Page 1

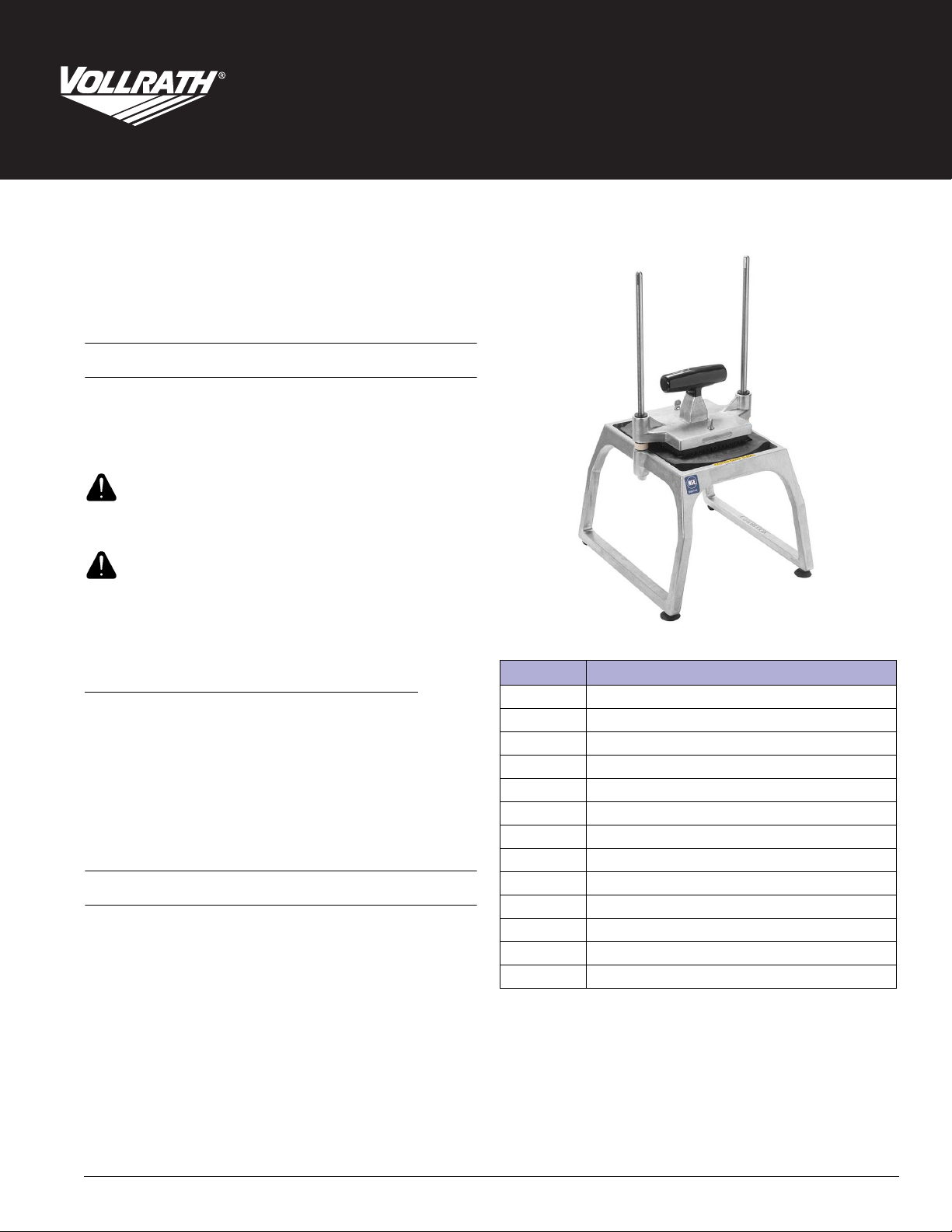

Instacut™ 5.1 Slicer, Dicer, Wedger and Corer

Thank you for purchasing this Vollrath equipment. Before operating the

equipment, read and familiarize yourself with the following operating

and safety instructions. SAVE THESE INSTRUCTIONS FOR FUTURE

REFERENCE. Save the original box and packaging. Use this packaging

to ship the equipment if repairs are needed.

SAFETY PRECAUTIONS

To ensure safe operation, read the following statements and understand

their meaning. This manual contains safety precautions which are

explained below. Please read carefully.

WARNING

Warning is used to indicate the presence of a hazard that will or can

cause severe personal injury or death.

CAUTION

Caution is used to indicate the presence of a hazard that will or can

cause minor or major personal injury if the caution is ignored.

Operator’s Manual

NOTICE: Notice is used to note information that is important but not

hazard-related.

To reduce risk of injury or damage to the equipment:

• Inspect the equipment before each use to make sure it is clean.

• Inspect for broken, nicked or dull blades and if found, replace the

blade assembly.

• Verify the pusher block head assembly and blade pack are a matched

set and are properly aligned.

• Lubricate the guide rods as instructed, using a light coating of

mineral oil, Petrol-Gel, or other food grade lubricant. DO NOT USE

COOKING OIL AS IT WILL BECOME STICKY AND MAY

PERMANENTLY DAMAGE THE EQUIPMENT.

FUNCTION AND PURPOSE

The InstaCut™ 5.1 manual food processor is intended for slicing,

dicing, wedging and coring soft vegetables and fruits. It not intended to

cut hard root vegetables such as carrots and sweet potatoes.

