Volvo 2001, 2002, 2003, 2003T Workout Manual

FOREWORD

workshop

This

The

instructions

the

heading

Both the

when

ordering

reserve

We

binding

.

UNIT

SI

Units

accordingtothe

Power

TorqueisgiveninNm

is

earlier unithp(horse-power)

earlier unit

earlier unit

PressureisgiveninPa

earlier

earlier

manual

"Special

engine

designation

parts

the

right

giveninkW

kpm

lbf

unit

kp/cm

unit

Ibf/in2(pounds

concerning overhauling

tools"

.

to

SYSTEM

internationalSIsystem

(kilowatt)

(kilopond

ft (poundfoot)earlier unit

2

(kiloponds

contains

.

and

carry

out

(newton

metre)

(Pascal)

metre)

per

repair

its

serial

design

per

square

square

instructions

describe

number

modifications

inch)

the

mustbeclearly

have been

Imp

centimetre)

for

the 2001,

most

and,

for

usedinthis

. gal (Imperial gallon)

2002

suitable

working

statedinall

this

reason,

Speedisgiven

earlier

Volume

earlier

earlier

and

the

book.The

unit

is

givenindm3(cubic

unitl(litre)

unitUSgal

2003

engines

method

correspondence

contentsofthis

rev/min

earlier

in

rev/s

using

Technical

units

(revolutions

(revolutions

(United

.

the

special

concerning

manual cannotberegarded

Publications

are

decimetre)

States

given

per

per

tools

AB

VOLVO

after

second)

minute)

gallon)

listed

the

engine

Department

the

PENTA

SI

under

and

as

units

.

INDEX

Components

DISASSEMBLY

Cylinder

Transmission

Piston,

Flywheel

Crankshaft

Camshaft

OVERHAUL

Disassembling

Valve

Valve

Valves......

Valve

Rocker

Injector

Injectors....

Assembling

Feed-pump.. . ... . . . . . ... . . . . . ... . . . . . ... . . . . . .....

Pistons...... . ....... . ... . . . . . ... . . . . . ..... . . . .....

Crankshaft..

Camshaft.... . ....... . ....... . ....... . ....... . .....

Connecting

Thermostat.. . ....... . ... . . . . . ... . . . . . ... . . . . . ... . .

Sea-water

guide..

head

. ... . ... . .....

. ... . ... . ....... . ..... . . . ....... . ... . . .

piston

. . ... . .

. . . . ... . ... . ....... . ... . . . . . ... . ... . ... . . .

. ... . ... . ... . ....... . .....

..... . ........... . ..... . . . ... . . . . . ... . . .

guides

seats.. . ....... . ....... . ... . . . . . ... . . . . . . . . . . .

. . ....... . ... . ... . ....... . .....

springs

. ....... . ....... . ....... . ... . ... . ... . . .

arm

mechanism...... . ... . . . . . ....... . ..... .

sleeve..

. . ....... . ....... . ..... . . . ....... . ... . ..8

the

...

rods

pump....

. . ....... . ... . . . . . ... . . . . . ... . .

.

. . ....... . ....... . ... . . .

rods..

. . ... . ... . ... . . . . . ....... . ... . . .

... . ....... . ....... . ... . ... . ... . . .

...

. . .

...

.

.

.

the

cylinder

. . ... . ....... . ..... . . . ....... . .....

cylinder

.

...

.

. . . . . . . . . . . ....... . ... . ... . . ... . . .

head.... . . . ..... . . . ... . . .

... .

head

. . ..... . . . ... . . . . . ... . ..9

.

.

. . . . . . ... . . . . . ... . ... . .....

. .

. . ... . . . . . ... . . . . . ..... . . . .....

. . ... . . .

.

. .

. .

.12

.

2

3

4

5

5

5

5

7

7

7

7

8

8

8

.

10

11

11

11

13

13

ASSEMBLY

Crankshaft

Pistons...... . ..... . . . ... . . . . . ....... . ... . ... . ... . .

Flywheel

Transmission

Adjusting the

Checking

2003

Fresh

Electrical

Fault tracing

Special

Technical

... . ... . ... . ... . ... . ... . . . . . ....... . ... . .

. . . . . . ... . ... . ... . ... . ..:........ . ... . ... . .

. ... . ... . ... . ... . ........... . ... . ... . .

valve

clearance

the

injection

Turbo..

water

. . ... . . . . . . . . . . . . . . . .

cooling

system

scheme

tools.. . . . . . . . . . . . ... . . . . . . . . ... . . . . . . . . . . . .

Data.. . . . . . . . ..... . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . ... . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . ... . . . . . . . . . . . .

. . . . ... . . . ... . . ....... .

angle

. . . . . ... . . . ... . . ... . ... .

. . . . . . . . . ..... . . .

