Page 1

IP Surveillance

Installation Guide

AE Series

Rev. 1.0

Outdoor Housing

Ordering part no.:

AE-238 900041100G

AE-239 900041200G

AE-243 900041900G

AE-244 900042400G

AE-23A 900042300G

AE-23B 900042200G

AE-23C 900041700G

AE-23D 900041800G

AE-23E 900041600G

AE-23F 900042100G

Page 2

2

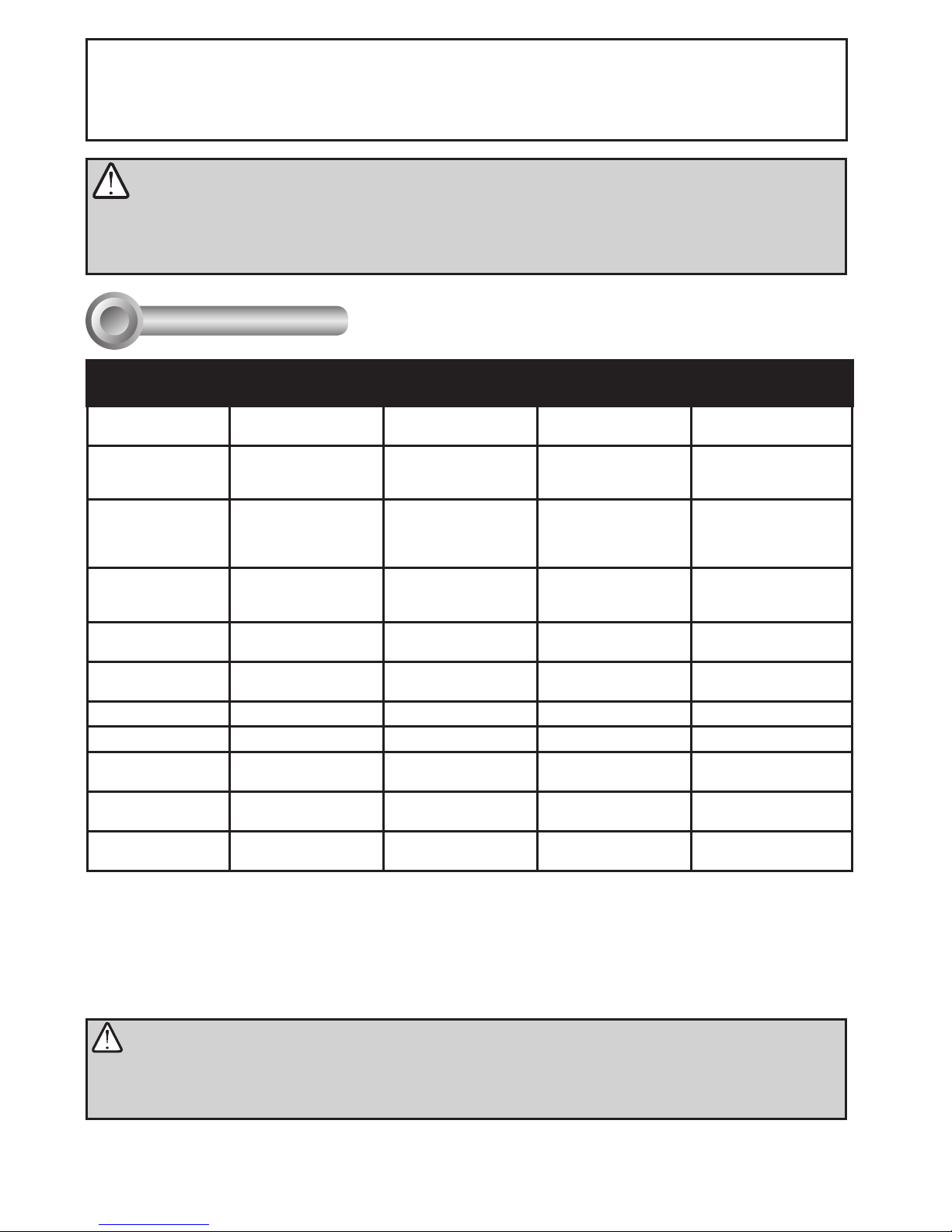

Specications

I

Model Number AE-238, AE-243 AE-23A, AE-23B, AE-

23C, AE-23D

AE-239, AE-244 AE-23E, AE-23F

Power Input 24V AC/ DC 24V AC/ DC PoE: 50~57V DC PoE: 30/60/95W, 50~57V

DC

Max. Output power

budget

30W 80W, 100W (-AIW) 30W 25W - 30W PoE PSE

48W - 60W PoE PSE

72W - 95W PoE PSE

Power Consumption Window heater: 10W;

Blower: 2W; Camera: 6 ~

8W

Window heater: 10W;

Blower: 2W; Camera: 6

~ 8W; Cold start heater:

30W

Window heater: 10W;

Blower: 2W; Camera: 6 ~

8W; IR: 6W

Window heater: 10W;

Blower: 2W; Camera: 6 ~

8W; Wiper: 6W

Environmental

Operation Temp.

-20°C ~ +65°C (-4°F ~

+149°F)

-20°C ~ +65°C

-20°C ~ +50°C (w/ IR)

-24°C ~ +50°C (Cold start)

-20°C ~ +65°C

-20°C ~ +50°C (w/ IR)

-20°C ~ +65°C

-20°C ~ +50°C (w/ IR)

Window heater ON/OFF ≤ 30°C (86°F) ON; ≥ 35°C

(95°F) OFF

≤ 30°C (86°F) ON; ≥ 35°C

(95°F) OFF

≤ 30°C (86°F) ON; ≥ 35°C

(95°F) OFF

≤ 30°C (86°F) ON; ≥ 35°C

(95°F) OFF

Blower Control ≥40°C (104°F) ON; ≤ 35°C

(95°F) OFF

≥40°C (104°F) ON; ≤ 35°C

(95°F) OFF

≥40°C (104°F) ON; ≤ 35°C

(95°F) OFF

≥40°C (104°F) ON; ≤ 35°C

(95°F) OFF

Protection Level IP67, IK10 IP67, IK10 (IP66 w/ wiper) IP67, IK10 IP67, IK10 (IP66 w/ wiper)

