Volvo 120 Operating & Service Manual

2-DOOR

CARS

(120 T)

DESCRIPTION

OPERATING INSTRUCTIONS

SERVICING

BEFORE YOU START DRIVING YOUR NEW VOLVO PLEASE

READ THROUGH THIS INSTRUCTION BOOK CAREFULLY.

I

T CONTAINS ALL THE INFORMATION YOU NEED TO

BE ABLE TO DRIVE AND SERVICE YOUR VEHICLE IN THE

BEST POSSIBLE WAY. BY FOLLOWING THE INSTRUCTIONS

GIVEN IN THIS BOOK, YOU WILL FIND THAT YOUR

VOLVO WILL COME UP TO ALL THE EXPECTATIONS

CONCERNING ECONOMICAL OPERATION AND EXCELLENT

PERFORMANCE THAT YOU HAVE EVERY RIGHT TO

EXPECT OF A TOP-QUALITY VEHICLE. DO NOT WAIT

UNTIL SOMETHING GOES WRONG BEFORE YOU START

READING THIS BOOK. READ IT NOW. THE SHORT TIME

THIS TAKES WILL MORE THAN REPAY YOU IN THE

LONG RUN. THIS INSTRUCTION BOOK IS NOT INTENDED

TO BE A COMPREHENSIVE TECHNICAL MANUAL AND

DOES NOT CLAIM TO MAKE THE READER INTO A PERFECT

CAR MECHANIC. IT WILL, HOWEVER, SHOW YOU HOW

TO LOOK AFTER YOUR VEHICLE SO THAT TROUBLE

I

N FUTURE CAN BE AVOIDED. FOR A MORE DETAILED

MECHANICAL DESCRIPTION AND REPAIR PROCEDURES, YOU

ARE REFERRED TO THE SPECIAL SERVICE MANUAL

FOR THE VEHICLE.

CONTENTS

VOLVO SERVICE

page

The Volvo Service Organization

4

Warranty and Service Booklet

5

Service Inspections

5

TECHNICAL DESCRIPTION

page

Type designations

6

Engine

8

Electrical system

9

Power transmission

1

0

Brakes

11

Wheels and tyres

11

Body

1

2

I

nstruments and controls

1

6

OPERATING INSTRUCTIONS

page

Running-in

22

Starting the engine

23

Gear-changing

24

Points worth noting

25

S E R V I C I N G

page

General

27

Maintenance scheme

28

Lubrication

30

Engine

34

Electrical system

39

Power transmission

43

Brakes

43

Front end

43

Wheels and tyres

44

Body

46

Servicing before long-distance trip

49

Procedure in cold weather

50

Lubricating chart

60

FAULT TRACING

page 52

SPECIFICATIONS

page53

3

VOLVO SERVICE

4

Volvo Service Organization

I

n order to get the most out of the invested capital represented by a car,

itmust be looked after and serviced regularly. Volvo has gone to a great

deal of trouble in the design and selection of material to ensure that

the car in question only requires a minimum of servicing. All this work

will

be in vain unless we can count on your co-operation - that is to

say, that you make sure that your vehicle gets the regular servicing it

needs. In order to help you, Volvo has built up a world-wide service

organization.

All

Volvo dealers have specially trained personnel and

receive a continuous supply of technical information from the Volvo

Service Organization concerning repairs and adjustment work. They

have also special tools, designed at the Volvo factory.

All

Volvo dealers have a comprehensive stock of spare parts which is

your guarantee for genuine Volvo spares. Our dealers are, therefore, in

the very best position to give your vehicle first-class service concerning

both maintenance operations and repairs. You should also refer to your

dealer if you need information about your Volvo that is not included in

this instruction book .

Not only is there a Volvo workshop within easy reach in your own

country:

Volvo has also a widely distributed service network in other

countries.

VOLVO SERVICE

Warranty and Service Booklet

A warranty and service booklet accompanies each vehicle when it is

delivered. This book contains a coupon entitling you to a free service

i

nspection after 2 500 km (1 500 miles). If possible, let the dealer who

supplied the vehicle carry out this service inspection. If necessary,

however, any of our dealers can do this.

If

our six-month guarantee is to apply, we make one absolute condition

and that is that the above-mentioned free inspection is carried out

at roughly the mileage shown and that the vehicle has been looked after

i

n accordance with the instructions in this book.

Service Inspections

After the free service inspection has been carried out, you should

make an agreement with your dealer concerning continued, regular ser-

vice inspections in accordance with the suggestions made in our Ser-

vice Book. Thorough and regular servicing is of vital importance for the

performance and length of life of the vehicle.