14

14

15

15

17

17

21

25

26

28

29

30

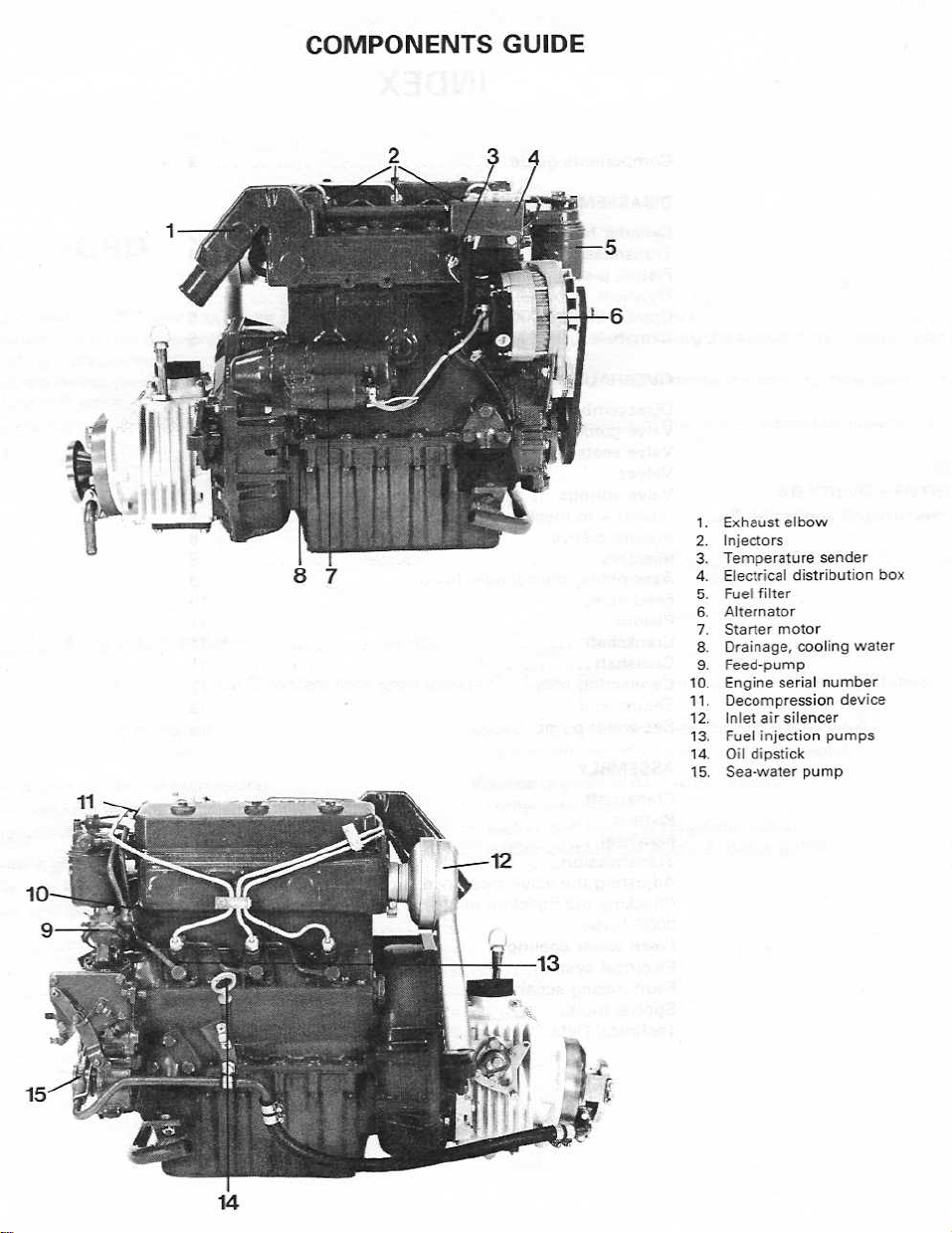

COMPONENTS

8

GUIDE

1

.Exhaust

2.Injectors

3.Temperature

4

.Electrical

5

.Fuel

6.Alternator

7

8

9.Feed-pump

10

11

12

13

14.Oil

15

filter

.Starter

.Drainage,

Engine

.

