Page 1

User manual

Premium DSP

40-80KVA – PF0.9

3 phase in / 3 phase out

Double conversion online UPS

Page 2

All rights reserved.

The information in this document is subject to change without notice.

Thank you for purchasing this series UPS.

Read this manual carfully before installation. This manual provides technical support to the operator of the

equipment.

Page 3

CONTENTS

I. GENERAL DESCRIPTION ....................................................................................... 4

1.1 Introduction ........................................................................................................ 4

1.2 Design Concept ................................................................................................. 6

1.2.1 Description of Blocks ................................................................................ 7

1.2.2 Operating Conditions of UPS .................................................................... 7

1.3 Front view of UPS Conditions of ups ................................................................. 8

1.4 Technical Specifications .................................................................................... 10

II. UPS INSTALLATION ............................................................................................... 11

2.1. Introduction ........................................................................................................ 11

2.2. Unpacking ......................................................................................................... 11

2.3. Equipment Positioning ....................................................................................... 11

2.4. Connecting the UPS Power Cables ................................................................... 12

2.5. Safety Earth ....................................................................................................... 12

2.6. Cable Connection Procedure ............................................................................. 12

2.6.1. Description of Connection Terminals of the UPS ........................................ 13

2.7. Battery Installation ............................................................................................. 14

III. FRONT PANEL ........................................................................................................ 18

3.1. Introduction ........................................................................................................ 18

3.2. Front Panel Menu Descriptions .......................................................................... 18

3.2.1 MEASUREMENTS menu ............................................................................ 21

3.2.2 ALARM LOGS menu ................................................................................... 22

3.2.3 INFORMATION menu ................................................................................. 22

3.2.4 OPTIONS menu .......................................................................................... 23

3.2.5 COMMAND menu ....................................................................................... 25

3.2.6 TIME menu ................................................................................................. 25

3.2.7 SERVICE menu .......................................................................................... 25

3.2.8 ADJUST menu ............................................................................................ 26

3.2.9 User Pasword ............................................................................................. 26

3.3. Alarms and warning messages .......................................................................... 26

3.4. Status Codes ..................................................................................................... 29

3.5. Alarm messages and quick troubleshooting ....................................................... 35

IV. PARALLEL OPERATION ........................................................................................ 40

4.1 Introduction ........................................................................................................ 40

4.2 Parallel Operation Mode setting of DSP0.9 Series UPSs ................................... 41

4.3 Parallel mode status codes of the UPS .............................................................. 44

Page 4

PREMIUM DSP 40-80 KVA PF0.9 3/3 - UPS www.visionups.com

2

V. PARALLEL OPERATING INSTRUCTIONS ............................................................. 50

5.1 Introduction ........................................................................................................ 50

5.2 Operating instructions for parallel connected UPSs ............................................ 50

5.2.1 Starting UPSs from a completely shut down position ................................. 50

5.2.2 Shutting down the UPS ............................................................................. 50

5.2.3 Switching the UPS from a normal Operation to

Maintenance Bypass Condition ................................................................ 51

5.2.4 Switching the UPS from a Maintenance Bypass

Conditio nto Normal Operation ................................................................. 51

VI. NORMAL OPERATING INSTRUCTIONS ................................................................ 52

6.1 Operating UPS in Online Mode .......................................................................... 52

6.1.1 Starting UPS from a completely shut down position .................................. 52

6.1.2 Shutting down the UPS ............................................................................. 52

6.1.3 Switching the UPS from a Normal Operation to

Maintenance Bypass Condition ................................................................ 52

6.1.4 Switching the UPS from a Maintenance Bypass

Condition to Normal Operation ................................................................. 53

6.2 UPS Behavior during Mains Outage ................................................................... 53

VII. MAINTENANCE...................................................................................................... 54

7.1 Scheduled maintenance ..................................................................................... 54

7.2 Daily checks ....................................................................................................... 54

7.3 Weekly checks ................................................................................................... 54

7.4 Annual Maintenance .......................................................................................... 55

7.5 Storage conditions and transportation of ups ..................................................... 55

VIII. FAULTS AND TROUBLESHOOTING .................................................................. 56

8.1 General Procedure for fault checking and troubleshooting ................................. 56

8.2 Before calling service ......................................................................................... 56

IX. UPS REMOTE MONITORING AND CONTROL ..................................................... 57

9.1 Using Serial Port ................................................................................................ 57

9.2 Serial Communication port connection cable ..................................................... 57

9.3 Modem connection ............................................................................................ 58

9.3.1 Hardware configuration ............................................................................... 58

9.3.2 Functioning Principle ................................................................................... 58

9.3.3 Modem Programming Procedure ................................................................ 58

9.3.3.1 Smart modem (SM) programming ................................................... 58

9.3.4 Modem – UPS Connection Cable ................................................................ 59

9.4 Dry contact (ınterface) connections ................................................................... 59

9.5 Remote monitoring panel connection of UPS ..................................................... 59

X. EFFICIENT USAGE OF UPS IN TERMS OF ENERGY CONSUMPTION .............. 60

Page 5

PREMIUM DSP 40-80 KVA PF0.9 3/3 - UPS www.visionups.com

3

SAFETY

IMPORTANT NOTICES

1. Read instructions carefully before installing and starting the UPS.

2. All warnings in the manual should be adhered to.

3. All operating instructions should be followed.

4. The unit should be supplied by a grounded outlet. Do not operate the unit without a ground

source.

5. Power cables of the UPS should be routed carefully so that they are not to be walked on.

6. Please save this manual.

7. Please save or recycle the packaging materials.

WARNING!

Do not insert any object into ventilation holes or other openings.

To reduce the risk of fire or electric shock, install in temperature and humidity controlled

indoor area free of conductive contaminants.

To reduce the risk of fire, replace fuses with the same type and rating when necessary.

CAUTION!

Only qualified personnel should install or service UPS/batteries.

Risk of electric shock, do not remove cover. No user serviceable parts inside,

refer servicing to qualified service personnel.

The output may be energized even when the unit is not connected to a mains supply.

Risk of electric shock! Hazardous live parts inside. This unit is energized from the

battery supply even when the input AC power is disconnected.

To reduce the risk of electric shock, disconnect the UPS from the mains supply before

installing a computer interface signal cable. Reconnect the power cables only after signaling

interconnections have been made.

CAUTION!

Units are designed to operate on the concrete floor.

ABOUT THE BATTERIES

CAUTION: RISK OF ELECTRIC SHOCK!

The battery circuit is not isolated from the mains voltage. Hazardous

voltages may occur between the battery terminals and the ground!

A battery can present a risk of electric shock or burn from high short circuit currents.

The following precautions should be taken when working on batteries :

* Remove watches, rings or other metal objects.

* Use tools with insulated handles.

The batteries in this UPS are recyclable. Batteries must be disposed of according to

local environmental laws. The batteries contain lead and pose a hazard to the environment and

human health if not disposed of properly.

Do not dispose of batteries in a fire. The batteries may explode. Do not open or mutilate

the batteries. They contain an electrolyte which is toxic and harmful to the skin and eyes. If

electrolyte comes into contact with the skin the affected area should be washed

immediately.

Page 6

PREMIUM DSP 40-80 KVA PF0.9 3/3 - UPS www.visionups.com

4

The internal energy source (the battery) cannot be de-energized by the user.

When changing batteries, install the same number and same type of batteries.

I. GENERAL DESCRIPTION

1.1 Introduction

VISION DSP0.9 Series Uninterruptible Power Supplies are double-conversion; on-

line UPS’s manufactured with the latest IGBT and PWM technology, to produce an

uninterruptible, fully DSP (Digital Signal Processor) controlled pure sine wave output

to critical loads.

VISION DSP0.9 Series units are 3-phase in/3-phase out devices, and they are

installed between a three phase critical load, and a 3-phase+N mains supply

The advantages of using DSP0.9 UPS:

Power blackout protection:

If the mains power fails, the UPS continues to supply the critical load using the

energy stored in its batteries, keeping the load immune from power disturbances.

Increased power quality:

The UPS has its own internal voltage and frequency regulating software, which

ensures that, its output to the critical load is maintained within close tolerances,

independent of voltage and frequency variations on the mains power lines.

Fully digital control by three DSP controller for each UPS:

The UPS is controlled by 3 independent DSP chips which are communicating

each other continuously. Rectifier, Inverter and User Interface modules have separate

DSP’s to achieve the highest performance. Each DSP module has many parameters to

control and monitor the system to have the best electrical power output and to help

diagnostic.

Increased noise rejection:

By rectifying the input AC power to DC power and then converting it back to AC

(Double-Conversion) any electrical noise present on the input mains supply line is

effectively isolated from the UPS output. Therefore the critical load is supplied with only

clean and uninterrupted AC power.

Page 7

PREMIUM DSP 40-80 KVA PF0.9 3/3 - UPS www.visionups.com

5

Basic Features:

PWM and IGBT technology

Pure sinusoidal output wave form and true on-line topology

High input power factor (IGBT rectifier), Input current limiting

Low input current THD (IGBT rectifier)

Low output voltage THD

High AC/AC and DC/AC efficiency (up to 94%)

3 separate DSP (Digital Signal Processor) control

Cold-start feature

Static By-Pass feature: Provides uninterruptable transfer to bypass source in case of

overload or UPS fault.

Bypass leakage current sense system

Maintenance bypass switch and warning system, by-pass short circuit protection

Separate bypass input facility (split bypass), generator operation sense input

LCD alphanumeric display panel providing battery, load, voltage, power and status

information in detail to user

Improved diagnostics and correct fault information

Up to 192 event memory record system (7000 alarms or warnings total)

Real time clock and calendar system

Overload operation 10 minutes at 100% - 125% load, 1 minute at 125% - 150% load

Output overload, over-current and short circuit protection, output current limiting

Reliable operation at even 100% unbalanced load condition

Non-linear load supply feature (CF 3:1)

Double polarity battery (with common terminal)

Automatic and manual battery test and battery temperature compensation features

3 separate maintenance clock counters

Battery charge with current limiting

Automatic and manual boost charge feature

Battery deep discharge protection

Temperature protection with 3 separate sensors

Interactive communication

Diagnostic and settings with PC ability

2 separate RS232 communication ports (standard)

Multi UPS monitoring on same communication line by RS485 (optional)

4 dry contact alarm relay outputs as standard (8 optional relay outputs)

Improved remote monitoring panel system (optional)

RS232 port multiplexer (optional)

Direct network connection with optional SNMP support

MODBUS Adapter (optional)

AT command set definitions for dump modems

Communication via Windows based T-MON software and remote monitoring and

control of UPS via modem

Optional softwares compatible for most computer platforms

Ability for labeling of UPSs by users

Emergency power-off support

Conformity to international and local standards

AC input and output filters

Optional graphic front panel

CE compliance

Input, bypass and load phase order protection

Optional leakage current alarm system

Input and output isolation transformers (optional)