Construction Die-cast Aluminum Alloy Die-cast Aluminum Alloy Die-cast Aluminum Alloy Die-cast Aluminum Alloy

Coating White epoxy powder

coating

White epoxy powder

coating

White epoxy powder

coating

White epoxy powder

coating

Dimensions 415 (L) x 170 (W) x 125 (H) mm502.8 (L) x 170 (W) x

135.5 (H) mm

415 (L) x 170 (W) x 125 (H)

mm - IR not included

502.8 (L) x 170 (W) x 135.5

(H) mm - IR not included

Net Weight 2,2kg (4.84 lb) 2,7kg (5.95 lb), 2,8kg (6.18

lb - wiper model)

2,2kg (4.85 lb) 2,7kg (5.95 lb), 2,8kg (6.18

lb - wiper model)

UNPACKING:

Unpack carefully. Electronic components can be damaged if improperly handled or

dropped. If an item appears damaged in shipment, place it properly in its carton and

notify the shipper.

IMPORTANT!:

1. Read and follow Instructions: All operating and user instructions should be read and

followed before the unit is to be operated.

2. Electrical Connections: Only a qualied electrician is allowed to make electrical

connections.

If you plan to install this camera enclosure into a tropical, sea coastal, or an environment

where salt water or corrosive industrial waste water/moist are present, please seal each

stainless steel screws and ttings with a silicon grease compounds. This will help prevent

electrolysis to occur and extend the life span of the camera and housing.

IMPORTANT:

1. Disconnect devices: A readily accessible disconnect device in the building installation wiring

should be incorporated.

