Vollrath 403NH Owner’s Manual

ENGLISH

ENGLISH

Operator’s Manual

Fruit Cutter

TM

403NH

Thank you for purchasing this Vollrath Food Processing Equipment. Before operating the equipment, read and familiarize yourself with

the following operating and safety instructions. SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE. Save the original box and

packaging. Use this packaging to ship the equipment if repairs are needed.

Item No. 2350215-1 Rev 07/13

Manual Food Processing equiPMent

Safety PrecautionS

To ensure safe operation, read the following statements and understand

their meaning. This manual contains safety precautions which are

explained below. Please read carefully.

WARNING

Warning is used to indicate the presence of a hazard that can cause

severe personal injury, death, or substantial property damage if the

warning is ignored.

CAUTION

Caution is used to indicate the presence of a hazard that will or can

cause minor personal injury or property damage if the caution is

ignored.

NOTE

Note is used to notify people of installation, operation, or maintenance

information that is important but not hazard-related.

For Your Safety!

These precautions should be followed at all times. Failure to follow

these precautions could result in injury to yourself and others or

damage the equipment.

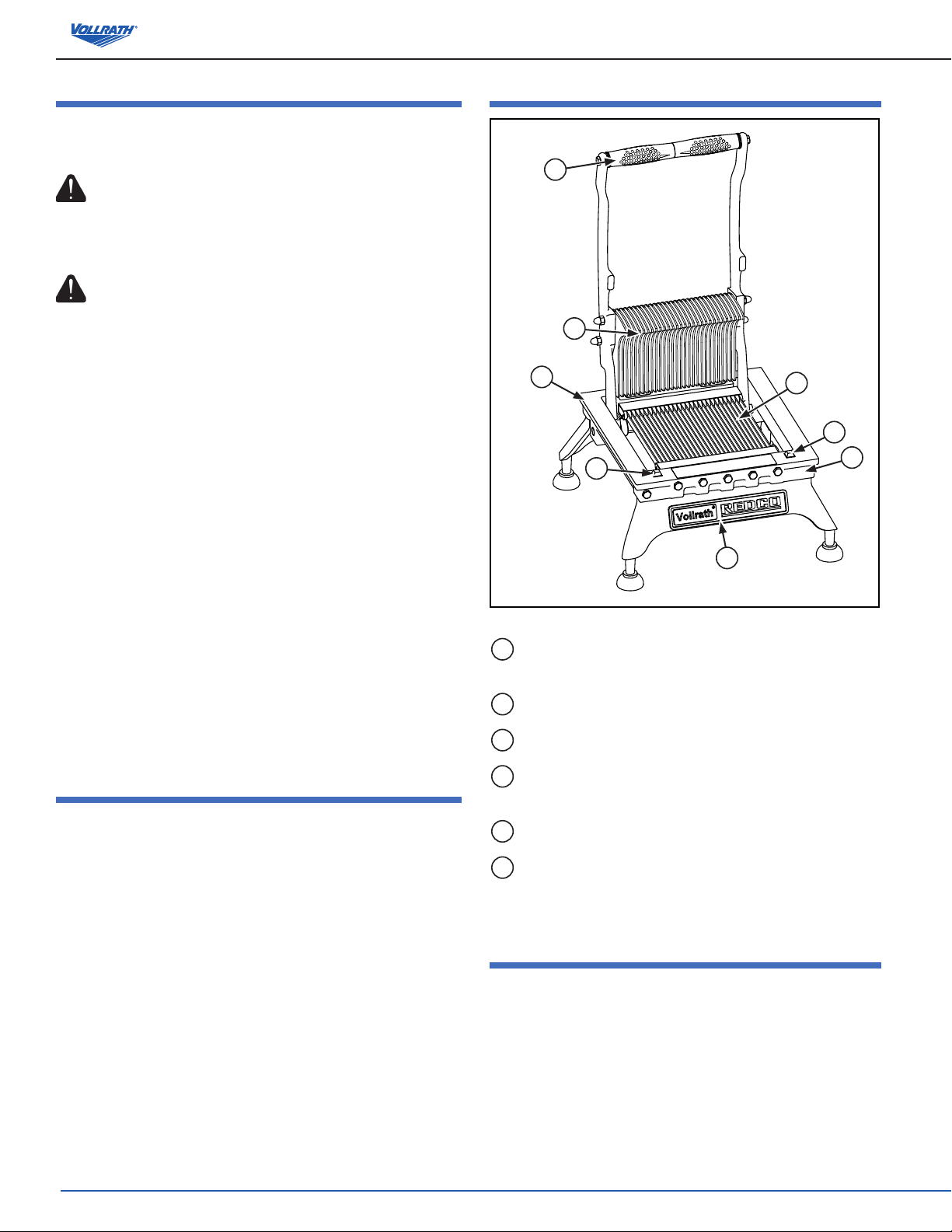

featureS and controlS

B

D

C

E

A

E

G

To reduce risk of injury or damage to the equipment:

Check equipment before each use to insure the equipment is clean.

