Page 1

SiC413DB

SiC413 Reference Board User's Manual

4 A, 26 V Integrated Synchronous Buck Regulator

THE CHIP

PRODUCT SUMMARY

Input Voltage Range 4.75 V to 26 V

Output Voltage Range 0.6 V to 13.2 V

Operating Frequency 500 kHz

Continuous Output Current 4 A

Peak Efficiency 93 %

Highside/Lowside R

Package SO-8

DS_ON

DESCRIPTION

The SiC413 is an integrated, dc-to-dc power conversion

solution with built-in PWM-optimized high- and low-side

n-channel MOSFETs and advanced PWM controller. The

SiC413 provides a quick and easy to use POL voltage

regulation solution for a wide range of applications. Vishay

Siliconix proprietary packaging technology is used to

optimize the power stage and minimize power losses

associated with parasitic impedances and switching delays.

The co-packaged Gen III TrenchFET power MOSFETs

deliver higher efficiency than lateral DMOS monolithic

solutions.

35 mΩ/19 mΩ

Vishay Siliconix

FEATURES

• 4.75 V to 26 V input voltage range

• Integrated PWM controller and Gen III trench MOSFETs

• Built-in bootstrap diode

• 500 kHz fixed switching frequency

• Internal soft start

• Break-before-make operation

• Integrated current sense

• Cycle by cycle overcurrent protection

• Output over voltage protection

• Thermal shutdown

• Quick and easy single chip converter

• SO-8 package

APPLICATIONS

• LCD TV, set-top box and DVD player

• Desktop PC and server

• Add-in graphic board

• Memory, FPGA and µP device power supplies

• Point of load dc-to-dc conversion

• Telecom and networking equipment

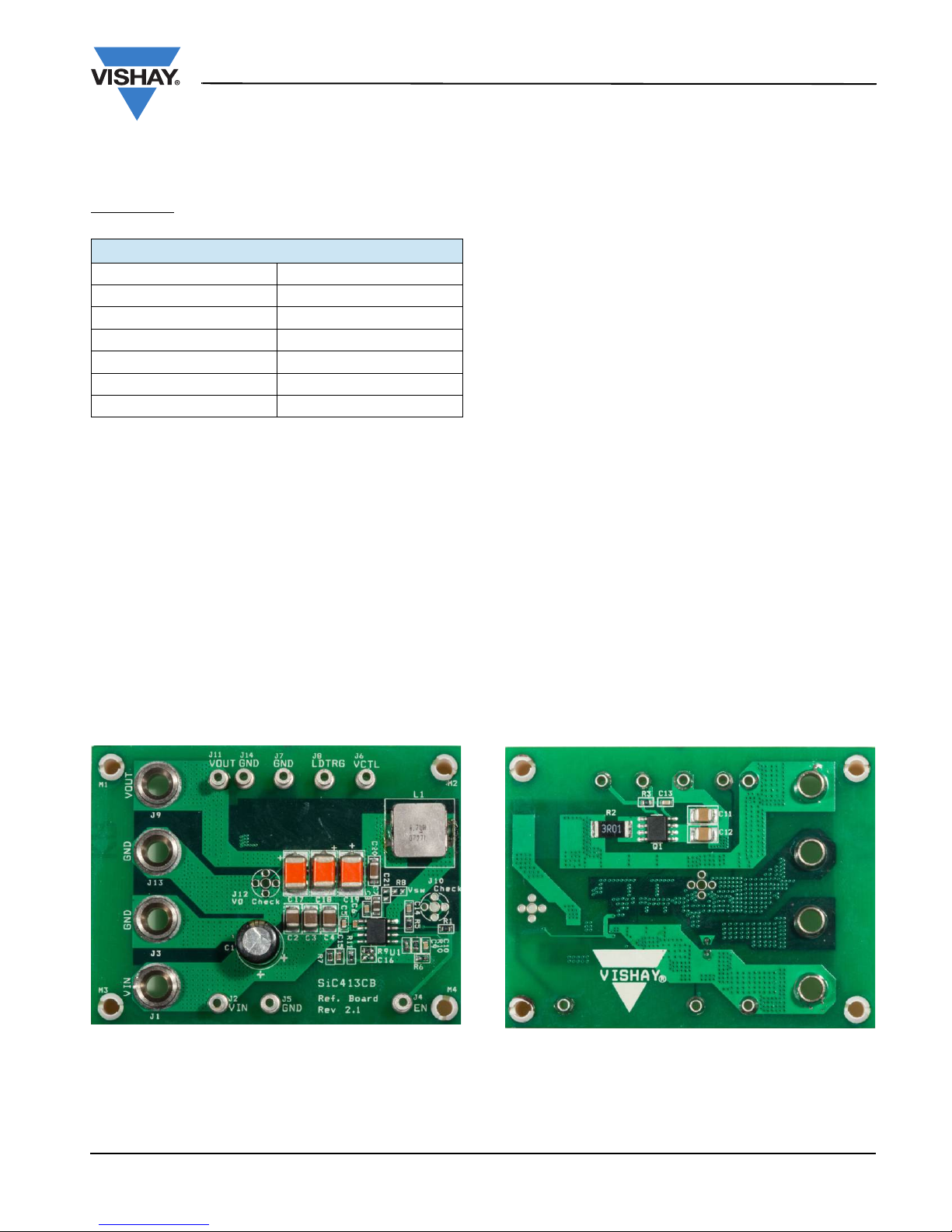

REFERENCE BOARD PHOTOS

Figure 1. Top of the PCB

Document Number: 65172

S09-1350-Rev. A, 20-Jul-09

Figure 2. Bottom of the PCB

www.vishay.com

1

Page 2

SiC413DB

Vishay Siliconix

THE REFERENCE BOARD

This reference board allows the end user to evaluate the

SiC413 chip for its features and all functionalities. It can also

be a reference design for a user’s application.

SPECIFICATION

Input voltage (V): 4.75 to 24

Output voltage (V): 0.6 to 12.0

Output current (A): 0 to 4

Notes:

• This board is, by default, preset to 3.3 V output with 12 V input

• This board can be set to any output voltage between 0.6 V and

12 V, and any input voltage between 4.75 V and 24 V. For a

specific input/output voltage combination, the values of inductor

and compensation network may need to be modified and the

output capacitors may need an increase or decrease.

