Operating manual

EN

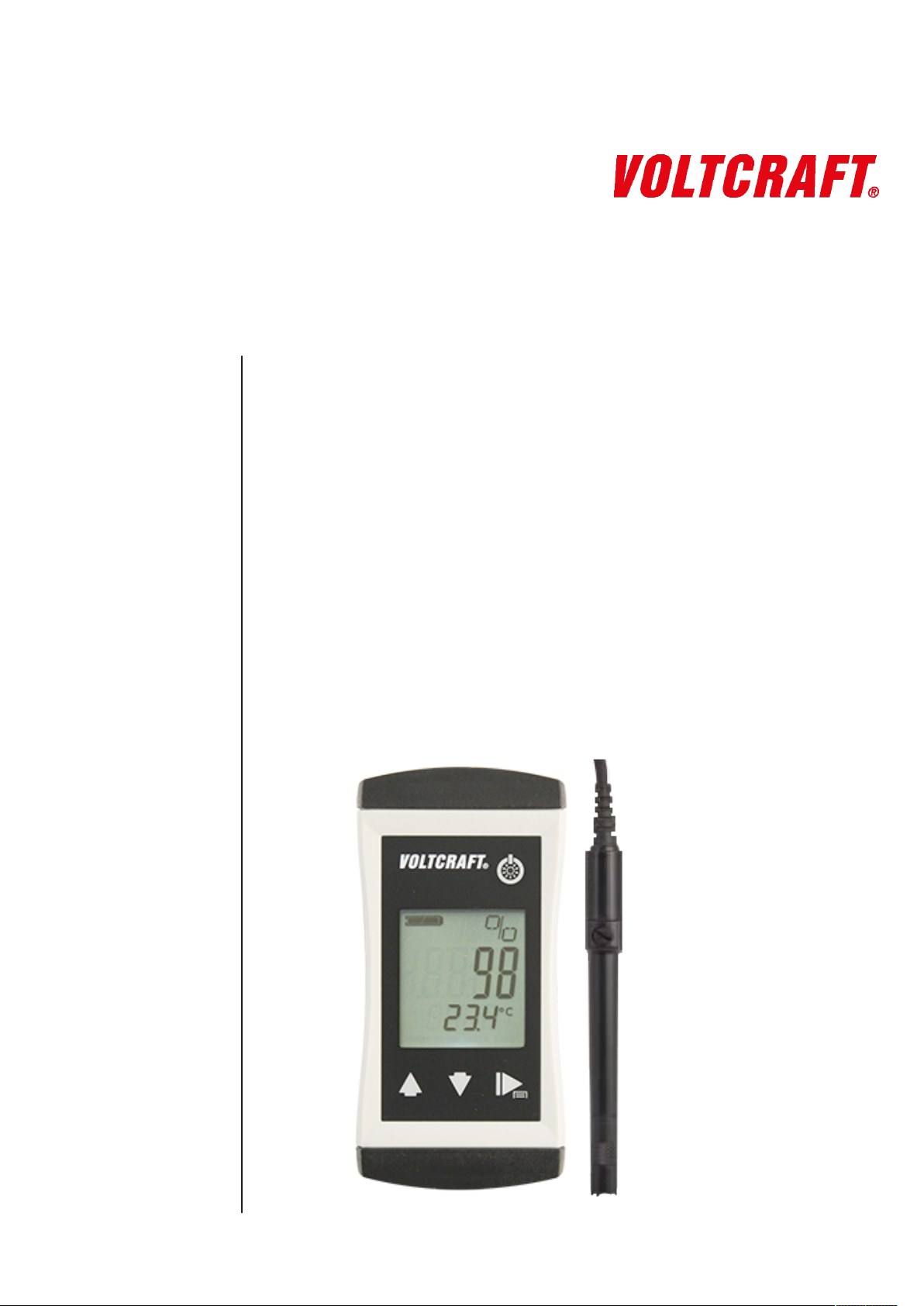

DO-400

Oxygen measuring device

Permanently connected oxygen sensor

Waterproof

Table of contents

Table of contents

1 Legal address of the manufacturer................................................................................................... 4

2 About this documentation ................................................................................................................. 5

2.1 Foreword............................................................................................................................................... 5

2.2 Purpose of the document...................................................................................................................... 5

2.3 Correctness of content.......................................................................................................................... 5

2.4 Layout of this document........................................................................................................................ 5

2.5 Further information ............................................................................................................................... 6

3 Safety ................................................................................................................................................... 7

3.1 Explanation of safety symbols .............................................................................................................. 7

3.2 Foreseeable misuse ............................................................................................................................. 7

3.3 Safety instructions ................................................................................................................................ 8

3.4 Intended use ......................................................................................................................................... 9

3.5 Qualified personnel............................................................................................................................... 9

4 Description ........................................................................................................................................ 10

4.1 Scope of delivery ................................................................................................................................ 10

4.2 Job description.................................................................................................................................... 10

5 The product at a glance ................................................................................................................... 11

5.1 The DO-400 / -410.............................................................................................................................. 11

5.2 Display elements ................................................................................................................................ 11

5.3 Operating elements ............................................................................................................................ 11

6 Bases for measurement ................................................................................................................... 13

6.1 Oxygen sensor.................................................................................................................................... 13

6.1.1 Explanation ......................................................................................................................................... 13

6.1.2 Design................................................................................................................................................. 14

6.1.3 Service life .......................................................................................................................................... 14

6.1.4 Operating position............................................................................................................................... 15

6.1.5 Measurement accuracy ...................................................................................................................... 15

6.1.6 Residue............................................................................................................................................... 15

6.2 Instructions for oxygen measurement................................................................................................. 15

6.2.1 Salinity correction ............................................................................................................................... 15

6.2.2 Environmental pressure, water depth and air pressure ...................................................................... 16

6.3 Commissioning, filling and maintenance of the sensor....................................................................... 16

7 Maintenance ...................................................................................................................................... 18

7.1 Operating and maintenance notices ................................................................................................... 18