Always use genuine Volvo spares.

5

Type designations

This instruction book deals with cars having the

following type designations (note that some variations are not to be found on certain markets)

6

DESCRIPTION

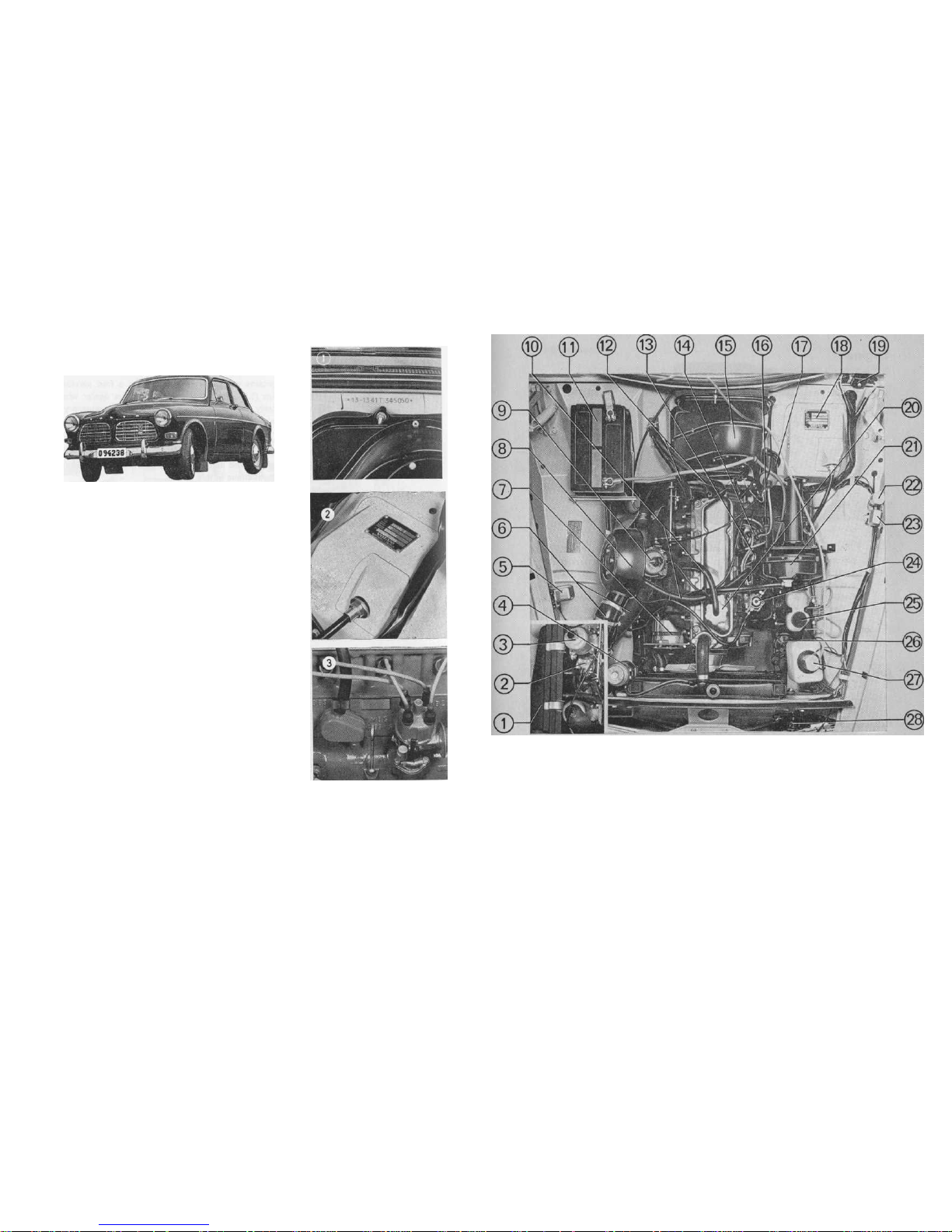

1.

The car type designation and chassis number

are stamped on the cowl under the bonnet.

2.

Stamped on a plate to the left under the bonnet

i

s the type designation together with the code

numbers for colour and upholstery.

3.

The engine type designation, part number and

serial number are given on the left-hand side of

the cylinder block. The last figures of the part

number are stamped on a tab. The serial number

follows this with all the figures stamped on. For

i

dentifying the engine, both the part number and

serial

number should be quoted, for example

496918-3456.

I

n all correspondence concerning your vehicle with

the dealer and when orderi

ng spare parts, the type

designation,

chassis

and

engine number should always be quoted.

Engine compartment (B 20 A)

7

Engine (B 20 B)

1.

