Air Handler

Owner's Manual

Commercial Air Conditioners

Thank you for choosing Commercial Air Conditioners, please read this

owner’s manual carefully before operation and retain it for future reference.

Contents

1. Specications of the Air Handlers ...................................................................................... 1

1.1 Physical Dimension

1.2 General Information

2. Pre-Installation Instruction

2.1 Checking Product Received

2.2 Before Beginning Installation

2.3 Codes & Regulations

2.4 Replacement Parts

3. Important Safety Instructions

3.1 Recognize Safety Symbols, Words, and Labels ...................................4

3.2 Unit Inspection

4. Location

5. Ductwork ..................................................................................................6

6. Electric Heat

.....................................................................................................5

..............................................................................................6

...............................................................................1

............................................................................... 1

........................................................................ 3

..................................................................3

................................................................ 3

............................................................................ 3

............................................................................... 4

................................................................... 4

...................................................................................... 5

6.1 “VAFd” Electric Heater Kits Available

6.2 “VAFd” Heater Kits Installation

7. Electrical Supply Wire and MOP

7.1 Inspection of the Building Electrical Service

7.2 Wire Sizing

7.3 Maximum Overcurrent Protection (MOP)

7.4 Electric Connections-Supply Voltage

.........................................................................................10

.............................................................8

...............................................................9

..................................................8

................................................. 11

......................................... 9

........................................... 11

7.5 Schematic Wiring Diagram ................................................................. 12

7.6 Thermostat Wiring

8. Refrigerant Pipe.......................................................................................13

8.1 Piping Preparation

8.2 Special Instructions

9. Drain Pan Ret

10. Condensate Removal

11. Start-Up Procedure

12. Regular Maintenance

..............................................................................13

.............................................................................. 13

............................................................................14

........................................................................................15

............................................................................ 16

............................................................................... 16

...........................................................................17

Air Handler

C

E

1. Specications of the Air Handlers

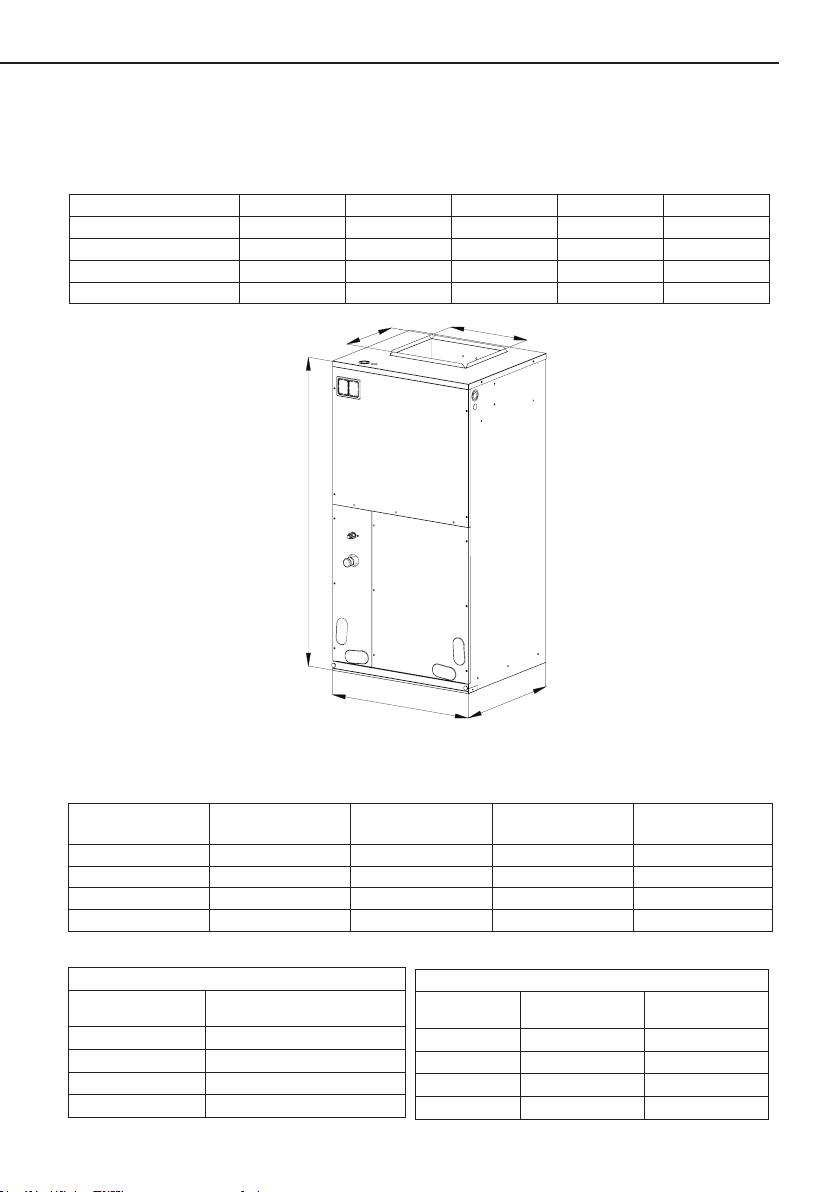

1.1 Physical Dimension

table 1 Unit: Inch

Model A B C D E

VAF-24A308I 21" 21-5/16" 10-3/4" 11-5/16" 43-1/2"