.Decompression

air

.Inlet

injection

.Fuel

dipstick

.Sea-water

elbow

sender

distribution

motor

cooling

serial

number

silencer

pumps

pump

box

water

device

Halpert@Optonline.net

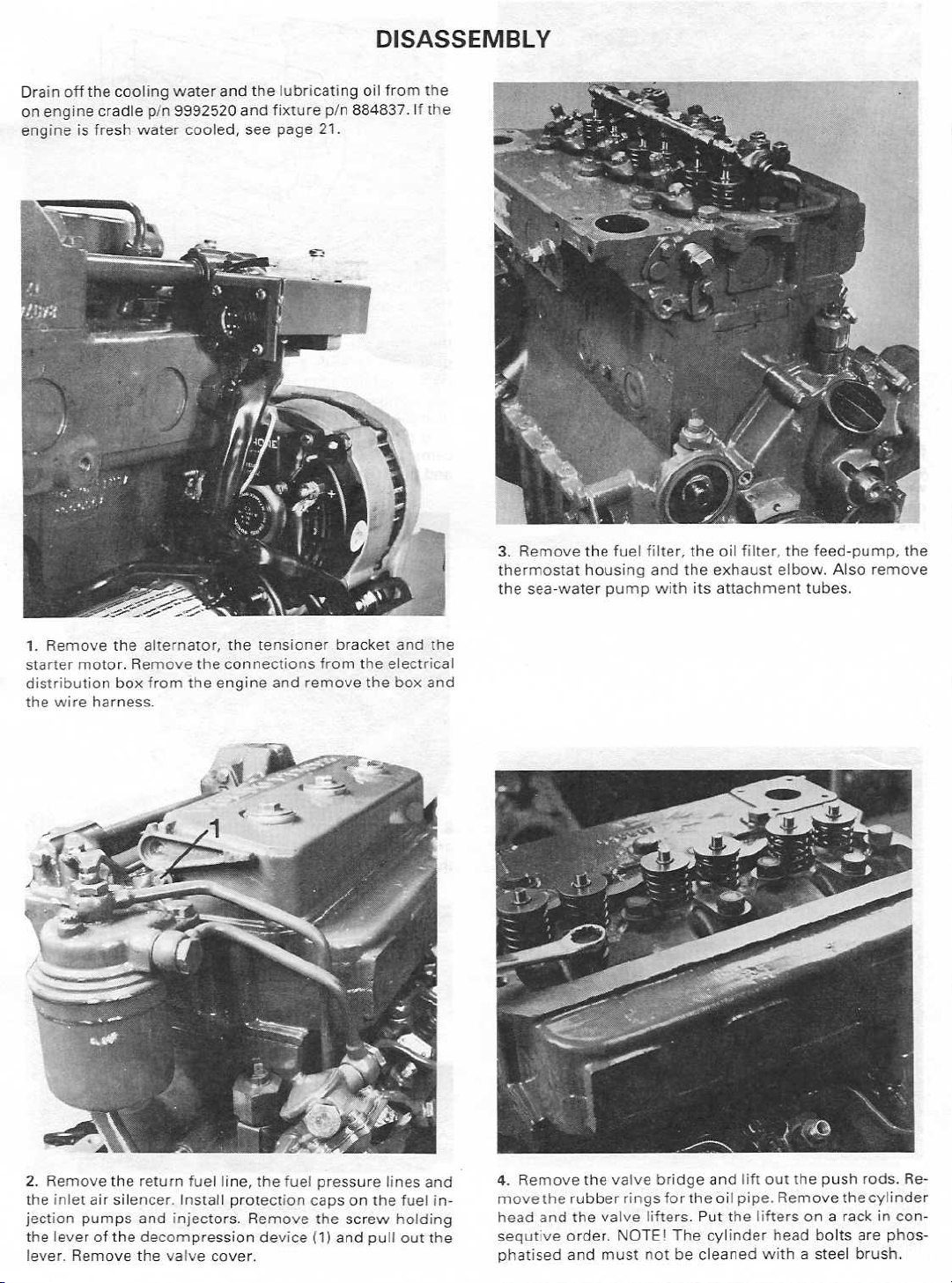

Drain

off

the

on

engine

engineisfresh

cradle

cooling

p/n

water

water

9992520

cooled,

and

the

and

see

lubricating

fixture

p/n

page21.

DISASSEMBLY

oil

from

the

.Ifthe

884837

1.Remove

starter

motor.Remove

distribution

wire

the

harness

the

alternator,

box

from

.

the

the

the

tensioner

connections

engine

and

from

remove

bracket

the

the

and

the

electrical

box

and

3.Remove

thermostat

the

sea-water

the

fuel

housing

pump

filter,

and

with

the

the

its

oil

filter,

exhaust

attachment

the

feed-pump,

elbow.Also

tubes

the

remove

.

2

.

Remove

the

inlet

the leverofthe

lever.Remove

the

air

silencer.Install

pumps

return

fuel

and

injectors

decompression

the

valvecover

line,

the

protection

.

Remove

device

.

fuel

pressure

capson

the

screw

and

(1)

the

pull

lines

fuel

holding

out

and

injection

the

4.Remove

the

head

and

the

rubber

the

valve

rings

valve

and

bridge

fortheoil

lifters.Put the

lift

out

the

pipe.Remove

liftersona

push

the

rack

rods

.

cylinder

in

consecutive

Remove

order, NOTE!Thecylinder

head

boltsare

phosphatised

andmustnot becleanedwitha

steel

brush.