Air cleaner (B 20 B)

10.Hoses for positive

19.Fusebox

2.

Floatchamber (B 20 B)

3.

Carburettors (B 20 B)

11.

crankcase ventilation

Battery

20.

Oil filler cap

21.

Brake servo cylinder

4.

Expansion tank with

1

2.

Hoses for heater system

22.

Relay for reversing lights

filler cap for coolant13.

Oil dipstick

23.

Relay for headlight flasher

5.

Voltage regulator

14.

Distributor

24. Fuel pump

6.

Hoses for air preheating

7.

Alternator

8.

Air cleaner (B 20 A)

15.Car heater

1

6.

Starter motor

25.

Brake fluid container

26. Steering box

27.

Windscreen wipers

17.I

gnition coil

9.

Carburettor (B 20 A)

18.

Data plate - type,

28.

Horn

upholstery colour code

Type designation

Engine

Gearbox

1

3-134

B 20 A

M 40

1

3-334

B 20 B

M 40

1

3-344

B 20 B

M 40

Engine

8

DESCRIPTION

The engine is a four-cylinder carburettor unit with overhead valves. The

pistons are made of light-alloy and the upper compression rings on

each piston are chromed. The main bearing and big-end bearing shells

are replaceable. The crankshaft is statically and dynamically balanced.

Engine type B 20 A has an output of 90 h.p. (SAE) and is equipped with

a Zenith-Stromberg horizontal carburettor. (On certain markets SU horizontal carburettor.)

Engine type B 20 B has an output of 118 h.p. (SAE) and is equipped

with twin SU horizontal carburettors. (On certain markets twin ZenithStromberg horizontal carburettors.)

Fuel system

Fuel is fed from the tank to the carburettor by a fuel pump which is

driven by a cam on the engine camshaft. There is a filter in the fuel

pump which traps water and other impurities in the fuel.

Exhaust emission control

The engine is fitted with exhaust emission control, that is, a system as a

result of better mixing and distributing of fuel and air provides a more

complete combustion and thereby cleaner exhaust gases. On the B 20 A

engine, the exhaust emission control is obtained through the carburettor

which is specially designed for this purpose. On the B 20 B engine the

exhaust emission control is provided partly through carburettors specially

designed for this purpose and partly by the engine having a special induction manifold with throttles and preheating chamber. When driving at

l

ow speeds the throttles are closed so that the fuel-air mixture is forced

to pass the preheating chamber.

When higher output is required, the throttles open so that the fuel-air

mixture flows directly to the cylinders.

It

DESCRIPTION

Air preheating

Certain variations of the 120 models are provided with thermostatically

controlled air preheating.

With this arrangement the induced air is maintained at a constant, favourable temperature. Air preheating counteracts ice formation in the carburettor and also contributes to a shorter warming up period after starti

ng from cold.

Lubricating system

The engine lubrication is taken care of by a gear pump which sucks up

oil from the sump on the bottom of the engine and forces it through the

oil filter out to the lubricating points in the engine. A relief valve is built

i

nto the oil filter which prevents the oil pressure from reaching exces-

sively high values.

Cooling system

The engine is water-cooled and the cooling system is of the pressure

type.

Water is circulated by means of a pump fitted on the fan shaft.

A wax-type thermostat with an opening temperature of about 82

°

C

(180°F)

prevents the cooling water from passing through the radiator

before the engine has reached its normal working temperature. On

certain

markets a fan with a slip-type coupling is fitted.

Electrical system

The electrical system is of the 12-volt type and is fitted with a voltage-

regulated alternator. The starter motor is operated from the instrument

panel by the ignition key, which also switches on the rest of the electrical

system. The cables to the headlights, parking lights and internal lighting,

however, are not taken over the ignition switch but can be switched on

and off without the ignition key being in position.

9

DESCRIPTION

Lighting

The lighting on the car consists of two headlights (mainbeam and

dipped) together with two combined flasher and parking lights. The rear

l i

ghting consists of two tail lights including flashers, combined lamps

for the tail lights and brake warning lights as well as the reversing light.

I

nternal lighting consists of a roof light above the rearview mirror and

a light for the parcel shelf.

See pages 40-42 concerning replacement of bulbs.

Fuses

The electrical system is protected by means of fuses fitted in a fusebox

to the left on the bulkhead under the bonnet. When replacing a fuse,

be sure that you use one with the right rating. If any fuse should blow

repeatedly

,

do not fit a more powerful fuse. Instead, have a workshop

check the electrical system.

Power transmission

The clutch is of the single dry plate type with diaphragm spring. The

diaphragm spring functions partly as a lever when declutching and partly

as a pressure spring when engaging. Clutch pedal pressure is transmitted

mechanically to the release fork.