Item No. Description

55457 ¼" Dice

55458 ³⁄₈" Dice

55459 ½" Dice

55460 ¼" Slice

55461 ³⁄₈" Slice

55462 ½" Slice

55463 4 Section Wedge

55464 6 Section Wedge

55465 8 Section Wedge

55466 10 Section Wedge

55467 12 Section Wedge

55468 6 Section Core

55469 8 Section Core

©

2019 The Vollrath Company L.L.C. Part No. 351753-1 ml 1/30/19

Page 2

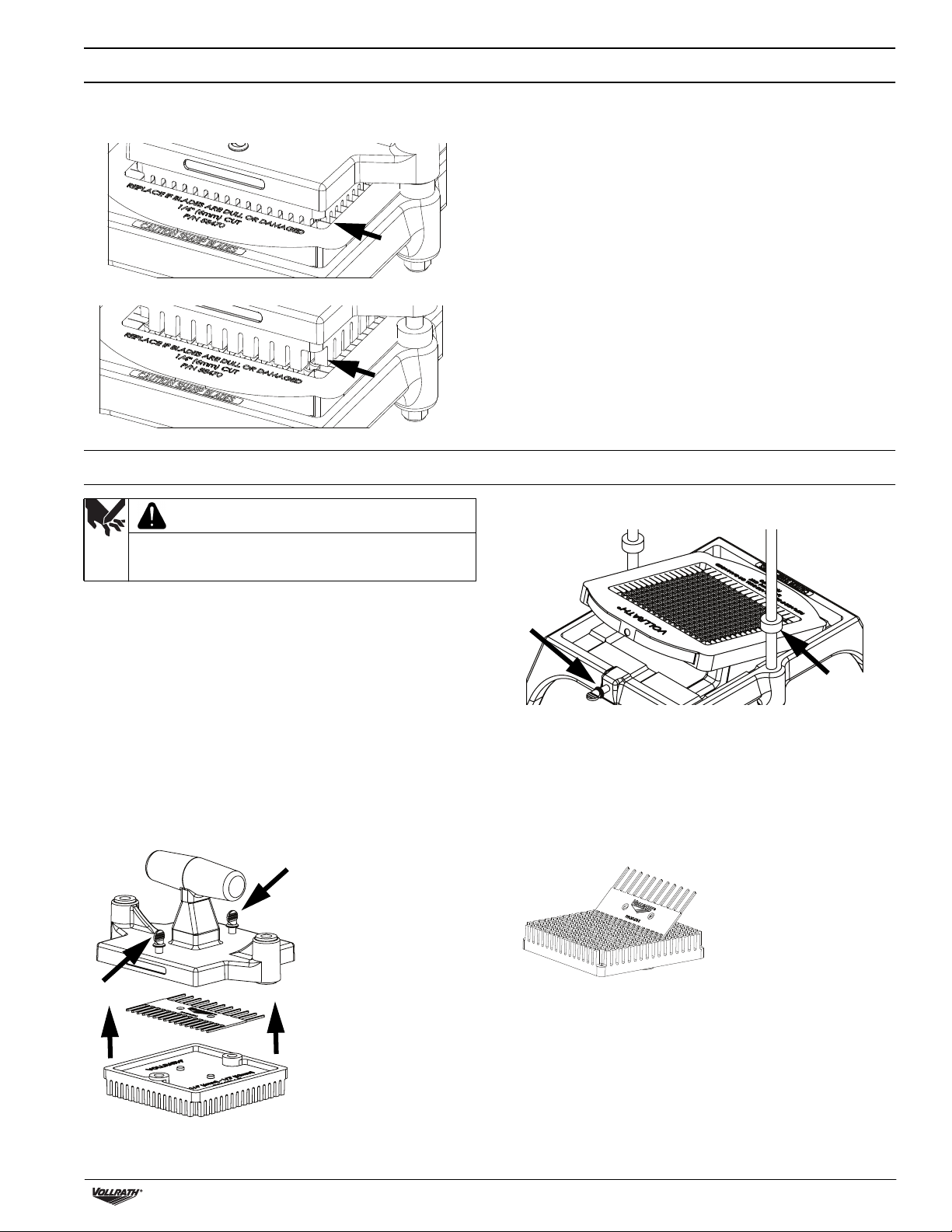

FEATURES

E

OPERATION

WARNING

Sharp Blade Hazard

F

Blades are sharp and can cause cuts. To avoid injury from

sharp blades, handle with caution.

D

G

C

B

A

A Base Assembly

B Bumpers

C Guide Rods

D Thumbscrew

E T-Handle

F T-Handle Assembly. Consists of the pusher head, cleaning tool

and the pusher block.

G Cleaning Tool. (Dicer and slicer blade packs only)

H Pusher Block. Pushes the food product through the blade

assembly. Must match the slice, dice, core or wedge size of

blade assembly.

I Blade Assembly. Houses the blades, wedger or corer. Must

match the slice, dice, core or wedge size of the pusher head

block.

H

I

D

Prepare the Food

Prepare the food to be processed. Maximum food size for:

• Slicing and dicing: 5" (12.7 cm) wide.

• Wedging and coring: 3½" (8.9 cm) in diameter.

Prepare the Equipment

1. Verify the blade assembly and pusher block match. Each component

must be for the same size slice, dice, core or wedge.

2. Verify the equipment is clean and the blades are in good condition. If

blades are loose, broken or dull, replace the blade assembly.

3. Place the equipment on a clean, flat work surface.

4. Verify the bumpers are in place on the guide rods. DO NOT USE

EQUIPMENT IF BUMPERS ARE NOT IN PLACE.

NOTICE: Using this equipment without the bumpers in place may

damage the equipment.

5. Verify the blade assembly is properly installed in the base. The

thumb screw must be fully tightened and the blade assembly fully

tight against the side of the frame opposite the thumbsrew.

Thumbscrew

BEFORE FIRST USE

Clean the equipment. See the Cleaning section of this manual.

2 Instacut™5.1 Slicer, Dicer, Wedger and Corer Operator’s Manual

Fully tight.

No space.

Page 3

OPERATION (CONTINUED)

6. Check for proper blade alignment by slowly setting the pusher head

onto the blade assembly.

Correct - The pusher block passes between the blades.

Incorrect - The pusher block contacts the blades.

CLEANING

WARNING

Sharp Blade Hazard

Blades are sharp and can cause cuts. To avoid injury from

sharp blades, handle with caution.

7. Lift the T-handle and place the food product on the blade assembly

with the flat side facing down.

8. Using a strong, quick, downward thrust, push the food through the

blade assembly.

9. Repeat this process until you have prepared enough food.

10.Clean and lubricate this equipment immediately after each use. See

the Cleaning section of this manual for more information.

3. Raise the bumpers approximately 2" (5.0 cm).

4. Loosen the thumbscrew and carefully remove the blade assembly.

NOTICE: Food acids will dull the blades and corrode the metal.

Clean this equipment immediately after every use.