Enhanced accessory options

100.000 hours MTBF

2 years system warranty

10 years spare parts warranty

Page 8

PREMIUM DSP 40-80 KVA PF0.9 3/3 - UPS www.visionups.com

6

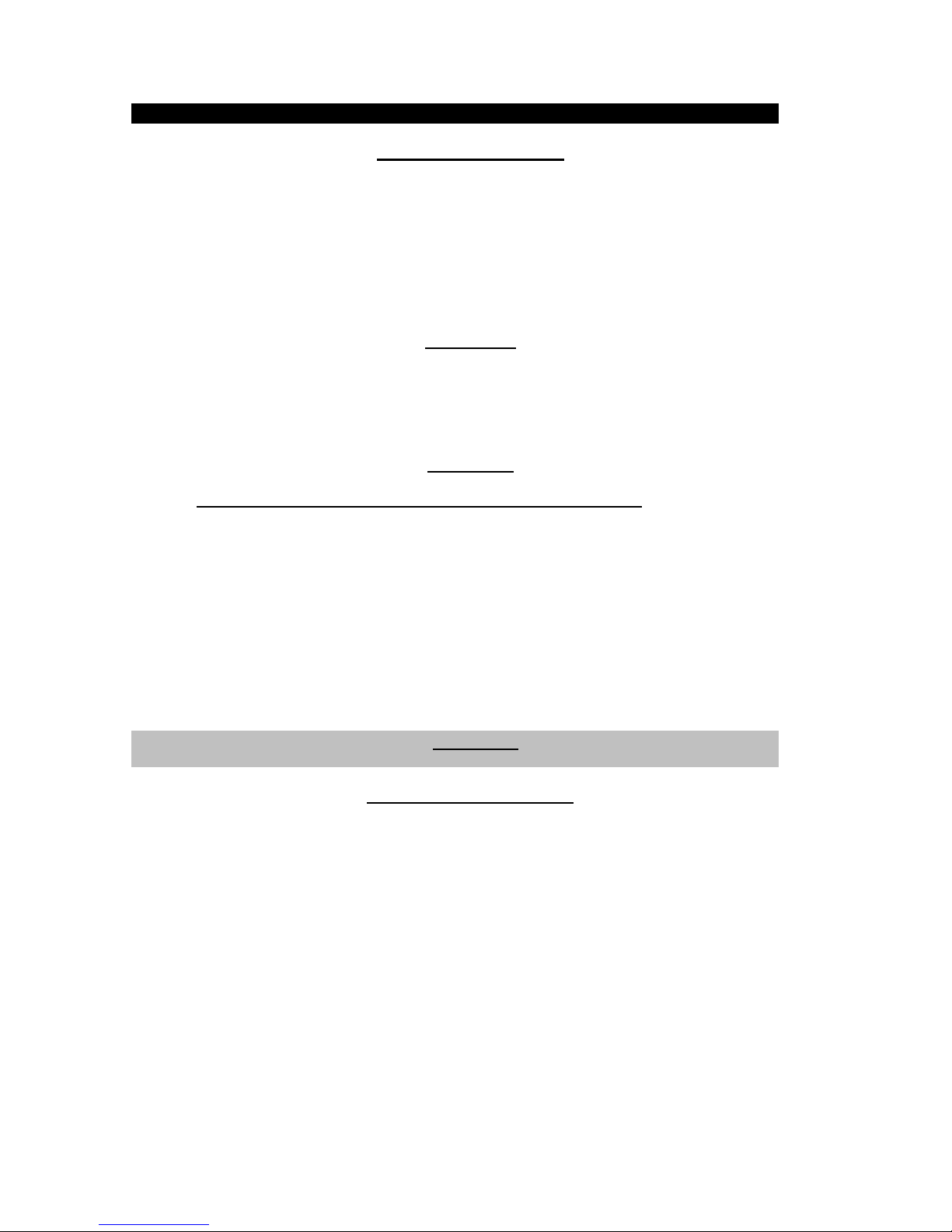

1.2 Design Concept

S1 (F1-F2-F3) : Rectifier Input Switch / Fuse

S2 (F4-F5-F6) : Bypass Input Switch / Fuse

S3 : Maintenance Bypass Switch

S4 (F7-F8-F9) : Output Switch / Fuse

S5 (F10-F11-F12) : Battery Switch / Fuse

K1 : Rectifier Input Contactor

K2 : Inverter Output Contactor

Rectifier /

Charger

3 PHASE

MAINS I/P

Battery

(Dual Polarity)

Maintenance

Bypass Switch

Static

Bypass

S2

(F4-F5-F6)

S1

(F1-F2-F3)

S5

(F10-F11-F12)

S3

S4

(F7-F8-F9)

Inverter

K2

3 PHASE

AC Output

K1

-

-

SB

Page 9

PREMIUM DSP 40-80 KVA PF0.9 3/3 - UPS www.visionups.com

7

1.2.1 Description of Blocks

RECTIFIER: In DSP0.9 Series UPSs, a DSP controlled IGBT rectifier with PWM technique is used to

increase input power factor (PFC) and to decrease input current harmonics (THDI).

The IGBT rectifier accepts 3-phase AC input and produces a dual polarity DC voltage for both

supplying the inverter and charging the batteries.

BATTERIES: Batteries are used as reserve DC power supply for the Inverter in case of mains failure.

In DSP0.9 Series, batteries are connected in series with a center-tap output to obtain a dual polarity

DC supply.

Batteries are discharged by the inverter during mains failure. The discharged batteries are re-charged

by the IGBT Rectifier on a constant voltage / current limiting basis, if AC mains power is available.

INVERTER: It is manufactured by using the latest IGBT and DSP (Digital Signal Processing)

technologies, and Pulse Width Modulation (PWM) technique. The Inverter converts the DC BUS

voltage supplied by the IGBT Rectifier and / or the batteries into a well regulated, fully digital controlled

3-phase AC voltage with fixed voltage and frequency.

The output of the inverter is used to supply the critical loads connected to the UPS output.

STATIC TRANSFER SWITCH (STATIC BYPASS): This is an electronically controlled transfer switch,

which enables the critical load to be connected either to inverter output or to by-pass power source.

During normal operation, the load is supplied by the inverter output, but in case of an overload or a

UPS failure it is automatically transferred to the bypass source without any interruption.

MAINTENANCE BYPASS SWITCH (MBS): This is a manually controlled mechanical switch, which is

used to supply the critical load, using the bypass source, when the UPS is shut down for maintenance

or troubleshooting purposes.

The load is unprotected against mains supply disturbances and black-outs when it is connected to

either static or maintenance bypass supply.

1.2.2. Operating Conditions of UPS

UPS may be in one of the following operating conditions:

A. Normal Operation (If Mains supply is available):

All fuses and power switches are closed (except the Maintenance Bypass Switch), and the load is

supplied by the Inverter Output. During normal operation, the Rectifier supplies DC power to the

Inverter and charges the Batteries at the same time.

B. Battery Operation :

The Batteries are connected to the Rectifier output. In case of a mains failure (mains power outage or

AC input voltage out of tolerance), the Rectifier stops operating and the DC voltage necessary for the

inverter operation is supplied by the batteries. Therefore the AC voltage output supplying the critical

load is not interrupted, until the batteries are fully discharged. At the end of the discharging time the

inverter is turned off and it start again automatically, together with the rectifier, when the mains power

is restored, and the UPS returns o normal operation. For UPS with a split bypass source, at the end of

discharging time, static transfer switch transfers the load to the split bypass source without interruption

if the split bypass source is available and in acceptable tolerances about voltage and frequency, as

still the rectifier input is not available.

The Rectifier is also turned off and inverter operates on batteries during automatic or manual battery

test procedure.

C. By-Pass Operation :

If the Inverter output is overloaded or in case of a problem in the UPS, the static switch transfers the

load to the bypass supply without any interruption, provided that the bypass supply is available and

within the tolerated limits regarding voltage and frequency. At the end of the overloading period, if the

fault condition is restored, static switch transfers the critical load again to the inverter output. Note that,

during operation from the bypass supply, the critical load may be effected by any possible

disturbances or power failure in the bypass supply.

Page 10

PREMIUM DSP 40-80 KVA PF0.9 3/3 - UPS www.visionups.com

8

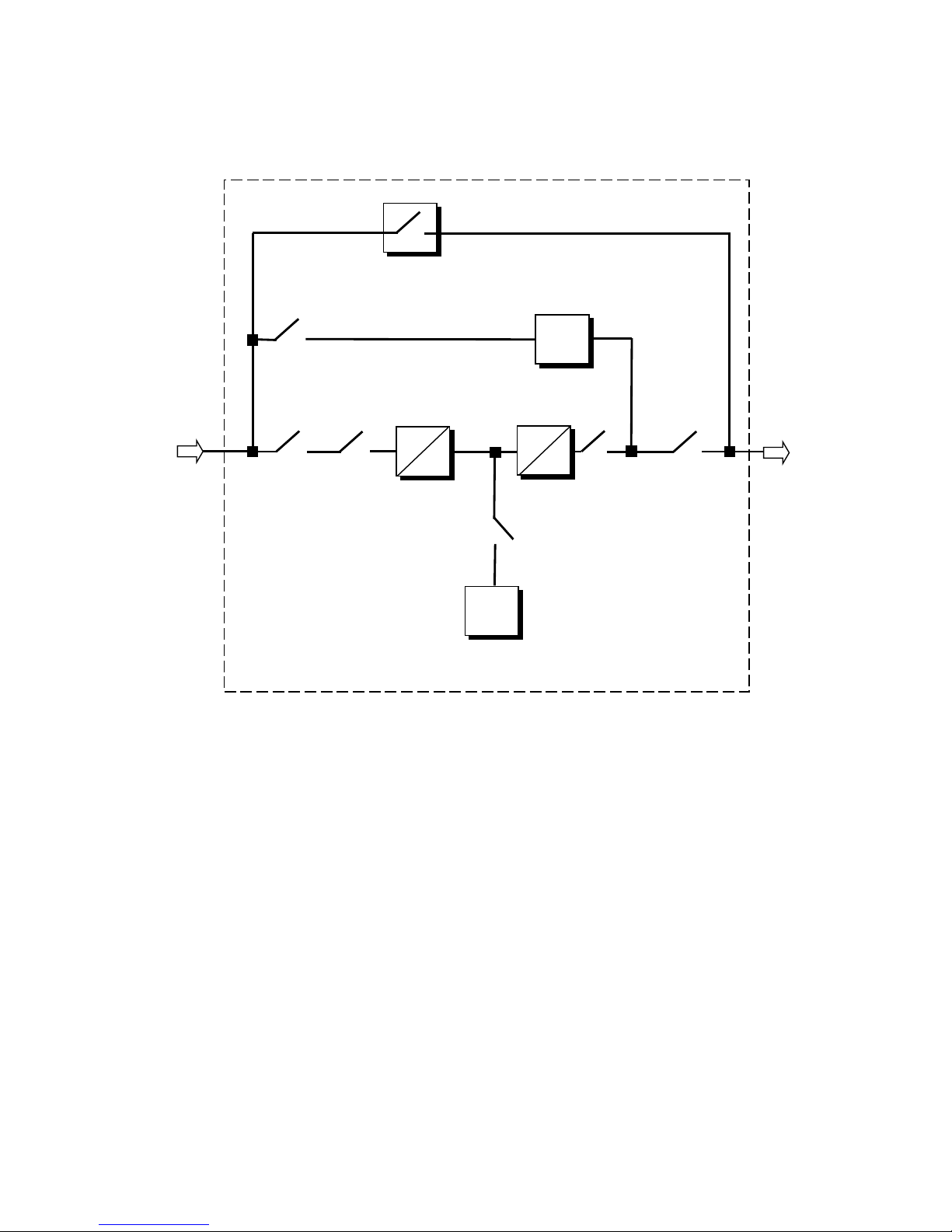

1.3 Front view of UPS Connection Panel

Figure 1.3 a 40 - 60 kVA switches, fuses and interface connections

COM1 - RS232

Communation Socket

(DB9 female)

Relay Output contacts

Batt. circuit

breaker

output

and input

Generator

input

Temperature

sensor

Relay

2

S7

On/off

switch

S5

(AC input, F10-F11-F12)

S1

(AC input, F1-F2-F3)

S3

(maintenance by-pass)

S2

(By-Pass, F4-F5-F6)

S4

(AC output, F7-F8-F9)

Relay

3

SNMP

(Optional)

Emergency

stop

Relay

4

COM2 - RS232

Communation Socket

(DB9 female)

