Vivax WFL-601, WFL-1001, WFL-801 Service Manual

'UXP:DVKLQJ0DFKLQH

Service Manual

9,9$;

:)/:)/:)/

1 ….........................................………………… ............

2 INTRODUCTION ………………....................…...........…..

2.1 C …………………….…………………………………….....

2.2 ………………….…………………………………………………...

2.3 ……………………………………………………............

2.4 …………………………………………………............

2.5 Introduction ……………….…………………………………………..

2.6 …………………………………………………………………………...

2.7F of s ……………………..........................................................

2.7.1 of a ……………………………………………………….

2.7.2 F of a ……………………………………..…..

2.7.3 F of b ……………………………………………………....

2.7.4 F of …………………………………………………….…....

2.7.5 F of c ……………………………………………………………..

2.7.6 m …………………………………………………………………..

2.7.7 F of less iron…………………………………………………..……….......

2.7.8 F of m ………………………………………..…….....

3 ………………………………………………………………………........

3.1 ……………………………………………………….....…………..

3.2 ……………………………………………………..……..…...

3.3 ……………………………………………………………...………………..

3.4 …………………………………………………………...………….

3.5 …………………………………………………………...……….…..

3.6 …………………………………………………………..……….

3.7 ……………………………………………………….....

4. …………………………………………………..

4.1 …………………………………………………………………………….

4.2 ………………………………………………………………………...

4.3 ………………………………………………………………………..

4.4 ……………………………………………………………………………….

4.5 ……………………………………………………………………………..

4.6 ……………………………………………………………………………...

4.7 ……………………………………………………………………………….

4.8 ………………………………………………………………………...….

4.9 ……………………………………………………………..……..……..…….

4.10 ………………………………………………………………..…..

4.10.1 …………………………………………………………………..…....

4.10.2 .....................................................................................................

4.11 ............................................................................................

4.12 ......................................................................................................

SAFETY PRECAUTION

OF WASHING MACHINE

haracteristics of product

Working principle

Summary model of product

Exploded view & List of parts

of control panel

Basic function

unction afety guard

Function void overflow

unction void heating without water

unction ubble checking

unction auto-balance

unction hild lock

Program emory

unction

unction otor self-protection

INSTALLATION

Select the location

Remove transport bolts

Adjust leg

Connect inlet pipe

Place outlet hose

Electrical connection

Installing and checking items

OVERVIEW OF MAIN COMPONENTS

Top cover kit

Drawer panel kit

Control panel kit

Front plate

Lower panel

Filter cover

Cabinet kit

Panel support

Absorber

Drum tub assembly

Rear tub kit

Drum kit

Detergent box hose

Inlet system

. ........

5

6

6

6

7

8

13

14

15

15

15

15

16

16

16

16

16

17

17

17

17

18

18

18

19

20

20

20

21

21

21

22

22

22

23

23

23

24

24

25

P.02

TABLE OF CONTENTS

26

27

27

27

28

28

29

29

29

29

30

30

31

33

34

35

35

36

36

36

36

37

37

37

38

38

39

39

40

40

40

41

41

41

42

42

42

43

43

25

4.12.2 ..................................................................................................

4.12.3 ........................................................................................

4.13 ....................................................................................................

4.13.1 .........................................................................................

4.13.2 .................................................................................................

4. 14 ...........................………………..............………………………….…….

4.15 ...........................………………..............…………………………………..

4.16 ...........................………………..............………………………….……

4.17 ...........................………………................................….

4.18 ...........................………………..............…………………………………...

4.19 ...........................………………..............…………………………………….

4.20 ...........................………………..............……………………………....

4.21 ...........................………………..............……………………………….…..

4.22 ...........................………………..............……………………………....

4.23 ...........................………………..............……………………....

4.24 Sub- ...........................………………..............………………………..

4.25 ...........................………………..............………………..

5 ...........................………………..............…….

5.1 ...........................………………..............……………………..

5.2 ...........................………………..............……………………….

5.3 ...........................………………..............…………………..

5.4 ...........................………………..............…………………….

5.5 ...........................………………..............………………………

5.6 ...........................………………..............………………….….

5.7 ...........................………………..............………………………….

5.8 ...........................………………..............………………….….

5.9 ...........................………………..............………………….

5.10 ...........................………………..............……………………

5.11 ...........................………………..............……...……….

5.12 ...........................………………..............……………………..….

5.13 ...........................……………….......……………...

5.14 ...........................………………..............…………..……...

5.15 ...........................………………..............…………………………..

5.16 ...........................………………..............…………….……..

5.17 ...........................………………..............…………………….…..

5.18 ...........................……………..………………...

5.19 ...........................………………..............……………..……..

5.20 ...........................………………..............………………...

5.21 ...........................………………..............…………...

4.12.1 ..............................................................................................Pressure switch

Inlet valve

Detergent box kit

Drain system

Drainage system

Drain pump

Door kit

Gasket

Door lock

NTC temperature sensor

Heater

Filter

Condenser

Motor

PCB panel

Main harness assy

harness assy

Bill of damageable parts

UNPACKING WAYS OF MAIN PARTS

Undo the back cover

Undo the top cover

Undo the control panel

Undo the lower panel

Undo the door lock

Undo the front panel

Undo the gasket

Undo the PCB panel

Undo the detergent box

Undo the inlet valve

Undo the pressure switch

Undo the pulley

Undo the upper counterweight

Undo the absorber pin

Undo the filter

Undo the drain pump

Undo the heater

Undo the NTC temperature sensor

Undo the door glass

Undo the panel support

Undo the drum tub assembly

P.03

TABLE OF CONTENTS

5.22 ...........................………………..............……………………...

5.23 ...........................……….…………………………..

5.24 ...........................………………..............…………………………

6 ……...........................………………..............……………......

6.1 ...........................….....………………

6.2 ...........................………………..............……………………....

6.3 ...........................…….....…....…....…......

6.4 ...........................………..……………

6.5 ...........................………………..............…………………………........

6.6 ...........................………………......………….

6.7 ...........................………………..............…………………………..........

6.8 ...........................………………..............…………………………….

7 T ...........................……………….....………………......

7.1 .......................……………………….…..

7.2 ...........................………………..............……………..

Undo the absorber

Undo the lower counterweight

Undo the motor

TROUBLESHOOTING

Circuit program & wiring connection figure

PCB wiring figure

Schedule of failure alarm & its disposal

Electrical parts working & testing principle

Self-check

Marketing-show (no-water testing)

Fault tree

Service tools

ECHNICAL SPECIFICATION

Product technical specification parameter

Table of washing procedure

TABLE OF CONTENTS

44

44

44

45

45

46

47

50

55

55

56

64

65

65

66

P.04

1.SAFETY PRECAUTION

P.05

1.Do not try to repair the machine by yourself. The machine may be damaged and its life

be shortened. What is worse, it will injure yourself.

2.Pull out its plug from the power socket before maintenance. Electricity!

3.Do not use several power plug with one socket.

To avoid fire, don’t use any socket with its actual current more than rated current.

4.Please check the power plug and socket whether damaged or not.

To avoid an electrical shock and fire, the power plug and socket should be replaced if

they are damaged.

.Don’t try to clean up the washing machine with water, or else, it’s possible to cause an

electrical shock or fire and shorten its life.

6.Forbid the harness contact with water for avoiding wet and don’t extend it during

maintenance. Don’t twist the harness to avoid it distorted.

7.Please clean up the dirt and dust on the surface of the cabinet, harness and connection

parts during maintenance.

Please avoid fire because of the electric leakage of harness.

8.Check electrical parts, harness whether they have become moist and replace them if

they are wet.