NOTICE: Do not put this equipment in a dishwasher or dish machine

with soaps, detergents, or other alkaline chemicals that

can harm the equipment.Handwash only.

NOTICE: Do not use abrasive materials, scratching cleansers or

scouring pads to clean this equipment. These can damage

the finish.

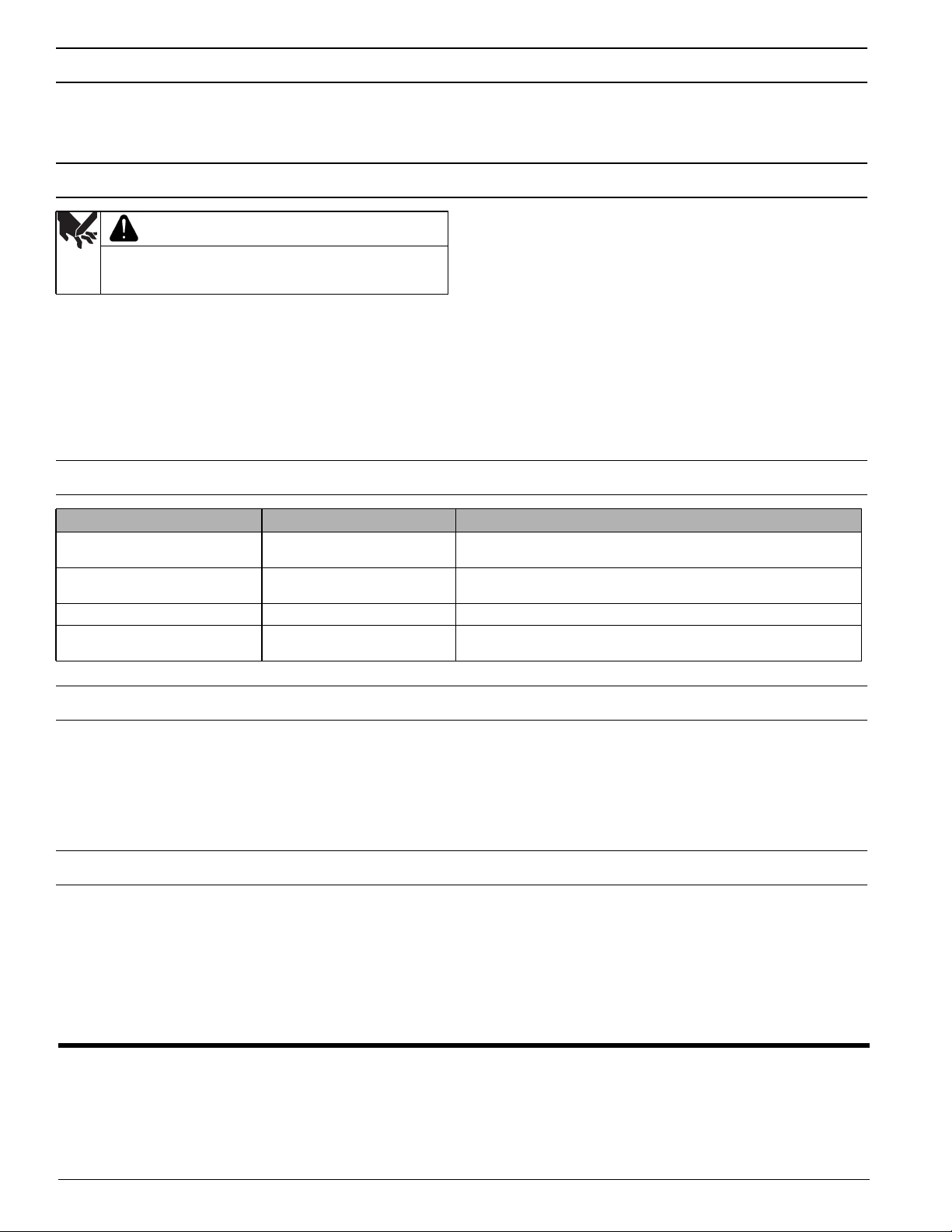

Disassemble

1. Slide the pusher head assembly up and off of the guide rods.

2. Loosen the two thumbscrews. Thumbscrews are captive – do not

attempt to remove them. Separate the pusher block from the pusher

head.

Wash

1. Wipe, rinse or spray off the base, pusher head, pusher block and

blade assembly thoroughly with HOT water.

2. Do not wipe across the blades.

NOTICE: Wiping across the sharp edge of the blade can cause

injury and will dull the blades.

3. Use the included cleaning tool to push food particles out from the

pusher block or blade assembly.

4. Let the equipment air dry.

Reassemble

1. Return the cleaning tool to the pusher head assembly and

reassemble the pusher head assembly.

2. Install the blade assembly into the base. Tighten the thumbscrew to

push blade securely against the frame.

3. Lubricate the guide bar with mineral oil or Petrol-Gel.

NOTICE: Do not use cooking oil as it will become sticky and may

permanently damage the equipment.

4. Slide the bumpers into place.

Instacut™5.1 Slicer, Dicer, Wedger and Corer Operator’s Manual 3

Page 4

PREVENTATIVE MAINTENANCE

1. Use for the intended purposes only.

2. Inspect the equipment before each use. Do not use this equipment with missing, broken or worn components.

3. Clean the equipment after every use.

REPLACE THE BLADE ASSEMBLY

5. Install the new blade assembly by inserting the tab on the frame that

WARNING

Sharp Blade Hazard

Blades are sharp and can cause cuts. To avoid injury from

sharp blades, handle with caution.

1. Wash the blade assembly with warm, soapy water. Rinse thoroughly

to remove the thin protective oil film.

2. Sliding the T-handle assembly off the guide rods.

3. Raise the bumpers approximately 2" (5.0 cm).

4. Remove the old blade assembly by loosing the thumbscrew and

then carefully pressing upward on the underside of the frame that

surrounds the blades into the groove in the base. Then lower the

blade assembly into a seated and flush position in the base. Tighten

the thumbscrew.

6. Slide the bumpers down the guide rods so they rest on the base.

7. Position T-handle assembly onto the guide rods and slowly lower

the assembly. Check the pusher head block to blade assembly

alignment.