Page 11

PREMIUM DSP 40-80 KVA PF0.9 3/3 - UPS www.visionups.com

9

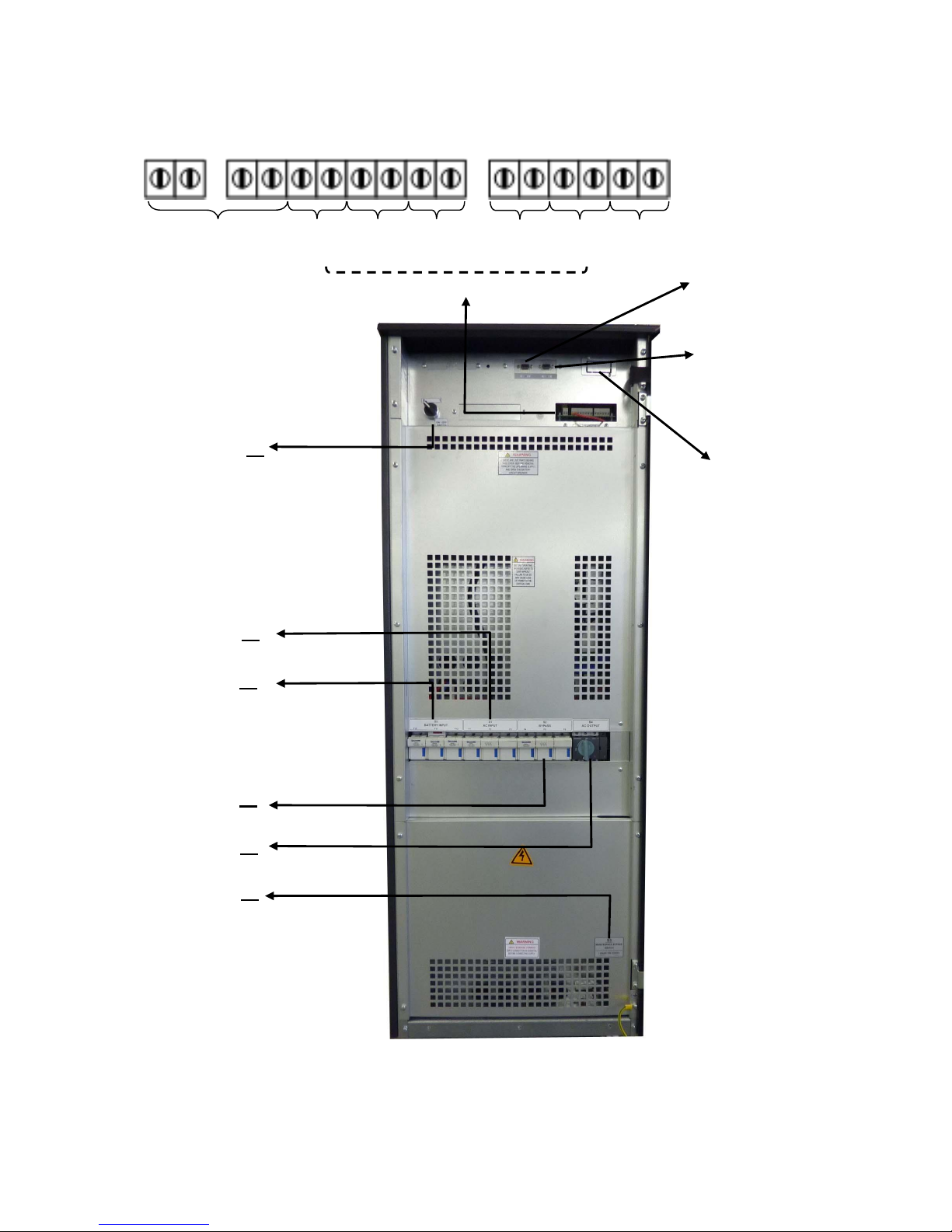

Relay Output contacts

Batt. circuit

breaker

output

and input

Generator

input

Temperature

sensor

Relay

2

Relay

3

Emergency

stop

Relay

4

COM1 - RS232

Communation Socket

(DB9 female)

SNMP

COM2 - RS232

Communation Socket

(DB9 female)

Figure 1.3 b 80 kVA switches, fuses and interface connections

PARALLEL

PORT 2

PARALLEL

PORT 1

S7

On/off

switch

S5

(Battery input, F10-F11-F12)

S1

(AC input, F1-F2-F3)

S3

(maintenance by-pass’ı)

S2

(By-Pass, F4-F5-F6)

S4

(AC output, F7-F8-F9)

Page 12

PREMIUM DSP 40-80 KVA PF0.9 3/3 - UPS www.visionups.com

10

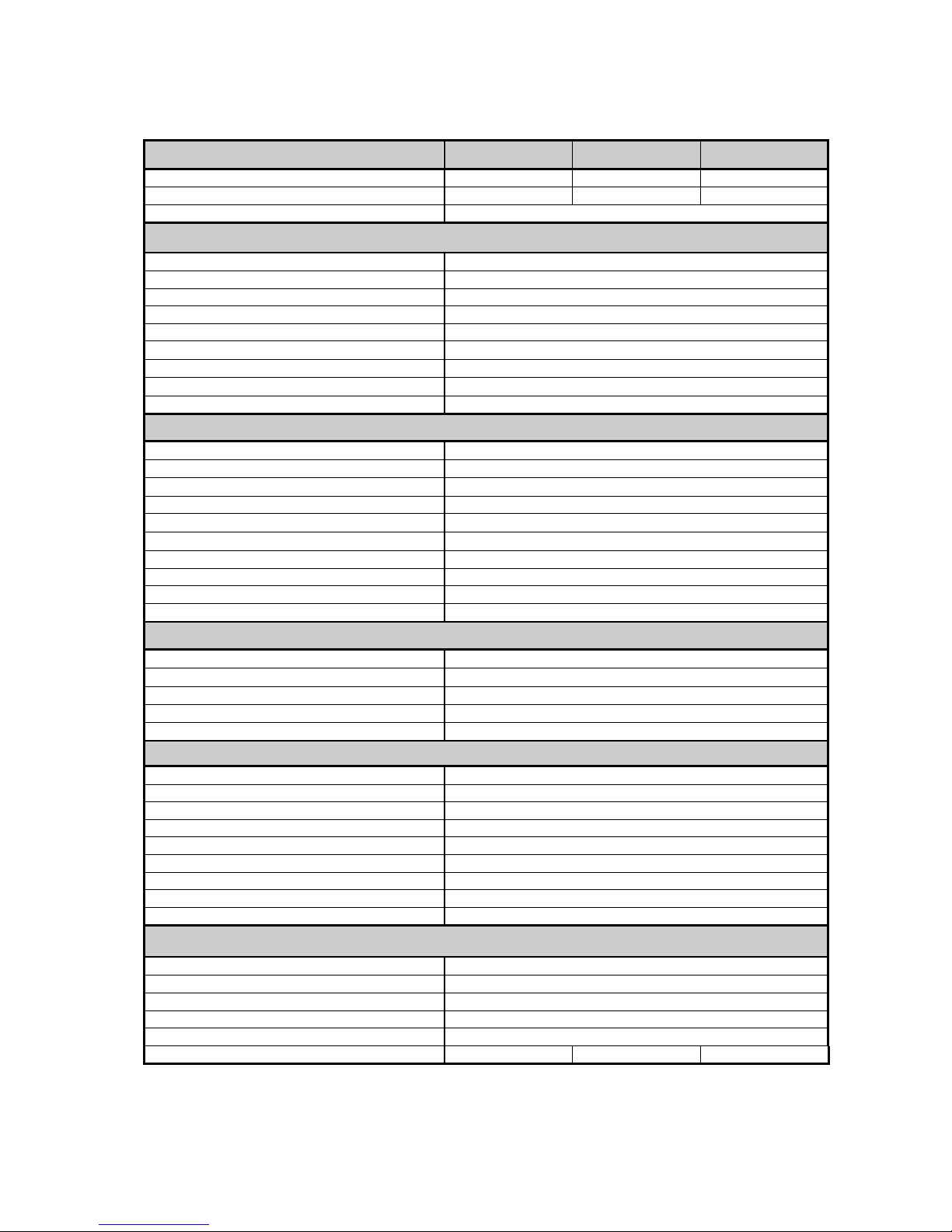

1.4 Technical Specifications

MODEL

DSP340

DSP360

DSP380

Output (KVA)

40 kVA

60 kVA

80 kVA

Output (KW)

36 kW

54 kW

72 kW

Output Power Factor

0,9

INPUT

Number of Phases

3 Phase + Neutral

Input Voltage

220/380, 230/400 or 240/415 Vac

Input Voltage Tolerance

+20% , -25% (+15% at 240/415Vac)

Input Power Factor (PF)

0,98 - 0,99 (at full load)

Input THDI

<= 5% (at full load)

Input Frequency

50 Hz. 5%

By-pass Voltage

220/380, 230/400 or 240/415 Vac 3 Phase + Neutral

By-pass Frequency

50 Hz. 2%

RFI Level

EN62040-2

OUTPUT

Number of Phases

3 Phase + Neutral

Output Voltage

220/380, 230/400 or 240/415 Vac

Output Voltage Tolerance

1%

Output Frequency

50 Hz.

Output Frequency Tolerance (Synchronous)

2%

Output Frequency Tolerance (Battery)

0,2%

Efficiency (100% Load)

up to 94%

Load Crest Factor

3:1

Output Voltage THD (linear load)

<3%

Overload

125% Load 10min. , 150% Load 1min.

BATTERY

Total Number

60 blocks 12V (2x30 serial 60 batteries)

Float Charge Voltage (250C)

405V DC

End of Discharge Voltage

300V DC

Battery Test

Automatic and Manual

Boost Charge

Available

COMMUNICATION INTERFACES

RS232 Com Port

2 each standard (COM1 and COM2)

External Temperature Measurement Input

Available (standard)

RS485 Comm. Port

Optional

Remote Monitoring Panel

Optional

SNMP Adapter

Optional

Modbus Adapter

Optional

Alarm Relay Contacts

4 each dry contacts (function programmable) 8 optional

Digital Inputs

2 each optional

Emergency Power-Off Input

Available (standard)

ENVIRONMENT

Operating Temperature

0 – 400C

Operating Humidity

<= %90 (non-condensing)

Acoustic Noise

<62dB

Dimensions (WxDxH) (mm)

515 x 855 x 1450

Device Type and Protection Class

Class 1 – IP20

Weight (Without Batteries) (app. kgs)

175

180

194

Page 13

PREMIUM DSP 40-80 KVA PF0.9 3/3 - UPS www.visionups.com

11

II. UPS INSTALLATION

2.1 Introduction

WARNING!!!

Do not apply electrical power to the UPS equipment before the arrival of authorized service

personnel.

The UPS equipment should be installed only by qualified service personnel.

The connection of the batteries and the maintenance should be done by qualified service

personnel.

Do not make any short- circuit to the battery poles. Because of high voltage and high short-circuit

current, there is risk of electrical shock or burn.

Eye protection should be worn to prevent injury from accidental electrical arcs. Remove rings,

watches and all metal objects. Only use tools with insulated handles. Wear rubber gloves.

This chapter contains location installation information of the UPS and the batteries. All the

establishments have their own specialties and needs. So in this part, the installation procedure is not

being explained step by step. Instead, general procedure and the applications are explained for the

technical personnel.

2.2 Unpacking

The UPS is packed and enclosed in a structural cardboard carton to protect it from damage.

1) Inspect for damage that may have occurred during the shipment. If any damage is noted, call the

shipper immediately and retain the shipping carton and the UPS.

2) Carefully open the carton and take the UPS out.

3) Retain the carton and packing material for future use.

Unit package contents:

1) A user manual and Guarantee certificate.

2) Battery cabinet and/or shelf (optional).

3) Battery connection cables.

2.3 Equipment Positioning

ATTENTION: Units are designed to operate on the concrete floor.

1. The equipment’s installation place must be an easy serving place.

2. Install the UPS in a protected area with adequate air flow and free of excessive dust.

3. You must therefore allow for a minimum gap of 250 mm behind the unit to allow adequate air flow

4. Select a suitable place (temperature between 0C and 40C) and the relative humidity (%90 max)

5. It is recommended to place the equipment in an air-conditioned the room (24C)

6. Temperature is a major factor in determining the battery life and capacity. Keep batteries away

from main heat sources or main air inlets etc.