5.Remove

ensure

were

removed.Take

on

the

.

the

fuel

injection

installationinthe

careofthe

side of

the

engine

pumps.Mark

same

block

cylinders

shims.Remove

and

fromwhich

lift

out the

the

pumps

the

pump

they

screws

to

lifters

7.Remove

throttle

the spring

gear

(When

facing

using

camshaft.Remove

and

the

control

the

spring

(3).Remove

wheels

outwards).Remove

the

pinbypunching

pullitstraight

withacolour-pen

installing

special

transmission

cover.Usea

(1).Then

the

the

gear

tool

p/n

it

out,

the

screws

outwards

cover:Startbyremoving

suitable

remove

oil

wheels,

the

bracing

884839.Never

this

.

pump

on

the

before

the

can

the

typeofpliers

end-nipple

cover

removing

marked

pinofthe

remove

very

transmission

and

side

well

to

(2)

and

mark

them

must

camshaft

the

bracing

bend

cover

the

remove

the

.

be

the

6.

Remove

using

the

puller

damaged

puller

and

.

the

pulley

9992265.Place

p/n

the

crankshafttoavoid

center

bolt

a

and

pull

protection

the

crankshaft

off

the

pulley

padbetween

being

8.The

are

set

this

will

9.Remove

the

rearof

holding

max

.-volume-screw

Volvo

by

affect

the

the

block

the

control

Penta

the

engineoutput

control

and

rod

(1)

and

the

max

and

must

never

be

.

rod.Startbyremoving

thetwo

.

screwsonthe

.-rev-screw

changed

the

plug

pump

(2)

since

at

plane,

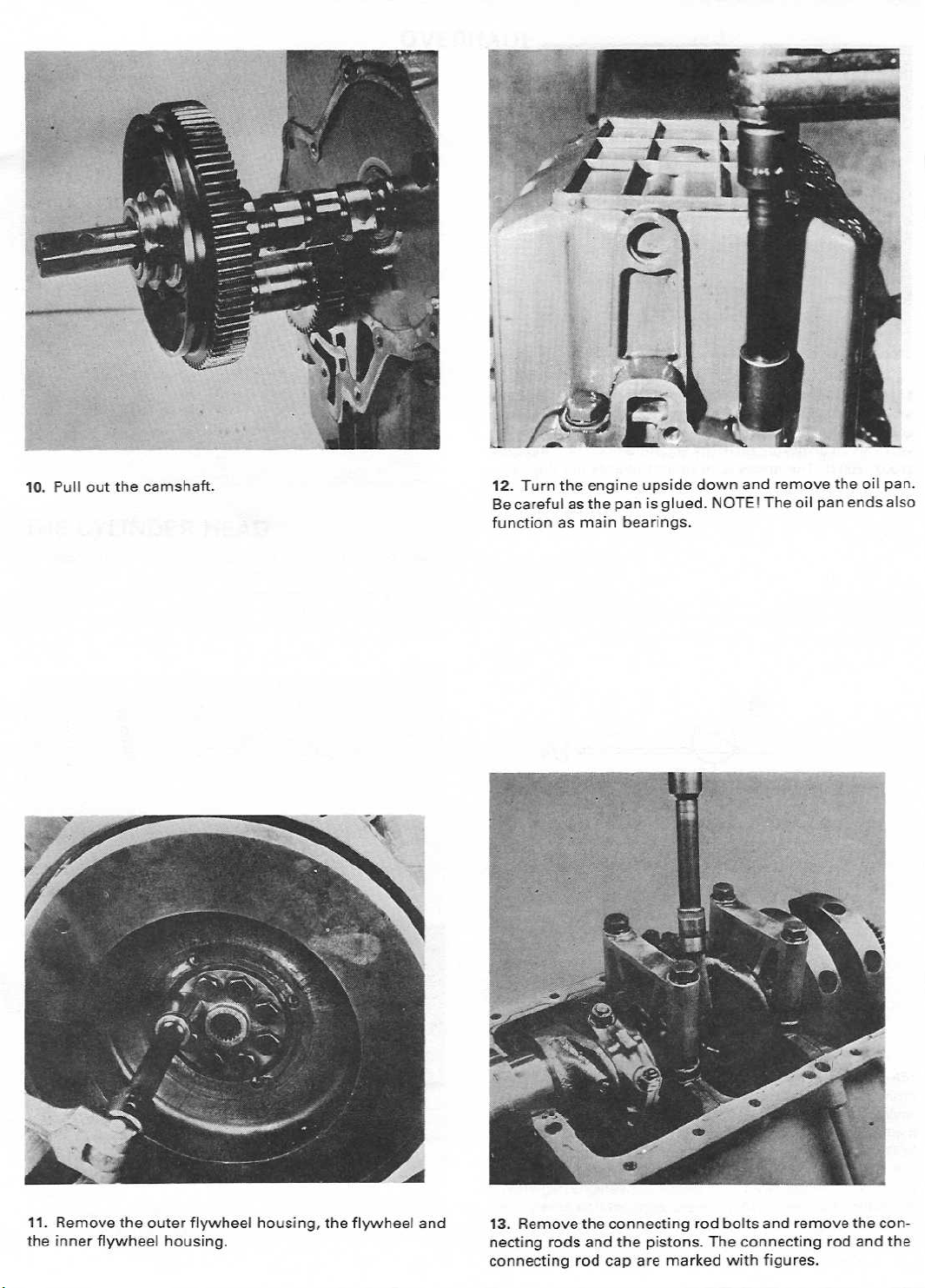

10.Pull

out the

camshaft

oil

pan

.

