Page 1

ENGLISH

ENGLISH

Operator’s Manual

SOMERVILLE BUFFET SERVICE

Item Description

4634010 9 qt. Full-size Roll Top Chaffer

4635710 7 qt. Soup Urn

4635410 4 qt. Gravy Urn

4635310 3 gallon Coffee Urn

4635510 5 gallon Coffee Urn

Thank you for purchasing this Vollrath equipment. Before operating the equipment, read and familiarize yourself with the following operating and

safety instructions. SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE. Save the original box and packaging. Use this packaging to

ship the equipment if repairs are needed.

Item Description

4635110 Milk Dispenser

4635810 Juice/Cold Beverage Dispenser

4635210 Double Cereal Dispenser

4634110 6 qt. Round Drop-In Chafer

4635610 6 qt. Round Roll Top Chafer

Item No. 2350039-1 en Rev 02/12

Page 2

Buffet and taBletop Service

Safety PrecautionS

To ensure safe operation, read the following statements and

understand their meaning. This manual contains safety precautions

which are explained below. Please read carefully.

WARNING

Warning is used to indicate the presence of a hazard that can cause

severe personal injury, death, or substantial property damage if the

warning is ignored.

CAUTION

Caution is used to indicate the presence of a hazard that will or can

cause minor personal injury or property damage if the caution is

ignored.

NOTE

Note is used to notify people of installation, operation, or maintenance

information that is important but not hazard-related.

For Your Safety!

These precautions should be followed at all times. Failure to follow

these precautions could result in injury to yourself and others or

damage the equipment.

To reduce risk of injury or damage to the unit:

Equipment should only be used in a at, level position.

Do not store or place any materials below the unit or near the heating

source.

Always turn off and unplug electric chafer heaters when not in use.

Always use a snuffer paddle or saucer to extinguish ame when using a

chafer fuel heating source.

Allow equipment to cool before moving or cleaning.

Do not operate unattended.

Do not operate without water in the water pan body.

WARNING

Burn Hazard.

Do not touch heating surfaces, liquid, or while unit

is heating or operating.

and liquids can burn skin. Use gloves, mitts or

pot holders if it is necessary to handle hot pans,

plates and equipment.

Hot food, surfaces, steam

WARNING

Fire Hazard.

Use only chafer fuel designed for chafer use.

Do not install chafer fuel near combustible material.

Fire could occur.

WARNING

Electrical Shock Hazard.

Keep water and other liquids from entering the

inside of the heater. Liquid inside the heater could

cause an electrical shock. Do not damaged power

cord.

