Page 1

055

Flush Mount PIR Detectors

,1752'8&7,21

The MR-4000 (vertical unit) and MR-4000R (horizontal unit) are

flush mounted PIRs for wired installations. They fit into virtually

any standard single-gang elec tri cal box, but may also be i nstal led

directly int o the wall without a box or a special inst allation kit.

Superior engineering gives you these added features:

• Flush mounting in a standard

electrical box

• Ideal for pre-wired installations

• 145 ultra-wide angle lens

• Super RFI protection

• Virtually zero fal se alarms

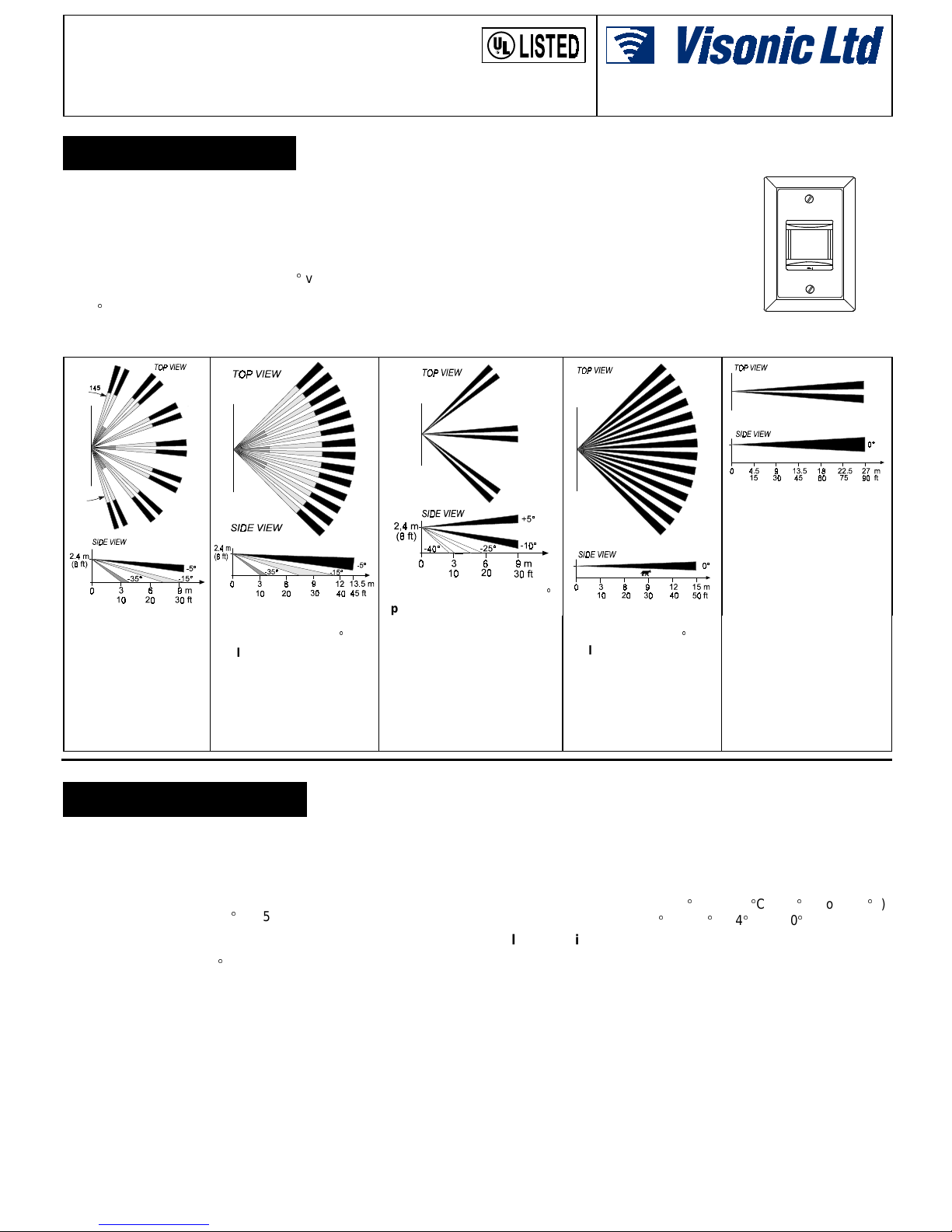

Maximum coverage:

10 m (30 ft) radius/145°

Application: provides the

largest and widest room

coverage for generalpurpose applications.

