Vollrath 36429, 36430, 36434, 36436, 36438 Installation Manual

...

ENGLISH

Operator’s Manual

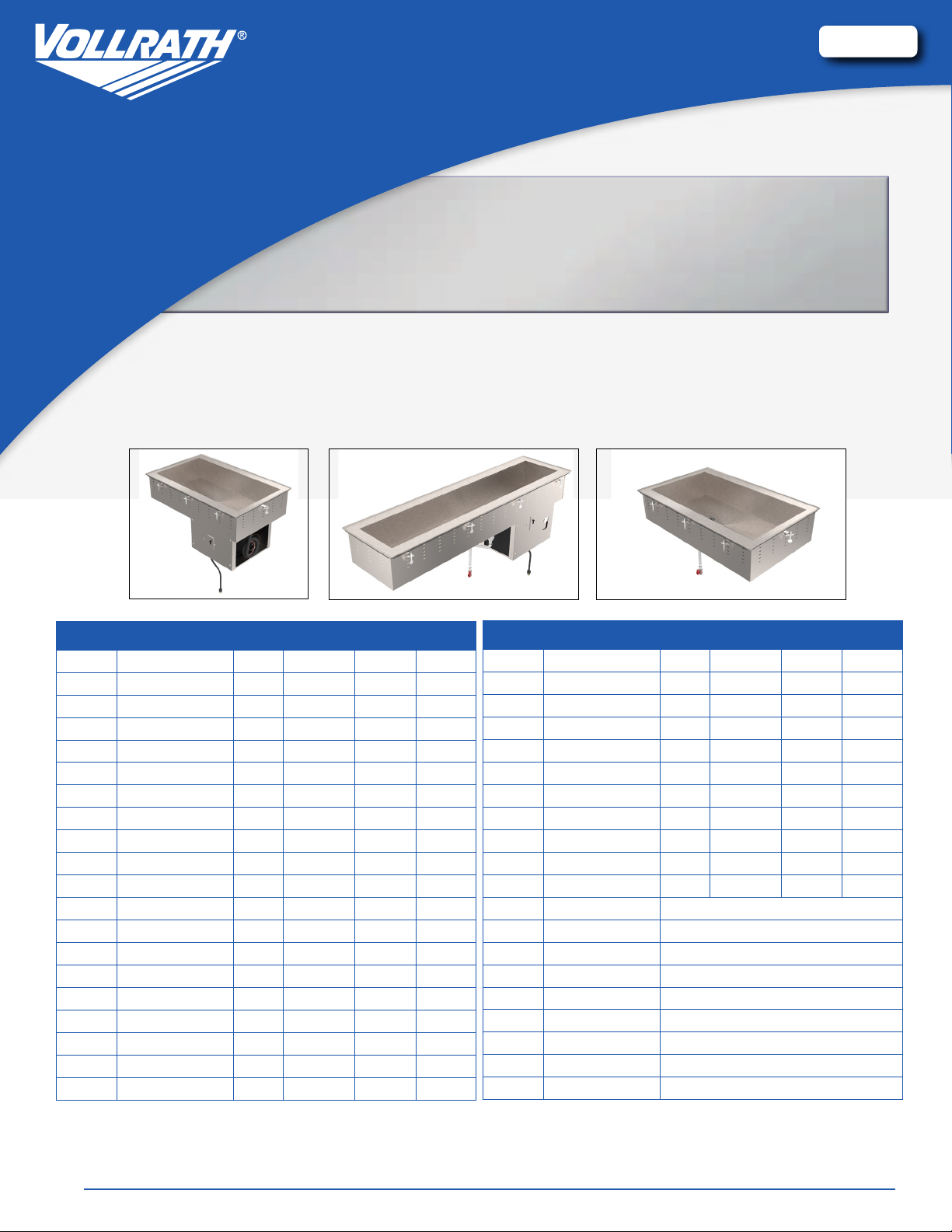

NSF7 REFRIGERATED, STANDARD REFRIGERATED,

SHORT SIDE AND NON-REFRIGERATED DROP-INS

Item Description HP Voltage Amps Plug

36456 NSF7 One-pan 1/5 hp 120V 3.8 5-15P

36429 NSF7 Two-pan 1/4 hp 120V 3.8 5-15P

36430 NSF7 Three-pan 1/4 hp 120V 4.9 5-15P

36434 NSF7 Four-pan 1/3 hp 120V 7.2 5-15P

36436 NSF7 Five-pan 1/2 hp 120V 11.0 5-20P

36438 NSF7 Six-pan 1/2 hp 120V 11.0 5-20P

36490 One-pan 1/5 hp 120V 3.8 5-15P

36456R NSF7 One-pan -- -- -- -36429R NSF7 Two-pan -- -- -- -36430R NSF7 Three-pan -- -- -- -36434R NSF7 Four-pan -- -- -- -36436R NSF7 Five-pan -- -- -- -36438R NSF7 Six-pan -- -- -- --

