Vogt Ice P34FL Service Manual

P-34F

TUBE-ICE®

MACHINE

5/5/15

Service Manual

$5000

NOTICE

This manual is the property of the owner of this particular Tube-Ice®

machine.

Model #____________________ Serial #____________________.

It is to be left on the premises with this machine at all times. After start-up,

it should be stored in a safe place where it can be readily available when

needed for future reference in maintaining troubleshooting or servicing.

Failure to comply with this notice will result in unnecessary inconvenience

and possible additional expenses.

This manual is intended as an informational tool for the installation,

operation, maintenance, troubleshooting, and servicing of this equipment.

If an existing situation calls for additional information not found herein, we

suggest that you contact your distributor first. If further assistance or

information is needed, please feel free to contact the factory at 502-6353000 or FAX at 502-635-3024 or 502-634-0479.

IMPORTANT: The Warranty Registration/Start-Up Report found in the

front of this manual is to be completed and returned to the factory promptly

after the official start-up.

Please return to: Vogt Ice LLC

1000 W. Ormsby, Suite #19

5/5/15

Louisville, KY 40210

Att. Tube-Ice Service Department

5/5/15

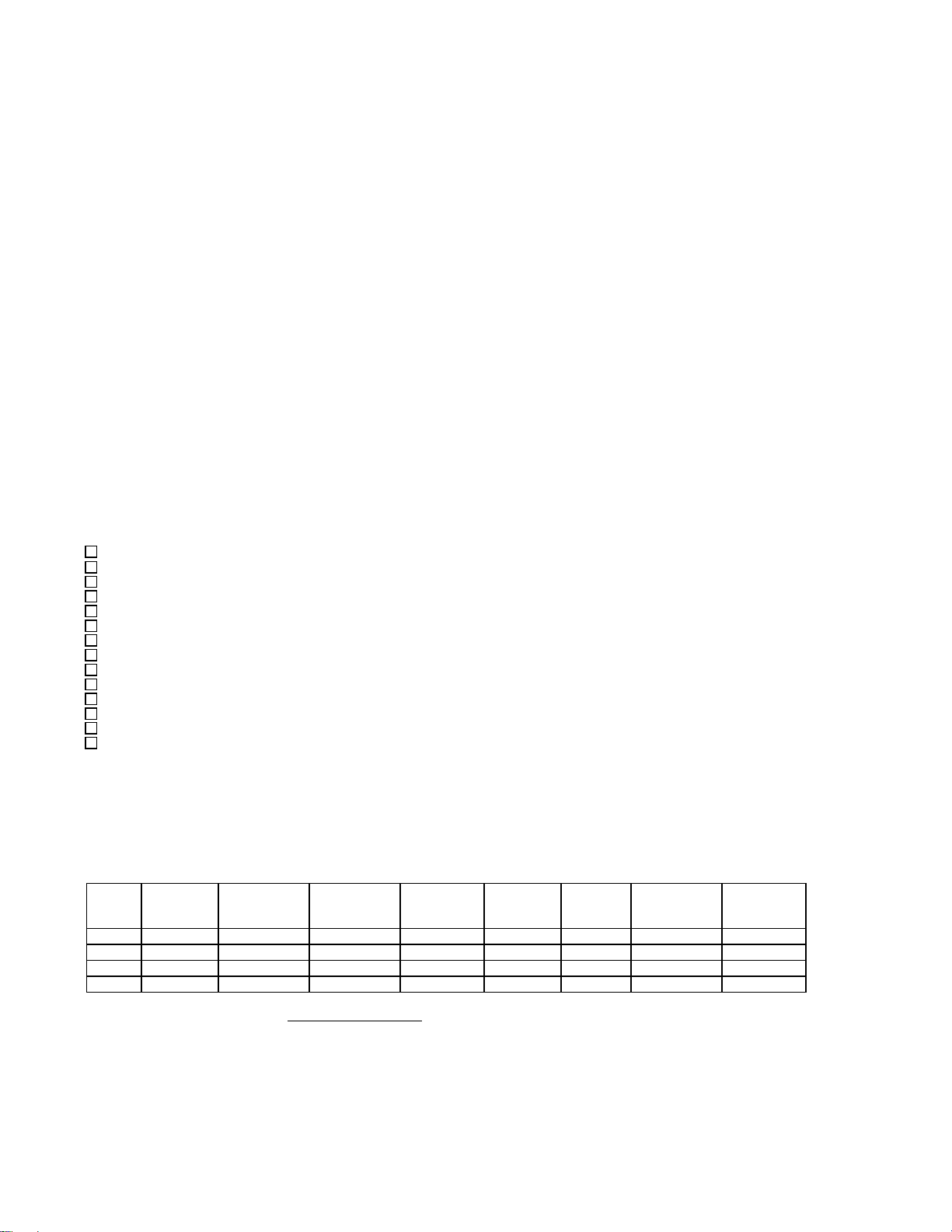

MID & LARGE MACHINE WARRANTY REGISTRATION/START-UP REPORT

Vogt Tube-Ice Machine

MUST COMPLETE AND RETURN TO INITIATE WARRANTY

Machine Model No. ________________________________ Serial No. ____________________________________________

Installed at: ____________________________________________________________( )_______________________________________

Company Name Phone

_______________________________________________________________________________________________________

Address City State Zip

______________________________________________________________________________________________________

Installed by: ___________________________________________________________( )________________________/____/________

Company Name Phone Date

_______________________________________________________________________________________________________

Address City State Zip

Describe any damage to machine/repairs made: _____________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

Start up by: ___________________________________________________________( )________________________/____/_________

Company Name Phone Date

_______________________________________________________________________________________________________

Address

Name of person starting up machine: ____________________________________________________________________________________

PRE START-UP CHECK

CHECK

Service Manual on hand

Machine room suitable 50F minimum, 110F maximum

Proper power supply, actual voltage _______________, _________________, _________________ (machine not running)

Compressor crankcase heater on 12 hour minim um

Necessary hand valves opened as required

Solenoid valve stems in auto position

System leak checked/tight

Auxiliary equipment overloads wired into control circuit

Compressor oil level _______ (1/4 glass min.)

All water distributors in place (visually inspected)

Water supply and drain lines installed and connected properly

Compressor, pump, cutter and other motor direction of rotation correct

Make-up water float valve adjusted properly

Hour meter in control panel connected

OPERATION CHECK

Machine charged with refrigerant lbs.______________ Actual voltage ____________ , _______________, ________________(machine running)

Ambient temp. _____ F Fan cycles On _____ Off _____ Tower water in _____F out ______ F

Comp motor RLA _____________, _____________, _____________, Actual _____________, _____________, _____________,

Pump RLA _____________, _____________, _____________, Actual _____________, _____________, _____________

Cutter motor RLA _____________, _____________, _____________, Actual _____________, _____________, _____________

Suction pressure end of freezing _______, end of harvest _______ Discharge pressure end of freezing ___________, end of harvest __________

Evaporator/suction line frost _____________________________ Receiver liquid level operating ___________________

Test

Cycle

Water

Temp

FreezeTime

Min/Sec

Harvest Time

Min/Sec

First Ice Out

Min/Sec

All Ice Out

Min/Sec

Avg. Hole

Size

Ice Lb. Per

Harvest

Ice Lb. Per

Day

#1

#2

#3

#4

Note: Ice lb. per day can be found by: ice lb. per harvest x 1440

(freeze time + harvest time)

The machine operated satisfactorily for ___ continuous hours. Date _______________________________________

Comments__________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

Installer signature ____________________________________________ End user signature _________________________________

Please return to: Vogt Ice LLC, 1000 W. Ormsby, Suite #19, Louisville, KY 40210

Vogt Ice LLC, located in

Louisville, Kentucky since 1880.

Sales & Service - (502) 635-3000

Parts - Your Local Distributor

Call your local distributor first for all of your parts and service needs.

5/5/15

Since 1938, Manufacturers of Quality

®

Tube-Ice

Machines

VOGT

®

TUBE-ICE

MACHINES

Installation, Service Manual, and Parts Catalog #12A-4171L19

Vogt Ice LLC

1000 W. Ormsby, Suite #19

Louisville, Kentucky 40210

502-635-3000

FAX #502-634-0479

P34F Model

P34F Service Manual

TABLE OF CONTENTS

TABLE OF CONTENTS

®

Vogt

TUBE-ICE® MACHINES

Model P34F

Page No.