VAF-36A308I 21" 21-5/16" 12-1/4" 11-5/16" 48-3/16"

VAF-42A308I 24-1/2" 21-5/16" 13-3/4" 11-1/2" 48-3/16"

VAF-55A308I 24-1/2" 21-5/16" 13-3/4" 11-1/2" 48-3/16"

D

1.2 General Information

Model Cooling capacity Blower (inch)

VAF-24A308I

VAF-36A308I

VAF-42A308I

VAF-55A308I

Model Filter size (inch)

VAF-24A308I

VAF-36A308I

VAF-42A308I

VAF-55A308I

table 3 table 4

2.0 Ton 9.5×8 706 0-10

3.0 Ton 10×10 1150 0-20

3.5 Ton 11×11 1300 0-20

4.5 Ton 11×11 1420 0-20

Filters

19-5/16"X21-1/8"X1"

19-5/16"X21-1/8"X1"

20-5/16"X23"X1"

20-5/16"X23"X1"

A

Figure 1

table 2

VAF-24A308I 126/135lb. 154

VAF-36A308I 139/152lb. 112

VAF-42A308I 163/178lb. 81

VAF-55A308I 163/178lb. 81

B

Nominal SCFM

Model Net Wt/Gross Wt

Shipping Data

1

Electric heat(kw)

Loading QTY(40’

Container)

table 5

Air Handler

Motor @ 230V 1Ph 60Hz

HP FLA

DD Blower Wheel

(inch)

Model

VAF-24A308I

VAF-36A308I

VAF-42A308I

VAF-55A308I

Airow Tonnage

Range

2.0 1/17 0.52 9.5×8

3.0 1/2 3.6 10×10

3.5 3/4 4.6 11×11

4.5 3/4 4.6 11×11

The air ow of indoor unit

table 6

Model VAF-24A308I VAF-36A308I VAF-42A308I VAF-55A308I

ESP(in.wg) Air volume(CFM) Air volume(CFM) Air volume(CFM) Air volume(CFM)

0 808.4 1287.9 1377.4 1504.5

0.04 776.2 1250.8 1367.8 1483.8

0.08 742.1 1218.0 1339.6 1462.7

0.12 706.8 1181.2 1326.8 1441.6

0.16 666.6 1147 1300.4 1420.5

0.2 623.4 1113.1 1288.6 1400.6

0.24 576.4 1083.0 1271.4 1379.4

0.28 514.1 1055.8 1242.8 1357.8

0.32 452.3 1014.8 1214.3 1335.3

0.36 384.2 963.1 1208.1 1312.1

0.4 306.4 906.5 1182.5 1288.5

Notes:

Based upon W/nominal tonnage, dry coil and lter should be installed.

①

Use 0.96 as approximate CFM correction factor for wet coil.