36490 One-pan 1/5 hp 120V 3.8 5-15P

36441 Two-pan 1/5 hp 120V 3.8 5-15P

36442 Three-pan 1/5 hp 120V 3.8 5-15P

36444 Four-pan 1/4 hp 120V 4.9 5-15P

36446 Five-pan 1/4 hp 120V 4.9 5-15P

36448 Six-pan 1/3 hp 120V 7.2 5-15P

36490R One-pan -- -- -- --

Item Description HP Voltage Amps Plug

36441R Two-pan -- -- -- -36442R Three-pan -- -- -- -36444R Four-pan -- -- -- -36446R Five-pan -- -- -- -36448R Six-pan -- -- -- --

36652 Two-pan 1/4 hp 120V 4.9 5-15P

36655 Three-pan 1/4 hp 120V 4.9 5-15P

36658 Four-pan 1/2 hp 120V 4.9 5-15P

36653 NSF7 Two-pan 1/4 hp 120V 4.9 5-15P

36656 NSF7 Three-pan 1/4 hp 120V 14.9 5-15P

36659 NSF7 Four-pan 1/2 hp 120V 14.9 5-15P

36491 One-pan Non-Refrigerated

36450 Two-pan Non-Refrigerated

36451 Three-pan Non-Refrigerated

36452 Four-pan Non-Refrigerated

36453 Five-pan Non-Refrigerated

36454 Six-pan Non-Refrigerated

36654 Two-pan Non-Refrigerated

36657 Three-pan Non-Refrigerated

36660 Four-pan Non-Refrigerated

Thank you for purchasing this Vollrath equipment. Before operating the equipment, read and familiarize yourself with the following operating

and safety instructions. SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE. Save the original box and packaging. Use this

packaging to ship the equipment if repairs are needed.

Item No. 2350083-1 en Rev 10/13

Fabricator components

SaFety precaUtionS

To ensure safe operation, read the following statements and

understand their meaning. Please read carefully.

Unpacking the eqUipment and initial SetUp

When no longer needed, dispose of all packaging and materials in an

environmentally responsible manner.

1. Remove all packing material and tape, as well as any protective plastic

WARNING

Warning is used to indicate the presence of a hazard that can cause

severe personal injury, death, or substantial property damage if the

warning is ignored.

CAUTION

Caution is used to indicate the presence of a hazard that will or can

cause minor personal injury or property damage if the caution is

ignored.

NOTE

Note is used to notify people of installation, operation, or

maintenance information that is important but not hazard-related.

For Your Safety!

These precautions should be followed at all times. Failure to follow

these precautions could result in injury to yourself and others.

To reduce risk of injury or damage to the equipment:

Use only grounded electrical outlets matching the nameplate rated

voltage.

Have the equipment installed by qualied personnel.

Do not use an extension cord with this equipment. Do not plug this

from the equipment.

2. Clean any glue residue left over from the plastic or tape.

NOTE

The refrigerated models must be provided with adequate

ventilation. The minimum requirement is the equivalent of 80 square

inches (516 cm2) of air exhaust.

Have the unit installed only by qualied service personnel. The cutout

opening in counter must be in accordance with the chart below. All openings

must be within 1/8” of the stated dimension and have a 7/8” radius at the

corners. Use the watertight gasket provided to seal between counter and unit

to prevent water from leaking into control areas.

NOTE

All cutout openings must be within 1/8” of listed opening sizes and

have a corner radius of 7/8”. Cutout dimensions given in inches and

(cm).

3. Refer to the Cutout Dimension Chart in this Operator’s Manual for cutout

dimensions.

4. Place the watertight gasket over the cut-out and center the well.

5. Tighten the thumbscrews (C) slowly and in an alternating pattern to

evenly compress the gasket. See Figure 1. The gasket should create a

even gap between the well and the mounting surface.

equipment into a power strip or multi-outlet power cord.