1. INTRODUCTION

A Brief History of Our Company .................................................................................................................................. 1-1

Vogt Energy-Savings Tube-Ice® Machines .................................................................................................................. 1-1

Preview ..................................................................................................................................................................... 1-1

Important Safety Notice ................................................................................................................................................. 1-1

Safety Symbols and What They Mean .......................................................................................................................... 1-2

Special Precautions To Be Observed When Charging Refrigeration Systems .............................................................. 1-3

Assembly Drawing Model P34F Tube-Ice

2. RECEIPT OF YOUR TUBE-ICE MACHINE

Inspection ..................................................................................................................................................................... 2-1

Description of Machine ................................................................................................................................................. 2-1

Safety Tags and Labels .................................................................................................................................................. 2-1

Model designation for P-Series Ice Machine, Figure 2-1 .............................................................................................. 2-2

Rated Capacity .............................................................................................................................................................. 2-3

Storage (prior to installation and start-up) ..................................................................................................................... 2-3

3. INSTALLING YOUR TUBE-ICE MACHINE

Machine Room .............................................................................................................................................................. 3-1

Space Requirements....................................................................................................................................................... 3-1

Foundation……...……………………………………………………………………………………………………....3-1

Lifting Procedures ......................................................................................................................................................... 3-1

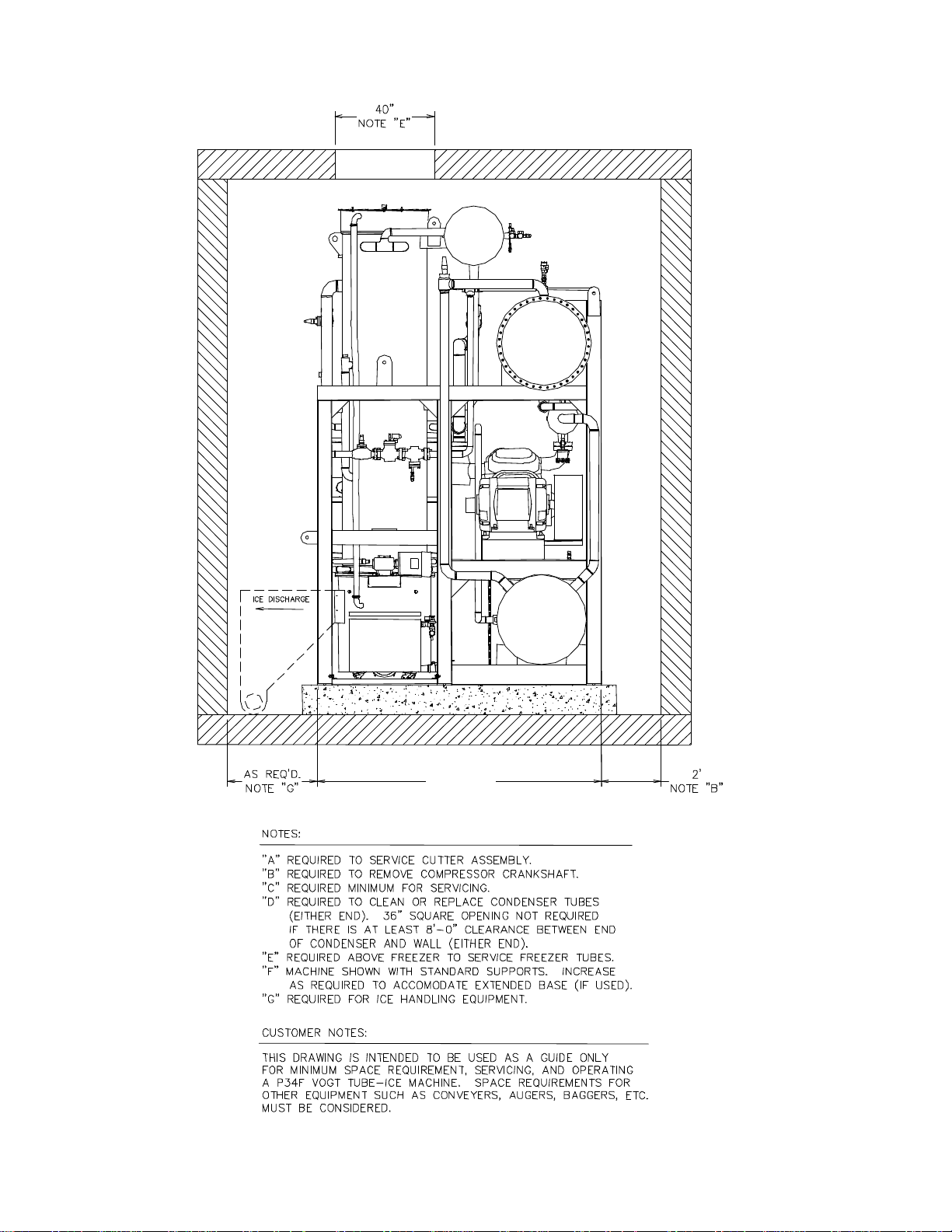

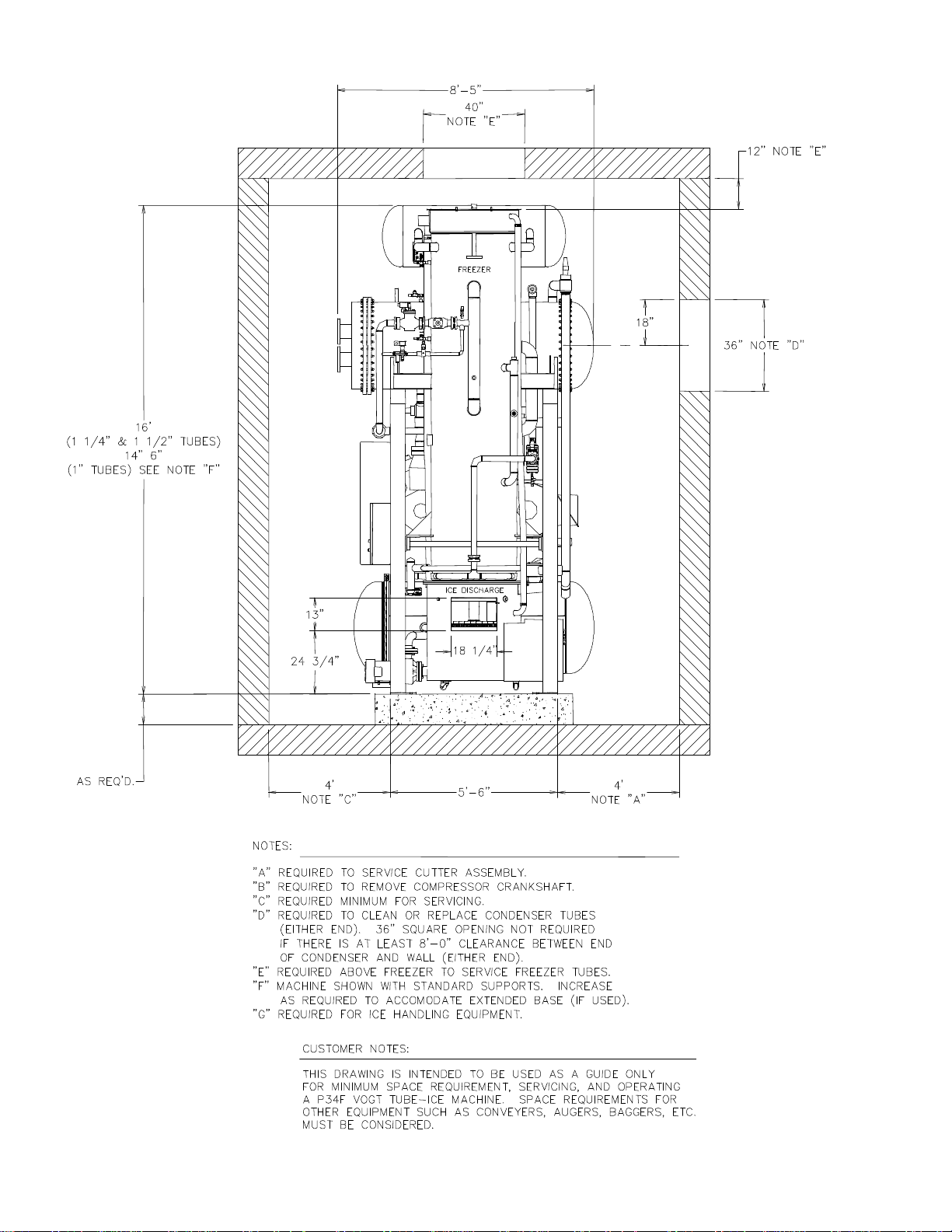

P34F Space Diagram, FIGURE 3-1 ............................................................................................................................... 3-2,3-3

