Page 1

PHOENIX

ENGRA VING

T ABLE

OPERATING MANU AL

T able Of Contents

Liability Statement ................................................................ 2

Safety ...........................................................................3

Table of

Contents

Chapter 1. Unpacking and Taking Inventory..................5

Chapter 2: Table Description ........................................ 7-9

Chapter 3: Setting Up The Table....................................11

Chapter 4: Table Adjustments ..................................13-16

Chapter 5: Table Maintenance .................................17-21

Chapter 6: Optional Accessories and Uses ...........23-31

Chapter 7: Troubleshooting ......................................33-36

This manual is designed to provide you with information about your Vision

Computerized Engraving and Routing Systems table, beginning with

unpacking the table and continuing through installation and lifetime table

maintenance. This manual does not attempt to teach you how to engrave,

how to use a computer, or how to use your engraving software. Some

previous knowledge of engraving terms and the engraving process is

assumed. For information on your individual computer system, see your

computer’s user manual or contact your computer distributor. For

information on the engraving software you use to drive your engraving

system, see the manual for the individual software package supplied by

the software developer .

Page1

Page 2

Copyright 1999 Vision Computerized Engraving & Routing SystemsCopyright 1999 Vision Computerized Engraving & Routing Systems

Copyright 1999 Vision Computerized Engraving & Routing Systems

Copyright 1999 Vision Computerized Engraving & Routing SystemsCopyright 1999 Vision Computerized Engraving & Routing Systems

(A Division of W(A Division of W

(A Division of W

(A Division of W(A Division of W

All Rights ReserAll Rights Reser

All Rights Reser

All Rights ReserAll Rights Reser

This publication is protected by copyright, and all rights are reserved. No part of this manual may be reproduced or

transmitted by any means or in any form, without prior written consent from Vision.

estern Engravers Supplyestern Engravers Supply

estern Engravers Supply

estern Engravers Supplyestern Engravers Supply

vedved

ved

vedved

, Inc.), Inc.)

, Inc.)

, Inc.), Inc.)

Limits of Liability / Disclaimer of WLimits of Liability / Disclaimer of W

Limits of Liability / Disclaimer of W

Limits of Liability / Disclaimer of WLimits of Liability / Disclaimer of W

The information contained within this manual has been carefully checked and is believed to be accurate, however,

Vision makes no representations or warranties for this manual, and assumes no responsibility for inaccuracies, errors,

or omissions that may be contained within this manual. In no event shall Vision be liable for any loss of profit including

(but not limited to) direct, indirect, special, incidental, consequential, or other damages resulting from any defect or

omission in this manual, even if previously advised of the possibility of such damages.

In the interest of continued product development, Vision reserves the right to make improvements to this manual and

the products it describes at any time, without notice or obligation.

Vision Computerized Engraving and Routing Systems WVision Computerized Engraving and Routing Systems W

Vision Computerized Engraving and Routing Systems W

Vision Computerized Engraving and Routing Systems WVision Computerized Engraving and Routing Systems W

Vision Computerized Engraving and Routing Systems warrants that for a period of one (1) year from the date of

delivery to the user of the Vision table, that the table will be free from defects in material and workmanship under

normal use and service. It is specifically understood that this warranty covers normal use only and shall be null and void

in the event that the Vision table is altered or modified by the user without authorization, or is subject to abuse,

neglect, or other misuse by the user. The spindle is covered by a ninety-day (90) warranty. Other equipment may be

purchased which is not included in this warranty, and may have a separate manufacturer’s warranty, which applies.

Other items considered “consumable”, are not covered and are excluded from any and all warranties. Specifically these

items include spindle motor brushes, spindle belts, lubricant, and cutters furnished with the table.

In the event a defect is discovered during the warranty period, the user shall contact Vision Computerized Engraving

and Routing Systems for instructions regarding resolution of the problem. Vision Computerized Engraving and Routing

Systems shall at its option, replace the Vision table or correct the defect or problem by repair at Vision’s manufacturing

facility or at one of its authorized field service offices. In the event of either replacement or repair, Vision Computerized

Engraving and Routing Systems shall be liable only for the cost of repairs, including parts and labor. Any incidental costs,

including the cost of shipment from the user’s location to the point of repair, and subsequent return, shall be at the

expense of the user. Vision Computerized Engraving and Routing Systems shall have no further liability hereunder.

Vision Computerized Engraving and Routing Systems shall have no obligation or liability to repair or replace, during the

warranty period, those items that form a part of the Vision table and are considered expendable by design, including

but not limited to, cutters, spindle motor brushes, and spindle belts.

arar

ranty for this Tranty for this T

ar

ranty for this T

arar

ranty for this Tranty for this T

able Manual:able Manual:

able Manual:

able Manual:able Manual:

arar

ranty Franty F

ar

ranty F

arar

ranty Franty F

or The Vision Tor The Vision T

or The Vision T

or The Vision Tor The Vision T

able:able:

able:

able:able:

The above and foregoing is the only warranty of any kind, either express or implied, including but not limited to any

warranties of merchantability and fitness for a particular purpose, made by Vision Computerized Engraving and Routing

Systems on the Vision table. Any warranties expressed by law are hereby expressly disclaimed. No oral or written

information, advice, or other communications given by Vision Computerized Engraving and Routing Systems, its

dealers, distributors, agents, or employees shall create a warranty or in any way increase the scope of this warranty.

Neither Vision Computerized Engraving and Routing Systems nor anyone who has ever been involved in the creation,

production, or delivery of the Vision table shall be liable for any direct, indirect, consequential, or incidental damages

(including but not limited to damages for loss of business profits, business interruption, loss of business information, and

the like) arising out of the use or inability to use this product.

Any software supplied by Vision Computerized Engraving and Routing Systems in conjunction with the purchase of the

Vision Engraving table, for use therewith, shall be governed by its own separate software license and warranty agreement.

Page2

Page 3

Safety PrecautionsSafety Precautions

Safety Precautions

Safety PrecautionsSafety Precautions

for The Phoenix Engraverfor The Phoenix Engraver

for The Phoenix Engraver

for The Phoenix Engraverfor The Phoenix Engraver

!Keep hands clear of the spindle belt during operation.

!Keep hands clear of the bottom of the spindle during operation.

!Always stop the machine before making any adjustments.

!Disconnect the table cable before servicing.

!Do not operate the system with covers removed.

!Wear safety glasses when cutting any materials that emit chips. Use of the optional vacuum

system will remove most chips

!Use extreme caution when inserting or removing cutters.

Safety

Page3

Page 4

Page4

Page 5

Chapter 1:Chapter 1:

Chapter 1:

Chapter 1:Chapter 1:

UU

nn

packing and Tpacking and T

U

n

packing and T

UU

nn

packing and Tpacking and T

The engraving system has been shipped in more than one carton. Examine the condition of all

containers for external damage. In the event of apparent external damage, notify your carrier upon

receipt, and call your sales representative or Vision immediately.

Note: The shipping containers are considered reusable and should be stored for use in the event

of service need or upgrade.

Step 1.

Open the foam packed shipping cartons. The following items should be included:

a. The table

b. Control unit

c. Control unit accessory kit (with power strip)

d. Optional accessories you may have purchased

Check all the items in the cartons to assure they are of the correct type. Should any of the

contents be missing, damaged, or of the incorrect type, please call your sales representative

immediately.

aking Inaking In

aking In

aking Inaking In

vv

entent

v

ent

vv

entent

oror

or

oror

yy

y

yy

Chapter 1

Step 2.

Prepare a clean, level surface to put the engraving table and controller on. Carefully lift the table

and controller out of the cartons and place each on the table.

Step 3.