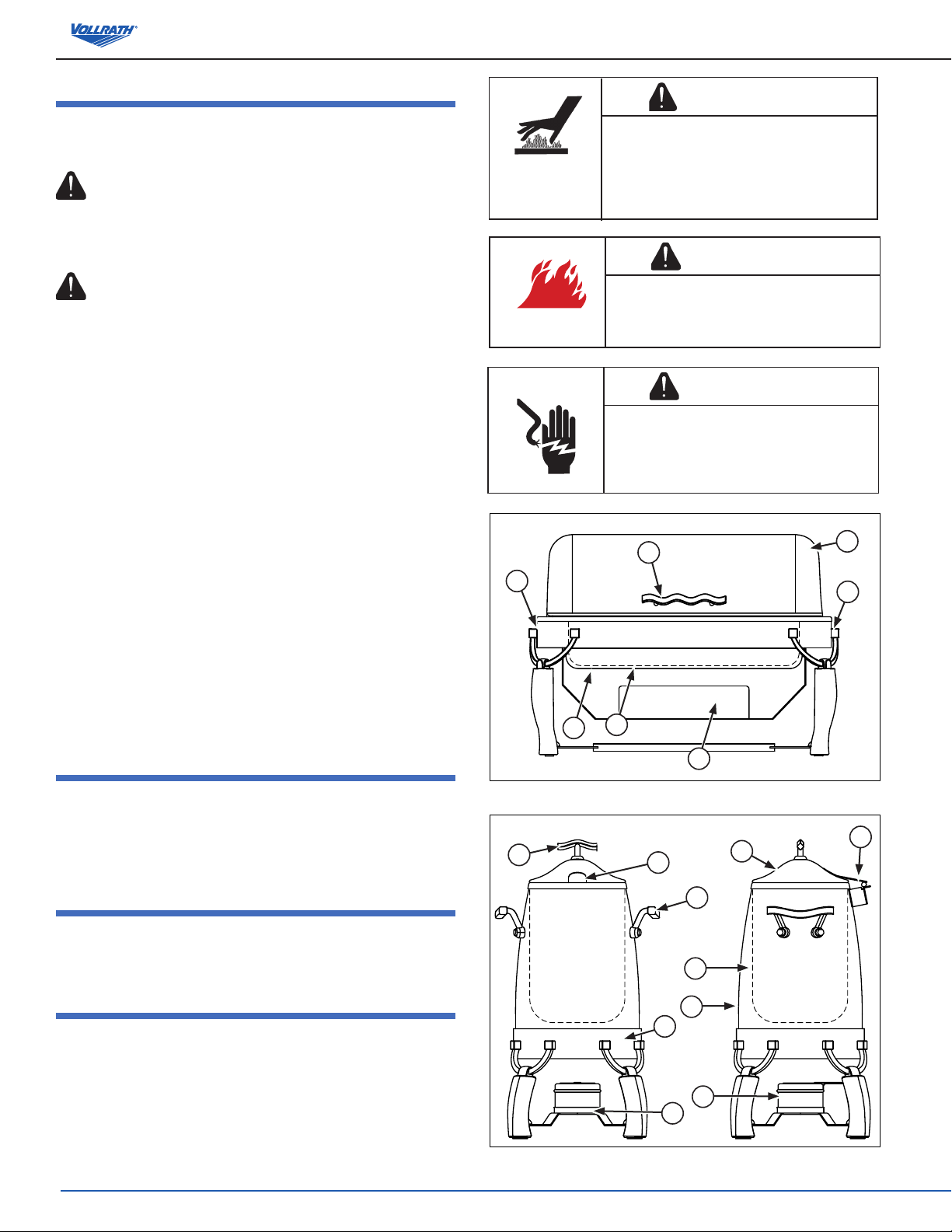

A

C

D

H

B

C

function and PurPoSe

This equipment is intended and designed to keep food at proper serving

temperatures. This equipment is not intended or designed to cook raw food or

to reheat prepared food. This equipment is not intended or designed to chill

beverages or food. Food and beverages must be prepared and placed into the

chafers, urns or dispensers at proper serving temperatures.

unPacking the equiPment and initial SetuP, all modelS

Carefully remove crating or packaging materials from the unit. When no longer

needed, dispose of all packaging materials in an environmentally responsible

manner. Follow any special instructions for specic models.

oPeration, tabletoP hot food and beverage

This equipment is designed to heat with an electric chafer heater or chafer fuel

designed specically for chafer application.

If using an electric chafer heater, we recommend that a Vollrath Universal

Chafer Heater is used.

If using fuel, use only high quality chafer gel fuel. Always follow the

manufacture’s recommendations for safety and usage.

2

OperatOr’s Manual

F

Figure 1. Chafer Features and Controls.

A

L

I

K

F

B

J

E

G

Figure 2. Soup Urn or Gravy Urn Features and Controls.

C

Page 3

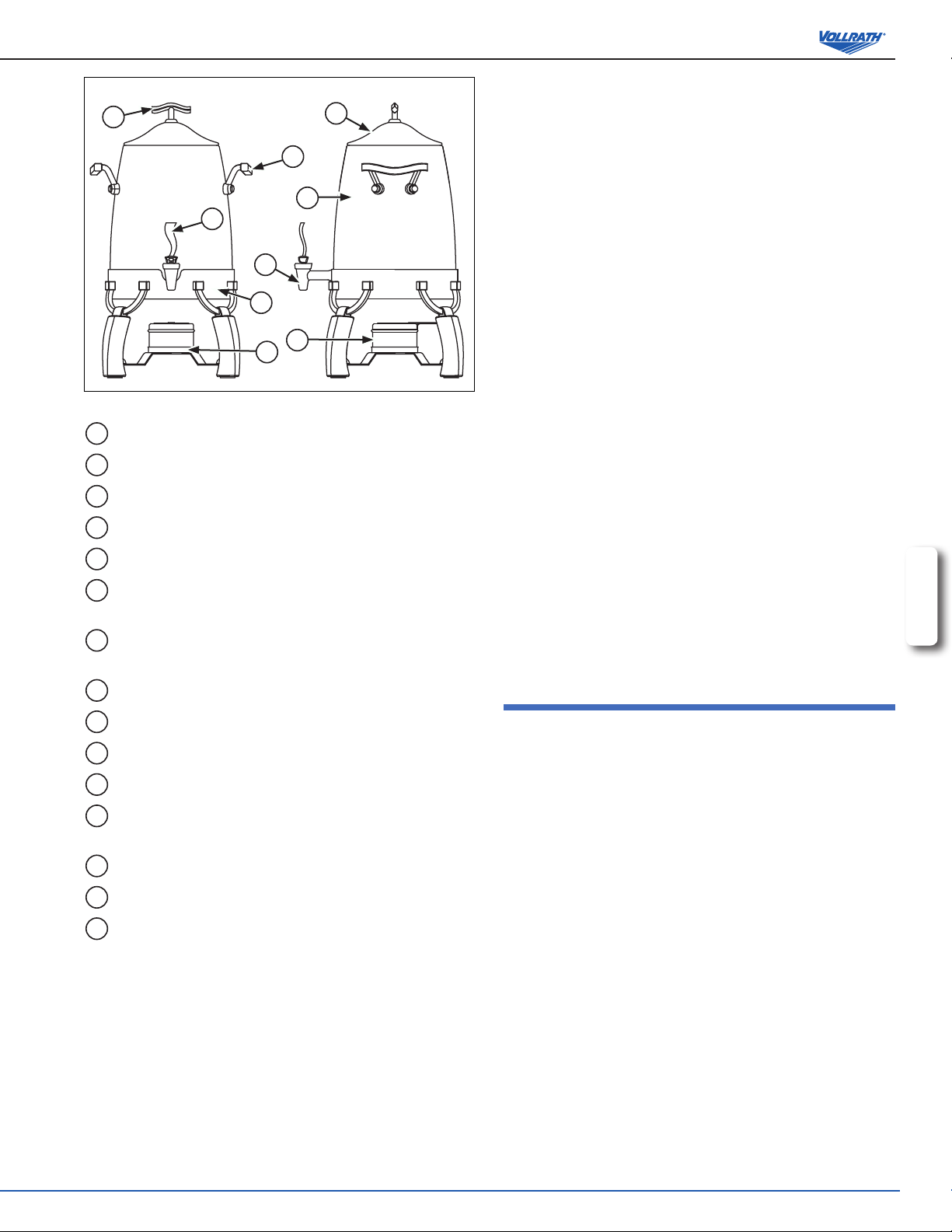

A

O

N

K

F

B

J

M

G

Figure 3. Coffee Urn Features and Controls.

A

COVER HANDLE. Used to open and close the cover.

B

COVER. Covers the food/beverage product.

C

HINGE. Allows the cover to rotate.