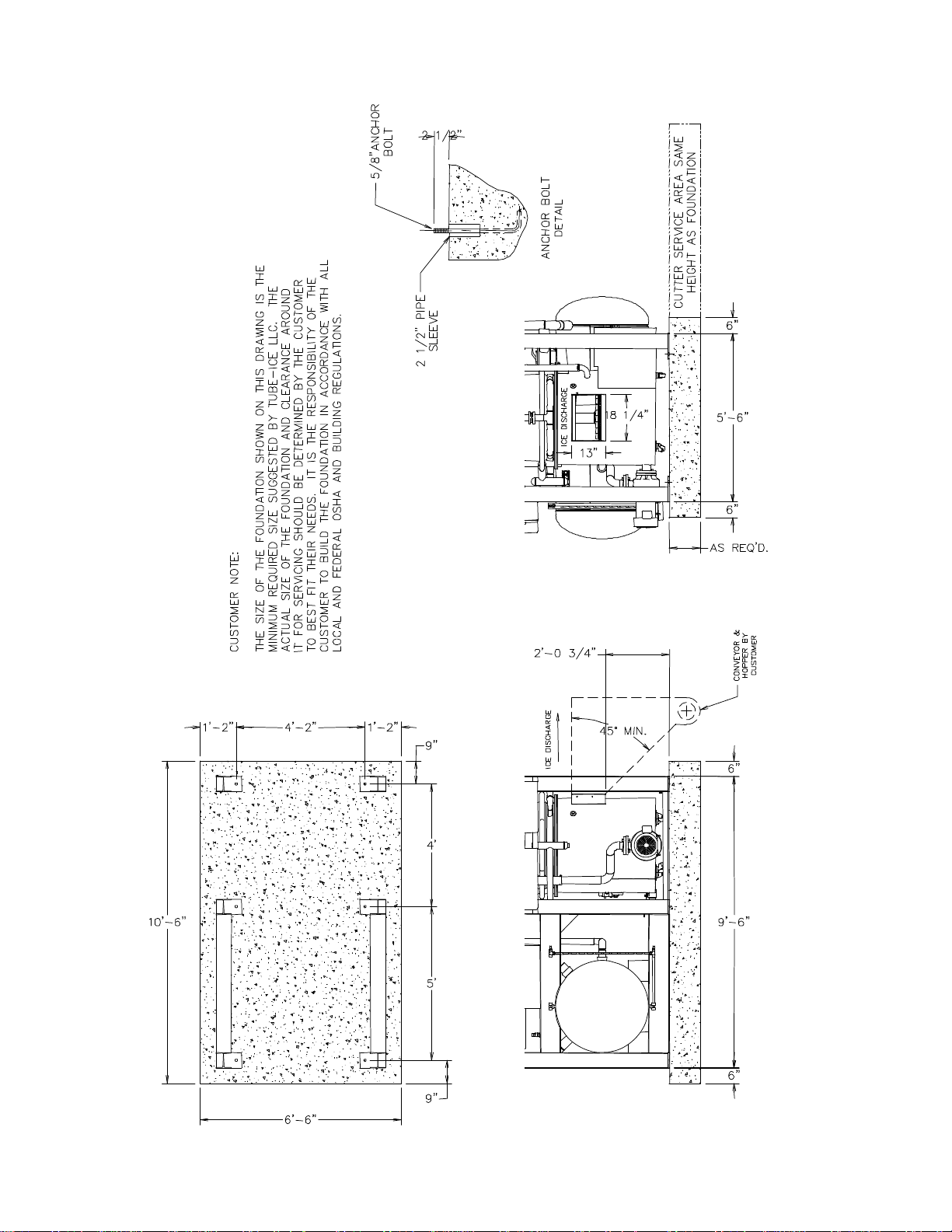

P34F Foundation Layout, FIGURE 3-2 ......................................................................................................................... 3-4

Lifting Procedure for P34F, FIGURE 3-3 ..................................................................................................................... 3-5

Piping and Drain Connections, TABLE 3-1 ...................................................................................... ............................ 3-6

Make-Up Water In ......................................................................................................................................................... 3-6

Flushing Water In .......................................................................................................................................................... 3-6

Water Tank Drain .......................................................................................................................................................... 3-6

Water Tank Overflow .................................................................................................................................................... 3-6

Condenser water In and Out .......................................................................................................................................... 3-7

Cooling Tower ............................................................................................................................................................... 3-7

Condenser Water Requirements, TABLE 3-2 ............................................................................................................... 3-8

Safety Valves ............................................................................................................................................................... 3-8

Cooling Tower Piping Diagram, FIGURE 3-4 ................................................................................ .............................. 3-9

Freeze Protection, FIGURES 3-5, 3-6, 3-7 .................................................................................................................... 3-10, 3-11

Wiring and Electrical Connections ................................................................................................................................ 3-11

Power Supply Connections, FIGURE 3-13 ................................................................................................................... 3-12

Machine .................................................................................................... 1-4, 1-5, 1-6, 1-7

i

5/5/15

ii

P34F Service Manual

TABLE OF CONTENTS

Page No.

3. INSTALLING YOUR TUBE-ICE MACHINE (cont.)

Voltage Unbalance ........................................................................................................................................................ 3-12

Current Unbalance .......................................................................................................................................................... 3-12

Rotation Check ............................................................................................................................................................... 3-13

Auxiliary Controls or Equipment ................................................................................................................................... 3-14

Installation Review: A Checklist .................................................................................................................................... 3-15

4. HOW YOUR TUBE-ICE MACHINE WORKS

Operating Features ......................................................................................................................................................... 4-1

Principle of Operation.................................................................................................................................................... 4-1

Freeze Period ................................................................................................................................................................. 4-1

Harvest Period ............................................................................................................................................................... 4-2

Piping Nomenclature ..................................................................................................................................................... 4-2

Piping Schematic for P34F, FIGURE 4-1 ...................................................................................................................... 4-3

5. START-UP AND OPERATION

Refrigeration System Review ........................................................................................................................................ 5-1

Start-up Checklist .......................................................................................................................................................... 5-2

Refrigerant Charge ........................................................................................................................................................ 5-2

Start-Up ..................................................................................................................................................................... 5-3

Adding Refrigerant ........................................................................................................................................................ 5-4

Operating Tips ............................................................................................................................................................... 5-5

6. ELECTRICAL CONTROLS & THEIR FUNCTIONS

Bin Level Control .......................................................................................................................................................... 6-1

Safety Switches ............................................................................................................................................................. 6-1

Control Panel (Door Opened), FIGURE 6-1.................................................................................................................. 6-2

Description of Control Panel Parts (Inside), TABLE 6-1 .............................................................................................. 6-2

Control Panel (Door Closed), FIGURE 6-2 ................................................................................................................... 6-3

Description of Control Panel Parts (Outer Door), TABLE 6-2 ...................................................................................... 6-3

Electrical Schematic All Voltages 50-60 Hz. Across Line Start, FIGURE 6-3 ............................................................. 6-4

Level Column Wiring, FIGURE 6-4 ............................................................................................................................. 6-5

Part Wind Start, Compressor Motor Starter FIGURE 6-5 ............................................................................................. 6-6

Description of Control Panel Parts TABLE 6-5 ............................................................................................................ 6-6

Across Line Start, Compressor Motor Starter FIGURE 6-6 .......................................................................................... 6-7

Description of Control Panel Parts TABLE 6-6 ............................................................................................................ 6-7

7 MAINTENANCE

Preventive Maintenance ................................................................................................................................................. 7-1

Preventative Maintenance Form .................................................................................................................................... 7-2

Ice-Making Section ........................................................................................................................................................ 7-3

Cleaning Procedure ........................................................................................................................................................ 7-3

Water Distributors, TABLE 7-1 .................................................................................................................................... 7-3

Average Hole Size in Tube-Ice

, TABLE 7-2 ............................................................................................................... 7-4

Water Tank .................................................................................................................................................................... 7-4

Water Cooled Condenser Cleaning ................................................................................................................................ 7-4

P34F Service Manual

7 MAINTENANCE (cont.) Page No.

Cooling Tower / Evap Condenser .................................................................................................................................. 7-5

Cooling Tower Maintenance Schedule, TABLE 7-3 ..................................................................................................... 7-5

Compressor .................................................................................................................................................................... 7-6

Compressor Maintenance, TABLE 7-4 ......................................................................................................................... 7-6

Cutter Gear Reducer ...................................................................................................................................................... 7-7

V-Belt Maintenance ....................................................................................................................................................... 7-7

8. TROUBLESHOOTING

List Of Symptoms .......................................................................................................................................................... 8-1

Machine Stopped ........................................................................................................................................................... 8-2, 8-3

Freeze-Up Due To Extended Freeze Period .................................................................................................................. 8-4