9.Check all parts of the machine and make sure to keep them in good condition after

maintenance.

10.Fasten upon the power plug and pull it out .

Be careful of a fire and electric shock when power cord is damaged.

11.Pull out its power plug when this machine doesn’t work.

Be careful of an electric shock and fire because of levin.

12.Don’t put tinder or sprayer beside the washing machine.

Be careful of a fire and explosion because of electric spark.

13.Don’t put a basin of water or wet clothes on the washing machine.

It is possible to cause an electric shock or fire if water from wet clothes leaks in to

the washing machine.

14.Do not place the washing machine in the place where it can be exposed to rain and

snow. Or else, it may cause an electric shock or fire, and therefore shorten its life.

15.Don’t press the button with sharp items such as nail, screw etc. Or else, it may cause

an electric shock or other damages.

16.This machine should be placed on the horizontal ground and installed correctly.

The machine is liable to shift on the gradient ground.

17.If the harness is damaged, it should be replaced completely.

18.It is necessary to put a mat on the floor and recline down the washing machine along

its side when repair it.

It is possible to damage the electrical components if the front of the washing machine

is placed at the ground.

19.During changing the heater of this machine, please check whether it is fixed on the

blanket correctly and whether the screw is fastened tight or not.

5

2.INTRODUCTION OF PRODUCTS

P.06

2.1 haracteristics of product

It is the latest designed machine, which have many advantages such as fashion, large

rated washing capacity and large washing range. Specifically, its feature is as following:

1.Large washing range from cotton to wool and silk.

2.Gentle washing: no twist and little abrasion.

3.Electron auto-balance system, that is, the PCB panel controls the speed of spin and

ensures uniform distribution of clothes to reduce the wear of textile caused by its

vibration.

4.The drum of this machine is made of stainless steel of high quality and the cabinet is

durable.

5.The maximum temperature of washing water could be controlled independently and it

is up to 90℃.

6.Unique washing methods: rain, soak, throwing-knocking knead and so on, which can

wash clothes uniformly and improve washing performance.

7.Safety guard: water level control, door lock, child lock etc.

8.Anti-crease function: there is an automatic anti-crease and soak function in the

synthetic program, that’s, it doesn't drain at the end of washing and leave the clean

textile in the water of the drum to achieve the function of less crease, especially silk.

9.Function of adjusting spin speed : select different spin speed according to textile.

10.Electronic water distribution system: The machine uses PCB to control the inlet valve

and distribute water properly at the different stages and dissolve detergent and softener

absolutely to improve washing performance.

2.2.Working principle

Drum washing machine wash clothes mainly in virtue of mechanical friction, chemical

force and temperature force. When the machine works, the motor runs clockwise several

seconds and runs anti-clockwise several seconds to drive the drum whose three lifters

hold up the clothes pressing against the inside of the drum. When clothes rise close to the

top, because the speed of motor is low and the centrifugal force is not enough to overcome

the gravity, clothes fall and impinge with washing liquid (like manual throwing-knocking

washing). The second force is the extrusion force of clothes (like manual extrusion). The

last force is the friction between clothes, clothes and lifters(like manual knead). To

improve washing performance, automatic drum washing machine could automatically

heat the washing liquid, whose temperature can be adjusted from 30℃ to 90℃. The high

temperature quickens the movement of the numerator of the washing liquid and speedups

C

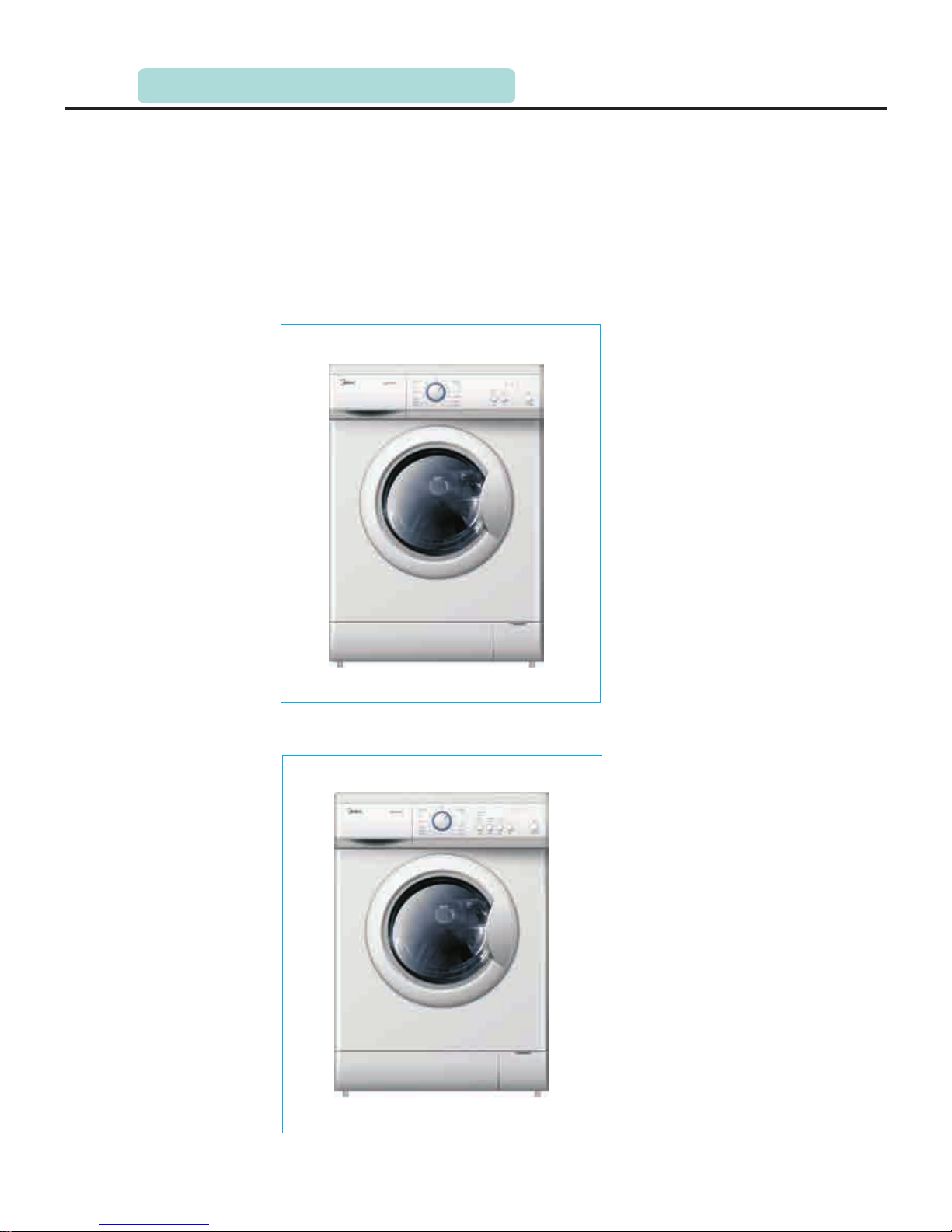

2.3 Summary model of product

P.07

MG52-6001

MG52-6510/8002

2.Overview of products2.INTRODUCTION OF PRODUCTS

the Chemical reaction. In a word, drum washing machine destroys bonding force between

dirt and clothes in virtue of intergraded force of water, detergent and mechanical force, to

clean away the dust.