After unpacking the table and control unit, SAVE THE CARTONS AND FOAM PACK and

ANY OTHER BOXES. They can be reused in the event the system must be transported

to another location or returned for service. Improper packaging for shipment can

damage the table or controller and may void the warranty.

Page5

Page 6

Page6

Page 7

Chapter 2:Chapter 2:

Chapter 2:

Chapter 2:Chapter 2:

TT

able Descriptionable Description

T

able Description

TT

able Descriptionable Description

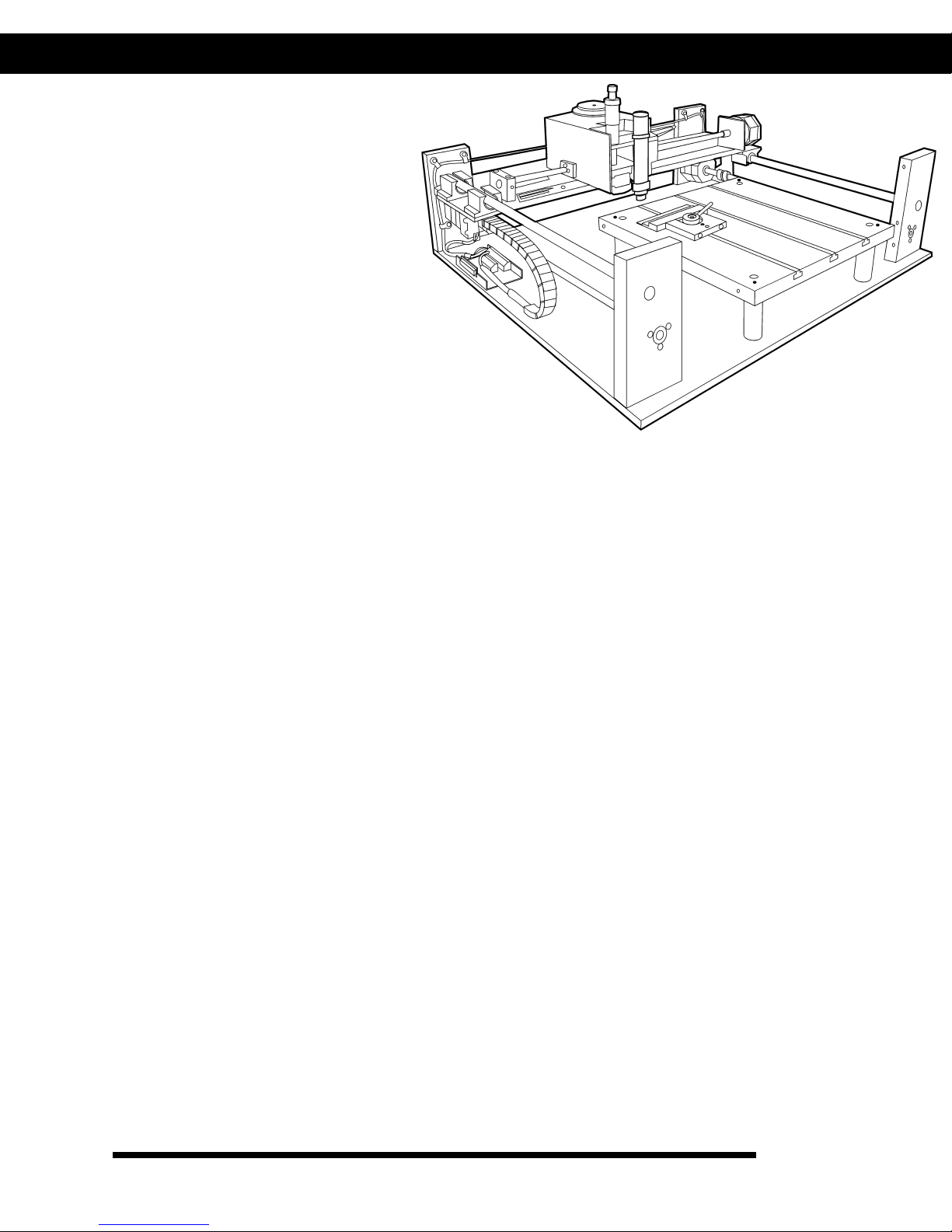

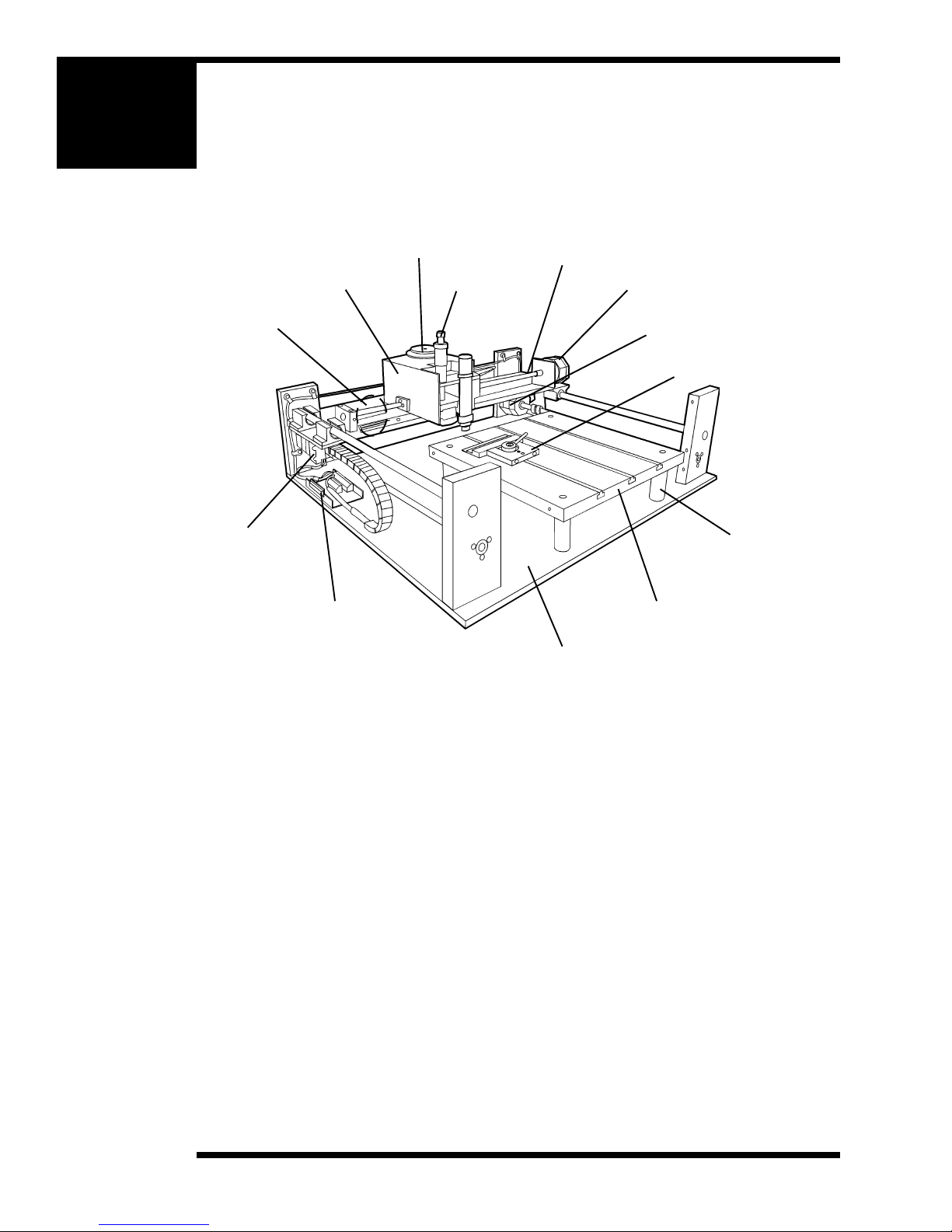

This chapter briefly describes the major components of the Phoenix table. Figure 2.1 shows a

labeled drawing of the Phoenix Engraver. This chapter will help you identify the parts of your table

discussed elsewhere in the manual.