(Standard Lens)

Maximum coverage:

13.5 m (45 ft) radius/90

Application: general use -

high density coverage.

Figure 2

Lens No. 4, Ultra-Wide

Lens No. 1, Wide-Angl e

• Interchangeable lenses

• 12 vertical and hori zontal

adjustment

• Programmable pulse counter

• Plug-in wiring connector

• Entirely sealed construction

Max. coverage:

Application: 3 vertical "finger

curtains" which may be used as

3 individual traps within the

protected area. The coverage of

each curtain should be walktested-separately.

NOTE! A wide dead zone exists

between the curtains.

Figure 3

Lens No. 3, Triple Curtain

Figure 4

Installation Instructions

The MR-4000 provides a vari ety of

outstanding features including

adjustable pulse counter and RFl

protection up to 1000 MHz, to

ensure the highest level of reliability

and false alarm immunit y along wi th

added flexibility.

User-friendl y design includes installation aids for precise positioning at

the desired height.

9 m (30 ft) / 90

.

Maximum coverage:

15 m (50 ft) radius/90.

Application: allows pets to

move freely under coverage

pattern, undetected.

Mounting Height:

0.8 to 1.5 m (2.5 to 5 ft)

Figure 5

Lens No. 5, Pet Alley

Figure 1. Model MR-4000

for Vertical Installation

Maximum coverage:

27 x 3 m (90 x 10 ft)

Application: corridors and

long walls.

Mounting Height:

0.8 to 1.2 m (2.5 to 4 ft)

Beam Splitting: By dual-

element detector that creates

two detection zones for each

segment in the lens array,

doubling the number of detecting beams in the coverage

pattern

.

Figure 6

Lens No. 2, Long-Range

63(&,),&$7,216

OPTICAL

Standard Lens: Lens No. 4 is the standar d pattern s upplied wi th

each MR-4000. It provides 34 beams in 3 detec tion layers, 145 °

ultra-wide angle, maximum c overage area of 9 m (30 ft) radius.

Interchangeable Lenses (same as used with MR-3000 series):

Lens No. 1 - Wide-Angle 90, 13.5 m (45 ft) radius.

Lens No. 2 - Long-Range, 27 m x 3 m (90 ft x 10 ft )

Lens No. 3 - Triple curtain, 9 m (30 ft)

Lens No. 5 - Pet Alley, 90, 15 m (50 ft) radius.

Calibration: 0° to -12° (vertical); ±7.5° (horizontal)

ELECTRICAL

Voltage: 9 to 16 VDC.

Current Drain: 25 mA.

Relay Output: Normally Closed (fail safe) contacts. 18-ohm

resistor in series with contacts. Rat ing - 0.1 A resistive /30 VDC.

Alarm Period: 2-3 seconds.

Pulse Counter: Selectable 1 or 3 pulse operation.

Tamper Contacts (opti onal): N. C., 0.5 A resisti ve / 30 VDC.

LED: Switchable ON or OFF.

Detector: Dual-element low-noise pyroelectric sensor.

DE1141 1

MOUNTING

Flush mounted into virtually any standard single-gang electrical

box or installed directly into the wall (without box).

ENVIRONMENTAL

Operating Temperature: -10C to 50C (14F to 122F).

Storage Temperature: -20C to 60C (-4F to 140F).

RFl Protection: No alarm when tested on 21 different

frequencies fr om 20 to 1000 MHz with 124 W att radio trans mitter

at 3 m (10 ft) distance (equivalent to field strengt h of 20 V/m).

PHYSICAL

Dimensions: 125 x 85 x 48 mm (5 x 3.3 x 1.9 in.).

Weight: 90 g (3 oz).

Color: Soft white.

MODELS AVAILABLE

MR-4000: Standard model for vertical mounting.

MR-4000R: For horizontal mounting.

ACCESSORIES:

TS-1: Tamper switch module.

MRB-403: Standard single-gang back box.