7.2 Battery ................................................................................................................................................ 18

7.2.1 Battery indicator.................................................................................................................................. 18

7.2.2 Changing battery ................................................................................................................................ 18

7.3 Calibration and adjustment ................................................................................................................. 19

7.3.1 Automatic calibration in the air............................................................................................................ 19

8 Operation........................................................................................................................................... 21

8.1 Commissioning ................................................................................................................................... 21

8.1.1 Explanation ......................................................................................................................................... 21

8.2 Configuration ...................................................................................................................................... 21

8.2.1 Explanation ......................................................................................................................................... 21

2 / 29 B-H86.0.21.DB214-1.0

Table of contents

8.2.2 Opening the configuration menu......................................................................................................... 21

8.2.3 Configuring parameters of the configuration menu............................................................................. 22

8.2.4 Adjustment of the measuring input ..................................................................................................... 23

8.2.5 Configuring parameters of the adjustment menu................................................................................ 24

9 Error and system messages............................................................................................................ 26

10 Disposal............................................................................................................................................. 27

11 Technical data................................................................................................................................... 28

12 Service ............................................................................................................................................... 29

12.1 Manufacturer....................................................................................................................................... 29

B-H86.0.21.DB214-1.0 3 / 29

1 | Legal address of the manufacturer DO-400

1 Legal address of the manufacturer

Conrad Electronic SE

Klaus-Conrad-Str. 1

D-92240 Hirschau

http://www.conrad.com

WEEE reg. no. DE 28001718

4 / 29 B-H86.0.21.DB214-1.0

DO-400 About this documentation | 2

2 About this documentation

2.1 Foreword

Read this document carefully and familiarise yourself with the operation of the product

before you use it. Keep this document ready to hand and in the immediate vicinity of

the product so that it is available to the personnel/user for reference at all times in

case of doubt.

The product was developed according to the state of the art and fulfils the requirements of the applicable European and national Directives. All corresponding documents are available from the manufacturer.

Only technically qualified persons are permitted to carry out commissioning, operation,

maintenance and decommissioning. The qualified personnel must have carefully read

and understood the operating manual before beginning any work.

2.2 Purpose of the document

– This document describes the operation and maintenance of the product.

– Provides important information for working safely and efficiently with the product.

– In addition to the quick reference guide with all relevant legal and safety content in

hard copy, this document is a detailed reference option for the product.

2.3 Correctness of content

The contents of this document were checked for corrected and are subject to a continuous correction and updating process. This does not rule out potential errors. In the

event that errors are discovered or in case of suggestions for improvement, please inform us immediately via the indicated contact information in order to help us make this

document even more user-friendly.

2.4 Layout of this document

Description

Each chapter is explained at the beginning in the description.

Prerequisite

All mandatory prerequisites are then listed for each step.

Instruction

Tasks to be carried out by the personnel / user are represented as numbered instructions. Adhere to the sequence of the specified instructions.

Representation

Shows an illustrative instruction or a configuration of the product.

Formula

Some instructions include a formula for a general understanding of a configuration,

programming or a setting of the product.

B-H86.0.21.DB214-1.0 5 / 29

2 | About this documentation DO-400

Outcome of an action

Result, consequence or effect of an instruction.

Emphases

In order to simplify legibility and provide a clearer overview, various sections / information are emphasised.

– 1234 Display elements

– Mechanical controls

– Product functions

– Product labels

– Cross-reference [}p.5]

– Foot notes

2.5 Further information

Software version of the product:

– V1.2 or later

For the exact product name, refer to the type plate on the rear side of the product.

NOTE

For information about the software version, press and hold the ON button to switch on

the product for longer than 5 seconds. The series is shown in the main display and the

software version of the product is shown in the secondary display.

6 / 29 B-H86.0.21.DB214-1.0

DO-400 Safety | 3

3 Safety

3.1 Explanation of safety symbols

DANGER

This symbol warns of imminent danger which can result in death, severe bodily injury,

or severe property damage in case of non-observance.

DANGER

This symbol indicates danger for living tissue as well as a variety of materials, which

can be damaged or destroyed when coming into contact with this chemical. Caustic

effect, protective equipment required!

DANGER

This symbol indicates danger for all life forms, which can result in death or acute or

chromic damage to the health after inhaling, swallowing or absorbing this chemical

through the skin.

CAUTION

This symbol warns of potential dangers or harmful situations which can cause damage

to the device or to the environment in case of non-observance.

NOTE

This symbol indicates processes which can have a direct influence on operation or

can trigger an unforeseen reaction in case of non-observance.

NOTE

This symbol instructs the use of eye protection which protects the eyes from harmful

influences when working with powerful light, UV radiation, laser, chemicals, dust,

splinters or weather influences.

NOTE

This symbol instructs the use of protective gloves which offer protection from mechanical, thermal, chemical, biological or electrical hazards.

3.2 Foreseeable misuse

The fault-free function and operational safety of the product can only be guaranteed if

generally applicable safety precautions and the device-specific safety instructions for

this document are observed.

If these notices are disregarded, personal injury or death, as well as property damage

can occur.

B-H86.0.21.DB214-1.0 7 / 29

3 | Safety DO-400

DANGER

Incorrect area of application!

In order to prevent erratic behaviour of the product, personal injury or property damage, the product must be used exclusively as described in the chapter Description

[}p.10] in the operating manual.

– Do not use in safety / Emergency Stop devices!

– The product is not suitable for use in explosion-prone areas!

– The product must not be used for diagnostic or other medical purposes on pa-

tients!

– The product is not intended to come into direct contact with food. For measure-

ment in foods, samples must be taken and discarded after the measurement!

3.3 Safety instructions

This product has been designed and tested according to the safety requirements for

electronic measuring devices.

DANGER

Potassium hydroxide!

The electrode contains potassium hydroxide. This causes burns. All contact with the

skin, clothing and eyes should be avoided. Nevertheless, should contact occur, take

the following measures.