Clutch

Gearbox

The gearbox is used to regulate the speed ratio between the engine and

the rear axle so that the engine always operates in its most favourable

speed range. The gearboxes are fully synchronized. The M 40 gearbox

i

s four-speed.

10

DESCRIPTION

Propeller shaft

The propeller shaft, which is the connecting link between the gearbox

and the rear axle, is divided into two sections. The front section is

journalled at its rear end in a bearing housing consisting of a rubberized

ring.

Rear axle

The engine driving power is transmitted via the propeller shaft to the

rear wheels through the rear axle. The rear axle is of the hypoid type,

that is, the drive pinion is below the centreline of the drive shafts.

On certain markets, the rear axle is fitted with a differential brake as

extra equipment. The function of the differential brake is to transfer

automatically the pulling power to the wheel with the best grip on the

road surface when one of the wheels begins to skid. Except for the

differential, the rear axle is similar to a conventional rear axle.

Brakes

The brake system is of the two-circuit type with disc brakes front and

drum brakes rear. The system is provided with a tandem-type master

cylinder and a directly-operating booster cylinder.

The principle of the two-circuit system is that both front wheels are

connected to a rear wheel. Should there be a failure in one of the circuits

there is always braking power on both front wheels and the other rear

wheel. The pressure lines to the rear wheels are fitted with relief valves

which prevent involuntary locking of the rear wheels.

This system has a warning light located on the instrument panel. The

warning light shows if there is a failure in one of the circuits when

braking. It also serves as a warning light for the handbrake.

Wheels and tyres

The car has pressed steel wheels with lugs for the attachment of the

hub caps. All wheels are carefully balanced and the tyres are of the

tubeless type. Tyre size: 165 S 15, 165 SR 15, or 6.85-15.

11

DESCRIPTION

Body

Bonnet

•

The bonnet is fitted with a locking catch

which is operated from the driving seat

by means of a handle located to the

l

eft under the dashboard.

Pulling out the handle releases the bon-

net.

•

When the bonnet locking catch has been

released, the bonnet is still retained by

a safety catch. Press up this catch as

shown in the picture opposite and the

bonnet can be lifted up. Closing the

bonnet locks it so that it can only be

opened by pulling out the release handle.

Always make sure that the bonnet locks

properly when closed.

Boot

•

The boot is locked with the same key

as that used for the doors. The lid is

opened by pressing the handle upwards

as shown in the picture opposite. The

li

d is balanced and will thus remain in

the position opened. In the boot to the

l

eft there is space sufficient for the

spare wheel and a tool kit. Always make

sure that the spare wheel is fastened

securely and that the tool kit is firmly

stowed, otherwise irritating rattles can

occur.

1

2

Doors and locks

•

Both the doors are fitted with a lock

and keyhole.

Both doors can be locked from inside

the

car

by pressing down the lock

button on the window ledge. The lock

button lifts automatically when the door

isopened from the inside. The doors

can be locked from the outside by pressi

ng the lock button on the window ledge

and shutting the door. Do not leave the

keys in the car.

•

The doors are opened from the inside by

pulling the door handle to the rear. The

ventilation

windows for the doors are

opened by unscrewing the lock stud,

pressing it in and then turning the handle

upwards. Screwing in the stud locks the

handle.

•

The rear side windows can be partly

opened by turning up the catch as

shown in the picture.

To prevent the locks from freezing up

i

n cold weather, apply a suitable antifreeze agent. If the locks are already

frozen, do not exert undue force on the

key otherwise you might break it. Instead, heat it with a match or similar and

place it quickly in the keyhole.

Should you lose the car keys, contact

your nearest Volvo dealer for new keys

and quote the code number of the keys

which have been lost.