2. Electrical Connection: Only a qualied electrician is allowed to make electrical connections.

Page 3

3

English

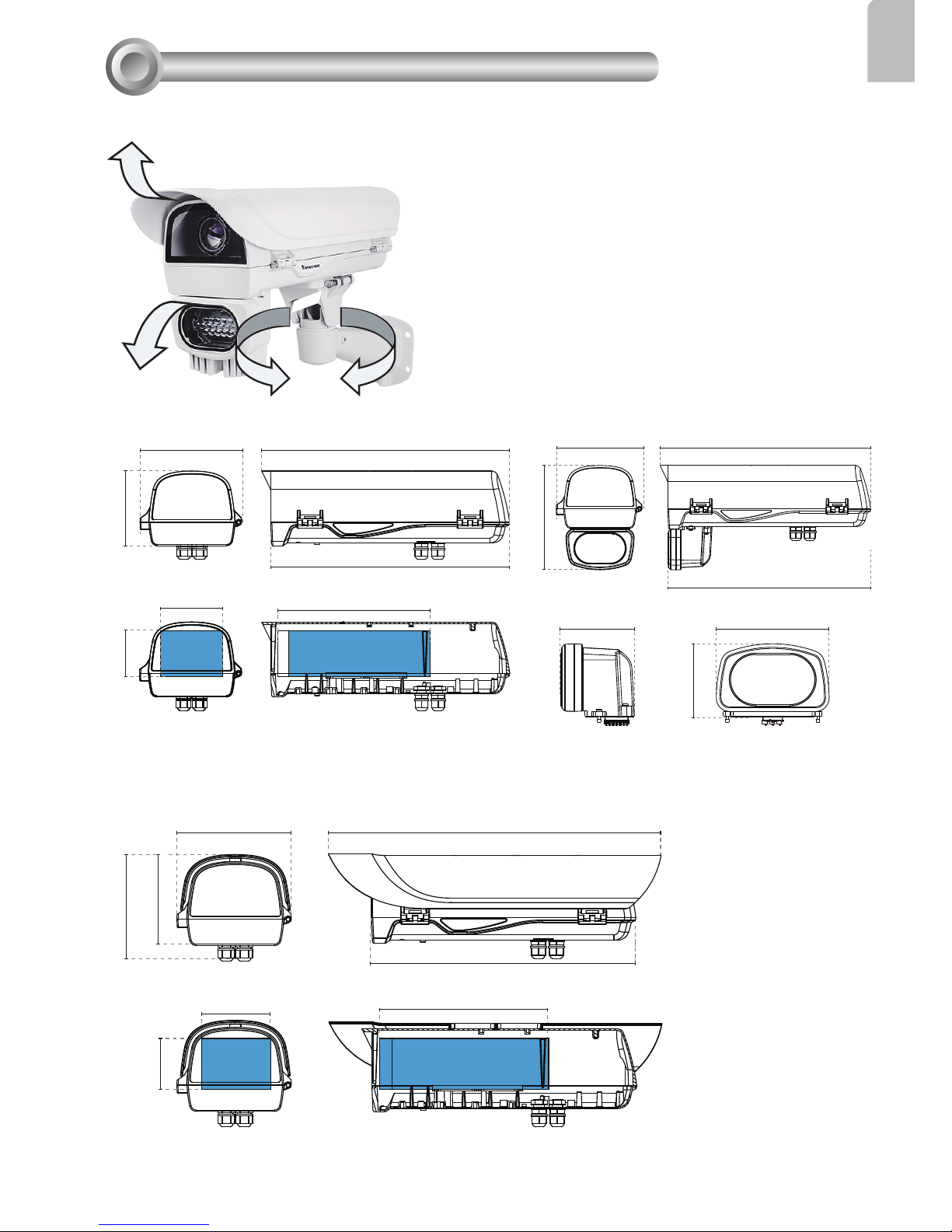

Mounting Conguration & Dimensions

II

Swivel Positions and Directions

415 mm

125 mm

170 mm

400 mm

255 mm

USABLE AREA

105 mm

77.4 mm

USABLE

AREA

105 mm

502.8 mm

135.5 mm

158.5 mm

170 mm

400 mm

77.4 mm

USABLE

AREA

255 mm

USABLE AREA

AE-238, AE-239

AE-23A, 23B, 23C, 23D, 23E, 23F

415 mm

206.9 mm

170 mm

400 mm

135 mm

88.05 mm

87.01 mm

AE-243, AE-244

Page 4

4

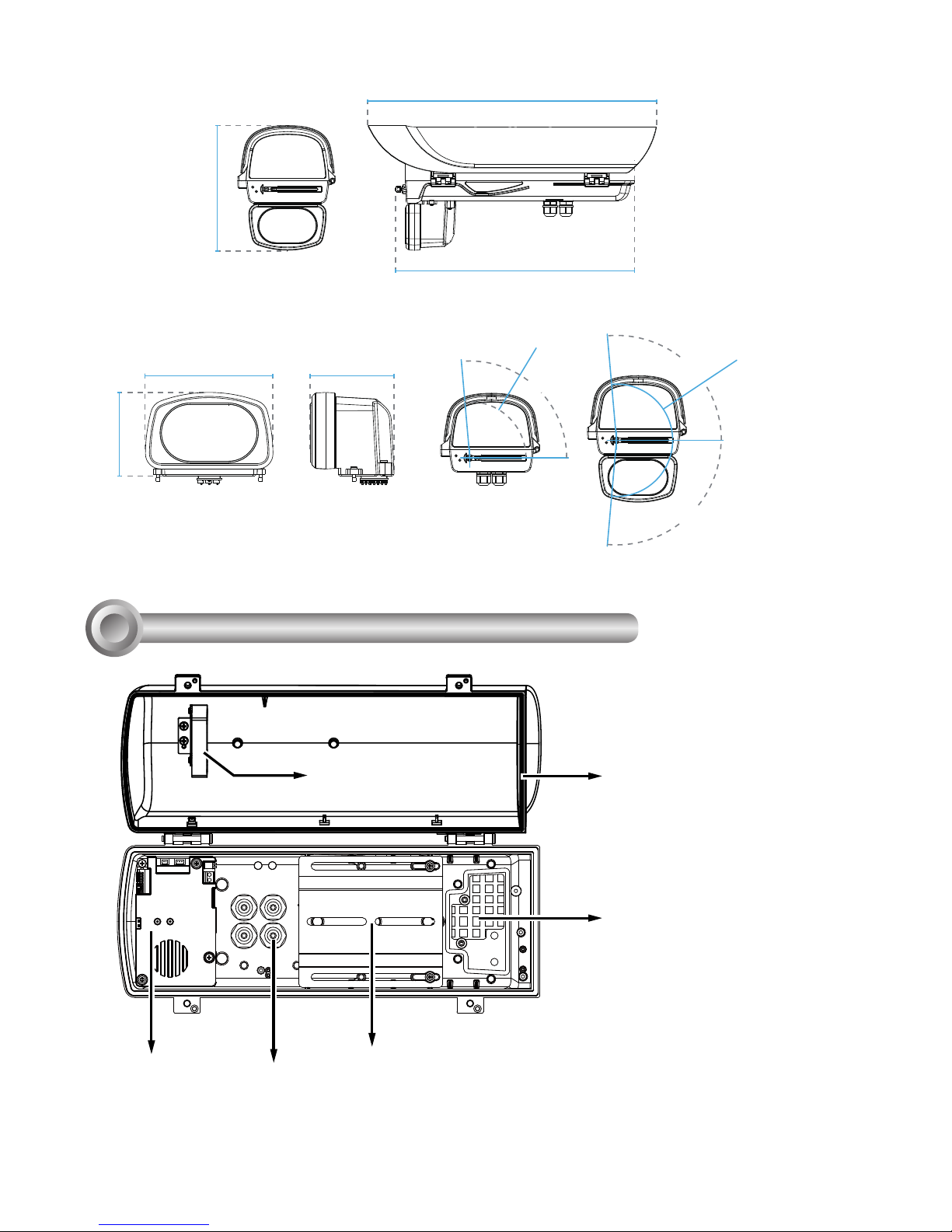

Component Description

III

Camera Mounting Platform

M16 1/2" Waterproof cable glands

AC/DC or PoE Power

distribution board

Ventilation fan

Window frame

heater coil

217.4 mm

502.8 mm

417 mm

135 mm

88.05 mm

87.01 mm

95˚

R96.5

95˚

95˚

R96.45

Dimensions with the IR unit and wiper

VAIR module

Page 5

5

English

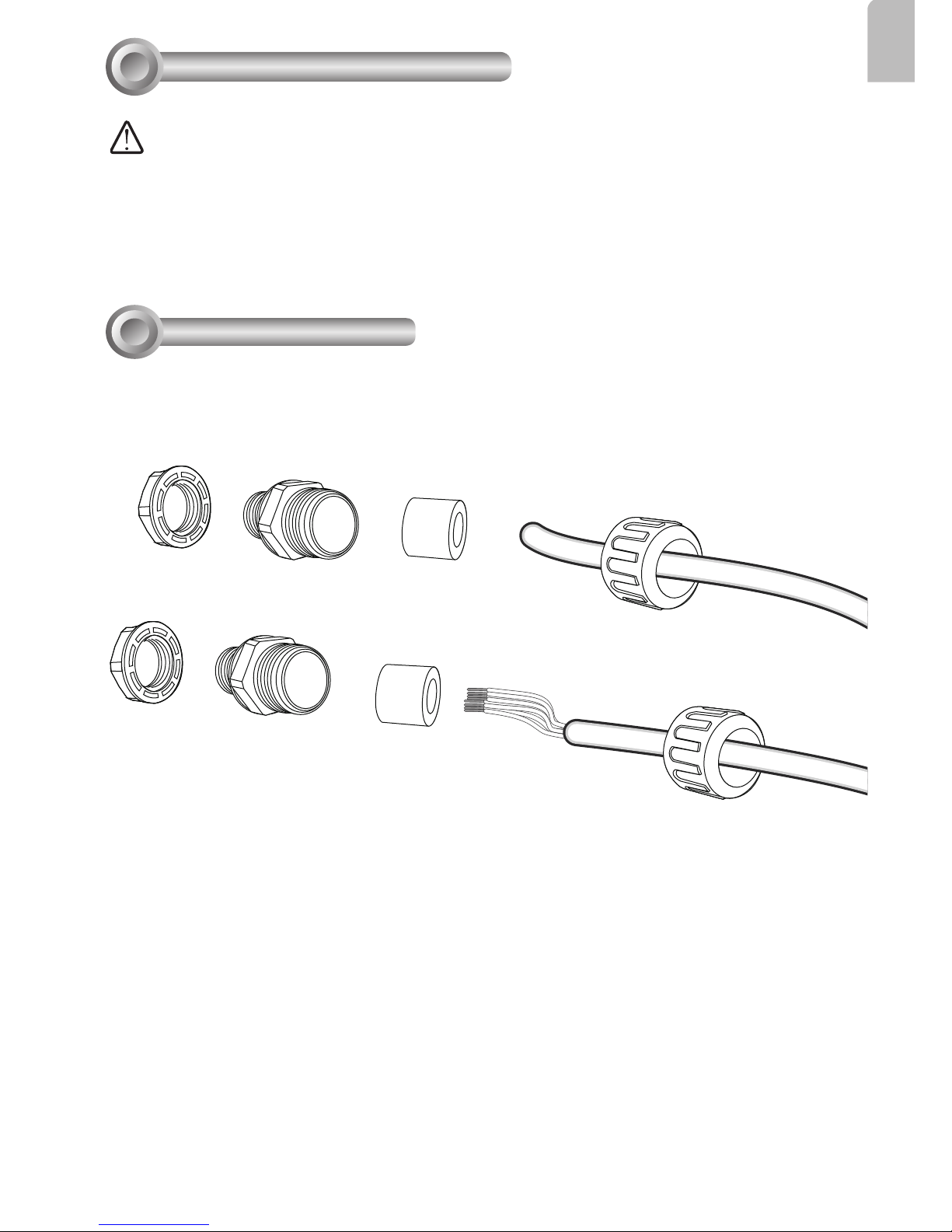

Installation

V

Installation Suggestions

IV

1.

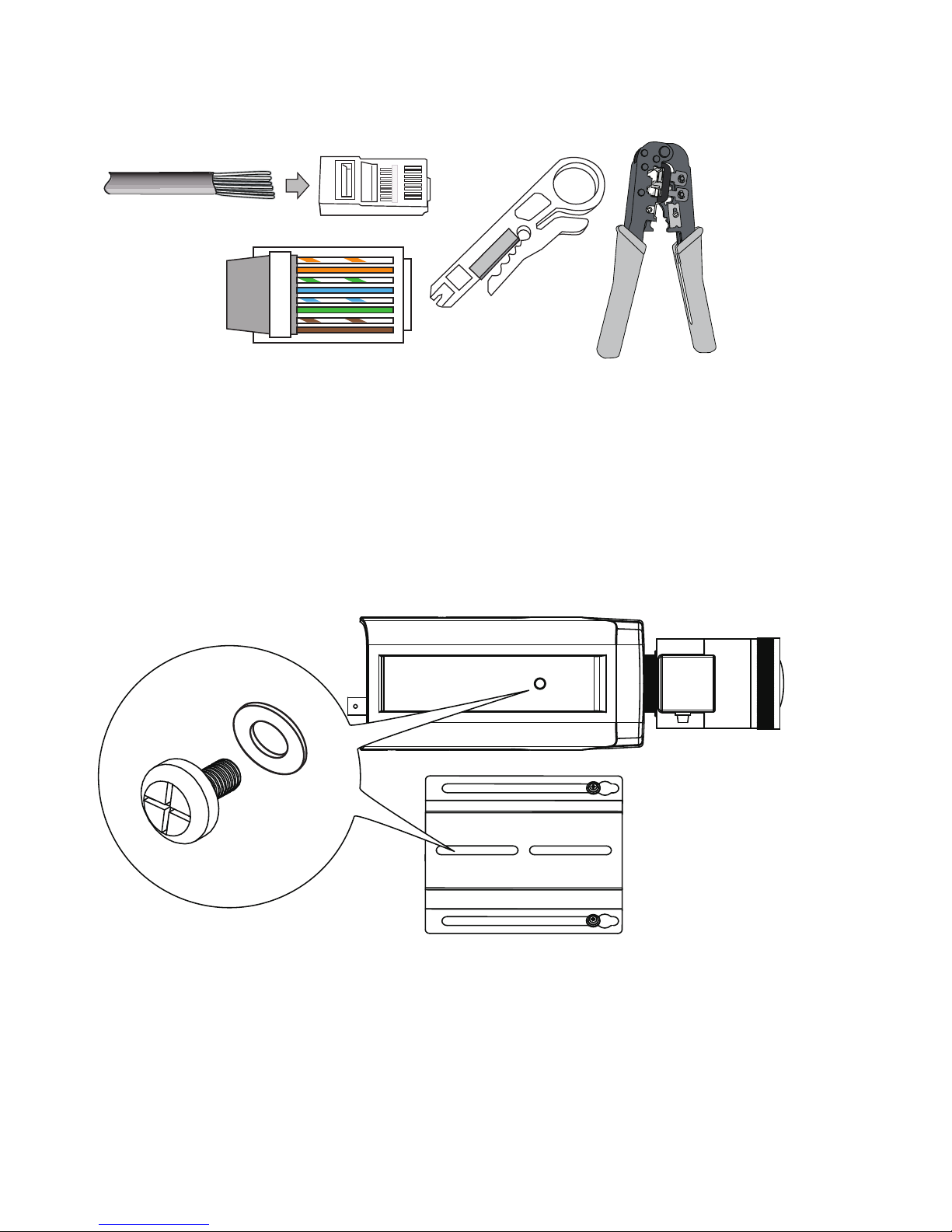

Prepare power wires, a ground wire, and a CAT5e Ethernet cable. Pass them through

the M16 waterproof connectors and its waterproof components.

• When install a housing with an IR illuminator:

Please avoid eye exposure or apply appropriate protection, such as wearing a pair of Infrared

protection glasses, when working with the product. Always use camera live view to oberve IR

lighting effects.

WARNING:

Ethernet cable Ø4 ~ 6.5mm

Power wires & DI/DO wires,

a combo cable from IR illuminator

(if applied)

Note that some cables are connected when shipped. You do not need to connect heater,

blower, and the front IR powere wires.

Page 6

6

o

O

g

B

b

G

br

BR

1

2

3

4

5

6

7

8

o: white/orange stripe

O: orange solid

g: white/green stripe

B: blue solid

b: white/blue stripe

G: green solid

br: white/brown stripe

BR: brown solid

You may need to remove the RJ45 connector, and use a crimping tool to connect the

Ethernet wires to an RJ45 connector inside the enclosure. Use an Ethernet cable of the

width of 5 ~ 6.5mm.