②

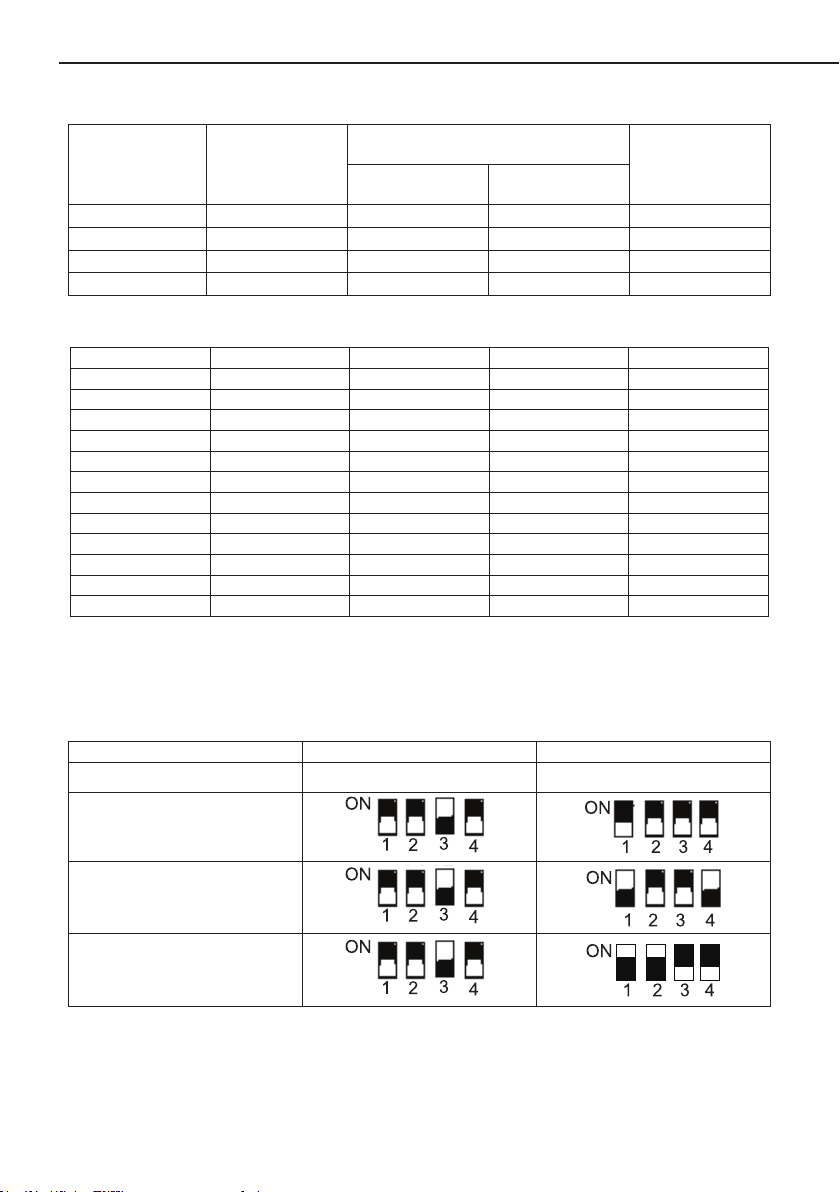

See the following table for how to set the DIP switch of the unit VAF-36A308I and VAF-42A308I:

table 7

Model/DIP Switch COOL HEAT

VAF-24A308I

/ /

VAF-36A308I

VAF-42A308I

VAF-55A308I

Note: The black part presents the switch rod.

2

Air Handler

2. Pre-Installation Instruction

2.1 Checking Product Received

After receiving the product, please check if there is any damage caused by transportation.

Shipping damage is the responsibility of the carrier. Verify the model number, specications and

accessories are correct prior to installation. The distributor or manufacturer will not accept claims

from dealers for transportation damage or installation of incorrectly shipped units.

2.2 Before Beginning Installation

Carefully read all instructions for the installation prior to installing product. Make sure each step

or procedure is understood and any special considerations are taken into account before starting

installation. Assemble all tools, hardware and supplies needed to complete the installation. Some

items may need to be purchased locally. Make sure everything needed to install the product is on

hand before starting.

2.3 Codes & Regulations

DANGER

IMMEDIATE HAZARDS WHICH WILL RESULT IN PROPERTY DAMAGE, PRODUCT

DAMAGE, SEVERE PERSONAL INJURY OR DEATH.

WARNING

HAZARDS OR UNSAFE PRATICES COULD RESULT IN PROPERTY DAMAGE, PRODUCT

DAMAGE, SEVERE PERSONAL INJURY OR DEATH.

CAUTION

HAZARDS OR UNSAFE PRACTICES WHICH MAY RESULT IN PROPERTY DAMAGE,

PRODUCT DAMAGE, SEVERE PERSONAL INJURY OR DEATH.

WARNING

BEFORE SERVING OR INSTALLING THIS EQUIPMENT.THE ELECTRICAL POWER TO

THIS UNIT MUST BE IN THE “OFF” POSITION. CAUTION, MORE THAN ONE DISCONNECT

MAY EXIST. FAILURE TO OBSERVE THIS WARNING MAY RESULT IN AN ELECTRICAL SHOCK

THAT CAN CAUSE PERSONAL INJURY OR DEATH .

WARNING

THE UNITED STATES ENVIRONMENTAL PROTECTION AGENCY (‘EPA”) HAS

ISSUED VARIOUS REGULATIONS REGARDING THE INTRODUCTION AND DISPOSAL

OF REFRIGERANTS INTRODUCED INTO THIS UNIT. FAILURE TO FOLLOW THESE

REGULATIONS MAY HARM THE ENVIROMENT AND CAN LEAD TO THE IMPOSITION OF

SUBSTANTIAL FINES. THESE REGULATIONS MAY VARY DUE TO THE PASSAGE OF LAWS.

A CERTIFIED TECHNICIAN MUST PERFORM THE INSTALLATION AND SERVICE OF THIS

PRODUCT. SHOULD QUESTIONS ARISE, CONTACT YOUR LOCAL EPA OFFICE.

