Page 1

MBA/SMA 0204, MBB/SMA 0207, MBE/SMA 0414 - Professional

Vishay Beyschlag

Professional Leaded Resistors

FEATURES

• Approved according to CECC 40101-806

• Advanced thin film technology

• Power dissipation rating up to 1 W

• Excellent overall stability: class 0.25

• Wide professional range: 0.22 Ω to 22 MΩ

• Lead (Pb)-free solder contacts

• Pure tin plating provides compatibility with lead (Pb)-free

and lead containing soldering processes

• Compatible with “Restriction of the use of Hazardous

Substances” (RoHS) directive 2002/95/EC (issue 2004)

DESCRIPTION

MBA/SMA 0204, MBB/SMA 0207 and MBE/SMA 0414

professional leaded thin film resistors are the general

purpose resistor for all fields of professional electronics

where reliability and stability is of major concern. Typical

applications include industrial, telecommunication and

medical equipment.

APPLICATIONS

• Industrial

• Telecommunication

• Medical equipment

METRIC SIZE

DIN: 0204 0207 0414

CECC: A B D

TECHNICAL SPECIFICATIONS

DESCRIPTION MBA/SMA 0204 MBB/SMA 0207 MBE/SMA 0414

CECC size A B D

Resistance range 0.22 Ω to 10 MΩ 0.22 Ω to 22 MΩ 0.22 Ω to 22 MΩ

Resistance tolerance ± 5 %; ± 1 %; ± 0.5 %

Temperature coefficient ± 50 ppm/K; ± 25 ppm/K

Operation mode long term standard long term standard long term standard

Climatic category (LCT/UCT/days) 55/125/56 55/155/56 55/125/56 55/155/56 55/125/56 55/155/56

Rated dissipation, P

Operating voltage, U

Film temperature 125 °C 155 °C 125 °C 155 °C 125 °C155°C

Max. resistance change at P

for resistance range, ΔR/R max., after:

70

AC/DC 200 V 350 V 500 V

max

70

1000 h ≤ 0.25 % ≤ 0.5 % ≤ 0.25 % ≤ 0.5 % ≤ 0.2 % ≤ 0.4 %

0.25 W 0.4 W 0.4 W 0.6 W 0.65 W 1.0 W

1 Ω to 332 kΩ 1 Ω to 1 MΩ 1 Ω to 2.4 MΩ

8000 h ≤ 0.5 % ≤ 1.0 % ≤ 0.5 % ≤ 1.0 % ≤ 0.4 % ≤ 0.8 %

225 000 h ≤ 1.5 % - ≤ 1.5 % - ≤ 1.2 % -

Specified lifetime 225 000 h 8000 h 225 000 h 8000 h 225 000 h 8000 h

Permissible voltage against ambient:

1 minute 300 V 500 V 800 V

continuous 75 V 75 V 75 V

Failure rate ≤ 0.7 x 10

Note:

MB_ series has been merged with the related SMA series to form one series “MB_/SMA__”.

www.vishay.com For technical questions, contact: ff3cresistors@vishay.com Document Number: 28766

22 Revision: 28-Aug-07

-9

/h ≤ 0.3 x 10-9/h ≤ 0.1 x 10-9/h

Page 2

MBA/SMA 0204, MBB/SMA 0207, MBE/SMA 0414 - Professional

Professional Leaded Resistors

PART NUMBER AND PRODUCT DESCRIPTION

PART NUMBER: MBB02070C1001FCT00

B2 0C10FCT0BM 701000

MODEL/SIZE SPECIAL CHARACTER TCR/MATERIAL VALUE TOLERANCE

2

3

4

5

6

PA CK A GI N G

D = ± 0.5 %

F = ± 1 %

J = ± 5 %

Z = Jumper

CT

C1

RP

R1

R2

R4

N4

(1)

MBA0204

MBA/SMA 0204

MBB0207

MBB/SMA 0207

MBE0414

MBE/SMA 0414

PRODUCT DESCRIPTION: MBB/SMA 0207-50 1 % CT 1K0

Notes:

(1)

Please refer to table PACKAGING for complete information.

