Page 1

PowerMaster-33 G2

Version 18

Installer’s Guide

Table of Contents

1. INTRODUCTION ................................................. 2

1.1 System Features .......................................... 2

2. CHOOSING THE INSTALLATION LOCATION .. 6

3. POWERMASTER-33 G2 INSTALLATION .......... 7

3.1 PowerMaster-33 G2 Wiring Diagram ........... 7

3.2 Opening the PowerMaster-33 G2 Control

Panel and Bracket Mounting ............................. 8

3.3 Connecting to the Telephone Line (detail

"K" in Figure 3.1) ................................................ 8

3.4 Connecting Wired Zone and Siren (detail

"B" in Figure 3.1) ................................................ 9

3.5 GSM Module and SIM Installation (detail

"L" in Figure 3.1) .............................................. 10

3.6 PGM-5 Installation (located in place of

detail "E" in Figure 3.1) .................................... 11

3.7 Installing the PowerLink3 .......................... 12

3.8 Optional Expander Module (detail "I" in

Figure 3.1) ......................................................... 13

3.9 Connecting Power to the Control Panel ... 15

3.9.1 Battery Insertion ................................. 16

3.9.2 Connect AC Power to the Unit ........... 16

3.10 Closing the PowerMaster-33 G2 Control

Panel ................................................................. 17

4. VISUAL INDICATIONS, FIRST KEYPAD

ENROLLMENT AND USING PROX TAG .............. 18

4.1 PowerMaster-33 LED Indications .............. 18

4.2 Enrollment of the First KP-250 PG2 Keypad

........................................................................... 18

4.3 Using the Prox Tag ..................................... 19

5. MAINTENANCE ................................................. 19

5.1 Dismounting the Control Panel ................. 19

5.2 Replacing the Backup Battery ................... 19

5.3 Fuse Replacement ...................................... 19

5.4 Replacing/Relocating Detectors ................ 19

5.5 Annual System Check ................................ 19

APPENDIX A. Specifications ............................... 20

A1. Functional ................................................... 20

A2. Wireless ...................................................... 20

A3. Electrical ..................................................... 20

A4. Communication .......................................... 21

A5. Physical Properties .................................... 21

A6. Peripherals and Accessory Devices ......... 21

APPENDIX B. Compliance with Standards .......... 22

Quick User Guide to Main Alarm Control

Operations by KP-250 PG2 Keypad .................... 23

D-304267 PowerMaster-33 G2 Installer's Guide 1

Page 2

Feature

Description

How to configure and use

Visual Alarm

Verification

The PowerMaster when used with Next CAM

PG2 PIR-camera detector and GPRS

communication is able to provide the

Monitoring Station with clips captured in

alarm situations. The system sends the clips

to the Monitoring Station automatically for

burglary alarms and, depending on setup,

also for fire and personal emergency alarms.

1. Setup GPRS communication: see GSM

Module Installation section 3.5)

2. Configure camera settings: refer to the

Next CAM PG2 Installation Instructions

3. Enable fire and personal alarm

verification: see KP-250 PG2 Installer’s

Guide, section 3.6.6 Configuring Motion

Cameras for Video Alarm Verification

On demand clips from

cameras

The PowerMaster can provide images from

the Next CAM PG2 by demand from a

remote PowerManage server. Pictures are

taken based on a command from the

monitoring station. To protect customers'

privacy, the system can be customized to

enable the "On Demand View" only during

specific system modes (i.e. Disarm, Home &

Away) and also to a specific time window

following an alarm event.

1. Setup the On demand feature: see

KP-250 PG2 Installer’s Guide, section 3.6.6

Configuring Motion Cameras for Video Alarm

Verification

2. To request and view images: refer to the

PowerManage User's Guide, Chapter 5

Viewing and Handling Events

Easy Enrollment

PowerG devices are enrolled from the control

panel. "Pre-enrollment" can also be

performed by entering the PowerG device ID

number and then activating the device in the

vicinity of the panel.

To enroll or pre-enroll devices: see

KP-250 PG2 Installer’s Guide, section 3.4.2

Adding New Wireless Devices or Wired

Sensors

1. INTRODUCTION

PowerMaster is a PowerG-enabled professional all-in-one wireless security, fire and safety system supporting advanced

applications and Visonic's PowerG™ Two-Way, Time Division Multiple Access (TDMA) and Frequency Hopping Spread

Spectrum (FHSS) wireless technology. This offers unmatched wireless robustness, superior range and long battery life; a

perfect and user friendly solution for both monitoring service providers and professional installers.

The system consists of the PowerMaster-33 G2 control panel that does not include a built-in keypad and that operates

in conjunction with a wireless keypad display device (KP-250 PG2). The control panel accommodates all control

circuitry and operation software for a programmable 64-zone alarm system, while the keypad display unit enables the

installer and the user to enter their commands and provides visual and audible feedback.

This manual refers to PowerMaster-33 G2 v18 and above. The most updated manuals can be downloaded from the

Visonic Web site http://www.visonic.com.

Note: "Pmaster" is used as an abbreviation for "PowerMaster".

The system is supplied with 3 instruction manuals:

PowerMaster-33 G2 Installer's Guide (this manual) – for use of system installer during system installation.

KP-250 PG2 Installer’s Guide -– for use of system installer during KP-250 PG2 installation and PowerMaster-33 G2

configuration.

KP-250 PG2 User’s Guide -– also for use of system installer during system installation and configuration, but also for

the master user of the system, once installation is completed. Hand over this manual to the master user of the system.

1.1 System Features

The following table lists the PowerMaster features with a description of each feature and how to use it.

2 D-304267 PowerMaster-33 G2 Installer's Guide

Page 3

Device Configuration

Device parameters and related system

behavior can be configured from the KP-250

PG2 keypad or from a remote location.

Each PowerG device has its own settings

which can be configured through the KP-250

PG2 keypad by entering the "DEVICE

SETTINGS" menu.

To configure devices from the KP-250

PG2: see KP-250 PG2 Installer’s Guide,

Chapter 3 Programming and also the

individual device's Installation Instructions.

To configure devices from a remote

location: refer to the PowerManage User's

Guide Chapter 3 Working with Panels and to

the Remote Programmer PC software User's

Guide, Chapters 6 and 7.

Diagnostics of the

control panel and

peripherals

You can test the function of all wireless

sensors deployed throughout the protected

area, to collect information about the

received signal strength from each

transmitter and to review accumulated data

after the test.

To perform diagnostics and to obtain

signal strength indication: see KP-250

PG2 Installer’s Guide, section 3.9

Diagnostics

Conducting periodic

tests

The system should be tested at least once a

week and after an alarm. The periodic test

can be conducted locally or from a remote

location (with the assistance from a nontechnical person in the house).

To conduct a walk test locally: see KP-250

PG2 Installer’s Guide, Chapter 4 Periodic

Test by Installer Code or KP-250 PG2 User’s

Guide, Chapter 8 Periodic Test by User

Code

To conduct a walk test from remote

location: refer to the Remote Programmer

PC software User's Guide, Chapter 6 Data

Details Tables.

Partitions

The partitioning feature, when enabled,

divides your alarm system into distinct areas

each of which operates as an individual

alarm system. Partitioning can be used in

installations where shared security systems

are more practical, such as a home office or

warehouse building.

1. Enable partitioning: see KP-250 PG2

Installer’s Guide, section 3.13 Partitioning

2. Setup partition association for each

device: see KP-250 PG2 Installer’s Guide,

section 3.4.2 Adding New Wireless Devices

or Wired Sensors

To understand more about partitioning:

see KP-250 PG2 Installer’s Guide,

APPENDIX B. Working with Partitions.

Device configuration

templates

The default parameters with which a new

device is enrolled into the system can be set

before you enroll devices. This default

template saves time on device configuration.

1. Define enrollment defaults for devices:

see KP-250 PG2 Installer’s Guide, section

3.4.7 Defining Configuration Defaults for

"Device Settings"

2. Enroll or pre-enroll devices: see KP-250

PG2 Installer’s Guide, section 3.4.2 Adding

New Wireless Devices or Wired Sensors

SirenNet - distributed

siren using Smoke

detectors

All PowerG smoke detectors are able to

function as sirens, alerting on any of 4 types of

alarm in the system: burglary, gas, fire or

flood.

Enable and configure SirenNet for each

smoke detector: refer to the SMD-426 PG2

/ SMD-427 PG2 Installation Instructions

Wired Siren outputs

The control panel can operate a wired siren

and strobe devices

Install and connect wired siren: see

section 3.8 Optional Expander Module

D-304267 PowerMaster-33 G2 Installer's Guide 3

Page 4

Wired zones and

programmable

outputs (PGM)

The control panel can support wired detectors

and control automation devices with

programmable wired outputs.