3

Air Handler

WARNING

DUE TO HIGH SYSTEM PRESSURE AND ELECTRICAL SHOCK IN POTENTIAL,

INSTALLATION AND SERVICE WORK CAN BE DANGEROUS. ONLY TRAINED AND QUALIFIED

PERSONNELS ARE PERMITTED TO INSTALL OR SERVICE THIS EQUIPMENT. OBSERVE

ALL WARNINGS CONTAINED IN THIS MANUAL AND LABELS/TAGS ATTACHED TO THE

EQUIPMENT.

WARNING

THIS PRODUCT IS FACTORY SHIPPED FOR USE WITH A 208-230/1/60 ELECTRICAL

POWER SUPPLY. THIS AIR HANDLER MUST NOT BE RECONFIGURED TO OPERATE WITH

ANY OTHER POWER SUPPLY.

WARNING

THE UNIT MUST HAVE AN UNINTERRUPTED, UNBROKEN ELECTRIC GROUNDING TO

MINIMIZE THE POSSIBILITY OF PERSONAL INJURY IF AN ELECTRIC FAULT OCCURS. THE

ELECTRIC GROUNDING CIRCUIT MAY CONSIST OF AN APPROPRIATE SIZED POWER CORD

WHICH CONNECTED WITH THE GROUNDING PIECE LOCATED IN THE UNIT CONTROL BOX

AND ALSO CONNECTING TO THE BUILDING ELECTRIC SERVICE PANEL. OTHER METHODS

OF GROUNDING ARE PERMITTED IF PERFORMED IN ACCORDANCE WITH THE “NATIONAL

ELECTRIC CODE” (NEC)/ “AMERICAN NATIONAL STANDARDS INSTITUTE” (ANSI)/ “NATIONAL

FIRE PROTECTION ASSOCIATION” (NFPA) 70 AND LOCAL/STATE CODES. IN CANADA,

ELECTRIC GROUDING CONFORMS TO THE CANADIAN ELECTRIC CODE CSA C22.1.

FAILURE TO OBSERVE THIS WARNING CAN RESULT IN ELECTRICAL SHOCK THAT CAN

CAUSE PERSONAL INJURY.

This product is designed and manufactured to comply with national codes. It is installer’s

responsibilities to install the product in accordance with such codes and/or any prevailing local

codes/regulations. The manufacturer assumes no responsibilities for equipment installed in violation

of any codes or regulations.

2.4 Replacement Parts

When reporting shortages or damages, or ordering repair parts, give the complete product

model and serial numbers as stamped on the product. Replacement parts for this product are

available through your contractor or local distributor.

3. Important Safety Instructions

3.1 Recognize Safety Symbols, Words, and Labels

The following symbols and labels are used throughout this manual to indicate immediate or

potential hazards. It is the owner’s responsibility to read and comply with all safety information and

instructions accompanying these symbols. Failure to heed safety information increases the risk of

serious personal injury or death, property damage and/or product damage.

4

Air Handler

CARBON MONOXIDE POISONING HAZARD

Special warning for installation of furnaces or air handling units in enclosed areas, such

as garages, utility rooms or parking areas.

Carbon monoxide producing devices (such as an automobile, space heater, gas water heater,

etc.) should not be operated in enclosed areas such as unventilated garages, utility rooms or

parking areas because of the danger of carbon monoxide (CO) poisoning resulting from the

exhaust emissions.If a furnace or air handler is installed in an enclosed area such as a garge, utility

room or parking area and a carbon monoxide producing device is operated therein, there must be

adequate ventilation directly to outside.

This ventilation is necessary to avoid the danger of CO poisoning which can occur if a carbon

monoxide producing device continues to operate in the enclosed area. Carbon monoxide emission

can be (re)circulated throughout the building if the furnace or air handler is operating in any mode.

CO can cause serious illness including permanent brain damage or death.

3.2 Unit Inspection

Upon delivery, inspect the unit for damage. Any damage must be reported immediately to the

carrier. Do not install such an equipment damaged by freight which determines the integrity and

safety of the unit.

Please check the equipment model number to ensure the unit is appropriately sized for the

condensing unit.

If an incorrect unit is supplied, it must not be installed and it is to be returned to the supplier.

The manufacturer assumes no responsibility for the installation of incorrectly delivered units.

evaporator coil contains high-pressure inert gas for holding charge.

The

4. Location

WARNING

THIS AIR HANDLER IS DESIGNED FOR INDOOR INSTALLATION ONLY. DO NOT INSTALL

IT OUTDOORS.

When installing the air handler, minimize the length of refrigerant piping as short as possible.

Do not install the air handler at a place either above or below the condensing unit, which violates

5

Air Handler

the installation instructions of the condensing unit. The clearance between a combustible surface

and the unit is “0”; however, service clearance takes precedence. Allow a minimum of 24” in front of

the unit for service clea

attic), a drain pan for emergency is required. Check local and state codes for requirements. When

installing this unit in an area that may become wet, elevate the unit with a rm and non-porous

material. To avoid of personal injury during installation (i.e. in a garage), it is advised to install a

protective barrier to prevent such damage.

rance. When installing in an area directly over a nished ceiling (such as an

5. Ductwork

This air handler is designed for a complete supply and return ductwork system.