Freeze-Up Due To Ice Failing To Discharge ................................................................................................................. 8-5

Low Ice Capacity ........................................................................................................................................................... 8-6, 8-7

Poor Ice Quality ............................................................................................................................................................. 8-7

High Discharge Pressure ................................................................................................................................................ 8-8

Low Discharge Pressure ................................................................................................................................................ 8-9

High Suction Pressure .................................................................................................................................................... 8-9

Compressor Running Unloaded During Freeze ............................................................................................................. 8-9

Compressor Oil Pressure Low ....................................................................................................................................... 8-10

Compressor Loosing Oil Excessively ............................................................................................................................ 8-10

Machine Short Cycles .................................................................................................................................................... 8-11

Shut Down By Oil Pressure Switch ............................................................................................................................... 8-11

High Compressor Discharge Temperature ..................................................................................................................... 8-11

Suction Line Frosting To Compressor ........................................................................................................................... 8-12

9. SERVICE OPERATIONS

Automatic Blowdown (Harvest Cycle) .......................................................................................................................... 9-1

Cleaning the Ice Making Section ................................................................................................................................... 9-1

Float Valve (Make-Up Water) ....................................................................................................................................... 9-1

Capacitive Level Control ............................................................................................................................................... 9-1to 9-4

Trouble-shooting Guide for level controller, TABLE 9-1 ............................................................................................. 9-5

Hand Expansion Valve .................................................................................................................................................. 9-6

Freezer Pressure Switch ................................................................................................................................................. 9-6

Freezer Pressure Switch, FIGURE 9-2 .......................................................................................................................... 9-6

High/Low Pressure Switch ............................................................................................................................................ 9-7

High/Low Pressure Switch, FIGURE 9-3 ...................................................................................................................... 9-7

Compressor Crankcase Heater ....................................................................................................................................... 9-7

Fan Control (cooling tower) .......................................................................................................................................... 9-8

Fan Control Switch, FIGURE 9-4 ................................................................................................................................. 9-8

Oil Pressure Switch........................................................................................................................................................ 9-8

Oil Pressure Switch, FIGURE 9-4 ................................................................................................................................. 9-8

Control Circuit Protection .............................................................................................................................................. 9-9

Thawing Timer .............................................................................................................................................................. 9-9

5/5/15

iii

TABLE OF CONTENTS

iv

TABLE OF CONTENTS

9. SERVICE OPERATIONS (cont.) Page No.

Thawing Timer, FIGURE 9-6 ........................................................................................................................................ 9-9

Condenser Cleaning ....................................................................................................................................................... 9-10

P34F Cutter Assembly, FIGURE 9-7A .......................................................................................................................... 9-11

P34F Water Tank Assembly, FIGURE 9-7B ................................................................................................................. 9-11

P34F Cutter and Water Tank Part No., TABLE 9-2 ...................................................................................................... 9-12

Cutter Gear Replacement ............................................................................................................................................... 9-13

Drive Gear Replacement ................................................................................................................................................ 9-13

Gear Reducer Replacement ........................................................................................................................................... 9-14

Water Tank and Cutter Parts Weights, TABLE 9-3 ...................................................................................................... 9-15

Water Tank Removal ..................................................................................................................................................... 9-15

Cutter Assembly Removal and Installation ................................................................................................................... 9-15

Bearing Bracket and Cutter Disc Removal .................................................................................................................... 9-16

Cutter Shaft and Bearing Removal ................................................................................................................................ 9-16

Cutter Shaft and Bearing Installation ............................................................................................................................. 9-17

Cutter Height Adjustment .............................................................................................................................................. 9-18

Water Tank Installation ................................................................................................................................................. 9-18

Cutter Ring Gear Replacement ...................................................................................................................................... 9-19

Cutter Blade Replacement ............................................................................................................................................. 9-19

Cutter Blade and Adapter Plate Adjustment, FIGURE 9-8 ........................................................................................... 9-20

Cutter Adapter Plate Installation .................................................................................................................................... 9-20

Pumpdown 9-21

Removal of R22 / R404a Refrigerant from the Machine ............................................................................................... 9-21

Refrigerant Leaks .......................................................................................................................................................... 9-22

Non-Condensable Gases ................................................................................................................................................ 9-22

Water Contamination of R22 / R404a ........................................................................................................................... 9-22

Circulating Water Pump Motor ..................................................................................................................................... 9-22

The Thaw Gas Solenoid Valve ...................................................................................................................................... 9-23

Thaw Gas Solenoid Valve, FIGURE 9-9 ....................................................................................................................... 9-23

The Liquid Feed Solenoid Valve ................................................................................................................................... 9-24

The Liquid Feed Solenoid Valve, FIGURE 9-10 ........................................................................................................... 9-24

Water Flush Solenoid Valve .......................................................................................................................................... 9-25

Compressor Oil Changing ............................................................................................................................................. 9-25

Compressor Inspection .................................................................................................................................................. 9-25

Belt Tension ................................................................................................................................................................... 9-26

Compressor Servicing .................................................................................................................................................... 9-26

10. OPTIONS AND ACCESSORIES

Crushed Ice Production ................................................................................................................................................. 10-1

Length of Ice ................................................................................................................................................................. 10-1

Power Monitor .............................................................................................................................................................. 10-2

P34F Service Manual

P34F Service Manual

Page No.

11. TABLES AND CHARTS

P34A Specifications, TABLE 11-1 ................................................................................................................................ 11-2

P34A Capacity Ratings, TABLE 11-2 ........................................................................................................................... 11-3

P34A Condenser Water Usage, TABLE 11-3 ................................................................................................................ 11-4

P34A Make-Up Water Usage, TABLE 11-4 ................................................................................................................. 11-4

P34A Normal Operating Vitals, TABLE 11-5 ............................................................................................................... 11-5

Temperature - Pressure Chart for Common Refrigerants, TABLE 11-6 ....................................................................... 11-6

Conversion Factors: English to Metric, TABLE 11-7 ................................................................................................... 11-7

Constants, TABLE 11-8 ................................................................................................................................................ 11-7

APPENDIX

v

TABLE OF CONTENTS

5/5/15

P34F Service Manual

A Brief History Of Our Company. In 1938, Vogt built the first Tube-Ice

revolutionized the ice-making industry. Our first “sized-ice” machine quickly replaced the old canice plants, which required hard labor and large amounts of floor space for freezing, cutting, and

crushing ice by hand.

Vogt Energy-Saving Tube-Ice Machines Are Cost Effective. Today, Vogt-Ice

well-earned reputation as the most energy efficient, dependable ice-making equipment in the world.

Using as little as one-half to one-third the energy required by competitors ‘ice makers, Vogt-Ice

machines produce the same amount of ice in restaurants, sports arenas, packing plants, and

wholesale operations around the globe at great savings.

In addition, Vogt-Ice

35 years of dependable service. Ask someone who owns one.

Preview. All the skill in engineering and fabrication that we’ve learned in over a century of

experience is reflected in every Vogt-Ice® machine. Since Vogt introduced Tube-Ice® machines in

1938, the process of making Tube-Ice® ice has been widely recognized as the most economical

means of production. The machine’s economic and reliable operation has been proven over and

over again, in a network of varied types of installations throughout the world.

Furnished with your machine is the Certificate of Test--the report of operating data, which is a

record of the unit’s satisfactory operation at our factory test floor. It is evidence of our desire to

deliver to you “the finest ice-making unit ever made.”

This manual is designed to assist you in the installation, start-up, and maintenance of your unit.

Your Vogt-Ice

service it properly.

Please read your manual carefully before attempting installation, operation, or servicing of this

professionally designed piece of equipment. Also, make sure the Warranty Registration/Start-up

Report is completed and returned.

If you have additional questions, please call your distributor. Also, feel free to phone the factory

direct at (502) 635-3000.

Important Safety Notice. This information is intended for use by individuals possessing adequate

backgrounds in electrical, refrigeration and mechanical experience. Any attempt to repair major

equipment may result in personal injury and/or property damage. The manufacturer or seller cannot

be responsible for the interpretation of this information, nor can it assume any liability in connection

with its use. It is important that personnel understand the properties of these refrigerants and that

they be thoroughly trained in safe practices for their use and handling. Refer to the enclosed “Freon

Compounds and Safety” in Appendix A.

INTRODUCTION

1. Introduction

Vogt Ice LLC

®

machine and

®

machines enjoy a

®

machines are renowned for their long life, giving many customers more than

®

machine will give you a lifetime of service provided you install, maintain, and

1-1

®

5/5/15

1-2

INTRODUCTION

Safety Symbols & What They Mean. Prior to installation or operation of the Vogt-Ice® machine,

please read this manual. Are you familiar with the installation, start-up, and operation of a VogtIce® machine? Before you operate, adjust or service this machine, you should read this manual,

understand the operation of this machine, and be aware of possible dangers.