Page 2

,167$//$7,21

&ORVLQJDQG2SHQLQJ WKH 'HWHFW RU

Position the fr ont cover (see Fig. 7) in the detect or housing, the

small latches al igned wi th t hei r c or res pondi ng lat c h holder s . Pus h

the front cover gentl y until a click is heard. The l ens assembly,

which is located behind the front cover, is adjustable vertically.

Locking screws are provided to secure the lens assembly after

vertical adjustment and to hold the detector in the electrical box.

Opening the detector:

Using a screwdr iver, release the cover by gently pushing on the

latches from t he rear of the det ector hous ing, until the fr ont c over

disengages.

Figure 7. MR-4000 Constr uction

&KDQJLQJ/HQVHV

Fig. 8 shows parts and construction of MR-4000 Lens Assembly.

Note: The Positioning Guides of model MR-4000R are slightly

different from model MR-4000 and are located on the sides of the

lens housing - see Fi gure 11. To change or adjust a lens, r elease

and remove the two lens-lock ing cl ips, l ocated on both s ides of the

lens, by pushing them from inside the cover (see Figure 9).

Install the new l ens with t he smooth sur face out side and the lens

number held at the upper lef t corner, opposite the l ens positioning

pointer - see figure 8. From inside the lens assembly, carefully

center the lens by sliding it to the right or left. The lens is

centered when both lens edges emerge equally above the frame

of the lens housing.

Holding firmly in place, insert the lens locking clips from the

outside (flanges pointed outwar d) and firmly pus h into place unti l

a click is heard - see Figures 8 and 10.

Before closing the detect or, the lens assembl y should be held in

the correct position relative to the detector. The positioning

guides and the pointer of the lens assembly assure correct

positioning of the lens ass embly r elati ve to the f ront c over. Fi gure

11 shows the lens hous ing positioning of bot h models: MR-4000

and MR-4000R.

Model MR-4000:

The pointer is placed

close to "A" (imprinted on the inner side

of the cover).

Model MR-4000R:

The pointer is pl aced

close to "B". The two

guiding studs assure

correct pos itioning of

the lens assembly in

each model and

allow movement of

the lens assembly for

vertical adjustment.

Figure 8. Lens Assembly ( M R-4000)

Figure 9. Removing Lens

Locking Clips

Figure 10. Locking the Lens

Figure 11. Positi oning the Lens Housing

6HOHFWLQJWKH 0RXQWLQJ/RFDWLRQ

A. The MR-4000 detector is much more sensitive to motion

crossing the beams of its coverage pattern than to motion

towards or away from the detector. Therefore, select the

mounting location s o that t he expected mot ion of an int r uder wi ll

cross the beams of the selected pattern.

NOTE: Passive infrared detectors are sensitive to changes in

infrared energy caused by an object moving across the unit's field of

view. The changes in infrared energy, detec ted by a PIR, depend

on the amount of infrared energy transmitted by t he moving object.

The changes also depend on the temperature difference bet ween

the object and the background. As a result, the PIR may fail to

respond under certain temperature and background conditions, in

which the temperature difference is too small. It is therefore

recommended that the PIR be aimed towards the coolest place in

the protected area, to obtain the maximum sensiti vi ty in ins tal lati ons

where high ambient temperatures are expected.

B. Select the most convenient mounting height . An adjustment table

determines the recommended angle for any combinat ion of range

and mounting height (see Table 1) . Remember that unprotected

areas directly above and below the detector increase when the

covered area is increased.

C. Where pets are present, consi der the use of lens No. 5 (Pet

Alley). For best detecti on performance inst all the MR-4000 at

the lowest possible height that enables di rec ting of the patt ern

above the level of the pets ' activity.

D . MAGIC-RED is extremely immune to air turbulence and RFl

interference. However, to minimize false alarms, it is highly

recommended to avoid aiming the detec tor at heater s, sour ces

of bright light, or windows subjected to direct sunlight. Also

avoid running wiring close to high-power electrical cables.

0RXQWLQJ

A. The MR-4000 is a flush mounted PIR designed to fit into

virtually any st andard s i ngle- gang elec t ri c al s wi tc h box (Fi gure

7). The box should

B. Due to its sealed design, the MR-4000 can also be installed

directly into a prepared space in the wall, without requiri ng a box

enclosure. Figure 12 provides an actual size cutout drawing

which may be used when drilling the holes in the wall.

be

installed per its specific instructions.