*Optional equipment such as accessory vises, clamps, fixtures or vacuum systems may*Optional equipment such as accessory vises, clamps, fixtures or vacuum systems may

*Optional equipment such as accessory vises, clamps, fixtures or vacuum systems may

*Optional equipment such as accessory vises, clamps, fixtures or vacuum systems may*Optional equipment such as accessory vises, clamps, fixtures or vacuum systems may

haha

vv

e been included with ye been included with y

ha

v

e been included with y

haha

vv

e been included with ye been included with y

individual insindividual ins

individual ins

individual insindividual ins

software used in your system, see the manuals from the manufacturers of these units.software used in your system, see the manuals from the manufacturers of these units.

software used in your system, see the manuals from the manufacturers of these units.

software used in your system, see the manuals from the manufacturers of these units.software used in your system, see the manuals from the manufacturers of these units.

tructions ftructions f

tructions f

tructions ftructions f

our sysour sys

our sys

our sysour sys

or these opor these op

or these op

or these opor these op

tt

t

tt

em. Fem. F

em. F

em. Fem. F

tions. Ftions. F

tions. F

tions. Ftions. F

or infor inf

ormation regarormation regar

or inf

ormation regar

or infor inf

ormation regarormation regar

or descripor descrip

or descrip

or descripor descrip

ding this eqding this eq

ding this eq

ding this eqding this eq

tions of contrtions of contr

tions of contr

tions of contrtions of contr

uipment, see theuipment, see the

uipment, see the

uipment, see theuipment, see the

olleroller

s, coms, com

oller

s, com

olleroller

s, coms, com

putput

put

putput

erer

s, ands, and

er

s, and

erer

s, ands, and

TABLE SPECIFICATIONS:

Z-Axis ClearanceZ-Axis Clearance

Z-Axis Clearance

Z-Axis ClearanceZ-Axis Clearance

(definition: the distance between the bottom of the spindle and the work surface)

Phoenix Table: 3-Inches (76 mm) Clearance

Z-Z-

Axis StrAxis Str

Z-

Axis Str

Z-Z-

Axis StrAxis Str

(definition: the travel distance of the Z-axis mechanism or spindle)

Phoenix Table: 1 Inch (25.4 mm)

okok

ok

okok

ee

e

ee

Chapter 2

TT

able Rable R

able R

able Rable R

esolutionesolution

esolution

esolutionesolution

Engraving Overall Table Shipping

Area Dimensions Type Weight

(non-moving)

T

TT

(definition: the smallest controlled motion the table is capable of)

.0005 inch on all tables (when connected by a Vision Controller)

PHOENIX 12”x12” 21”x22”x11” T-Slot 75lbs.

DEFINITION OF TERMS (as labeled in Fig.2.1)

1. Table Base Plate. This is the large flat plate upon which everything else is mounted. All

mechanical alignments are referenced to this plate, so the space upon which you place the

engraving table must be a reasonably level surface.

2. X-Axis Linear Rails. The steel V-rails, which allow the motion of the carriage in the Xaxis direction.

3. X-Axis Stepper Motor. Drives the carriage in the X-Axis.

4. T-Slot Table. Also referred to as the work surface, this aluminum bed supported by the

linear rails allows placement of the engraving material or special clamps and fixtures. The

slots in this table are shaped with an upside-down T, with the bottom of the T being a singleline slot across the top of the table. The slots are used to hold various accessory holders,

clamps, and jigs. (A selection of various T-slot accessories appears in chapter 7.).

5. Gantry Assembly. The gantry or “bridge” is a large, rectangular bar suspended across

the width of the table in the X-axis. Supports the carriage assembly and travels along. the Yaxis.

Page7

Page 8

Chapter 2

(Figure 2.1) The Phoenix 1212 (non-moving T-slot table)

6. Carriage Assembly

5. Gantry Assembly

8. Y-Axis Stepper

Motor (Dual)

7. Breakout Connector

9. Engraving Motor

13. Spindle

Up/Down

Knob

2. X-Axis Linear Rails

3. X-Axis Stepper Motor

8. Y-Axis Stepper Motor (Dual)

10. Quick Lock Vise

11. Stantions

(risers)

4. T-Slot Table

1. Table Base Plate

Page8

6. Carriage Assembly. The carriage assembly houses the engraving spindle, Z-Axis

mechanism and engraving motor. The carriage moves along the gantry assembly on a V-Rail.

The carriage assembly holds the engraving spindle; it raises and lowers the spindle during the

engraving process using a lead screw and stepper motor.

7. Breakout Connector. This electrical access is used to connect the table to the system

controller. The breakout connector is located on the left side of the table near the back.

8. Y-Axis Stepper Motors (2). Drives the carriage in the Y-Axis. Incorporates a dual drive

mechanism.

9. X-Axis Stepper Motor. Drives the carriage in the X-Axis. Located under the protective

sheet metal cover.

10. Engraving Motor. Drives the spindle for rotary engraving.

11. Quick-Lock Vise. A “cam” type locking device that allows quick change of parts for

engraving..

12. Stantions (Risers). Larger ones are pictured in Fig.2.1.and come standard with the

Phoenix Engraver. For added clearance, shorter ones may replace these to get more

distance between the T-Slot table and the spindle.