P34F Service Manual

These safety symbols will alert you

when special care is needed.

Please heed them.

! DANGER !

Indicates an immediate hazard, and that special precautions

are necessary to avoid severe personal injury or death.

! DANGER !

! WARNING !

Indicates a strong possibility of a hazard, and that an

unsafe practice could result in severe personal injury.

! WARNING !

! CAUTION !

Means hazards or unsafe practices could result

in personal injury or product or property damage.

! CAUTION !

5/5/15

P34F Service Manual

Special Precautions To Be Observed When Charging Refrigeration Systems. Only technically

qualified persons, experienced and knowledgeable in the handling of R-22/ R404a refrigerant, and

the operation of refrigeration systems, should perform the operations described in this manual. All

local, federal, and EPA regulations must be strictly adhered to when handling R-22/ R404A

refrigerant. See “Material Safety Data Sheet”, MSDS Code No. DU000025 (R-22 / R404a) in

Appendix A. For further information concerning refrigerants and handling practices see internet

web site: www.dupont.com/suva/

If a refrigeration system is being charged from refrigerant cylinders, disconnect each cylinder when

empty or when the system is fully charged. A gage should be installed in the charging line to

indicate refrigerant cylinder pressure. The cylinder may be considered empty of liquid refrigerant

when the gauge pressure is 25 pounds or less, and there is no frost on the cylinder. Close the

refrigerant charging valve and cylinder valve before disconnecting the cylinder. Loosen the union in

the refrigerant charging line--carefully to avoid unnecessary, excessive or illegal release of

refrigerant into the atmosphere.

Immediately close system charging valve at commencement of defrost or thawing cycle if

refrigerant cylinder is connected. Never leave a refrigerant cylinder connected to system

except during charging operation. Failure to observe either of these precautions can result in

transferring refrigerant from the system to the refrigerant cylinder, over-filling it, and

possibly causing the cylinder to rupture because of pressure from expansion of the liquid

refrigerant brought on by an increase in temperature.

Always store cylinders containing refrigerant in a cool place. They should never be exposed to

temperatures higher than 120F (R-22/ R404A), and should be stored in a manner to prevent

abnormal mechanical shocks.

Also, transferring refrigerant from a refrigeration system into a cylinder can be very dangerous and

is not recommended.

It is not recommended that refrigerant be transferred from a refrigeration system directly into

a cylinder. If such a transfer is made, the refrigerant cylinder must be an approved, CLEAN

cylinder--free of any contaminants or foreign materials--and must be weighed continuously to

assure contents do not exceed net weight specified by cylinder manufacturer or any applicable

code requirements.

1-3

INTRODUCTION

! CAUTION !

! CAUTION !

! CAUTION !

! CAUTION !