WARNING

DO NOT OPERATE THE UNIT WITHOUT ALL DUCTWORK COMPLETED.

To ensure correct system performance, the ductwork is to be sized to accommodate 375-

425 CFM per ton of cooling with the static pressure or less than 5" WC. Inadequate ductwork that

restricts airow may result in improper performance and compressor or heater failure. Ductwork

is designed with less restrictions of airow and maintains suitable airow speed. And keep the

ductwork sealed with good hermeticity.

Return Ductwork. Do not place the duct inlet at a place where is filled with toxic gas or

harmful fume/odor. For upow conguration, duct terminal connects to the bottom of the air handler.

Return Air Filters. Each installation must include a return air filter. This filtering may be

performed at the air handler or externally such as a return air lter grille.

6. Electric Heat

The air handlers listed in this manual do not have factory installed electric heat. Electric heat is

available as an accessory. The only heater kits that can be used are VAFd series. Please refer to

installation instructions provided with heater kit for the correct installation procedure.

WARNING

REFER TO THE “INSTALLING ELECTRIC HEAT” SECTION OF THIS MANUAL AND THE

INSTRUCTIONS PROVIDED WITH THE HEATER KIT FOR THE CORRECT INSTALLATION

PROCEDURE.

WARNING

THE ELECTRICAL CHARACTERISTICS OF THE AIR HANDLER, THE ELECTRIC HEATER

KIT, AND THE SUPPLY POWER MUST AGREE. THIS AIR HANDLER DOES NOT HAVE

FACTORY INSTALLED ELECTRIC HEAT. ELECTRIC HEAT IS AVAILABLE AS AN ACCESSORY.

IF INSTALLING THIS OPTITION, THE ONLY HEATER KITS THAT CAN BE USED ARE THE

VAFd SERIES AS INDICATED BELOW.

6

Air Handler

The heating mode temperature rise is dependent upon the system airow, the supply voltage,

and the heater kit size (KW) selected. Use Tables 8-10 to determine the temperature rise(ºF).

table 8

CFM

600 28 41 56

800 21 31 42

1000 17 25 34 50

1200 14 21 28 42 56

1400 12 18 24 36 48

1600 10 15 21 31 42

1800 9 14 19 28 37

5 8 10 15 20

230/1/60 Supply Voltage-Temperature Rise Table ºF

CFM

600 27 39 52

800 20 30 40

1000 16 24 32 48

1200 13 20 27 40 53

1400 11 17 23 34 46

1600 10 15 20 30 40

1800 9 13 18 27 36

5 8 10 15 20

220/1/60 Supply Voltage-Temperature Rise Table ºF

CFM

600 25 37 50

800 19 28 38

1000 15 22 30 46

1200 13 19 25 38 56

1400 11 16 22 33 48

1600 9 14 19 28 42

1800 8 12 17 25 37

5 8 10 15 20

208/1/60 Supply Voltage-Temperature Rise Table ºF

Note: For installations not indicated above the following formula is to be used:

TR=(kW*3412)*(Voltage Correction)*1.08/CFM

Where:TR=Temperature Rise

KW=Heater Kit Actual kW

3412=Btu per kW

Voltage Correction= 0.96(230 Supply Volts)

0.92(220 Supply Volts)

0.87(208 Supply Volts)

1.08=Constant CFM=Measured Airow

HEATER KIT NOMINAL KW

table 9

HEATER KIT NOMINAL KW

table 10

HEATER KIT NOMINAL KW

7

Air Handler

Note: The Temperature Rise Tables can also be used to determine the air handler airflow

delivery. When using these tables for this purpose, set the room thermostat to maximum heat and

allow the system to reach steady state conditions. Set two thermometers, one in the return air inlet

and the other one in the supply air outlet.

6.1 “VAFd” Electric Heater Kits Available

table 11

SN. Kit# Description Ref. Air Handler use

1 VAFd5-D Circuit Breaker, 5kw Heat Strip 24,36,42,55

2 VAFd8-D Circuit Breaker, 8kw Heat Strip 24,36,42,55

3 VAFd10-D Circuit Breaker, 10kw Heat Strip 24,36,42,55

4 VAFd15-D Circuit Breaker, 15kw Heat Strip 36,42,55

5 VAFd20-D Circuit Breaker, 20kw Heat Strip 36,42,55

6.2 “VAFd” Heater Kits Installation

CAUTIONS

ENSURE THAT ALL POWER SUPPLY IS DISCONNECTED PRIOR TO INSTALLING THE

HEATER KIT.