1

3

DESCRIPTION

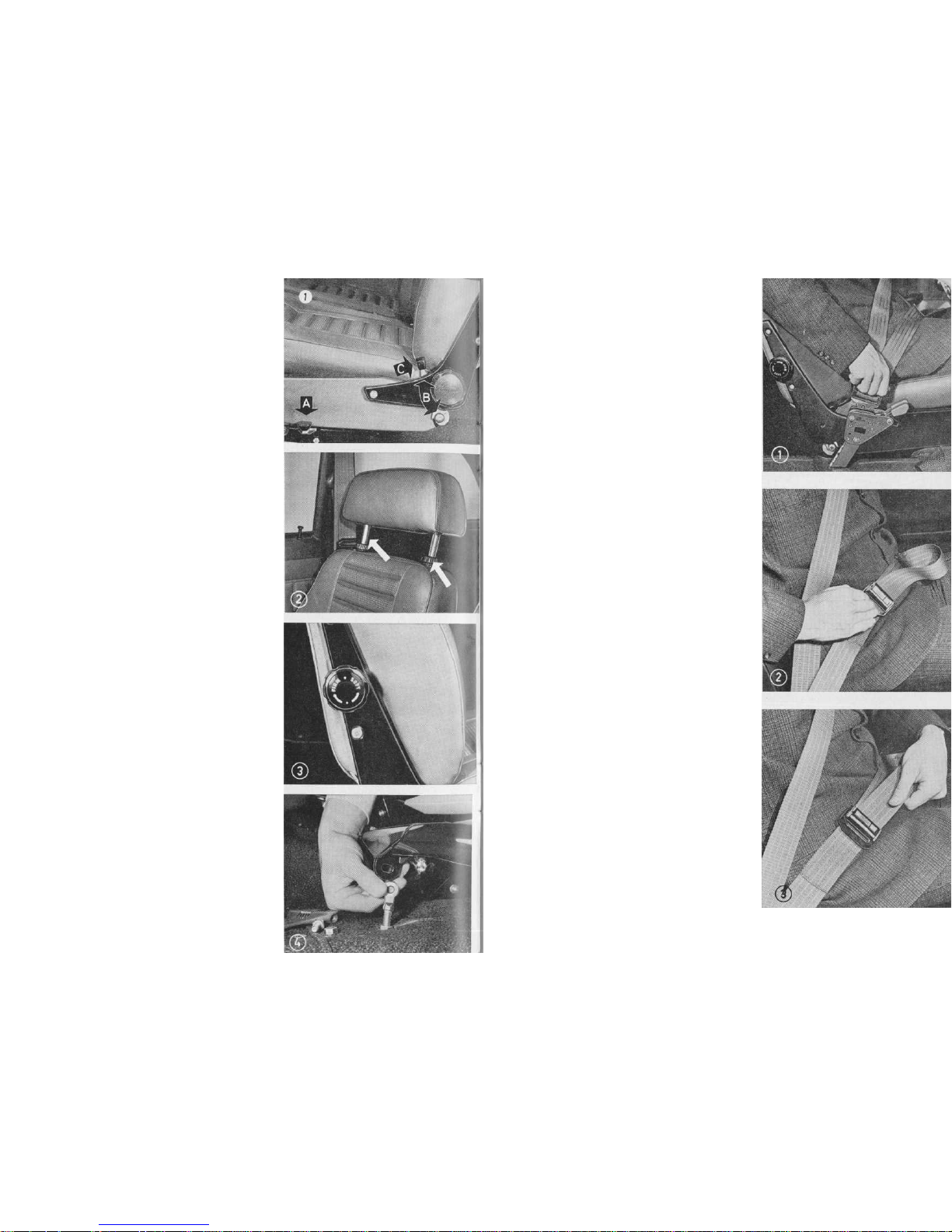

Front seats

•

The front seats can be moved backwards or forwards after the knob (A) is

pressed down. If necessary, the seats

can be moved further to the rear than

permitted by the slide rail by using the

extra holes in the seat frames.

The backrest inclination of the front

seats is smoothly adjusted by means of

a knob (B) on the outside of the seat.

A catch automatically locks the backrest

and thus prevents it from falling forwards. To fold the backrest backwards,

release the catch (C).

•

The front seats are provided with head-

rests.

Before driving, always make sure

that the headrest is at the proper height.

To adjust, slacken the plastic nuts on

the headrest holders. The car is delivered

with the headrests adjusted to a standard height. After adjusting lock them

by turning the plastic nuts clockwise.

•

The front seats are also provided with

an adjustable lumbar support. To tension

the lumbar support, and thus exert more

pressure against the small of the back,

turn the knob clockwise. Turning it anticlockwise slackens the tension on the

support

and

reduces

the

pressure

against the small of the back.

•

The inclination

angle of the entire seat

can be adjusted with the eyelet screw

at the front under the seat. Remove the

screw which goes through the eyelet

and tip the seat backwards as shown in

the picture. Then slacken the locknut on

the floor and screw the eyelet screw upwards or downwards to the desired

height.

Then secure the eyelet screw

with the locknut.

The whole seat can be raised or lowered,

which is done as follows: Remove the

seat cushion, also the screw and nut on

the seat frame attachment on the floor.

Then place the screw in one of the other

holes in the attaching bracket.

1

4

Safety belts

•

Always use the safety belt when driving.