The PART NUMBER shown above is to facilitate the unified part numbering system for ordering products.

=

=

=

MBB/SMA 0207 - 50 1 % CT 1K0

MODEL/SIZE TCR TOLERANCE

MBA/SMA 0204

MBB/SMA 0207

MBE/SMA 0414

0 = neutral

N = RB Radial 5 mm

S = UB Radial 2.5 mm

D = ± 25 ppm/K

C = ± 50 ppm/K

Z = Jumper

± 25 ppm/K

± 50 ppm/K

3 digit value

1 digit multiplier

MULTIPLIER

-3

7 = *10

8 = *10

9 = *10

0 = *100 5 = *10

1 = *101 6 = *10

2 = *10

-2

3 = *10

-1

4 = *10

0000 = Jumper

± 0.5 %

± 1.0 %

± 5.0 %

Vishay Beyschlag

PA CK A GI N G

(1)

CT

C1

RP

R1

R2

R4

N4

RESISTANCE

1K0 = 1 kΩ

51R1 = 51.1 Ω

SPECIAL

00 = standard

PACKAGING

MODEL

MBA/SMA 0204

MBB/SMA 0207

MBE/SMA 0414 2500 R2 1000 C1

PIECES CODE PIECES CODE

1000

5000

1000

4000

5000

REEL BOX

R1

RP

R1

R4 (for RB, UB)

RP

1000

5000

1000

4000

5000

C1

CT

C1

N4 (for RB, UB)

CT

12NC CODE FOR HISTORICAL CODING REFERENCE OF MBA 0204/MBB 0207/MBE 0414

DESCRIPTION

TYPE TCR TOL. C1 1000 units CT 5000 units R1 1000 units R2 2500 units RP 5000 units

± 50 ppm/K

MBA 0204

± 25 ppm/K

jumper - 900 90001 905 90001 700 90001 - 805 90001

± 50 ppm/K

MBB 0207

± 25 ppm/K

jumper - 910 90001 915 90001 710 90001 - 815 90001

± 50 ppm/K

MBE 0414

± 25 ppm/K

Document Number: 28766 For technical questions, contact: ff3cresistors@vishay.com

Revision: 28-Aug-07 23

± 5 % 900 3.... 905 3.... 700 3.... - 805 3....

± 1 % 900 1.... 905 1.... 700 1.... - 805 1....

± 0.5 % 900 5.... 905 5.... 700 5.... - 805 5....

± 1 % 901 1.... 906 1.... 701 1.... - 806 1....

± 0.5 % 901 5.... 906 5.... 701 5.... - 806 5....

± 5 % 910 3.... 915 3.... 710 3.... - 815 3....

± 1 % 910 1.... 915 1.... 710 1.... - 815 1....

± 0.5 % 910 5.... 915 5.... 710 5.... - 815 5....

± 1 % 911 1.... 916 1.... 711 1.... - 816 1....

± 0.5 % 911 5.... 916 5.... 711 5.... - 816 5....

± 5 % 920 3.... - - 825 3.... -

± 1 % 920 1.... - - 825 1.... -

± 0.5 % 920 5.... - - 825 5.... -

± 1 % 921 1.... - - 826 1.... -

± 0.5 % 921 5.... - - 826 5.... -

AMMOPACK REEL

ORDERING CODE 2312 ... .....

www.vishay.com

Page 3

MBA/SMA 0204, MBB/SMA 0207, MBE/SMA 0414 - Professional

Vishay Beyschlag

Professional Leaded Resistors

12NC INFORMATION

Last Digit of 12NC Indicating Resistance Decade

RESISTANCE DECADE LAST DIGIT

0.1 Ω to 0.999 Ω 7

1 Ω to 9.99 Ω 8

10 Ω to 99.9 Ω 9

100 Ω to 999 Ω 1

1 kΩ to 9.99 kΩ 2

10 kΩ to 99.9 kΩ 3

100 kΩ to 999 kΩ 4

1MΩ to 9.99 MΩ 5

10 MΩ to 99.9 MΩ 6

12NC Example (for Historical Coding reference of

MBA 0204/MBB 0207/MBE 0414)

The 12NC code of a MBA 0204 resistor, value 47.5 kΩ and

TCR 50 with ± 1 % tolerance, supplied on bandolier in a box

of 5000 units is: 2312 905 14753.