01

02

03

04

05

06

07

08

09

10

12

11

13

14

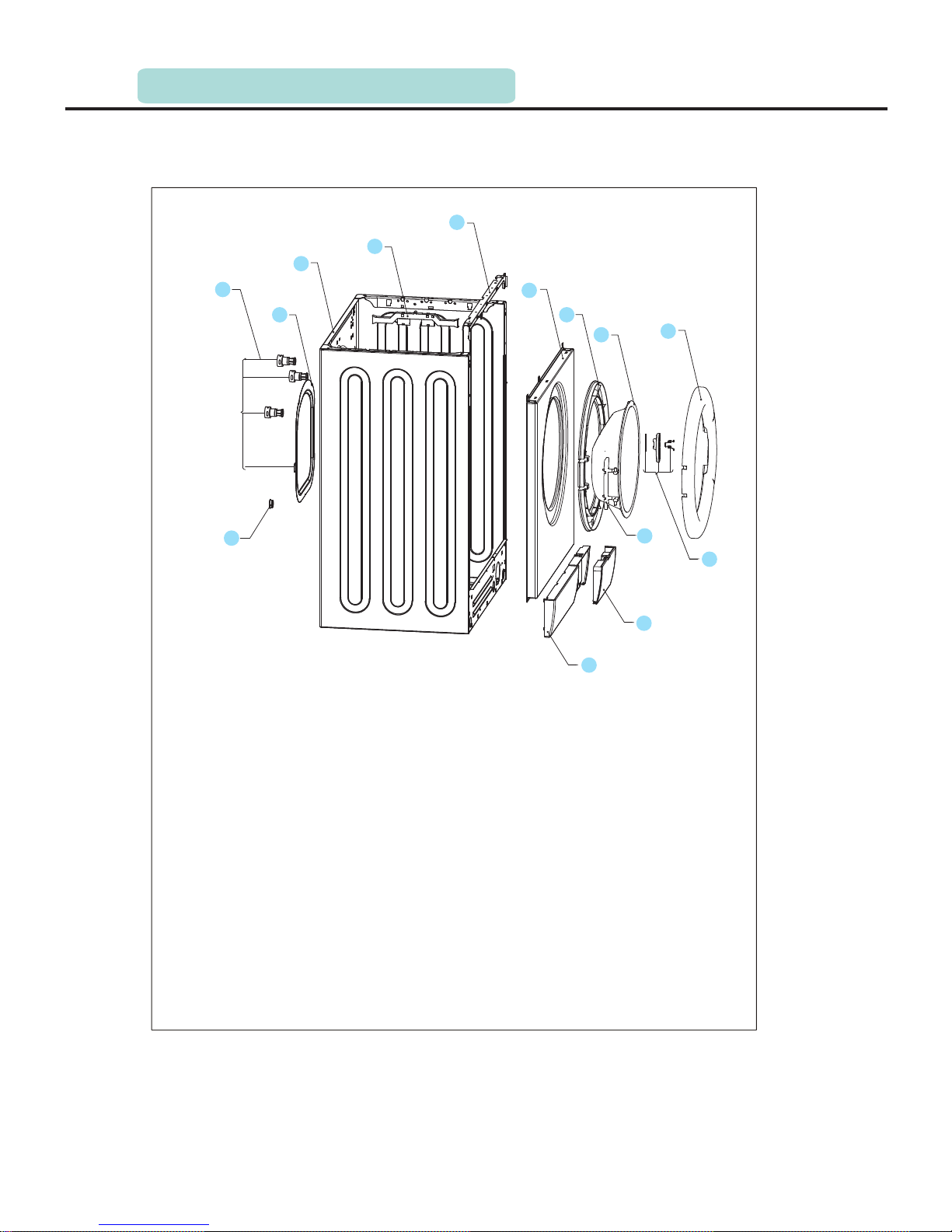

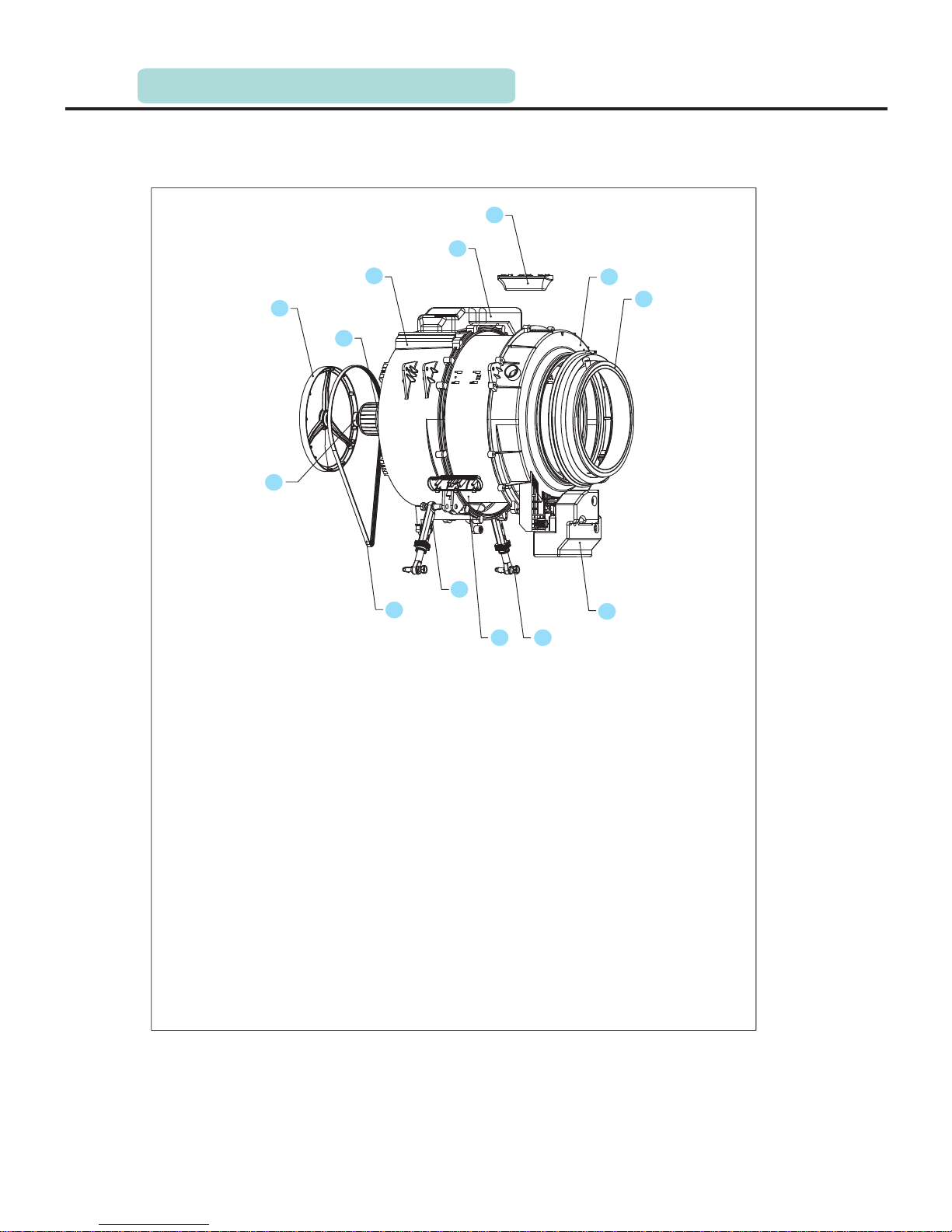

2.4 Explored & list of partsview

P.08

Mode l MG52-600 1/ /MG52-8002MG52 -6510

01 Transport bolt kit

02 Hole plug 09 Door glass

03 Back cover 10 Outer door

04 Cabinet kit 11 Door handle

05 Cable channel 12 Hinge

06 Panel support 13 Filter cover

07 Front plate 14 Lower panel

08 Inner door

2.INTRODUCTION OF PRODUCTS

15

16

17

18

19

20

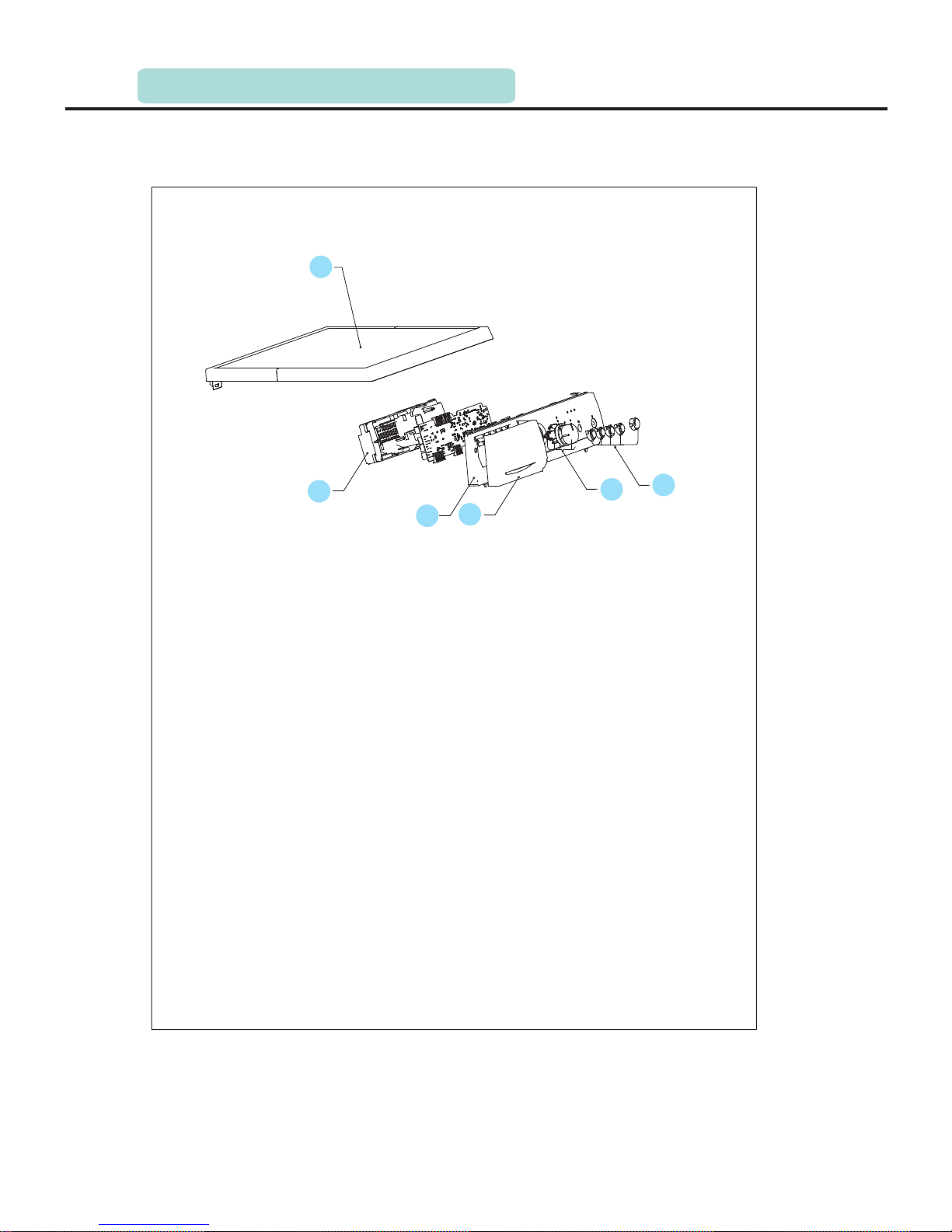

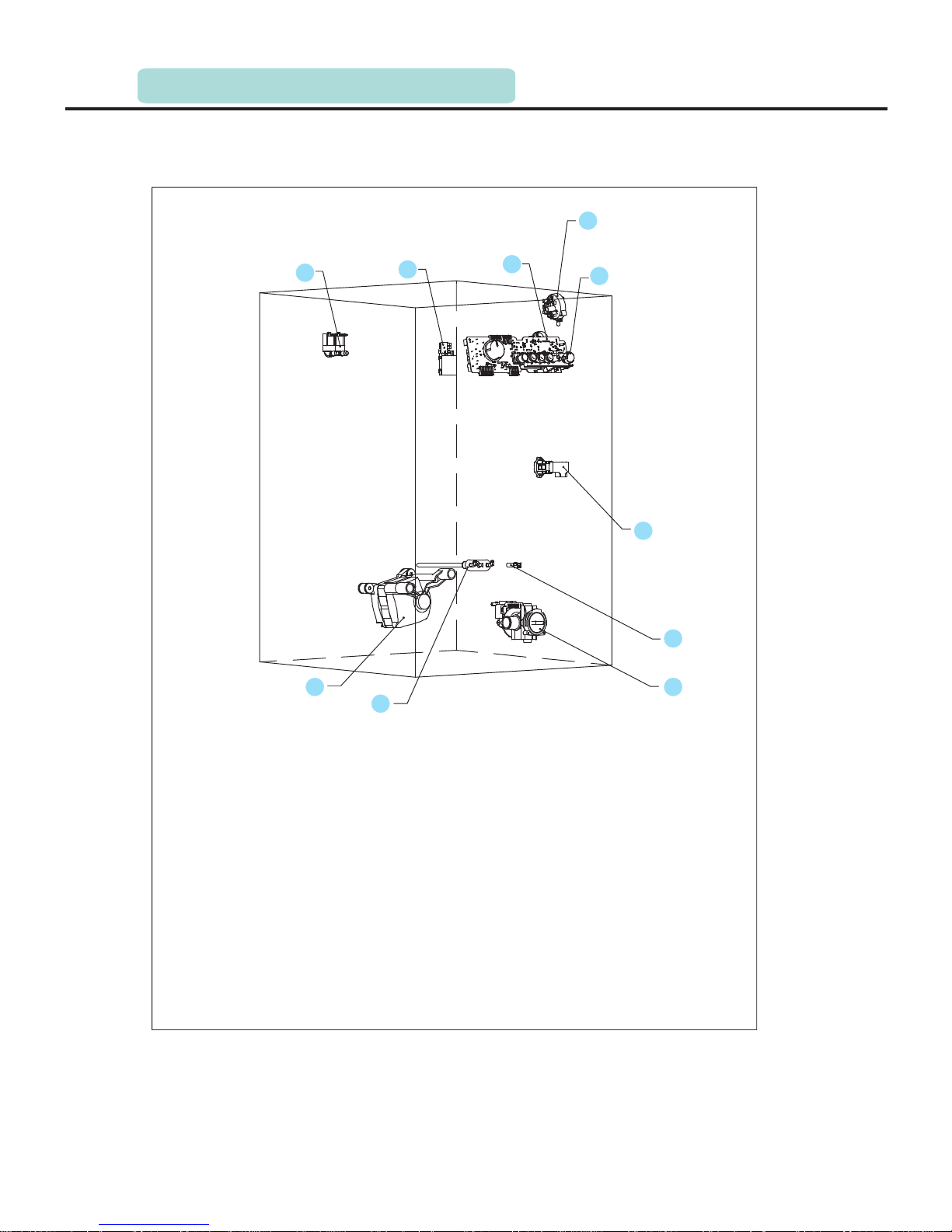

P.09

Mode l MG52-600 1/ /MG52-8002MG52 -6510

2.4 Explored & list of partsview

15 Top cover kit

16 E-housing

17 Control panel

18 Drawer panel

19 Knob

20 Push button

2.INTRODUCTION OF PRODUCTS

21

22

23

24

25

26

27

29

28

30

31

32

33

P.10

Mode l MG52-600 1/ /MG52-8002MG52 -6510

2.Overview of products

2.4 Explored & list of partsview

21 Pulley

22 Bearing hosing

23 Rear tub

24 Upper counterweight

25 Lifter

26 Front tub

27 Gasket

28 Lower counterweight

29 Absorber pin

30 Inner drum assy

31 Absorber

32 Belt

33 Ball bearing 62032

2.INTRODUCTION OF PRODUCTS

34

35

36

37

38

39

40

41

42

43

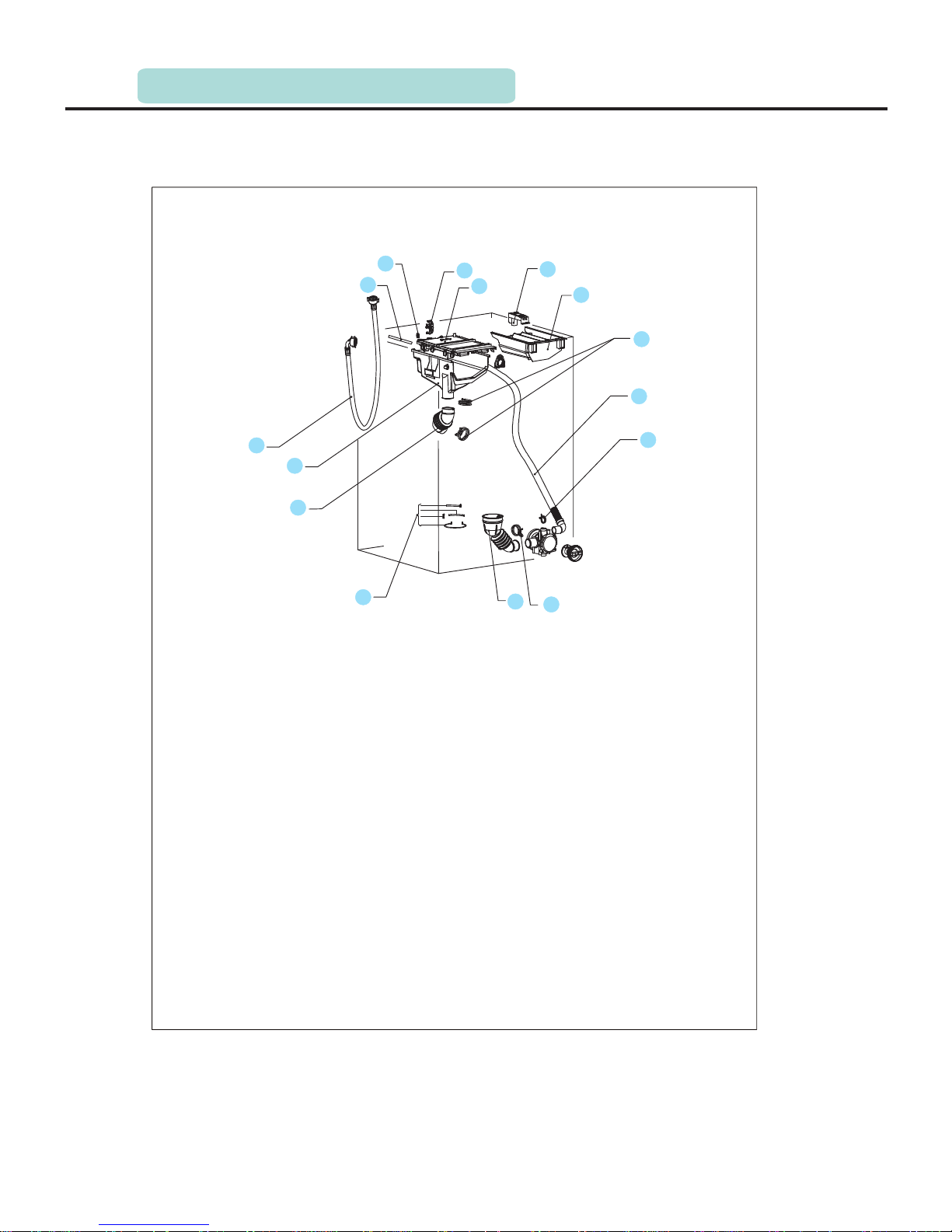

P.11

Mode l MG52-600 1/ /MG52-8002MG52 -6510

2.4 Explored & list of partsview

34 Inlet valve

35 Filter

36 PCB

37 Pressure switch

38 Silicon

39 Door lock

40 NTC

41 Drain pump

42 Heater

43 Motor

2.INTRODUCTION OF PRODUCTS

45

44

46

47

48

49

50

51

52

53

54

55

56

57

58

P.12

Mode l MG52-600 1/ /MG52-8002MG52 -6510

2.Overview of products

2.4 Explored & list of partsview

44 Inlet hose

45 Inlet hose clamp

46 Outlet hose support

47 Detergent box-upper

48 Softener cap

49 Drawer

50 detergent hose clamp

51 Outlet hose

52 Hose clamp

53 Hose clamp

54 Drain hose

55 Hose clamp

56 Detergent box hose

57 detergent box

58 Inlet hose assy

2.INTRODUCTION OF PRODUCTS

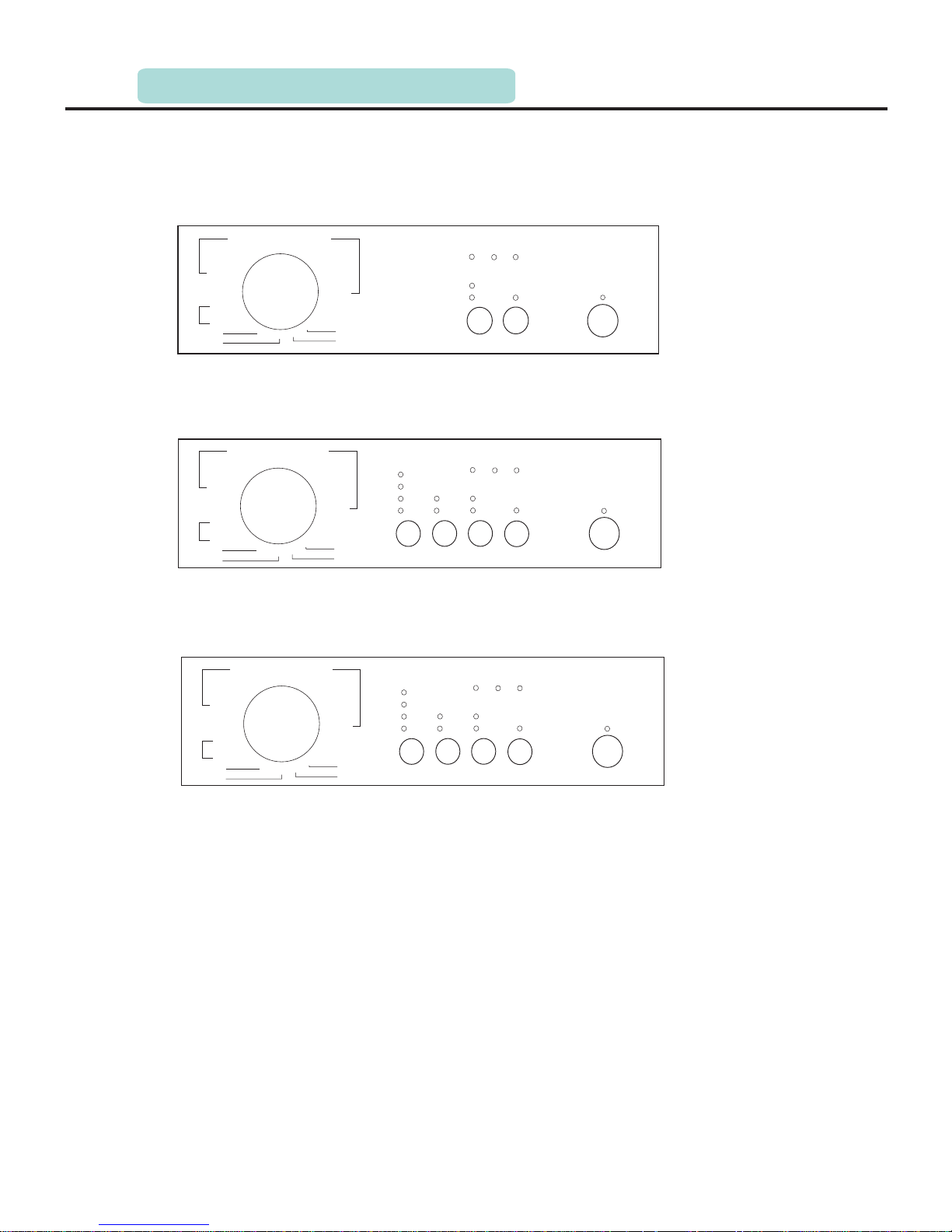

2.5 Introduction of control panel

MG52-8002

MG52-6510

P.13

MG52-6001