1. Connect a wired zone or PGM device: see

section 3.4 Adding a Wired Zone and Siren.

2. Program the wired zone: see KP-250

PG2 Installer’s Guide, section 3.4.2 Adding

New Wireless Devices or Wired Sensors

3. Program PGM outputs behavior: see

KP-250 PG2 Installer’s Guide, section 3.7

PGM Output.

Reporting to Private

Users and/or

Monitoring Station by

telephone, SMS and

IP communication

The PowerMaster system can be

programmed to send notifications of alarm

and other events to 4 private telephone

subscribers by voice* and also to 4 SMS

cellular phone numbers and to report these

events to the Monitoring Station by SMS,

PSTN or IP communication.

To configure notifications to Private

phones: see KP-250 PG2 User’s Guide,

Chapter 6, section B.12 Programming

Private Phone and SMS Reporting

To configure reporting to the Montioring

Station: see KP-250 PG2 Installer’s Guide,

section 3.6.4 Configuring Events Reporting

to Monitoring Stations

Quick installation with

link quality indication

With PowerG devices, there is no need to

consult the KP-250 PG2 keypad when

mounting a wireless device, because

PowerG devices include a built-in link quality

indicator. Choosing the mounting location is

a quick and easy process.

To choose the ideal location to mount a

wireless device, see Chapter 2 Choosing the

Installation Location.

Device Locator

Helps you to easily identify the actual device

displayed on the KP-250 PG2 LCD display.

To read more on the Device Locator: see

KP-250 PG2 User’s Guide, Chapter 3,

Arming and Disarming the System

To use the device locator when bypassing

a zone or when clearing a bypassed zone:

see KP-250 PG2 User’s Guide, Chapter 6,

section B.1 Setting the Zone Bypass Scheme

To use the device locator when conducting

the periodic test: see KP-250 PG2 Installer’s

Guide, Chapter 4 Periodic Test by Installer

Code or KP-250 PG2 User’s Guide, Chapter 8

Periodic Test by User Code.

Guard key-safe

PowerMaster is able to control a safe that

holds site keys that are accessible only to the

site's guard or Monitoring Station's guard in

the event of an alarm.

1. Connect the safe to the panel: see

section 3.8 Optional Expander Module

Mounting, Figure 3.8b

2. Configure the safe's zone type to

"Guard Zone": see KP-250 PG2 Installer’s

Guide, section 3.4.2 Adding New Wireless

Devices or Wired Sensors

3. Setup guard code: see KP-250 PG2

Installer’s Guide, section 3.3 Setting Installer

Codes

Arming key

External system may control arming and

disarming of the PowerMaster system

Connect the external system output to the

panel: see section 3.8 Optional Expander

Module Mounting, Figure 3.8b

*

Supported in specific PowerMaster-33 G2 variants (for further details, please contact your Visonic representative).

4 D-304267 PowerMaster-33 G2 Installer's Guide

Page 5

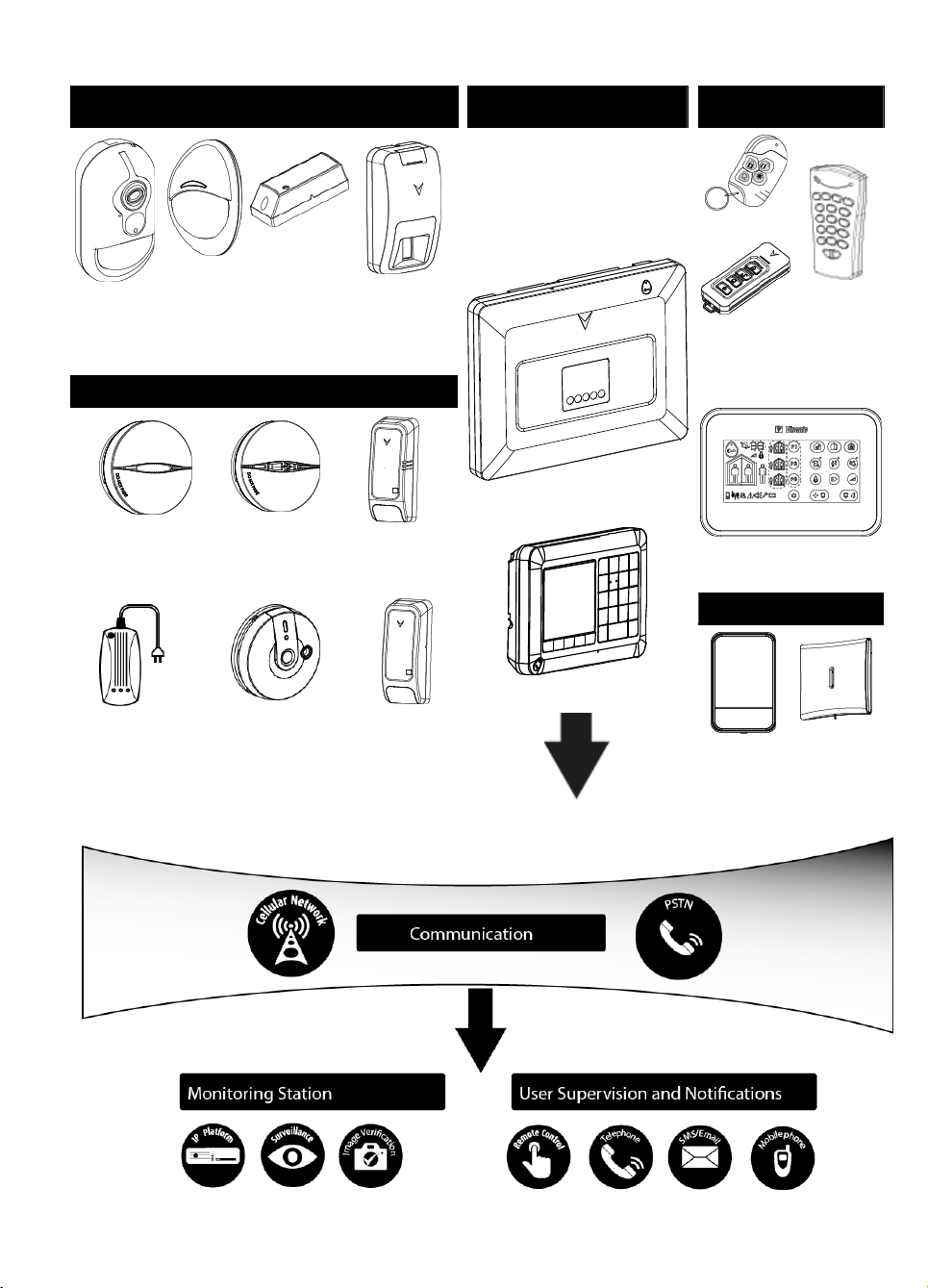

Security Detectors and Transmitters

Control Panel and Display

Keypad

Keyfobs, Keypad and

Keyprox

Next CAM

PG2 Motion

Detector

with Camera

Next PG2

Motion

Detector

MC-302 PG2

Magnetic

Contact

TOWER-30AM

PG2

Mirror Detector

PowerMaster-33 G2

KP-250 PG2

KF-234 PG2

KF-235 PG2

Two-way

Keyfobs

KP-140 PG2

Two-way

Keypad

Safety Detectors

KP-160 PG2 Keyprox

SMD-426 PG2

Smoke Detector

SMD-427 PG2

Smoke & Heat

Detector

TMD-560 PG2

Temperature

Detector

GSD-441 PG2

Gas (Methane)

Detector

GSD-442 PG2

Carbon Monoxide (CO)

Detector

FLD-550 PG2

Flood

Detector

Sirens

SR-730 PG2

Outdoor

Siren

SR-720 PG2

Indoor Siren

System Architecture:

D-304267 PowerMaster-33 G2 Installer's Guide 5

Page 6

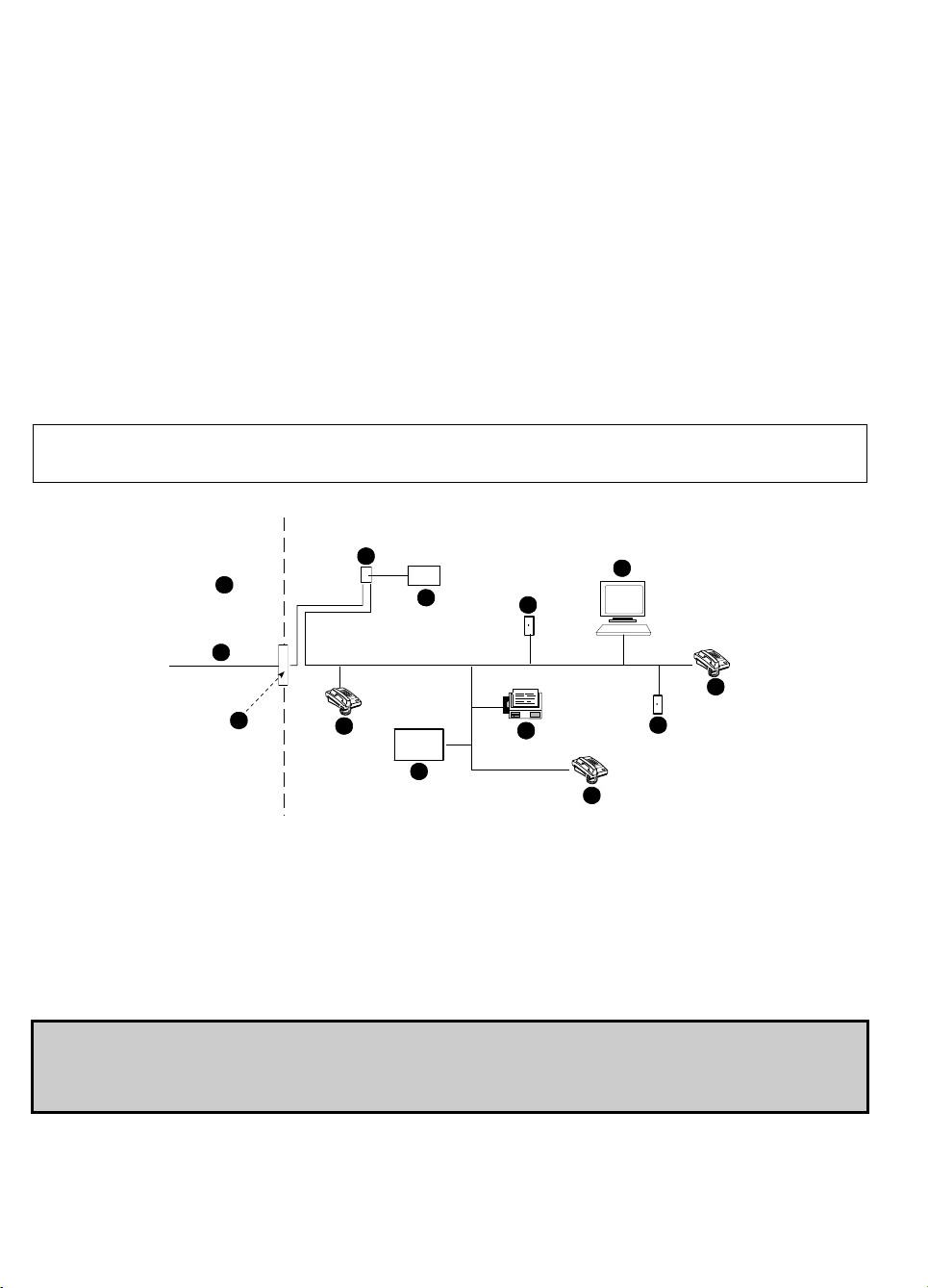

A

B

C

D

E

F

G

H

I

E

E

H

J

A. Network Service Provider's Facilities

F. Alarm Dialing Equipment

B. Telephone Line

G. Answering System

C. Network Demarcation Point

H. Unused RJ-11 Jack

D. RJ-31X Jack

I. Fax Machine

E. Telephone

J. Computer

2. CHOOSING THE INSTALLATION LOCATION

To ensure the best possible mounting location of the PowerMaster control panel, the following points should be

observed:

The selected location should be approximately in the center of the installation site between all the transmitters,

preferably in a hidden location.

In close proximity to an AC source

In close proximity to a telephone line connection (if PSTN is used)

Where there is good cellular coverage, if GSM-350 PG2 is used

Far from sources of wireless interference, such as:

o Computers or other electronic devices, power conductors, cordless phones, light dimmers, etc.

o Large metal objects (such as metal doors or refrigerators)

Note: A distance of at least 1 meter (3 ft) is recommended.

When mounting wireless devices:

Make sure that the signal reception level for each device is either "Strong" or "Good", but not "Poor".

Wireless magnetic contacts should be installed in a vertical position and as high up the door or window as possible.

Wireless PIR detectors should be installed upright at the height specified in their Installation Instructions

Repeaters should be located high on the wall in mid-distance between the transmitters and the control panel.

WARNING! To comply with FCC and IC RF exposure compliance requirements, the control panel should be located at

a distance of at least 20 cm from all persons during normal operation. The antennas used for this product must not be

co-located or operated in conjunction with any other antenna or transmitter.

Customer Premises Equipment and Wiring

Note: The REN is used to determine the number of devices that may be connected to a telephone line. Excessive RENs on a telephone line

may result in the devices not ringing in response to an incoming call. In most but not all areas, the sum of RENs should not exceed five (5.0).

To be certain of the number of devices that may be connected to a line, as determined by the total RENs, contact the local telephone

company.

Connection to telephone company provided coin service is prohibited. Connection to party lines service is subject to state tariffs.

The installer should verify line seizure. Be aware of other phone line services such as DSL. If DSL service is present on the

phone line, you must install a filter. It is suggested to use the DSL alarm filter model Z-A431PJ31X manufactured by

Excelsus Technologies, or equivalent. This filter simply plugs into the RJ-31X jack and allows alarm reporting without

breaking the internet connection.