DIMENSIONS

L

I

I

D

M

d

DIMENSIONS - leaded resistor types, mass and relevant physical dimensions

TYPE

D

max

(mm)

L

max

(mm)

MBA/SMA 0204 1.6 3.6 0.5 29.0 5.0 125

MBB/SMA 0207 2.5 6.3 0.6 28.0 10.0

MBE/SMA 0414 4.0 11.9 0.8 31.0 15.0 700

Note:

(1)

For 7.5 ≤ M < 10.0 mm, use version MBB/SMA 0207 ... L0 without lacquer on the leads.

d

nom

(mm)

I

min

(mm)

M

min

(mm)

(1)

MASS

(mg)

220

TEMPERATURE COEFFICIENT AND RESISTANCE RANGE

DESCRIPTION

RESISTANCE VALUE

TCR TOLERANCE MBA/SMA 0204 MBB/SMA 0207 MBE/SMA 0414

0.22 Ω to 0.91 Ω

± 50 ppm/K

± 5 % 0.22 Ω to 0.91 Ω 0.22 Ω to 0.91 Ω

± 1 % 1 Ω to 10 MΩ 1 Ω to 10 MΩ 1 Ω to 22 MΩ

11 MΩ to 22 MΩ

± 0.5 % 10 Ω to 475 kΩ 10 Ω to 1 MΩ 10 Ω to 2.4 MΩ

± 1 % 10 Ω to 475 kΩ 10 Ω to 1 MΩ 10 Ω to 2.4 MΩ

± 25 ppm/K

± 0.5 % 10 Ω to 475 kΩ 10 Ω to 1 MΩ 10 Ω to 2.4 MΩ

Jumper - ≤ 10 mΩ; I

= 3.0 A ≤ 10 mΩ, I

max

max

Note:

(2)

Resistance value to be selected from E24 series for ± 5 % tolerance, from E24/E96 series for ± 1 % tolerance and from E24/E192 for ± 0.5 %

tolerance.

Resistance ranges printed in bold are preferred TCR/tolerance combinations with optimized availablility.

(2)

= 5.0 A -

www.vishay.com For technical questions, contact: ff3cresistors@vishay.com Document Number: 28766

24 Revision: 28-Aug-07

Page 4

MBA/SMA 0204, MBB/SMA 0207, MBE/SMA 0414 - Professional

Professional Leaded Resistors

DESCRIPTION

Production is strictly controlled and follows an extensive

set of instructions established for reproducibility. A

homogeneous film of metal alloy is deposited on a high grade

ceramic body (85 % Al

desired temperature coefficient. Nickel plated steel

termination caps are firmly pressed on the metallised rods. A

special laser is used to achieve the target value by smoothly

cutting a helical groove in the resistive layer without

damaging the ceramics. Connecting wires of electrolytic

copper plated with 100 % pure tin are welded to the

termination caps. The resistor elements are covered by a

light blue protective coating designed for electrical,

mechanical and climatic protection. Four or five colour code

rings designate the resistance value and tolerance in

accordance with IEC 60062.

The result of the determined production is verified by an

extensive testing procedure performed on 100 % of the

individual resistors. Only accepted products are stuck

directly on the adhesive tapes in accordance with

IEC 60286-1.

) and conditioned to achieve the

2O3

Vishay Beyschlag

APPROVALS

The resistors are tested in accordance with CECC

40101-806 which refers to EN 60 115-1 and EN 140 100.