1.Drawer Panel: put detergent into detergent box by pulling out Drawer.

2.Control Panel: manipulate washing machine with the panel.

3.Knob: revolve this knob and select washing program accordingly ( cotton, synthetic,

wool, delicate, quick) can be selected circularly.

4.Function Button: achieve functions of speed selection, temperature selection, number

of rinse etc.

5.Start/Pause Button: press this button to restart or pause will be done.

6. Display screen: show washing process and relative error information.

START/PAUSE

FUNC TION2FUNC TION

1

INTE NSIVE

WASH SPINRINS E

PRE

WASH

ECO WAS H

60

30

40

40

40

60

90

30

SILK

WOOL

WASH

RINS E

SPIN

DRAI N

STOP

COLDCOLD

COLD

COTT ON

QUIC K

SYNT HETIC

MG5 2-60 01

WASH

RINSE

SPIN

60

30

40

40

40

60

90

30

SILK

WOOL

WASH

RINSE

SPIN

DRAI N

STOP

COLDCOLD

COLD

COTTON

QUICK

SYNT HETIC

INTE NSIVE

ECO WAS H

BABY CARE

LESS

IRON

400

600

800

NOSP IN

SPEE D

PRE

WASH

FUNC TION

1

FUNC TION

2

MG52 -8002

START/PAUSE

WASH

RINSE

SPIN

60

30

40

40

40

60

90

30

SILK

WOOL

WASH

RINSE

SPIN

DRAI N

STOP

COLDCOLD

COLD

COTTON

QUICK

SYNT HETIC

INTE NSIVE

ECO WAS H

BABY CARE

LESS

IRON

400

500

600

NOSP IN

SPEE D

PRE

WASH

FUNC TION

1

FUNC TION

2

MG52 -6510

START/PAUSE

2.INTRODUCTION OF PRODUCTS

P00 P08

P01 P09

P02 P10

P03 P11

P04 P12 Silk

P05 P13

P06 P14

P07 P15

Stop Rinse

Cotton cold Wash

Cotton 40℃ Wool cold

Cotton 60℃ Wool 40℃

Cotton 90℃ 30℃

Quick 30℃ Synthetic 60℃

Drain Synthetic 40℃

Spin Synthetic cold

Programs corresponding with the encoder knob of MG52-6001/6510/8002

P.14

2.6 of basic

1.Cotton

You can select this program to wash the daily washable clothes. The washing period is

quite long with quite strong washing intensity. It is recommended to wash the daily

cotton articles, such as: bed sheets, quilt covers, pillowcases, gowns, underwear etc.

2.Synthetic

You can select this program to wash the quite delicate clothes. The procedure is shorter