Page 9

13. Spindle Up/Down Knob. Raises and lowers head when power is off the the stepper

motor

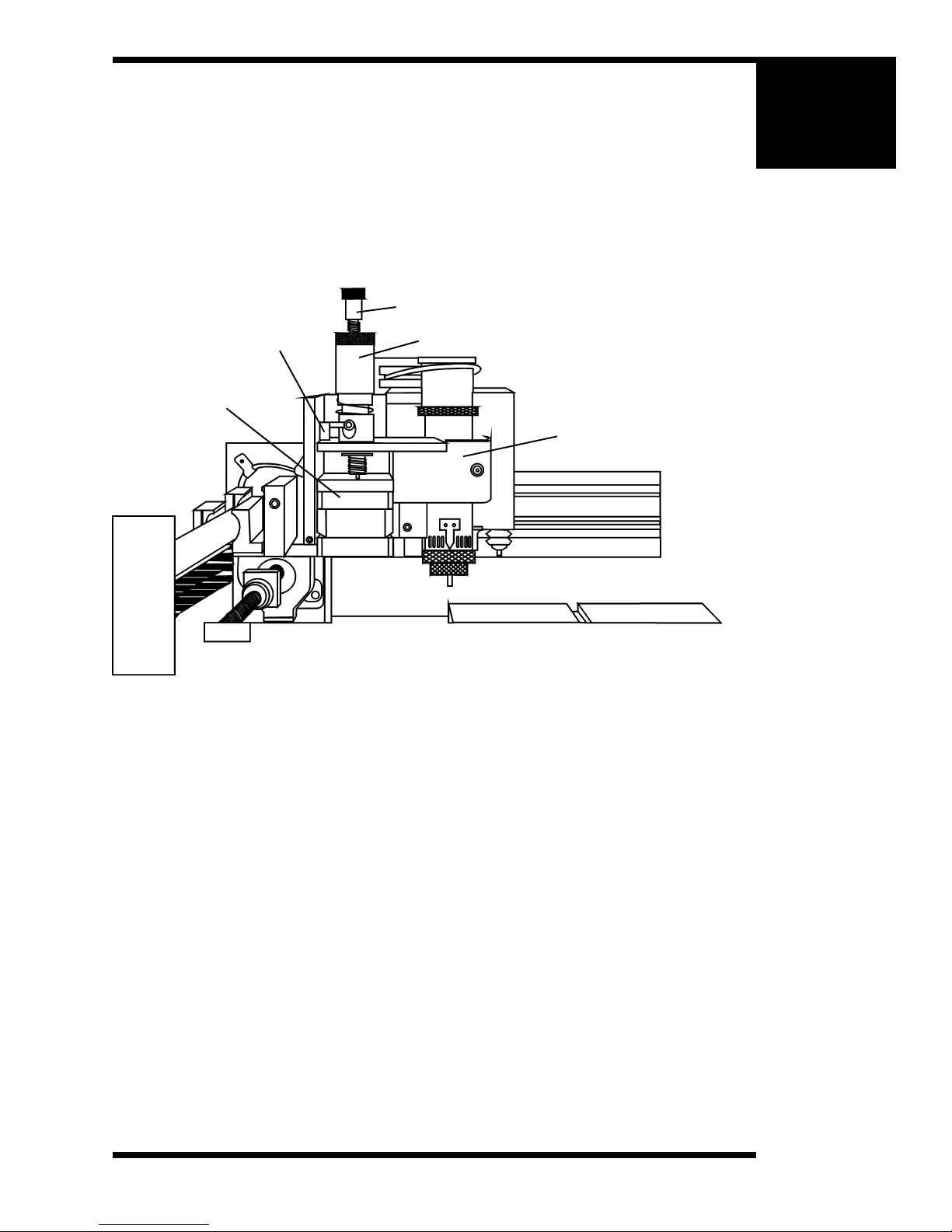

(Figure 2.2) Current Phoenix Carriage Front view with metal covers removed

Spindle Up/Down Knob

Chapter 2

Proximity Switch

Z-Axis Stepper Motor

Down Pressure Spring Adjust

Spindle Block

Page9

Page 10

Page10

Page 11

Chapter 3:Chapter 3:

Chapter 3:

Chapter 3:Chapter 3:

SeSe

tting Utting U

Se

tting U

SeSe

tting Utting U

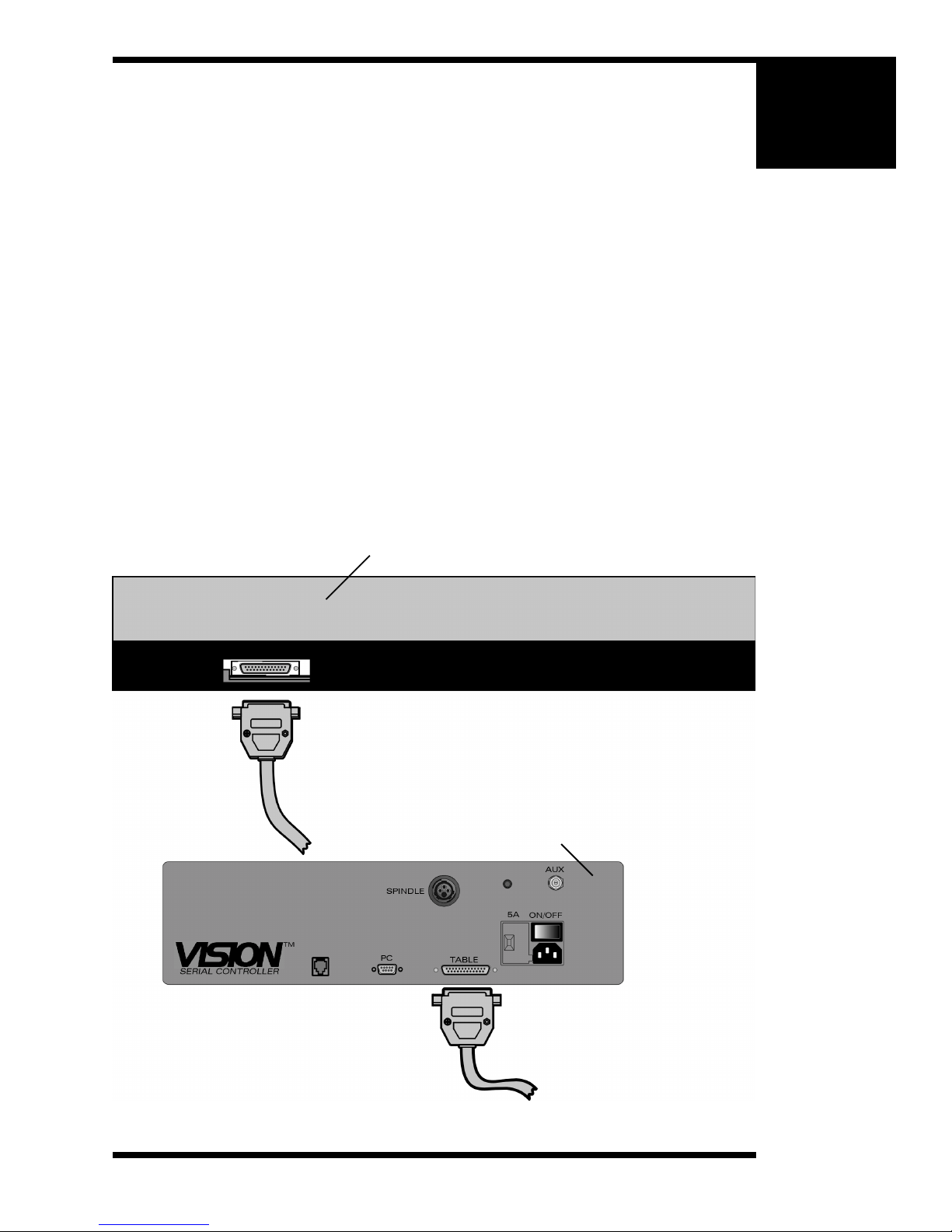

Connection of Power, Cables, and Controllers

Additional boxes may have been shipped along with your table, depending on the system ordered.

These will typically include a control unit and associated cables. The proper connection of these

cables is essential. Check the appropriate user’s manuals for your controller before attempting to

connect them it to the table. After connection of the cables as directed by your controller manual,

power can be connected to the system. It is suggested that a surge protector be used. (Surge

protectors--often called “power strips” can be purchased inexpensively at your local hardware

store.) This will allow powering all of the elements of the system at once.

NOTE: Most of the newer Vision Serial Controller s include a surge protector.

(Figure 3.1) 25-pin Breakout Connector to the Vision Serial Controller

p The Tp The T

p The T

p The Tp The T

Left side view of the Phoenix Engraver

ableable

able

ableable

Chapter 3

Back view of the Vision Serial Controller

Page11

Page 12

Page12

Page 13

Chapter 4:Chapter 4:

Chapter 4:

Chapter 4:Chapter 4:

TT

able Aable A

T

able A

TT

able Aable A

All Phoenix Table models include one of the following spindles:

(Figure 4.1) Top-Loading Spindle

djustmentsdjustments

djustments

djustmentsdjustments

(Figure 4.2) Top-and-Bottom

Chapter 4

Loading Collet Spindle

12.

7.

5.

4.

2.

10.

3.

1.

11.

6.

9.

8.

1. Pulley

2. Spindle Housing

3. Micrometer

4. Retainer Ring

5. Nose cone

6. Draw Bar

7. Cutter

8. Solid Collet

9. Split Collet

10 . Pointer

11. Cutter Knob

12. Cutter Knob Setscrew

Page13

Page 14

Chapter 4

Zeroing Cutters for Top-Loaded Spindles (see figure 4.1)

1. Turn the micrometer to zero. This provides a starting point and reference for setting the

depth accurately. It’s important to note that the micrometer should be threaded onto the

spindle housing sufficiently to prevent excessive play in the micrometer and nosecone. If

there are too few threads holding the micrometer in place it will move during the engraving

process. The best starting position is 3 or 4 complete revolutions from the top.