8. Lubricate the guide rod with mineral oil, Petrol-Gel or other foodgrade lubricant after each use.

NOTICE: Do NOT use cooking oil as it will become sticky and may

permanently damage the equipment.

surrounds the blades.

NOTICE: Do NOT touch the sharp understand of the blades.

TROUBLESHOOTING

Problem Might be Caused By Course of Action

Broken Blade Blades were dull.

Pusher head does not slide easily.

Guide rods improperly or

insufficiently lubricated.

Cuts poorly. Blades are dull. Replace blade assembly.

Cannot push food through.

Blades are misaligned or incorrect

pusher block is installed.

Replace the blade assembly. Also inspect the pusher block. Replace if

damaged.

Clean and lubricate the guide rides. See Cleaning.

Confirm the pusher block is correct for the blade assembly and that there

is no interference between the pusher block and blade assembly.

SERVICE AND REPAIR

Serviceable parts are available on Vollrath.com.

To avoid serious injury or damage, never attempt to repair the unit or replace a damaged power cord yourself. Do not send units directly to

The Vollrath Company LLC. Please contact Vollrath Technical Services for instructions.

When contacting Vollrath Technical Services, please be ready with the item number, model number (if applicable), serial number, and proof of

purchase showing the date the unit was purchased.

WARRANTY STATEMENT FOR THE VOLLRATH CO. L.L.C.

This warranty does not apply to products purchased for personal, family or household use, and The Vollrath Company LLC does not offer a written

warranty to purchasers for such uses.

The Vollrath Company LLC warrants the products it manufactures or distributes against defects in materials and workmanship as specifically

described in our full warranty statement. In all cases, the warranty runs from the date of the end user’s original purchase date found on the receipt.

Any damages from improper use, abuse, modification or damage resulting from improper packaging during return shipment for warranty repair will

not be covered under warranty.

For complete warranty information, product registration and new product announcement, visit www.vollrath.com.

The Vollrath Company, L.L.C. Headquarters

1236 North 18th Street

Sheboygan, Wisconsin

53081-3201 USA

Main Tel: 800-624-2051 or 920-457-4851

Main Fax: 800-752-5620 or 920-459-6573

Canada Customer Service: 800-695-8560

Tech Services: techservicereps@vollrathco.com

www.vollrath.com

Pujadas

Ctra. de Castanyet,

132 P.O. Box 121

17430 Santa Coloma de Farners

(Girona) – Spain

Tel. +34 972 84 32 01

info@pujadas.es

Vollrath of China

Vollrath Shanghai Trading Limited

Room 201, Building A

Xin Yi Plaza

1618 Yi Shan Road

Shanghai, 201103

China, P.R.C.

Tel: +86-21-5058-9580

Vollrath de Mexico S. de R.L. de C.V.

Periferico Sur No. 7980 Edificio 4-E

Col. Santa Maria Tequepexpan

45600 Tlaquepaque, Jalisco | Mexico

Tel: (52) 333-133-6767

Tel: (52) 333-133-6769

Fax: (52) 333-133-6768

©

2019 The Vollrath Company L.L.C. Part No. 351753-1 ml 1/30/19

Page 5

Manuel d'utilisation

Vide-pomme, découpeuse en tranches et découpeuse

™

en quartiers et en dés Instacut

Merci d’avoir acheté cet appareil Vollrath. Avant d’utiliser cet appareil,

lisez et familiarisez-vous avec le mode d’emploi et les consignes

d’utilisation qui suiven. CONSERVEZ CES INSTRUCTIONS POUR

RÉFÉRENCE ULTÉRIEURE. Conservez l’emballage et le carton d’origine.

L'emballage devra être réutilisé pour expédier l’appareil si une

réparation est nécessaire.

CONSIGNES DE SÉCURITÉ

Pour garantir un fonctionnement sûr, lisez les avertissements suivants

et comprenez leur signification. Ce manuel contient des consignes de

sécurité, présentées ci-dessous. Lisez-les attentivement.

AVERTISSEMENT

Un avertissement permet d'indiquer la présence d'un danger qui

causera ou peut causer des blessures personnelles graves ou la mort.

ATTENTION

Une mise en garde indique la présence d'un danger qui causera ou

pourra causer des blessures mineures ou majeures si elle est ignorée.

5.1

AVIS : Un avis met en évidence des informations qui sont

importantes mais sans rapport avec un danger.

Pour réduire le risque de blessures et d'endommagement

de l'appareil :

• Vérifiez l'équipement avant chaque utilisation pour vous assurer

qu'il est propre.

• Vérifiez si les lames ne sont pas cassées, ébréchées ou émoussées

et, s'il y a lieu, remplacez le jeu de lames.

• Vérifiez si le bloc de tête de poussée et le jeu de lames

correspondent et sont correctement alignés.

• Lubrifiez les tiges-guides comme indiqué, avec un film d'huile

minérale, du Petro Gel ou un lubrifiant de qualité alimentaire.

N'UTILISEZ PAS D'HUILE DE CUISSON, CAR ELLE FINIRA PAR

COLLER ET RISQUE D'ABÎMER L'ÉQUIPEMENT À TOUT JAMAIS.

FONCTION ET OBJET

L'appareil manuel de transformation des aliments InstaCut™ 5.1

est destiné à trancher, couper en dés, évider et tailler en quartiers

les légumes et fruits mous. Il n'est pas destiné à couper des légumes

racines durs comme les carottes et les pommes de terre douces.

Num. d’art. Description

55457 Dés de ¼" (6 mm)

55458 Dés de ³⁄₈" (9,5 mm)

55459 Dés de ½" ((12,7 mm)

55460 Tranches de ¼" (6 mm)

55461 Tranches de ³⁄₈" (9,5 mm)

55462 Tranches de ½" (12,7 mm)

55463 4 quartiers

55464 6 quartiers

55465 8 quartiers

55466 10 quartiers

55467 12 quartiers

55468 6 sections à évider

55469 8 sections à évider

©

2019 The Vollrath Company L.L.C. Num. d’art. 351753-1 ml 1/30/19

Page 6

CARACTÉRISTIQUES/FONCTIONS

E

D

MODE D'EMPLOI

AVERTISSEMENT

Danger - Lames coupantes

F

G

Les lames sont affûtées et peuvent causer des coupures.