Unit should only be used in a at, level position.

FeatUreS and controlS

Do not spray controls or outside of equipment with liquids or cleaning

agents.

Do not clean the equipment with steel wool.

Keep equipment and power cord away from open ames, electric

burners or excessive heat.

Do not operate unattended.

Do not operate equipment in public areas and/or around children.

Do not operate if equipment has been damaged or is malfunctioning in

any way.

FUnction and pUrpoSe

This unit is intended to hold containers of pre-chilled cold food at the proper

serving temperature for service. This unit is not designed or intended to cool

hot food or cool any item not properly chilled before being placed in the unit.

Refrigerated cold pans are best used for holding periods up to four hours.

For best performance, stainless steel containers are recommended.

Before using this equipment it must be cleaned and dried thoroughly.

This equipment is not intended for household, industrial or laboratory use.

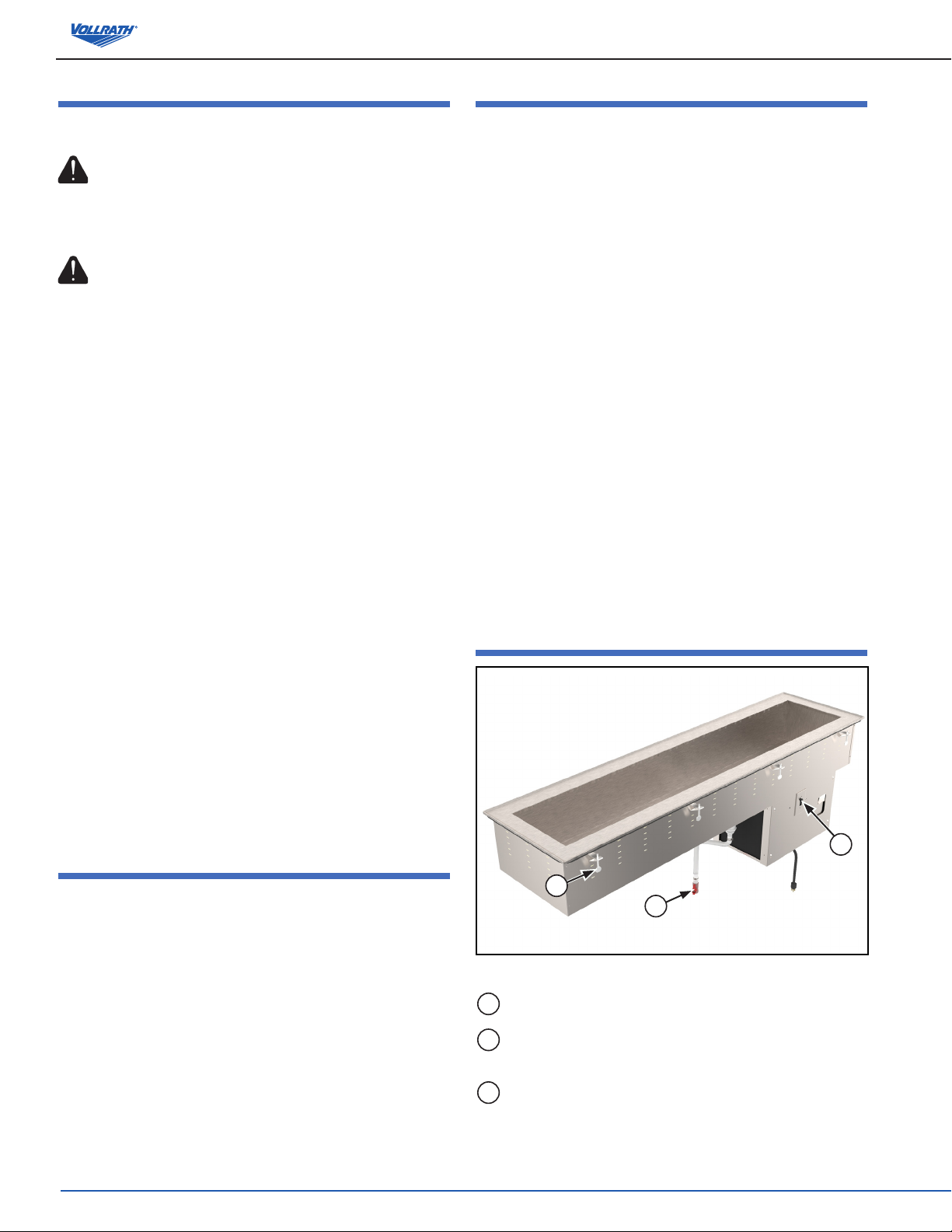

Figure 1. Features and Controls.

