Page 1

WEIGH SYSTEM TECHNOLOGY

BLH

DXP10/15 Weigh Transmitters

Operator’s Manual

TM002

RevG

6/1/11

Doc 35102

Page 2

NOTICE

BLH makes no representation or warranties of any kind whatsoever with respect to the

contents hereof and specifically disclaims any implied warranties or merchantability or

fitness for any particular purpose. BLH shall not be held liable for errors contained herein

or for incidental or consequential damages in connection with the furnishing,

performance, or use of this publication or its contents.

BLH reserves the right to revise this manual at any time and to make changes in the

contents hereof without obligation to notify any person of such revision or changes.

Call (781) 298-2216 for BLH Field Service

Page 3

Table of Contents

SECTION 1. General Information ...................................................................................................................... 1-1

1.1 INTRODUCTION ...................................................................................................................................... 1-1

1.1.1 General Description. ............................................................................................................................. 1-1

1.1.2 Standard Instrument. ............................................................................................................................ 1-1

1.2 OPTIONS ................................................................................................................................................. 1-1

1.2.1 Mounting Options. ................................................................................................................................ 1-1

1.2.2 Optional Terminal Computer Interface. ................................................................................................ 1-1

1.2.3 Optional Modbus RTU Interface. .......................................................................................................... 1-2

1.2.4

Optional Fisher ProVox Protocol .......................................................................................................... 1-2

1.2.5 Optional Allen-Bradley Remote I/O ...................................................................................................... 1-2

1.2.6 Analog Option. ...................................................................................................................................... 1-2

1.2.7 Software Filter Option. .......................................................................................................................... 1-2

1.3 DXp-10/15 SPECIFICATIONS ................................................................................................................. 1-2

1.4 ORDERING SPECIFICATIONS ............................................................................................................... 1-4

1.5 WARRANTY POLICY ............................................................................................................................... 1-4

1.6 FIELD ENGINEERING ............................................................................................................................. 1-4

SECTION 2. Installation..................................................................................................................................... 2-1

2.1 INTRODUCTION ...................................................................................................................................... 2-1

2.1.1 General. ................................................................................................................................................ 2-1

2.2 MOUNTING .............................................................................................................................................. 2-1

2.2.1 Standard Units. ..................................................................................................................................... 2-1

2.2.2 Explosion-Proof and Division 2 Options. .............................................................................................. 2-1

2.3 ELECTRICAL ........................................................................................................................................... 2-2

2.3.1 Transducer Inputs. ................................................................................................................................ 2-2

2.3.2 Serial Communication. ......................................................................................................................... 2-2

2.3.3 Analog Output. ...................................................................................................................................... 2-3

2.3.4 Mains (AC) Power (Figure 2-4)............................................................................................................. 2-3

2.3.5 Auxiliary I/O Port. .................................................................................................................................. 2-3

SECTION 3. Configuration ................................................................................................................................ 3-1

3.1 GENERAL ................................................................................................................................................ 3-1

3.2 SET-UP .................................................................................................................................................... 3-1

3.2.1 Power Selection .................................................................................................................................... 3-1

3.2.2 Excitation Voltage. ................................................................................................................................ 3-1

3.2.3 Serial Format, Address, and Baud Rate. .............................................................................................. 3-1

3.2.4 Input Range Selection. ......................................................................................................................... 3-1

3.3 CALIBRATION .......................................................................................................................................... 3-1

iii

Page 4

3.3.1 Digital Calibration. ................................................................................................................................ 3-1

3.3.2 Analog Calibration. ............................................................................................................................... 3-2

3.3.3 Monitor Mode Calibration. .................................................................................................................... 3-2

3.3.4 LCp-40 Calibration. ............................................................................................................................... 3-2

3.4 CHECK CAL ............................................................................................................................................. 3-5

3.5 FILTER SELECTION ................................................................................................................................ 3-6

3.5.1 Standard Filter. ..................................................................................................................................... 3-6