Pour éviter les blessures causées par les lames coupantes,

manipulez avec prudence.

Préparation des aliments

Préparez le produit alimentaire à transformer. Taille d'aliment maximum

pour :

• Tranches et dés : 5" (12,7 cm) de largeur.

• Quartiers et évidage : 3½" (8,9 cm) de diamètre.

C

B

A

A Socle

B Caoutchoucs amortisseurs

C Tiges-guides

D Vis à oreilles

E Poignée en T

F Ensemble de la poignée en T. Comporte la tête de poussée,

l'outil de nettoyage et le bloc de poussée.

G Outil de nettoyage. (Paquets de lame tranches et dés

seulement)

H Bloc de poussée. Pousse le produit alimentaire à travers le jeu

de lames. Doit correspondre à la taille de tranche, dé, évidage ou

quartier du jeu de lames.

I Jeu de lames. Contient les lames, découpeuse en quartiers ou

vide-pomme. Doit correspondre à la taille de tranche, dé,

évidage ou quartier du bloc de tête de poussée.

H

I

D

Préparation de l'appareil

1. Assurez-vous que le jeu de lames et le bloc de poussée concordent.

Chaque composant doit être pour des tranches, dés, pulpe évidée ou

quartiers de la même taille.

2. Assurez-vous que l'appareil est propre et les lames en bon état.

Si les lames sont desserrées, cassées ou émoussées, remplacez

la lame.

3. Placez l'appareil sur un plan de travail propre et plat.

4. Vérifiez que les caoutchoucs sont en place sur les tiges-guides.

N'UTILISEZ PAS L'APPAREIL SANS LES CAOUTCHOUCS.

AVIS : L'utilisation de cet appareil sans les caoutchoucs en

place risque d'endommager l'appareil.

5. Vérifiez que le jeu de lames est correctement installé dans le socle.

La vis à oreilles doit être serrée à fond et le jeu de lames bien plaqué

contre le côté du cadre à l'opposé de la vis à oreilles.

Vis à oreilles

AVANT LA PREMIÈRE UTILISATION

Nettoyez l'appareil. Suivez la section « Nettoyage » de ce manuel.

2 Manuel d'utilisation du vide-pomme, découpeuse en tranches et découpeuse en quartiers et en dés Instacut™5.1

Bien plaquée.

Pas d'espace.

Page 7

MODE D'EMPLOI (SUITE)

6. Vérifiez si l'alignement des lames est correct en posant doucement

la tête de poussée sur le jeu de lames.

Correct - Le bloc de poussée passe entre les lames.

Incorrect - Le bloc de poussée touche les lames.

NETTOYAGE

AVERTISSEMENT

Danger - Lames coupantes

Les lames sont affûtées et peuvent causer des coupures. Pour

éviter les blessures causées par les lames coupantes,

manipulez avec prudence.

7. Soulevez la poignée en T et placez le produit alimentaire sur le jeu de

lames le côté plat en bas.

8. En appuyant fort et vite, poussez le produit alimentaire à travers le

jeu de lames.

9. Reprenez jusqu'à ce que vous ayez transformé assez de produit

alimentaire.

10.Nettoyez et lubrifiez l'appareil juste après chaque utilisation.

Pour plus de renseignements, reportez-vous à la section Nettoyage

de ce manuel.

3. Relevez les caoutchoucs amortisseurs de 2" (5,0 cm) environ.

4. Desserrez la vis à oreilles et enlevez avec précaution le jeu de lames.

AVIS : Les acides alimentaires émoussent les lames et corrodent

le métal. Nettoyez cet appareil juste après chaque

utilisation.

AVIS : Ne passez pas cet appareil au lave-vaisselle avec des

savons, détergents ou autres produits chimiques alcalins

susceptibles de l'abîmer. Lavez uniquement à la main.

AVIS : N'utilisez pas de produits ou nettoyants abrasifs, ni de

tampons récurants pour nettoyer cet appareil sous peine

d'endommager le fini.

Démontage

1. Glissez la tête de poussée vers le haut et en dehors des tiges-guides.

2. Desserrez les deux vis à oreilles. Les vis à oreilles sont captives –

n'essayez pas de les enlever. Séparez le bloc de poussée de la tête de

poussée.

Lavage

1. Essuyez, rincez ou pulvérisez minutieusement le socle, la tête de

poussée, le bloc de poussée et le jeu de lames à l'eau CHAUDE.

2. N'essuyez pas les lames avec un chiffon.

AVIS : Ne passez pas l'éponge sur le tranchant de la lame sous

peine de causer des blessures et d'émousser les lames.

3. Utilisez l'outil de nettoyage inclus pour expulser les particules

alimentaires du bloc de poussée ou du jeu de lames.

4. Laissez sécher l'appareil à l'air.

Remontage

1. Remettez l'outil de nettoyage sur la tête de poussée et remontez la

tête de poussée.

2. Installez le jeu de lames dans le socle. Serrez la vis à oreille pour

bien caler la lame contre le cadre.

3. Lubrifiez la barre-guide à l'huile minérale ou au Petro Gel.

AVIS : N'utilisez pas d'huile de cuisson, car elle finira par coller

et risque d'abîmer l'équipement à tout jamais.

4. Glissez les caoutchoucs en place.

Manuel d'utilisation du vide-pomme, découpeuse en tranches et découpeuse en quartiers et en dés Instacut™5.1 3

Page 8

ENTRETIEN PRÉVENTIF

1. Utilisez uniquement aux fins indiquées.

2. Inspectez l'appareil avant chaque utilisation. N'utilisez pas cet appareil avec des composants usés, cassés ou manquants.

3. Nettoyez l'appareil après chaque utilisation.

REMPLACEMENT DU JEU DE LAMES

5. Installez la lame neuve en insérant l'ergot du cadre qui entoure les

AVERTISSEMENT

Danger - Lames coupantes

Les lames sont affûtées et peuvent causer des coupures.

Pour éviter les blessures causées par les lames coupantes,

manipulez avec prudence.