A MEANS OF STRAIN RELIEF AND CONDUCTOR PROTECTION MUST BE PROVIDED AT

THE SUPPLY WIRE ENTRANCE INTO CABINET.

USE COPPER CONDUCTORS ONLY.

INSTALLATION MUST FOLLOW NATIONAL ELECTRIC CODE AND OTHER APPLICABLE

CODES.

IF THIS APPLIANCE IS INSTALLED IN AN ENCLOSED AREA SUCH AS A GARAGE OR

UTILITY ROOM WITH ANY CARBON MONOXIDE PRODUCING APPLIANCE, ENSURE THE

AREA IS PROPERLY VENTILATED.

1) Refer to Table 11 for appropriate VAFd heater kit.

2) Check any physical damage, do not install damaged heater kit.

3) Remove the upper access panel from air handler.

4) Remove cover plate from air handler.

5) Slide the heater kit in to the slot and secure element plate with previously removed screws.

6) Insert power leads into the circuit breaker lugs or stripped red and black wires (For heater kit

without circuit breaker) and tighten.

7) Power leads must be routed through a means of strain reliefs they enter the air handler

cabinet.

8) Connect ground wire to ground lug.

9) Break out appropriate area of the plastic circuit breaker cover on the access panel of the air

handler.

10) Replace access panel and check operation.

8

Air Handler

7. Electrical Supply Wire and MOP

WARNING

THE UNIT MUST HAVE AN UNINTERRUPTED, UNBROKEN ELECTRIC GROUNDING TO

MINIMIZE THE POSSIBILITY OF PERSONAL INJURY IF AN ELECTRIC FAULT OCCURS. THE

ELECTRIC GROUNDING CIRCUIT MAY CONSIST OF AN APPROPRIATE SIZED POWER CORD

WHICH CONNECTED WITH THE GROUNDING PIECE LOCATED IN THE UNIT CONTROL BOX

AND ALSO CONNECTING TO THE BUILDING ELECTRIC SERVICE PANEL. OTHER METHODS

OF GROUNDING ARE PERMITTED IF PERFORMED IN ACCORDANCE WITH THE “NATIONAL

ELECTRIC CODE” (NEC)/ “AMERICAN NATIONAL STANDARDS INSTITUTE” (ANSI)/ “NATIONAL

FIRE PROTECTION ASSOCIATION” (NFPA) 70 AND LOCAL/STATE CODES. IN CANADA,

ELECTRIC GROUDING CONFORMS TO THE CANADIAN ELECTRIC CODE CSA C22.1.

FAILURE TO OBSERVE THIS WARNING CAN RESULT IN ELECTRICAL SHOCK THAT CAN

CAUSE PERSONAL INJURY.

WARNING

MORE THAN ONE DISCONNECT MAY EXIST. FAILURE TO OBSERVE THIS WARNING MAY

RESULT IN AN ELECTRICAL SHOCK THAT CAN CAUSE PERSONAL INJURY OR DEATH.

WARNING

TO AVOID THE RISK OF THE FIRE OR EQUIPMENT DAMAGE, ONLY USE COPPER

CONDUCTORS. BEFORE SERVICING OR INSTALLING THIS EQUIPMENT, THE ELECTRICAL

POWER TO THIS UNIT MUST BE IN “OFF” POSITION AND ALL POWER SUPPLIES SHOULD

BE DISCONNECTED.

7.1 Inspection of the Building Electrical Service

This product is designed for single-phase electrical supply. DO NOT OPERATE ON A THREE-

PHASE POWER SUPPLY. Measure the power supply to the unit. The supply voltage must be in

agreement with the unit nameplate power requirements and within the range shown in table 12.

table 12

Nominal Input Minimum Voltage Maximum Voltage

208/230 187 254

9

Air Handler

7.2 Wire Sizing

Wire size is important to the operation of your equipment. Use the following check list when

selecting the appropriate wire size for your unit.

● Wire size must carry the Minimum Circuit Ampacity (MCA).

table 13

Max. Fuse or Breaker

(HACR) Ampacity

Model

VAF-24A308I

VAF-36A308I

VAF-42A308I

VAF-55A308I

Nominal

CFM

1150 35000

1300 42000

1420 55000

Nominal

Capacity

BTU/H

706 24000

Electric Heat

Kw

240V 208V 240V 208V 240V 208V

5 3.8 26.9 23.4 30 25

8 6 42.5 36.9 45 40

10 7.5 52.9 45.9 60 50

5 3.8 28.0 24.4 30 25

8 6 43.6 37.8 45 40

10 7.5 54.0 47.0 60 50

15 11.3 54.0/26.0 47.0/22.5 60/30 50/25

20 15 54.0/52.1 47.0/45.1 60/60 50/50

5 3.8 28.1 24.6 30 25

8 6 43.7 38.1 45 40

10 7.5 54.2 47.1 60 50

15 11.3 54.2/26.0 47.1/22.5 60/30 50/25

20 15 54.2/52.1 47.1/45.1 60/60 50/50

5 3.8 29.3 25.8 30 25

8 6 44.9 39.3 45 40

10 7.5 55.3 48.3 60 50

15 11.3 55.3/26.0 48.3/22.5 60/30 50/25

20 15 55.3/52.1 48.3/45.1 60/60 50/50

Min. Circuit Ampacity

Wire size allows for no more than a 2% voltage drop from the building breaker/fuse panel to

the unit.