INPUT CAPACITORS

The input capacitors are chosen as a combination of

electrolytic and ceramics so that the capacitance, the rms

current, the ESR, the input voltage ripple and the cost can

be all fairly satisfied. For a combination of high voltage input

and low voltage output (low duty cycle), the electrolytic

capacitors (C1) may not be required.

INDUCTORS

If off-the-shelf inductors are to be used, then their DCR and

saturation current parameters are the key besides their

inductance values. The DCR causes an I2R loss, which will

decrease the system efficiency and generate heat on the

board. The saturation current has to be higher than the

maximum output current plus ripple current. In over current

condition the inductor current may be drastically high. All

these need to be put into consideration when selecting the

inductor.

On this board Vishay IHLP4040DZ series inductors are

used to meet cost requirement and get better efficiency.

OUTPUT CAPACITORS

Voltage, ESR, rms current capability and capacitance are

essential elements to consider when choosing output

capacitors. The ESR and capacitance affect the output

voltage ripple, transient response and system stability. The

rms current capability determines the capacitor power

dissipation and life time. To meet all the 4 element

requirements, combination of ceramics and tantalum can be

used.

CONNECTION AND SIGNAL/TEST POINTS

Power sockets

(J1), GND (J3): Input voltage source with VIN to be

V

IN

positive. Connect to a 4.75 V to 24 V source that powers

SiC413.

(J9), GND (J13): Output voltage with V

V

OUT

positive. Connect to a load that draws less than 4 A current.

Signal and test leads

VIN (J2), GND (J5): Intput voltage sense pins with VIN to be

positive. Connect to a volt meter or an oscilloscope probe if

display or waveform is needed.

(J11), GND (J14): Output voltage sense pins with

V

OUT

to be positive. Connect to a volt meter or an

V

OUT

oscilloscope probe if display or waveform is needed.

V

(J6), LDTRG (J8), GND (J7): Load step control signal

CTRL

input. Connect V

and GND to a power source, V

CTRL

which supplies enough voltage to generate the load step

needed. Connect LDTRG and GND to a pulse generater

that creates the MOSFET on/off signal for the load step.

EN: SiC413 enable signal input. To enable the system leave

this point open, otherwise connect it to any GND.