1. Lavez la lame à l’eau savonneuse chaude. Rincez minutieusement

pour enlever le film d'huile de protection.

2. Glissez la poignée en T en dehors des tiges-guides.

3. Relevez les caoutchoucs amortisseurs de 2" (5.0 cm) environ.

4. Enlevez la lame usagée en desserrant la vis à oreilles puis en

pressant avec précaution vers le haut sous le cadre qui entoure les

lames dans la rainure du socle. Ensuite, abaissez et calez bien la

lame en position affleurante dans le socle. Serrez la vis à oreilles.

6. Abaissez les caoutchoucs amortisseurs sur les tiges-guides pour

qu'elles reposent sur le socle.

7. Positionnez la poignée en T sur les tiges-guides et abaissez

lentement l'ensemble. Vérifiez l'alignement du bloc de tête de

poussée et de la lame.

8. Lubrifiez les tiges-guides à l'huile minérale, au Petrol-Gel® ou avec

un autre lubrifiant sans danger pour les aliments après chaque

utilisation.

AVIS : N'UTILISEZ PAS d'huile de cuisson, car elle finira par

coller et risque d'abîmer l'équipement à tout jamais.

lames.

AVIS : NE TOUCHEZ PAS au côté coupant des lames.

DÉPANNAGE

Problème Cause possible Mesure corrective

Lame cassée Les lames sont émoussées.

La tête de poussée ne glisse pas

facilement.

Tiges-guides mal ou

insuffisamment lubrifiées.

Coupe mal. Les lames sont émoussées. Remplacez l'ensemble des lames.

Impossible de pousser les aliments

au travers.

Les lames sont mal alignées ou un

bloc de poussé incorrect est

installé.

Remplacez le jeu de lames. Inspectez aussi le bloc de poussée.

Remplacez-le s'il est endommagé.

Nettoyez et lubrifiez les tiges-guides. Voir « Nettoyage ».

Confirmez que le bloc de poussée est correct pour l'ensemble des lames

et qu'il n'y a pas d'interférences entre le bloc de poussée et l'ensemble

des lames.

SAV ET RÉPARATIONS

Des pièces détachées sont disponibles sur Vollrath.com.

Pour éviter toute blessure grave ou tout dommage sévère, n’essayez jamais de réparer l'appareil ou de remplacer vous-même un cordon

d’alimentation endommagé. N’envoyez aucun appareil directement à The Vollrath Company LLC. Pour des instructions, contactez les services

techniques de Vollrath.

Lorsque vous contacterez les services techniques de Vollrath, tenez-vous prêt à fournir le numéro d'article, le numéro de modèle (s'il y a lieu),

le numéro de série et le justificatif d’achat indiquant la date d’achat de l’appareil.

GARANTIE DE THE VOLLRATH CO. L.L.C.

Cette garantie ne s'applique pas aux produits achetés pour un usage personnel, familial ou ménager, et The Vollrath Company LLC ne propose

aucune garantie écrite aux acheteurs pour de telles utilisations.

The Vollrath Company L.L.C. garantit que les produits qu'elle fabrique et distribue seront dépourvus de vices de matériaux et de malfaçons, comme

indiqué dans notre déclaration complète de garantie. Dans tous les cas, la garantie entre en vigueur à la date d'achat par l'utilisateur initial indiquée

sur le reçu. Tous les dommages subis lors d’une utilisation impropre ou abusive, ou résultant d’une modification ou d'un emballage inadapté lors

d’un renvoi du produit pour une réparation sous garantie ne seront pas couverts par la garantie.

Pour des informations complètes sur la garantie, l'enregistrement des produits et l'annonce de nouveaux produits, consultez www.vollrath.com.

The Vollrath Company, L.L.C. Headquarters

1236 North 18th Street

Sheboygan, Wisconsin

53081-3201 USA

Main Tel: 800-624-2051 or 920-457-4851

Main Fax: 800-752-5620 or 920-459-6573

Canada Customer Service: 800-695-8560

Tech Services: techservicereps@vollrathco.com

www.vollrath.com

Pujadas

Ctra. de Castanyet,

132 P.O. Box 121

17430 Santa Coloma de Farners

(Girona) – Spain

Tel. +34 972 84 32 01

info@pujadas.es

Vollrath of China

Vollrath Shanghai Trading Limited

Room 201, Building A

Xin Yi Plaza

1618 Yi Shan Road

Shanghai, 201103

China, P.R.C.

Tel: +86-21-5058-9580

Vollrath de Mexico S. de R.L. de C.V.

Periferico Sur No. 7980 Edificio 4-E

Col. Santa Maria Tequepexpan

45600 Tlaquepaque, Jalisco | Mexico

Tel: (52) 333-133-6767

Tel: (52) 333-133-6769

Fax: (52) 333-133-6768

©

2019 The Vollrath Company L.L.C. Num.d’art. 351753-1 ml 1/30/19

Page 9

Manual para operadores

Rebanadora, cortadora en cubos,

segmentador y descarozador InstaCut

Gracias por comprar este equipo Vollrath. Antes de usar el equipo, lea y

familiarícese con las siguientes instrucciones de operación y seguridad.

CONSERVE ESTAS INSTRUCCIONES COMO REFERENCIA PARA EL

FUTURO. Conserve la caja y embalado originales. Deberá utilizarlos

para devolver el equipo en caso de que requiera reparaciones.

PRECAUCIONES DE SEGURIDAD

Para garantizar una operación segura, lea las siguientes afirmaciones y

comprenda su significado. Este manual contiene precauciones de

seguridad que se explican a continuación. Léalas atentamente.

ADVERTENCIA

Advertencia se usa para indicar la presencia de un peligro que

provocará o puede provocar lesiones graves o letales.

PRECAUCIÓN

Precaución se usa para indicar la presencia de un peligro que provocará

o puede provocar lesiones leves o importantes si se ignora el aviso.

AVISO: Aviso se usa para señalar información importante no

relacionada con peligros.

Para disminuir el riesgo de lesiones personales o daños

al equipo:

• Inspeccione el equipo antes de cada uso para asegurarse de que

esté limpio.

• Inspeccione si hay hojas rotas, melladas o desafiladas, y si es así,

reemplace el conjunto de hojas.