Place one strap across the lap and the

other over the shoulder and chest and

fasten the belt by inserting the buckle

tongue into the locking device between

the front seats. A loud clicking noise

i

ndicates that the belt is locked.

Make sure that the parts of the belt in

contact with the body are not twisted.

Always ensure that the belt is so adjusted that it fits well against the body.

•

Ifthe belt requires lengthening, make

sure that the upper part of the lap strap

i

s slack and take hold of the adjusting

grip

with one hand and with the other

hand pull out to the desired length. Tidy

up any slackness by pulling in the upper

part.

•

I

f the belt is to be shortened, pull in the

upper part of the lap strap. The belt is

released from the locking device by

moving to the rear the lever concerned

on the locking device. Do not let the

belt lie on the floor otherwise it will

become dirty and probably be a hindrance

when getting in and out of the

car. Now and again check that the bolts

anchoring the belt are properly tightened and that the belt is in good condition.

Use water mixed with a synthetic

washing agent for cleaning the belt.

As the safety belts lose much of their

strength

when

exposedtoviolent

stretching, they should be replaced after

a collision,even though they may

appear to be undamaged. Never modify

or repair the belt on your own but have

this done by a Volvo workshop.

Rear seat

On certain markets, two rear safety belts

are fitted as standard. These are of the

2-point lap type.

The belts are fastened by pushing the

buckle tongue on one part of the belt

i

nto the lock of the other.

To release simply lift up the spring-

l

oaded cap on the lock.

I

n principle the belts are adjusted in the

same way as for the front seat belts.

DESCRIPTION

1

6

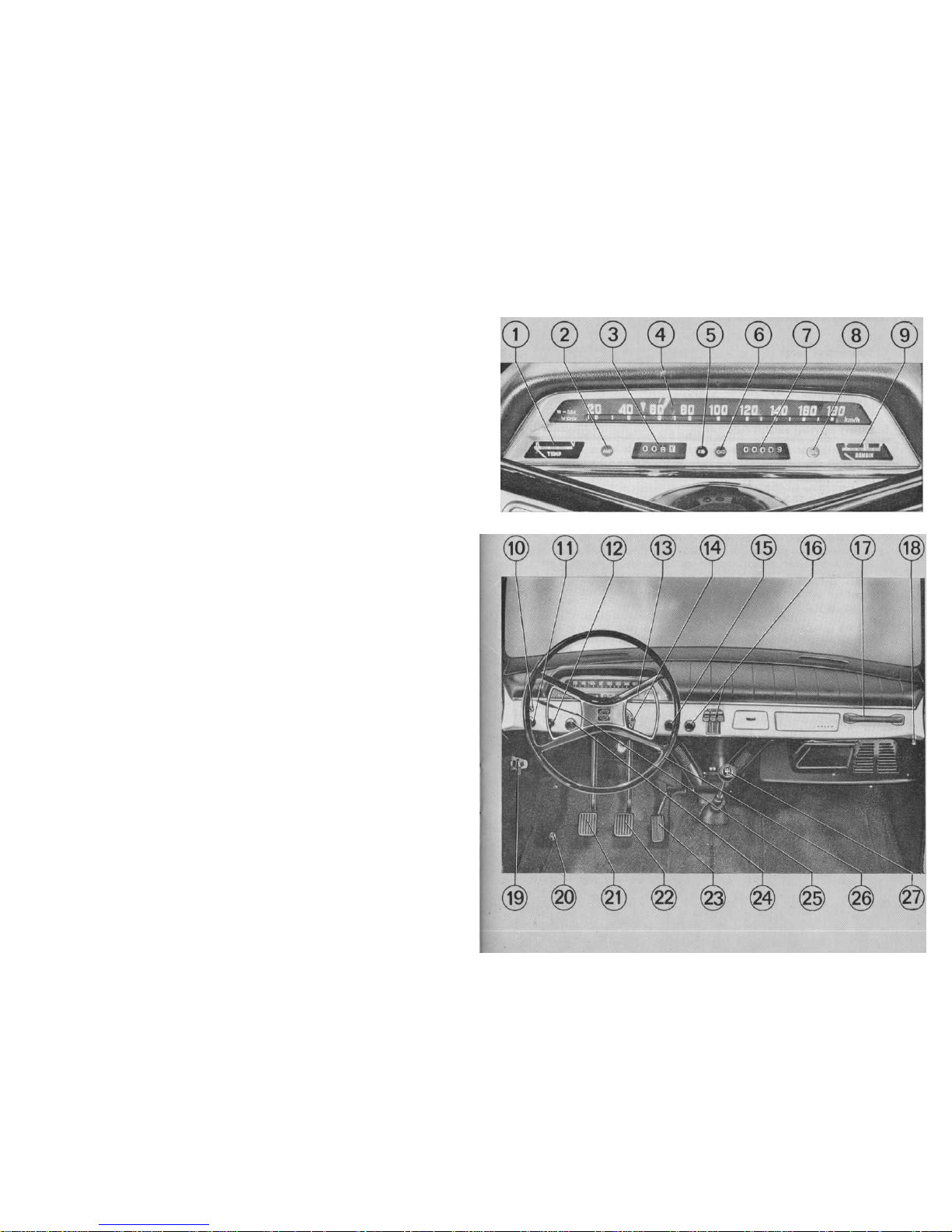

1.