3.5.2 Optional Digital Filtering. ...................................................................................................................... 3-6

3.6 Factory Default Calibration ....................................................................................................................... 3-7

SECTION 4. Serial Communication .................................................................................................................. 4-1

4.1 GENERAL ................................................................................................................................................ 4-1

4.1.1 LCp-40 Digi System Network. .............................................................................................................. 4-1

4.1.2 Standard Simplex Output (Continuous Output). ................................................................................... 4-1

4.1.3 Computer/Terminal Interface (Optional). .............................................................................................. 4-2

4.1.4 MODBUS BTU Protocol (Optional). ..................................................................................................... 4-4

4.1.5 Fisher ProVox Protocol (Optional) ........................................................................................................ 4-7

4.1.6 Allen-Bradley Remote I/O (Optional). ................................................................................................... 4-8

SECTION 5. Operation ...................................................................................................................................... 5-1

5.1 GENERAL ................................................................................................................................................ 5-1

5.2 GROSS WEIGHT WEIGHING ................................................................................................................. 5-1

5.3 ZERO OPERATION ................................................................................................................................. 5-1

5.4 NET WEIGHT WEIGHING ....................................................................................................................... 5-1

5.5 TARE OPERATION .................................................................................................................................. 5-1

5.6 ERROR DETECTION ............................................................................................................................... 5-1

5.7 CHECK CAL OPERATION ....................................................................................................................... 5-1

