0.0236in

punrp

set-

as

in

/

Qa,s

zTazzzz

II

E

c19

Remove dial indicator and holder 5194. lnstall

plug

with new

Tishtening

seal

torque 9 Nm

(6.5

ft

lbs).

c20

Reconnect cold

Press

ever forwards and turn

start device

sleeve 90". Retighten

c21

Install valve

Use

new

cover

gaskets

and timing

if necessary.

gear

covers

'

Two types

h€ve

damage

Late ard eu ry

pin

ol

studs are

a spacer, and hoie in

gasker

to

by overrightening,

pa.ts

type

musr

avaitabte, see tig.

gaskel

is larger

not be inlerchanged.

Lare ryDes

prevenl

to

21

Group 21 Engine

Cylinder head, removal

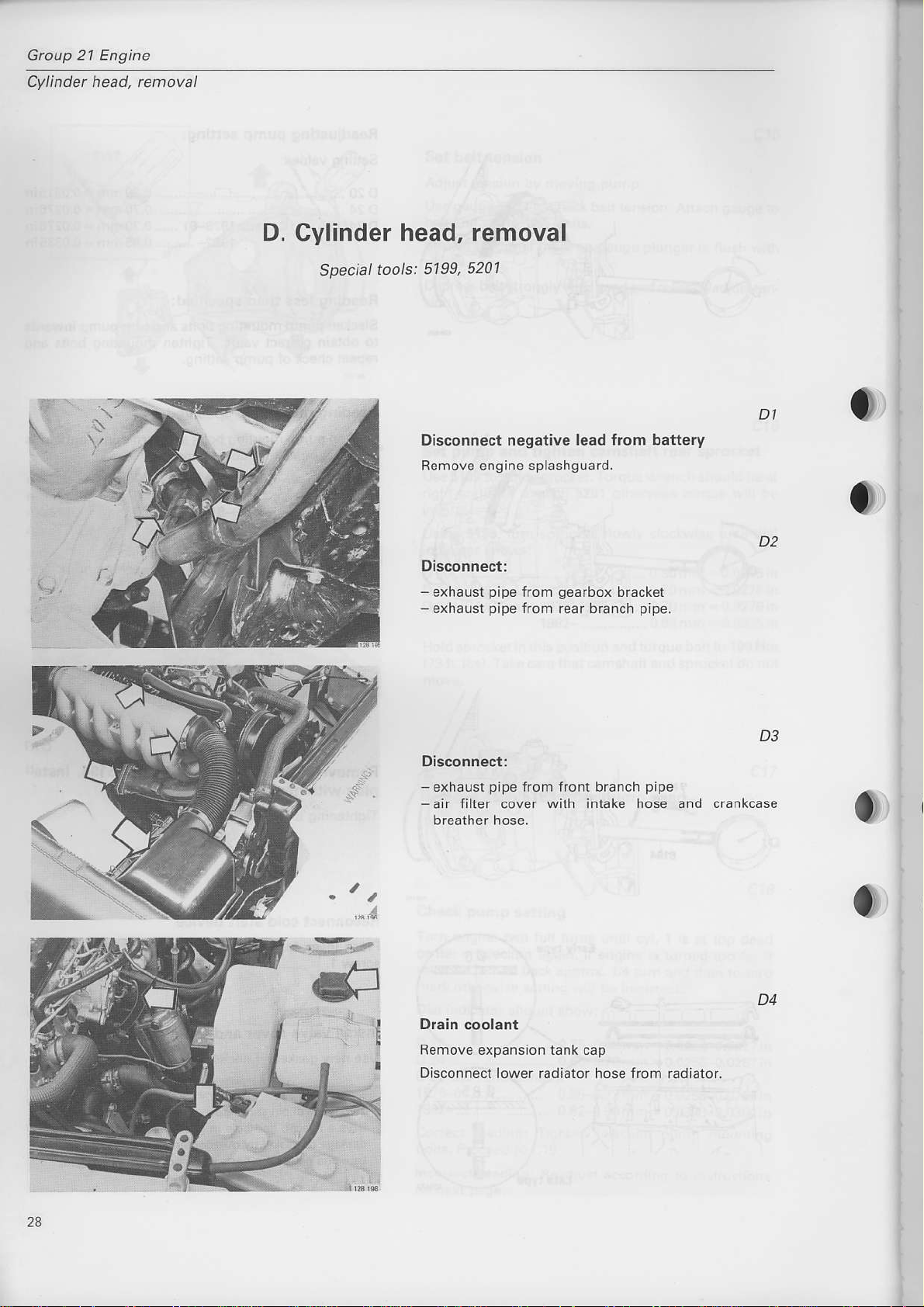

D.Cylinder head, removal

Special

tools:

5199, 5201

Disconnect negative lead from battery

Remove engine splashguard.

Disconnect:

-

exhaust

exhaust

pipe

pipe

gearbox

from

from rear branch

D1

D2

bracket

pipe.

Disconnect:

-

exhaust

-air

Drain

Remove expansion tank cap

Disconnect lower radiator hose from radiator

pipe

filter

cover

coolant

from front branch

with intake hose and crankcase

pipe

D3

D4

2a

Loading...

Loading...