– Eyes: Flush with flowing water for at least 15 minutes, seek medical attention!

– Skin: Wash with large amounts of water for several minutes!

– Clothing: Remove immediately!

– If swallowed: Drink large amounts of water, do not induce vomiting and seek med-

ical attention!

CAUTION

Erratic behaviour!

On suspicion that the product can no longer be operated without danger, it must be

decommissioned and prevented from recommissioning with appropriate labelling. The

safety of the user can be impaired by the device if, for example, if it shows visible

damage, it no longer works as specified or if it was stored for an extended period of

time under unsuitable conditions.

– Visual inspection!

– In case of doubt, send the product to the manufacturer for repair or maintenance!

NOTE

If the product is stored at a temperature above 50 °C, or is not used for an extended

period of time, the batteries must be removed. Leaks from the batteries are avoided as

a result.

NOTE

This product does not belong in children's hands!

8 / 29 B-H86.0.21.DB214-1.0

DO-400 Safety | 3

For this purpose, also refer to

2 Technical data [}28]

3.4 Intended use

The product is designed for analysis of the oxygen concentration and/or oxygen saturation in freshwater and salt water. It is used, for example, for the monitoring of wells,

sewer lines and aquaria. A minimum flow to the sensor of approx. 30 cm/sec is necessary for a correct measurement.

See Technical data [}p.28].

3.5 Qualified personnel

For commissioning, operation and maintenance, the relevant personnel must have adequate knowledge of the measuring process and use of the measurements, for which

purpose this document makes a valuable contribution. The instructions in this document must be understood, observed and followed.

In order to ensure that no risks arise from the interpretation of the measurements in

the concrete application, the user must have additional technical knowledge, because

the user is liable in case of damage/danger due to misinterpretation as a result of inadequate technical knowledge.

B-H86.0.21.DB214-1.0 9 / 29

4 | Description DO-400

4 Description

4.1 Scope of delivery

Please check to ensure the completeness of the product after opening the package.

You should find the following components:

– Quick reference guide

– Handheld measuring device, ready for operation, including batteries

– Permanently connected oxygen sensor

4.2 Job description

The product offers precision, speed and reliability in a compact, ergonomic housing.

Additional impressive features include the dust-proof and waterproof design in accordance with IP 65/67 and the 3-line illuminated display, which offers overhead display at

the push of a button. The product can be switched on, switched off and configured and

the measurements and parameters can be adjusted and held with the operating elements. The product with maintenance-friendly galvanised O2 sensor is an entry-level

device suitable for everyday use. Concentrations in mg/l or ppm and saturation in percentage can be read directly without using tables. Calibration with environmental air

takes place at the push of a button. Use of a GSKA protective cap is recommended for

field use in bodies of water in order to protect the membrane.

10 / 29 B-H86.0.21.DB214-1.0

DO-400 The product at a glance | 5

5 The product at a glance

5.1 The DO-400 / -410

LCD Display DO-400 / -410 DO-400 / -410

5.2 Display elements

Display

Battery indicator Evaluation of the battery status

Unit display Display of units, if applicable, with unstable symbol

or type of mode, min/max/hold

Main display Measurement of the current O2 value or value for

Auxiliary display Corresponding temperature for the displayed O

Bar graph Progress for calibration and visualisation of the

NOTE

The unit display shows a rotating circle segment in the first position as long as the

measurement is unstable, if the position is unoccupied by the unit display.

5.3 Operating elements

On / Off button

Press briefly Switch on the product

Long press Switch off the product

min/max/hold

2

value with unit.