7. In case of an operating the UPS in a dusty place, clean the air with a suitable air filtration system.

8. Keep out of your equipment from explosive and flammable items.

9. Avoid direct sunlight, rain, and high humidity.

WARNING!!! Check the capacity of the forklift if it is available for lifting.

DO NOT LEAN OR LIFT THE UPS CABINET AFTER THE BATTERIES HAVE BEEN

INSTALLED.

Page 14

PREMIUM DSP 40-80 KVA PF0.9 3/3 - UPS www.visionups.com

12

2.4 Connecting the UPS Power Cables

WARNING!!! A separate power line should be used to supply the UPS AC input. Never use the

same line to supply another electrical device. Do not use any additional cable to

increase the length of the UPS’s input cable. It is advised to use an MCCB suitable for

the input current on the UPS’s input line.

The connection of the electrical panel should be supplied by a grounded outlet. Otherwise, the

UPS and the load connected to the output will be left ungrounded. The grounding

system must be checked, and must be strengthen if required. Potential difference

between ground and neutral must be less than 3V AC.

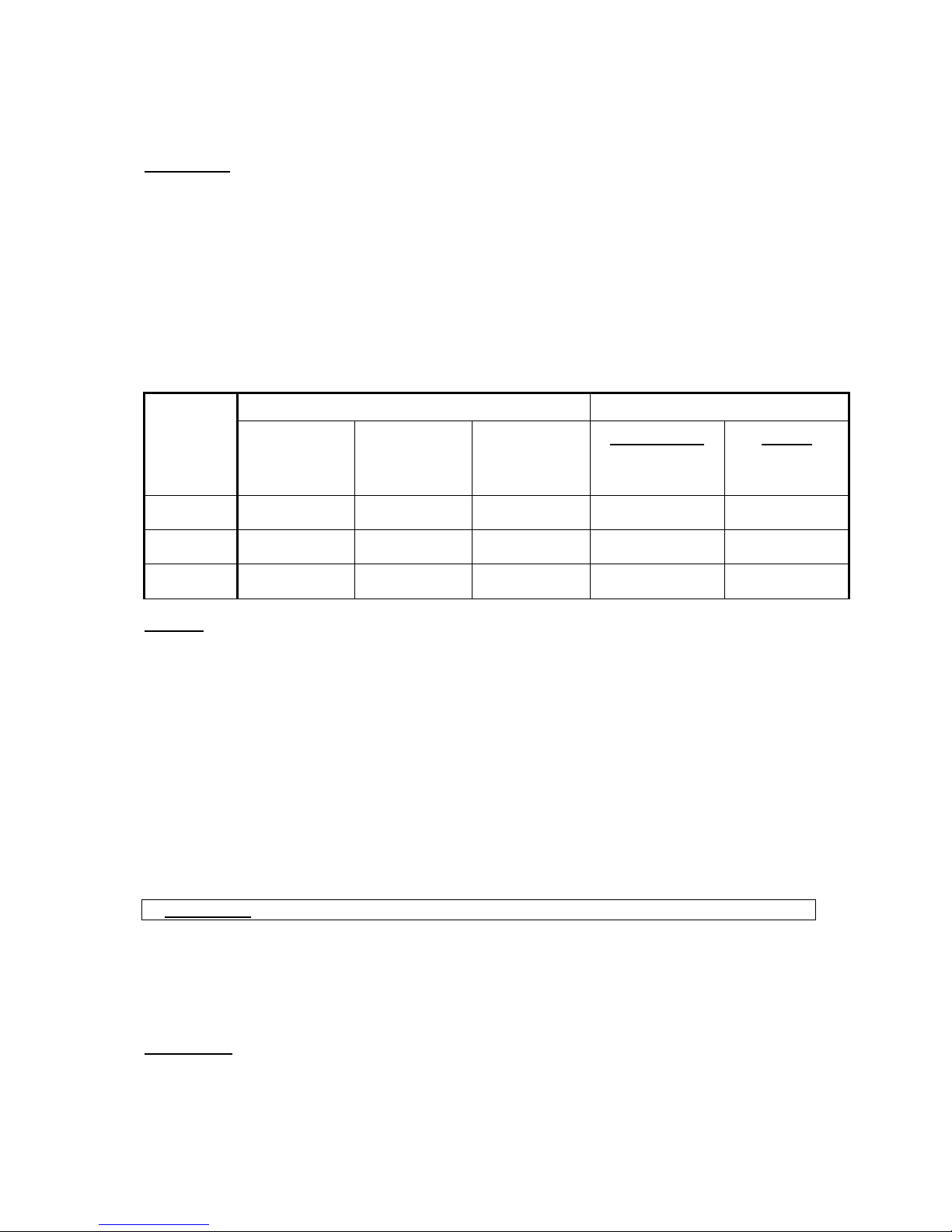

Descriptions of the UPS input output cable connection terminals are shown in figure 2.1

Recommended input line cable and fuse ratings are given in the table below.

UPS power

(kVA)

Recommended cable size (mm2)

Line input

Bypass input /

UPS output

External Battery

Input / output

Cable connections

U-V-W-N

Battery

connections

+ & -

40

16

16

16

16mm

2

terminal block

16mm

2

terminal block

60

25

25

25

25mm

2

terminal block

25mm

2

terminal block

80

25

25

25

25mm

2

terminal block

25mm

2

terminal block

NOTES: The neutral conductor should be sized for 1,5 times the output/bypass phase current.

These recommendations are for guideline purposes only and are superceded by local

regulations and codes of practice.

2.5 Safety Earth

The safety earth cable must be connected to the earth BUS BAR and bonded to each cabinet in the

system and also the earthing and neutral bonding arrangements must be in accordance with the local

laws.

ATTENTION!!! Failure to follow adequate earthing procedures can result in electric shock hazard to

personnel, or the risk of fire.

2.6 Cable connection procedure

WARNING!!! All connections of the UPS must be done by qualified service personnel

After positioning the UPS, the cables must be connected as described below:

1. Verify all switches and fuses in front of the UPS are at “0” position. (OFF)

2. Connect the 3 phase AC input coming from the mains distribution panel to the AC input terminals

as shown on the label. (Figure 2.1)

ATTENTION! ENSURE CORRECT PHASE SEQUENCE.

If there is a phase sequence error, UPS doesn’t transfer the load to INVERTER

output. If you can’t see SYNC:OK in the INFORMATION MENU on LCD, then change the input phase

sequence.

Page 15

PREMIUM DSP 40-80 KVA PF0.9 3/3 - UPS www.visionups.com

13

3. Connect the output of the UPS to the load distribution panel.

4. Connect the battery groups. Refer to battery installation section.

WARNING:

- CHECK BOTH OF THE BATTERY GROUPS FOR CORRECT POLARITY AND VOLTAGE

- DO NOT TURN ON THE BATTERY SWITCH (F5) BEFORE STARTING THE UPS

5. Connect the copper earth bus, to the safety earth of the mains distribution panel.

NOTE: The earth and the neutral connections must be in accordance with the local rules.

WARNING: Note that the Input Neutral (N1) MUST also be connected to K10 terminal

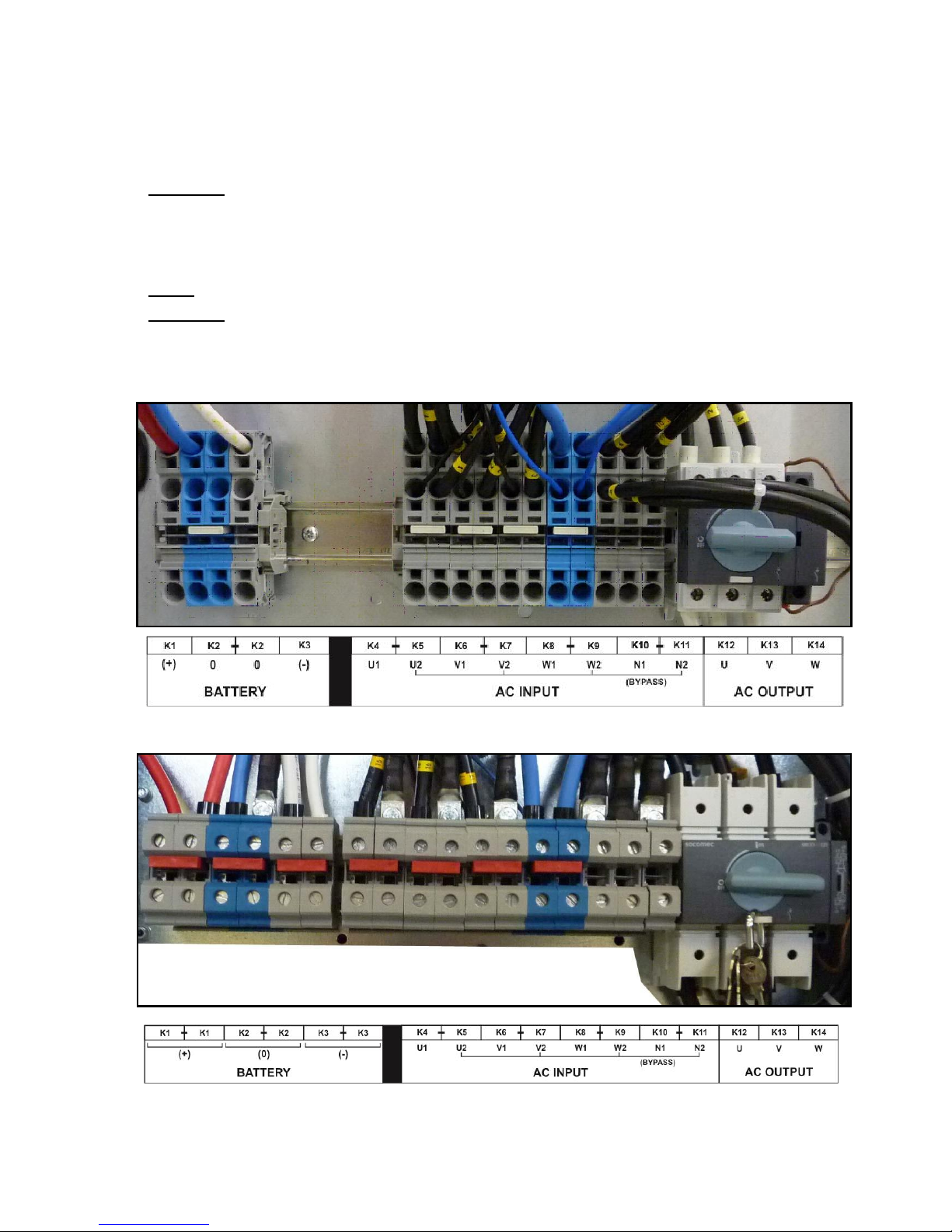

2.6.1 Description of connection terminals of the UPS:

Figure 2.2 a 40 - 60 kVA Cable Connection

Figure 2.2 a 80 kVA Cable Connection

Page 16

PREMIUM DSP 40-80 KVA PF0.9 3/3 - UPS www.visionups.com

14

As shown on the power connection label of the UPS, U1, V1 and W1 phase of the incoming 3

phase supply are used as the bypass inputs under normal conditions, if there is not a separate

bypass supply (split bypass).

If there is a separate 3- phase AC supply for bypass (Split Bypass):

a-) Remove the links between K4 – K5, K6 – K7 and K8 – K9.

b-) Connect the phases of the bypass source U2, V2 and W2 to K5, K7 and K9 respectively.

c-) Connect the Neutral (N2) of the Bypass source to K11.

Note that the Neutral of the 3 phase input supply (N1) and the Neutral of the 3-phase bypass supply

(N2) must always be connected together to form the Neutral of the AC output.

2.7 Battery Installation

WARNING!!! Be careful while connecting batteries.