6 D-304267 PowerMaster-33 G2 Installer's Guide

Page 7

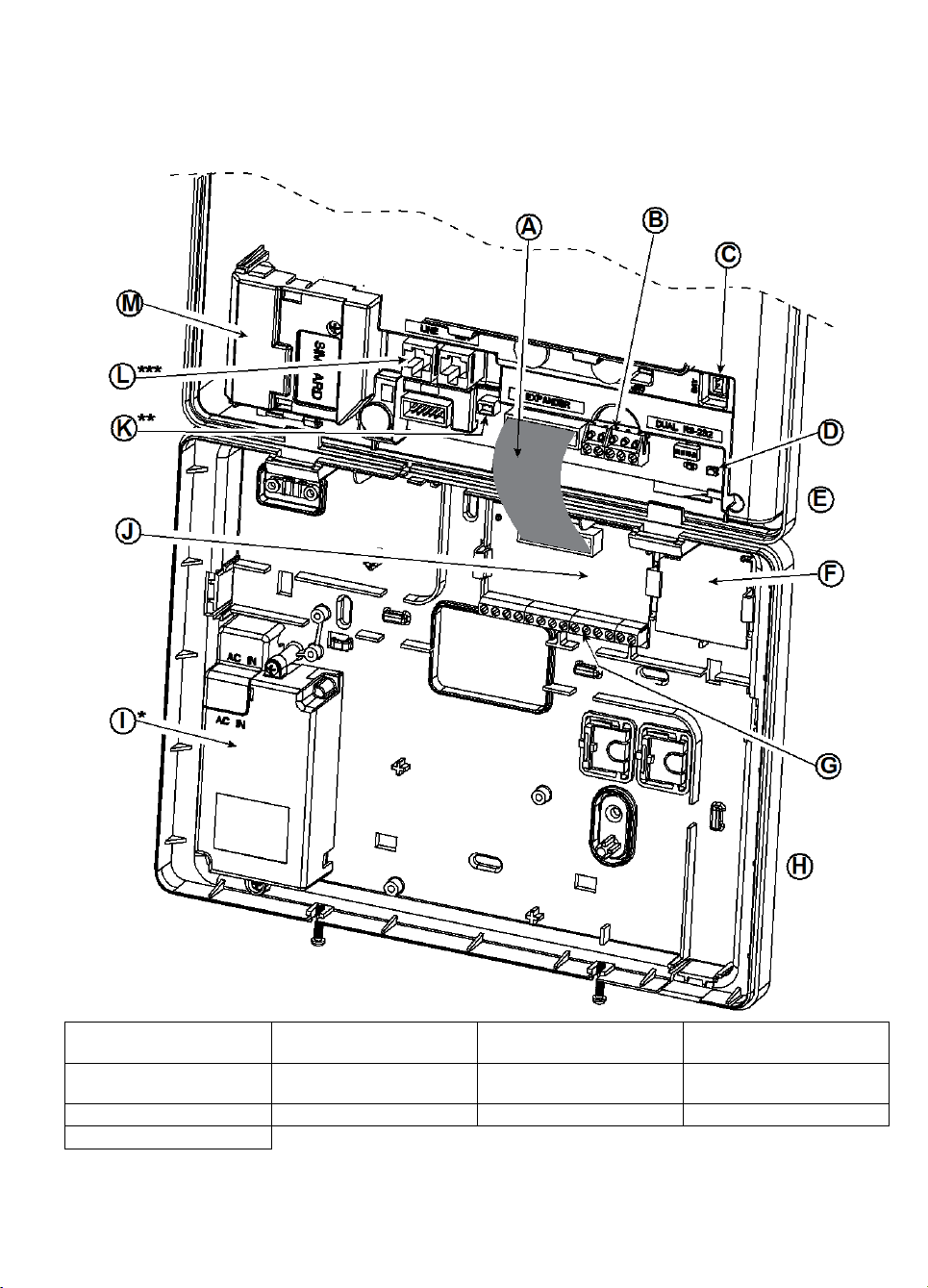

A. Expander Module Flat

Cable

B. Wired Zone / Special

Siren Terminal Block

C. Battery Connector

D. ENROLL button

E. Front Unit

F. PGM-5 Module

G. Expander Module Wiring

Terminal Blocks

H. Back Unit

I. Power Supply

J. Expander Module

K. Power Connector

L. Phone Wiring Connectors

M. GSM-350 PG2

3. POWERMASTER-33 G2 INSTALLATION

Required tool: Philips screwdriver #2.

PowerMaster-33 G2 mounting process is shown in Figures 3.1 - 3.10.

3.1 PowerMaster-33 G2 Wiring Diagram

* or External Power Supply Unit

** or External Power Connector

*** or Terminal Block in North American Panels

D-304267 PowerMaster-33 G2 Installer's Guide 7

Figure 3.1 – PowerMaster-33 G2 Wiring Diagram

Page 8

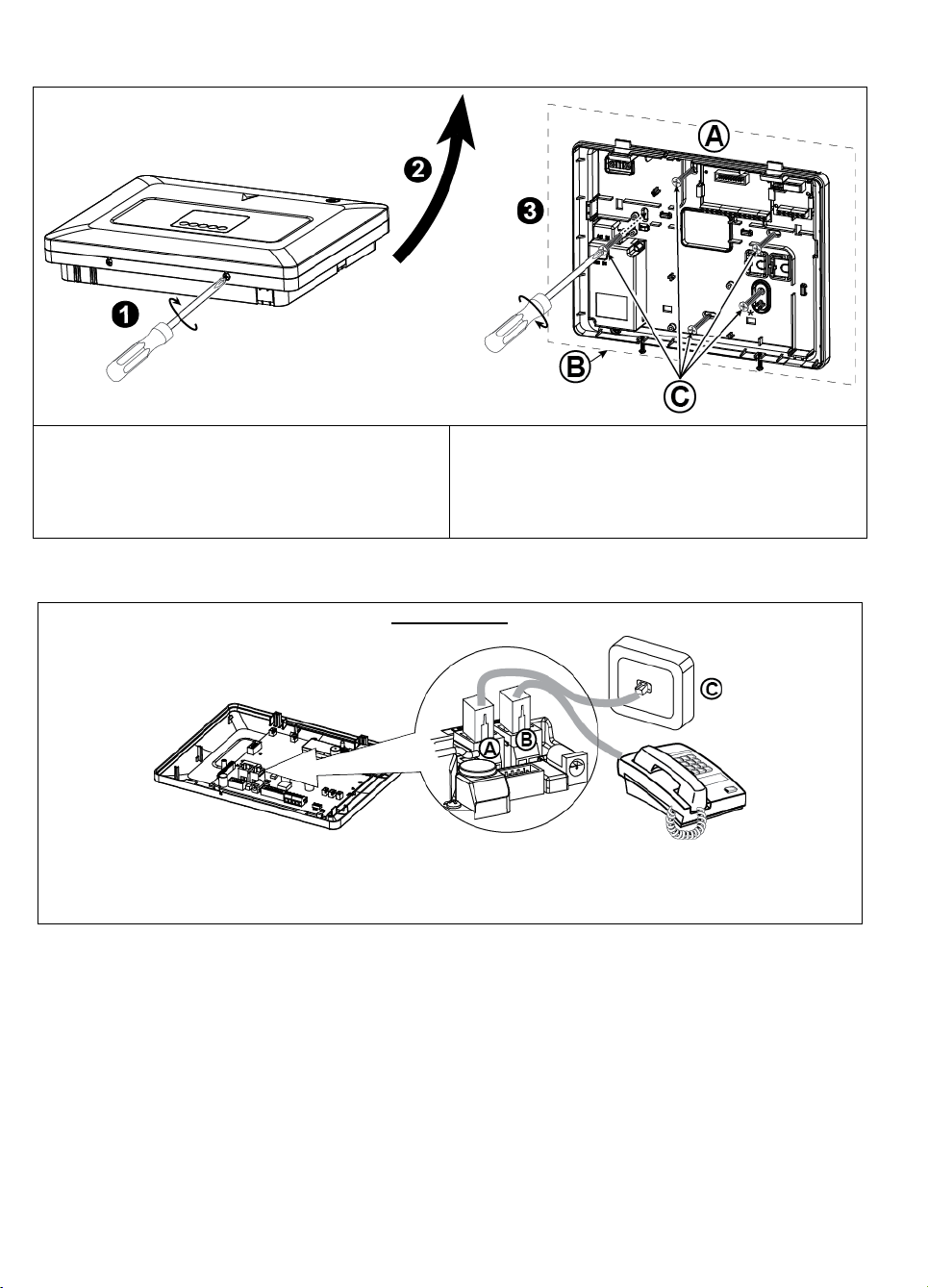

To Mount the Unit:

1. Release the screws

2. Remove the front cover

3. Mark 5 drilling points on the mounting surface, then

drill 5 holes and insert wall anchors and then fasten

the back unit with 4 screws

A. Mounting surface

B. Back unit

C. 5 screws

* For back tamper

PHONE WIRING

Connect the telephone cable to the SET connector and connect the telephone line cable to the LINE connector

(through the desired wiring cable entry).

Note: The telephone cable should be no longer than 3 meters.

A. LINE B. SET C. Tel line wall jack

3.2 Opening the PowerMaster-33 G2 Control Panel and Bracket Mounting

Figure 3.2 – Back Unit Mounting

3.3 Connecting to the Telephone Line (detail "K" in Figure 3.1)

Figure 3.3a – Phone Wiring

8 D-304267 PowerMaster-33 G2 Installer's Guide

Page 9

PHONE WIRING IN NORTH AMERICA

A. LINE

B. SET

C. RJ-31X cord

D. 8-position RJ-31X plug

E. Brown

F. Red

G. Green

H. Gray

I. RJ-31X jack

J. Line from street

K. House phones

A. GND

B. Wired Zone

C. Siren

D. For future use

E. Site external siren MG electronics

MG441PDS or equivalent 6-12VDC,

150 mA Max

F. Magnetic contact or any other contact

(not a detector)

G. Alarm N.C.

*

Figure 3.3b – Phone Wiring in North America

Phone wiring in the UK: Line terminals must be connected to pins 2 and 5 of the wall jack.

For all installations: If DSL service is present on the phone line, you must route the phone line through a DSL filter

(refer to MESSAGE TO THE INSTALLER on page 2 for further details).

3.4 Connecting Wired Zone and Siren (detail "B" in Figure 3.1)

If an expander module is not used, one wired zone and one low voltage siren can be connected directly to the front

panel PCB.

WIRED ZONE* &SIREN WIRING

Wired zones can be enrolled in any zone in the PowerMaster-30 G2 control panel from 01 to 64

D-304267 PowerMaster-33 G2 Installer's Guide 9

Figure 3.4 – Wired Zone and Siren Wiring

Page 10

Plug in the GSM module and fasten it as shown in the above

drawing making sure that the two leading slots on both sides of

the GSM module slide along the two leading ribs on the front

unit.

A. GSM module

B. Leading ribs

C. Leading slot (1 of 2)

D. Front unit

Caution! Do not install or remove the GSM module when the

system is powered by AC power or backup battery.

Insert the SIM card into the GSM module as shown in

the above drawing.

1. Slide top cover.

2. Open cover

3. Align SIM card in cover (note cover orientation)

4. Slide SIM card into cover

5. Rotate cover to close

6. Lock cover to close

IMPORTANT! Do not insert or remove SIM card when

the control panel is powered by AC power or battery.