compared with that for cottons and the washing intension is quite gentle. It is

recommend to wash synthetic articles, such as: shirt, coats, blending. As for curtains

and laced textiles, the program “Synthetic 40℃”should be selected. While washing the

knitting textiles, less detergent due to its loose string construction and easily forming

bubbles.

3.Wool

You can select this program to wash the wool textiles labeled “machine wash”. Please

select the proper washing temperature according to the label on the articles to be

washed, and furthermore, the proper detergent shall be selected for wool textiles.

4.Silk

You can select this program to wash your silk clothes. It is gentler than synthetic

program due to less speed. It’s recommend to the textiles to be washed softly.

5.Quick

This program is suitable to wash few and not very dirty clothes quickly.

6.Intensive

To improve the washing performance, main wash time is increased. Except single

quick, wash, drain and spin programs, the other procedure can select intensive function.

It is recommend to wash clothes for babies or persons with allergic skin.

7.Eco-wash

As for few clothes, heating temperature and water quantity are reduced during wash/pre

wash program and water quantity is reduced during rinse procedure so as to achieve the

Function

2.INTRODUCTION OF PRODUCTS

P.15

energy to save. It should be set effectively before work, and once the cotton synthetic

and silk program, which have this function runs, it can’t be paused and reset.

Only cotton, synthetic and silk programs have this function.

8.Pre-wash

One washing program is added before main wash to improve the washing performance.

Only cotton program has pre-wash function.

9.Baby care

This is to increase the level of rinse water.

Baby care function can make the rinse performance better to protect the baby skin.

Except single wash, rinse, drain and spin program, the other programs can select baby

care function.

10.Spin/no spin function

The last spin speed can be selected and set.

As for model MG52-6001, the defaulted speed is 600rpm.