Approval of conformity is indicated by the CECC logo on the

package label.

Vishay BEYSCHLAG has achieved "Approval of

Manufacturer" in accordance with EN 100114-1.

SPECIALS

This product family of leaded thin film resistors for

professional applications is complemented by Zero Ohm

Jumpers and isolators.

On request, resistors are available with established reliability

in accordance with CECC 40 101-806 Version E. Please

refer to the special data sheet for information on failure rate

level, available resistance ranges and ordering codes.

ASSEMBLY

The resistors are suitable for processing on automatic

insertion equipment and cutting and bending machines.

Excellent solderability is proven, even after extended

storage. They are suitable for automatic soldering using

wave or dipping. The encapsulation is resistant to all

cleaning solvents commonly used in the electronics industry,

including alcohols, esters and aqueous solutions. The

suitability of conformal coatings, if applied, shall be qualified

by appropriate means to ensure the long-term stability of the

whole system. The resistors are completely lead (Pb)-free,

the pure tin plating provides compatibility with lead (Pb)-free

and lead-containing soldering processes. The immunity of

the plating against tin whisker growth has been proven under

extensive testing. All products comply with the

CEFIC-EECA-EICTA list of legal restrictions on hazardous

substances. This includes full compliance with the following

directives:

• 2000/53/EC End of Vehicle Life Directive (ELV)

2000/53/EC Annex II to End of Vehicle Life Directive (ELV II)

•

• 2002/95/EC Restriction of the use of Hazardous

Substances Directive (RoHS)

• 2002/96/EC Waste Electrical and Electrical Equipment

Directive (WEEE)

Document Number: 28766 For technical questions, contact: ff3cresistors@vishay.com