5/5/15

1-4

INTRODUCTION

P34F Service Manual

5/5/15

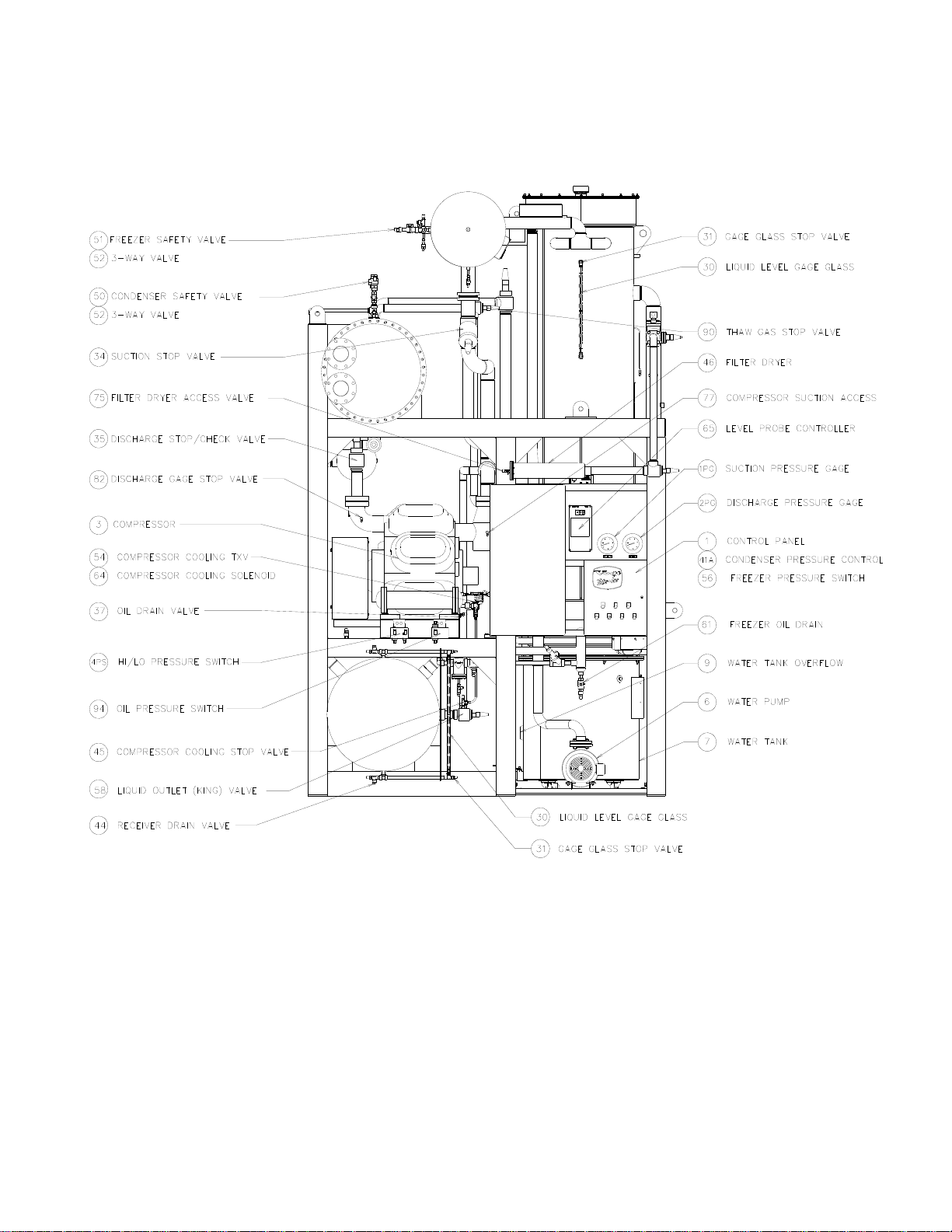

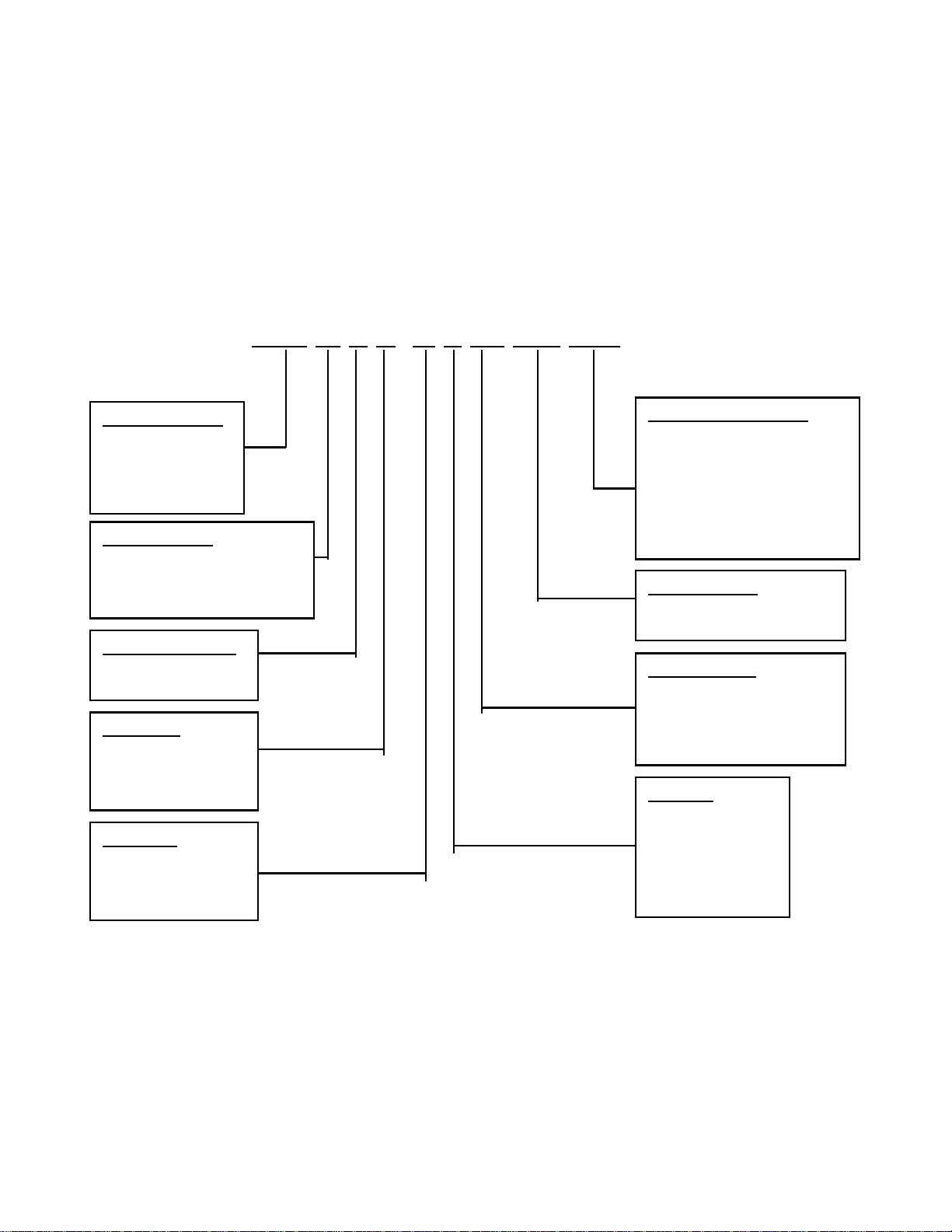

FIGURE 1-1

P34F Front Side (Control Panel)