ATTENTION!!! Open the battery switch/fuse before making any connection on the batteries.

The batteries associated with the UPS equipment are usually contained in a purpose-built battery

cabinet. In DSP0.9 Series 40-60 KVA UPSs, there is enough space for 60 pieces of 12V 7Ah

maintenance free batteries.

Where battery racks are used, they should be sited and assembled in accordance with the battery

manufacturer’s recommendations. In general, batteries require a well-ventilated, clean and dry

environment at reasonable temperatures to obtain efficient battery operation.

In general a minimum space of 10 mm must be left on all vertical sides of the battery block. A

minimum clearance of 20 mm should be allowed between the cell surface and any walls. All metal

racks and cabinets must be earthed.

1. Unpack each battery and check its terminal voltage with a suitable load. Any battery with terminal

voltage less than 10,5V must be charged before installation.

2. Please check the battery connecting hardware and documents. (cables, trays, connection

diagrams)

3. Please locate suitable number of batteries on each rack, according to the battery installation and

connection diagram given with the unit.

4. Start locating the batteries from top to the bottom on the racks.

5. Be careful about the connection between the racks and polarities.

6. After interconnecting the batteries, connect “+”, “0” and “-“ leads of the batteries to the battery

input terminals on the UPS. Be careful to connect the batteries correctly and do not turn on (S5)

before checking all connections and before starting the UPS. In DSP0.9 Series UPS, 60 blocks of

batteries are connected in series, in such a way that they form two strings of batteries with

opposite polarity; with a center tap connection to the NEUTRAL (N1-N2) internally.

NOTE THAT SEPARATE CABLES FROM EACH BATTERY GROUP SHOULD BE CONNECTED

TO K2 TERMINALS TO FORM THE MIDPOINT CONNECTION.

WARNING!!! NEVER TURN ON S5 (BATTERY FUSE) WITHOUT CENTER POINT CONNECTION TO

K2.

Page 17

PREMIUM DSP 40-80 KVA PF0.9 3/3 - UPS www.visionups.com

15

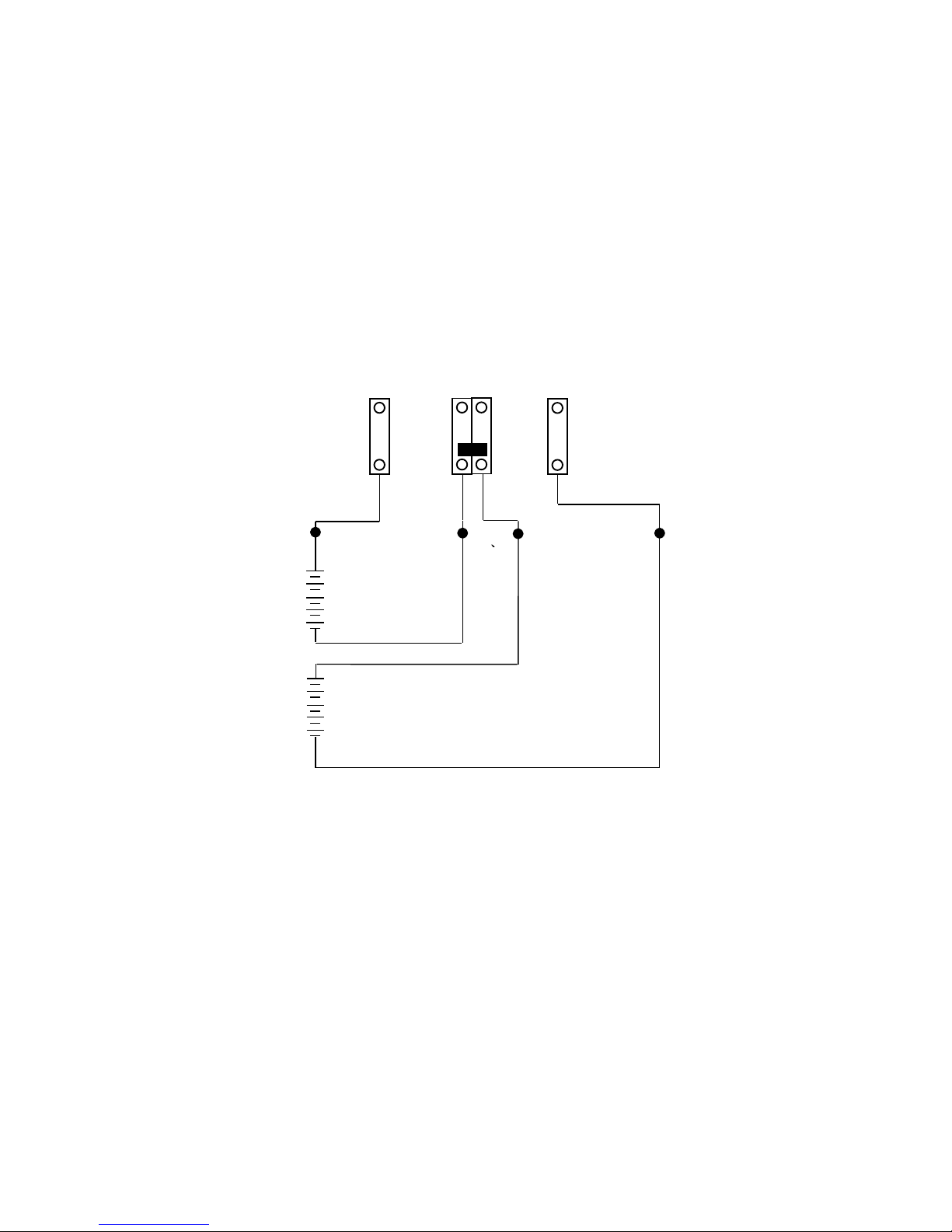

30x12V

30x12V

Batteries

( + )

( 0 )

( - )

360V

360V

( 0

K1

K2

K3

K2

Figure 2.3 External Battery Connections (60x12V)

Page 18

PREMIUM DSP 40-80 KVA PF0.9 3/3 - UPS www.visionups.com

16

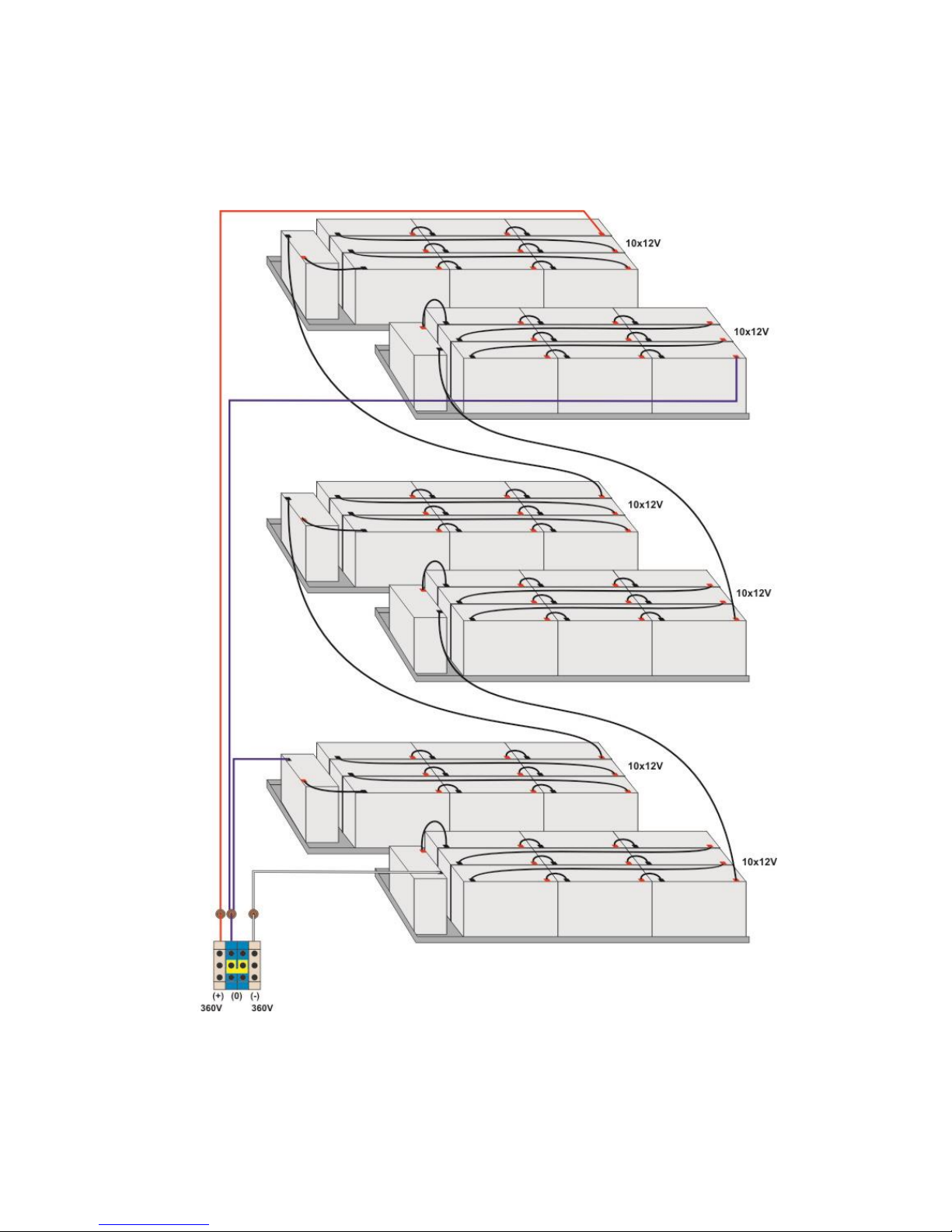

Figure 2.3a DSP0.9 Series, 40 - 60 - 80 KVA Internal Battery Connections (2x30=60x12V 7Ah)

Page 19

PREMIUM DSP 40-80 KVA PF0.9 3/3 - UPS www.visionups.com

17

Figure 2.3b

DSP0.9

Series, 4

0 - 60

- 80 KVA

Internal Battery Connect

ions (2x60=12

0x12V 7Ah)

two groups of batteries (with common

-point) in parallel

Page 20

PREMIUM DSP 40-80 KVA PF0.9 3/3 - UPS www.visionups.com

18

III. FRONT PANEL

3.1 Input

The front panel of UPS, consisting of a 4 lines alphanumeric display, 7 status lamps, plus 5 function

keys, allows the complete monitoring of the UPS status. The mimic flow diagram helps to

comprehend the operating status of the UPS. By using the function keys operator can move on menus

and change some parameters.

Figure 3.1 Control panel oft he UPS

L1

:

Maintenance bypass switch

L2

:

Load on bypass indicator lamp

L3

:

Input voltage indicator lamp

L4

:

Rectifier run pilot lamp

L5

:

Battery operation indicator lamp

L6

:

Load on UPS indicator lamp

L7

:

Output switch on indicator lamp

There are 5 control buttons on the UPS Front panel, ENTER button provides selection decleration, up

and down buttons provides to surf on menus, (+) and (-) buttons are used for adjustments or option

selection.

3.2 Front Panel Menu Descriptions:

By using (), () and ENTER buttons you can access the following menus. At the end of each menu

there is <ENTER> EXIT message will be showed, if you press enter you will exit to upper menu. All

menus have 3 or 4 levels.