electrode evaluation

Activate / deactivate lighting

Reject changes in a menu

B-H86.0.21.DB214-1.0 11 / 29

5 | The product at a glance DO-400

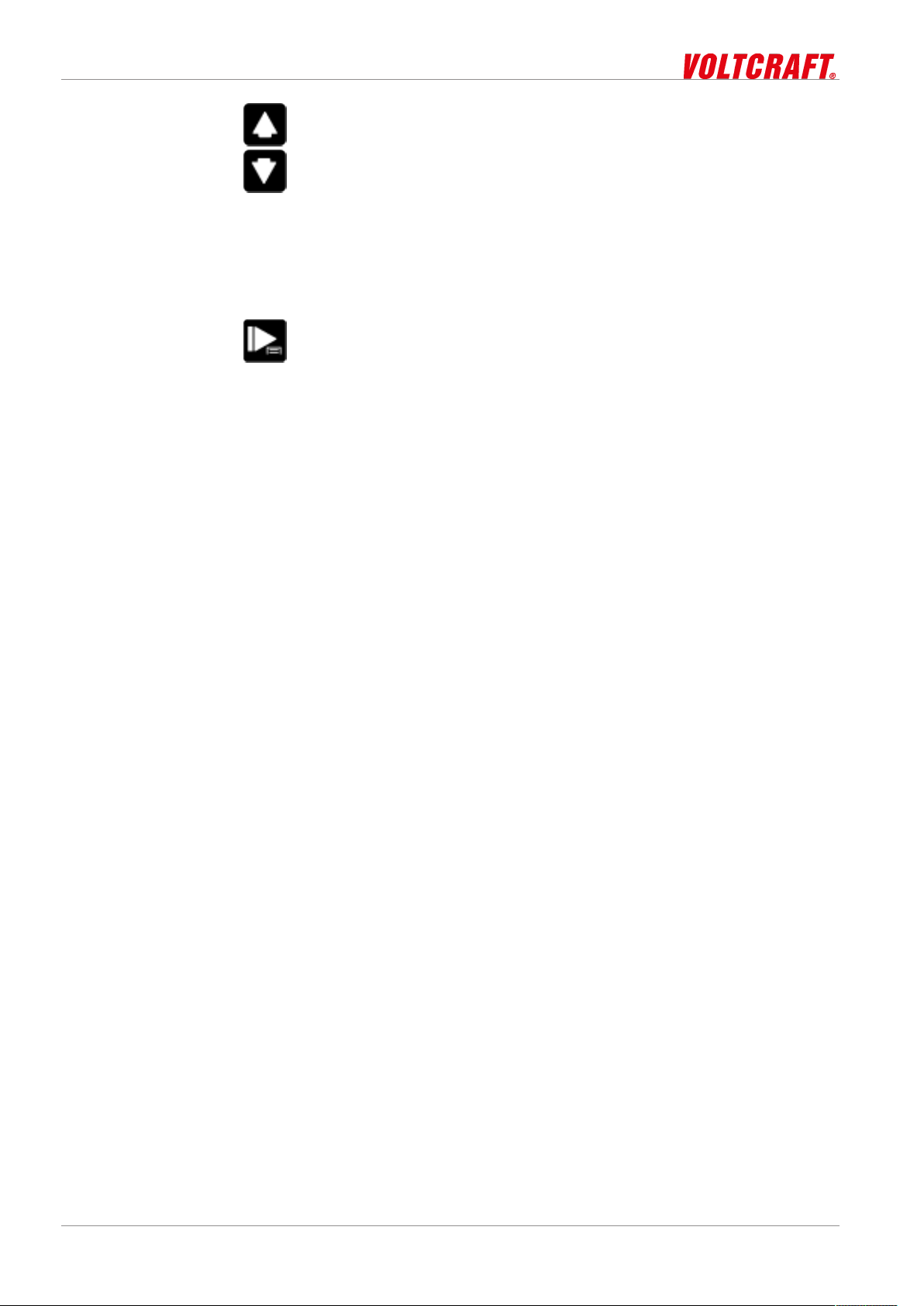

Up / Down button

Press briefly Display of the min/max value

Change value of the selected parameter

Long press Reset the min/max value of the current measure-

ment

Both simultaneously Rotate display, overhead display

Function key

Press briefly Freeze measurement

Return to measurement display

Call up next parameter

Long press, 2s

Start menu configuration, (ONF appears in the display

Long press, 4s

Start automatic calibration, (AL appears in the display

12 / 29 B-H86.0.21.DB214-1.0

DO-400 Bases for measurement | 6

6 Bases for measurement

6.1 Oxygen sensor

6.1.1 Explanation

The oxygen sensor is an active sensor. It consists of a platinum cathode, a lead anode

and potassium hydroxide (KOH) as an electrolyte. If oxygen is present, it is reduced

on the platinum cathode and the sensor delivers a signal. If no oxygen is present, no

signal is delivered. The anode is consumed by the oxygen measurement. The sensor

ages. Furthermore, the sensor loses water through the permeable membrane, in particular, when it is stored in dry air. Therefore, it should be checked and maintained

regularly and replaced as necessary.

DANGER

Potassium hydroxide!

The electrode contains potassium hydroxide. This causes burns. All contact with the

skin, clothing and eyes should be avoided. Nevertheless, should contact occur, take

the following measures.

– Eyes: Flush with flowing water for at least 15 minutes, seek medical attention!

– Skin: Wash with large amounts of water for several minutes!

– Clothing: Remove immediately!

– If swallowed: Drink large amounts of water, do not induce vomiting and seek med-

ical attention!

NOTE

Protective goggles must be worn for all of the following activities!

NOTE

Protective gloves must be worn for all of the following activities!

NOTE

Always store the oxygen sensor damp. It should always be stored in a storage bottle

filled with water or in a container filled with water. After storage for an extended period,

any potential deposit layers, such as algae, must be cleaned off of the membrane with

a soft paper towel prior to measurement.

B-H86.0.21.DB214-1.0 13 / 29

6 | Bases for measurement DO-400

Storage bottle

Shaft

Membrane head

Refill opening

Platinum electrode

6.1.2 Design

Platinum electrode

Storage bottle

Membrane head

Refill opening

If oxygen is present, it is reduced on the platinum electrode and the sensor delivers a

signal. Soiling on the platinum electrode or between the membrane and electrode can

influence the measurement.

The storage bottle is provided to keep the membrane moist. The service life of the

sensor is extended as a result. Distilled or deionised water is in the storage bottle; do

not add any other liquids!

The membrane head is covered with a thin plastic membrane. Faulty measurements

will occur if the membrane is damaged or there are large air bubbles or even an air

bubble ring on the membrane. This can also be the cause if a sensor can no longer be

calibrated. The GWOK 02 membrane head is a spare part and can be re-ordered separately.

Electrolyte must be filled or added for the initial commissioning of a sensor which is

delivered dry, when performing maintenance or after use at high temperatures.

6.1.3 Service life

The sensor signal deteriorates relatively quickly at the end of the service life of the

sensors. The electrode evaluation in %, therefore, can only be used as a guide value.

A value of 70% does not mean that exactly 70% of the service life is still available,

rather that the electrode signal has 70% of a comparison signal.

NOTE

The sensor evaluation is updated by the measuring device after a successfully performed calibration of the oxygen sensor.

The nominal service life can be reduced significantly due to use. Influential factors include:

– Storage / operating temperature

14 / 29 B-H86.0.21.DB214-1.0

– Contamination of the measured water

DO-400 Bases for measurement | 6

– Mechanical stress of the sensor membrane

– Storage in dry air

– Continuous use in elevated carbon dioxide concentrations

6.1.4 Operating position

The oxygen sensor should be arranged vertically upwards with the connecting cable.

A slight angle of inclination does not impair the measurement.

6.1.5 Measurement accuracy

The measurement accuracy can be impaired by:

– An inadequate flow below the necessary value of approx. 30cm/sec.

– The water temperature and sensor temperature must be the same. The most ac-

curate measurements are provided when the measuring temperature is calibrated.

6.1.6 Residue

Visible residue collecting as a reaction product in the interior of the membrane cap on

the lead-oxide lead anode is red or brown from reaction with oxygen and lead carbonate and is white from reaction with carbon dioxide. These substances can collect on

the membrane, but do not normally impair the measuring function and can be mostly

removed in the course of maintenance of the sensor. Prior to screwing on the membrane cap, they should be removed as far as possible in order to prevent particles

from being trapped between the membrane and the platinum cup. A rapid or excessive formation of lead carbonate after commissioning is an indication of air in the

sensor. This is usually due to incomplete filling or a leak due to improper fitting of the

cap / fill screw or membrane leak.