OUT

to be

EXT

,

0.3

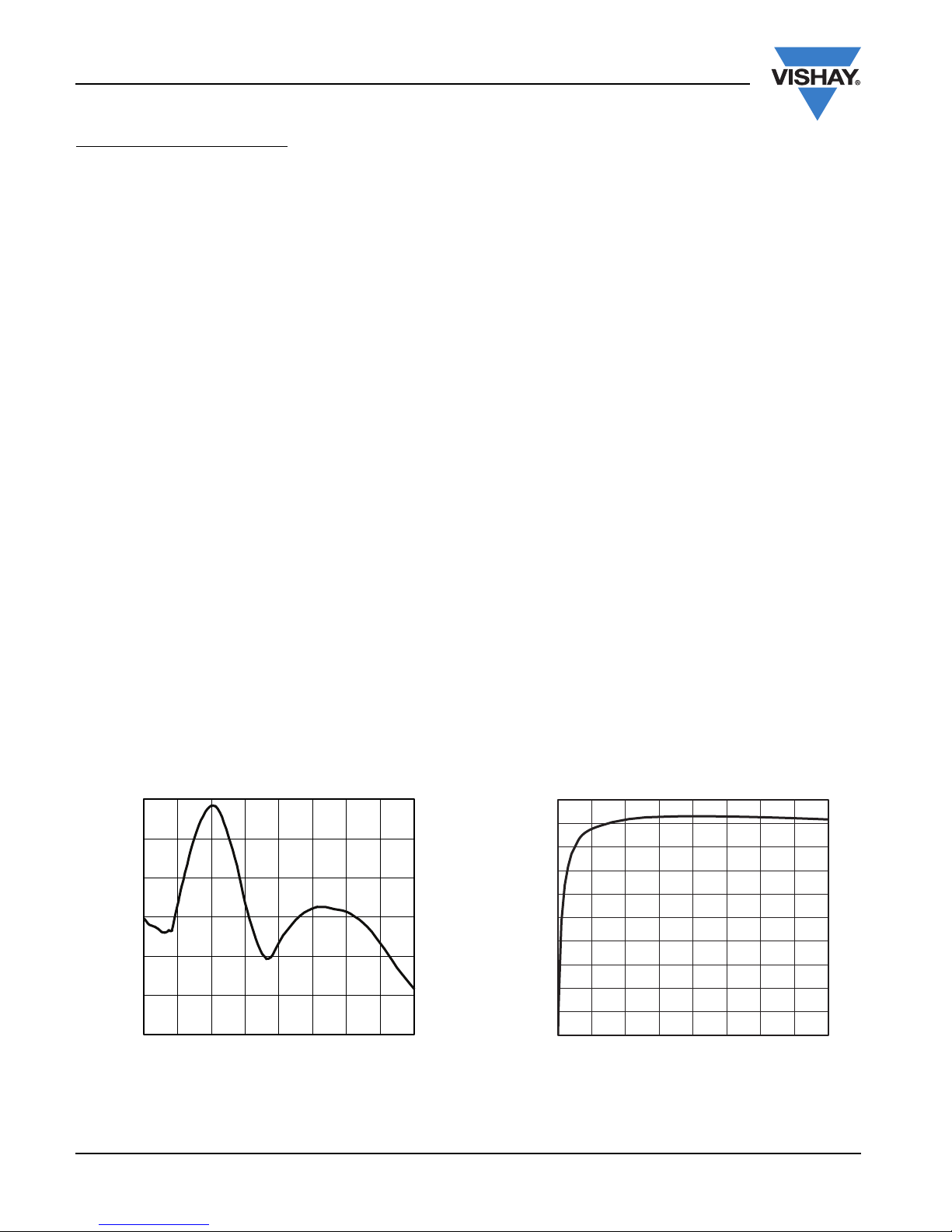

0.2

0.1

0

- 0.1

Output Voltage Variation (%)

- 0.2

- 0.3

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0

Load Current (A)

Figure 3. 12 V - 3.3 V Load Regulation

www.vishay.com

2

100

90

80

70

60

50

40

Efficiency (%)

30

20

10

0

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0

Load Current (A)

Figure 4. 12 V - 3.3 V Efficiency

Document Number: 65172

S09-1350-Rev. A, 20-Jul-09

Page 3

SET UP LOAD STEP

The hardware to test transient response is included in the

board, which allows users to see how the transient response

performs. The setup steps are:

1. Decide what load step is wanted, then based on the

output voltage calculate the external voltage V

will be connected between V

and GND. For

CTRL

example, a load step of 2 A between 0.5 A (I

(I2) is required and the output voltage is 3.3 V. V

VO - (I2 - I1) * 3.01 Ω = VO - (2.5 A - 0.5 A) * 3.01 Ω =

- 2.72 V. Preset a DC source voltage to V

EXT

(current capability around 1 A) and connect it to the

board with positive side to GND and negative side to

(if V

V

CTRL

source positive to V

is a positive value, then connect the DC

EXT

and negative to GND).