P34F Service Manual

1-5

INTRODUCTION

5/5/15

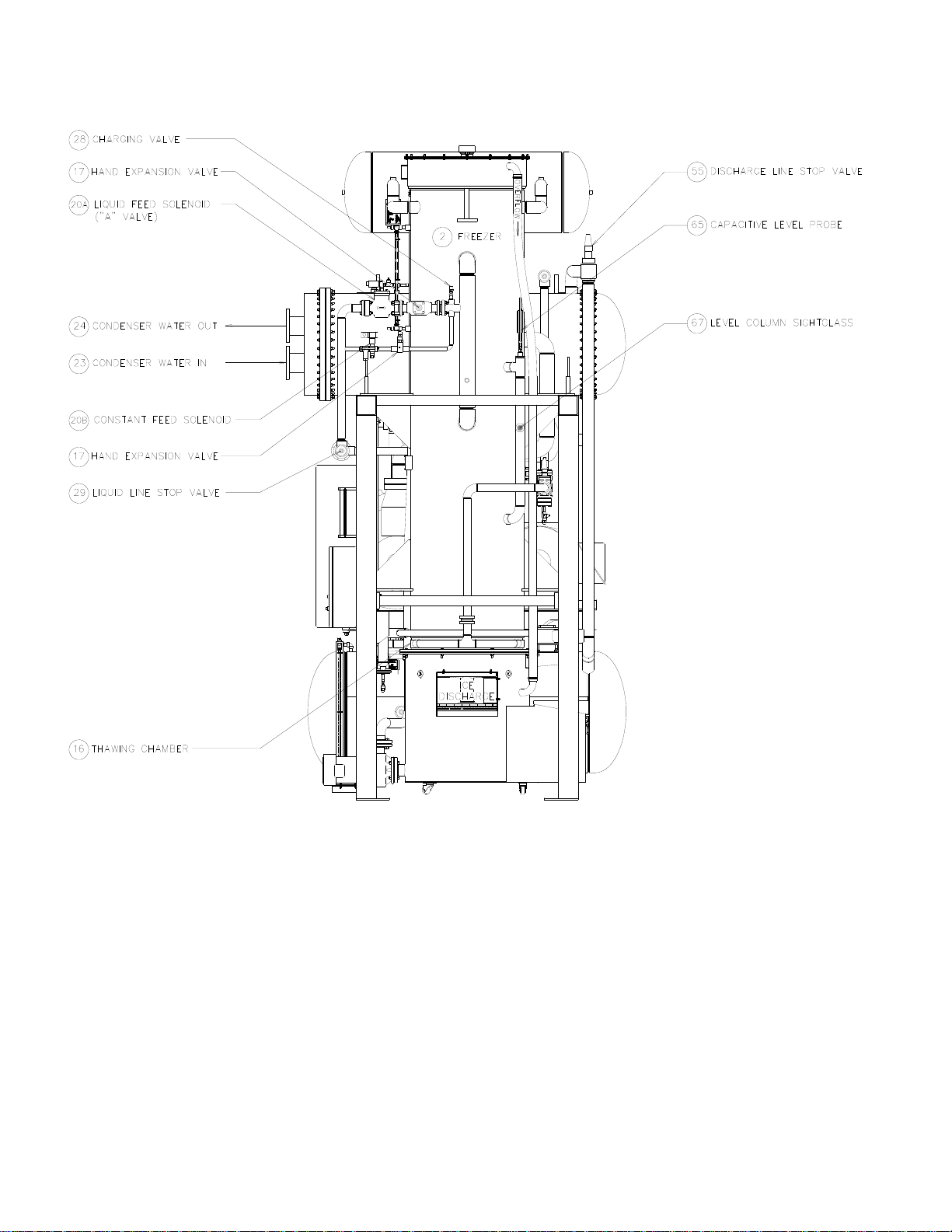

FIGURE 1-2

P34F Right Side

1-6

INTRODUCTION

P34F Service Manual

5/5/15

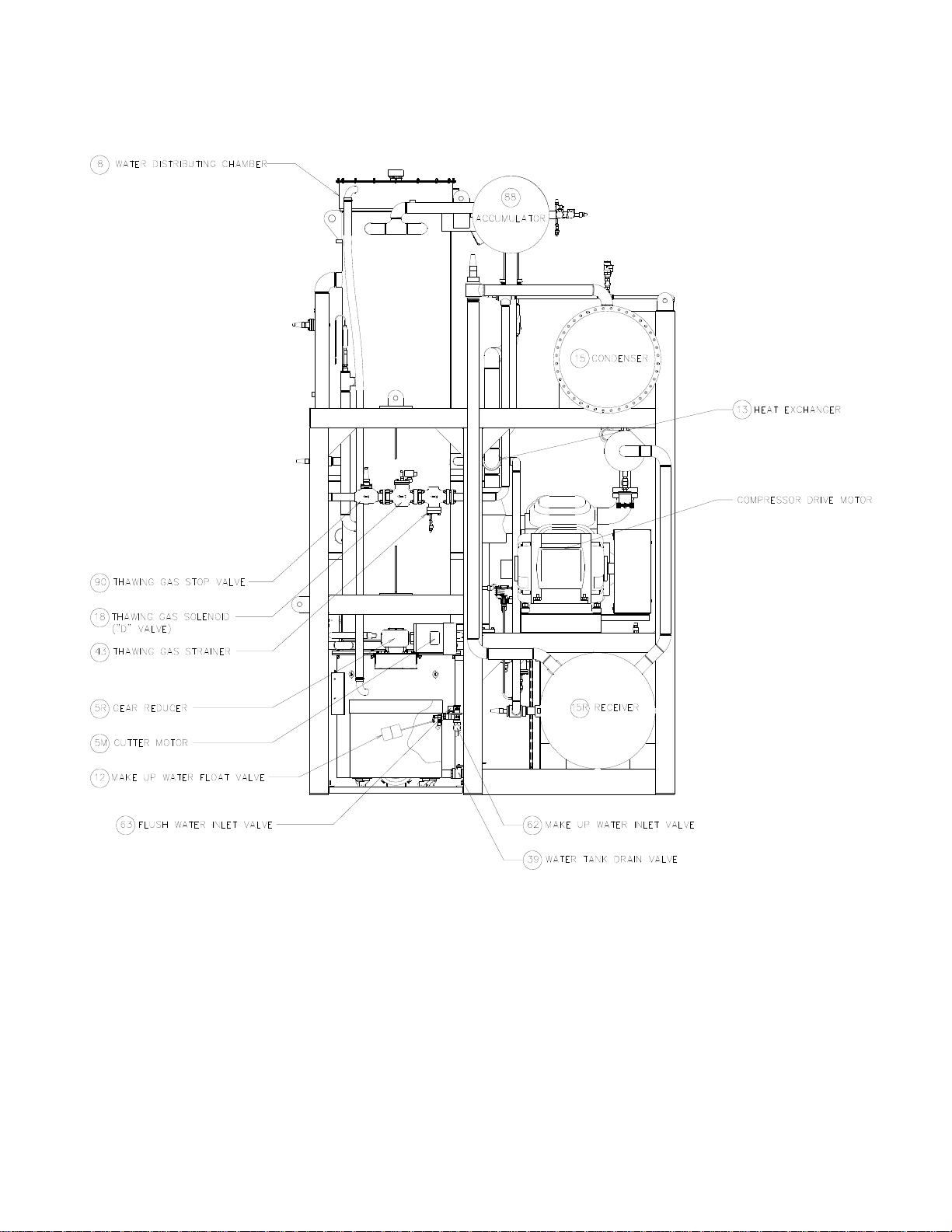

FIGURE 1-3

P34F Back Side

P34F Service Manual

1-7

INTRODUCTION

5/5/15

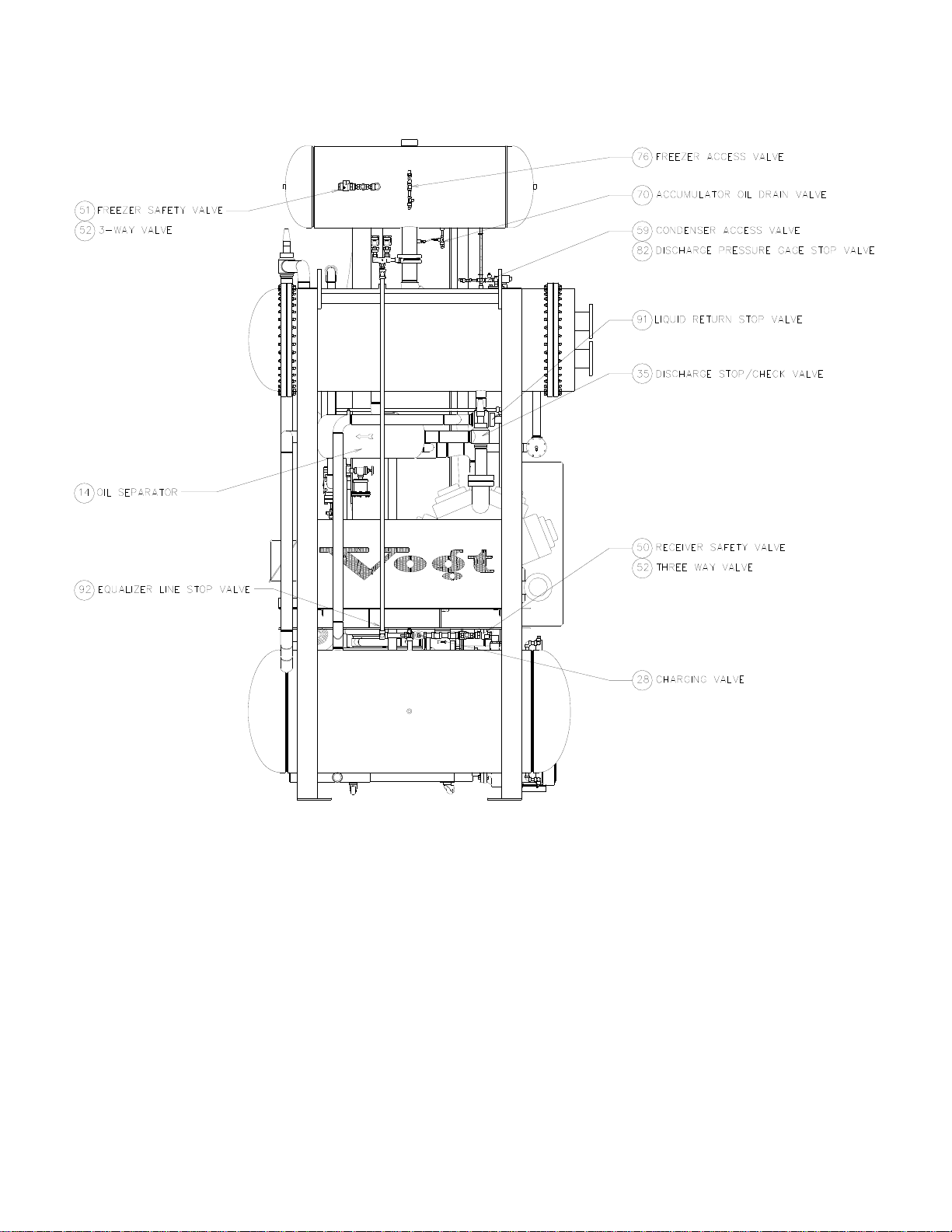

FIGURE 1-4

P34F Left Side

1-8

INTRODUCTION

P34F Service Manual

This page is blank.

5/5/15

P34F Service Manual

Inspection. As soon as you receive your machine, inspect it for any damage. If damage is

suspected, note it on the shipper’s papers (i.e., the trucker’s Bill of Lading). Immediately make a

separate written request for inspection by the freight line’s agent. Any repair work or alteration to

the machine without the permission of Vogt Ice LLC can void the machine’s warranty. You should

also notify your Vogt distributor or the factory.

Description Of Machine. A Vogt package Tube-Ice machine is a complete ice producing plant

requiring only make-up water supply, condenser water supply, electrical connection, and the proper

refrigerant charge.

The machine has been fully factory tested prior to shipment and should require minimum

adjustment.

The compressor oil is drained and the compressor suction strainer is cleaned and the cloth filter is

removed. The crankcase is inspected and cleaned by removing the side hand hole cover, swabbing

out the remaining oil and wiping the interior sides and bottom with a clean dry cloth. New oil is

added, and the compressor is evacuated then pressurized to 20-25 psig with refrigerant.

Refer to your compressor manual for additional operation, service, maintenance instructions, and

information.

Safety Tags and Labels. Be sure to read and adhere to all special tags and labels attached to valves

or applied to various areas of the machine. They provide important information necessary for safe

and efficient operation of your equipment.

RECEIPT OF YOUR TUBE-ICE MACHINE

2. Receipt Of Your Tube-Ice Machine

! CAUTION !

Only service personnel experienced in refrigeration systems and

qualified to work on high amperage electrical equipment should

be allowed to install or service this Vogt-Ice

Eye protection should be worn by all personnel

working on or around the Vogt-Ice

It is very important that you are familiar with and adhere to

all local, state, and federal, etc. ordinances and laws regarding

the handling, storing, and use of R-22/R404a refrigerant.

An approved refrigerant mask should be readily available

for use in an emergency and all personnel should be aware

of its location and proper use.

! CAUTION !

®

machine.

®

machine.

2-1

5/5/15

–

2-2

RECEIPT OF YOUR TUBE-ICE MACHINE

The machine is available in three different tube sizes for producing ice 7/8” OD x 1” long, 1 1/8”

OD x 1” long, or 1 3/8” OD x 1” long (1” long ice is standard length). The ice is cut to length by a

rotating breaker type cutter. Ice can be produced up to 1 1/2” long by modifying the spacers under

the adapter plates (see Chapter 10, “Ice Length” for modifying instructions). Crushed ice is also

available by modifying the cutter and making minor adjustments to the machine (see Chapter 10,

“Crushed Ice”).

50T A P F B 5 46 NC 000

Nominal Capacity

(“T”= tons/day)

“25T” – 25 tons/day

“50T” – 50 tons/day

“80T” – 80 tons/day

Model Variation

A letter assigned to indicate

major variations within any one

family series

Basic Configuration

“P” – Package

“L” - Lowside

Refrigerant

“F” – R-22

“A” – Ammonia

“H” – R-404a

Type of Ice

“B” – Cylinder

“K” – Crushed

“L” – 1 ½” Long Ice

P34F Service Manual

Product Variation Code

A number or letter designator

assigned to specific variations

within a family series

“000 or Blank” – Standard

Product

Consult factory for specific

code interpretation

Condenser Type

“WC” – Water Cooled

“NC” – No Condenser

Electrical Codes

“26” – 208/230-3-60

“46” – 460-3-60

“25” – 200-3-50

“45” – 400-3-50

Tube Size

(In ¼’s of an inch)

“4” – 1”

“5” – 1 ¼”

“6” – 1 ½”

“7” – 1 ¾”

2”

“8”