6.2 Instructions for oxygen measurement

The following must be observed when measuring dissolved oxygen:

– The storage bottle must be removed before the measurement.

– The sensor must have been calibrated.

– The sensor and the liquid to be measured must have the same temperature. The

temperatures of the two must match.

– The sensor must be immersed at least 3 cm into the liquid to be measured.

– A flow speed of at least approx. 30 cm/sec is necessary for exact measurements.

Either stir continuously or use an appropriate stirring device

– The measurement is sensitive to jarring! Therefore, make sure that the container

is not struck with the sensor while stirring, because this can significantly impair the

measured value.

– The oxygen partial pressure, oxygen concentration in mg/l and oxygen saturation

in % are calculated from the sensor signal and temperature. In accordance with

DIN38408-C22, the measurement is relative to water-vapour-saturated air.

6.2.1 Salinity correction

With increasing salinity SAL, which is the value for the salt content in the water, the solubility of oxygen in water decreases, i.e. with the same oxygen partial pressure, fewer

mg of oxygen are dissolved per litre of water. To determine this oxygen concentration,

therefore, the salinity of the medium must be entered first; see Configuring parameters

of the configuration menu [}p.22]. A salinity correction is not necessary in freshwa-

B-H86.0.21.DB214-1.0 15 / 29

6 | Bases for measurement DO-400

ter; the value is 0. A salinity of approx. 35 PSU is normal for sea water. The salinity

correction is adjusted to aqueous media having a chemical composition corresponding

to sea water. The International Oceanographic Tables (IOT) are used as a basis for

the correction.

6.2.2 Environmental pressure, water depth and air pressure

The environmental pressure, water depth and air pressure play an important role at

the place of measurement for the following points:

– Calculation of oxygen saturation in % SAT. Clean water can achieve 100 % satura-

tion in air. There must be no oxygen-depleting processes, such as biological decaying processes, chemical effects or oxygen enhancing processes, such as excessive ventilation or photosynthesis. This could result in an oversaturation above

100%.

– Calculation of the oxygen concentration in mg/l

– The valuation of calibration

Adjusting the pressure parameter on the product is recommended prior to calibration.

In the scope of measuring accuracy, specifying the current air pressure in the region

based on meteorological data or the standard pressure based on sea level is sufficient.

For example:

0 m above NN: 1013 hPa

300 m above NN: 978 hPa

600 m above NN: 943 hPa

1000m above NN: 899 hPa

Description

Prerequisite

Instruction

6.3 Commissioning, filling and maintenance of the sensor

The sensor is delivered dry. Therefore, the sensor is well-suited for storage. The

sensor must be filled in good time before the measurement. A wait time of approx. 2

hours after filling should be planned in order to allow the sensor to stabilise. Commissioning with initial filling, filling and maintenance of the sensor are explained in the following chapter.

– Protective goggles

– Protective gloves

– A suitable screwdriver

– Pipette

– Household towel

– KOH electrolyte

– A spare GWOK 02 membrane head, if applicable

1. Unscrew the membrane head.

2. Unscrew the seal screw from the refill opening.

NOTE

If the sensor was already filled and deposits have formed, it should be cleaned with

KOH via the fill opening or removed. Loose residue can be rinsed out in the process.

The platinum cup on the front of the membrane must be clean. Remove any soiling or

electrolyte solution with a paper towel.

16 / 29 B-H86.0.21.DB214-1.0

Outcome of an action

DO-400 Bases for measurement | 6

3. Fill the pipette with the KOH electrolyte and initially fill the membrane head to ¾

full. Rinse off the excess electrolyte.

4. Slowly fill the sensor via the fill opening. In the process, tilt the sensor from side to

side and tap the shaft to force out air bubbles. The sensor holds approximately 5

ml. If air bubbles no longer appear and the refill opening is filled up to the rim with

KOH, screw the in the seal screw again.

5. Rinse off excess KOH and screw the sensor on with the membrane head. In the

process, if there are any recognisable air bubbles under the membrane, KOH

must be added.

6. After filling, the sensor should rest for 2 hours before a calibration is started.

The sensor has now been refilled. A sensor evaluation during the calibration should

produce a result of 100%.

NOTE

Should it no longer be possible to calibrate the sensor or it only delivers unstable

measurements, it must be maintained and/or the membrane head must be replaced

B-H86.0.21.DB214-1.0 17 / 29

7 | Maintenance DO-400

7 Maintenance

7.1 Operating and maintenance notices

NOTE

If the product is stored at a temperature above 50 °C, or is not used for an extended

period of time, the batteries must be removed. Leaks from the batteries are avoided as

a result.

NOTE

The electrode should be stored in dry rooms at a temperature between 10 °C and 30

°C. If the storage temperature range is exceeded or undercut, the electrode can be

destroyed. It should always be stored wet in distilled or deionised water.

7.2 Battery

7.2.1 Battery indicator

If the empty frame in the battery display blinks, the batteries are depleted and must be

replaced. However, the device will still operate for a certain length of time.

If the BAT display text appears in the main display, the battery voltage is no longer adequate for operation of the product. Now the battery is fully depleted.

7.2.2 Changing battery

DANGER

Danger of explosion!

Using damaged or unsuitable batteries can generate heat, which can cause the batteries to crack and possibly explode!

– Only use high-quality and suitable alkaline batteries!

CAUTION

Damage!

If the batteries have different charge levels, leaks and thus damage to the product can

occur.

– Use new, high-quality batteries!

– Do not use different types of batteries!

– Remove depleted batteries and dispose of them at a suitable collection point!

NOTE

Unnecessary screwing places the water-tightness of the product, among other things,

at risk and should be avoided.