As for model MG52-8002, the rotating speed’s range selected through spin button can

be no spin-400-600-800rpm.

No spin means the drum rotating speed is zero after the last spin program complete its

drain stage.

During rinse, its spin speed is unchanged.

11.Wash

Single wash program.

12.Rinse

Single rinse program.

13.Spin

Single spin program. Soap liquid or rinse water shall be drained before spin.

14.Drain

During draining procedure, the clothes will only be drained but no spin to protect the

delicate and soft textiles.

2.7 Function of safety guard

2.7.1 Function of avoid overflow

When the water level is up to the abnormal height in the drum(the set warning level),

washing machines will automatically switch on drainage pump to drain by pressure

switch, even if the inlet valve failure which can not stop the inflowing water, the

washing machine will not be in the overflow. At the same time, the pressure switch will

feed back to control panel a signal of fault and the washing machine will alarm.

2.7.2 Function of avoid heating without water

When there is no water or not enough to submerge the heater, and at the same this

machine is in fault, the fuse in the heater will melt to cut off the heater and avoid danger.

2.7.3 Function of bubble checking

About wiping off bubble: When the water level is lower than level I during draining, the

2.INTRODUCTION OF PRODUCTS

P.16

spin function will start. If there is over much bubble in the drum, it will increase the

pressure in the drum and switch on the pressure switch , at the same time the PCB panel

begin the bubble checking function and clean it away.

2.7.4 Function of auto-balance

1. This function will start before spin and after drainage.

2. Drum reverses the speed of 50 rounds per minute in the first six seconds.

3. In the next 10 seconds, the rotational speed from 50r/m to 100r/m slowly.

4. In the following 18 seconds, the washing machine rotates in the speed of 100r/m and

estimates the degree of imbalance according to the signal of the motor.