FIGURE 2-1

Model Designation for P-Series Ice Machines

5/5/15

P34F Service Manual

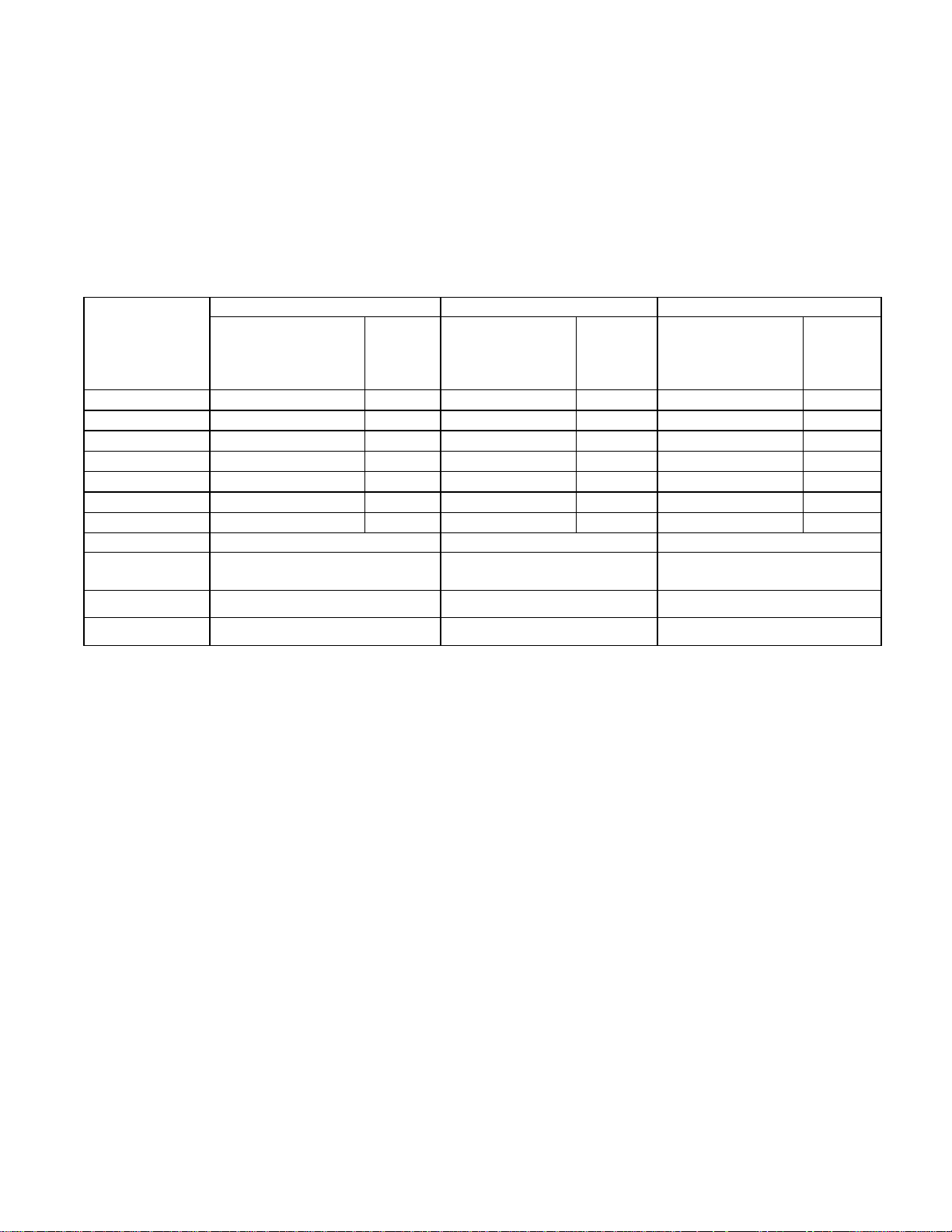

Rated Capacity. The Tube-Ice machine is rated to produce a given amount of ice when operating

under the proper conditions as specified in this manual. You should be prepared to handle the ice

produced as it is discharged from the machine and move it to your storage or bagging area promptly.

The following specifications are given to help you do just that.

Makeup Water

85F/29C

80F/24C

75F/23C

70F/21C

65F/18C

60F/15C

55F/13C

Ice lb/harvest 1728lbs/785 Kg 1414lbs/642 Kg

Shipping weight 25,250 lbs/11,453 Kg 25,250 lbs/11,453 Kg 25,250 lbs/11,453 Kg

Temp.

RECEIPT OF YOUR TUBE-ICE MACHINE

Model P34F-1.5” Model P34F-1.25” Model P34F-1”

Capacity Tons/day

(2000 lbs/24 hours)

45.8

12.7 48.8 13.7 45.6 13.4

46.8

13.0 49.9 14.0 46.6 13.8

47.8

13.4 51 14.4 47.6 14.2

48.8

13.7 52.1 14.7 48.6 14.5

49.8

14.1 53.2 15.1 49.6 14.9

50.8

14.4 54.3 15.4 50.6 15.2

51.8

14.8 55.4 15.8 51.6 15.6

Makeup

Water

GPM

Capacity Tons/day

(2000 lbs/24 hrs.)

Makeup

Water

GPM

Capacity Tons/day

(2000 lbs/24 hours)

998lbs/453 Kg

Makeup

Water

GPM

2-3

5/5/15

Operating weight 27,000 lbs/ 12,250 Kg 27,000 lbs/ 12,250 Kg 27,000 lbs/12,250 Kg

Notes:

1. Makeup water is average flow and includes 25% blowdown. Peak flow rate is 15 GPM. at 40 PSI minimum. When water quality is good,

machine can be operated with 5% to 10% blowdown.

2. Ratings are at 90F ambient for ice machine.

3. Capacity ratings are based on 85F water entering condenser. For entering water temperatures above 85F, deduct 4% in capacity for each 5F.

4. Capacity shown is the average for model. Individual machines may vary up to 5% above or below depending on field conditions.

TABLE 2-1

P34F Specifications

Storage (prior to installation or start-up). The machine must not be stored or installed in an area

that is subject to reach temperatures at or above 110F (43.3C). Temperatures above this may

cause the relief valves to open and result in the loss of refrigerant.

2-4

RECEIPT OF YOUR TUBE-ICE MACHINE

P34F Service Manual

This page is blank.

5/5/15

P34F Service Manual

INSTALLING YOUR TUBE-ICE MACHINE

3-1

3. Installing Your Tube-Ice Machine

Your machine will be shipped to you as one package. You will need to arrange for the handling of

the package as soon as it arrives, see the machine specifications Table 2-1 for shipping and operating

weight. Before you remove the unit from the truck, be certain that any sign of damage, however

slight, is noted on the carrier’s papers.

Note: See “Lifting Procedure” drawing furnished with this manual, Figure 3-3.

Machine Room. The machine must be located inside a suitable building and must not be subjected

to ambient temperatures below 50F (10C) or above 110F (43.3C). Heat radiation from other

sources (sunlight, furnaces, condenser, etc.) and unusual air current may affect the operation of the

machine and should be avoided. The electrical components of the Vogt-Ice® machine are rated

IEC. Therefore, the machine should not be located in a hazardous area or sprayed with water.

The machine should be installed in an area where water will not stand, but will readily drain away

from the machine.

Space Requirements. Refer to the space diagrams, Figures 3-1A and 3-1B, for recommended

minimum clearance around the machine for ease of servicing and observation. Pay particular

attention to the additional space required. If it ever becomes necessary to mechanically clean the

condenser tubes, extra space will be required on one end (preferably on the opposite end from the

water inlet and outlet) for the cleaning tools.

Foundation. Refer to the foundation drawings, Figure 3-2, for recommended minimum foundation

requirements. The figures show anchor bolt details and machine anchor hole details. Contact your

local distributor for seismic anchoring requirements in your area.

! WARNING !

Lifting or moving heavy equipment should only be attempted by

competent rigging and hoisting contractors. Never allow personnel

near or under heavy equipment when it is being moved or lifted.

Failure to comply could result in personal injury or loss of life.

! WARNING !

Lifting Procedures. Your Tube-Ice machine is provided with lifting lugs for the purpose of

unloading and moving the machine to its operation location. Refer to the enclosed drawings for

instructions and illustrations of their use.

P34F - Figure 3-3. Machine weight 25,000 lbs. (See TABLE 2-1)

This figure is intended as a guide to unloading and lifting the P34F Tube-Ice

LLC is not responsible for product damage or personnel injury or loss of life during the

loading or lifting procedure.

®

machine. Vogt-Ice

5/5/15

P34F Service Manual

3-2

INSTALLING YOUR TUBE-ICE MACHINE

5/5/15

10’-0”

FIGURE 3-1A

P34F Space Diagram (Side View)

P34F Service Manual

INSTALLING YOUR TUBE-ICE MACHINE

3-3

5/5/15

FIGURE 3-1B

P34F Space Diagram (RearView)

P34F Service Manual

3-4

INSTALLING YOUR TUBE-ICE MACHINE

5/5/15

FIGURE 3-2

P34F Foundation Layout

Loading...

Loading...