18 / 29 B-H86.0.21.DB214-1.0

DO-400 Maintenance | 7

NOTE

Read the following handling instructions before replacing batteries and follow them

step by step. If disregarded, the product could be damaged or the protection from

moisture could be diminished.

Description

Prerequisites

Instruction

Outcome of an action

Proceed as follows to replace the batteries.

– The product is switched off.

1. Unscrews the Phillips screws and remove the cover.

2. Carefully replace the two Mignon AA batteries. Ensure that the polarity is correct!

It must be possible to insert the batteries in the correct position without using

force.

3. The O-ring must be undamaged, clean and positioned at the intended depth. In order to facilitate assembly and avoid damage, a suitable grease can be applied.

4. Fit the cover on evenly. The O-ring must remain at the intended depth!

5. Tighten the Phillips screws.

The product is now ready for use again.

7.3 Calibration and adjustment

Description

Prerequisite

Instruction

7.3.1 Automatic calibration in the air

The following steps describe how to calibrate the product automatically.

– The product is switched on.

NOTE

Calibration takes place in air saturated with water vapour. The GCAL 3610 calibration

container or the storage bottle can be used for this purpose. The membrane of the

electrode must be dry for the calibration. Prior to performing the calibration of the

membrane, dab away water droplets from the membrane with a soft, dry cloth. The following must be observed when using the storage bottle:

Only insert the electrode far enough into the storage bottle that the membrane does

not come into contact with the water in the bottle.

Unscrew the lid of the storage bottle and only position it so that a small exchange of

air and pressure equalisation can take place

1. Place the electrode in the calibration container. If necessary, wait until the temperature has equalised and a stable value has been achieved.

2. Press the Function key for 4 seconds to open the Calibration menu. The display

shows (AL.

3. Release the Function key.

4. The product determines the correct value automatically.

B-H86.0.21.DB214-1.0 19 / 29

7 | Maintenance DO-400

Outcome of an action

After successful completion of the calibration the assessment of the electrode condition is displayed briefly in percent. An aged or contaminated electrode, incorrect adjustment of the pressure, contamination of the platinum electrode or a damaged membrane can be the cause for a lower evaluation.

If the calibration is not completed successfully an error message is displayed. (AL ERR.

appears in the display See Error and system messages [}p.26]. Confirm the error

message pressing the Function key. The product restarts and the value of the last successful calibration is restored.

20 / 29 B-H86.0.21.DB214-1.0

8.1.1 Explanation

Description

Prerequisite

Instruction

Outcome of an action

DO-400 Operation | 8

8 Operation

8.1 Commissioning

The product is switched on with the On/Off button. It may be necessary to configure

the product after switching on. See Configuration [}p.21].

– Sufficiently full batteries are inserted in the product.

– Press On/Off button.

Information about the configuration of the product appears in the display.

POFF

T.OF

T.SL

SAL

The product is now ready for measurement.

Automatic shutoff

Zero point correction

Gradient correction

Salinity correction Links when the salinity correction is active

NOTE

The product must be calibrated to the electrode prior to starting the measurement.

See Calibration and adjustment service.

8.2 Configuration

8.2.1 Explanation

The following steps describe how to adapt the product for your purposes.

Automatic shut-off activated. The product is

switched off if no buttons have been pressed after

the adjusted time

If a zero point correction of the temperature sensor

was made

If a gradient correction of the temperature sensor

was made

NOTE

There are various configuration parameters available depending on the product version and configuration. They can differ depending on the product version and configuration.

8.2.2 Opening the configuration menu

Description

Prerequisite

Instruction

B-H86.0.21.DB214-1.0 21 / 29

In order to configure the product, you must first open the Configuration menu. The

menu is opened as shown in the illustration.

– The product is switched on.

1. Press the Function key for 2 seconds to open the Configuration menu.

2. (ONF appears in the display. Release the function key.

3. By briefly pressing the Function key, you can scroll through the parameters. Select

the parameter you would like to configure.

8 | Operation DO-400

4. When you have selected the desired parameter, change the parameter to the desired value with the Up button and the Down button.

5. The changes are saved after running through the entire Configuration menu. STOR

appears in the display. The Configuration menu can be exited from any arbitrary

parameter by pressing and holding the Function key for 2 seconds. The changes

made up that point are saved.

Representation

Outcome of an action

Call up menu Next parameter Change value Save changes Discard

2s Press: Single

step

Hold: Rapid

change

The Configuration menu is closed after the last parameter.

NOTE

If the product is switched off without saving the configuration, the last save value is reproduced on the next start-up of the product.

changes

2s 2s

Description

Prerequisite

Instruction

Representation

8.2.3 Configuring parameters of the configuration menu

The following representation shows the available parameters and various configuration options.

– The Configuration menu is open. See Opening the configuration menu [}p.21].

1. Select the desired parameter you would like to configure.

2. Adjust the desired configuration in the selected parameter with the Up button and

Down button.

3. The available configuration options are listed for each parameter in the following

representation.