D

FOOD PAN. Holds the food product.

E

INSERT. Holds the food product.

F

HEATER/FUEL TRAY. Holds the electric chafer heater or

chafer fuel.

G

FUEL HOLDER with COVER. Designed to hold chafer fuel.

Includes a paddle for extinguishing the fuel ame.

H

WATER PAN. Holds the water.

I

URN BODY. Holds the water.

J

HANDLE. Used to lift the urn body.

K

BASE. Supports the urn body or beverage body.

L

UTENSIL CUTOUT. Opening that allows the handle of a

serving utensil remain in the insert with the cover closed.

M

BEVERAGE BODY. Holds the beverage product.

N

FAUCET. Opening that the beverage ows through.

O

FAUCET HANDLE. Controls the ow of beverage.

Buffet and taBletop Service

1. Remove the food pan (D) from the water pan (H) or remove the insert (E)

from the urn body (I). See Figures 1 and 2.

2. Pour about 2 quarts (2 L) of clean fresh water into the water pan (H) or

urn body (I).

NOTE:

Follow the manufacture’s instructions for usage and safety for the

electric chafer heater of chafer fuel.

3. Put the cover (B) in the closed position. Preheat the water by using a

universal electric chafer heater on “HI” or by using chafer fuel for 30

minutes.

4. Open the cover (B).

5. Place the food pan (D) or insert (E) containing food product that is

already at proper serving temperatures into the water pan (H) or urn

body (I). Close the cover (B).

NOTE:

Monitor food temperature closely for food safety. The United States

Public Health Service recommends that hot food be held at a minimum

of 140 ºF (60 ºC) to help prevent bacteria growth.

6. Regularly check the food temperature.

7. If necessary adjust the electric chafer heater between “HI” and “LO” to

maintain correct food temperature.

8. When nished with the equipment turn the electric chafer heater to the

“OFF” position and unplug or extinguish the ame on the chafer fuel

source.

ENGLISH

9. Open the cover (B). Remove the food pan (D) or the insert (E). When

removing hot food containers from unit use gloves, mitts or pot holders to

protect hands. See Figures 1 and 2.

10. Allow ample time for the water to cool. Remove the water pan (H) or the

urn body (I) and dispose of water.

cleaning, tabletoP hot food and beverage

To maintain the appearance and increase the service life, clean your

equipment daily.

1. Unplug the electric chafer heater or extinguish the ame on chafer fuel

and let it completely cool.

2. Remove the heating source.

3. Wipe the unit exterior with a clean damp cloth.

4. For coffee urns: Thoroughly clean the inside of the beverage body (E)

with hot water and mild soap. Run the hot soapy water through the faucet

(H). Rinse the beverage body (E) and faucet (H) completely with warm

water. Dry the equipment thoroughly.

5. Do not use abrasive materials, scratching cleansers or scouring pad to

clean the unit. These can damage the nish.

6. Thoroughly wipe off any mild soap or chemical cleaners. Residue could

corrode the surface of the unit.