Check for broken, nicked or dull blades and if found, replace the blade

assembly.

Figure 1. Features and Controls Fruit Cutter.

Check to insure that the pusher head sits down completely on the rubber

bumpers.

If necessary, lubricate guide rods using a light coating of mineral oil, Petro

Gel, or food grade lubricant. DO NOT USE COOKING OIL AS IT WILL

BECOME STICKY AND MAY PERMANENTLY DAMAGE THE PUSHER

HEAD BEARINGS

function and PurPoSe

Intended for cutting, dicing and wedging vegetables and fruits.

unPacking the equiPment and initial SetuP

Carefully remove crating or packaging materials from the equipment.

Dispose of all packaging ,materials in an environmentally responsible

manner.

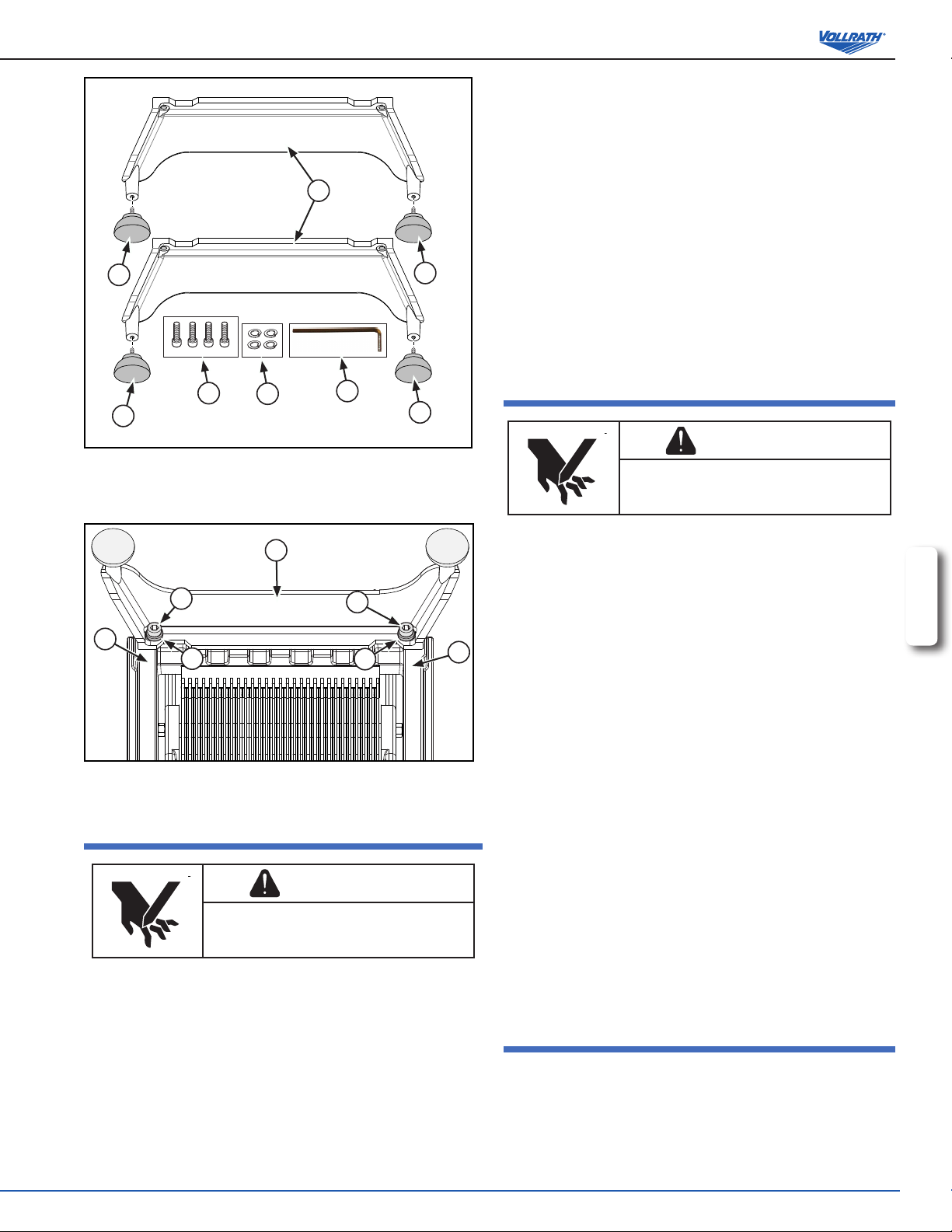

Leg installation Fruit Cutter:

1. Install the rubber feet (E) on to the legs (C). See Figure 2.

2. Use the screws (A) and washers (B) to install legs (C) tightening with

C

A

BLADE ASSEMBLY. Houses the blades. Specically sized to

match the corresponding pusher head block.

B

HANDLE. Used to lower and raise the pusher head.

C

LEGS. Supports the equipment.

D

PUSHER HEAD ASSEMBLY. Made up of the guides and the

pusher head block (and the handle for tabletop models).

E

BUMPERS. Cushions the stop of the pusher head.

G

BASE ASSEMBLY. Holds the guide rods and parts of the

equipment.

wrench (D).

2

OperatOr’s Manual

Manual Food Processing equiPMent

3. Verify that the blade assembly and pusher head assembly are the

desired size.

4. Prepare the food product to be processed.

5. Lift the handle (B) and place the food on the blade assembly (G) with the

at side down. See Figures 1.

C

E

E

6. Remove hand from the blade assembly (G) area and place that hand on

the leg (C).

7. Using a strong, quick, downward thrust, force the food product through

the blade assembly.

8. Repeat this process until you have prepared enough food product for

your daily needs.

9. Clean and lubricate your equipment immediately after each use. See the

CLEANING section of this manual for more information.

B

E

A

D

E

cleaning

Figure 2. Legs, Hardware and Tool for the Fruit Cutter.

3. Secure legs (C) to base (D) using screws (A) and washers (B). See

Figure 3.

C

To maintain the appearance and increase the service life, clean your daily.