Revision: 28-Aug-07 25

www.vishay.com

Page 5

MBA/SMA 0204, MBB/SMA 0207, MBE/SMA 0414 - Professional

Vishay Beyschlag

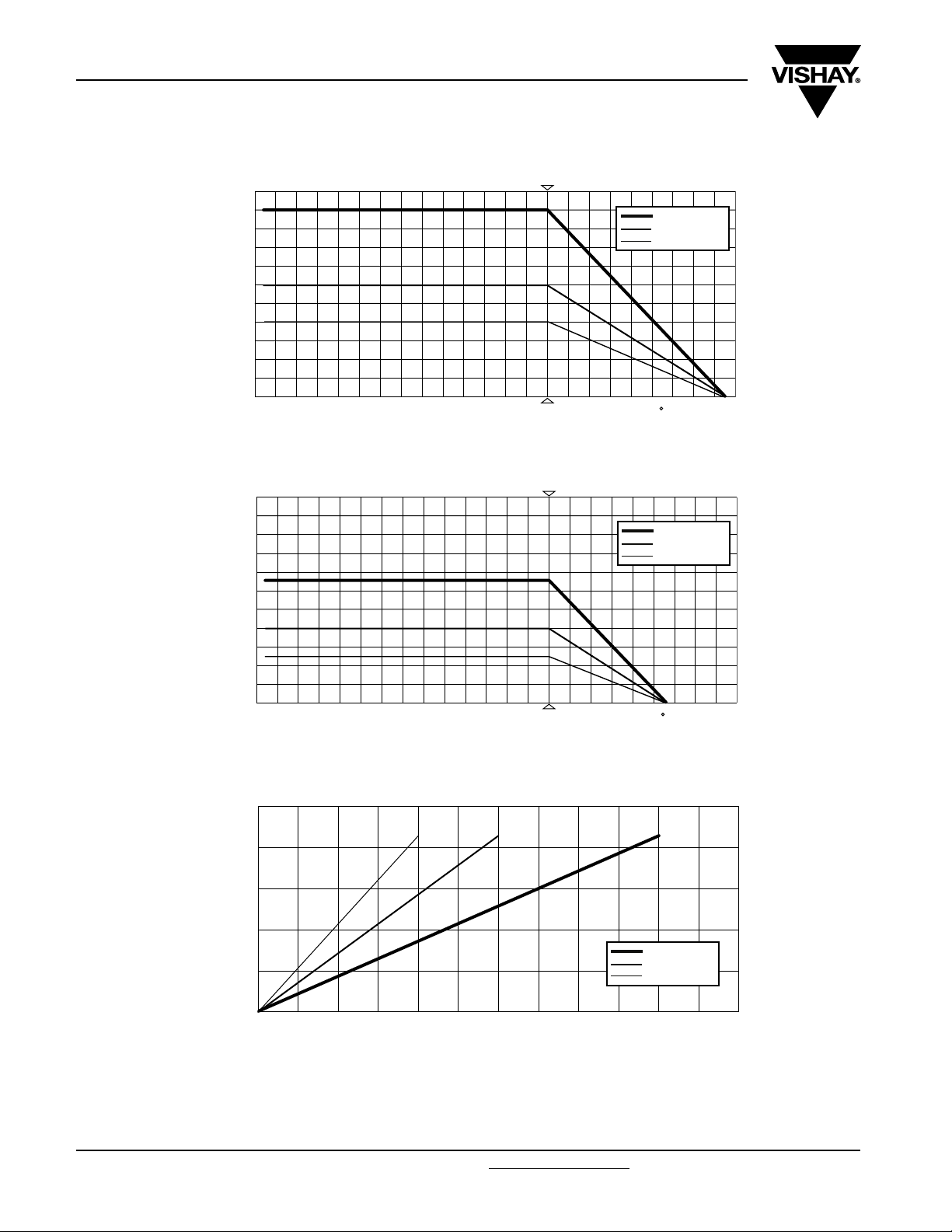

FUNCTIONAL PERFORMANCE

P

1

W

0.5

Power Dissipation

0

- 50 50

Derating - Standard Operation

P

1

W

Professional Leaded Resistors

0

70

Ambient Temperature

MBE/SMA 0414

MBB/SMA 0207

MBA/SMA 0204

100 150

C

ϑ

MBE/SMA 0414

MBB/SMA 0207

MBA/SMA 0204

amb

0.5

Power Dissipation

0

- 50 50

Derating Long Term Operation

r

T

80

K

60

Temperature Rise

40

20

0

0 0.4 0.8 1 1.20.2 0.60.1 0.3 0.5 0.7 0.9 1.1 W

Temperature Rise

0

Rise of surface temperature

70

100 150

Ambient Temperature

C

MBE/SMA 0414

MBB/SMA 0207

MBA/SMA 0204

Load

ϑ

amb

P

www.vishay.com For technical questions, contact: ff3cresistors@vishay.com Document Number: 28766

26 Revision: 28-Aug-07

Page 6

MBA/SMA 0204, MBB/SMA 0207, MBE/SMA 0414 - Professional

Professional Leaded Resistors

max

P

100

W

10

Pulse Load

1

0.1

10 µs 100 ms

Maximum pulse load, single pulse; for permissible resistance change equivalent to 8000 h operation.

100 µs 1 ms 10 ms

Single Pulse

max

P

100

W

MBE/SMA 0414

MBB/SMA 0207

MBA/SMA 0204

1 s

Pulse Duration

MBE/SMA 0414

MBB/SMA 0207

MBA/SMA 0204

Vishay Beyschlag

10 s

t

i

10

1

Continuous Pulse Load

0.1

10 µs 100 ms

Maximum pulse load, continuous pulses; for permissible resistance change equivalent to 8000 h operation.

100 µs 1 ms 10 ms

1 s

Pulse Duration

10 s

t

i

Continuous Pulse

max

U

Pulse Voltage

100 V

1 kV

100 µs 1 ms 10 ms

MBE/SMA 0414

MBB/SMA 0207

MBA/SMA 0204

1 s

Pulse Duration

10 s10 µs 100 ms

t

i

Maximum pulse voltage, single and continuous pulses; for permissible resistance change equivalent to 8000 h operation.