OperatOr’s Manual

3

Page 4

Buffet and taBletop Service

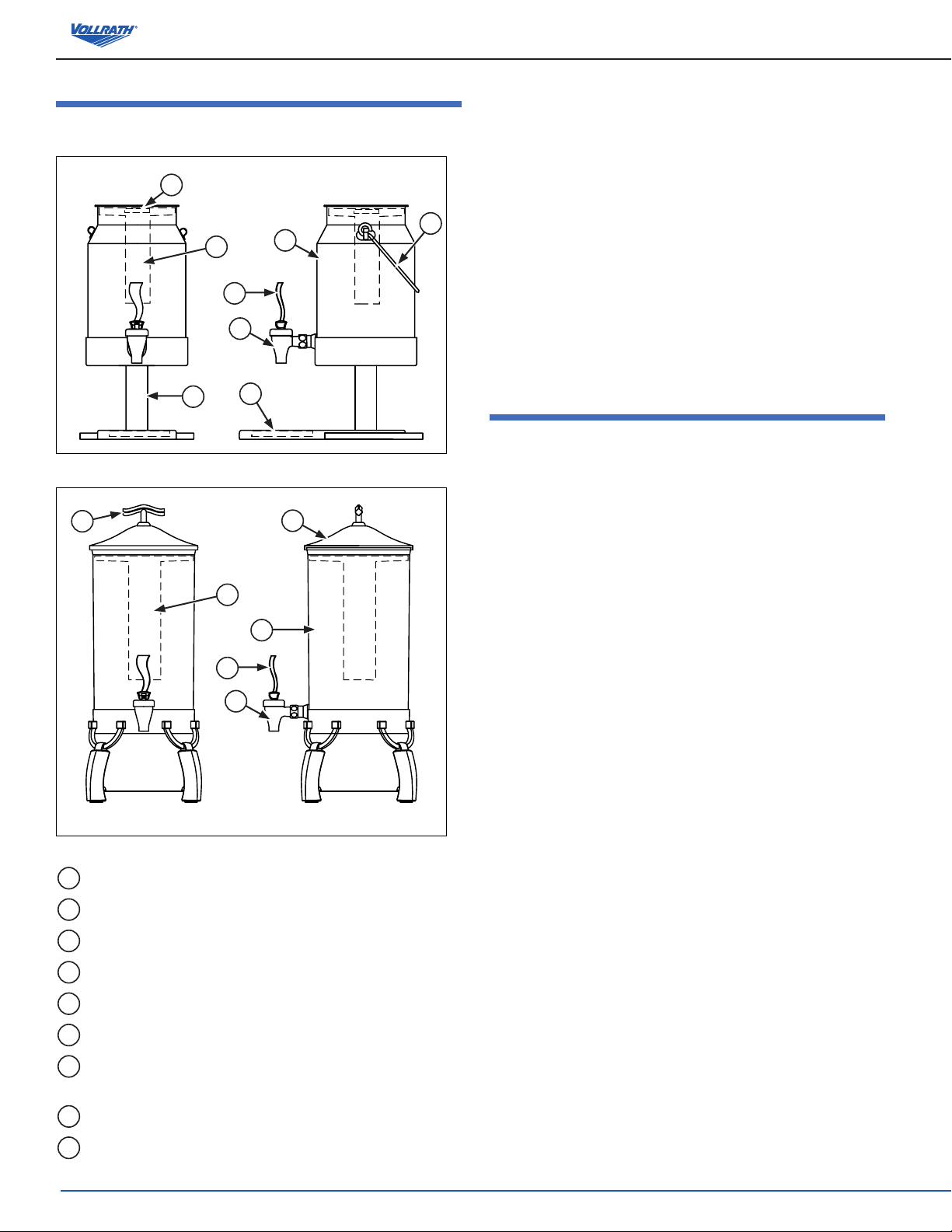

oPeration, cold beverage diSPenSerS

This equipment is designed to help keep beverages chilled and at proper

1. Remove the cover (A) and ice tube(D). See Figure 4 and 5.

2. Place the pre-chilled beverage product into the beverage body (E). Leave

serving temperature.

3. Fill the ice tube (D) with ice and place into the beverage body (E).

B

I

D

E

NOTE:

Monitor food temperature closely for food safety. The United States

Public Health Service recommends that cold food/beverage be held at a

maximum of 41 ºF (5 ºC) to help prevent bacteria growth.

4. Regularly check the beverage temperature.

5. Remove the drip cover (G) from time to time and clean any spilled

I

H

6. When nished using the equipment remove cover (B). Remove and drain

7. Remove and empty the beverage body (E).

F

G

cleaning, cold and beverage

To maintain the appearance and increase the service life, clean your

equipment daily.

Figure 4. Milk Dispenser Features and Controls.

NOTE:

Do not use ammonia based cleaners on acrylic or plastics. Do not use

abrasive materials, scratching cleansers or scouring pad to clean the

A

B

unit. These can damage the nish.

1. Wipe the unit exterior with a clean damp cloth.

2. Thoroughly clean the inside of the beverage body (E) with hot water and

D

E

3. Thoroughly wipe off any mild soap or chemical cleaners. Residue could

I

room for the ice tube (D).

beverage.

the ice tube (D).

mild soap. Run the hot soapy water through the faucet (H). Rinse the

beverage body (E) and faucet (H) completely with warm water. Dry the

equipment thoroughly.

corrode the surface of the unit.

H

Figure 5. Juice and Beverage Features and Controls.

A

COVER HANDLE. Used to open and close the cover.

B

COVER. Covers the food/beverage product or ice tube.

C

HANDLE. For lifting or carrying the milk beverage body.

D

ICE TUBE. Holds ice to keep the beverage products cold.

E

BEVERAGE BODY. Holds the beverage product.

F

BASE. Supports the beverage dispenser.

G

DRIP COVER. Covers the drip trough on the base. Can be

removed for cleaning.

H

FAUCET. Opening that the beverage ows through.

I

FAUCET HANDLE. Controls the ow of beverage.