:LULQJ

Use 22 AWG or larger wires. The maximum wiring length

between the unit and its power sour ce depends on the number of

units connected in parallel and the wire gauge.

2 DE1141

Page 3

Actual size

MR-4000

Note!

For

MR-4000R

the cutout

drawing should

be rotated 90°.

The table below provides maximum wiri ng lengt h f or a si ngle uni t,

using different gauge wires. If two or more uni ts are c onnected in

parallel, the maximum wiri ng length indicated in the table should

be divided by number of units .

Wiring Gauge 22 20 18 16

Wiring length (m)

Wiring length (ft)

Relay connection

Connect Relay N.C. term inals (pins 1 &

2) to a normally cl osed bur gl ar pr otec t ion

zone of the control panel. Relay cont acts

(rated at 100 mA, 30 VDC max., resistive

load only) open when an intruder is

detected or during power loss. An

18-ohm resistor is int er nall y c onnect ed in

series with the relay contacts.

Supply Voltage connection

Connect the 12 VDC (–) and (+) t erminals (pins 3 & 4) to a 9-16

VDC source. Check for corr ect pol arit y. The power s ource s hould

have a back-up battery that is capable of supplying power for at

least four hours of operation dur i ng power f ail ur e. Cur r ent dr ain of

each sensor is approximately 20 mA.

Plugging in the Connector

Plug the connector into the connec tor pins in the unit (Fig. 14) .

Verify that:

The connector is mounted in the correct position - i.e., the

A .

+12 VDC wire is plugged into pi n 4.

The connector is

B.

installed to the

end of its pins.

Tamper Switch

(optional)

Tamper switch modul e

TS-1 must be installed

first (see Figure 14).

Connect

terminals to a nor mall y

closed 24-hour prot ection zone of the control

panel. Tamper contact

will open when the

cover is removed.

,

Figure 12. Wall Cutout and Drilling Diagram

250 370 545 1000

750 1100 1800 3000

Figure 13. Plug-In

Connector Wiri ng

Tamper TS-1

Figure 14. Mounting the Connector and

the Optional Tamper Switch TS-1

Important!

between the back wall of the ins tallat ion box and t he tamper s wit ch

lever (in depressed position) must be filled with material. In this

manner, the tamper switch is depressed when unit is installed in the

mounting box. For this purpose, attach a piece of w ood to the back

wall of the mounting box, just behind the location of the tamper

switch. Afterwards, carefully adjust the height, by trimming the

wood, until MR-4000 can be inst alled into the box and the tamper

switch functions properly. Make sure the piece of wood is reliably

secured to the mounting box and that no excessive pressure is

exerted on the tamper switch.

For proper operation of the tamper switch, the gap

$GMXVWLQJWKH &RYHUDJH$UHD

MR-4000 provides the most powerful tools for quick, easy and

accurate pattern adjustments. The LED selector, horizontal

adjustment, vertical calibrated scale, height selection table and

beam masking material are all unique features which enable

precise pinpointing of the pattern both vertically and horizontally.

LED Selector

The LED selector is a

3-pin connector with a

jumper to switch the walk

test LED ON or OFF - see

Figure 15.

ON is used for walk-test.

The LED lights for a few

seconds whenever motion

is detected.

OFF is used to disable t he

LED after testing, to

prevent unauthorized

persons from tracing the

coverage pattern.

Horizontal Adjustment

The MAGIC-RED coverage pattern c an be adjusted horizontally

approximately ± 7.5°, by rotating the lens to the lef t or right si de.

To adjust, remove the lens locking clips, rotate the lens to the

desired position and lock the lens in place.

Vertical Adjustment

The vertical adjust ing scale ( printed on t he lens as sembly), indicates

the angle (in degrees) between the upper layer of the coverage

pattern and the horizontal line of the unit. The scale enabl es pattern

adjustment from 0° to -12° downward according to the installation

height and the required coverage range.

The vertical adjust ing scale is i mprinted on the lens assembly i n

two parts. Settings from 0° to –6° are imprinted on the frame

below the lens and settings from –6° to –12° are imprinted on the

frame above the lens - see Figure 16.