Pulse Voltage

Document Number: 28766 For technical questions, contact: ff3cresistors@vishay.com

Revision: 28-Aug-07 27

www.vishay.com

Page 7

MBA/SMA 0204, MBB/SMA 0207, MBE/SMA 0414 - Professional

Vishay Beyschlag

10 kV

Test Voltage

1 kV

100 V

10 V

Pulse load rating in accordance with IEC 60115-1, 4.27; 1.2 µs/50 µs; 5 pulses at 12 s intervals;

1.2/50 Pulse

10 kV

10 Ω

Professional Leaded Resistors

MBE/SMA 0414

MBB/SMA 0207

MBA/SMA 0204

100 Ω 1 kΩ 100 kΩ 1 MΩ

for permissible resistance change 0.5 %.

10 kΩ

Resistance Value

10 MΩ

R

Test Voltage

1 kV

100 V

10 V

10 Ω

Pulse load rating in accordance with IEC 60115-1, 4.27; 10 µs/700 µs; 10 pulses at 1 minute intervals;

10/700 Pulse

1

A

1

µV/V

Current Noise

0.1

0.01

1 kΩ

100 Ω 1 kΩ 100 kΩ 1 MΩ

for permissible resistance change 0.5 %.

10 kΩ

MBE/SMA 0414

MBB/SMA 0207

MBA/SMA 0204

Resistance Value

1 MΩ

Resistance Value

MBE/SMA 0414

MBB/SMA 0207

MBA/SMA 0204

10 MΩ10 kΩ 100 kΩ

10 MΩ

Current noise - A1 In Accordance With IEC 60195

R

R

www.vishay.com For technical questions, contact: ff3cresistors@vishay.com Document Number: 28766

28 Revision: 28-Aug-07

Page 8

MBA/SMA 0204, MBB/SMA 0207, MBE/SMA 0414 - Professional

Professional Leaded Resistors

TESTS AND REQUIREMENTS

Essentially all tests are carried out in accordance with the

following specifications:

EN 140000/IEC 60115-1, Generic specification (includes

tests)

EN 140100/IEC 60115-2, Sectional specification (includes

schedule for qualification approval)

CECC 40101-806, Detail specification (includes schedule for

conformance inspection)

Most of the components are approved in accordance with the

European CECC-system, where applicable. The Test and

Requirements table contains only the most important tests.

For the full test schedule refer to the documents listed above.

The testing also covers most of the requirements specified

by EIA/IS-703 and JIS-C-5202.

Vishay Beyschlag

Unless otherwise specified the following values apply:

Temperature: 15 °C to 35 °C

Relative humidity: 45 % to 75 %

Air pressure: 86 kPa to 106 kPa (860 mbar to 1060 mbar).

For testing the components are mounted on a test board in

accordance with IEC 60115-1, 4.31 unless otherwise

specified.

In Test and Requirements Table, only the tests and

requirements are listed with reference to the relevant clauses

of IEC 60115-1 and IEC 60068-2; a short description of the

test procedure is also given.

The tests are carried out in accordance with IEC 60068 and

under standard atmospheric conditions in accordance with

IEC 60068-1, 5.3. Climatic category LCT/UCT/56 (rated

temperature range: Lower Category Temperature, Upper

Category Temperature; damp heat, long term, 56 days) is

valid.