4

OperatOr’s Manual

Page 5

Buffet and taBletop Service

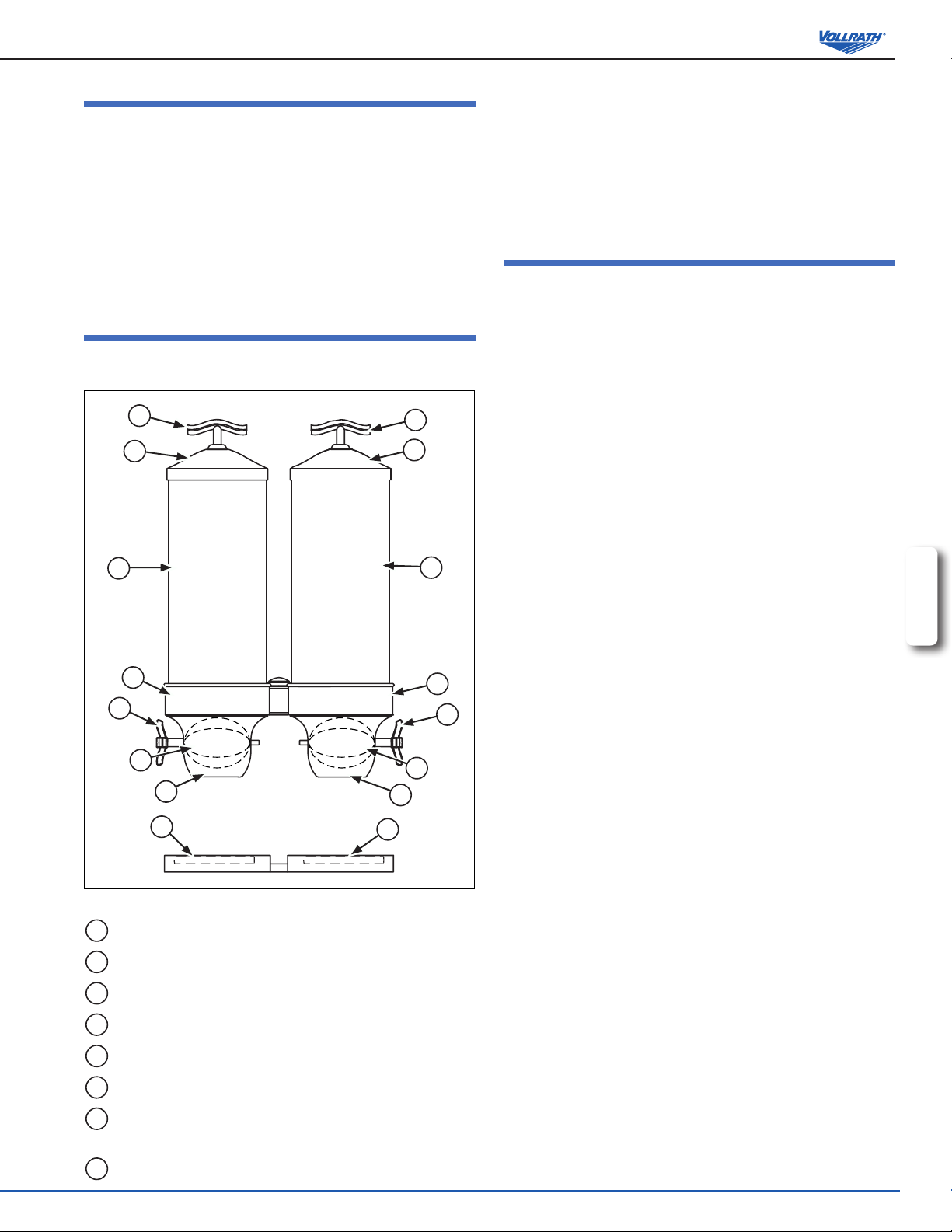

SetuP, cereal diSPenSer

Carefully remove crating or packaging materials from the unit. When no

longer needed, dispose of all packaging materials in an environmentally

responsible manner.

1. Set the food chute (F) into the base (D). See Figure 7. The food chute (F)

is wider at the bottom. It ts onto the base (D) one way.

2. Set the paddle (H) into the food shoot (F) and align the holes.

3. Push the dispensing handle (E) through the holes of the paddle (H) and

food chute (F).

4. Set the food tube (C) onto the base (D) and set the cover (B) into place.

oPeration, cereal diSPenSer

This equipment is designed to dispense cereal type food product. A variety of

food products may be used with this dispenser.

1. Remove the cover (B) and place the food product into the food tube (C)

and return the cover (B). See Figure 7.

2. Place a bowl or other container under the food chute (F).

3. Rotate the dispensing handle (E) until the desired amount of food

product has been dispensed.

4. Remove the drip cover (G) from time to time and clean any spilled food

product.

cleaning, cereal diSPenSer

To maintain the appearance and increase the service life, clean your

equipment daily.

NOTE:

Do not use ammonia based cleaners on acrylic or plastics. Do not use

abrasive materials, scratching cleansers or scouring pad to clean the

unit. These can damage the nish.

1. Slide the dispensing handle (E) out of the food chute (F) and paddle. See

A

B

A

B

Figure 7.

2. Lift the food tube (C), food chute (F) and cover (B) out of the base (D).

3. Remove the cover (B). Store or discard the food product following local

food handling and storage codes. Retain the paddle (H) for reuse.

4. Thoroughly wash the components with hot soapy water and a soft cloth.

Wipe the unit exterior with a clean damp cloth.

C

D

E

H

F

G

F

G

Figure 7. Cereal Dispenser Features and Controls.

A

COVER HANDLE. Used to open and close the cover.

B

COVER. Covers the food/beverage product.

C

FOOD TUBE. Holds the food product.

D

BASE. Holds food tube and dispensing mechanism.

E

DISPENSING HANDLE. Dispenses food product when rotated.

F

FOOD CHUTE. Area where the food product is dispensed.

G

DRIP COVER. Covers the drip trough on the base. Can be

removed for cleaning.

H

PADDLE. Controls the ow of food product.

ENGLISH

C

D

E

H

OperatOr’s Manual

5

Page 6

Buffet and taBletop Service

initial SetuP, droP-in chafer

Carefully remove crating or packaging materials from the unit. When no longer

needed, dispose of all packaging materials in an environmentally responsible

manner.

For new installations:

Cutout dimensions are for reference only. Vollrath recommends that actual

cutouts be made when the chafer is received. Small variances in chafer

dimensions can happen and it is best to mate the chafer with the counter-top

before cutting.

1. Cut out counter opening using chafer and Figure 6.

19” (48.25 cm)

Figure 6. Cutout Dimensions.

2. Remove the food and water pan from the chafer.

3. Remove two (2) nuts from beneath spacer on underside rim of chafer.

4. Gently place chafer into the opening.

5. Decide which mounting clips are appropriate for your application (short clips

for thin counters and long clips for thicker counters).

6. Using the hole that is already threaded start threading the thumbscrew

into the clip approximately 1/2”. Do not thread too far or you may not have

enough room to insert the clip under the chafer in the next step.

7. From below, slide the clips over the studs where you removed the two nuts

in step 3, so that the clip hangs down and points out from the chafer rim.

Reattach nuts to the studs and tighten. Finish threading thumbscrews to

tighten the chafer to the bottom side of the counter. This will work with either

composite or stainless steel countertops.

8. Attach the heater tray assembly to the inside band of the chafer. Remove

Phillips head screw from each side of band by hinge. Attach tray bracket so

the tray is under the counter with the tray facing. Reattach screws.

9. Follow the steps in the OPERATION, DROP-IN CHAFER Section of this

manual.

For Retrot Installations:

NOTE:

Always size the hole and make sure it meets min/max cut out

dimensions below. Always receive the chafer and retrot kits prior

to cutting any countertops. Due to changes in manufacturer’s

specications, and to different installation requirements, Vollrath’s

retrot kits will t a majority of installations. Extreme care must be made

to measure cut out holes prior to ordering and installation.