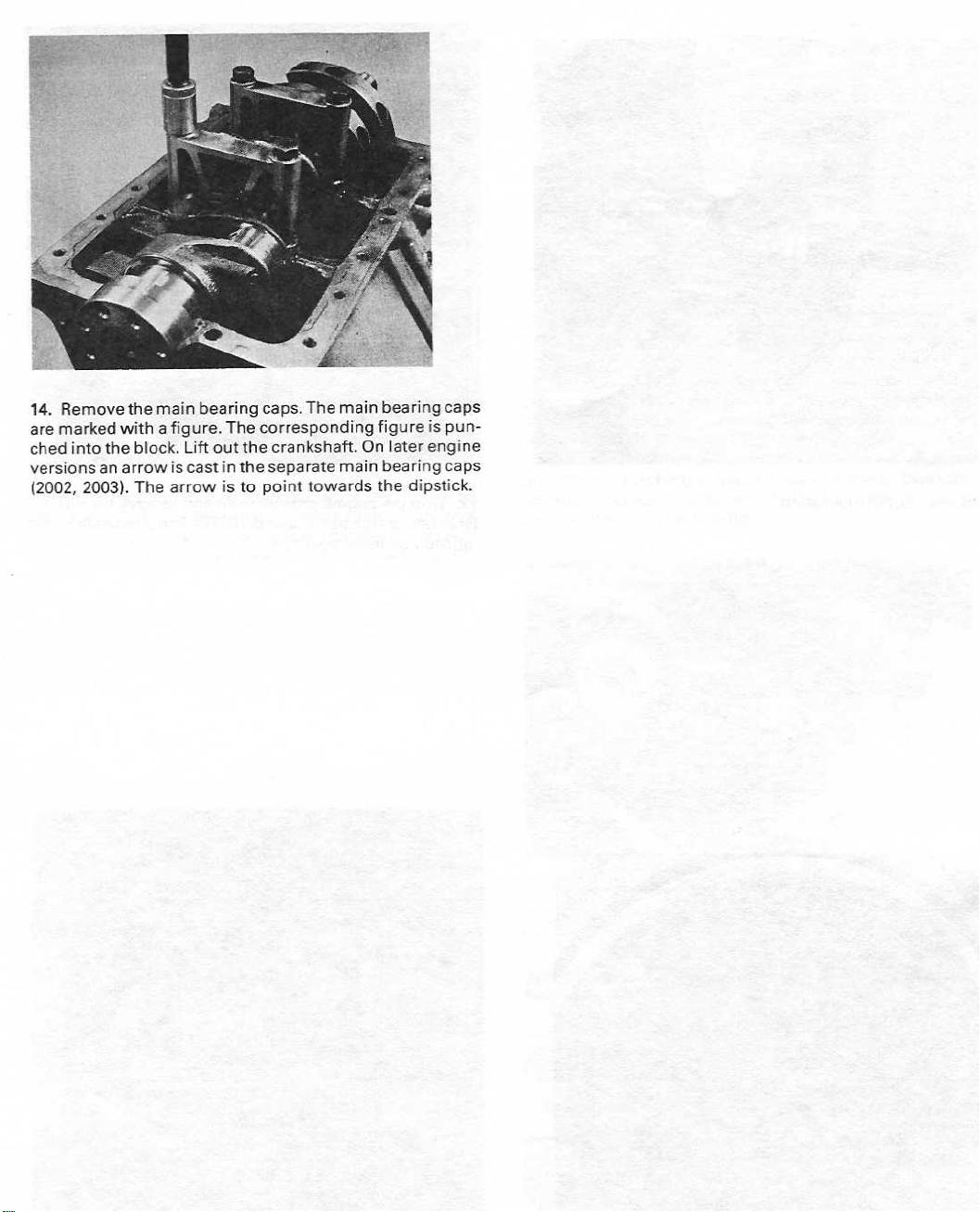

12.Turn

Be

functionasmain

the

engine

carefulasthe

upside

panisglued

bearings

.

down

.

NOTE!

and

remove

The

oil

pan

the

ends

.

also

11

.