L1

L2

L3

L4

L5

L6

L7

Page 21

PREMIUM DSP 40-80 KVA PF0.9 3/3 - UPS www.visionups.com

19

Main menu (Level 1)

Menu

Usage

1

STATUS

Enter Status menu

2

MEASUREMENTS

Enter Measurements menu

3

ALARM LOGS

Enter Alarm logs menu

4

INFORMATION

Enter Information menu

5

OPTIONS

Enter Options menu

6

COMMAND

Enter Command menu

7

TIME

Enter Time menu

8

SERVİCE

Enter Service menu

9

PASSWORD

Enter Password screen

10

ADJUST

Enter Adjust menu

Goto 1

Sub menus (Level 2)

Level 1

Level 2

Page

Level 3

STATUS

Status of the UPS

MEASUREMENTS

INPUT

Input measurements

BYPASS

Bypass measurements

INVERTER

Inverter measurements

OUTPUT

Output measurements

DC DC measurements

GENERAL

General measurements

ENTER - EXIT

ALARM LOGS

UPS LOG RECORD

Page1

ENTER CLEAR LOG

Page1

INFORMATION

RS232 Comm 1:--

Page1

RS232 Comm 2:--

Page1

Maximum UPS power

Page1

Nominal voltage and frequency

Page1

Inverter firmware version

Page2

PFC firmware version

Page2

Panel firmware version

Page2

UPS Model

Page3

Communication protocol

Page3

Chassis nr

Page3

OPTIONS

LCD OPTIONS

LCD panel options

COMMUNICATION OPTIONS

Communication options

ALARM OPTIONS

Alarm options

BYPASS OPTIONS

Bypass options

COMMAND

By-pass transfer

Page1

Boost charge start

Page1

Short battery test start

Page1

Relay check

Page2

Dialup modem programming

Page2

Alarm sound ON/OFF

Page3

Warning sound interval

Page3

ENTER - EXIT

TIME

Current time

Page1

Current date

Page1

Set hour

Page2

Set minute

Page2

Set day

Page3

Page 22

PREMIUM DSP 40-80 KVA PF0.9 3/3 - UPS www.visionups.com

20

Level 1

Level 2

Page

Level 3

Set month

Page3

Set year

Page3

Update time and date

Page4

ENTER - EXIT

SERVİCE

Operating hourmeter

Page1

Maximum load

Page1

ENTER Fault reset

Page1

Fan maintenance hourmeter

Page2

Batt.maintenance hourmeter

Page2

General maintenance

hourmeter

Page2

Logout command

Page3

ENTER - EXIT

PASSWORD

Getting service code

Page1

Type service password

Page1

Type user password

Page1

ENTER - EXIT

ADJUST

(in English)

Group adjustments

Automatic settings

Inverter factory options

Options list

Rectifier factory options

Options list

Panel adjustments

Options list

AC input adjustments

AC input settings

AC Bypass adjustments

AC bypass settings

AC output adjustments

AC output settings

DC adjustments

DC settings

Power adjustments

Power settings

ENTER - EXIT

Page 23

PREMIUM DSP 40-80 KVA PF0.9 3/3 - UPS www.visionups.com

21

3.2.1 MEASUREMENTS menu

All mesasured values of the UPS can be monitored from this menu.

Use up and down buttons to move on submenu

MEASUREMENTS / INPUT (Level 2)

All rectifier input measurements are located in this menu, use up and down buttons to move on

submenu

MEASUREMENTS / INPUT (Level 2)

P-N L1 L2 L3

Page header

V: 221/222/223 V

Phase to neutral measured AC input voltages

I: 000/000/000 A

Measured RMS AC input phase currents

P-P L13 L21 L32

Page header

V: 381/382/383 V

Phase to phase measured AC input voltages

FREQ: 49.6 Hz

Measured rectifier input frequency

MEASUREMENTS / BYPASS (Level 2)

All by-pass input measurements are located in this menu, use up and down buttons to move on

submenu

MEASUREMENTS / BYPASS (Level 2)

P-N L1 L2 L3

Page header

V: 221/222/223 V

Phase to neutral measured AC bypass input voltages

OK OK --

Bypass voltage status

P-P L13 L21 L32

Page header

V: 381/382/383 V

Phase to phase measured AC bypass input voltages

FREQ: OK / 50.0 Hz

Measured bypass input frequency

MEASUREMENTS / INVERTER MENU (Level 2)

All inverter measurements are located in this menu, use up and down buttons to move on submenu

MEASUREMENTS / INVERTER (Level 2)

P-N L1 L2 L3

Page header

V: 221/222/223 V

Phase to neutral measured AC Inverter output voltages

FREQ: 50.0 Hz

Measured Inverter output frequency

MEASUREMENTS / OUTPUT MENU (Level 2)

All UPS output measurements are located in this menu, use up and down buttons to move on

submenu

MEASUREMENTS / OUTPUT Page 1 (Level 2)

P-N L1 L2 L3

Page header

V: 221/222/223 V

Phase to neutral measured AC UPS output voltages

I: 00.0/00.0/00.0 A

Measured AC RMS load currents

P-P L13 L21 L32

Page header

V: 381/382/383 V

Phase to phase measured AC UPS output voltages

FREQ: 50.0 Hz

Measured UPS output frequency

Left previous page, right next page

MEASUREMENTS / OUTPUT Page 2 (Level 2)

L1 L2 L3

Page header

Load 000/000/000 %

Measured load percentage

KW 000.0/000.0/000.0

Measured output watt power

KVA 000.0/000.0/000.0

Measured output KVA power

PF: ---- ---- ----

Load power factor

C.F: 0.0 / 0.0 / 0.0

Load crest factor

Left previous page, right next page

Page 24

PREMIUM DSP 40-80 KVA PF0.9 3/3 - UPS www.visionups.com

22

MEASUREMENTS / DC MENU (Level 2)

All DC measurements are located in this menu, use up and down buttons to move on submenu

MEASUREMENTS / DC (Level 2)

VBAT 405/-405 V

Measured battery voltages

ICHRG 00.0/00.0 A

Measured battery charge currents

IDSCHRG 00.0/00.0 A

Measured battery discharge currents

BATTERIES : 30 x 2

Batteries in one group

PAR. BAT : 1

Parallel battery groups

BATT. A/H : 007 Ah

Battery amper / hour rating

BACKUP TIME 0000 min

Calculated remaining time

MEASUREMENTS / GENERAL MENU

Temperature measurements are located in this menu, use up and down buttons to move on submenu

MEASUREMENTS / GENERAL (Level 2)

TH1: ---- C

Measured external sensor temperature

TH2: 24.2 C

Measured battery cabinet inside temperature

TH3: ---- C

Measured internal sensor temperature

3.2.2 ALARM LOGS MENU

Use this menu to see the alarm log records

ALARM LOGS Page 1 (Level 1)

>191>03.10.12 14:33:26

Event no ,date and time (up and down buttons move)

>000>07.12.12 16:58:26

Event no ,date and time (up and down buttons move)

>001>07.12.12 12:24:26

Event no ,date and time (up and down buttons move)

ALARM LOGS

Alarm Logs

- - - PRESS & HOLD ENTER FOR 3 SEC TO CLEAR LOGS - - -

3.2.3 INFORMATION MENU

Some usefull informations are located in this menu , use up and down buttons to move on submenu

INFORMATION MENU Page 1 (Level 1)

RS232 COMM: 1:--

RS232 activity indicator for com1

RS232 COMM: 2:--

RS232 activity indicator for com2

MAX POWER (VA): 60000

Maximum ups output power as VA

NOMINAL VALUE:220/050 220/050

Nominal input, output voltage and frequency

INV VERSION: 00001

Inverter module firmware version

PFC VERSION: 00001

PFC rectifier module firmware version

LCD VERSION: 00001

Front panel modul firmware version

MODEL: NEO 60

Model name of the UPS

Up previous page, down next page

INFORMATION MENU Page 2 (Level 1)

Protocol:TX301

Communication protocol version

Chassis nr: 123456

UPS chassis nr

Up previous page, down next page

Page 25

PREMIUM DSP 40-80 KVA PF0.9 3/3 - UPS www.visionups.com

23

3.2.4 OPTIONS MENU

Use up and down buttons to move cursor on submenu at the end of page you move to next page.

Menu has 3 level structure, if user password is enabled some parameters requires user password.

Level 2 LCD panel options group

Panel language selection

Page1

Button click ON/OFF

Page1

LCD backlight brigthness

Page1

Backlight delay

Page1

Backlight dim.delay

Page1

ENTER - EXIT

Page1

OPTIONS / LCD OPTIONS Page 1 (Level 1)

LANGUAGE:ENGLISH

Press enter to select change panel language

CLICK: ON/OFF

Press enter to select buton click sound ON/OFF

BACKLIGHT: 08

Press enter to select LCD backlight brightness adjust

BL DELAY:CLOSED

Backlight delay

BL DIM:CLOSED

Back light half option selection

ENTER - EXIT

ENTER exit to upper menu

Up upper line, down next line ,(+) or (-) options ,ENTER select an option

Level 2 – Communication options

Remote control ON/OFF

Page1

COM2 port function

Page1

SNMP internal/external

Page1

REPO input ON/OFF

Page1

RELAY-ALARM ASSIGN

Page1

ENTER - EXIT

Page1

OPTIONS / COMMUNICATION OPTIONS Page 1 (Level 2)

REMOTE CNTRL: ON/OFF

Press enter to select remote control ON/OFF

COM2:SERVICE PORT

Com 2 serial port function selection

SNMP : INTERNAL/EXTERNAL

SNMP adaptor location

REPO : ON / OFF

Emergency stop input enabled or disabled

RELAY-ALARM ASSIGN

Press enter to assign alarm

ENTER - EXIT

ENTER exit to upper menu

Up upper line, down next line ,(+) or (-) options, ENTER select an option

Page 26

PREMIUM DSP 40-80 KVA PF0.9 3/3 - UPS www.visionups.com

24

RELAY-ALARM ASSIGN Page 1 (Level 3)

RELAY 1:

Left and right buton relay function selection

RELAY 2:

Left and right buton relay function selection

RELAY 3:

Left and right buton relay function selection

RELAY 4:

Left and right buton relay function selection

RELAY 5:

Left and right buton relay function selection (option)

RELAY 6:

Left and right buton relay function selection (option)

RELAY-ALARM ASSIGN Page 2 (Level 3)

RELAY 7:

Left and right buton relay function selection (option)

RELAY 8:

Left and right buton relay function selection (option)

RELAY 9:

Left and right buton relay function selection (option)

RELAY 10:

Left and right buton relay function selection (option)

RELAY 11:

Left and right buton relay function selection (option)

RELAY 12:

Left and right buton relay function selection (option)

ENTER - EXIT

ENTER exit to upper menu

Up upper line, down next line ,(+) or (-) options, ENTER select an option

Level 2 Alarm options

WARNING INTRVL

Page1

WARNING LOG ON/OFF

Page1

STATUS LOG ON/OFF

Page1

ALF RESTART USER/AUTO

Page1

ENTER - EXIT

Page1

OPTIONS / ALARM OPTIONS Page 1 (Level 3)

WARNING INTRVL:10 sc

Warning beep interval adjustment in seconds

WARNING LOG:ON/OFF

Press enter to select warning LOG record ON/OFF

STATUS LOG:ON/OFF

Press enter to select status log record ON/OFF

ALF RESTART: USER/AUTO

During mains restore start USER/AUTO

ENTER - EXIT

ENTER exit to upper menu

Level 3 - Bypass options

VAT TRANSFER ON/OFF

Page1

GEN. BYPASS FORBIDDEN/FREE

Page1

GEN. SET SYNC XTAL/SYNC

Page1

OPERAT. MOD

Page1

ONLİNE / ECONO / SYNC / PARALLEL

ENTER - EXIT

Page1

OPTIONS / BYPASS OPTIONS Page 1 (Level 3)

VAT TRANSFER:ON/OFF

Press enter to select VAT transfer system ON/OFF

GEN SET BYP:FORBID/FREE

Press enter to select bypass to generator FORBID/FREE

GEN SET SYNC:XTAL/SYNC

Press enter to select generator synchron XTAL/SYNC

OPERAT. MOD

Press enter to select mode ONLİNE / ECONO / SYNC / PARALLEL

ENTER - EXIT

ENTER exit to upper menu

Page 27

PREMIUM DSP 40-80 KVA PF0.9 3/3 - UPS www.visionups.com

25

3.2.5 COMMAND MENU

This menu contains UPS commands be carefull while using commands.