iv

Page 5

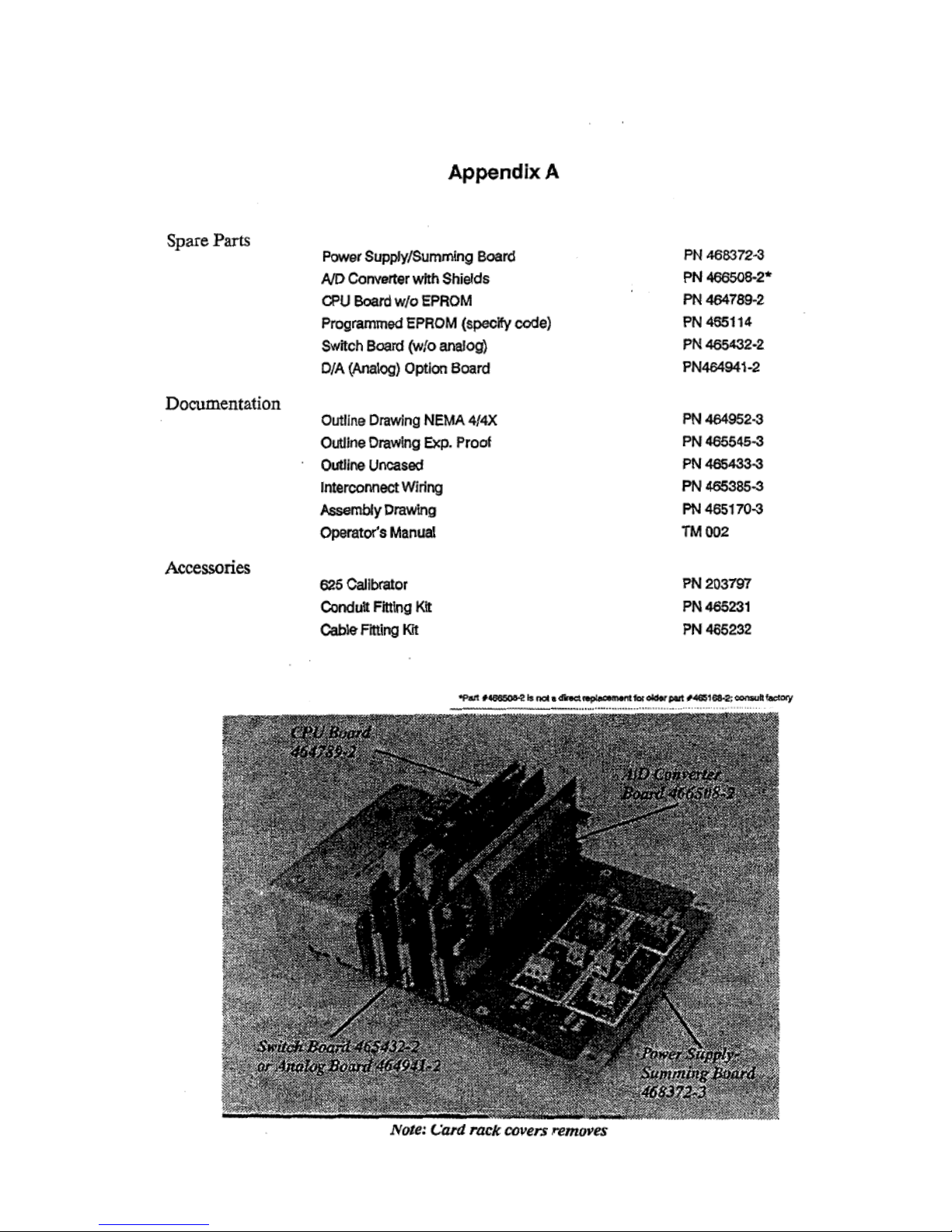

SECTION 1. General Information

1.1 INTRODUCTION

1.1.1 General Description

The DXp-10 and DXp-15 (Figure 1-1) are

microprocessor based weight transmitters. DXp10/15 transmitters sum and convert the millivolt

signal from up to four strain gage type load cells

into a digital and/or analog voltage or current

signal (up to eight cells can be summed using

an external 308A summing unit). Bridge

excitation voltage is factory selectable for 10 or

15 volts. Units are available in NEMA 4, NEMA

4X or explosion proof enclosures for field

mounting. The unit operates from either 110 or

220 VAC at 50/60 Hz, and is equipped with

screw terminal connections for power input, and

serial/analog outputs. Set-up and calibration is

per-formed using three internal switches (see

SECTION III). Communication baud rate and

instrument address values are selected via a

bank of internal DIP switches (see SECTION

III).

Class I, II, Division 2, Group A-G hazardous

location requirements and are optionally

available with FM and CSA approvals and

certifications.

1.2 OPTIONS

1.2.1 Mounting Options

For corrosive, hose down, or sanitary

environments, a NEMA 4X stainless steel

enclosure is available. An explosion proof

enclosure is available for Class I, II, Division 1,

Group B-G locations. Note: BLH 404 or 405

Intrinsic Safety Barriers must be specified for

weigh systems located in a Division I area.

The DXp-10 Transmitter performance

specifications are designed for inventory and

other static weighing applications where

moderate resolution and speed is required. The

DXp-15 Process Transmitter is equipped with

high performance circuitry that provides the

greater resolution and speed for dynamic

process applications. Externally and in regard to

set-up and operation, each model is identical

Using RS 485 serial communication protocol, up

to sixteen DXp transmitters can be networked to

an LCp-40, 41, or 42 Network Controller. The

serial format can also be configured to provide

point to point or network communication to a

customer supplied computer.

1.1.2 Standard Instrument

The standard instrument includes an RS 485

serial port with BLH Digi-System network or a

simplex output protocols, a four cell summing

circuit, 10 or 15 volt excitation, averaging filter,

and a NEMA 4 mild steel, painted enclosure.

Standard instruments are designed to meet

Figure 1-1. DXp-10 Weight Transmitter

1.2.2 Optional Terminal Computer

Interface.

The terminal/computer interface option provides

a simple mnemonic half-duplex ASCII

communications protocol via a built-in macro

language consisting of 1 to 3 character command

strings (reference Table 4-3).

This powerful feature allows direct keyboard

control (using easily remembered commands) of

1-1

Page 6

DXp-10/15 calibration, and programming or

recall of weight variables (gross, net, tare, zero,

etc.) An on-line help function is available by

transmitting an ASCII Ir.