A

DRAIN VALVE. Used to empty water from the well(s).

B

C

A

2

OperatOr’s Manual

B

ON/OFF SWITCH (some models). Switches the equipment power ON

or OFF.

C

THUMBSCREW. Secures the unit to the mounting surface.

Fabricator components

operation

WARNING

Electrical Shock Hazard.

Keep water and other liquids from entering the

inside of the unit. Liquid inside the unit could cause

an electrical shock. Do not damaged power cord.

Do not over ll wells, pans or trays. Liquid could contact the

electrical components and cause a short circuit or an electrical

shock. Unplug unit before performing service, draining or removing

spillage pans and trays. Do not spray water or cleaning products.

Do not use a power cord that has been modied or damaged.

reFrigerated UnitS:

1. Check the drain valve (A) to verify it is in the CLOSED position to prevent

water from draining out. See Figure 1. The valve is in the CLOSED

position when the handle of the valve forms a “T” with the body of the

valve.

2. Plug the equipment into a properly grounded electrical supply matching

the nameplate rating. Damage to the equipment can occur if incorrect

power is supplied to equipment.

3. Turn the power switch (B) to the “ON” position. This unit does not have

an adjustable temperature setting. Allow the unit to run for approximately

30 minutes. For the best performance when using ice with this unit, allow

unit to run for approximately 2 hours before adding ice. This will help the

ice remain solid.

4. Place containers of properly chilled food into the pre-chilled unit.

5. Regularly check the food temperature.

NOTE:

Monitor food temperature closely for food safety. The United States

Public Health Service recommends that hot food be held at a maximum

of 41 ºF (5 ºC) to help prevent bacteria growth.

6. When nished using the unit turn the power switch (B) to the “OFF”

position. Remove the food containers.

7. Open the drain valve (A) and drain the water. The valve is in the OPEN

position when the handle of the valve is aligned with the body of the

valve.

8. Close the drain valve. Rotate the valve to the CLOSED position, when

the handle of the valve forms a “T” with the body of the valve.

NOTE:

Monitor food temperature closely for food safety. The United States

Public Health Service recommends that hot food be held at a maximum

of 41 ºF (5 ºC) to help prevent bacteria growth.

4. When nished using the unit, remove the food containers.

5. Open the drain valve (A) and drain the water. The valve is in the OPEN

position when the handle of the valve is aligned with the body of the

valve.

6. Close the drain valve (A). Rotate the valve to the CLOSED position,

when the handle of the valve forms a “T” with the body of the valve.

cleaning

To maintain the appearance and increase the service life, clean your

equipment daily.

NOTE:

Do not use caustic cleaning chemicals, steel wool or

commercial lime removal products to clean the equipment.

Thoroughly rinse equipment with water after cleaning.

Do not over ll wells, pans or trays. Liquid could contact the

electrical components and cause a short circuit or an electrical

shock. Unplug unit before performing service, draining or removing

spillage pans and trays. Do not spray water or cleaning products.

Do not use a power cord that has been modied or damaged.

1. When nished using the unit turn the power switch (B) to the “OFF”

position. Remove the food containers.

2. Open the drain valve (A) and drain the water. The valve is in the OPEN

position when the handle of the valve is aligned with the body of the

valve.

3. Using a damp cloth, sponge dipped in soapy water to clean the inside of

the well and the outside of the equipment.

4. Close the drain valve (A). Rotate the valve to the CLOSED position,

when the handle of the valve forms a “T” with the body of the valve.

WARNING

Electrical Shock Hazard.

Keep water and other liquids from entering the

inside of the unit. Liquid inside the unit could cause

an electrical shock. Do not damaged power cord.

ENGLISH

non-reFrigerated UnitS:

1. Check the drain valve (A) to verify it is in the CLOSED position to prevent

water from draining out. The valve is in the CLOSED position when the

handle of the valve forms a “T” with the body of the valve.

1. Place ice into the non-refrigerated well. For best performance allow unit

to cool for approximately 1 hour before using.

2. Place containers of properly chilled food into the pre-chilled unit.

3. Regularly check the food temperature.

OperatOr’s Manual

3

Fabricator components

troUbleShooting chart

Problem It might be caused by Course of Action

Unit does not get to correct temperature.