2.

When done, tighten up and install the waterproof connectors.

3.

Assemble the camera components, e.g., the CS ring and lens module. Secure the

mounting plate to the bottom of the camera (the label side) using the included screw.

Page 7

7

English

Lens flush

w/ edge of

enclosure

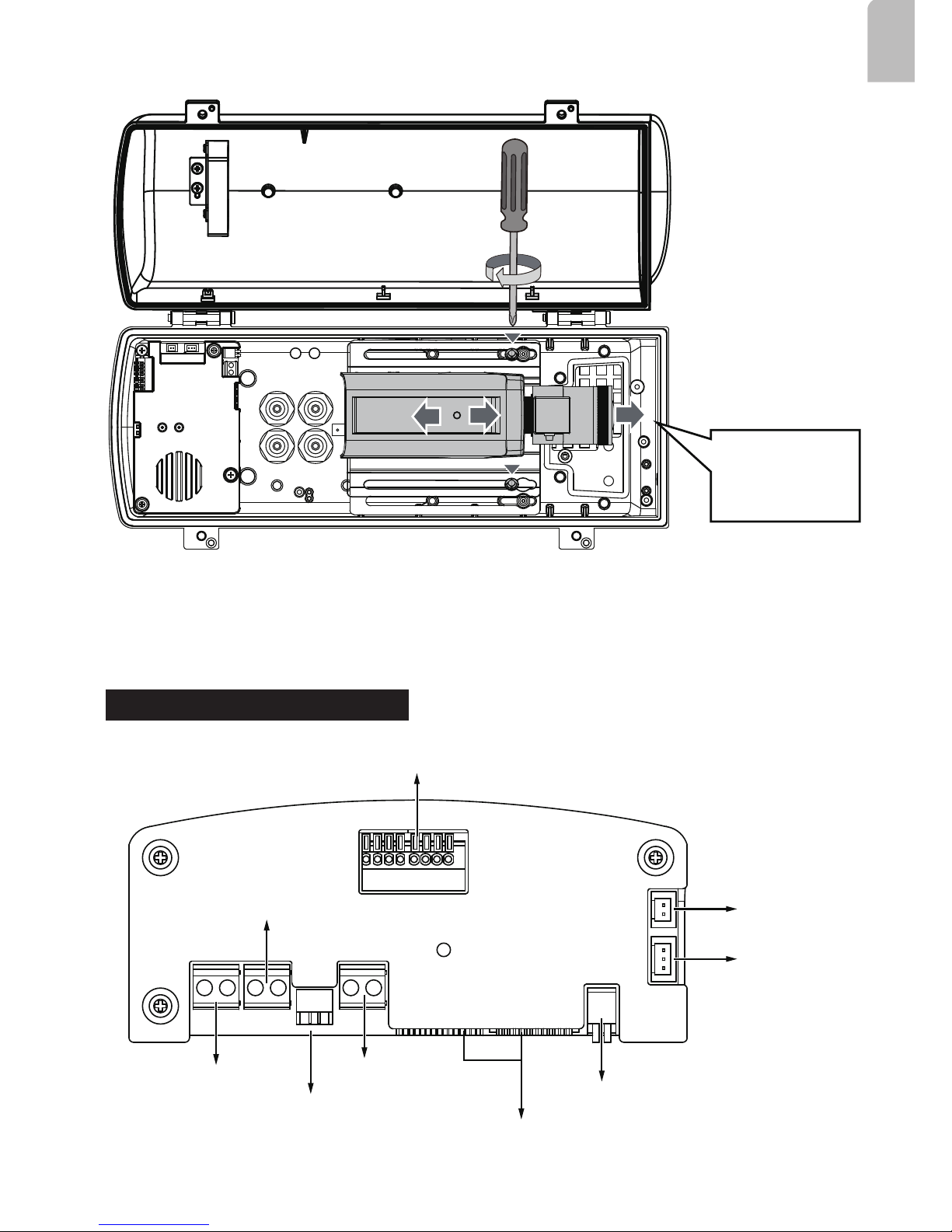

4.

Adjust the camera's position so that the lens module can ush align with the tempered

glass. Secure the camera using the screws and washers to the bottom of the housing.

5.

Connect 24V power source to the power input terminal. Connect power wires from the

DC 12V output to the camera. You may also connect the 24V power to drive an external

IRs.

Below is the distribution board drawing power from 24V AC/DC.