Remove

the inner

the

flywheel

outer

flywheelhousing,

housing

the

flywheel

.

and

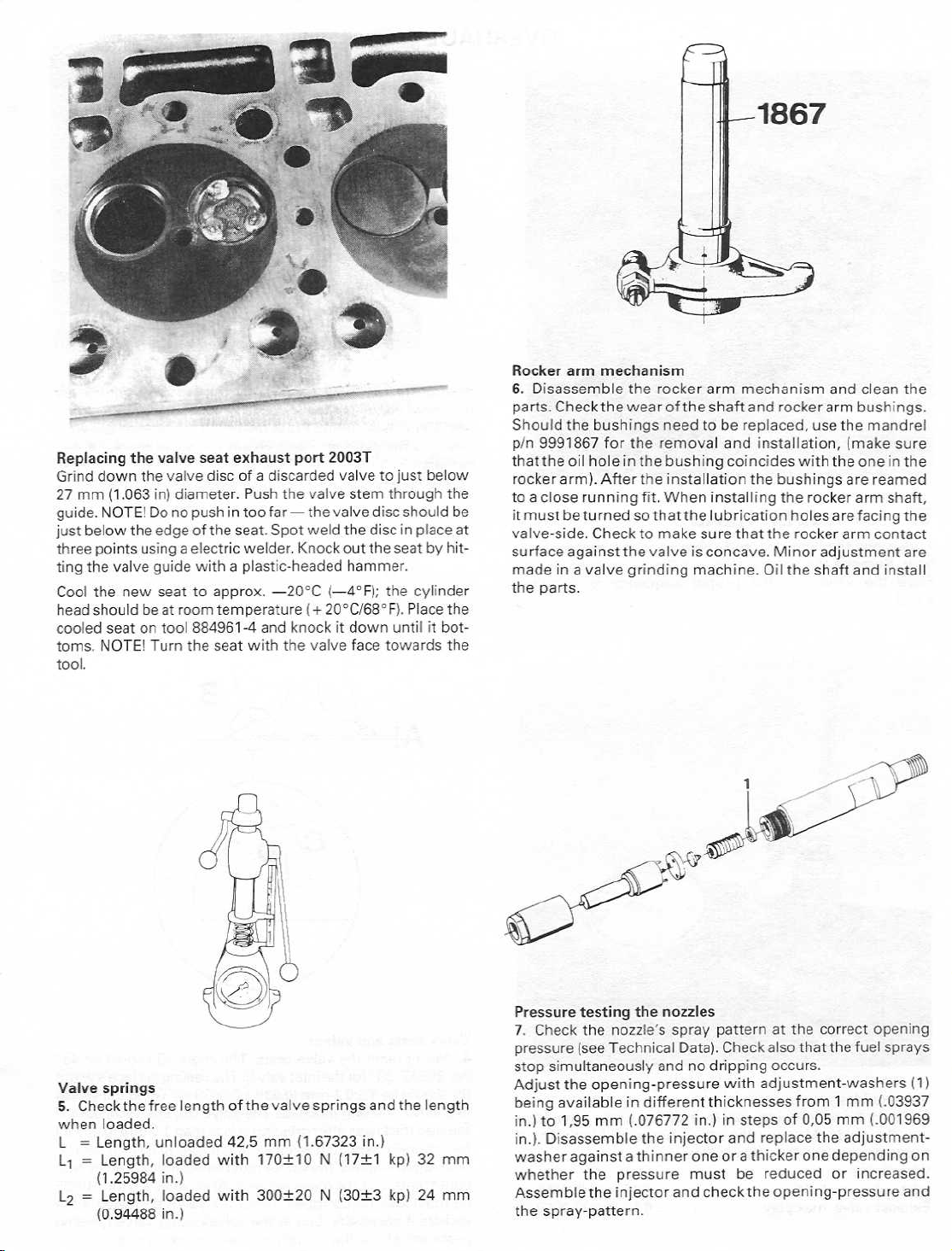

13.Remove

connecting

rods

the

and

rod

connecting

the

pistons

cap

are

marked

rod

.

bolts

The

with

and

remove

connecting

figures

the

rod

and

the

connecting

.