• Verifique que el conjunto del bloque del cabezal de empuje y el

paquete de hojas coincidan y estén alineados correctamente.

• Lubrique las varillas guía según las instrucciones usando una capa

delgada de aceite mineral, Petrol Gel o lubricante apto para

alimentos. NO USE ACEITE DE COCINA YA QUE SE TORNARÁ

PEGAJOSO Y PUEDE DAÑAR PERMANENTEMENTE EL EQUIPO.

FUNCIÓN Y PROPÓSITO

El procesador manual de alimentos InstaCut™ 5.1está diseñado para

rebanar, cortar en cubos, segmentar y descarozar verduras y frutas

blandas. No está diseñado para cortar tubérculos duros como

zanahorias y batatas.

™

5.1

Núm. art. Descripción

55457 Cubo de ¼" (6 mm)

55458 Cubo de ³⁄₈" (9,5 mm)

55459 Cubo de ½" (12,7 mm)

55460 Rebanada de ¼" (6 mm)

55461 Rebanada de ³⁄₈" (9,5 mm)

55462 Rebanada de ½"(12,7 mm)

55463 Segmento de 4 secciones

55464 Segmento de 6 secciones

55465 Segmento de 8 secciones

55466 Segmento de 10 secciones

55467 Segmento de 12 secciones

55468 Descarozado de 6 secciones

55469 Descarozado de 8 secciones

©

2019 The Vollrath Company L.L.C. Núm. pieza 351753-1 ml 1/30/19

Page 10

CARACTERÍSTICAS

E

FUNCIONAMIENTO

ADVERTENCIA

Peligro con hojas filosas

F

Las hojas son filosas y pueden causar cortes. Manipule el

equipo con cuidado para evitar lesiones con las hojas filosas.

D

G

Prepare el alimento

Prepare el alimento que va a procesar. Tamaño máximo del alimento

para:

• Rebanar y cortar en cubos: 5" (12,7 cm) de ancho.

• Segmentar y descarozar: 3½" (8,9 cm) de diámetro.

Prepare el equipo

C

B

A

H

I

D

1. Verifique que coincidan el conjunto de hojas y el bloque de empuje.

Cada componente debe ser para el mismo tamaño de corte en

rebanadas, cubos, descarozados o segmentos.

2. Verifique que el equipo esté limpio y las hojas estén en buen estado.

Si las hojas están sueltas, rotas o desafiladas reemplace el conjunto

de hojas.

3. Coloque el equipo en una superficie de trabajo limpia y plana.

4. Verifique que los topes estén en su lugar sobre las varillas guía.

NO USE EL EQUIPO SI LOS TOPES NO ESTÁN EN SU LUGAR.

AVISO: Usar este equipo sin los topes en su lugar puede

dañarlo.

A Conjunto de la base

B Topes

C Varillas guía

D Tornillo de mano

E Mango en T

F Conjunto del mango en T. Está compuesto por el cabezal de

empuje, la herramienta de limpieza y el bloque de empuje.

G Herramienta de limpieza. (paquetes de hojas cortadoras en

cubo/rebanadoras solamente)

H Bloque de empuje. Empuja el alimento a través del conjunto de

hojas. Debe coincidir con el tamaño de los cortes en rebanadas,

cubos, descarozados y segmentados del conjunto de hojas.

I Conjunto de hojas. Alberga las hojas, el segmentador o el

descarozador. Debe coincidir con el tamaño de los cortes en

rebanadas, cubos, descarozados y segmentados del bloque

del cabezal de empuje.

ANTES DEL PRIMER USO

Limpie el equipo. Consulte la sección Limpieza de este manual.

5. Verifique que el conjunto de hojas esté correctamente instalado en la

base. El tornillo de mano debe estar completamente apretado y el

conjunto de hojas firmemente afianzado contra el lado del bastidor

opuesto al tornillo de mano.

Tornillo de mano

Firmemente

apretado.

Sin espacio.

2 Manual para operadores de la rebanadora, cortadora en cubos, segmentador y descarozador Instacut™5.1

Page 11

FUNCIONAMIENTO (CONTINUACIÓN)

6. Verifique el alineamiento correcto de las hojas fijando lentamente el

cabezal de empuje sobre el conjunto de hojas.

Correcto - El bloque de empuje pasa entre las hojas.

Incorrecto - El bloque de empuje hace contacto con las hojas.

LIMPIEZA

ADVERTENCIA

Peligro con hojas filosas

Las hojas son filosas y pueden causar cortes. Manipule el

equipo con cuidado para evitar lesiones con las hojas filosas.

7. Suba el mango en T y coloque el alimento en el conjunto de hojas

con el lado plano hacia abajo.

8. Fuerce el alimento a través del conjunto de hojas empujándolo hacia

abajo en forma rápida y firme.

9. Repita este proceso hasta que haya preparado suficiente alimento.

10.Limpie y lubrique inmediatamente este equipo tras usarlo. En la

sección Limpieza de este manual encontrará más información.

4. Afloje el tornillo de mano y retire cuidadosamente el conjunto de

hojas.

AVISO: Los ácidos de los alimentos desafilan las hojas y corroen

el metal. Limpie este equipo inmediatamente tras usarlo.

AVISO: No coloque este equipo en un lavavajillas ni máquina para

lavar platos con jabones, detergentes ni productos

químicos alcalinos que puedan dañarlo. Lávelo a mano

solamente.

AVISO: No emplee materiales abrasivos, limpiadores que rayen ni

esponjas metálicas para limpiarlo, ya que pueden dañar el

acabado.

Desmontaje

1. Deslice el conjunto del cabezal de empuje hacia arriba y afuera para

retirarlo de las varillas guía.

2. Afloje los dos tornillos de mano. Los tornillos de mano son

prisioneros, no intente extraerlos. Separe el bloque de empuje del

cabezal de empuje.

3. Suba los topes aproximadamente 2" (5,0 cm).

Lavado

1. Limpie, enjuague o rocíe totalmente la base, el cabezal de empuje,

el bloque de empuje y el conjunto de hojas con agua CALIENTE.

2. No limpie las hojas con un paño.

AVISO: El pasar un paño por el borde filoso puede causar

lesiones y desafilar las hojas.