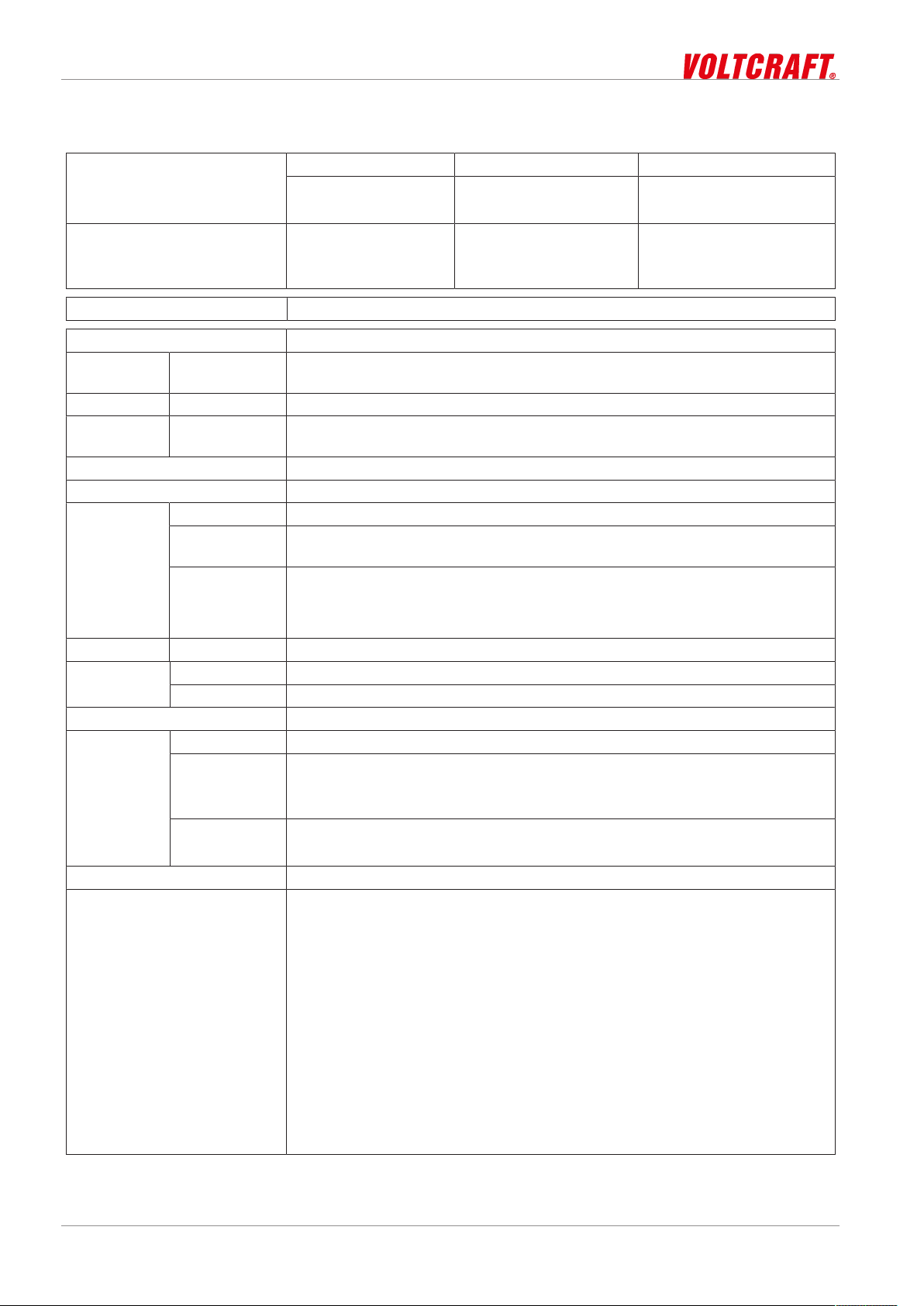

Parameter Values Meaning

Input

INP

SAT %

(ONC mg/l

(ONC ppm

Pressure

Oxygen saturation in per cent

Oxygen concentration in mg/l

Oxygen concentration in ppm

SET.P

500 .. 4000

Salinity correction

SAL

0 .. 70

22 / 29 B-H86.0.21.DB214-1.0

Environmental pressure in hPa, corresponding to

mbar

Salinity in the measuring medium in PSU, corresponding to g/kg

Shut-off time

POFF

Backlighting

L,TE

Temperature unit

UN,T

OFF

15 30 60 120 240

OFF

15 30 60 120 240

ON

°(

°F

DO-400 Operation | 8

No automatic shut-off

Automatic shut-off after a selected time in minutes,

during which no buttons have been pressed

Backlighting deactivated

Automatic shut-off of the backlighting after a selected time in seconds, during which no buttons have

been pressed

No automatic shut-off of the backlighting

Temperature display in °C

Temperature display in °F

Outcome of an action

8.2.4 Adjustment of the measuring input

Description

Prerequisites

Instruction

Factory settings

IN,T

NO

YES Reset product to factory settings. IN,T DONE appears

The changed value is saved and the Configuration menu is closed. STOR appears in

the display. If necessary, the product is restarted automatically in order to adopt the

changed values.

Use current configuration

in the display

NOTE

The configuration is closed if no button is pressed for 2 minutes. Any changes made

up to that point are not saved. C.END appears in the display.

The temperature input can be adjusted with the zero point correction and the gradient

correction. If an adjustment is made, you change the pre-adjusted factory settings.

This is signalled with the T.OF or T.SL when the product is switched on. The standard

settings of the zero point value and the gradient value is 0.00. It signals that no correc-

tion is made.

In order to adjust the product, you must first open the Adjustment menu. The menu is

opened as shown in the illustration.

– Sufficiently full batteries are inserted in the product.

– The product is switched off.

1. Press and hold the Down button.

2. Press the On/Off button to switch on the product and open the Configuration

menu. Release the Down button. The display shows the first parameter.

3. By briefly pressing the Function key, you can scroll through the parameters. Select

the parameter you would like to configure.

B-H86.0.21.DB214-1.0 23 / 29

8 | Operation DO-400

4. When you have selected the desired parameter, change the parameter to the desired value with the Up button and the Down button.

5. In order to save the new parameter value, press and hold the Function key for

longer than 1 second.

Representation

Call up menu

Hold Release

Outcome of an action

The Configuration menu is closed after the last parameter.

NOTE

If the product is switched off without saving the configuration, the last save value is reproduced on the next start-up of the product.

8.2.5 Configuring parameters of the adjustment menu

Description

Prerequisites

Instruction

Representation

The following representation shows the available parameters and various configuration options.

The Adjustment menu is open. See Adjustment of the measuring input [}p.23].

1. Select the desired parameter you would like to configure.

2. Adjust the desired configuration in the selected parameter with the Up button and

Down button.

3. The available configuration options are listed for each parameter in the following

representation.

Parameter Values Meaning

Formula

Example calculation

Zero point correction

T.OF

0.00

-5.00 .. 5.00

No zero point correction

Zero point correction in °C. and/or at °F -9.00 ..