Use up and down buttons to move cursor on submenu at the end of page you move to next page.

<ENTER> button applies the related command.

COMMAND MENU Page 1 (Level 1)

ENTER <BYPASS>

ENTER transfer the load to bypass

ENTER <BOOST>

ENTER start boost charge mode

ENTER B.TEST > 405

ENTER start short battery test

RELAY TEST:OFF

Left and right test dry contact relays

ENTER : MODEM INIT

ENTER initialize dialup modem

ALARM SOUND: ON/OFF

Press enter to select disable alarm buzzer

3.2.6 TIME MENU

You can see Time and date information of the RTC in the UPS ,also you can set date and time from

this menu.

Follow the arrows to set date and time

3.2.7 SERVICE MENU

This menu contains some helpfull service information and some commands.

Use up and down buttons to move cursor on submenu at the end of page you move to next page.

SERVİCE MENU Page 1 (Level 1)

HOURMETER:00075

Total operating hour of the UPS

MAXLOAD:015 020 025 %

From power on recorded maximum power

ENTER<FAULT RESET>

ENTER fault reset

FAN MAINT: 01000

Remaining hours to FAN maintenance

BAT MAINT :01200

Remaining hours to battery maintenance

GEN.MAINT: 00500

Remaining hours to general maintenance

LOGOUT: --

ENTER Exit from service login status

If maintenance counters are disabled CANCEL word is shown.

Page 28

PREMIUM DSP 40-80 KVA PF0.9 3/3 - UPS www.visionups.com

26

3.2.8 ADJUST MENU

This menu is prepared for service purposes there is no user adjustable parameter in this menu.

3.2.9 USER PASSWORD

Some commands or some option selections are required user password, if menu position is

required password window comes to screen and UPS asks for user password. If you lost user

password our service personnel will recover your user password.

User password is 4 digits numbers, move cursor with left and right buttons, select digit and adjust

the number with up and down buttons. Do this for all digits and if password is typed completely

press ENTER button if the password is correct A43 USER LOGIN message will be shown on the

LCD panel of the UPS.

Password screen

SERV. PASS: 00000000

USER PASS: 0000

- - - Enter user or service password - - -

3.3 Alarms and warning messages

The internal structure of the EF300 Series UPS is modular, these are:

-PFC Rectifier module

-Inverter module

-Front panel module

Module alarms and warnings are cathegorized according to modules at the front of the Alarm or

warning message module information is added:

-RXX Rectifier alarms and warnings

-AXX Inverter alarms and warnings

-LXX LCD front panel alarms and warnings

More then one alarm can be shown on the UPS front panel with time shared order. If 4 alarms are

occurred at the same time every 2 seconds 1 message will be showed, next 2 seconds 2.message will

be showed etc.

If A00 or R00 Alarm is shown on the LCD panel we understand that there is a system fault at the

related module. We saw the message in the A00 INV FAULT = XXXX or R00 PFC FAULT = XXXX

format. Numbers shown in X determines the status code which tells the problem to us. See status code

table for details of codes.

Page 29

PREMIUM DSP 40-80 KVA PF0.9 3/3 - UPS www.visionups.com

27

Rectifier module alarm codes

REC CODE = XXXX

XXXX SYSTEM fault occured at the rectifer module

R00 REC FAULT = XXXX

Fault

Rectifier AC input voltage is high

CALL SERVICE !

R01 AC INPUT HIGH

Alarm

Rectifier AC input voltage is low

R02 LINE FAILURE

Alarm

Rectifier DC output voltage is high

R03 DC BUS HIGH

Alarm

The rectifier DC output voltage is high, rectifier stop

R05 FREQ TOLER

Alarm

Rectifier input frequcny out of tolerant

R06 OVERTEMPERATURE

Alarm

Rectifier heatsink temperature high

R07 BLACKOUT

Alarm

Short voltage blackout at rectifier AC input

R08 I/P OVERCURRENT

Alarm

Rectifier IGBT saturation alarm

R09 ROTATE PHASE

Alarm

Rectifier input phase sequency incorrect

R14 PFC MANUAL STOP

Alarm

Inverter module stopped rectifier

R15 DC LOW

Alarm

DC BUS voltage is lower then DC rectifier start voltage

R17 BATTERY TEST

Warning

Currently battery test is performing

R18 BOOST CHARGE

Warning

Currently rectifier is in boost charge mode

R19 AC HIGH

Alarm

AC Peak voltage is bigger then 20% of nominal range

R20 INPUT CB OPEN

Warning

Input CB is off

R21 PFC STOP

Warning

Currently Rectifier module stop

R22 POS CHG LIMIT

Warning

(+)Battery charge current limited

R23 NEG CHG LIMIT

Warning

(-)Battery charge current limited

R24 WAITING DC BUS

Warning

Rectifier is waiting DC BUS to raise for startup

R25 BATTERY FAILURE

Warning

Battery test failed

R26 BATT TEMP SENSOR

Warning

Battery temperature sensor is defected or not connected

R27 BATT TEMP HIGH

Warning

Battery ambient temperature is high

R29 PFC RESET

Warning

Rectifier module power on

R30 PLEASE WAIT

Warning

Rectifier waits as adjusted startup delay

R31 RECTIFIER START

Warning

Rectifier is in soft start stage

Panel module alarm codes

L01 TH1 TEMP HIGH

Warning

TH1 temperature is high

L02 TH2 TEMP HIGH

Warning

TH2 temperature is high

L03 TH1 TEMP LOW

Warning

TH1 temperature is low

L04 TH2 TEMP LOW

Warning

TH2 temperature is low

L05 FAN MAINT

Warning

FAN maintenance time

L06 BATTERY MAINT

Warning

Battery maintenance time

L07 OPT MAINTENANCE

Warning

Optional maintenance time

L08 TH1 SENSOR FAIL

Warning

TH1 temperature sensor failure

L09 TH2 SENSOR FAIL

Warning

TH2 temperature sensor failure

L10 ENTER FAULT RESET

Warning

UPS is waiting fault reset for startup

L11 BATT CB OPEN

Warning

External interactive battery switch is off

L12 GENERAL MAINT

Warning

General maintenance time

L13 PFC CAN COMM ERR

Warning

PFC module CAN communication timeout

L14 INV CAN COMM ERR

Warning

INV module CAN communication timeout

Inverter module alarm codes

INV CODE = 0XXX

Current inverter modüle status code

A00 INV FAULT = XXXX

Hata

XXXX fault occured at the inverter module

CALL SERVICE !

A01 O/P OVERCURRENT

Alarm

IGBT saturation alarm on inverter module

A02 OVERTEMP SHUT

Alarm

Overtemperature at inverter power module

A03 BATT HIGH

Alarm

Inverter module measured battery voltage high

A04 OUTPUT V.LOW

Alarm

Inverter output voltage is low

A05 OUTPUT V.HIGH

Alarm

Inverter output voltage is high

A06 OVERLOAD SHUT

Alarm

Overload at UPS output

A07 SHORT CIRCUIT

Alarm

Short circuit at UPS output

Page 30

PREMIUM DSP 40-80 KVA PF0.9 3/3 - UPS www.visionups.com

28

A08 ON MAINTENANCE

Alarm

Maintenance by-pass switch on

A09 MANUAL BYPASS

Alarm

Load is transferred to by-pass from front panel

A10 BATTERY LOW SHUT

Alarm

Inverter measured battery voltage is low (shutdown level)

A11 REPO STOP

Alarm

External REPO input signal sensed

A12 DC BALANCE BAD

Alarm

Before inverter start fitler capacitors dont discharged

A13 PEAK CURRENT

Alarm

Very high current at the UPS output

A14 INV NOT START

Alarm

Inverter module start failed

A17 BYPASS FAILURE

Warning

By-pass input voltage failure

A18 BYPASS VOLT

Warning

By-pass input voltage out of tolerance

A19 BYP FREQ.TOLER

Warning

By-pass input frequency out og tolerance

A20 OVERLOAD

Warning

Currently the load exceeded 100% capacity

A21 OVERTEMP

Warning

Currently inverter power modul heatsink temperature is high

A22 OUTPUT OFF

Warning

There is no UPS output voltage

A23 ON BYPASS

Warning

Load is on bypass

A24 REVERSE CURRENT

Warning

Regenerative backfeed to UPS output

A25 INV RESET

Warning

Inverter module power on

A26 BATTERY LOW

Warning

Batteries are going to full discharge

A27 GENERATOR MODE

Warning

Generator set is running

A28 O/P PHASE LOSS

Warning

Anyone of the UPS output phases there is no voltage

A29 SYNCHRON BAD

Warning

Inverter is not synchron to by-pass input

A30 SHORT CIRCUIT

Warning

Short circuit occured at the UPS output currenty normal

A31 OUTPUT SWITCH

Warning

Output switch of the UPS is off

A32 SERVICE LOGIN

Warning

Service login active

A34 BYP ROTATE PHASE

Warning

By-pass phase sequency incorrect

A35 INV STOP

Warning

Inverter module interrupted

A36 INV DC DOWN

Warning

DC BUS voltage is less then 120 volts DC

A37 AC CURR LIMIT

Warning

Inverter output current limited

A38 FUSE FAILURE

Warning

Any fuse in UPS is blowned

A39 PSP FAILURE

Alarm

Inverter control board power supply out of tolerant

A40 INVERTER START

Warning

Inverter is in soft start stage wait for finish

A43 USER LOGIN

Warning

User logged in to UPS

A45 SERV.PASSWORD

Fault

For UPS startup service password required

If any alarm shown on the LCD panel without A00 and R00 message UPS will start automatically if the

conditions are normal. But if you see A00 or R00 code with any alarm together you must CALL

SERVICE !

If the message is warning UPS continues to run there is no problem.

To support technical service status cods are used, each status code tells different event to us.

Page 31

PREMIUM DSP 40-80 KVA PF0.9 3/3 - UPS www.visionups.com

29

3.4 STATUS CODES

Inverter module status codes

INV L1-L2-L3 phase status codes

163

During soft start at the end of 4 seconds L1 output voltage is less then 30 volts AC

263

During soft start at the end of 4 seconds L2 output voltage is less then 30 volts AC

363

During soft start at the end of 4 seconds L3 output voltage is less then 30 volts AC

164

During soft start at the end of 4 seconds L1 output voltage is bigger then (output high/2) value

264

During soft start at the end of 4 seconds L2 output voltage is bigger then (output high/2) value

364

During soft start at the end of 4 seconds L3 output voltage is bigger then (output high/2) value

165

During inverter run the L1 phase AC output voltage is bigger then output high alarm level

265

During inverter run the L2 phase AC output voltage is bigger then output high alarm level

365

During inverter run the L3 phase AC output voltage is bigger then output high alarm level

166

During inverter run the L1 phase AC output voltage is less then output low alarm level

266

During inverter run the L2 phase AC output voltage is less then output low alarm level

366

During inverter run the L3 phase AC output voltage is less then output low alarm level

167

L1 phase by-pass SCR must be off but at there is AC voltage at the L1 output of the UPS

267

L2 phase by-pass SCR must be off but at there is AC voltage at the L2 output of the UPS

367

L3 phase by-pass SCR must be off but at there is AC voltage at the L3 output of the UPS

168

L1 phase overload shutdown

268

L2 phase overload shutdown

368

L3 phase overload shutdown

169

Overcurrent occured on L1 phase longer then allowed time

269

Overcurrent occured on L2 phase longer then allowed time

369

Overcurrent occured on L3 phase longer then allowed time

170

On L1 phase momentary short circuit conditions occured but now inverter is running

270

On L2 phase momentary short circuit conditions occured but now inverter is running

370

On L3 phase momentary short circuit conditions occured but now inverter is running