CTRL

2. Preset a waveform from a function generator using the

following parameters and set its output to OFF (refer to

the specific function generator manual for its setup):

Shape: square

Freqency: 50 Hz or whatever is required

Duty cycle: 1 % to 2 % or whatever is required

Amplitude: -12 V low level and + 10 V high level

Rising time and falling time: 1 µs or whatever is

required.

3. Connect the function generator output positive to

LDTRG and negative to GND.

4. Preset the current of an electronic load to I

1

on.

5. Set up an oscilloscope using the following parameters.

Channel 1 for probing output voltage: AC coupled,

20 mV/div to 50 mV/div, 100 mV offset, or whatever is

required .

that

EXT

) and 2.5 A

1

EXT

= 2.72 V

and turn it

=

SiC413DB

Vishay Siliconix

Channel 2 for probling the current on the 3.01 Ω

resistor (R2) (needs to be an isolated probe): DC

coupled, 3 V/div (corresponds to 1 A/div) for I

5 V/div (corresponds to 1.661 A/div) for I

Time base: 100 µs/div

Bandwidth: 20 MHz

6. Connect oscilloscope channel 1 probe positive to V

(J11) and negative to GND (J14), and channel 2 probe

positive to V

(J11) and negative to Q1 DRAIN.

OUT

7. Turn on the system power. Output voltage should be

shown on the electronic load with current of I1.

8. Turn on the power source for V

EXT

.

9. Set the function generator output to be ON. The transient

response waveforms should be seen on the oscilloscope.

10. If needed, re-adjust the trigger waveform’s rising and

falling time on the function generator so that the current

slew rate is satisfied (the current slew rate can be seen

on oscilloscope channel 2 waveform by setting the time

base to 1 µs or 500 ns).

11. To change load step, decrease or increase the value of

.

V

EXT

12. To cease transient response test, simply set the function

generator output to off, turn off the power source for

V

, and then shut down the system power.

EXT

CHANGE OUTPUT VOLTAGE

If, at any time, different output voltage is needed, then

simply change the value of R9 based on the following

formula:

R9 = R7/(V

- 1) = 10K/(VO/0.6 - 1)

O/VREF

O

> 2.5 A.