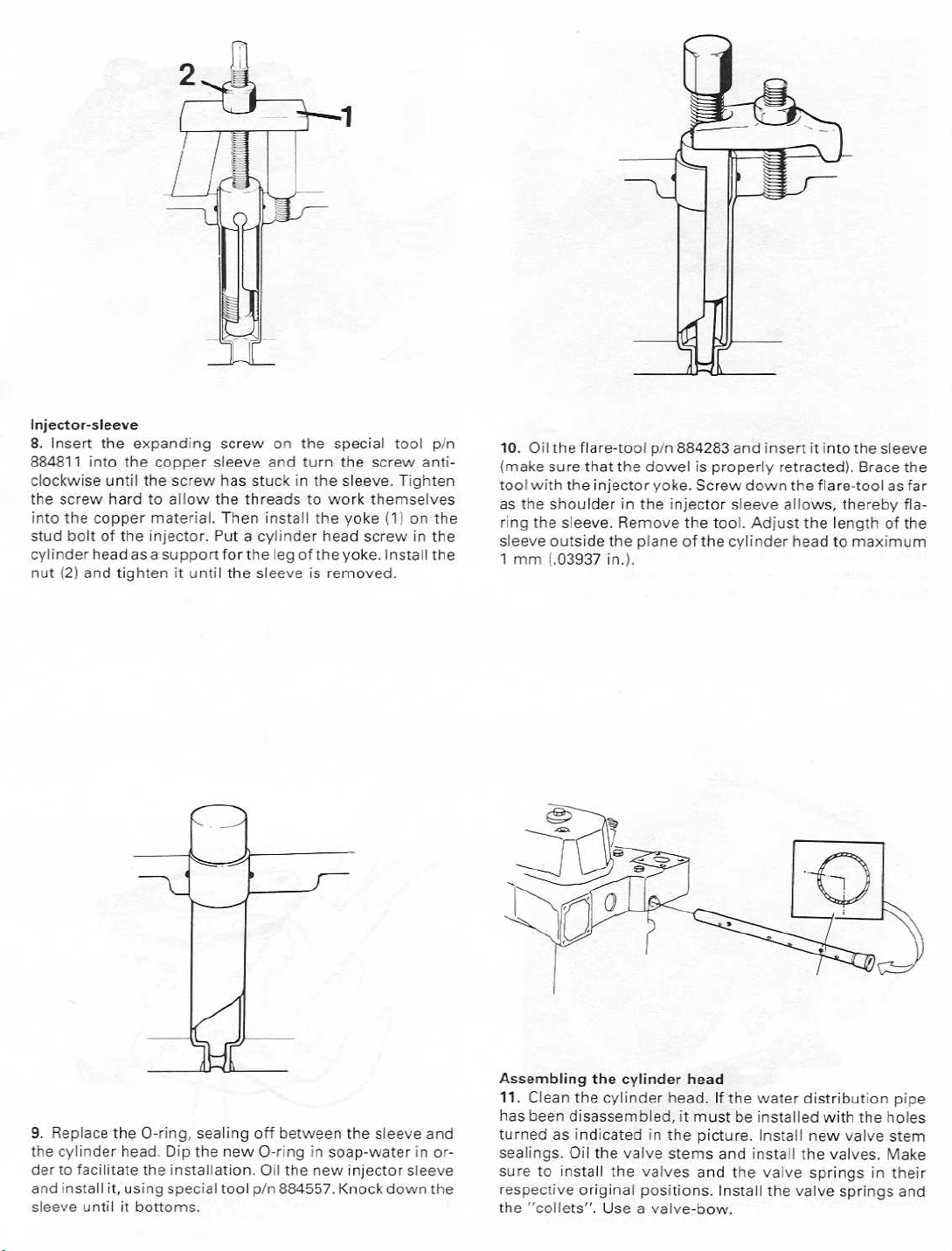

14.Remove

are

marked

versions

(2002,

the

with

into

the

block.Lift

arrowiscastinthe

an

2003).Thearrowisto

main

bearing

a figure.The

out

caps.The

corresponding

crankshaft.On

the

separate

point

main

main

towards

bearing

figure

later

bearing

the

dipstick

caps

is

engine

punched

caps

.

3.Use

the

884559

down

new

mandrel

valve

install

to

to

the

.

p/n

guides

them.Press

cylinder

5218topress

externally

down

head.Ream

out the

and

the

mandrel

the

valve

use

valve

guides.Oil

mandrel

all

the

guides

p/n

way

if

necessary

THECYLINDER

1 .

Remove

bow.Remove

Place

stand

the

"collets"

the valves.Removethe

the

valves

.

HEAD

valve

springs

sequence

and

in

the

proper

valve

using

a

stem

inavalve

valve

seals

.

Valve

guides

2.Check

into

the

necessary,

Wear

limits

Inlet

valve,

Exhaust

the valve

guide.Measure

replace the

valve,

:

max

guide

play

max

wearbyinserting

the play

valve

guides

. ...

. . . . . . ... . .0.15

play

. . . . . . . . . . . .0.15

using

.

anew

a

dial

mm(0.0059

mm(0.0059

valve

stem

indicator.If

in)

in)

Valve

seats

and

valves

4.Millorream

(for

2003T,

(B)

shouldbe1±0.1

in

a valve

the

disc

thickness

for

naturally

bent

stems,orif

in)

must

rockersifnecessary.Lapinthe

paste

and

the

valve

seats.The

30°

for

the

inlet

valve).The

mm(0.039±0

grinding

engines,

alsobescrapped.Grind

check

machine.The

after

aspirated

the

the

the

grindingisless

engines

valves

measurement

contact

area

angle

sealing

.0039

in).Grind

angle

(D),

than

or 0.8mm

must

bescrapped.Valves

(A)

exceeds2.5mm(0

valve

the

valves

using

with

marking

shouldbe45°

(C)

surface's

the

valves

Tech.data.If

see

1.0mm(0.039

in)

for

(0.031

tip

towards

valve

grinding

dye

.