3. Use la herramienta de limpieza que se incluye para empujar las

partículas de alimento fuera del bloque de empuje o del conjunto

del hojas.

4. Deje que el equipo se seque al aire.

Montaje

1. Vuelva a colocar la herramienta de limpieza en el conjunto del

cabezal de empuje y vuelva a montar dicho conjunto.

2. Instale el conjunto de hojas en la base. Apriete el tornillo de mano

para empujar las hojas firmemente contra el bastidor.

3. Lubrique la barra guía con aceite mineral o Petrol-Gel.

AVISO: No use aceite de cocina ya que se tornará pegajoso y

puede dañar permanentemente el equipo.

4. Deslice los topes a su posición.

Manual para operadores de la rebanadora, cortadora en cubos, segmentador y descarozador InstaCut™5.1 3

Page 12

MANTENIMIENTO PREVENTIVO

1. Use el equipo solo para los propósitos para los cuales está diseñado.

2. Inspecciónelo antes de cada uso. No use este equipo si le faltan componentes, estos están rotos o desgastados.

3. Limpie el equipo después de usarlo.

REEMPLACE EL CONJUNTO DE HOJAS

5. Instale el conjunto de hojas nuevo introduciendo la lengüeta en el

ADVERTENCIA

Peligro con hojas filosas

Las hojas son filosas y pueden causar cortes. Manipule el

equipo con cuidado para evitar lesiones con las hojas filosas.

1. Lave el conjunto de hojas en una solución jabonosa tibia. Enjuáguelo

totalmente para eliminar la delgada película protectora de aceite.

2. Deslice el conjunto del mango en T hacia afuera para retirarlo de las

varillas guía.

3. Suba los topes aproximadamente 2" (5,0 cm).

4. Retire cuidadosamente el conjunto de hojas antiguo aflojando el

tornillo de mano y luego presionando con cuidado hacia arriba en la

bastidor que rodea las hojas en la ranura de la base. Luego baje el

conjunto de hojas a una posición asentada y a ras de la base. Apriete

el tornillo de mano.

6. Deslice los topes hacia abajo por las varillas guía de modo que

descansen en la base.

7. Coloque el conjunto del mango en T sobre las varillas guía y bájelo

lentamente. Verifique el alineamiento entre el bloque del cabezal de

empuje y el conjunto de hojas.

8. Lubrique la varilla guía con aceite mineral, Petrol-Gel u otro

lubricante apto para alimentos.

AVISO: NO use aceite de cocina ya que se tornará pegajoso y

puede dañar permanentemente el equipo.

parte inferior del bastidor que rodea las hojas.

AVISO: NO toque los bajos del pedestal de las hojas, pues es

filoso.

SOLUCIÓN DE PROBLEMAS

Problema Podría deberse a Curso de acción

Hoja rota Hojas desafiladas.

El cabezal de empuje no se desliza

fácilmente.

Las varillas guía están lubricadas

de manera inadecuada o

insuficiente.

Cortes deficientes. Hojas desafiladas. Reemplace el conjunto de hojas.

Las hojas están desalineadas o se

No se puede empujar el alimento.

instaló un bloque de empuje

incorrecto.

Reemplace el conjunto de hojas. Inspeccione también el bloque de

empuje. Reemplácelo si está dañado.

Limpie y lubrique las varillas guía. Consulte la sección Limpieza.

Confirme que el bloque de empuje sea el correcto para el conjunto de

hojas y que no haya interferencia entre el bloque y el conjunto.

SERVICIO Y REPARACIÓN

En Vollrath.com. encontrará las piezas que puedan ser reparadas.

Para evitar lesiones o daños materiales graves, no trate de reparar la unidad ni reemplazar un cable eléctrico por su cuenta. No envíe las unidades

directamente a The Vollrath Company LLC. Pida instrucciones a los Servicios de asistencia técnica de Vollrath.

Al comunicarse con los servicios, esté listo para proporcionar el número de artículo, número de modelo (si corresponde), número de serie y el

comprobante de compra que muestre la fecha en que adquirió la unidad.

CLÁUSULA DE GARANTÍA DE THE VOLLRATH CO. L.L.C.

Esta garantía no se aplica a los productos adquiridos para uso personal, familiar ni doméstico, y The Vollrath Company LLC no ofrece una garantía

por escrito a los compradores para dichos usos.

The Vollrath Company LLC garantiza los productos que fabrica o distribuye contra defectos en materiales y fabricación, según se especifica en

nuestra cláusula de garantía completa. En todos los casos, la garantía rige desde la fecha de compra original del usuario final que aparece en el

recibo. La garantía no cubrirá ningún daño que resulte del uso indebido, abuso, modificación o daños causados por el embalado incorrecto durante

la devolución para obtener servicio de reparación dentro del período de vigencia de la garantía.

Para obtener información de garantía, inscripción de productos y anuncios de productos nuevos, visite www.vollrath.com.

The Vollrath Company, L.L.C. Headquarters

1236 North 18th Street

Sheboygan, Wisconsin

53081-3201 USA

Main Tel: 800-624-2051 or 920-457-4851

Main Fax: 800-752-5620 or 920-459-6573

Canada Customer Service: 800-695-8560

Tech Services: techservicereps@vollrathco.com

www.vollrath.com

Pujadas

Ctra. de Castanyet,

132 P.O. Box 121

17430 Santa Coloma de Farners

(Girona) – Spain

Tel. +34 972 84 32 01

info@pujadas.es

©

2019 The Vollrath Company L.L.C. Núm. pieza 351753-1 ml 1/30/19

Vollrath of China

Vollrath Shanghai Trading Limited

Room 201, Building A

Xin Yi Plaza

1618 Yi Shan Road

Shanghai, 201103

China, P.R.C.

Tel: +86-21-5058-9580

Vollrath de Mexico S. de R.L. de C.V.

Periferico Sur No. 7980 Edificio 4-E

Col. Santa Maria Tequepexpan

45600 Tlaquepaque, Jalisco | Mexico

Tel: (52) 333-133-6767

Tel: (52) 333-133-6769

Fax: (52) 333-133-6768

Loading...

Loading...