Identify the model that you are replacing and measure the opening.

Round Adaptor Ring: Part# 46281 - Sized to replace Many round chafers of

approximately 6 quart capacities.

Minimum Cutout Dimension: 18 5/8” diameter.

Maximum Cutout Dimension: 19-1/2” diameter.

NOTE:

6 qt. Chafers are far less standardized in size than rectangle chafers.

Measure everything carefully and conrm measurements with actual

chafer before making nal cut.

10. Place adaptor ring over opening. Remove cover, food and water pans

from chafer and then place the chafer body into the adapter opening and

center both over the existing opening in the counter top.

11. Remove the two (2) nuts from beneath spacer on rim of chafer.

12. Decide which mounting clips are appropriate for your application (short

clips for thin counters and long clips for thicker counters).

13. Using the hole that is already threaded start threading the thumbscrew

into the clip approximately 1/2”. Do not thread too far or you may not have

enough room to insert the clip under the chafer in the next step.

14. From below, slide the clips over the studs where you removed the two

nuts in step 3, so that the clip hangs down and points out from the chafer

rim. Reattach nuts to the studs and tighten. Finish threading thumbscrews

to tighten the chafer to the bottom side of the counter. This will work with

either composite or stainless steel countertops.

15. Follow the steps in the OPERATION, DROP-IN CHAFER Section of this

manual.

6

OperatOr’s Manual

Page 7

Buffet and taBletop Service

oPeration, droP-in chafer

This equipment is designed to heat with an electric chafer heater only.

WARNING

Burn Hazard.

Do not touch heating surfaces, liquid, or while unit

is heating or operating.

and liquids can burn skin. Use gloves, mitts or

pot holders if it is necessary to handle hot pans,

plates and equipment.

Hot food, surfaces, steam

WARNING

Electrical Shock Hazard.

Keep water and other liquids from entering the

inside of the heater. Liquid inside the heater could

cause an electrical shock. Do not damaged power

cord.

A

C

B

C

1. Remove the food pan (D) from the water pan (E) ). See Figures 7.

2. Pour about 2 quarts (2 L) of clean fresh water into the water pan (E).

NOTE:

Follow the manufacture’s instructions for usage and safety for the

electric chafer heater.

3. Put the cover (B) in the closed position. Preheat the water by using a

universal electric chafer heater on “HI” for 30 minutes.

4. Open the cover (B).

5. Place the food pan (D) containing food product that is already at proper

serving temperatures into the water pan (E). Close the cover (B).

NOTE:

Monitor food temperature closely for food safety. The United States

Public Health Service recommends that hot food be held at a minimum

of 140 ºF (60 ºC) to help prevent bacteria growth.

6. Regularly check the food temperature.

7. If necessary adjust the electric chafer heater between “HI” and “LO” to

maintain correct food temperature.

8. When nished with the equipment turn the electric chafer heater to the

“OFF” position and unplug.

9. Open the cover (B). Remove the food pan (D). When removing hot food

containers from unit use gloves, mitts or pot holders to protect hands.

See Figures 6.

10. Allow ample time for the water to cool. Remove the water pan (E) and

ENGLISH

dispose of water.

E

D

F

Figure 7. Drop-In Chafer Features and Controls.

A

COVER HANDLE. Used to open and close the cover.

B

COVER. Covers the food/beverage product.

C

HINGE. Allows the cover to rotate.

D

FOOD PAN. Holds the food product.

E

WATER PAN. Holds the water.

F

HEATER/FUEL TRAY. Holds the electric chafer heater.

cleaning, tabletoP hot food and beverage

To maintain the appearance and increase the service life, clean your

equipment daily.

1. Unplug the electric chafer heater and let it completely cool.

2. Remove the heating source.

3. Wipe the unit exterior with a clean damp cloth.

4. Do not use abrasive materials, scratching cleansers or scouring pad to

clean the unit. These can damage the nish.

5. Thoroughly wipe off any mild soap or chemical cleaners. Residue could

corrode the surface of the unit.

OperatOr’s Manual

7

Page 8

Buffet and taBletop Service

SPare PartS liSt - and eXPloded vieW - model 4634010

1

5

7

66

66

66

2

4

63

13

8

10

11

6

610

610

12

13

66

5

9

13

610

8

13

6

8

Callout Part Number Description

1 4634020-1 Cover with Handle

2 N/A Handle

3 N/A Bolt, Hex Head

4 46259 Water Pan

5 K4634010-1 Hinge, Complete Assembly, Kit

6 N/A Bolt, Hex Head

7 N/A Outer Ring

8 N/A Power Cord Support

9 N/A Inner Ring

10 N/A Nut and Screw

OperatOr’s Manual

614

Callout Part Number Description

11 N/A Fuel Band and Tray

12 N/A Leg Frame

13 N/A Leg with Yoke

14 46864 Fuel Holder with Cover

N/A Rubber Feet (not shown)

Kit, includes 2 Legs with Yoke,

K4634010-2

K4634010-3

Leg Frame, Fuel Band and Tray,

and all necessary hardware.

Kit, includes Handle and bolts, 4

Rubber Feet, and all hardware.

Page 9

Buffet and taBletop Service

SPare PartS liSt - and eXPloded vieW - modelS 4635710 and 4635410

8

10

7

9

66

1

5

66

2

Callout Part Number Description

1 4635730-1 Soup Insert, 7 Quart

2 N/A Soup Body, 7 Quart

3 4635430-1 Gravy Insert, 4 Quart

4 N/A Gravy Body, 4 Quart

5 N/A Handle, Side

6 N/A Nuts, Special

7 4635720-1 Soup Cover with Handle

7 4635420-1 Gravy Cover with Handle

8 N/A Handle

9 N/A Stand Ring

10 N/A Leg with Yoke

11 46864 Fuel Holder with Cover

12 N/A Leg Frame

N/A Rubber Feet (not shown)

K4635710-1 Leg Kit, includes 2 Legs with Yokes, Leg Frame and all hardware

K4634020-1 Kit, includes 2 Side Handles, Special Nuts and 2 Rubber Feet.