3.5 GSM Module and SIM Installation (detail "L" in Figure 3.1)

Figure

3.5 – Optional GSM Module Mounting and SIM Card Insertion

10 D-304267 PowerMaster-33 G2 Installer's Guide

Page 11

A. Front panel receptacle

(marked “IP”)

B. Front unit

C. PGM-5 Module

D. Back unit

E. Wiring Cable

F. Flat cable

F1. This side for front unit

F2. This side for back unit

G. PGM-5 flat cable receptacle

3.6 PGM-5 Installation (located in place of detail "E" in Figure 3.1)

PGM-5 is an output interface module designed to provide alarm, trouble events and status signals to external devices

such as long range wireless monitoring transmitters, CCTV systems, home-automation systems and LED annunciation

panels (for further details see the PGM-5 Installation Instructions).

The PGM-5 provides 5 solid state relay contact outputs and is designed to be used as a plug-in internal add-on module

with the PowerMaster-33 G2 control panel.

Mount the PGM-5 module as shown in Figure 3.6.

1. Press downward on the PGM-5 module (C), located in the back panel, between its 2 clips.

2. Connect the PGM-5 module flat cable (F) to the front panel receptacle (marked “IP”) and to the flat cable receptacle

of the PGM-5 (G).

Caution! The connector with strain relief clip (F1) is for the front unit – do not connect it to the back unit!

Notes:

The PGM-5 will be active only if the PGM-5 option was enabled in the control panel (see section 4.7.6, “PGM Output

Configuration”.

For wiring instructions, refer to the PGM-5 Installation Instructions included in the module's package.

Caution! When mounting the PGM-5 module it is strongly recommended to route the wiring cable (E) as shown in

Figure 3.6) to prevent interference which may occur if routed too close to the control panel antennas.

D-304267 PowerMaster-33 G2 Installer's Guide 11

Figure 3.6 – PGM-5 Module Mounting

Page 12

Note: PowerLink3 operation is not backed up by

the control panel’s battery and it is shut down

during AC failure.

1. Mount the internal PowerLink3 into the back

unit and fasten it with 2 screws.

2. Connect the flat cable (B) from the front panel

to the PowerLink3, as follows: Connector B1

to the front panel; connector B2 to the

PowerLink3.

3. Connect the Cat-5 cable from the PowerLink3

to the home router.

Note: In order to prevent interference to the

antenna, do not route the Cat-5 cable through

the cable entry knockout on the right side of

the panel.

A. Cat-5 cable to home router

B. Flat cable

B1. This side for front unit

B2. This side for PowerLink3

Figure 3.7 – PowerLink3 Mounting

3.7 Installing the PowerLink3

The PowerLink3 is used to view and control the PowerMaster system over the Internet.

Perform the following instructions for the PowerLink3 installation.

12 D-304267 PowerMaster-33 G2 Installer's Guide

Page 13

3.8 Optional Expander Module (detail "I" in Figure 3.1)

The Expander module is an optional module. If this optional module is used, the wired zone or special siren on the front

panel should not be used.

Mount the Expander module as shown in Figure 3.8a.

1. Press downward on the Expander module (located in the back panel) between its 2 clips.

2. Connect the Expander module flat cable to the front panel Expander receptacle.

Caution! The receptacle with strain relief clip is for the front unit – do not connect it to the back unit!

A. 2 clips

B. Flat cable with one strain relief clip

B1. This side for front unit

B2. This side for back unit

Figure 3.8a –Expander Module

D-304267 PowerMaster-33 G2 Installer's Guide 13

Page 14

OPTIONAL EXPANDER MODULE, ZONES, SIRENS, AUDIO BOX AND WIRED DETECTORS WIRING

A. Back Unit

B. Expander

C. Internal siren or strobe 6-12 VDC,

150 mA Max.

D. External siren MG441PDS or similar siren 12 VDC

(nominal) 350 mA Max.

E. Connect wired detectors as illustrated.

Note:

The wired detector should be installed at least 2

meters away from the control panel.

Regarding the two wired zones, the control panel

classifies the events according to the resistance it

measures as shown in the table below.

E.O.L or Arming Key Resistance

Range

Zone

Arming Key

0 kΩ 1.76 kΩ

Tamper

Tamper

1.76 kΩ 2.64 kΩ

Normal

Arm

2.64 kΩ 3.52 kΩ

Tamper

Tamper

3.52 kΩ 5.26 kΩ

Alarm

Disarm

5.26 kΩ ∞

Tamper

Tamper

F. Detector without tamper switch or arming key

G. Detector with tamper switch or arming key's tamper

H. PGM device

I. Wired zone A or B

J. Ground (GND)

Notes for EXPANDER module wiring:

* Wired zone terminals can be connected to a normally closed contact of a detector, switch (for example a Tamper

switch of any device), or a pushbutton, via a 2.2 K resistor. The 12V terminal can be used to supply 12V (up to

36mA) to a detector (if necessary).

** The EXT terminal can be used to trigger an external siren.

The INT terminal can be programmed for an "internal siren" or "strobe" (see par. 4.7).

The 12V and "GND" terminals can be connected to a siren (for constant DC power supply).

*** The.12V supply to the PGM device is fused. Current is limited to 100 mA.

WARNING! When plugging terminals back into place, be sure to align them carefully with the pins on the PCB.

Misaligned or reverse insertion of terminals may damage internal PowerMaster-33 G2 circuits!

IMPORTANT! The terminals for internal and external sirens are DC outputs intended for 12V sirens. Connecting a

loudspeaker to any of these outputs will cause a short circuit and will damage the unit.

14 D-304267 PowerMaster-33 G2 Installer's Guide

Figure 3.8b – Zone and Siren Wiring

Page 15

POWER CABLE CLAMP EXTRACTION AND POWER CONNECTION FOR INTERNAL POWER SUPPLY

Perform steps 1 & 2 on a workbench before mounting.

1. Thick cable entry: Pull out a desired wiring plastic

cap (1 of 4).

2. Extract cable clamp (I) for use in the next step.

3. Insert the power cable through the desired wiring

channel (A). Route it to the power supply unit (E) and

remove the safety cover (D). Connect the 2 wires of

the power cable to the power supply terminal block

(F) with a screwdriver. Fasten the screws tightly.

Fasten the power cable by its clamp (B or C) and

close the safety cover (D).

4. Connect the power supply output cable (G) to the

power connector (H) in the front panel.

A. Optional wiring channels

B. For thin cable

C. For thick cable (reversed clamp)

D. Safety cover

E. Power supply unit

F. Power supply terminal block

G. Power supply output cable

H. Power connector

(*) Do not route wiring in this area, to enable proper

closure of the control panel.

I. Cable clamp.

3.9 Connecting Power to the Control Panel

Note: This equipment should be installed in accordance with Chapter 2 of the National Fire Alarm Code, ANSI/NFPA 72.

Connect the power cable and close the control panel as shown in Figures 3.9a –3.10.

Figure 3.9a – Power Cable Clamp Extraction and Power Connection for Internal Power Supply

D-304267 PowerMaster-33 G2 Installer's Guide 15

Page 16

EXTERNAL POWER CONNECTION

Connect the power adaptor to the front panel power connector.

Open battery compartment cover.

Insert one 6-battery pack or 8-battery

pack and connect its connector as

shown in Figure 3.8c.

A. Front unit

B. Battery cable

C. Battery cable connector

D. Slot for battery cable

Figure 3.9b – External Power Connection

3.9.1 Battery Insertion

Figure 3.9c – Battery Insertion

3.9.2 Connect AC Power to the Unit

Connect power to the PowerMaster-33 G2 to mains power outlet (see Figures 3.8a and 3.8b).

Disregard any “trouble” indications pertaining to lack of battery or lack of telephone line connection.

For Europe Safety Compliance:

a. The model shall be installed according to the local electrical code.

b. The circuit breaker shall be readily accessible.

c. The rating of the external circuit breaker shall be 16A or less.

16 D-304267 PowerMaster-33 G2 Installer's Guide

Page 17

To Close the Control Panel:

1. Connect the flat cables, between front and back units, in their

respective connectors (up to 3, according to options).

2. Make sure that the "Power" indicator on the control panel lights

green.

3. Close the panel and fasten the 2 screws.

Figure 3.

10 - Final Closure

3.10 Closing the PowerMaster-33 G2 Control Panel

Control panel final closure is shown below.