Refer to the latest edition of the National Electric Code (NEC) in USA or the Canadian Electric

Code (CSA) in Canada when determining the correct wire size. The following table shows the

current carrying capabilities for copper conductors rated at 75ºC with a 2% voltage drop. Use the

Table 10 to determine the voltage drop per foot of various conductors.

table 14

Maximum Allowable Length in Feet to Limit Voltage Drop to 2% *

Wire

Size(AWG)

14 75 50 37

12 118 79 59 47

10 188 125 95 75 63 54

8 301 201 150 120 100 86 75 68

6 471 314 235 188 157 134 11 8 11 0

10 15 20 25 30 35 40 45

Minimum Circuit Ampacity(MCA)

*Based on NEC 1996

10

Air Handler

7.3 Maximum Overcurrent Protection (MOP)

Every installation must include an NEC (USA) or CEC (Canada) approved overcurrent

protection device. Also, check with local or state codes for any special regional requirements.

This protection can be in the form of fusing or HACR style circuit breakers.

NOTE: Fuses or circuit breakers are to be sized larger than the equipment MCA but not to

exceed the MOP.

7.4 Electric Connections-Supply Voltage

USE COPPER CONDUCTORS ONLY

A knockout is provided on the air handler top panel or side to allow for the entry of the supply

voltage conductors. If the knockouts on the cabinet side are used for electrical conduit, an adapter

ring must be used in order to meet UL 1995 safety requirements. An NEC or CEC approved strain

relief is to be used at this entry point.

The wire needs to be sized in accordance with

the “Wire Sizing and MOP” section of this manual.

Air Handler Only (Non-Heater Kit Models)

The power cord connects to L1 and L2 terminal located on the electrical box in the air handler.

Note to grounding well. The power cord adopts appropriately sized solderless connector or other

NEC or CEC approved means. Check the unit wiring diagram attached for reference.

Air Handler with Heater Kits (Non-Circuit Breaker)

The power supply should be connected to the stripped black and red wires on the heater kit.

Air Handler with Heater Kits Containing Circuit Breaker

VAFd models with a “B” sufx contain a circuit breaker(s). The air handler has a plastic cover

on the access panel that will require either one or both sections to be removed to allow the heater

kit circuit breaker(s) to be installed. See theVAFd Installation Instruction for further detail. The air

handler wires and supply wires are installed directly onto the VAFd circuit breaker(s) as shown in

the VAFd Installation Manual and wiring diagram.

Low Voltage Connections

Several combinations of low voltage schemes are available, depending on the presence of a

heater kit and whether the heater kit is single-stage or multi-stage. The low voltage connections

are determined by whether the outdoor unit is a condenser or heat pump. The 24V-control voltage

connects the air handler to the room thermostat and condenser. Low voltage wiring is to be

copper conductors. A minimum of 18AWG must be used for installations up to 50’ and 16AWG for

installations over 50’. Low voltage wiring can be made through the top of the cabinet or through

either side. See the “Thermostat Wiring” section of this manual .

11

7.5 Schematic Wiring Diagram

Figure 2 Wiring Diagram(VAF-24A308I)

Air Handler

Figure 3 Wiring Diagram(VAF-36A308I/VAF-42A308I/VAF-55A308I)

12

Air Handler

Notes:

1) For air handler without installing electric heater, connect the power cord to “L1” and “L2” on

terminal board.

2) For air handler with electric heater, connect the power cord to circuit breaker. If the heat kit

without circuit breaker, connect the power cord to the stripped black and red wires.

3) Remove the black lead from "X7" terminal on the main board and then connect the blue lead

to "X7" terminal for 208 volts, taping the unused black lead.

4) 90 seconds off delay when "G" is de-energized.

5) Jumper "R" and "O" together if working with cooling only condensing unit.

7.6 Thermostat Wiring

INDOOR UNIT

OUTDOOR UNIT

Figure 4

WIRED-CONTROLLER

8. Refrigerant Pipe

WARNING

WHEN WELDING ON THE PAINTED SURFACES OF THE UNIT, QUENCHING CLOTH IS

STRONGLY ADVISED TO PREVENT SCORCHING OR DAMAGING THE UNIT SURFACES.

SOLDER WITH A MINIMUM OF 5% SILVER IS RECOMMENDED.