3

11

10

12

4

5

66

10

10

ENGLISH

OperatOr’s Manual

9

Page 10

Buffet and taBletop Service

SPare PartS liSt - and eXPloded vieW - model 4635310 and 4635510

2

13

1

4

63

6

7

8

8

7

5

63

13

9

610

4

12

11

13

13

Callout Part Number Description

1 4635510-1 Cover with Handle

2 N/A Handle, Cover

3 N/A Bolt, Hex Head

4 N/A Handle, Urn

5 K4635510-1

6 K4635310-1

7 N/A Faucet Nut

8 K4635520-1

9 N/A Ring

10 N/A Nut and Screw

Coffee Urn, 5 gallon (includes

Faucet Kit, Handle and hardware)

Coffee Urn, 3 gallon (includes

Faucet Kit, Handle and hardware)

Faucet Assembly

(includes Faucet Nut)

Callout Part Number Description

11 46864 Fuel Holder with Cover

12 N/A Fuel Frame

13 N/A Leg with Yoke

N/A Rubber Feet (not shown)

Leg Kit, includes 2 Legs with Yoke,

K4635710-1

K4634020-1

Leg Frame, Fuel Band and Tray,

and all necessary hardware.

Kit, includes Handle and bolts, 4

Rubber Feet, and all hardware.

10

OperatOr’s Manual

Page 11

11

13

Buffet and taBletop Service

SPare PartS liSt - and eXPloded vieW - modelS 4635810 and 4635110

10

15

14

1

9

3

8

5

4

5

13

7

612

13

4

6

2

ENGLISH

13

Callout Part Number Description

1 4635110-1 Cover, Ice Tube

2 4635120-1 Ice Tube, Milk

3 K4635110-1

4 N/A Faucet Nut

5 K4635520-1 Faucet Kit (includes Faucet Nut)

6 4635130-1 Milk Base (includes Drip Cover)

7 4635210-1 Drip Cover

8 4635810-1

Body, Milk (includes Faucet Kit,

Handle and hardware)

Body, Juice (includes Faucet Kit,

Handle and Hardware)

Callout Part Number Description

9 4635820-1 Ice Tube, Juice

10 4635830-1 Cover, Juice (includes Handle)

11 N/A Handle

12 N/A Screws

13 N/A Leg with Yoke

14 N/A Cross Support

15 N/A Ring

15 4635840-1

Kit, includes 2 Legs with Yokes, Leg

Frame and all hardware

OperatOr’s Manual

11

Page 12

Buffet and taBletop Service

SPare PartS liSt - and eXPloded vieW - model 4635210

8

8

7

7

6

6

2

1

5

4

4

3

3

5

4

4

2

Callout Part Number Description

1 4635220-1 Base, Cereal (includes Cover)

2 4635210-1 Cover, Drip

3 K4635210-1 Handle, Dispensing Kit (includes Food Chute)

4 N/A Chute, Food

5 4635230-1 Paddle

6 4635240-1 Food Tube

7 4635250-1 Cover (includes Handle)

8 N/A Handle

12

OperatOr’s Manual

Page 13

Buffet and taBletop Service

SPare PartS liSt - and eXPloded vieW - model 4634110

5

1

63

5

2

4

8

69

69

7

6

ENGLISH

8

10

Callout Part Number Description

1 4634130-1 Cover with Handle

2 N/A Handle

3 N/A Bolt, Hex Head

4 4634100-1 Water Pan

5 4634120-1 Hinge, Complete Assembly, Kit

6 N/A Outer Ring

7 N/A Inner Ring

8 N/A Power Cord Support

9 N/A Nut and Screw

10 N/A Fuel Band and Tray

OperatOr’s Manual

13

Page 14

Buffet and taBletop Service

11

1

5

2

8

7

4

63

5

8

6666

7

610

10

12

6

13

6

13

13

SPare PartS liSt - and eXPloded vieW - model 4635610

14

Callout Part Number Description

1 4634130-1 Cover with Handle

2 N/A Handle

3 N/A Bolt, Hex Head

4 4634100-1 Water Pan

5 K4634010-1 Hinge, Complete Assembly, Kit

6 N/A Bolt, Hex Head

7 N/A Outer Ring

8 N/A Power Cord Support

OperatOr’s Manual

9 N/A Inner Ring

10 N/A Nut and Screw

11 N/A Fuel Band and Tray

12 N/A Leg Frame

13 N/A Leg with Yoke

N/A Rubber Feet (not shown)

Kit, includes 2 Legs with Yoke,

K4635610-1

Leg Frame, Fuel Band and Tray,

and all necessary hardware.

Page 15

Buffet and taBletop Service

Warranty Statement for the vollrath co. l.l.c.

The Vollrath Company LLC warrants the products it manufactures and distributes against defects in materials and workmanship for a period of one year, except as specically

provided below. The warranty runs 12 months from the date of original installation. (End user receipt)

1. Refrigeration compressors – The warranty period is 5 years.

2. Replacement parts – The warranty period is 90 days.

3. Fry pans and coated cookware – The warranty period is 90 days

4. EverTite™ Riveting System – The warranty covers loose rivets

only, forever.

5. Cayenne® Heat Strips – The warranty period is 1 year plus an

additional 1 year period on heating element parts only.

6. Ultra and Professional Induction Ranges – The warranty period

is 2 years.