Easily learned macro language syntax greatly

simplifies the writing of a host computer

communication interface (customer supplied).

1.2.3 Optional Modbus RTU

Interface.

The Modbus interface option provides a simple

seamless communication link to any PC, PLC or

DCS with a mod-bus RTU Driver Option. Use of

this industry standard protocol (see paragraph

4.1.4) eliminates the requirement for custom

software driver development.

1.2.4

DXp-15 transmitters may be ordered with the

Fisher ProVox protocol. ProVox protocol allows

the DXp-15 to interface directly with a Fisher

ProVox distributed control system (DCS).

Optional Fisher ProVox

Protocol

1.2.5 Optional Allen-Bradley Remote

I/O

Optional Allen-Bradley Remote I10 (RIO) allows

13Xp¬15 transmitters direct access to a PLC

master processor. In essence, DXp-15

transmitters become direct coprocessors with

the PLC. DXp-15 data is read directly into the

main ladder logic program without using BCD or

serial interface cards. A simple three wire RIO

network connection ties all units together, even if

multiple DXp15s are used. Within the RIO

network link, each DXp-15 is addressed as 1/4

'logical rack'. Since a PLC logical rack consists

of 128 input and 128 output bits (or points), DXp

units communicate 32 input and 32 output bits;

1/4 logical rack format. For a full description of

logical rack addressing and data

communications formatting, reference the Allen

Bradley Remote I/O technical manual, BLH part

number TM010.

1.2.6 Analog Option.

An optional analog output provides both a 4-20 mA

and a 0-10 VDC output representing the gross

weight value. The circuit uses a 12 bit D-A

converter providing up to 4096 counts of resolution.

The current output drives up to a 1000 ohm load

and the voltage output will operate with a 25,000

ohm minimum load resistance.

1.2.7 Software Filter Option.

The digital filtering option offers eight software

filtering selections. The filter algorithms dampen

noise by averaging successive A-D conversions.

Digital filtering allows East response to true

weight changes by setting limits on averaging

based upon the magnitude of signal change.

Filter selections are presented in SECTION III.

Note: BLH tech note TD-071 provides a full

discussion of filter operation.

1.3 DXp-10/15 SPECIFICATIONS

PERFORMANCE

Resolution:

DXp-10 20,000 counts

DXp-15 50,000 counts

Sensitivity

DXp-10 1.0 μV/count

DXp-15 0.5 μV/count

Full Scale Range 25 of 35 mV (selectable)

Dead Load Range 100%

Input Impedance 10 M-ohms, max.

Load Cell Excitation 10 V for up to eight 350 ohm load cells (250 mA)

(Factory Selectable) 15 V for up to six 350 ohm load cells (250 mA)

Linearity ± 0.01% of full scale

1-2

Page 7

Temperature Coefficient

Span 2ppm/°C

Zero ± 2ppm/°C

Common Mode Rel. 100 db or better at or below 35Hz

Normal Mode Rej. 100 db or better at or below 35Hz

Conversion Speed DXp-10 400 msec

DXp-15 50 msec

Environment

Operating Temperature -10 to 55°C (12 to 131°F)

Storage Temperature -20 to 85°C (-4 to 185°F)

Humidity 5 to 90% rh, non-condensing

Voltage 117/230 1: 15% 50/60 Hz

Power 10 watts max

Parameter Storage EEPROM

EMVRFI Shielded from typical industrial interference

ENCLOSURE

Dimensions (NEMA 414X) 11.5 x 8.0 x 4.3 HWD

Explosion Proof 12.875 x 10.875 x 8.188 HWD

OPTIONS

Isolated Analog Output

Type 12 bit Digital to Analog Conversion

Voltage 0 to 10 volt (25K ohm min load)

Current 4 to 20 mA (1000 ohm max load)

SERIAL COMMUNICATION

LCp-40 Network (Standard)

Type RS 485 Half Duplex (Multi-Drop)

Baud 56.7k

Simplex Data Output (Standard)