5. If the degree of imbalance is more than the setting value, the auto-balance system will

feed back imbalance information of 12 cycles.

2.7.5 Function of child lock

To avoid the fault operation by children and then making this wash procedure work

abnormally, you can select this function in which other buttons can't be work except knob.

As for MG52-6001, press the second button and the first button at the same time for 2.5

seconds from left , the buzzer rings and the pre-wash button, auxiliary function button,

start/stop and knob are locked. And then, press them at the same time for another 2.5

seconds, the buzzer rings again and the locked buttons are unlocked. Child lock function

is cancled after the whole program is completed when child lock is effective, press the

non-child lock button and then buzzer rings to remind that operation is invalid. As for

MG52-6510/8002, press the second button from left and the pre-wash button at the same

time for 2.5 seconds, the buzzer rings and locks the pre-wash button. Other steps is same

as MG52-6001.

2.7.6 Program memory

If the running washing machine is powered off, its washing procedure will be stored in

chips. When the power is on, washing machine will run from the memorying procedure.

If washing machine is powered off during spin, the machine will spin from the start of the

procedure again.

2.7.7 Function of less iron

Less iron(anti-crease) means washing machine neither drains nor spins, and what is

more, it will run every several seconds to spread out textiles. Less iron can be used in all

procedures but wash, rinse, drain and spin.

NOTE: To achieve anti-crease completely, you have to iron them.

2.7.8 Function of motor self-protection

When the washing machine works in the poor conditions, the enormous load on the motor

will make its temperature increase and its performance decrease even burned motor.

When its temperature increases to a set value, the thermal protector of motor will

automatically cut off the power supply to achieve self-protection and alarm.

2.INTRODUCTION OF PRODUCTS

P.17

3.1 Select the location

1. Washing machine must be placed in the formation, firm, dry and well-ventilated places.

2. Washing machine need a certain space and the shortest distance from the wall is not

less than 12cm generally.

3. Don't place the washing machine in the condition of freeze-easy.

4. Washing machine should be placed away from heat, sunlight to prevent pieces of

plastic and rubber become aging.

5. Do not put the washing machine in the place where it can be exposed to rain and snow.

6. It is not suitable to use the washing machine on vessels, aeroplanes and vehicles.

7. To avoid walling up the vent, please don't put washing machine on the carpet.

NOTE: Washing machine should be put in the room which have enough space, such as its

door can be fully opened.

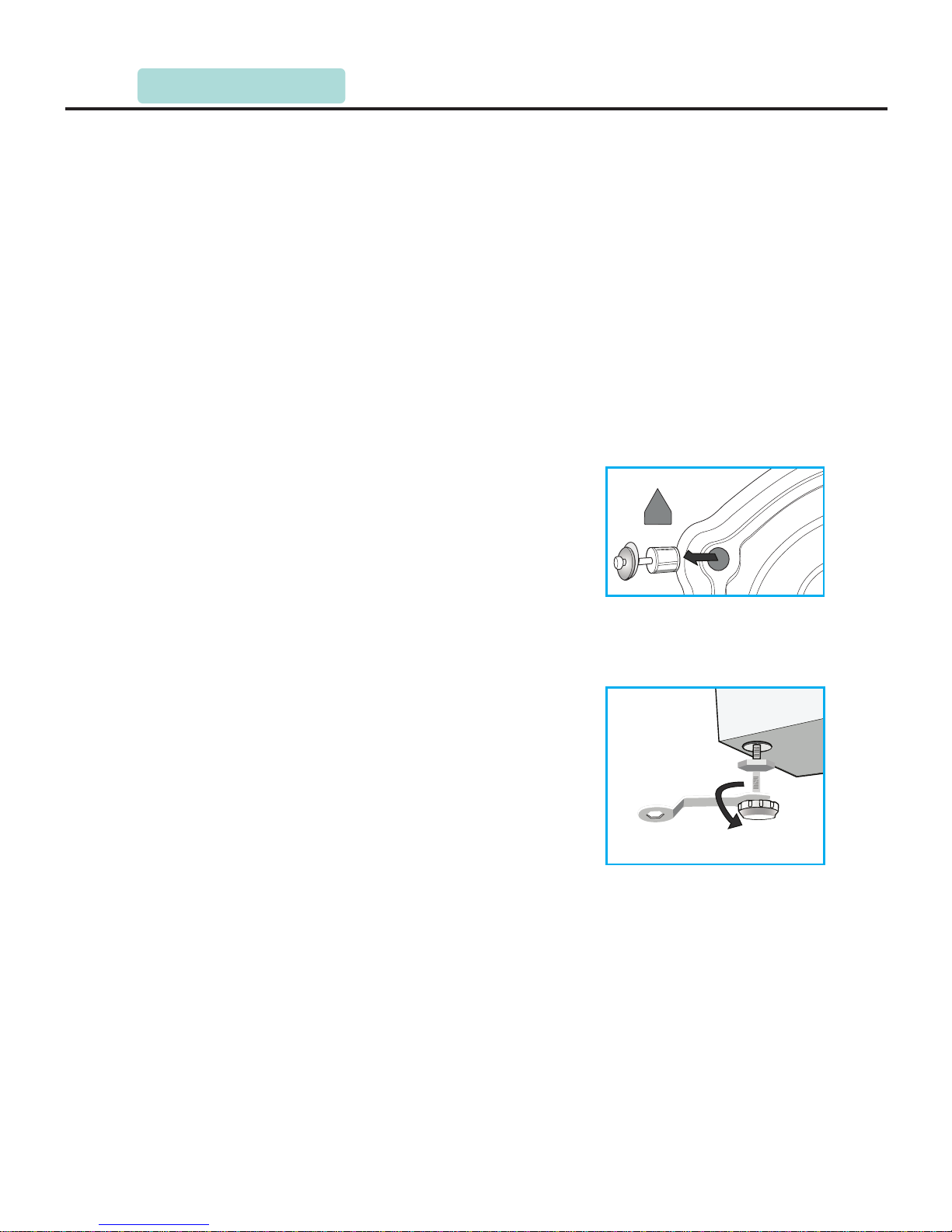

3.2 Remove transport bolts

Before using this washing machine, transport

bolts must be removed from the backside of

this machine.

Please take the following steps to remove the bolts:

1. Loosen all bolts with spanner and then

remove bolts.

2. Stop the holes with transport holes plugs.

3. Keep the transports bolts properly for future

use.

3.3 Adjust leg

1. When positioning the washing machine,

please first check whether the leg are closely

attached to the cabinet. If not, please turn them

to the original position with hand or spanner

and tighten them with spanner.

2. After position washing machine, press four

corners on top cover of this machine in

sequence. If the machine is not stable, this

leg should be adjusted.

3. To ensure the positioning status of washing machine, loosen the lock nut with spanner

and turn the leg with hand until it closely attaches to floor. Press the leg with one hand

and fasten the nut closely to the cabinet with the other hand.

4. After being locked properly, press four corners again to make sure that they have been

adjusted properly. If it is still unstable, above-mentioned steps shall be repeated by 2

to 3.

NOTE: In principle, there is only one loosen leg at most. If this leg is located at back of

this machine and it is inconvenient for adjustment, then another leg at its diagonal position

can be adjusted to achieve the same effect.