171

On L1 phase output short circuit occured output shutdown

271

On L2 phase output short circuit occured output shutdown

371

On L3 phase output short circuit occured output shutdown

172

Within time window 4 times L1 phase output is less then output low alarm level

272

Within time window 4 times L2 phase output is less then output low alarm level

372

Within time window 4 times L3 phase output is less then output low alarm level

173

Within time window 4 times L1 phase output is higher then output high alarm level

273

Within time window 4 times L2 phase output is higher then output high alarm level

373

Within time window 4 times L3 phase output is higher then output high alarm level

174

On L1 phase UPS output at last 100 milliseconds the alternance don't changed

274

On L2 phase UPS output at last 100 milliseconds the alternance don't changed

374

On L3 phase UPS output at last 100 milliseconds the alternance don't changed

175

On L1 bypass input phase at last 100 milliseconds the alternance don't changed

275

On L2 bypass input phase at last 100 milliseconds the alternance don't changed

375

On L3 bypass input phase at last 100 milliseconds the alternance don't changed

176

On L1 inverter output phase at last 100 milliseconds the alternance don't changed

276

On L2 inverter output phase at last 100 milliseconds the alternance don't changed

376

On L3 inverter output phase at last 100 milliseconds the alternance don't changed

177

L1 phase output current sensor open

277

L2 phase output current sensor open

377

L3 phase output current sensor open

Page 32

PREMIUM DSP 40-80 KVA PF0.9 3/3 - UPS www.visionups.com

30

INV L1-L2-L3 phase status codes

178

Inverter stopped but on inverter L1 phase output still DC voltage sensed

278

Inverter stopped but on inverter L2 phase output still DC voltage sensed

378

Inverter stopped but on inverter L3 phase output still DC voltage sensed

179

During inverter run at last 25 milliseconds the L1 phase output alternance is not changed

279

During inverter run at last 25 milliseconds the L2 phase output alternance is not changed

379

During inverter run at last 25 milliseconds the L3 phase output alternance is not changed

180

At the end of 4 times retry During soft start after 4 seconds still the L1 phase output voltage is

less then 30 volts AC

280

At the end of 4 times retry During soft start after 4 seconds still the L2 phase output voltage is

less then 30 volts AC

380

At the end of 4 times retry During soft start after 4 seconds still the L3 phase output voltage is

less then 30 volts AC

181

At the end of 4 times retry During soft start at the end of 4 seconds L1 output voltage is bigger

then (output high/2) value

281

At the end of 4 times retry During soft start at the end of 4 seconds L2 output voltage is bigger

then (output high/2) value

381

At the end of 4 times retry During soft start at the end of 4 seconds L3 output voltage is bigger

then (output high/2) value

182

During power on L1 phase bypass SCR must be off but at the L1 phase output there is AC

voltage

282

During power on L2 phase bypass SCR must be off but at the L2 phase output there is AC

voltage

382

During power on L3 phase bypass SCR must be off but at the L3 phase output there is AC

voltage

183

L1 phase by-pass SCR must be on but there is only positive alternance at the UPS output

283

L2 phase by-pass SCR must be on but there is only positive alternance at the UPS output

383

L3 phase by-pass SCR must be on but there is only positive alternance at the UPS output

184

L1 phase by-pass SCR must be on but there is only negative alternance at the UPS output

284

L2 phase by-pass SCR must be on but there is only negative alternance at the UPS output

384

L3 phase by-pass SCR must be on but there is only negative alternance at the UPS output

185

L1 phase by-pass SCR must be on but there is no output voltage at the UPS output

285

L2 phase by-pass SCR must be on but there is no output voltage at the UPS output

385

L3 phase by-pass SCR must be on but there is no output voltage at the UPS output

186

Output CB is energized but at the L1 phase output there is only positive alternance

286

Output CB is energized but at the L2 phase output there is only positive alternance

386

Output CB is energized but at the L3 phase output there is only positive alternance

187

Output CB is energized but at the L1 phase output there is only negative alternance

287

Output CB is energized but at the L2 phase output there is only negative alternance

387

Output CB is energized but at the L3 phase output there is only negative alternance

188

Output CB is energized but at the L1 phase output there is no AC voltage

288

Output CB is energized but at the L2 phase output there is no AC voltage

388

Output CB is energized but at the L3 phase output there is no AC voltage

189

During load on by-pass on the L1 output short circuit sensed

289

During load on by-pass on the L2 output short circuit sensed

389

During load on by-pass on the L3 output short circuit sensed

190

On L1 phase output reverse current sensed

290

On L2 phase output reverse current sensed

390

On L3 phase output reverse current sensed

191

During load on inverter ,on L1 phase by-pass line leakage current sensed

291

During load on inverter ,on L2 phase by-pass line leakage current sensed

391

During load on inverter ,on L3 phase by-pass line leakage current sensed

Page 33

PREMIUM DSP 40-80 KVA PF0.9 3/3 - UPS www.visionups.com

31

INV DC status codes

400

DC bus voltage high

401

Inverter controller board power supply 1 out of tolerant

402

Inverter controller board power supply 2 out of tolerant

404

Inverter stop because (+)DC bus voltage is low

405

Inverter stop because (-)DC bus voltage is low

406

Inverter within time window 4 times DC bus voltage is high

INV General status codes table

500

Inverter received remote power off signal from RS232

501

Inverter received remote power off signal from CAN interface

502

Inverter sensed IGBT fault alarm 4 times within time window (30 minutes)

503

Inverter sensed Overtemperature alarm 4 times within time window (30 minutes)

504

Inverter sensed 3 phase AC O/P voltage low alarm 4 times within time window (30 minutes)

505

Inverter sensed 3 phase AC O/P voltage high alarm 4 times within time window (30 minutes)

506

Inverter Timeout error during eprom read or write

507

Inverter Memory checksum error

508

Inverter 3 output phases overloaded output shutdown

509

Inverter maintenance by-pass switch closed

510

Inverter IGBT fault error

511

Inverter overtemperature shutdown

512

Inverter 3 phase AC output voltage low

513

Inverter 3 phase AC output voltage high

514

Inverter output CB energized but still it looks like not energized

515

Inverter output CB not energized but stil it looks like energized

516

Inverter fault occured for restart password required

517

Inverter output CB energized but at the UPS output there is no 3 phase AC voltage

518

Inverter By-pass voltage is OK but at the UPS output there is no 3 phase AC voltage

INV Control activity status codes

612

INV Over RS232 interface battery quantity updated

613

INV Over CAN1 interface battery quantity updated

614

INV Over RS232 interface by-pass and output frequency updated

615

INV Over CAN1 interface by-pass and output frequency updated

616

INV Over RS232 interface By-pass and output voltage updated

617

INV Over CAN1 interface By-pass and output voltage updated

618

INV Over RS232 interface factory options updated

619

INV Over CAN1 interface factory options updated

620

INV Over RS232 interface user options updated

621

INV Over CAN1 interface user options updated

622

INV Over RS232 interface general test command received

623

INV Over CAN1 interface general test command received

624

INV Over RS232 interface transfer load to by-pass command received

625

INV Over CAN1 interface transfer load to by-pass command received

626

INV Over RS232 interface transfer load to UPS command received

627

INV Over CAN1 interface transfer load to UPS command received

628

INV Over RS232 interface Copy operating RAM to Factory settings zone command received

629

INV Over CAN1 interface Copy operating RAM to Factory settings zone command received

630

INV Over RS232 interface Copy factory settings to operating RAM command received

631

INV Over CAN1 interface Copy factory settings to operating RAM command received

632

INV Over RS232 interface Copy operating RAM to User settings zone command received

633

INV Over CAN1 interface Copy operating RAM to User settings zone command received

634

INV Over RS232 interface regenerative back feed activated

635

INV Over CAN1 interface regenerative back feed activated

Page 34

PREMIUM DSP 40-80 KVA PF0.9 3/3 - UPS www.visionups.com

32

636

INV Over RS232 interface fault reset command received

637

INV Over CAN1 interface fault reset command received

638

INV Over RS232 interface short battery test command received

639

INV Over CAN1 interface short battery test command received

640

INV Over RS232 interface long battery test command received

641

INV Over CAN1 interface long battery test command received

642

INV Over RS232 interface battery test cancel command received

643

INV Over CAN1 interface battery test cancel command received

644

INV Over RS232 interface start boost charge command received

645

INV Over CAN1 interface start boost charge command received

646

INV Over RS232 interface stop boost charge command received

647

INV Over CAN1 interface stop boost charge command received

648

INV Over RS232 interface PFC short stop command received

649

INV Over CAN1 interface PFC short stop command received

650

INV Over RS232 interface generator mode start command received

651

INV Over CAN1 interface generator mode start command received

652

INV Over RS232 interface start sleep mode command received

653

INV Over CAN1 interface start sleep mode command received

654

INV Over RS232 interface exit sleep mode command received

655

INV Over CAN1 interface exit sleep mode command received

656

INV Over RS232 interface service login command received

657

INV Over CAN1 interface service login command received

658

INV Over RS232 interface logout command received

659

INV Over CAN1 interface logout command received

660

INV Over RS232 interface user login command received

661

INV Over CAN1 interface user login command received

662

INV over RS232 service level fault reset command received

663

INV over CAN1 service level fault reset command received

664

INV over RS232 delete fault profile memory command received

665

INV over CAN1 delete fault profile memory command received

666

INV over RS232 start regenerative mode command received

667

INV over CAN1 start regenerative mode command received

668

INV over RS232 user level fault reset command received

669

INV over CAN1 user level fault reset command received

Page 35

PREMIUM DSP 40-80 KVA PF0.9 3/3 - UPS www.visionups.com

33

PFC rectifier status codes

PFC L1-L2-L3 phase status codes

1101

PFC L1 phase AC input current LEM sensor error

1201

PFC L2 phase AC input current LEM sensor error

1301

PFC L3 phase AC input current LEM sensor error

1102

L1 phase AC input voltage sample is irregular or DC

1202

L2 phase AC input voltage sample is irregular or DC

1302

L3 phase AC input voltage sample is irregular or DC

1103

PFC AC rectifier input voltage is lower then R2187 on L1 phase input

1203

PFC AC rectifier input voltage is lower then R2187 on L2 phase input

1303

PFC AC rectifier input voltage is lower then R2187 on L3 phase input

1104

PFC AC rectifier input voltage is higher then R2186 on L1 phase input

1204

PFC AC rectifier input voltage is higher then R2186 on L2 phase input

1304

PFC AC rectifier input voltage is higher then R2186 on L3 phase input

1105

PFC L1 phase AC peak input voltage is bigger 20% from nominal range value

1205

PFC L2 phase AC peak input voltage is bigger 20% from nominal range value

1305

PFC L3 phase AC peak input voltage is bigger 20% from nominal range value

1106

PFC L1 phase AC input current limited

1206

PFC L2 phase AC input current limited

1306

PFC L3 phase AC input current limited

PFC DC status codes

1400

PFC +DC bus voltage is higher then R2131 adjustment

1401

PFC -DC bus voltage is higher the R2131 adjustment

1402

PFC DC LEM current sensor error

1403

PFC module +DC BUS voltage high alarm repeated 4 times within R2166 time window

1404

PFC module -DC BUS voltage high alarm repeated 4 times within R2166 time window

1405

PFC board isolated power supply voltage failure

1406

PFC rectifier power component DC leakage sensed

PFC General status codes

1500

PFC remote emergency power off command received from RS232 or CAN interface

1501

PFC IGBT saturation alarm

1502

PFC overcurrent alarm

1503

PFC input CB not energized but still it looks like energized

1504

PFC input CB energized but still it looks like not energized

1505

PFC eeprom timeout error

1506

PFC eeprom memory error

1507

PFC modul IGBT fault alarm repeated 4 times within R2165 time window

1508

PFC modul overtemperature alarm repeated 4 times within R2167 time window

1509

PFC 3 phase AC power failure on UPS input (2.5 seconds later after mains failure)

1510

PFC 3 phase AC rectifier input voltage is high (2.5 seconds later after mains failure)

1511

PFC AC power failure on L1-L2 phases(phase to phase)

1512