Temperature gauge

2.

Warning light, battery charging

3.

Trip meter

4.

Speedometer

5.

Mainbeam control light

6.

Turn indicator control light

7.

Mileometer

8.

Oil pressure warning light

9.

Fuel gauge

10.Warning lamp, handbrake,

brake system

11.

Windscreen wiper and washer

switch

12.Choke control

13.Horn ring

1

4. Ignition switch and steering

wheel lock

I

nstruments and controls

Before you start the car, sit behind the wheel and carefully check

through all the instruments and controls. The location of these is shown

i

n the illustration opposite. The instruments and controls are described

inmore detail on the following pages with reference to the numbers in

the illustration. Note that variations may occur on different markets.

I

mmediately after starting, and now and then while driving, glance at the

i

nstruments to make sure they are showing normal readings according

to the values given in the following text.

15.Cigarette lighter

1

6.

Fan switch, heater/ventilation

controls

17.Grab handle

18.Switch for glove locker light

19.Bonnet release handle

20. Foot dipper switch

21.

Clutch pedal

22.

Brake pedal

23.

Accelerator pedal

24. Lighting switch

25. Turn indicator, switch

headlight flasher

26.

Steering wheel

27.

Gear lever

DESCRIPTION

1

2

This light goes on when the battery discharges. If it goes on during

driving, this means either that there is some fault in the electrical system

or that the 'fan belt is not sufficiently tensioned and is thus slipping on

the pulley, causing poor charging.

3

Trip meter

The trip meter, which is graduated in tenths of a mile, can be used to

measure even short distances. The meter can be reset to zero by means

of a reset knob placed under the instrument panel to the left of the

steering column. The knob is turned first to the right and then to the left.

4

Speedometer

The speedometer has a horizontal red ribbon indicator, the ribbon point

showing the speed at which you are travelling. Since the length of the

red ribbon is proportional to the speed, this is in itself a safety factor

- the more red shown, the more dangerous your speed.

7

Mileometer

The mileometer shows the total distance covered in miles. After 99999

miles it returns to zero and starts going round again.

8

Oil pressure warning light

This light goes on when the engine oil pressure is too low. When the

i

gnition is switched on, the light should go on and then go out again

when the engine has been started. Never start driving until the light goes

out.

Should the light remain on during driving, the engine should be

stopped and the cause for this determined. In most cases it means that

the oil level is too low. After hard driving it may happen that the warning

li

ght comes on when the engine is at idling speed. This is normal provid-

i

ng it goes out again when the engine speed is increased.

18

The windscreen wiper and washer switch has four positions. When

pressed fully in, the switch is switched off. When the switch is pulled

out to the first position, the windscreen wipers operate at normal speed.

When it is pulled out to the second position, the wipers operate more

quickly. Pulling the switch out fully also operates the windscreen washers.

The liquid container for the windscreen washers is placed under the

bonnet and holds about 1.5 litres (2.6 Imp. pints = 3.2 US pints). Never

allow the wiper blades to operate on a dry and dusty surface since this

can easily scratch the glass and 'blades.

12

Choke control

The choke control is used when the engine is started from cold. When

pulled out about 10-15 mm ('/

2

") the control operates the throttle flap

and increases idling speed. Pulling the control out further, enriches the

fuel-air mixture, and this steps up the idling speed.