CAUTION: When you loosen the setscrew in this step, the cutter may

easily fall out of the spindle and can cause cutter tip damage. Use

one hand to hold the cutter before loosening.

2. With the appropriate cutter installed in the spindle, loosen the setscrew in the brass

cutter knob with a spline wrench (commonly referred to as the cutter wrench).

3. Gently place a piece of metal (brass preferred) against the nosecone so as to push the

cutter even with the bottom of the nosecone. Now the cutter should be flush with the

nosecone. Retighten the cutter knob setscrew. Your cutter is now zeroed. Rotating the

micrometer clockwise will adjust the depth of the cut. Each click of the micrometer = .001”.

A full revolution is .025”.

Zeroing Cutters for Top-and-Bottom-Loaded Collet Spindles (see

figure 4.2)

The collet spindle can be used for either top loaded or bottom loaded cutters. To install a top

loaded cutter in the collet spindle, first set the micrometer to zero. Loosen the knurled draw bar

on the very top of the spindle slightly. Remove the cutter knob from

the cutter, and slide the cutter into the spindle. Place a piece of flat

material against the bottom of the nosecone and lower the cutter until

it rests against the material. Tighten the draw bar around the cutter,

make sure it is tight. Then reattach the cutter knob to the top of the

cutter and screw it in counterclockwise until secure. Be careful

screwing the cutter knob in, as counterclockwise is the direction to

unscrew the draw bar (see fig 4.3). Never use pliers! The cutter

depth can be adjusted by turning the micrometer counter clockwise.

Note: If using 2" short cutters, install them from the bottom. Use the

draw bar on the very top of the spindle to tightly secure the cutter.

A solid collet, if purchased, can be installed in place of the split collet

for burnishing. Install the collet in the bottom of the spindle and

tighten the draw bar firmly. The spindle now acts as a normal top

loaded spindle for ease of operation. The split collet can be reinstalled

when required.

Page14

(Figure 4.3) Tightening the

cutter knob in the draw bar.

Page 15

Diamond Engraving

To install a diamond drag adapter, remove the retainer ring and nose cone from the bottom of the

spindle and replace with the diamond drag adapter. (See f ig.4.4) For diamond drag cutting, the

engraving motor is turned off and the cutter “drags” across the material. This is accomplished

with the motor on/off switch in the “off” position. Down pressure against the material can be

reduced or increased as necessary by adjusting the spindle pressure knob as described in the

next section.

(Figure 4.4) Diamond Drag Adapter

Pulley

Chapter 4

Spindle

Housing

Micrometer

Diamond Drag

Adapter

Leveling the Phoenix Table (see fig.4.5)

All current Phoenix tables will have table level adjustments. The table may be leveled by first

loosening the 4 hex head screws that secure the t-slot table to the risers (see figure 4.5), and

then tightening or loosening the small set screws located next to the hex head screws. Once

level, the hex head screws can be re-tightened. This is a tricky process without a dial indicator to

measure accurately the run out from corner to corner. Table level adjustment can be made

without the indicator but the accuracy and time may be prohibitive.

Page15

Page 16

Chapter 4

(Figure 4.5) Front Angled View of Phoenix Table

Showing the location of hex head shoulder bolts

(Figure 4.5a) Close Up

side view of a stantion

stantions (4)

hex head shoulder bolts (4)

Replacing The Stantions For Additional Clearance (see fig.4.5 and 4.6)

This procedure will allow the user to lower the t-slot table for fixturing of taller objects. It’s

important to understand that the total Z-axis stroke does not increase, however some additional

reach can be achieved by lowering the spindle in its block.

To change from the standard 2 3/8” stantions (risers) to the shorter 1 5/8” stantions, remove the

4 shoulder bolts from the top of the t-slot table. Use a 1/8” hex key. Be careful not to strip the

bolt head when removing or replacing. After the bolts are removed, the t-slot table may be set

aside. Mark the 4 stantions as shown in fig.4.6. Keep the orientation the same when you

replace the stantions. This will ensure that the table will be level when the taller stantions are put

back in place. A flat groove has been

machined into the sides (near the top) of

the stantions (see fig.4.5a). Use a 7/8”

open end or crescent wrench to remove the

stantions by turning counterclockwise. You

can add the shorter stantions to the table

base by following the above procedure in

reverse order. Tighten the stantion in place

and replace the t-slot table. If the table is

equipped with leveling screws, you may

further level the table using the procedure

mentioned in the previous section.

1

2

(Figure 4.6) Top View of

Current Phoenix Model

Page16

4

3

Page 17

Chapter 5:Chapter 5:

Chapter 5:

Chapter 5:Chapter 5:

TT

able Maintable Maint

T

able Maint

TT

able Maintable Maint

Vision strives for the highest quality in their manufacturing process to

provide you with the most cost effective, reliable engraving machine

in use today. Please remember that proper maintenance and care is

necessary to achieve maximum product life expectancy.

The engraving environment generates small plastic and metal chips as well as other particles

during operation. As with any machinery, your engraving system should be kept as clean as

possible to minimize wear and tear, and to improve final quality of the engraved product.

REMOVING CHIPS

Plastic and metal chips, generated during the engraving process, should be removed from the

engraving surface periodically. A portable vacuum is suggested for chip removal, but applying

direct suction to the spindle area is not recommended.

Note that this cleaning can be minimized and greatly simplified through the use of the optional

vacuum chip removal system. The vacuum chip removal system removes chips and dust created

by engraving. This system can also extend the life of other components in the system, as prompt

removal of chips reduces contamination and overheating in the spindle area. The vacuum chip

removal system also keeps the nose cone from skipping over letters due to chips on the

engraving surface.

enanceenance

enance

enanceenance

Chapter 5

Cleaning The Nose Cone

(Figure 5.1) Vacuum nose with hose

The nose cone around the cutter may accumulate dust and chips that cannot be removed by

sucking them off or blowing on them with low pressure air. (CAUTION! High pressure air can

damage the spindle.) Two types of nose cones are available; one nose cone is designed to be

used with the vacuum system, the other is not. Cleaning methods depend on the type of nose

cone in use.

With a vacuum chip removal system (see fig 5.1), most of the chips will be removed during the

engraving process. If the suction nozzle becomes clogged, remove the hose connection to the

nose cone. Remove the cutter, then unscrew the vacuum nose cone. Using a vacuum or an air

hose, clean out the nose and the vacuum tube leading to the nose cone. Reinstall the nose cone

and the vacuum hose.

Page17

Page 18

Chapter 5

Without a vacuum chip removal system you should remove the cutter before attempting to clean

the nose cone. The nose cone retainer ring, the nose cone, and the micrometer collar should all

be removed and cleaned using a vacuum or blowing air. The three nose cone components should

be removed and cleaned at least every day, and as frequently as necessary. Failure to clean the

nose cone regularly will result in premature spindle failure.

Cleaning the Vacuum Filter (only with the vacuum chip removal option)

On systems with a vacuum chip removal system, frequent cleaning of the vacuum filter is

necessary for proper performance. When engraving with the vacuum filter system, the filter

should be checked and cleaned several times a day, depending on the amount of engraving

done. If the vacuum does not appear to be functioning efficiently, clean the filter more frequently

as needed.