Unit is not plugged in. Plug unit in.

Compressor defective. Have the compressor replaced.

Service and repair

There are no user serviceable parts within this appliance. To avoid serious injury or damage, never attempt to repair the equipment or replace a damaged power

cord yourself. Do not send equipment directly to the Vollrath Company. Please contact the qualied professional repair service listed below.

VOLLRATH Technical Service • 1-800-628-0832

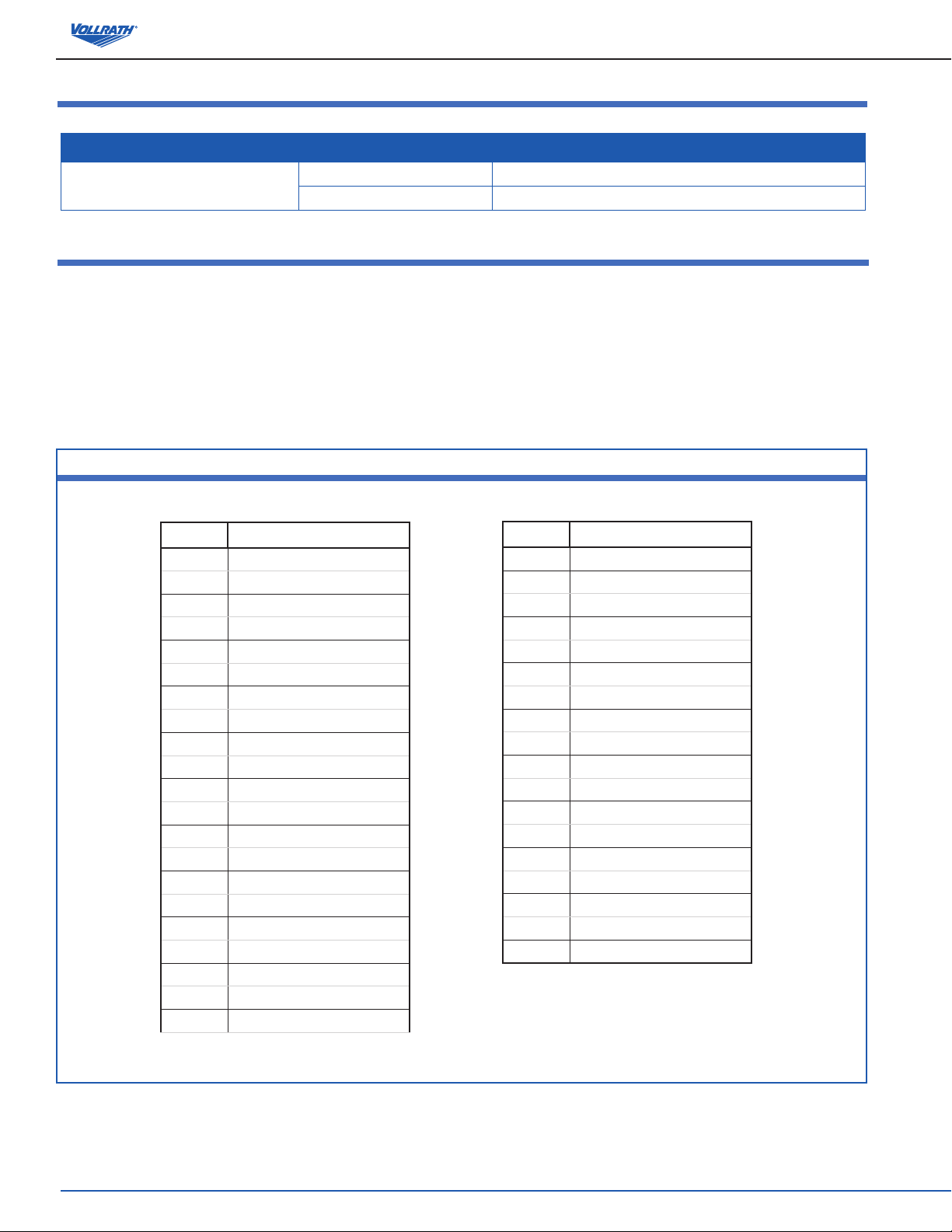

cUtoUt dimenSionS chart For nSF7 reFrigerated, Standard reFrigerated, Short Side and non-reFrigerated drop-inS

CUTOUT dimensions given in inches and (cm).