7. Mirage and Commercial Induction ranges - The warranty period

is 1 year.

8. ServeWell® Induction Workstations – The warranty period is one

year on the workstation table and 2 years on induction hobs.

9. Slicers – The warranty period is 10 years on gears and 5 years

on belts.

10. Mixers – The warranty period is 2 years.

11. Extended warranties are available at the time of sale.

12. Boxer Mixers – 1 Year exchange Warranty.

13. Vollrath – Redco products – The warranty period is 2 years.

14. Optio / Arkadia product lines – The warranty period is 90 days.

15. All non-stick products (i.e. fry pans and surfaces) are 90 days for

the non stick surfaces.

All products in the Jacob’s Pride® collection, including

the following, have a lifetime warranty:

• NSF Certied One-Piece Dishers

• NSF Certied Spoodle® Utensils

• NSF Certied Heavy-Duty Spoons with

Ergonomic Handle

• NSF Certied Heavy-Duty Basting Spoons

• Heavy duty Turners with Ergonomic handle

• One-Piece Tongs*

• Heavy-Duty One-Piece Ladles*

• Nylon Handle Whips

Items sold having no warranty:

• Meat Grinder Knives

• Light Bulbs in Convection Ovens and Hot

• Oven Door Seals

• Oven Door Glass

• Hot Food Merchandisers / Display Case

• Calibration and set up of gas equipment

• Slicer / Dicer blades (table top food prep) –

• One-Piece Skimmers

• Tribute®, Intrigue®, and Classic Select®

Cookware*

*Jacob’s Pride® warranty does not cover KoolTouch®, non stick coatings and silicone handles.

Food Merchandiser

Glass

Redco and Vollrath

THIS WARRANTY IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE

As The Vollrath Company LLC’s only responsibility and the purchaser’s only remedy, for any breach of warranty, The Vollrath Company LLC will repair or, at its option, replace the

defective product or part without charge, except as otherwise provided below:

ENGLISH

• For refrigeration compressors and the second year of the warranty on Cayenne® Heat Strips and mixers, The Vollrath Company LLC will provide the repaired

or replacement part only; and the buyer will be responsible for all labor charges incurred in performing the repair or replacement.

• To obtain warranty service, the buyer will be responsible to return to The Vollrath Company LLC any product (other than gas equipment that is permanently

installed) weighing less than 110 lbs. or located outside of a 50-mile radius of a certied technician designated by The Vollrath Company LLC to perform

warranty repairs. If a Vollrath Technician cannot be contacted check the website for service contact points. (Please refer to the Product Catalogue for weights

and sizes of product)

• No remedy will be available for products that have been damaged by accident, carelessness, improper installation, lack of proper setup or supervision when

required, neglect, improper use, installation or operation contrary to installation and operating instructions or other causes not arising out of defects in materials or workmanship. At the buyer’s request, The Vollrath Company LLC will repair and or replace such products at a reasonable cost.

• No remedy will be available for slicers where blade has not been sharpened (Refer to owner’s manual for sharpening instructions)

• No remedy will be available for mixers damaged by changing gears while unit is running or overloading, in either case as determined by a Vollrath Certied

Technician

• Warranty work must be authorized in advance by The Vollrath Company LLC. See the operating and safety instructions for each product for detailed warranty claim procedures.

• No remedy will be available for product returned and found to be acceptable to the product specication.

• No remedy will be available under any warranty not registered as required below.

LIMITATION OF LIABILITY:

THE VOLLRATH COMPANY LLC SHALL HAVE NO LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES OF ANY KIND,

WHETHER BASED UPON NEGLIGENCE OR OTHER TORT, BREACH OF WARRANTY, OR ANY OTHER THEORY.

OperatOr’s Manual

15

Page 16

Warranty Procedure

On all warranty calls, the following process and information is required:

• All warranty claims will start with a call to Vollrath Technical Service support line (800-628-0832).

• A technical support professional will work to diagnose the issues, and provide the details for the service solution.

• Name and phone number of person calling

• Business name, street address, city, state and zip

• Model and serial number

• Date of purchase and proof of purchase (Receipt)

• Name of dealer where unit was purchased

NOTE: Vollrath will not accept products sent without the proper procedure being followed.

Important:

TO MAKE A CLAIM FOR ANY REMEDY UNDER THIS WARRANTY, YOU MUST REGISTER YOUR WARRANTY.

regiSter today

ONLINE: Register your warranty on-line now at www.Vollrathco.com

NO WEB ACCESS: If you do not have access to the web, kindly register by completing the warranty registration form and faxing it to The Vollrath Co. LLC ofce in the country of

purchase.

Product regiStration

buSineSS name

key contact name email

Street addreSS

city State ZiP code

country Phone faX

model item number

Serial number

- -

oPeration tyPe

R Limited Service Restaurant R Full Service Restaurant R Bars and Taverns R Supermarket

R Convenience Store R Recreation R Hotel/Lodging R Airlines

R Business/Industry R Primary/Secondary School R Colleges/University R Hospitals

R Long-Term Care R Senior Living R Military R Corrections

reaSon for Selecting our Product

R Appearance R Full Service Restaurant R Availability R Sellers Recommendation

R Ease of Operation R Versatility of Use R Price R Brand

Would you like to receive our full-line catalog and remain on our mailing liSt? R Yes R No

www.vollrathco.com

The Vollrath Company, L.L.C.

1236 North 18th Street

Sheboygan, WI 53081-3201

U.S.A.

Main Tel: 920.457.4851

Fax: 800.752.5620

Technical Services: 800.628.0832

Service Fax: 920.459.5462

Canada Service: 800.695.8560

© 2013 The Vollrath Company, L.L.C.

Loading...

Loading...