Setting of the vert ic al adjus t ing s c al e is done by ali gni ng the edge

of the rectangular opening in t he front cover with the li ne marked

with the appropriate number on the scal e - see Fi gur e 16. Tabl e 1

gives recommended scale adjustment for combinations of

mounting height and coverage di stance.

Table 1 - Vertical Adjusting Scale

Example:

sensor at a height of 1.8 m (6 ft) from the ground, set the Vertical Adjustment

Scale to -6°.

If you require coverage range of 9 m (30 ft) and wish to install the

WARNING: Maximum range as stated for each lens type

shall not be exceeded!

Figure 15 . PCB Layout

DE1141 3

Page 4

Vertical adjustment is performed as

follows:

First, refer to table 1 and determine

•

the correct scale setting according to

unit’s mounting height and the

required coverage range. The table

should be used only to the maximum

coverage range of the selec ted lens,

as indicated in the Lens Selection.

Slightly loosen the two locking

•

screws which fasten the unit to the

mounting box until the lens assembl y

can be positioned up and down (with

slight friction) between the front

cover and the detector housing.

Moving the lens assembly up or

•

down, set the adjusting scale to the

correct setting according to table 1

and tighten the two screws firmly.

Beam Masking Material

Special beam masking material,

supplied with each MAGIC RED sensor

can be used to mask individual

segments in the lens array which are

exposed to potential sources of false

alarm (heaters, blowers, pets etc.).

The material is transparent to visible

light but blocks infrared energy. To

block individual beam(s), locate the

corresponding s egment(s) in the array.

Figure 16

the Vertical Sc ale

.

Setting

Cut the masking material to the exact dimensions of the

segment(s) to be bl ocked, remove the backing paper and apply

the masking material acc ur atel y t o the i ns ide ( grooved) s ur fac e of

the appropriate segment (s). In s ome cases, more t han one layer

of the lens maski ng material may be requir ed to complet ely bl ock

the infrared energy.

6HWWLQJWKH 3XOVH&RXQWHU

Model MR-4000 is equipped with a programmable puls e counter

which can be set to count 1 or 3 pulses, before activating the

alarm relay. To set the pulse counter, place the jumper at the

desired setting (1 or 3) - see figure 15.

3 pulses: This set ting provides the maximum protection agai nst

false alarms c aus ed by all t ypes of envi r onmental dis t urbanc es . 3

pulses may be selected for wide-angle, multi-beam lenses 1, 4

and 5.

Note: Do not select 3-pulse operat ion when using lenses 2 or 3.

When the pulse count er is s et to 3, no alarm will oc cur unles s t he

unit register s thr ee puls es wit hin approximat ely two mi nutes . Thi s

ordinarily requires crossing more than one beam (each dualbeam produces two puls es - one additional beam element must

be crossed to pr ovide the third pulse).

1 Pulse This setti ng actual ly dis ables the puls e count er. I t shoul d

be used when necessary to trigger an alarm on the fi rst detec ted

pulse, such as with long-range lenses. One pulse should be

selected with lenses 2 and 3, or in high security installations

when fast "catch" per formance is of greatest importance.

Self-Adjusting Walk-Test Override

The unique pulse counter i ncorporated in the MR-4000 features

an automatic switchover to single-pulse mode during walktesting. After alarm signaling, the pulse counter converts

automatically t o single-pulse setti ng for several sec onds. During

this time period each detection pulse will activate an immediate

alarm. This feature enables convenient walk-testing of each

beam in the coverage pattern - exactly as for a unit without a

pulse counter. Two minutes after the walk-test ends, the pulse

counter returns automatically to its original setting and is ready

for a new counting sequence.

)LQDO7HVWLQJ

A. Apply 12 VDC and allow 5 minutes for the unit to stabilize.

B. Adjust the vertical patter n angle according to Table 1.

C. Set pulse counter per Para. 3.7

D. MASK beams which face potential sources of false alarm.

E. Slowly walk-test the whole protected area across coverage

beams while observing the LED. The LED lights whenever

you enter or exit coverage beam. Allow a 5-minute interval

between tests for the unit to settle down.

F. Chec k the operation of the alarm relay and the tamper switch.

Warning: After walk t esting disable the LED by setti ng the

LED selector to OFF.