TEST PROCEDURES AND REQUIREMENTS

IEC

60115-1

CLAUSE

IEC

60068-2

TEST

METHOD

TEST PROCEDURE

stability for product

types:

MBA/SMA 0204 1 Ω to 332 kΩ 0.22 Ω to < 1 Ω > 332 kΩ

MBB/SMA 0207 1 Ω to 1 MΩ 0.22 Ω to < 1 Ω > 1 MΩ

STABILITY

CLASS 0.5

REQUIREMENTS

PERMISSIBLE CHANGE (ΔR

STABILITY

CLASS 1

max

)

STABILITY

CLASS 2

MBE/SMA 0414 1 Ω to 2.4 MΩ 0.22 Ω to < 1 Ω > 2.4 MΩ

4.5 - resistance ± 5 %; ± 1 %; ± 0.5 %

4.8.4.2 -

Document Number: 28766 For technical questions, contact: ff3cresistors@vishay.com

Revision: 28-Aug-07 29

temperature

coefficient

at 20/LCT/20 °C and

20/UCT/20 °C

± 50 ppm/K; ± 25 ppm/K

www.vishay.com

Page 9

MBA/SMA 0204, MBB/SMA 0207, MBE/SMA 0414 - Professional

Vishay Beyschlag

Professional Leaded Resistors

TEST PROCEDURES AND REQUIREMENTS

IEC

60115-1

CLAUSE

IEC

60068-2

TEST

METHOD

-

TEST PROCEDURE

stability for product

types:

MBA/SMA 0204 1 Ω to 332 kΩ 0.22 Ω to < 1 Ω > 332 kΩ

MBB/SMA 0207 1 Ω to 1 MΩ 0.22 Ω to < 1 Ω > 1 MΩ

MBE/SMA 0414 1 Ω to 2.4 MΩ 0.22 Ω to < 1 Ω > 2.4 MΩ

endurance at

70 °C: standard

operation mode

U = or

1.5 h on; 0.5 h off

P70 x R

U = U

max

REQUIREMENTS

PERMISSIBLE CHANGE (ΔR

STABILITY

CLASS 0.5

;

STABILITY

CLASS 1

max

)

STABILITY

CLASS 2

70 °C; 1000 h ± (0.5 % R + 0.05 Ω) ± (0.5 % R +0.05 Ω) ± 0.5 % R

4.25.1

endurance at

-

4.25.3 −

4.24 78 (Cab)

4.23

4.23.2 2 (Ba) dry heat 155 °C; 16 h

4.23.3 30 (Db)

4.23.4 1 (Aa) cold - 55 °C; 2 h

4.23.5 13 (M) low air pressure

4.23.6 30 (Db)

70 °C:

long term

operation mode

endurance at

upper category

temperature

damp heat,

steady state

climatic

sequence:

damp heat,

cyclic

damp heat,

cyclic

70 °C; 8000 h ± (1 % R +0.05 Ω)± (1 %R +0.05 Ω)± 1 %R

U = or

P70 x R

U = U

1.5 h on; 0.5 h off

70 °C; 1000 h ± (0.25 % R +0.05 Ω) ± (0.25 % R +0.05 Ω) ± 0.25 % R

70 °C; 8000 h ± (0.5 % R +0.05 Ω) ± (0.5 % R +0.05 Ω) ± 0.5 % R

125 °C; 1000 h ± (0.25 % R + 0.05 Ω) ± (0.5 % R + 0.05 Ω)± 1 %R

155 °C; 1000 h ± (0.5 % R + 0.05 Ω)± (1 %R + 0.05 Ω)± 2 %R

(40 ± 2) °C; 56 days;

(93 ± 3) % RH

55 °C; 24 h;

90 % to 100 % RH;

8.5kPa; 2h;

15 °C to 35 °C

55 °C; 5 days;

95 % to 100 % RH;

max

1 cycle

5 cycles

;

± (0.5 % R + 0.05 Ω)± (1 %R + 0.05 Ω)± 2 %R

± (0.5 % R + 0.05 Ω)

no visible

damage

± (1 % R + 0.05 Ω)

no visible

damage

± 2 % R

no visible

damage

www.vishay.com For technical questions, contact: ff3cresistors@vishay.com Document Number: 28766