To clean the vacuum filter system, disconnect the vacuum hose from the canister. On the lid of

the canister, note the three wing nuts. Loosen these nuts enough to allow the attached bolts to

swing away from the lid, allowing removal of the lid. Do not loosen the nuts enough to remove

them completely. Remove the canister lid and inside you will find two filters. Carefully remove the

inner, paper filter. (The paper and cloth filters tend to stick together.) Empty the paper filter, and

shake it out completely, being careful not to damage it as the filters are reusable. After shaking

out the paper filter remove and empty the cloth filter in the same manner as the paper filter. Do

not wash either filter. Place the paper filter back inside the cloth filter, and place the cloth filter

back inside the vacuum canister.

LUBRICATION FOR PHOENIX MODELS

Lubricating the Z-Axis Assembly

A light amount of oil (3-in-1 preferred) should be used to coat the V-rails. Do not allow any

excess oil to accumulate on the rails since it will attract dust and engraving chips. After applying

lubricant, run the mechanism up and down the rail to evenly distribute the oil.

Lubricating the X-Axis Bridge Assembly

Same as above.

Lubricating the Y-Axis Linear Rails

Apply 2-3 drops of light oil on the rail and rub in with your fingers. XY jog the bridge back and

forth to evenly distribute the oil.

Lubricating the X-Y-Z-Axis lead screws

A light lubrication of the X and Y lead screws should be performed after every week of

usage. Use silicone lubricant only. To reach the Z-Axis lead screw, turn the spindle up/

down knob to the furthest down position, which exposes the portion of the Z lead screw

that requires lubrication. Spray a light coating along the lead screw.

HINT: To avoid having to remove the metal covers, use a nozzle

extension for your can of spray lubricant. DO NOT use any lubricant

other than silicone, as it may become sticky and cause a

buildup that can cause mechanical failure.

Page18

Page 19

What not to lubricate

Many of the bearings and assemblies in your engraving machine are sealed and/or coated using

special low-friction methods and should not be lubricated.

DO NOT attempt to lubricate the spindle or the spindle bearings. If you suspect

lubrication problems, call your dealer/representative for instructions, as further

lubrication may harm the machine.

DO NOT oil the X or Y stepper motors. The only motor that requires lubrication is the

Z-motor and lead screw combination. (See lubricating the Z-axis assembly above.)

Oiling the stepper motors can permanently damage the motors.

REPAIRS, REPLACEMENTS, AND ADJUSTMENTS

How to replace a belt

A belt is used to drive the spindle engraving system. It runs between a drive pulley and the

spindle pulley. If it needs replacement, remove the old belt by rolling it to the top of the spindle

pulley, and give it a slight stretching motion to snap it off the end. Once loose, it can easily be

removed from the machine. Now position the new belt around the drive pulley, then stretch it to

snap over the top of the pulley.

Chapter 5

Motor Brushes

Current Phoenix 24V Motor

Carbon Motor Brush

Threaded Brush Cap

(Figure 5.2) The Phoenix

engraving motor and brushes

Shown from front and side view

Page19

Page 20

Chapter 5

The motor brushes on the engraving motor should be inspected regularly, and replaced when

worn. Two brush assemblies are included with the accessories package. (One for each side of

the motor.)

Inspect the brushes for possible replacement annually using the following procedure

(see figure 5.3).

The engraving motor is located under the sheet metal top cover. Remove the cover to gain acces

to the engraving motor.

CAUTION: Disconnect the gray table cable from the Phoenix table.

This will ensure that no power is applied to the table.

Locate and remove the 4 button head screws that mount the engraving motor to the carriage.

This will allow the engraving motor to be rotated to gain access to the motor brush caps. You do

not need to remove the motor from the carriage to get to the brush caps. Simply rotate the

motor left or right 1/4 turn to fully see the brush cap. Using a flat tip screwdriver, carefully

remove the motor brush caps and inspect the carbon brush for wear. DO NOT ATTEMPT TO

SEPARATE THE MOTOR BRUSH FROM THE SPRING. Replace brushes as necessary.

To complete the job, reverse the order of the above listed steps and ensure that the motor mount

is secure to the carriage before replacing the carriage top cover.

If either brush needs to be replaced, replace both brushes as a set.

(Figure 5.3) The Phoenix Carriage

Shown from rear view with top cover removed

Spindle Up/Down Knob

(for pressure spring adjustment)

Z-Axis Limit

Button Head

Screws (x4)

Motor Mount

Engraving Motor

Page20

Brush Cap (x2)

X-Axis Leadscrew

Page 21

MAINTENANCE SCHEDULE

Following is a suggested maintenance schedule. Remember that in conditions of prolonged use,

unusual environments, or unusual applications, maintenance items may need to be performed

more frequently than suggested in this schedule.

Frequency Maintenance Items

As needed 1. Vacuum and/or brush

2. Clean vacuum canister filters

Every Day 1 . Remove chips form the spindle if

you do not have a vacuum chip

removal assembly .

Every Week 1 . Lubricate steel X, Y lead screws

Every Month 1 . Lubricate the Z-Axis lead screw

Chapter 5

Every Six Months 1. Check the brushes and replace if

necessary.

2. Lubricate the Z-Axis linear bearing

Page21

Page 22

Page22

Page 23

Chapter 6:

Optional Accessories and Uses

Versa Vise

This low profile vise features a fixed top jaw and a moveable bottom jaw. Total opening is 3.5”.

It adapts to most systems with at least 1” clearance under the spindle. This vise is designed to

be directly mounted to many engraving tables and includes T-nuts to allow quick placement on Tslot tables. The jaws will hold a variety of clamps and jigs to secure odd shaped or difficult-tohold items.

(Figure 7.1)

Versa Vise

Chapter 6

Universal Clamping Bars (9” Jaws)

These clamping bars are specially designed to hold both 1/16” and 1/8” thick materials and

allow engraving up to the edge of the material without nosecone interference. Other uses

include: holding metal engraving stock, name badges or other rectangular shapes. The bars will

fit the Versa Vise or can be used directly on most T-slot table surfaces. The bars will also fit

Pantographs and other computerized systems that use the dowel pin system.

(Figure 7.2) 9” Jaws

Page23

Page 24

Chapter 6

Universal Seal / Medallion Holder

This universal clamp will hold 1-3 round objects at a time. It also has a place for the “eye” of a

medallion or tag. This clamp may be used to any diameter of notary seal. These clamps will fit

the Versa Vise or can be used directly on most T-slot table surfaces. They will also fit

Pantographs and other computerized systems that use the dowel pin system.

(Figure 7.3) Universal Seal / Medallion Holder

Pen & Seal Jig

These jaws enable engraving on all types of pens and other small cylindrical objects. Rotating

the jaws 180º allows engraving on medallions, notary seals, pet tags and other round objects.

These jaws will fit the Versa Vise or can be used directly on most T-slot table surfaces. They will

also fit Pantographs and other computerized systems that use the dowel pin system.

(Figure 7.4) Pen & Seal Jig

(Figure 7.5) Seal Jig

Seal Jig

Designed for notary seals of all diameters. Rotating the jaw 180º will allow clamping of both

large and small sizes. These jaws will fit the Versa Vise or can be used directly on most T-slot

table surfaces. They will also fit Pantographs and other computerized systems that use the dowel

pin system.

Page24

Page 25

Adjustable Pen Jig

Designed specially for pens and cylindrical items whose shape is not symmetrical. The

adjustment allows the capture of the small tapered diameter of pens or odd shaped items.

These jaws will fit the Versa Vise or can be used directly on most T-slot table sur faces. They will

also fit Pantographs and other computerized systems that use the dowel pin system.