D-304267 PowerMaster-33 G2 Installer's Guide 17

Page 18

Color

Definition

LED Operation

Green

Local Power indication

STEADY: Indicates that system has mains power

BLINKING: Low battery state

NO LIGHT: AC failure

Green

Ready / Not Ready

Indication

STEADY: All partitions are ready

NO LIGHT: Not Ready / at least one partition is Not Ready

Red

System Arming State

Indication

STEADY: AWAY / At least one partition is AWAY

BLINKING: HOME / At least one partition is HOME and no

partitions are in AWAY

NO LIGHT: The system is presently in the disarmed state

Orange

System Not Online

Indication

STEADY: System is unavailable (Sync/Updating/In-menu)

NO LIGHT: System is available

Orange

System Trouble indication

STEADY: System has trouble

NO LIGHT: No trouble – all is well

Step

Action

1

Press the "ENROLL" button (physically located inside the front unit of the PowerMaster-33 G2 control panel

– see Figure 3.1) for 2 seconds. If no keypad exists in the first location, the "ENROLL" LED on the

PowerMaster-33 G2 blinks slowly for 1 minute (go to step 3).

If a keypad already exists in the first location, the "ENROLL" LED on the PowerMaster-33 G2 control panel

lights steady for 10 seconds (go to step 2).

Note: Pressing the "ENROLL" button takes the system out of any menu mode (Installer Mode, User

Settings and Periodic Test).

2

Press the "ENROLL" button again within the timeout period (10 seconds). Any keypad that was enrolled in

keypad no. 01 is deleted from the system.

The "ENROLL" LED on the PowerMaster-33 G2 blinks slowly for 1 minute.

3

During this 1 minute period, hold the button for 5-7 seconds, until the LED on the keypad lights

red, and release*. The "ENROLL" LED on the PowerMaster-33 G2 will indicate the result of the enrollment

procedure.

PowerMaster-33 G2 "ENROLL" LED indication Result

Blinks fast for 5 sec. Successful enrollment of keypad

Lights steadily for 5 sec. Wrong device type

4

Upon completion of the enrolling procedure, the keypad is ready for immediate use even if the system is

currently in the Armed state.

Note: If the keypad was previously enrolled, it will be relocated automatically to Keypad no. 1. However, all

of the configured parameters will be lost and the keypad will revert to the default parameters.

*

4. VISUAL INDICATIONS, FIRST KEYPAD

ENROLLMENT AND USING PROX TAG

4.1 PowerMaster-33 LED Indications

The following table provides a detailed description of the LED indications on the PowerMaster-33 panel.

4.2 Enrollment of the First KP-250 PG2 Keypad

The PowerMaster-33 G2 is designed to operate wirelessly with the KP-250 PG2 keypad installed anywhere within the

protected premises.

The first keypad is always enrolled as Keypad no. 1.

Note: The enrollment procedure described here is for the first KP-250 PG2 keypad only. The enrollment of additional

keypads is performed via the first enrolled KP-250 PG2 keypad (for instructions, refer to the KP-250 PG2

Installer’s Guide, section 3.4.2).

If the KP-250 PG2 unit is battery-powered: first press any button on the KP-250 PG2 keypad momentarily to take the KP-250 PG2

keypad out of sleep mode and then hold the button for 5-7 seconds, until the LED on the keypad lights red, and release.

18 D-304267 PowerMaster-33 G2 Installer's Guide

Page 19

Proximity tags enable authorized people to enter

restricted areas. Presenting a valid proximity tag to the

tag reader (as shown in the drawing) while the system is

armed causes the system to disarm. Presenting a valid

proximity tag to the tag reader while the system is

disarmed causes the system to be armed in AWAY

(optional HOME) mode. To enroll / delete proximity tags,

refer to the KP-250 PG2 User’s Guide.

Notes:

1. Use of the Proximity tags is optional.

2. Proximity tags are not compatible for use when partition

is enabled.

4.3 Using the Prox Tag

5. MAINTENANCE

5.1 Dismounting the Control Panel

A. Remove the screw that fastens the front unit to the back unit, see Figure 3.2.

B. Remove the 4 screws that fasten the back unit to the mounting surface - Figure 3.2 - and remove the control panel.

5.2 Replacing the Backup Battery

Replacement and first-time insertion of battery pack is similar, see Figure 3.9c.

With a fresh battery pack, correct insertion and tightened battery compartment lid, the TROUBLE indicator on the kp-

250 PG2 keypad should extinguish. However, the “MEMORY” message will now blink in the display (caused by the

“tamper” alarm you triggered when opening the battery compartment lid). Clear it by arming the system and

immediately disarming.

5.3 Fuse Replacement

The PowerMaster-33 G2 has two internal fuses that has automatic reset. Therefore, there is no need to replace the

fuses.

When over current condition occurs, the fuse cuts off the circuit current. Upon fault current being removed for several

seconds, the fuse is automatically reset and allows current flow through the circuit again.

5.4 Replacing/Relocating Detectors

Whenever maintenance work involves replacement or re-location of detectors, always perform a full diagnostic test

according to the KP-250 PG2 User’s Guide, section 12.9.

Remember! A "poor" signal is not acceptable.

5.5 Annual System Check

Note: The PowerMaster system must be checked by a qualified technician at least once every three (3) years

(preferably every year).

The annual system check is designed to ensure proper operation of the alarm system by performing the following checks:

Periodic test

Arm/disarm function

No trouble messages are displayed on control panel

The clock displays the correct time

Reporting: generating an event to be transmitted to the Monitoring Station and to the user.

D-304267 PowerMaster-33 G2 Installer's Guide 19

Page 20

Zones Number

Up to 64 wireless zones, (including 2 hard-wired inputs).

Hard-wired Zone Requirements

2.2 kE.O.L. resistance (max. resistance of wires 220

Maximum Loop Current

1.5 mA

Maximum Loop Voltage

3.3 V

Loop Shorted

0 – 1.47 V (0 – 1.770 Ω)

Loop Normal

1.47 – 1.8 V and 2.02 – 2.3 V

Loop Open

2.3 – 3.3 V (5.06 - ∞ Ω)

Installer and User Codes

1 master installer (9999 by default)*

1 installer (8888 by default)*

1 master user, no. 1 (1111 by default)

Users nos. 2 - 48

* Codes must not be identical

Control Facilities

- Integral keypad, wireless keyfobs and keypads

- SMS commands via optional GSM/GPRS module.

- Remote control by telephone.

Arming Modes

AWAY, HOME, AWAY-INSTANT, HOME-INSTANT, LATCHKEY, FORCED, BYPASS.

Alarm Types

Silent, personal panic/emergency, burglary, gas, fire and flood.

Siren Signals

Continuous (intrusion / 24 hours / panic); triple pulse – short pause - triple pulse... (fire);

four pulses – long pause – four pulses... (gas);

long pulse – long pause – long pulse... (flood).

Siren (bell) Timeout

Programmable (4 min. by default)

Internal Sounder Output

At least 85 dBA at 10 ft (3 m)

Supervision

Programmable time frame for inactivity alert

Special Functions

- Chime zones

- Diagnostic test and event log.

- Local and Remote Programming over Telephone, GSM /GPRS connections.

- Calling for help by using an emergency transmitter.

- Tracking inactivity of elderly, physically handicapped and infirm people.

- Message center (recording and playback)

Data Retrieval

Alarm memory, trouble, event log

Real Time Clock (RTC)

The control panel keeps and displays time and date. This feature is also used for the log

file by providing the date and time of each event

Battery Test

Once every 10 seconds

RF Network

PowerG – 2-way synchronized Frequency Hopping (TDMA / FHSS)

Frequency bands (MHz)

433 – 434

868 - 869

912 - 919

Hopping frequencies

8 4 50

Region

Worldwide

Europe

North America and

selected countries

Encryption

AES-128

External AC/AC adaptor

NA

External AC/DC adaptor

External (wall-mounted) switching power supply 100VAC to 240VAC, 50/60 Hz, 0.5A

/ 12.5 VDC, 1.2A

Internal AC/DC

Internal switching power supply:

Input: 100-240VAC, 0.75A

Output: 12.5 VDC, 1.6A.

Current Drain

Approx. 260 mA standby at the beginning (power ON) and then goes down to 60 mA,

1400 mA max. current drain during alarm.

Low Battery Threshold

7.2 V (6-cell battery pack)

9.6 V (8-cell battery pack)

Backup Battery Pack

Backup Battery Options:

Backup

period

Maximum external devices current (1)

1300 mAh

6 Battery Pack (2)

1800 mAh

8-BatteryPack (3)

2200 mAh 8-Battery

Pack (4)

4h

180 mA

300 mA

380 mA

8h

70 mA

125 mA

160 mA

12h

35 mA

70 mA

95 mA

24h

max backup w/o

load 22 hours

12 mA

25 mA

32h

no backup

0 mA

10 mA

39h

no backup

no backup

0 mA

APPENDIX A. Specifications

A1. Functional

A2. Wireless

A3. Electrical

20 D-304267 PowerMaster-33 G2 Installer's Guide

Page 21

(1) The external devices must be connected between 12V and ground. The current

for each specified backup period can be drawn from the batteries with the

internal GSM and the proximity reader connected to the PowerMaster-33 G2.