3.INSTALLATION

100cm

140cm

Min60cm

Max100cm

110c m

P.18

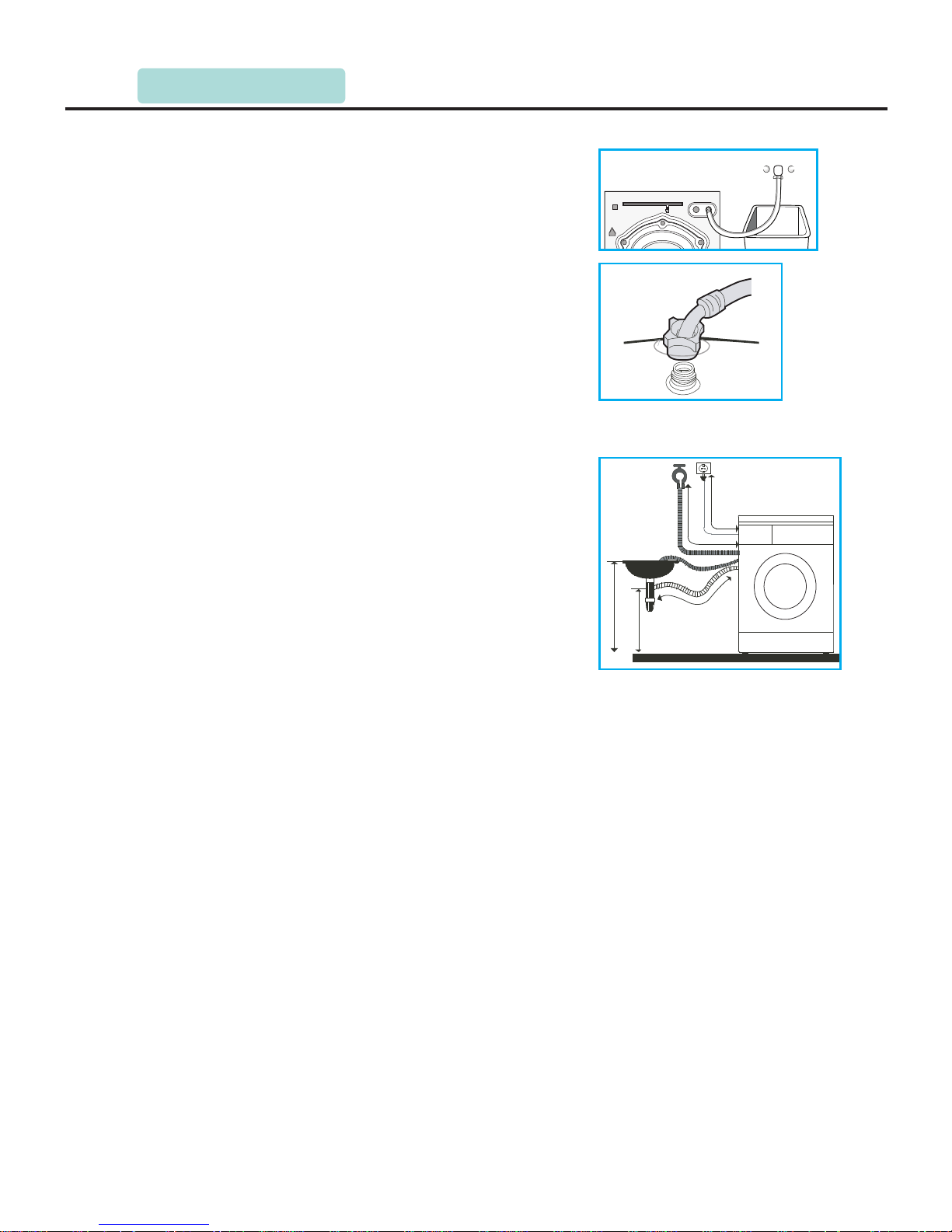

1.Connect the elbow to tap and fasten it clockwise.

2.Connect the other end of inlet pipe to the inlet

valve at the backside of washing machine and

fasten the pipe tightly clockwise.

NOTE: after connection, if there is any leakage with

hose, then repeat the steps to connect inlet pipe. The

most common type of tap shall be used to supply

water. If tap is square or too big, then standard tap

shall be changed.

3.4 Connect inlet pipe

Connect the inlet pipe as indicated in the figure.

3.5 Place outlet hose

There are two ways to place the end of outlet hose:

1. Put it beside the water trough.

1) Washing machine shall be located nearby the

slipway’s inlet so that it is convenient for this

machine to drain.

2) Take out splint from PE bag and fasten it on the

end of the drain hose, and then put it beside the

water through or the slipway’s inlet.

NOTE: clean up the filter of outlet valve, don’t fold it,

don’t clog the inlet/outlet hose to make sure them

expedite to inlet or drain.

2. Connect it to the branch drain pipe of the though.

3.6 Electrical connection

1. The maximum current through the unit is 10A when this machine heats the washing

liquid, and please make sure that your household power supply system (current, power

voltage and wire) can meet the normal loading requirements of the electrical appliances.

2. Please connect the power to a socket which is correctly installed and properly earthed.

3. Please make sure your household power voltage is same as that of the machine’s rating

label.

4. Power plug must match the socket and cabinet must be properly and effectively earthed.

5. Do not use multi-purpose plug or socket as extension cord.

6. Do not connect and pull out plug with wet hand.

7. When connect and pull out plug, hold the plug tightly and then pull it out. Do not pull

power cord forcibly.

8. If power cord is damaged or has any sign of being broken, special power cord must be

gotten from its manufacturer or service center for replacement.

9. Has been positioned, the plug of Washing machine should get to socket properly and

effectively.

3.INSTALLATION

P.1 9

3.7 Installing and checking items

1. Check whether remove transport bolts or not.

2. Check whether the socket is installed and properly earthed.

3. Check whether this machine is level or not.

4. Check whether inlet pipe/outlet pipe is wringed or not .

5. Guide user to operate the washing machine and make sure no leakage and no abnormal

sound.

NOTE: please read instruction manual carefully to ensure the proper operation of this

washing machine.

3.INSTALLATION

4.OVERVIEW OF MAIN COMPONENTS

P.20

4.1 Top cover kit

1. Parts component

Top cover is made up of hyperbaric plate, top

cover-f and top cover-b. Both top cover-f and

top cover-b are ABS materials. Front of top

cover lock to the panel support of this machine's

cabinet, and back of top cover fastnesses to the

U-type backside of cabinet with screw.

Two-piece of hyperbaric plate is covered by

melamine which is waterproof and fireproofing,

and furthermore, the dirt and smudge on its

surface could be erasured easily.

2. Summery about function

The two screws fixing the top cover screw into the

cabinet to avoid loosening.

Chang and maintain PCB kit, pressure sensor,

filter, inlet valve after unpack top cover kit.

4.2 Drawer panel kit

1. Drawer, Drawer panel and Softener cap

Drawer panel kit is consist of drawer, drawer panel and softener cap. Drawer panel is

clipped on the face of draw without screw and softener cap in the center of drawer.

According to the need of costumers, different detergent could be placed in three boxes

of drawer respectively, and concretely the right one is pre-wash box, the left one is main

wash box and the center one is softener box. Certainly user can put decolourant, spicery

and softener in the center one to improve washing performance.

After water fill in the drum through drawer, siphon structure of inlet system ensure that

drawer have no remanent water or wash liquid.

Drawer can be taken out and cleaned up: Unfold the drawer up to 10cm, and then take

out the drawer at the same time press the elastic plate to avoid injuring the softener box.

What is noticeable: during cut the softener cap in the detergent box, you have to press

the protuberant support of its end.

During the washing machine’s in work, it should remind user of closing the drawer, or

else, the detergent can’t be flowed into the drum completely, and what is worse water

may flow out from the outside of the cabinet.

2. Draw panel deck

The material of drawer panel kit is PMMA.

Loading...

Loading...