Heater

Blower

IR angle selector

I/O terminal block

Camera heater

24V AC/DC IN

12V DC OUT

24V AC/DC OUT

Connectors to the front IR

Power LED

AE-23A, AE-23B, AE-23C, AE-23D

Page 8

8

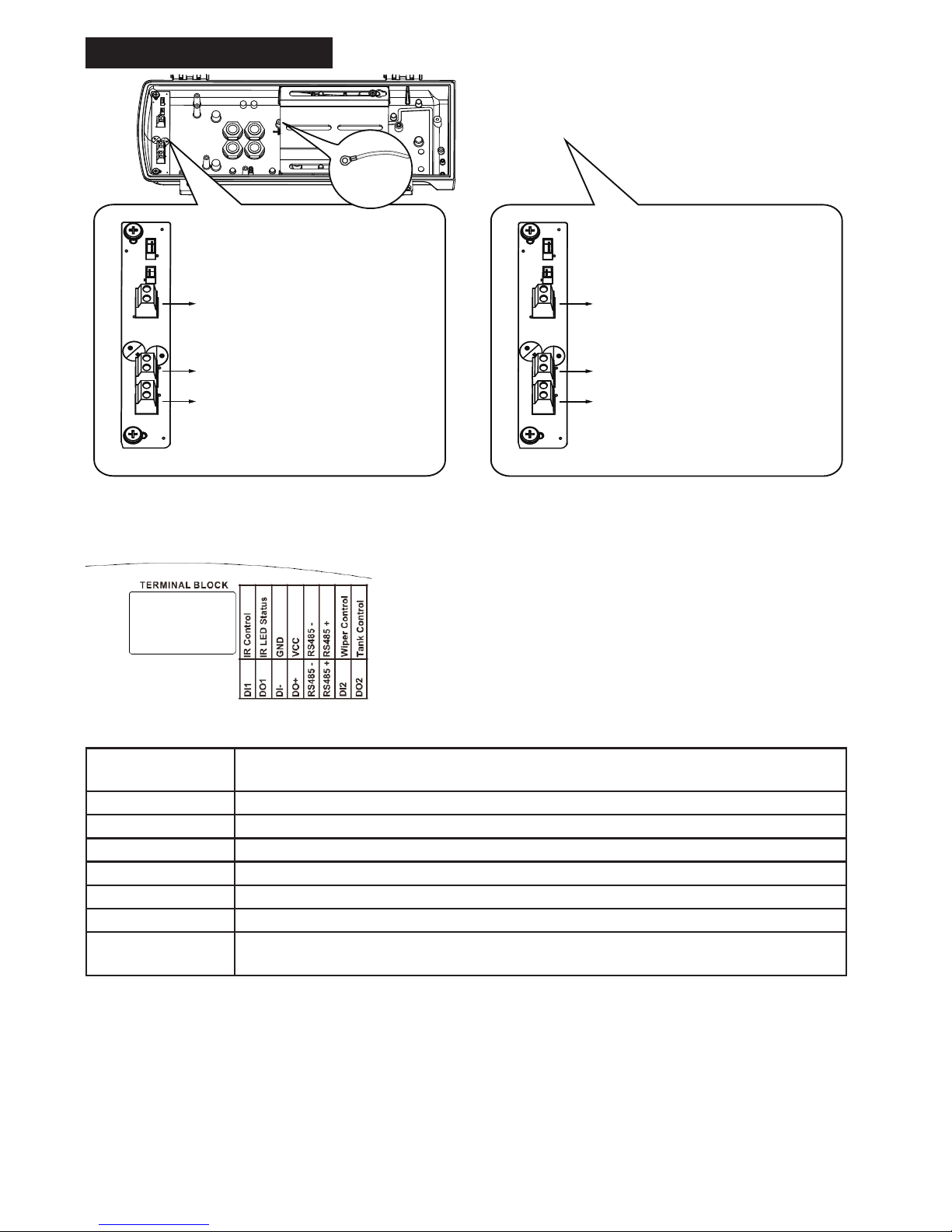

Below is the pinouts for the DI/DO terminal block:

Facing the rear side of the housing, from left to right:

DO2 Tank water pump control, connects to IP camera's DO for manually triggering

washer.

DI2 Wiper control.

RS485+ RS485+, RS485 can be used to control IR illuminator beam angles, etc.

RS485- RS485DO+ +5V VCC

DI- GND

DO1 IR LED status

DI1 IR control, synchronizes day/night mode switching for IP camera. It is related to IR

cut lter.

AE-238, AE-243

DC 12V OUT - to camera

AC 24V OUT - to external IR

AC 24V IN

Ground

for IR LED

AC 24V OUT - to camera

AC 24V IN

AE-238

AE-243

Page 9

9

English

Below is the distribution board (AE-239, -244, -23E, -23F) that draws power from a

30/60/95W PoE PSE. Note that the AE-239 and AE-244 provide 12V DC output.

Heater

Blower

IR angle selector

PoE power LED

24V DC OUT

PoE IN

Connectors to

the front IR

Wiper / Camera heater

PoE OUT

I/O terminal block

The PoE version housings have the same terminal pinouts with that of the 24V power

source models:

DO2 Tank water pump control, connects to IP camera's DO for manually triggering

washer.

DI2 Wiper control.

RS485+ RS485+, RS485- can be used to control IR illuminator beam angles, etc.

RS485- RS485DO+ +5V VCC

DI- GND

DO1 IR LED status

DI1 IR control, synchronizes day/night mode switching for IP camera. It is related to IR

cut lter.

Page 10

10

The 30W PoE version does not support external washer kit.

RS485+ RS485+, RS485 can be used to control IR illuminator beam angles, etc.

RS485- RS485DO+ +5V VCC

DI- GND

DO1 Tank water pump control, connects to IP camera's DO for manually triggering

washer.

DI1 IR control

Below are the parameters of the IR illuminator. Use the onboard jumpers to congure the

beam angle for different effective illumination range.

VAIR 48W 24W 12W

no. of

LEDs

18P/Dual 18P/36mil Single 18P/ 30mil Single

Beam

angle

10

°

20

°

25

°

30

°

10

°

20

°

25

°

30

°

10

°

20

°

25

°

30

°

Distance

(meter)

200m 180m 150m 120m 160m 140m 110m 80m 120m 100m 90m 60m

VAIR 6W

no. of LEDs 4P/42mil Single

Beam angle 10

°

20

°

30

°

40

°

Distance (meter) 100m 80m 40m 15m

Conguring IR illuminator

Page 11

11

English

6.

Connect the DI/DO signal lines from the distribution board, if applied, to the camera's

terminal block.

The day/night mode DI connection enables the synchronization of IR light and the

automated day/night switching mechanism on the camera.

DO+

DO-

DI1+

DI2+

DI3+

DI-

RS485-

RS485+

AC/DC pwr

AC/DC pwr

AWG20

AWG26

AC24V

DO2

DI2

DI-

RS485-

RS485+

DO1

DI1

DO+

DC12V

Tank ctrl

Wiper ctrl

GND

IR LED

IR ctrl

5V VCC

Tank ctrl

Tank low water

GND

Tank w/ pump

A sample connection diagram consisting of a housing with IR illuminators and the IP816A

camera is shown below. Please refer to your camera's documentation if your camera

comes with different pinouts.

AC/DC 24V IN

1. Pump motor ON/OFF

2. GND

3. Water level detector Low/high

4. GND

pin 1

pin 1

1. Water tank EN

2. Water low level

3. N/C

4. GND

Draws power

from AC24V or PoE

95W enclosure

See drawing on the right for the washer kit

control board pinouts.