Chapter 6

(Figure 7.6) Adjustable Pen Jig

(Figure 7.7) Edge Clamp

Top view and side view

Edge Clamps

This clamp is designed to secure plastic or metal engraving stock from the top. This avoids

bowing of the material in some applications. This clamp can be moved anywhere on a T-slot

table and will hold material thicknesses of .020, .032, .062, and .125 by simply tightening a

thumbscrew.

(Figure 7.8) Universal Pin Jig

Universal Pin Jig

This is a true universal clamp designed for holding odd shaped items such as state badges,

hearts, and medallions with unusual borders, pet tags, jewelry and more. The dowel pins may be

moved anywhere on the jaw to accomodate any odd shape. These jaws will fit the Versa Vise or

can be used directly on most T-slot table surfaces. They will also fit Pantographs and other

computerized systems that use the dowel pin system.

Page25

Page 26

Chapter 6

TYPICAL VERSA VISE COMBINATIONS

(Figure 7.9)

Versa Vise with

9” Jaws

Page26

(Figure 7.10)

Versa Vise with

Pen & Seal Jig

Page 27

(Figure 7.11)

Versa Vise with

Seal Jig

Chapter 6

(Figure 7.12)

Versa Vise with

Universal Seal /

Medallion Holder

Page27

Page 28

Chapter 6

The Vacuum Chip Removal System

The optional vacuum chip removal system is designed to simplify the engraving process and

minimize wear and tear on the engraver. The vacuum chip removal system uses a vacuum nose

cone to remove chips created during the engraving process before they have the chance to

create problems. The quiet pump, coupled with the microfine-layered filters assures that your

unwanted chips are whisked away effor tlessly. The vacuum pump canister uses replaceable

filters that can also be reused, to assure maximum efficiency and cost-effectiveness.

The vacuum chip removal system allows prompt removal of chips and dust created in the

engraving process, reducing contamination and overheating in the spindle area. Chip removal

also prevents the cutter from skipping over letters due to stray particles. This vacuum chip

removal system is available with or without a Vision vacuum nose cone.

(Figure 7 .15) Vacuum Chip

Removal System

Vac hose connector

(large end)

Vacuum Pump System

Elbow pipe connector

ALL PIECES CONNECTED

Vac hose connector

(small end)

Vacuum filter canister

Vac hose

(threaded)

Vac hose

(2" clear)

Vac nose - black

Page28

Page 29

VA CUUM CHIP REMOV AL S YSTEM ASSEMBLY AND INSTALLA TION

(approximate installation time = 10-15 minutes)

You should have:

1 Vacuum Pump System (silver with a box, and power cord attached)

1 Elbow pipe connector (black metal with USA stamped on it)

1 Vacuum filter canister (blue metal, with 3 wing-nut fastners)

1 Vacuum hose connector (white plastic, 2 pieces)

1 Vacuum hose (white/clear spiral, 3/4" diameter) 10'

1 Vacuum hose (clear, 2")

1 Vacuum nose (large or small)

To assemble the vacuum pump unit:

• Examine the vacuum pump system, you will find two large screw-holes. The "in" hole is labeled

with the arrow label on the side of the vacuum pump.

• Find the elbow-pipe.

• Make sure the screw-threads are clean on both the pump system and the elbow-pipe. (Clean with

a rag and water, do not use solvents. A dirty thread can make assembling screw-in parts

significantly more difficult.)

• Screw the elbow-pipe into the pump system through the port on the side with the yellow/black

arrow label(It will not screw all the way in, make sure the elbow is tightly screwed in and will not

unscrew–some threads will show).

• Find the vacuum filter unit, and make sure the bottom thread is clean. (The bottom has three

triangle-shaped spines, and an extended "nose". The inside of the "nose" is threaded to accept the

pipe connector.)

• Screw the canister onto the vacuum pipe, making sure the canister is tightly screwed on. (The

canister will not screw in completely.)

• Check the vacuum hose connector to make sure it is clean and trimmed. Brush off any plastic

bits that may be stuck to it, and make sure the threads on the inside are clean. Seperate the two

pieces and make sure the inside is clean. (The two pieces seperate so you can remove the vacuum

hose for convienent cleaning.)

• Screw the long threaded part of the vacuum hose connector (the larger end) into the top of the

vacuum canister, making sure the hose is securely screwed in.

• Check to make sure the vacuum hose is not tangled.

Also included are 2 Hose

clamps (black, 3/4" +

hardware to attach vac

hose to carriage assembly.

See below for instructions.)

Chapter 6

The following steps may have already been done if you purchased the entire assembly together.

• Screw the vacuum input hose into the top of the vacuum hose connector (small end). The hose

has a clear plastic nozzle and a threaded end; you want to use the threaded end, it screws into the

hexagonal-part of the larger end of the white hose connector.

• Plug the clear plastic end of the vacuum hose onto the long nose that comes off the black

vacuum nose attachment. (The clear plastic will cover about half of the black vacuum nose.)

Attaching the Vacuum System to the Phoenix (see 7 .14 next page)

The following items should be requested for attaching the vacuum system to the Phoenix:

•2 Plastic Clamps (5/8” for snug fit; 3/4” for loose fit)

•2 Lock Washers

•2 Screws

•1 Hex Wrench

Page29

Page 30

Chapter 6

(Figure 7.14) Attaching the Vacuum Hose to the Phoenix Carriage

Right Side of Phoenix Carriage

vacuum nose cone

To Install:

1. Remove two screws from carriage (a & b).

2. Spread apart plastic clamps (c) and place

around hose (d)

3. Place lock washer on the new longer screw

& insert through holes in the clamp (e).

4. Screw clamp (with hose inside) onto

carriage using the supplied hex wrench.

5. Put new vacuum nosecone on spindle

(adjust micrometer if needed).

6. Attach clear end of hose to new vacuum

nosecone.

a

b

d

Page30

c

e

Page 31

Spindle Options

Increase your profits and engraving quality with the split collet spindle (see fig 7.15). Designed to

be extremely accurate and durable, the collet spindle is simple to use. This collet retracts around

the cutter gripping it at the bottom, while firmly holding on the top. By holding the cutter in two

places the cutter is virtually vibration-free and nearly eliminates play and runout. The split collet

spindle can engrave with excellent clarity and resolution while averaging a longer product life than

any other spindle.

The collet spindle accepts both top loaded and bottom loaded cutters, including 2" short shank

cutters such as drill bits, router bits, dremel tools etc. Should you ever want your split collet

spindle to act like a standard spindle, simply install our solid collet in the spindle (available

separately).

Diamond Drag Adapters

Using your plastic cutters to engrave metal can seriously damage them. There is a better option;

Western offers high-quality diamond drag adapters. Don’t burn out your bearings on a job that

can be done just as easily as cutting plastic. The diamond drag adapter engraves virtually allmetallic surfaces, at high resolution and high speed. The results achieved with a diamond drag

adapter can be even more amazing when used with double- and triple-line fonts.

Chapter 6

Split

Collet

(Figure 7.15) Split Collet Top-and-

Bottom Loading Spindle

Cutter

Diamond

Drag Adapter

w/ Diamond

Standard

Spindle

Page31

Page 32

Page32

Page 33

Chapter 7:Chapter 7:

Chapter 7:

Chapter 7:Chapter 7:

TroubleshootingTroubleshooting

Troubleshooting

TroubleshootingTroubleshooting

ENGRAVING PROBLEMS

Problem: Engraving on the plate is “slanted”.

Possible solutions:

1. Check material for squareness. Maybe your shear does not cut squarely.

2. Check to see if the material on the table is indeed at a true home and is square to your scale

bars or stops.

3. If your table is equipped with scale bars insure that they are secure and flush to your T-Slot

table.

Hint: Always inspect your job before removing your plate from the system. You may be able to

salvage it by re-engraving the job, or at a minimum, you may be able to analyze the problem and

prevent repeating it. Perhaps the plate moved during engraving. Removing it without inspection

would prevent you from detecting this problem.