Item Cutout Dimensions

36456 17-1/4 x 25-1/4 (43.8 x 64.1)

36429 28-1/4 x 25-1/4 (71.8 x 64.1)

36430 40-3/4 x 25-1/4 (103.5 x 64.1)

36434 54 x 25-1/4 (137.2 x 64.1)

36436 67-1/4 x 25-1/4 (170.8 x 64.1)

36438 80-1/2 x 25-1/4 (204.5 x 64.1)

36456R 17-1/4 x 25-1/4 (43.8 x 64.1)

36429R 28-1/4 x 25-1/4 (71.8 x 64.1)

36430R 40-3/4 x 25-1/4 (103.5 x 64.1)

36434R 54 x 25-1/4 (137.2 x 64.1)

36436R 67-1/4 x 25-1/4 (170.8 x 64.1)

36438R 80-1/2 x 25-1/4 (204.5 x 64.1)

36490 14-1//4 x 25-1/4 (36.2 x 64.1)

36441 28-1/4 x 25-1/4 (71.8 x 64.1)

36442 40-3/4 x 25-1/4 (103.5 x 64.1)

36444 54 x 25-1/4 (137.2 x 64.1)

36446 67-1/4 x 25-1/4 (170.8 x 64.1)

36448 80-1/2 x 25-1/4 (204.5 x 64.1)

36490R 14-1//4 x 25-1/4 (36.2 x 64.1)

36441R 28-1/4 x 25-1/4 (71.8 x 64.1)

36442R 40-3/4 x 25-1/4 (103.5 x 64.1)

Item Cutout Dimensions

36444R 54 x 25-1/4 (137.2 x 64.1)

36446R 67-1/4 x 25-1/4 (170.8 x 64.1)

36448R 80-1/2 x 25-1/4 (204.5 x 64.1)

36652 44-11/16 x 17-5/16 (113.5 x 44)

36655 66-1/8 x 17-5/16 (168 x 44)

36658 87-9/16 x 17-5/16 (222.4 x 44)

36653 44-11/16 x 17-5/16 (113.5 x 44)

36656 66-1/8 x 17-5/16 (168 x 44)

36659 87-9/16 x 17-5/16 (222.4 x 44)

36491 14-1//4 x 25-1/4 (36.2 x 64.1)

36450 28-1/4 x 25-1/4 (71.8 x 64.1)

36451 40-3/4 x 25-1/4 (103.5 x 64.1)

36452 54 x 25-1/4 (137.2 x 64.1)

36453 67-1/4 x 25-1/4 (170.8 x 64.1)

36454 80-1/2 x 25-1/4 (204.5 x 64.1)

36654 44-11/16 x 17-5/16(113.5 x 44)

36657 66-1/8 x 17-5/16 (168 x 44)

36660 87-1/2 x 17-5/16 (222.4 x 44)

4

OperatOr’s Manual

Fabricator components

noteS

ENGLISH

OperatOr’s Manual

5

Fabricator components

Warranty Statement For the vollrath co. l.l.c.

The Vollrath Company LLC warrants the products it manufactures and distributes against defects in materials and workmanship for a period of one year, except as specically

provided below. The warranty runs 12 months from the date of original installation. (End user receipt)

1. Refrigeration compressors – The warranty period is 5 years.

2. Replacement parts – The warranty period is 90 days.

3. Fry pans and coated cookware – The warranty period is 90 days

4. EverTite™ Riveting System – The warranty covers loose rivets

only, forever.

5. Cayenne® Heat Strips – The warranty period is 1 year plus an

additional 1 year period on heating element parts only.

6. Ultra and Professional Induction Ranges – The warranty period

is 2 years.

7. Mirage and Commercial Induction ranges - The warranty period

is 1 year.

8. ServeWell® Induction Workstations – The warranty period is one

year on the workstation table and 2 years on induction hobs.

9. Slicers – The warranty period is 10 years on gears and 5 years

on belts.

10. Mixers – The warranty period is 2 years.

11. Extended warranties are available at the time of sale.

12. Vollrath – Redco products – The warranty period is 2 years.

13. Optio / Arkadia product lines – The warranty period is 90 days.

14. All non-stick products (i.e. fry pans and surfaces) are 90 days for

the non stick surfaces.