30 Revision: 28-Aug-07

Page 10

MBA/SMA 0204, MBB/SMA 0207, MBE/SMA 0414 - Professional

Professional Leaded Resistors

Vishay Beyschlag

TEST PROCEDURES AND REQUIREMENTS

IEC

60115-1

CLAUSE

- 1 (Aa) cold - 55 °C; 2 h ± (0.1 % R + 0.01 Ω) ± (0.25 % R + 0.05 Ω) ± 0.5 % R

4.13 -

IEC

60068-2

TEST

METHOD

TEST PROCEDURE

stability for product

types:

MBA/SMA 0204 1 Ω to 332 kΩ 0.22 Ω to < 1 Ω > 332 kΩ

MBB/SMA 0207 1 Ω to 1 MΩ 0.22 Ω to < 1 Ω > 1 MΩ

MBE/SMA 0414 1 Ω to 2.4 MΩ 0.22 Ω to < 1 Ω > 2.4 MΩ

short time

overload

room temperature;

U = 2.5 x or

P70 x R

U = 2 x U

max

; 5 s

PERMISSIBLE CHANGE (ΔR

STABILITY

CLASS 0.5

± (0.1 % R + 0.01 Ω)

no visible

damage

REQUIREMENTS

STABILITY

CLASS 1

± (0.25 % R + 0.05 Ω)

no visible

damage

max

)

STABILITY

CLASS 2

± 0.5 % R

no visible

damage

4.19 14 (Na)

4.29 45 (XA)

4.18.2 20 (Tb)

4.17 20 (Ta) solderability

4.22 6 (B4) vibration

21 (Ua

4.16

4.7 - voltage proof U

21 (Ub)

21 (Uc)

rapid change of

temperature

component

resistance

resistance to

soldering heat

)

1

robustness of

terminations

solvent

30 minutes at LCT and

6 h; 10 Hz to 2000 Hz

± (0.1 % R + 0.01 Ω)

30 minutes at UCT;

5cycles

isopropyl alcohol

+ 23 °C; toothbrush

method

unmounted

components;

(260 ± 5) °C;

(10 ± 1) s

+ 235 °C; 2 s

solder bath method

1.5 mm or 196 m/s

tensile, bending and

torsion

= 100 V; 60 s no flashover or breakdown

RMS

2

no visible

damage

± (0.1 % R + 0.01 Ω)

no visible

damage

good tinning (> 95 %

covered, no visible

damage)

± (0.1 % R + 0.01 Ω) ± (0.25 % R +0.05 Ω) ± 0.5 % R

± (0.1 % R + 0.01 Ω) ± (0.25 % R +0.05 Ω) ± 0.5 % R

± (0.25 % R + 0.05 Ω)

no visible

damage

marking legible;

no visible damage

± (0.25 % R +0.05 Ω)

no visible

damage

± 0.5 % R

no visible

damage

± 0.5 % R

no visible

damage

Document Number: 28766 For technical questions, contact: ff3cresistors@vishay.com

Revision: 28-Aug-07 31

www.vishay.com

Page 11

Legal Disclaimer Notice

Vishay

Notice

Specifications of the products displayed herein are subject to change without notice. Vishay Intertechnology, Inc.,

or anyone on its behalf, assumes no responsibility or liability for any errors or inaccuracies.

Information contained herein is intended to provide a product description only. No license, express or implied, by

estoppel or otherwise, to any intellectual property rights is granted by this document. Except as provided in Vishay's

terms and conditions of sale for such products, Vishay assumes no liability whatsoever, and disclaims any express

or implied warranty, relating to sale and/or use of Vishay products including liability or warranties relating to fitness

for a particular purpose, merchantability, or infringement of any patent, copyright, or other intellectual property right.

The products shown herein are not designed for use in medical, life-saving, or life-sustaining applications.

Customers using or selling these products for use in such applications do so at their own risk and agree to fully

indemnify Vishay for any damages resulting from such improper use or sale.

Document Number: 91000 www.vishay.com

Revision: 08-Apr-05 1

Loading...

Loading...