Page 12

12

DO+

DO-

DI1+

DI2+

DI3+

DI-

RS485-

RS485+

AC/DC pwr

AC/DC pwr

AWG20

AWG26

AC24V

DO2

DI2

DI-

RS485-

RS485+

DO1

DI1

DO+

DC12V

Tank ctrl

Wiper ctrl

GND

IR LED

IR ctrl

5V VCC

Tank ctrl

Tank low water

GND

Below is a diagram using wiper control. The wiper can be started by manually triggering

the Digital Output from the camera user interface.

Note the wire gauge requirements for making the power connections.

For 24VAC 24W load,

Wire Gauge 22 20 18 16 14 12

Distance 55 90 150 230 270 600 feet

Page 13

13

English

7.

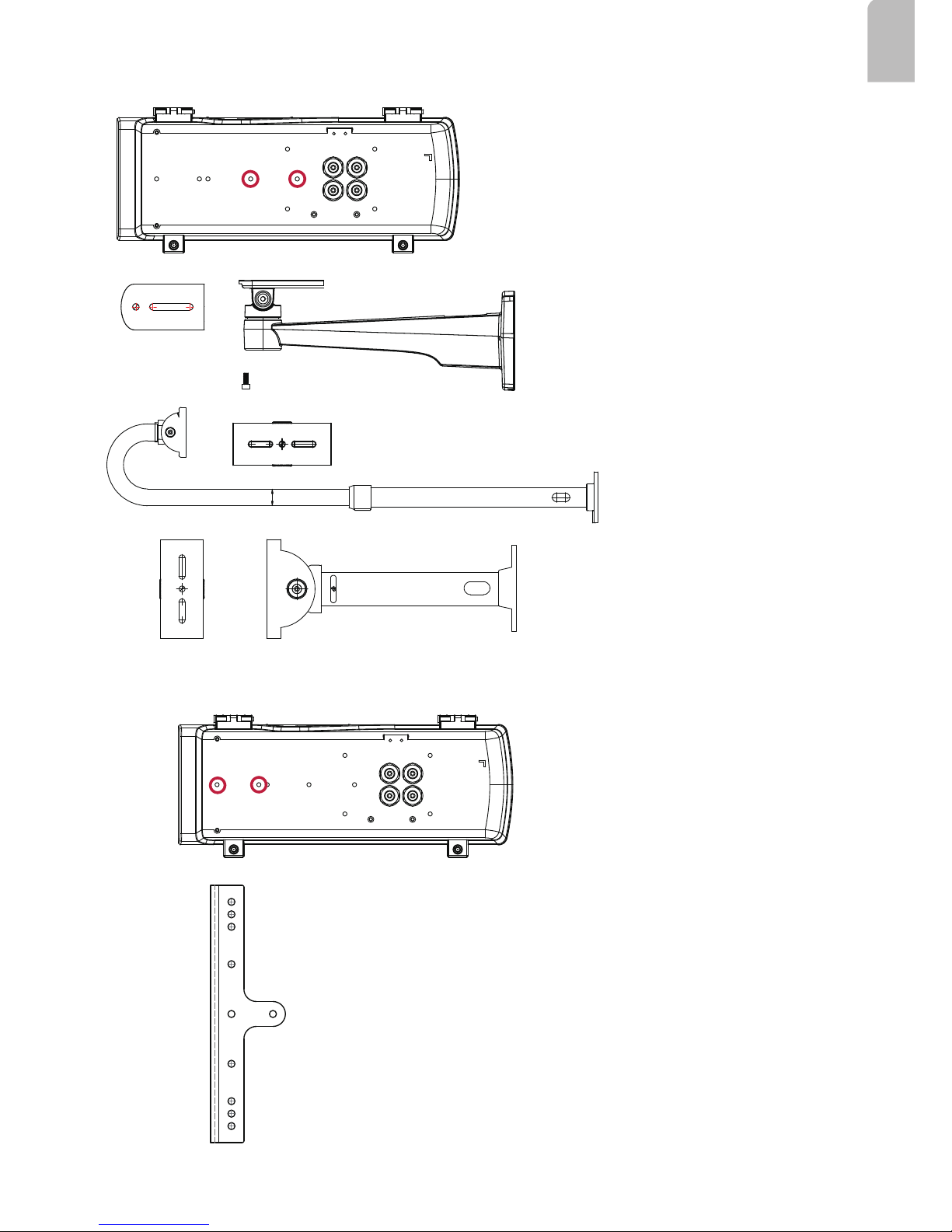

If using the AM-21E wall-mount bracket, secure the intersection bracket to the bottom

of the housing by driving two screws.

AM-11F

AM-811

AM-21D

AM-21E

Below are the mounting hole dimensions for the mounting brackets. Chances are you may

need to plan for the locations of the brackets.

Page 14

14

If using other mount brackets, use the included M6 screws to secure the housing to the

bracket. Use the mounting holes indicated below.

x2

thread

Safety

tether wire

8.

Install the housing to the wall-mount bracket by aiming and pressing the spring mortise,

and hook the bracket onto the groove in the spring mortise.

Secure the T30 anti-tamper screws

on the other side using the included

L-wrench.

Connect the included safety wire

between enclosure and bracket.

Page 15

15

English

The AM-21D wall-mount, AM-11E/F, and AM-811 pendant brackets use the two mounting

holes as indicated below.

AM-21D

AM-11E/F

AM-811

Another two mounting holes in the front can be used use an IR bracket, AM-219. The

bracket can be used to install external IRs.

AM-219

Page 16

16

9.

Adjust zoom and focus and open a web console with the camera to tune for the best image. When

zoom and focus is done, Close the top cover and fasten the top cover screws.

The housing can also be installed using the pole-mount or corner-mount options along with a power box

(AA-351, AA-352), outdoor PoE switch, or junction box.

CaMate IR illuminators

If external IRs are installed, you can contact VIVOTEK for a different type of waterproof connectors for

the 1/2" conduits. You can then route two of the conduits through the opening in the front of the bracket

to the corresponding connectors on the IR illuminators. The 24V power wires to the IR illuminators are

contained within.

Page 17

17

English

Use the included M10 hex socket screws to secure the power box to a pole-mount or corner mount

bracket.