All products in the Jacob’s Pride® collection, including

the following, have a lifetime warranty:

• NSF Certied One-Piece Dishers

• NSF Certied Spoodle® Utensils

• NSF Certied Heavy-Duty Spoons with

Ergonomic Handle

• NSF Certied Heavy-Duty Basting Spoons

• Heavy duty Turners with Ergonomic handle

• One-Piece Tongs*

• Heavy-Duty One-Piece Ladles*

• Nylon Handle Whips

• One-Piece Skimmers

• Tribute®, Intrigue®, and Classic Select®

Cookware*

*Jacob’s Pride® warranty does not cover Kool-Touch®,

non stick coatings and silicone handles.

Items sold having no warranty:

• Meat Grinder Knives

• Light Bulbs in Convection Ovens and

Hot Food Merchandiser

• Oven Door Seals

• Oven Door Glass

• Hot Food Merchandisers / Display Case

Glass

• Calibration and set up of gas equipment

• Slicer / Dicer blades (table top food

prep) – Redco and Vollrath

THIS WARRANTY IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE

As The Vollrath Company LLC’s only responsibility and the purchaser’s only remedy, for any breach of warranty, The Vollrath Company LLC will repair or, at its option, replace the

defective product or part without charge, except as otherwise provided below:

• For refrigeration compressors and the second year of the warranty on Cayenne® Heat Strips and mixers, The Vollrath Company LLC will provide the repaired

or replacement part only; and the buyer will be responsible for all labor charges incurred in performing the repair or replacement.

• To obtain warranty service, the buyer will be responsible to return to The Vollrath Company LLC any product (other than gas equipment that is permanently

installed) weighing less than 110 lbs. or located outside of a 50-mile radius of a certied technician designated by The Vollrath Company LLC to perform

warranty repairs. If a Vollrath Technician cannot be contacted check the website for service contact points. (Please refer to the Product Catalogue for weights

and sizes of product)

• No remedy will be available for products that have been damaged by accident, carelessness, improper installation, lack of proper setup or supervision

when required, neglect, improper use, installation or operation contrary to installation and operating instructions or other causes not arising out of defects in

materials or workmanship. At the buyer’s request, The Vollrath Company LLC will repair and or replace such products at a reasonable cost.

• No remedy will be available for slicers where blade has not been sharpened (Refer to owner’s manual for sharpening instructions)

• No remedy will be available for mixers damaged by changing gears while unit is running or overloading, in either case as determined by a Vollrath Certied

Technician

• Warranty work must be authorized in advance by The Vollrath Company LLC. See the operating and safety instructions for each product for detailed

warranty claim procedures.

• No remedy will be available for product returned and found to be acceptable to the product specication.

• No remedy will be available under any warranty not registered as required below.

LIMITATION OF LIABILITY:

THE VOLLRATH COMPANY LLC SHALL HAVE NO LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES OF ANY KIND,

WHETHER BASED UPON NEGLIGENCE OR OTHER TORT, BREACH OF WARRANTY, OR ANY OTHER THEORY.

6

OperatOr’s Manual

Fabricator components

Warranty procedure

On all warranty calls, the following process and information is required:

• All warranty claims will start with a call to Vollrath Technical Service support line.(800-354-1970).

• A technical support professional will work to diagnose the issues, and provide the details for the service solution.

• Name and phone number of person calling

• Business name, street address, city, state and zip

• Model and serial number

• Date of purchase and proof of purchase (Receipt)

• Name of dealer where unit was purchased

NOTE: Vollrath will not accept products sent without the proper procedure being followed.

Important:

TO MAKE A CLAIM FOR ANY REMEDY UNDER THIS WARRANTY, YOU MUST REGISTER YOUR WARRANTY.

register today

ONLINE: Register your warranty on-line now at www.Vollrathco.com

NO WEB ACCESS: If you do not have access to the web, kindly register by completing the warranty registration form and faxing it to The Vollrath Co. LLC ofce in the country of

purchase.