9.00

Gradient correction of the temperature

T.SL

0.00

-5.00 .. 5.00

No gradient correction

Gradient correction in %

Zero point correction:

Displayed value = measured value – T.OF

Gradient correction °C:

Display = (measured value – T.OF) * (1 + T.SL / 100)

Gradient correction °F:

Display = (measured value – 32 °F – T.OF) * (1 + T.SL / 100) + 32 °F

– Zero point correction T.OF to 0.00

– Gradient correction T.SL to 0.00

– Display unit UNIT to °C

– Display in ice water -0.2 °C

24 / 29 B-H86.0.21.DB214-1.0

Outcome of an action

DO-400 Operation | 8

– Display in ice water setpoint T.OF = 0.0 °C

– Display in water bath 36.6 °C

– Display in water bath setpoint T.SL = 37.0 °C

– T.OF = display zero point correction – setpoint zero point

– T.OF = -0.2 °C – 0.0 °C = -0.2 °C

– T.SL = (setpoint gradient correction / (display gradient correction – T.OF) – 1) *100

– T.SL = (37.0 °C / (36.6 °C – (-0.2)) -1) *100 = 0.54

The changed value is saved and the Configuration menu is closed.

NOTE

If the product is switched off without saving the configuration, the last save value is reproduced on the next start-up of the product.

B-H86.0.21.DB214-1.0 25 / 29

9 | Error and system messages DO-400

9 Error and system messages

Display Meaning Possible causes Remedy

No display,

unclear characters or no

response

when buttons are

pressed

BAT

BAT LO

(AL ERR.2

(AL ERR.3

(AL ERR.4

(AL ERR.5

ERR.1

ERR.2

SYS ERR

Battery depleted

System error

Product is defective

Battery depleted Battery depleted Replace battery

Battery depleted Battery depleted Replace battery

Slope is too low

Incorrect oxygen reference

Slope is too high

Incorrect oxygen reference

Incorrect calibration

temperature

Time exceeded during automatic calibration

Measuring range exceeded

Measuring range is

undercut

System error Error in the product Switch product on/off

Battery depleted

Error in the product

Product is defective

Electrode contaminated or defective

Electrode contaminated or defective

Temperature too low

or too high

Unstable electrode

signal

Contaminated electrode

Temperature not

equalised

Measurement too

high

Electrode or product

defect

Faulty calibration

Measurement too

low

Electrode or product

defect

Replace battery

Send in for repair

Perform calibration in damp

environmental air

Maintain the electrode

Perform calibration in damp

environmental air

Maintain the electrode

Range of 5..40 °C

Use calibration container

Maintain the electrode

Restart calibration

The measurement is above

the permissible range

Check electrode

Perform calibration

Send in for repair

Check electrode

Send in for repair

Replace batteries

Send in for repair

26 / 29 B-H86.0.21.DB214-1.0

10 Disposal

NOTE

The device must not be disposed of with household waste. If the product is disposed

of, please take it to a municipal collection point, where it will be transported to a disposal company in accordance with requirements of hazardous goods laws. Otherwise,

return it to us, freight prepaid. We will then arrange for the proper and environmentally-friendly disposal. Please dispose of empty batteries at the collection points intended for this purpose.

DO-400 Disposal | 10

B-H86.0.21.DB214-1.0 27 / 29

11 | Technical data DO-400

11 Technical data

Measuring range O2 concentration O2 saturation Temperature

0.0 .. 20.0 mg/l

0.0 .. 20.0 ppm

Accuracy (at nominal temperature)

Temperature compensation 0 .. 50 °C (or 32 .. 122 °F)

Nominal temperature 25°C

Measuring

cycle

Connections Permanently connected oxygen sensor

Display 3-line segment LCD, additional symbols, illuminated (adjustable white, perman-

Additional functions Min/Max/Hold

O2 calibration Automatic calibration in the air

Housing Break-proof ABS housing

Protection rating

Dimensions

L*W*H [mm]

and weight

Connections Permanently connected oxygen sensor

Operating

conditions

Storage temperature 0 .. 40 °C

Current supply

Auto-power-OFF function The device switches off automatically if this is activated

Directives and standards The devices conform to the following Directives of the Council for the harmon-

Device -20 to 50 °C; 0 to 95 % r.h. (temporarily 100 % r.h.)

Electrode 0 .. 40 °C

Current requirement/

battery life

Battery indicator

±1.5 % of measured

value

± 0.2 mg/l

approx. 2 measurements per second

ent illumination)

IP65 / IP67

108 * 54 * 28 mm without electrode

130 g, incl. battery, without electrode

190 g, incl. battery and electrode

2*AA battery (included in the scope of delivery)

approx. 0.8 mA, approx. 2.7 mA with lighting

Service life > 3000 hours with alkaline batteries (without backlighting)

4-stage battery status indicator,

Replacement indicator for depleted batteries: "BAT"

isation of legal regulations of the Member States:

2014/30/EU EMC Directive

2011/65/EU RoHS

Applied harmonised standards:

EN 61326-1:2013 Emission limits: Class B

Immunity according to Table 2

Additional errors: < 0.5 % FS

EN 50581:2012

0 .. 200 % 0 .. 50 °C

32 .. 122 °F

±1.5 % of measured

value

± 0.2 %

± 0.3 °C

The device is intended for mobile use and/or stationary operation in the scope

of the specified operating conditions without further limitations.

28 / 29 B-H86.0.21.DB214-1.0

Contact

DO-400 Service | 12

12 Service

12.1 Manufacturer

If you have any questions, please do not hesitate to contact us:

VOLTCRAFT

Distributed by

Conrad Electronic SE

Klaus-Conrad-Str. 1

92240 Hirschau, Germany

Tel.: +49 9604 40 87 87

Fax: +49 180 5 312110

kundenservice@conrad.de

WEEE reg. no. DE 28001718

B-H86.0.21.DB214-1.0 29 / 29

Loading...

Loading...