WARNING

THIS PRODUCT IS FACTORY-SHIPPED UNDER PRESSURE. FOLLOW THESE

INSTRUCTIONS TO PREVENT INJURY.

8.1 Piping Preparation

All cut ends are to be round, burr free, and cleaned. Failure to follow this practice increases the

chances for refrigerant leakage.

After Brazing

Quench all welded joints with water or a wet rag.

Piping Size

For the correct piping size, follow the specication for the condenser/heat pump.

13

Air Handler

8.2 Special Instructions

This air handler comes with a plastic accessory bag which contains: tailpiece and white teon

seal.

WARNING

THE COIL IS SHIPPED UNDER PRESSURE. RELEASE THE PRESSURE BEFORE

INSTALLATION.

Evaporator Throttling Device

1.Remove 9/16 nut, then press the Schrader valve to release pressure, no gas indicates a

possible leak.

2.After the gas has released, remove the 13/16 nut, Schrader valve and white teon seal from

the liquid line distributor.

3.Remove cap closure from suction line .

4.Take the tailpiece from the plastic accessory bag and slide the 13/16 nut into place.

5.Braze tailpiece to the line set liquid tube.

6.Insert the suction line into the connection, slide the rubber grommet at least 18’’away from the

braze joint. Braze suction line.

7.After the tailpiece has been cooled, conrm the position of white teon seal and tighten the

13/16 nut manually.

8.Torque the 13/16nut to 20-30 ft-lbs.

9.Replace suction line grommet.

13/16"Nut

Tailpiece

Flowrator

White teflon seal

Figure 5

14

Air Handler

Figure 6

Note:

The tightening torque of the 13/16 screw nut shall not be more than 30N·m.

9. Drain Pan Ret

The following instruction shows how to ret the auxiliary drain pan from left to right side of the

unit. As the auxiliary drain pan is universally used on both sides, only change the position of plastic

drain pan cap for replacement.

As shown in Figure 7, it is recommended that the drain pan should be ret before installation

and locate the air handler in an area that allows for access to all sides.

1. Disassemble the front panel.

2. Remove the “J” shaped hook that xing the evaporator coil. Remove the xed board that

xed under the drain pan.

3. Draw out the evaporator coil and the drain pan in horizontal.

4. Reset the drain pan in vertical at the right side of the evaporator coil. Note: Push the

evaporator coil backwards and make sure that there is no gap between the drain pan and the xed

bracket.

5. Fix the evaporator coil by “J” shaped hook and reset the xed board under the evaporator

coils as before.

6. Assemble the disassembled front panel as per the reverse disassembly order mentioned

above.

Secondary Drain

Figure 7

15

Primary Drain

Air Handler

10. Condensate Removal

The drain pan has primary and secondary drain connection (Figure 7). Condensate water

discharging is performed by attaching a 3/4” PVC pipe to the evaporator coil pan and terminated

in accordance with local or state Plumbing/HVAC codes. The installation must include a “P” style

trap that is located closely to the evaporator coil. Do not over-tighten the drain connection(s) in

order to prevent possible damage to the evaporator drain pan. See Figure 8 for details of a typical

condensate line “P” trap.

Installations that are above a nished ceiling may require a eld supplied auxiliary drain pan.

Consult local codes on this requirement.

Figure 8

Use a condensate removal pump when necessary. If the discharging pipe is blocked, the

condensate removal pump will be cut off to control voltage. A trap must be installed between the

unit and the condensate removal pump.

11. Start-Up Procedure

Prior to start-up, ensure that all electrical connections are properly sized and tightened.

All panels must be in place and secured. For air tight application, rubber gasket must be

positioned at prescribed locations to achieve 2% leakage.

Tubing must be leak free.

Unit should be elevated, trapped and pitched to allow for drainage.

Low voltage wiring is connected.

Auxiliary drain is installed when necessary and pitched to allow for drainage.

Drain pan and drain tubing has been leak checked.

Return and supply ducts are sealed.

Unit is elevated when installed in a garage or where ammable vapors may be present.

Return air is not obtained from many areas where there may be objectionable odors,

flammable vapors or products of combustion such as carbon monoxide(CO), which may cause

serious personal injury or death.

16

Air Handler

12. Regular Maintenance

WARNING

DISCONNECT ALL POWER SUPPLIES (MIGHT BE MORE THAN ONE POWER SUPPLY)

BEFORE SERVICE. FAILURE TO OBSERVE THIS WARING CAN RESULT IN ELECTRICAL

SHOCK THAT CAN CAUSE PERSONAL INJURY OR DEATH.

The only item to be maintained on a regular basis by the user is the circulating air filter(s).

Filter should be cleaned or replaced regularly. A certied service technician must perform all other

services.

This product must not be disposed together with the domestic waste.

This product has to be disposed at an authorized place for recycling of

electrical and electronic appliances.

17

Loading...

Loading...