(2) 7.2V 1300 mAh, rechargeable NiMH battery pack, p/n 130AAH6BMX,

manufactured by GP or p/n LTT-AA1300LSDX6B, manufactured by LTT.

(3) 9.6V 1800 mAh, rechargeable NiMH battery pack, p/n GP180AAH8BMX,

manufactured by GP or p/n LTT-AA1800LSDX8B, manufactured by LTT.

(4) 9.6V 2200 mAh, rechargeable NiMH battery pack p/n 220AAH8BMX,

manufactured by GP or p/n LTT-AA2200LSDX8B, manufactured by LTT.

Caution! Risk of explosion if battery is replaced by an incorrect type. Dispose of

used batteries according to the manufacturer's instructions.

Notes:

1. For compliance with CE standards the battery backup period must be at least 12 hours

2. For compliance with UL standards the battery backup period must be at least 24 hours

Time to Charge

80 % ( 30 Hrs) for all battery types

Optional Backup Battery Pack

See "Backup Battery Options" table above

Time to Charge (optional backup

battery pack)

NA

Wired Detectors Total (Sum) Current

36* mA max.

Site External Siren Current (EXT)

450* mA max @ 12.5 VDC when powered by AC/DC (10.5 VDC when in standby mode)

Site Internal Siren Current (INT)

450* mA max @ 12.5 VDC when powered by AC/DC (10.5 VDC when in standby mode)

* Total PowerMaster-33 G2 output current (of INT & EXT sirens, PGM output and

detectors) cannot exceed 550 mA.

PGM

Current sink to control panel GND 100 mA max.

Max. external DC voltage +15 VDC

High Current / Short Circuit

Protection

All outputs are protected (automatic reset fuse)

Communication

PSTN; GSM; GPRS; IP

Built-in Modem

300 baud, Bell 103 protocol

Data Transfer to Local Computer

Via RS232 serial port

Report Destinations

2 Monitoring Stations, 4 private telephones

Reporting Format Options

SIA, Contact ID, Scancom, SIA IP, Visonic PowerNet.

Pulse Rate

10, 20, 33 and 40 pps - programmable

Message to Private Phones

Tone or voice

Ring Detection

The unit does not support ring detection without DC voltage present on the telephone lines

Operating Temp. Range

14°F to 120°F (-10°C to 49°C)

Storage Temp. Range

-4°F to 140°F (-20°C to 60°C)

Humidity

85% relative humidity, @ 30°C (86°F)

Size (WxHxD)

266 x 201 x 46 mm (10-7/16 x 7-7/8 x 1-13/16 in.)

Weight

1.44Kg (3.2 pounds) (with battery)

Color

White

Modules

GSM/GPRS, IP

Additional wireless devices

64 detectors, 32 keyfobs, 32 keypads (10 KP-250 PG2), 8 sirens, 4 repeaters , 32

proximity tags

Wireless Devices and peripherals

Magnetic Contact: MC-302 PG2, MC-302E PG2, MC-302EL PG2, MC-302V PG2

Motion Detectors: Next PG2; Next K9 PG2, TOWER-32AM PG2, TOWER-32AM

K9 PG2, TOWER-30AM PG2, TOWER-30AM K9 PG2, TOWER-20 PG2, TOWERCAM PG2, CLIP PG2

PIR Camera Detectors: Next CAM PG2; Next CAM-K9 PG2

Smoke Detector: SMD-426 PG2, SMD-427 PG2

GSM Module: GSM-350 PG2

Keyfob: KF-234 PG2, KF-235 PG2

Keypad: KP-140 PG2/KP-141 PG2 (with proximity tag), KP-160 PG2, KP-250 PG2

Indoor Siren: SR-720 PG2

Outdoor Sirens: SR-730 PG2, SR-740 PG2, SR-740 HEX PG2

Repeater: RP-600 PG2

Gas: GSD-441 PG2, GSD-442 PG2

Glass-break: GB-501 PG2

Temperature: TMD-560 PG2

Flood: FLD-550 PG2

Shock: SD-304 PG2

A4. Communication

A5. Physical Properties

A6. Peripherals and Accessory Devices

D-304267 PowerMaster-33 G2 Installer's Guide 21

Page 22

Compliance with

Standards

Hereby, Visonic Group declares that the PowerG series of central units and accessories are designed to comply with:

European CE Standards

The PowerMaster complies with the RTTE requirements - Directive 1999/5/EC of the European Parliament and of the Council of 9

March 1999.

According to the European standard EN50131-1 and EN 50131-3, the PowerMaster security grading is 2 - "low to medium risk" and

environmental classification is II – "indoor general" and the power supply type is A. EN 50131-6, and ATS Category SP4, by

GPRS module only according to EN50136-1, EN50136-2 (pass through Operation Mode).

Certified by Applica T&C.

GSM standards:

Europe: Complies with CE standards 3GPP TS 51.010-1, EN 301 511, EN301489-7

Security Grade:

According to EN 50131-1:2006 and A1:2009, this equipment can be applied in installed systems up to and including Security Grade 2.

EN 50131-1 Environmental Class

Class II

WARRANTY

Visonic Limited (the “Manufacturer") warrants this product only (the "Product") to the original

purchaser only (the “Purchaser”) against defective workmanship and materials under normal use

of the Product for a period of twelve (12) months from the date of shipment by the Manufacturer.

This Warranty is absolutely conditional upon the Product havi ng been properly installed,

maintained and operated under conditions of normal use in accordance with t he

Manufacturers recommended installation and operation instructions. Products which have

become defective for any other reason, according to the Manufacturers discretion, such as

improper installation, failure to follow recommended installation and operational instructions,

neglect, willful damage, misuse or vandalism, accidental damage, alteration or tampering, or

repair by anyone other than the manufacturer, are not covered by this Warranty.

The Manufacturer does not represent that this Product may not be compromised and/or

circumvented or that the Product will prevent any death and/or personal injury and/or damage

to property resulting from burglary, robbery, fire or otherwise, or that the Product will in all

cases provide adequate warning or protection. The Product, properly installed and

maintained, only reduces the risk of such ev ents without warning and it is not a guarantee or

insurance that such events will not occur.

THIS WARRANTY IS EXCLUSIVE AND EXPRESSLY IN LIEU OF ALL OTHER

WARRANTIES, OBLIGATIONS OR LIABILITIES, WHETHER WRITTEN, ORAL, EXPRESS

OR IMPLIED, I NCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR

A PARTICULAR PURPOSE, OR OTHERWISE. IN NO CASE SHALL THE

MANUFACTURER BE LIABLE TO ANYONE FOR ANY CONSEQUENTIAL OR

INCIDENTAL DAMAGES F OR BREACH OF THIS WARRANTY OR ANY OTHER

WARRANTIES WHATSOEVER, AS AFORESAID.

THE MANUFACTURER SHALL IN NO EVENT BE LIABLE FOR ANY SPECIAL,

INDIRECT, INCIDENTAL, CONSEQUENTIAL OR PUNITIVE DAMAGES OR FOR LOSS,

DAMAGE, OR EXPENSE, INCLUDING LOSS OF US E, PROFITS, REVENUE, OR

GOODWILL, DIRECTLY OR INDIRECTLY ARISING FROM PURCHASER’S USE OR

INABILITY TO USE THE PRODUCT, OR FOR LOSS OR DESTRUCTION OF OTHER

PROPERTY OR FROM ANY OTHER CAUSE, EVEN IF MANUFACTURER HAS BEEN

ADVISED OF THE POSSIBILITY OF SUCH DAMAGE.

THE MANUFACTURER SHALL HAVE NO LIABILITY FOR ANY DEATH, PERSONAL

AND/OR BODILY INJURY AND/OR DAMAGE TO PROPERTY OR OTHER LOSS

WHETHER DIRECT, INDIRECT, INCIDENTAL, CONSEQUENTIAL OR OTHERWISE,

BASED ON A CLAIM THAT THE PRODUCT FAILED TO FUNCTION.

However, if the Manufacturer is held liable, whether directly or indirectly, for any loss o r

damage arising under this limited warranty, THE MANUFACTURER'S MAXIMUM LIABILITY

(IF ANY) SHALL NOT IN ANY CASE EXCEED THE PURCHASE PRICE OF THE

PRODUCT, which shall be fixed as liquidated damages and not as a penalty, and shall be the

complete and exclusive remedy against the Manufacturer.