width

in)

with

turbocharged

.098

the

Replacing

Grind

27

mm(1.063

guide.NOTE!Do

just

three points usingaelectric

Cool

head

cooled

tool

down

below

the

the

should

.

valve

new

seat on

NOTE!

the

the

the

beat

Turn

valve

seat

valve

discofa

in)

diameter

not

push

edge

of the

withaplastic-headed

guide

to

tool

approx.-20°C

room

temperature

884961-4

the seat

seat

exhaust

.

in too

seat.Spot

port

discarded

Push

the

valve

far-

the

weld

welder.Knockout

(+

and

knockitdown

with

the

valve

2003T

valve

to just

below

stem

through

valve

disc

should

the

discinplace

the seat

hammer

(-4°F);the

20°0168°F).Place

face

.

cylinder

until

towards

by

it

the

be

at

hitting

the

bottoms.

the

Rocker

6

parts.Check

Should

p/n

that

rocker

toaclose

it

valve-side

surface

made

the

arm

.

Disassemble

the

9991867

the

arm)

must

beturnedsothat

inavalve

parts

mechanism

the

bushings

for the

oil

holeinthe

.

After

running

.

Checktomake

againstthe

.

the

rocker

armmechanism

wearofthe

the

fit

valveisconcave.Minor

grinding

shaft

needtobe

removal

bushing

installation

. When

installing

the

lubrication

sure

machine.Oil

replaced,

and

coincides

that the

and

rockerarm

usethe

installation,

with

the

bushings

the rockerarm shaft,

holes

rocker

adjustments

the

shaft

and

(make

the

are

are

arm

and

clean

the

bushings

mandrel

sure

oneinthe

reamed

facing

the

contact

install

.

are

Valve

springs

5.Checkthe

when

loaded

L =

Length,

L

1 =

Length,

(1

.25984

L2=

Length,

(0

.94488in.)

free

length

.

unloaded

loaded

in

.)

loaded

of

42,5

with

with

the

valve

mm

170±10N

300±20

springs

(1

.67323in.)

(17±1

N

(30±3

and

kp)

kp)

the

length

32

24

Pressure

7.Check

pressure

stop

Adjust

being

in.)to 1,95

in.).

mm

whether

mm

Assemble

the

testing

the

nozzle's

(see

Technical

simultaneously

the

opening-pressure

available

mm(.076772in.)insteps

Disassemble

the

pressure

the

injector

spray-pattern

the

nozzles

spray

Data)

andnodripping

in

different

the

injector

and

.

patternatthe

Check

.

with

thicknesses

and

must

be

check

correct

also that the

occurs

.

adjustment-washers

from1mm

of

0,05

mm(.001969

replace

reduced

the

the

or

opening-pressure

opening

fuel

sprays

(1)

U3937

adjustment-washer

increased

againstathinneroneorathickeronedependingon

.

and

Injector-sleeve

8.Insert

884811

the

into

stud

cylinder

nut

screw

the

bolt of

(2)

and

into

the

hardtoallow

copper

the

headasa

tightenituntil

expanding

the

copper

material.Then

injector.Putacylinder

supportforthe

screw

sleeve

the

the

threads

on

the

special

and

turn

the

to

work

install

the

yoke

head

legofthe

sleeveisremoved

yoke.Install

tool

p/n

screw

anti-clockwise

themselves

(1)

on

the

screwinthe

the

.

until

the

screw

has

stuckinthe

sleeve. Tighten

10.Oil

(make

with

tool

as

the

sleeve

1

mm

theflare-tool

sure

that

the

shoulder

the

sleeve.Remove

outside

(

.03937in.)

the

injector

in

the

.

p/n

884283 and

dowelisproperly

yoke.Screw

the

injector

planeofthe

the

tool.Adjust

sleeve

cylinder

insertitintothe

retracted).Brace

down

the

flare-toolasfar

allows,

the

headtomaximum

thereby

length

sleeve

the

flaring

of the

9.Replace

the

cylinder

to

facilitate

and

install

sleeve

untilitbottoms

the

O-ring,

head.Dip the

the

installation.Oil

it,

using

special

sealing

new

tool

.

off

between

O-ring

the

p/n

884557.Knock

the

in

soap-water

new

sleeve

injector

down

and

in

order

sleeve

the

Assembling

11.Clean

has

been

turnedasindicatedinthe

sealings.Oil

suretoinstall

respective

the

"collets".Useavalve-bow

the

cylinder

the

cylinder

disassembled,

the

valve

the

valves

original

positions.Install

head.If

stems

head

the

water

it

must

be

installed

picture.Install

and

install

and

the

.

distribution

with

new

the valves.Make

valve

springs

the

valve

the

valve

in

springs

pipe

holes

stem

their

and

Loading...

Loading...