M10

3/4” conduit

AM-314

AM-315

AM-414

AM-21D

AM-21E

Box:

AA-351

AA-352

AM-718

Outdoor PoE switch:

AW-GEU-083A-240

AW-GET-083A-120

AW-GET-123A-240

AW-GEU-086A-240

AW-GET-086A-120

AW-GET-126A-240

Speed Dome:

SD9361/62/63/64/65/66

SD83xx

AM-212/221/220/21C

The mounting hole denition is illustrated below. The same mounting hole pattern apply to all pole-

mount and corner-mount brackets.

Page 18

18

AM-21D

AM-21E

If a power box or outdoor PoE switch is applied, Use the following mounting positions for the camera

housings (via AM-21D and AM-21E).

10.

If an IR illuminator is preferred, remove the metal cover from underneath the housing.

Install the IR unit (AI-106, -107, -108, -109) by fastening 4 T30 anti-tamper screws. Note

that the bubber gasket should be in place when you install the unit.

Page 19

19

English

11.

Firmware congurable options:

Open a web console with the camera.

Use the Media > Focus function to tune for a best image focus on your target area.

If preferred, e.g., shooting fast moving vehicles, select the 60fps frame rate.

Page 20

20

In the night mode, check if the input signals are correctly detected. You may simulate the

night mode by blocking the IR unit's light sensor. Change the triggering parameters when

necessary.

Make sure that external IR is turned on in the night mode, and that the IR cut lter option is

synchronized with the digital input you connected.

Page 21

21

English

Appendix: RS485 Commands

VI

For housings that come with IR illuminators, wiper, and washer, commands can be

delivered via the RS485 protocol. The RS485 connection uses the Pelco D protocol.

Conguration parameters:

Baud rate 2400

Data bits 8

Parity None

Stop bit 1

Command format:

Byte1 Byte2 Byte3 Byte4 Byte5 Byte6 Byte7

Sync Addr CMND1 CMND2 DATA1 DATA2 CKSM

Addr range: 0x00 ~ 0xFE. CKSM: check sum is the last 8 bits of the sum of Byte2 through

Byte6.

Command Group 1:

Command Description Command (hexadecimal, "ox" is

ommited)

Note

VaIR Lens Stop FF 01 00 00 00 00 01 Pelco D - Zoom Stop

VAIR Lens Wide FF 01 00 40 00 00 41 Pelco D - Zoom Wide

VaIR Lens Tele FF 01 00 20 00 00 21 Pelco D - Zoom Tele

Wiper On FF 01 00 09 00 01 0B Pelco D – Aux 1 On

Wiper Off FF 01 00 0B 00 01 0D Pelco D – Aux 1 Off

Wiper and Washer On FF 01 00 09 00 02 0C Pelco D – Aux 2 On

Wiper and Washer Off FF 01 00 0B 00 02 0E Pelco D – Aux 2 Off

IR Led Force On FF 01 00 09 00 03 0D Pelco D – Aux 3 On

IR Led Force Off FF 01 00 0B 00 03 0F Pelco D – Aux 3 Off

Command Group 2:

Command Name Command (hexadecimal, ox

is ommited)

Note

Addr conguration FF 01 00 18 01 dd CKSM dd: 0x00 ~ 0xFE; for example, when addr

is 2, the command looks like FF 01 00 18

01 02 1C

IRMode FF 01 00 18 02 mm CKSM mm: IR mode

mm=0x02: Light Sensor Auto (Default)

mm=0x03: DI Trigger

mm=0x04: via RS485 Command

(When receiving IR Led Force On / IR Led

Force Off command, will switch to using

the IR Mode -RS485 Command)

Page 22

22

For example,

IRmode_Auto

FF 01 00 18 02 02 1D

IRmode_DI

FF 01 00 18 02 03 1E

IRmode_CMD

FF 01 00 18 02 04 1F

LightSensorGate FF 01 00 18 03 LL CKSM When the IR Mode Light Sensor Auto,

the Lux value to turn IR LED can be

congured.

LL: Lux, changes is made by

every10Lux

For example:

LightSensorGate = 100

FF 01 00 18 03 0A 26

LightSensorGate = 200

FF 01 00 18 03 14 30

The parameters of IR illuminator can be controlled via the RS485 connection. You can

enable the connection in

Conguration

>

PTZ

>

Mechanical

window. Select the defaults

for the IR illuminator: Pelco D, baud rate - 2400, Data bits - 8, Stop bit - 1, Parity - none.

Defaults for IR:

Pelco D

2400

8

1

none

Customizable IR control

Page 23

23

English

You can create custom command buttons by entering the Button name and the command

itself:

VaIR: The VAIR control include those on the IR Led and VaIR Lens.

There are 3 IR mode commands

IRMode = Light Sensor Auto (Default)

sensor lux reading < LightSensorGate - LED On

sensor lux reading >= (LightSensorGate + 10 Lux ) - LED Off

IRMode = DI_1 Trigger (IR triggered on by DI

DI _1 shorted DI –(Low) - LED On

DI_1 open (High) - LED Off

IRMode = controlled by RS485 Command (Pelco D – Aux 3 On/Off)

IR Led Force On - LED On

IR Led Force Off - LED Off

DO_1 as IR Status Feedback

LED On, DO_1 is grounded via MOSFET (DI- connected)

LED Off, DO_1 no input

VaIR Lens Zoom control

Dip Switch

4 congurations using the Dip Switch on the distribution board.

When Lens stops, its last position will be memoried,and when powered on again, lens will move to the

previous position. When powered on for the rst time, Lens will follow the DIP switch conguration.

Wiper & Wahser control)

DI_2 Trigger:

When DI_2 connected to DI- (Low), wiper and washer operate for 3 times and then stop.

Using RS485 Command –Wiper Only (Pelco D – Aux 1 On/Off)

Wiper On, wiper takes action

Wiper Off, wiper starts one operation and then stops.

RS485 Command –Wiper & Washer (Pelco D – Aux2 On/Off)

Wiper and Washer On, pumps and spray water with wiper action.

Wiper and Washer Off, spraying and wiping starts one operation and then stops.

DO2 used for spraying control

DO_2 connected to DI- via MOSFET - starts spraying.

Spraying stops, and the LED turns Off when DO_2 is not triggered.

Page 24

24

This page is intentionally left blank.

Loading...

Loading...