NOTE:

Food acids will make blades dull and corrode the metal.

E

E

F

E

F

E

Always clean this food preparation equipment immediately

after every use.

1. Raise the handle to put the highest position. See Figures 1 and 2.

2. Clean large excess pieces of scrap with the special brush provided with

3. Wipe, rinse or spray off equipment, pusher head and blade assembly

4. Do not wipe across the blades or use scrub pads on this equipment.

Figure 3. Mounting the Legs on the Fruit Cutter.

5. The blade assembly (G) is best cleaned by forcing water under pressure

oPeration

WARNING

Sharp Blade Hazard.

Blades are sharp and can cause cuts. To avoid

injury from sharp blades, handle with caution.

Prior to rst use, it is important to clean the equipment. Wash new blades with

warm soapy water and rinse thoroughly to remove the thin protective oil lm.

6. Do not put this equipment in a dishwasher or dish machine with soaps,

7. After cleaning, let the equipment air dry.

8. Lubricate the guide bar with mineral oil or Petro Gel after each use.

WARNING

Sharp Blade Hazard.

Blades are sharp and can cause cuts. To avoid

injury from sharp blades, handle with caution.

ENGLISH

this equipment.

thoroughly with HOT water.

Wiping across the sharp edge of the blade can cause injury and will dull

the blades.

through the blades from the unsharpened side. If necessary, use a nylon

bristle cleaning brush to push food particles out from the unsharpened

side of the blade assembly (G).

detergents, or other alkaline chemicals that can harm the equipment.

Do not use cooking oil as it will become sticky and may permanently

damage the equipment.

1. Before each use, check that the equipment is clean and the blades are

in good condition. If loose or broken blades are found, blades must be

serviced.

2. Before each use, always check for proper blade alignment. Slowly set

the pusher head (D) onto the blade assembly. See Figures 1 and 2. They

Preventative maintenance

1. Clean equipment after every use.

2. Use for intended purposes only.

3. Change blades regularly - based on usage.

should slide together with no obstructions. If there are obstructions, verify

they are a matching set.

OperatOr’s Manual

3

Loading...

Loading...