When accepting the delivery of the Product, the Purchaser agrees to the said conditions of

sale and warranty and he recognizes having been informed of.

Some jurisdictions do not allow the exclusion or limitation of incidental or consequential

damages, so these limitations may not apply under certain circumstances.

The Manufacturer shall be under no liability whatsoever arising out of the corruption and/or

malfunctioning of any telecommunication or electronic equipment or any programs.

The Manufacturers obligations under this Warranty are limited solely to repair and/or replace

at the Manufacturer’s discretion any Product or part thereof that may prove defective. Any

repair and/or replacement shall not extend the original Warranty period. The Manufacturer

shall not be responsible for dismantling and/or reinstallation costs. To exercise this Warranty

the Product must be returned to the Manufacturer freight pre-paid and insured. All freight and

insurance costs are the responsibility of the Purchaser and are not included in this Warranty.

This warranty shall not be modified, varied or extended, and the Manufacturer does not

authorize any person to act on its behalf in t he modification, variation or extension of this

warranty. This warranty shall apply to the Product only. All products, accessories or

attachments of others used in conjunction with the Product, including batteries, shall be

covered solely by their own warranty, if any. The Manufacturer shall not be liable for any

damage or loss whatsoever, whether directly, indirectly, i ncidentally, consequentially or

otherwise, caused by the malfunction of the Product due to products, accessories, or

attachments of others, including batteries, used in conjunction with the Products. This

Warranty is exclusive to the original Purchaser and is not assignable.

This W arranty is in addition t o and does not affect your legal rights. Any provi sion in this

warranty which is contrary to the La w in the state or country were the Product is supplied

shall not apply.

Warning: The user must follow the Manufacturer’s installation and operational instructions

including testing the Product and its whole system at least once a week and to take all

necessary precautions for his/her safety and the protection of his/her property.

1/08

EMAIL:

info@visonic.com

INTERNET:

www.visonic.com

VISONIC LTD. 2014

POWERMASTER-33 G2 Installer's Guide D-304267 Rev 2 (4/16)

APPENDIX B. Compliance with Standards

WARNING! Changes or modifications to this unit not expressly approved by the party responsible for compliance could void the user’s authority to operate

the equipment.

Canada: Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux appareils radio exempts de licence. L'exploitation est autorisée aux

deux conditions suivantes : (1) l'appareil ne doit pas produire de brouillage, et (2) l'utilisateur de l'appareil doit accepter tout brouillage radioélectrique subi,

même si le brouillage est susceptible d'en compromettre le fonctionnement.

Industry Canada Declaration

This product meets the applicable Industry Canada technical specifications/Le présent materiel est conforme aux specifications techniques appliables

d’Industrie Canada.

The Ringer Equivalence Number is an indication of the maximum number of devices allowed to be connected to a telephone interface. The termination on an

interface may consist of any combination of devices subject only to the requirement that the sum of the RENs of all the devices does not exceed five/L’indice

d’équivalence de la sonnerie (IES) sert à indiquer le nombre maximal de terminaux qui peuvent être raccordés à une interface téléphonique. La terminaison

d’une interface peut consister en une combinaison quelconque de dispositifs, à la seule condition que la somme d’indices d’équivalence de la sonnerie de tous

les dispositifs n’excède pas 5.

The Ringer Equivalence Number (REN) for this terminal equipment is 0.3B.

This device complies with FCC Rules Part 15 and with Industry Canada licence-exempt RSS standard(s). Operation is subject to two conditions: (1) This

device may not cause harmful interference, and (2) this device must accept any interference that may be received or that may cause undesired operation.

This device has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference in residential installations. This equipment generates uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio and television reception.

However, there is no guarantee that interference will not occur in a particular installation. If this device does cause such interference, which can be verified by turning

the device off and on, the user is encouraged to eliminate the interference by one or more of the following measures:

– Re-orient or re-locate the receiving antenna.

– Increase the distance between the device and the receiver.

– Connect the device to an outlet on a circuit different from the one that supplies power to the receiver.

– Consult the dealer or an experienced radio/TV technician.

22 D-304267 PowerMaster-33 G2 Installer's Guide

Page 23

Step

Operation

User Actions

Key & Keypad

Response

Optional

1

Press the Partition Selection

button and then select a

PARTITION

(if Partition is enabled)

followed by any combination of

The selected key blinks.

2

Arm AWAY

+ [ ] or enter code

The selected key and the

"Present Prox Tag" LED

( ) begin to blink and

prompt you to present

your Tag or enter your

user code.

The keypad's LED blinks

red once to indicate

transmission of the

arming command to the

control panel.

The LED and the buzzer

then indicate the control

panel's response – refer

to the KP-250 PG2

User’s Guide, Chapter 4

“System Status and

Indications”.

Arm HOME

+

[ ]

or enter code

Disarm (OFF)

+ [ ] or enter code

Optional

Quick arm AWAY

(If Quick Arm is enabled)

Quick arm HOME

(If Quick Arm is enabled)

Forced arming AWAY

(system not ready)

+ [ ] or enter code

to silence the “protest” buzzer

Forced arming HOME

(system not ready)

+

[ ]

or enter code

to silence the “protest” buzzer

Optional

3

INSTANT

(After arming HOME/AWAY)

LATCHKEY

Alarms

Actions

Notes

Emergency alarm

( 2 sec.)

When pressing the Fire or Emergency icons, the KP-250

PG2 starts beeping. After pressing the button for approx. 2

seconds, the KP-250 PG2 sends the command.

Fire alarm

( 2 sec.)

Panic alarm

( 2 sec.)

Quick User Guide to Main Alarm Control Operations by

KP-250 PG2 Keypad

The Quick Start Guide is intended for the user of the system. Please remove

this detachable sheet and hand it to the user.

Arming and Disarming the System

Note: The factory default master user code is 1111. The code is not required if quick arming has been permitted by the

installer. Change the factory default code to a secret code without delay (refer to the KP-250 PG2 User’s Guide,

Chapter 6, section B.4).

Initiating Alarms

D-304267 PowerMaster-33 G2 Installer's Guide 23

Page 24

HH:MM READY

This indicates that all zones are secured and you may arm the system as desired.

HH:MM NOT READY

This indicates that the system is not ready for arming and in most cases that one or more

zones are not secured. However, it can also mean that an unresolved condition exists

such as certain trouble conditions, jamming etc., depending on system configuration.

Preparing to Arm

Before arming, make sure that READY is displayed.

If at least one zone is open (disturbed) the display will read:

To review the open zones click . The details and location of the first open zone detector (usually an open

door or window sensor) will be displayed. To fix the open zone, locate the sensor and secure it (close the door

or window) – see "device locator" below. Each click of will display another open zone or trouble indication.

It is highly recommended to fix the open zone(s), thus restoring the system to the state of “ready to arm”. If you

do not know how to do this, consult your installer.

Note: To quit at any stage and to revert to the "READY" display, click .

Device Locator: The PowerMaster system has a powerful device locator that helps you to identify open or

troubled devices indicated on the LCD display. While the LCD displays an open or faulty device, the LED on the

respective device flashes indicating "it's me". The "it's me" indication will appear on the device within max. 16

seconds and will last for as long as the LCD displays the device.

Zone Bypass Scheme

Bypassing permits arming only part of the system and at the same time allowing free movement of people within

certain zones when the system is armed. It is also used to temporarily remove from service faulty zones that

require repair work or to deactivate a sensor if, for example, you are decorating a room.

You can set the Zone Bypass Scheme i.e. to scroll through the list of registered (enrolled) sensors to your

PowerMaster system and to Bypass (deactivate) faulty or disturbed sensors (either READY or NOT-READY) or

to Clear (reactivate) BYPASSED zones (sensors).

Once you have set a Bypass Scheme you can use the following 3 options:

To quickly review the bypassed zones – refer to Chapter 6, section A.2 of the KP-250 PG2 User’s Guide.

To quickly clear a bypassed zone i.e. to reactivate the bypassed zone – refer to Chapter 6, section A.1 of

the KP-250 PG2 User’s Guide.

To repeat (recall) the last used zone bypassing scheme – refer to Chapter 6, section A.3 of the KP-250 PG2

User’s Guide.

Notes:

1. Zones will be bypassed throughout one disarm-arm period only. Disarming the system after arming will

suspend the entire bypassing scheme but you can recall and reuse it as described in Chapter 6, section A.3

of the KP-250 PG2 User’s Guide.

2. Fire zones cannot be bypassed.

Loading...

Loading...