Problem: You are using a nosecone, but your engraving is “shallow” across the top or left

margin of your plate. It engraves properly when the spindle is away from the edge.

Possible solutions:

1. Your nosecone is riding on the scale bars or side stops. Loosen and

lower the scale bars so that they are below the level of your material

surface. Retighten the thumbscrews.

2. Check to see if your material is riding on the scale bars or side stops. It’s not hard to miss

during set-up especially if the plate is thin material.

Chapter 7

Problem: You are using a nosecone and your engraving is uneven.

Possible solutions:

1. Your spindle is not “zeroed” to your material. Follow the steps in “Chapter 4” to zero your

spindle.

2. You are not using enough float and need to adjust the down stroke until your nosecone

touches the material with some pressure.

3. You may be engraving too fast for the type of material you are cutting. Check the

manufacturer’s recommendation. The cutter may be bouncing on the surface. Some hard

materials may exhibit this problem.

4. You may have a defective or broken cutter. Replace it.

5. Your material may be defective.

6. Your vac chip removal system is plugged and engraving chips are caught between the

nosecone and the material.

7. The nosecone or vac nose is loose.

Problem: “Shadowing” occurs while engraving certain materials.

Possible solutions:

1. Leave the protective film on the engraving material during engraving.

2. Use a plastic nosecone instead of a metal one.

3. The nosecone may be damaged. Inspect for burrs or roughness. Try using an emor y cloth to

polish the nose.

4. Back off on the spring pressure. Excessive down pressure will leave a rub mark on almost any

plastic material.

Page33

Page 34

Chapter 7

Problem: You are not using a nosecone and you have uneven engraving.

Possible solutions:

1. Switch to a nose-riding method.

2. Use a different method of holding the material. If you use double sided tape, it may be thick

enough to change your surface flatness by a few thousandths.

3. Parcel the job if possible so that you can have more direct control over the depth of each

specific area. This may be effective if you have uneven material or a large engraving bed.

4. Table tolerances may not be able to maintain the accuracy level you want.

5. Table may not be on a level surface.

Hint: While it’s true that you can do non-nose riding engraving, it’s not easy to hold any

controlled accuracy on the depth. This takes flat material, a very flat bed and some degree of skill

and confidence. It also takes an application where some amount of uneven engraving may be

tolerated.

Problem: I’m getting “tails” or “swirls” in the corners of my engraving.

Possible solutions:

1. Your cutter speed is too fast relative to your x-y speed. Slow your spindle speed down or

increase your table speed.

2. Your cutter is worn or damaged. Replace.

3. Turn down the dwell speed.

Problem: I’m getting “fuzz”, “fur” or can see lines in the bottom of my cut showing each

cutter path. I can even see steps in the bottom of my cut.

Possible solutions:

1. This problem is tough. Sometimes caused by dull cutters, the wrong cutter, or not enough

overlap for each cut. Try changing cutter size slightly. You may get better clean up.

2. Try taking a second pass cut at .001-.002 deeper. This may clean up the roughness.

3. Resharpen the cutter. There are various cutter angles that can cause these kinds of problems.

There is a relief angle that if too great can cause noticeable ridges in the bottom of the cut.

4. Ensure that the spindle is square in the mount or block. An unsquare spindle means an

unsquare cutter to the material surface.

5. Turn spindle speed up.

Problem: Poor letter quality.

Possible solutions:

1. You may be engraving too fast. Engraving quality improves with the right engraving and spindle

speeds.

2. If you are diamond drag engraving, you have too much down pressure or you are engraving too

deep. Also, check the grain of the material; it should be left to right.

3. You may have a worn or dull cutter.

4. Your material is not securely fastened to the table.

Probelm: Ragged Type.

Possible solutions:

1. If the quality of cut is ragged or exhibits steps, you may have play in the cutter.

Page34

Page 35

This could be in the gap between the cutter and the spindle shaft. Maybe the shaft is worn or the

spindle bearings need to be replaced. Once a shaft starts to wear and a cutter is loose, the

problem can worsen quickly.

2. The spindle is loose in the housing or block.

3. The carriage is loose or has excessive play, check the z-axis bearings or slide.

4. Lubricate lead screws with recommended lubricant.

Problem: My baseline is off.

Possible solutions:

1. You’re not at the mechanical or software home. Maybe the table or carriage was bumped

during set-up. Maybe the previous job was cut short and the system did not return back to its

mechanical home or limit switches. Move the table, bridge or carriage physically to home or send

it home via the software.

2. Check your software layout for keystroke errors.

Problem: While burnishing aluminum I have voids or non-engraved areas.

Possible solutions:

1. Tr y re-engraving the same plate again. Some of the anodized aluminum plates have very hard

surfaces and two passes are required.

2. Switch to a diamond burnisher. The more common carbide tools may have dif f iculty getting

through the tough surface and are more easily worn down, thus sometimes skipping across the

surface.

3. Increase the pressure of the z-axis or burnishing adaptor.

4. Try other materials. Same reasons as above. Some materials, from some vendors, are just

plain tough.

Chapter 7

Hints:

Always try to solve the problems yourself before seeking help. A little patience goes a long way.

Never work on any problem that gets you so frustrated that you become irritated at the machine,

the service technician, or the salesman. It’s only a machine, don’t let it get the best of you.

Contact your dealer.

MECHANICAL PROBLEMS

Problem: No X, Y or Z-Axis movement.

Possible solutions:

1. Check that the controller power is on.

2. Check that the drives are turned on.

3. Check the table cable for a solid connection. It may be helpful to remove the cable, reconnect

and tighten the hold down screws to ensure a good connection.

4. Ensure that the job has been transferred to the controller (Green start light is ON).

5. Ensure that the emergency STOP button is not depressed, then turn the drives on.

Page35

Page 36

Chapter 7

Problem: System has no movement in any one axis.

Possible solutions:

1. T ry to jog the problem axis using the X/Y/Z jog keys on the control unit. If OK, retry the job.

2. Check the table cable for a solid connection.

3. Call service technician for further instructions.

Problem: Unusually loud noises during the engraving process.

Possible solutions:

1. Isolate the cause of the unusual noise by:

a. Remove the cutt er .

b. T urn the engraving motor t o OFF .

c. Run the engraving job, or X/Y jog the system.

If the noise persists, it may be confined to the X, Y or Z-axis. Check for proper lubrication of lead

screws. Follow lubrication instructions in chapter 5.

If the noise goes away and to further isolate the cause, do the following:

a. Remove the motor belt.

b. Run the engraving motor without starting a job. Loose motor belts may cause some

noises, so removal will narrow down the problem. If the noise is present with the

spindle motor on, check the motor brushes.

If there is no unusual noise when running the spindle motor with no belt attached, do the following:

a. Attach the motor belt.

b. Run the spindle motor and vary the RPM by changing the control unit pot entiometer .

Noise levels may vary . If the noise persists, check the spindle for ov erheating.

Excessive overheating of the outside housing of the spindle is a sign of defective

bearings. The noise may be caused by the bearings.

Problem: Spindle is hot.

Possible solutions:

1. Ensure that the nose cone area is free of debris. Check the vacuum system (if used) for clogging.

2. Inspect the spindle for other obstructions that may prevent proper rotation.

3. Bearings may need to be replaced.

Problem: Spindle motor will not come on.

Possible solutions:

1. Check the auto/on/off switch to ensure the proper operational mode.

2. Check motor brushes.

Problem: Mot or belt will not stay on pulle y.

Possible solutions:

1. Motor belt is probably worn and needs to be replaced.

Page36

Loading...

Loading...