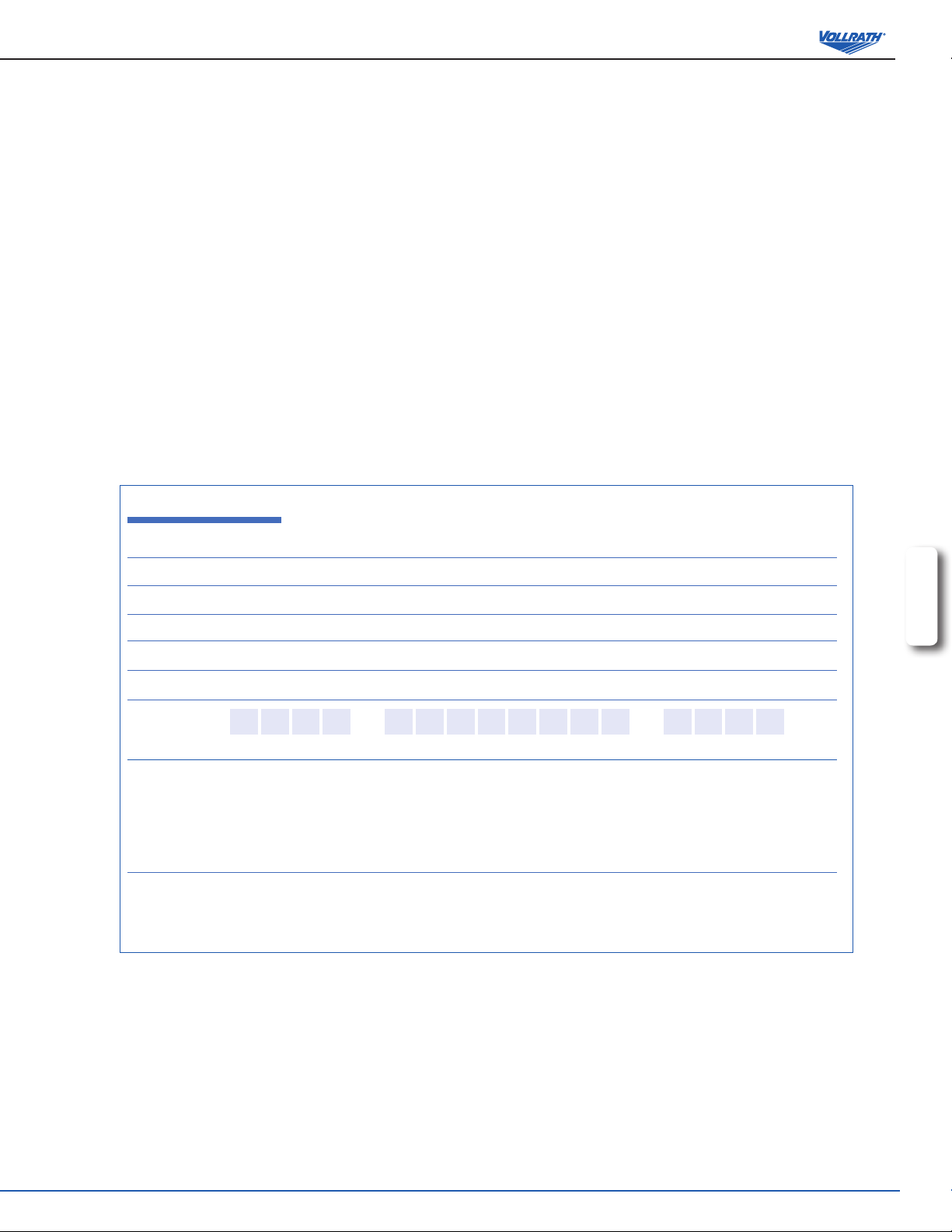

Warranty regiStration

business name

Key contact name email

street address

city state Zip code

country phone Fax

model item number

serial number - operation type

R Limited Service Restaurant R Full Service Restaurant R Bars and Taverns R Supermarket

R Convenience Store R Recreation R Hotel/Lodging R Airlines

R Business/Industry R Primary/Secondary School R Colleges/University R Hospitals

R Long-Term Care R Senior Living R Military R Corrections

reason For selecting our product

R Appearance R Full Service Restaurant R Availability R Sellers Recommendation

R Ease of Operation R Versatility of Use R Price R Brand

Would you liKe to receive our Full-line catalog and remain on our mailing list? R Yes R No

ENGLISH

OperatOr’s Manual

7

The Vollrath Company, L.L.C.

1236 North 18th Street

Sheboygan, WI 53081-3201

U.S.A.

Technical Services: 800.628.0832

Service Fax: 920.459.5462

Canada Service: 800.695.8560

www.vollrathco.com

Main Tel: 920.457.4851

Fax: 800.752.5620

© 2013 The Vollrath Company, L.L.C.

Loading...

Loading...