O

< 2.5 A or

OUT

Document Number: 65172

S09-1350-Rev. A, 20-Jul-09

COMP

Output Voltage

Inductor Current I

Figure 5. An Example of Load Step Waveforms

L

www.vishay.com

3

Page 4

SiC413DB

Vishay Siliconix

PCB LAYOUT

Figure 6. Top

Figure 7. Inner Layer 1

Figure 8. Inner Layer 2

Figure 9. Bottom Layer

www.vishay.com

4

Document Number: 65172

S09-1350-Rev. A, 20-Jul-09

Page 5

SCHEMATIC

SiC413DB

Vishay Siliconix

R10

750K

GND

5

GND

4

V

VSW Check Pin

1

VSW

4.7 µH

GND

3

GND

2

R8

R

C21

C

O

4K99 1.802 V

R9 V

open 0.6 V

12K 1.100 V

10K 1.200 V

1K37 4.980 V

6K65 1.502 V

3K16 2.499 V

2K21 3.315 V

523R 12.072 V

C10

R6

3K01

10 nF

J10

C9

100 pF

C14

R5

J4

1

EN

EN

2

3

1

EN

BOOT

R1

100K

COMP

FB8V

U1SiC413

IN

REG

V

7

6

0R

4

VSW

GND

5

0.1 µF

L1

C20

10K

3.3 nF

J12

10 µF

C19

100 µF

100 µF

C18

100 µF

C17

1

V

Check Pin

O

V

1

+

+

+

+

+

+

R9

2K21

C16

C

GND

2

GND

3

GND

4

GND

5

1

M4

Mounting Hole

Mounting Hole

M3

M2

Mounting Hole

Mounting Hole

M1

1

1

1

1

1

1

1

1

1

20K

100K

22 µF

22 µF

R11

R2

1

3R01

R7

C15

C130.1 µF

O

V

1

1

C8

0.1 µF

C7

4.7 µF

C6

0.01 µF

C5

0.1 µF

C4

10 µF

C3

10 µF

C2

10 µF

C1

150 µF

+

IN

V

1

1

1

1

Si4812BDY

Q1

1

R3

C12

C11

IN

IN

J2

J1

V

IN_GND

V

V

J3

IN_GND

J5

V

Document Number: 65172

S09-1350-Rev. A, 20-Jul-09

VCTL

J6

J7

J8

GND

LDTRG

J9

V

O

J11

O

V

J13

O_GND

V

J14

O_GND

V

www.vishay.com

5

Page 6

SiC413DB

Vishay Siliconix

BILL OF MATERIAL

Item Qty Reference Value Voltage PCB Footprint Part Number Manufacturer

1 1 C1 150 µF 35 V D8X11.5-D0.6X3.5 EEU-FM1V151 Panasonic

2 3 C2, C3, C4 10 µF 25 V SM/C_1210 TMK325B7106MN-T Taiyo Yuden

3 4 C5, C8, C13, C14 0.1 µF 50 V SM/C_0603 VJ0603Y104KXACW1BC Vishay

4 1 C6 0.01 µF 50 V SM/C_0402 VJ0402Y103KXACW1BC Vishay

5 1 C7 4.7 µF 10 V SM/C_0805 LMK212B7475KG-T Murata/Taiyo Yuden

6 1 C9 100 pF 50 V SM/C_0603 VJ0603Y101KXACW1BC Vishay

7 1 C10 10 nF 50 V SM/C_0603 VJ0603Y103KXACW1BC Vishay

8 2 C11, C12 22 µF 16 V SM/C_1210 GRM32ER71C226ME18L TAIYO YUDEN

9 1 C15 3.3 nF 50 V SM/C_0603 VJ0603Y332KXACW1BC Vishay

10 2 C16, C21 Not populated 50 V SM/C_0603 Vishay

11 3 C17, C18, C19 100 µF 20 V 595D-D 595D107X9020D2T Vishay

12 1 C20 10 µF 16 V SM/C_1206 C3216X7R1C106M TDK

13 1 J1 V

14 1 J2 V

15 1 J3 V

IN

IN

IN_GND

16 1 J4 EN Probe Hook 1540-2 Keystone

17 1 J5 V

IN_GND

18 1 J6 VCTL Probe Hook 1540-2 Keystone

19 1 J7 GND Probe Hook 1540-2 Keystone

20 1 J8 LDTRG Probe Hook 1540-2 Keystone

21 1 J9 V

O

22 1 J10 VSW check pin LECROY PROBE PIN PK007-015 LeCroy

23 1 J11 V

O

24 1 J12 Vo check pin LECROY PROBE PIN PK007-015 LeCroy

25 1 J13 V

26 1 J14 V

O_GND

O_GND

27 1 L1 4.7 µH IHLP4040 IHLP4040DZER4R7M01 Vishay

28 4 M1, M2, M3, M4 Mounting hole STACKING SPACER 8834 Keystone

29 1 Q1 Si4812BDY 30 V SO-8 Si4812BDY Vishay

30 2 R1,R3 100K 50 V SM/C_0603 CRCW0603100KFKEA Vishay

31 1 R2 3R01 200 V C_2512 CRCW25123R01FKTA Vishay

32 1 R5 0R 50 V SM/C_0603 CRCW06030000FKEA Vishay

33 1 R6 3K01 50 V SM/C_0603 CRCW06033K01FKEA Vishay

34 1 R7 10K 50 V SM/C_0603 CRCW060310K0FKEA Vishay

35 1 R8 R 50 V SM/C_0603 Vishay

36 1 R9 2K21 50 V SM/C_0603 CRCW06032K21FKEA Vishay

37 1 R10 750K 50 V SM/C_0603 CRCW0603750KFKEA Vishay

38 1 R11 20K 50 V SM/C_0603 CRCW060320K0FKEA Vishay

39 1 U1 SiC413 SO-8 SiC413 Vishay

SOLDER-BANANA 575-6 Keystone

Probe Hook 1540-2 Keystone

SOLDER-BANANA 575-6 Keystone

Probe Hook 1540-2 Keystone

SOLDER-BANANA 575-6 Keystone

Probe Hook 1540-2 Keystone

SOLDER-BANANA 575-6 Keystone

Probe Hook 1540-2 Keystone

Vishay Siliconix maintains worldwide manufacturing capability. Products may be manufactured at one of several qualified locations. Reliability data for Silicon

Technology and Package Reliability represent a composite of all qualified locations. For related documents such as package/tape drawings, part marking, and

reliability data, see www.vishay.com/ppg?65172

.

www.vishay.com

6

Document Number: 65172

S09-1350-Rev. A, 20-Jul-09

Page 7

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

Vishay:

SIC413DB

Loading...

Loading...