Important: Whenever you open and close the detector,

make sure that the scale is adjusted to the correct setting

and that the locki ng screws are firmly t ightened, so that t he

position of the l ens housing cannot be changed.

0DLQWHQDQFH

Proper operation, r ange and coverage pat ter n should be c hecked

at least once a week ac cording to Para. 3.8. To assure proper

continuous operation, the end user should be inst ructed to walk

through the entire coverage pattern and to assure an alarm

output each time before the alarm system is armed.

:$55$17<

:$55$17<

Visonic Ltd. and/or its subsidiaries and its affiliates ("the Manufacturer") warrants its

products hereinafter referred to as "the Product" or "Products" to be in conformance with

its own plans and specifications and to be free of defects in materials and workmanship

under normal use and service for a period of twelve months from the date of shipment by

the Manufacturer. The Manufacturer's obligations shall be limited within the warranty

period, at its option, to repair or replace the product or any part thereof. The Manufacturer

shall not be responsible for dismantling and/or reinstallation charges. To exercise the

warranty the product must be returned to the Manufacturer freight prepaid and insured.

This warranty does not apply in the following cases: improper installation, misuse,

failure to follow installation and operating instructions, alteration, abuse, accident or

tampering, and repair by anyone other than the Manufacturer.

This warranty is exclusive and expressly in lieu of all other warranties, obligations or

liabilities, whether written, oral, express or implied, including any warranty of

merchantability or fitness for a particular purpose, or otherwise. In no case shall the

Manufacturer be liable to anyone for any consequential or incidental damages for breach

of this warranty or any other warranties whatsoever, as aforesaid.

This warranty shall not be modified, varied or extended, and the Manufacturer does not

authorize any person to act on its behalf in the modification, variation or extension of this

warranty. This warranty shall apply to the Product only. All products, accessories or

attachments of others used in conjunction with the Product, including batteries, shall be

covered solely by their own warranty, if any. The Manufacturer shall not be liable for any

damage or loss whatsoever, whether directly, indirectly, incidentally, consequentially or

otherwise, caused by the malfunction of the Product due to products, accessories, or

attachments of others, including batteries, used in conjunction with the Products.

VISONIC LTD. (ISRAEL): P.O.B 22020 TEL-AVIV 61220 ISRAEL. PHONE: (972-3) 645-6789, FAX: (972-3) 645-6788

VISONIC INC. (U.S.A.): 10 NORTHWOOD DRIVE, BLOOMFIELD CT. 06002-1911. PHONE: (860) 243-0833, (800) 223-0020 FAX: (860) 242-8094

VISONIC LTD. (UK): UNIT 1, STRATTON PARK, DUNTON LANE, BIGGLESWADE, BEDS. SG18 8QS. PHONE: (01767) 600857 FAX: (01767) 601098

VISONIC LTD. 1998 MR-4000 D-1141-0 NEW: DE1141- (REV. 2, 12/98)

4 DE1141

The Manufacturer does not represent that its Product may not be compromised and/or

circumvented, or that the Product will prevent any death, personal and/or bodily injury

and/or damage to property resulting from burglary, robbery, fire or otherwise, or that the

Product will in all cases provide adequate warning or protection. User understands that a

properly installed and maintained alarm may only reduce the risk of events such as

burglary, robbery, and fire without warning, but it is not insurance or a guarantee that such

will not occur or that there will be no death, personal damage and/or damage to property

as a result.

The Manufacturer shall have no liability for any death, personal and/or bodily injury

and/or damage to property or other loss whether direct, indirect, incidental,

consequential or otherwise, based on a claim that the Product failed to function.

However, if the Manufacturer is held liable, whether directly or indirectly, for any loss or

damage arising under this limited warranty or otherwise, regardless of cause or origin, the

Manufacturer's maximum liability shall not in any case exceed the purchase price of the

Product, which shall be fixed as liquidated damages and not as a penalty, and shall be the

complete and exclusive remedy against the Manufacturer.

Warning: The user should follow the installation and operation instructions and among

other things test the Product and the whole system at least once a week. For various

reasons, including, but not limited to, changes in environmental conditions, electric or

electronic disruptions and tampering, the Product may not perform as expected. The user

is advised to take all necessary precautions for his/her safety and the protection of his/her

property.

6/91

Loading...

Loading...