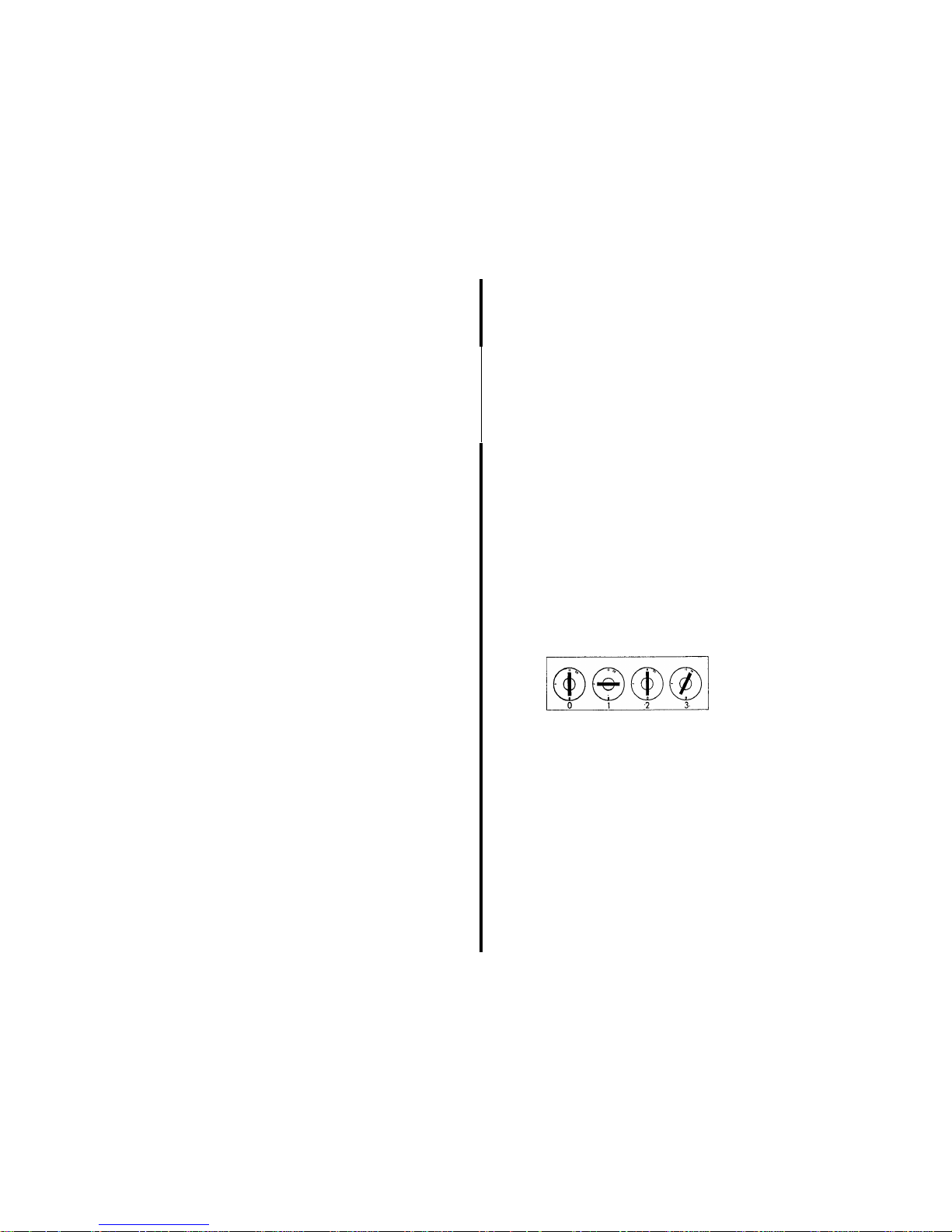

14

Combined ignition switch and steering wheel lock

The switch has four positions:

(0) Locking position, (1) Garage

position, (2) Driving position and

(3)

Starting position.

The key can be taken out of the

l

ock in the Locking position.

Removing the key when in the

Locking

position automatically

l

ocks the steering wheel. With

the key in the Garage position,

the entire electrical system is

DESCRIPTI

ON

connected up except for the

engine ignition system.

During driving, the key should

be in the Driving position.

To start the engine, turn the key

to the Starting position and this

automatically engages the starter

motor. As soon as the en-

gine starts,

release the key

which automatically returns to

the Driving position.

I

f the car is parked in such a

way as to make it difficult to un-

l

ock the steering wheel, unlock-

i

ng can be made easier by

slightly

turning

the

steering

wheel

one way and then the

other.

15

Cigarette lighter

To use the cigarette lighter, push it in. As soon as it attains sufficient

heat, it will automatically spring out.

19

Temperature

gauge

10

Handbrake warning light

Battery

The temperature gauge shows the temperature of the coolant and thus

1 t

This lights red when the handbrake is applied and the ignition is on.

The light also functions as a warning light should a failure arise in one

of the brake service circuits. If the light goes on when driving, the car

should be taken without delay to a workshop for a check on the brake

system. Observe due care when driving on such occasions.

Windscreen wiper and washer switch

i

ndicates the working temperature of the engine.

gauge should remain within the green sectors.

charging warning light

The pointer on this

Loading...

Loading...