Interface Type RS 485 (Simplex)

Data Format Simplex ASCII Data

7 Data Bit

Even Parity

1 Stop Bit

Terminal/Computer Interface (Optional)

Interface Type RS 485 Half Duplex (Standard)

Baud 1200 or 9600

Protocol Duplex Command/Response Format

MODBUS RTU Protocol (Optional)

Fisher ProVox Protocol (Optional)

Allen-Bradley Remote I/O (Optional)

Consult factory for details

1-3

Page 8

1.4 ORDERING SPECIFICATIONS

DXp-10 or DXp-15 [M]-[C]-[P]-[S] Includes: RS 485 Serial Output

[M] Mounting

(1) NEMA 4 Painted — standard

(2) NEMA 4X Stainless Steel

(3) NEMA 7 & 9 Explosion-Proof Class I, H, Div. 1,2 Grp. B—G

(8) #1 & FM/CSA Approved [Class l, Div 2, Group ABCD FG]

(9) #2 & FM/CSA Approved [Class l, Div 2, Group ABCD FG]

[C] Communication

(1) RS 485 LCp-40 Network — standard

(2) RS 485 LCp-40 Network and Terminal/Computer Interface

(4) Allen Bradley Remote I/O (DXp-15 only)

(5) MODBUS RTU Protocol (D4-15 only)

[P]Process Output

(1) No Process Output — standard

(2) 0-10 V & 4-20 mA analog

[S]Software

(1) Standard

(2) Dynamic Digital Filtering (DXp-15 only)

apply beyond their normal span of life to any

1.5 WARRANTY POLICY

BLH warrants the products covered hereby to be

free from defects in material and workmanship.

BLH's liability under this guarantee shall be

limited to repairing or furnishing parts to replace,

f.o.b. point of manufacture, any parts which,

within three (3) years from date of shipment of

said product(s) from BLH's plant, fail because of

defective workmanship or material performed or

furnished by BLH. As a condition hereof, such

defects must be brought to BLH's attention for

verification when first discovered, and the

material or parts alleged to be defective shall be

returned to BLH if requested. BLH shall not be

liable for transportation or installation charges,

for expenses of Buyer for repairs or

replacements or for any damages from delay or

loss of use for other indirect or consequential

damages of any kind. BLH may use improved

designs of the parts to be replaced. This

guarantee shall not apply to any material which

shall have been repaired or altered outside of

BLWs plant in any way so as, in BLH's

judgment, to affect its strength, performance or

reliability, or to any defect due in any part to

misuse, negligence, accident or any cause other

than normal and reasonable use, nor shall it

materials whose normal span of life is shorter

than the applicable period stated herein. In

consideration of the forgoing guarantees, all

implied warranties are waived by the Buyer, BLH

does not guarantee quality of material or parts

specified or furnished by Buyer, or by other

parties designated by buyer, if not manufactured

by BLH. If any modifications or repairs are made

to this equipment without prior factory approval,

the above warranty can become null and void.

1.6 FIELD ENGINEERING

The field service department at BLH is the most

important tool to assure the best performance

from your application. The expertise and

understanding of BLH's Field Engineers can

solve even the most perplexing installation

problem. Precise calibration and start-up

procedures, performed by a qualified,

experienced field engineer, assure not only the

reliability of BLH components, but the integrity of

the entire weigh system.

Call (Factory Number) (781) 298-2200

Ask for Field Service

Canada (416) 251-2554

1-4

Page 9

SECTION 2. Installation

2.1 INTRODUCTION

2.1.1 General.

The DXp-10/15 is designed to 'installed within the

length of the load cell(s) cable which is normally

35 ft or less. The standard NEMA 4 or optional

NEMA 4X enclosures are suitable for an outdoor

or wash down type environment. Both enclosures

are provided with pre-punched holes for

installation of conduit or cable fittings and holes for

mounting to a bracket or wall.

2.2 MOUNTING

2.2.1 Standard Units.

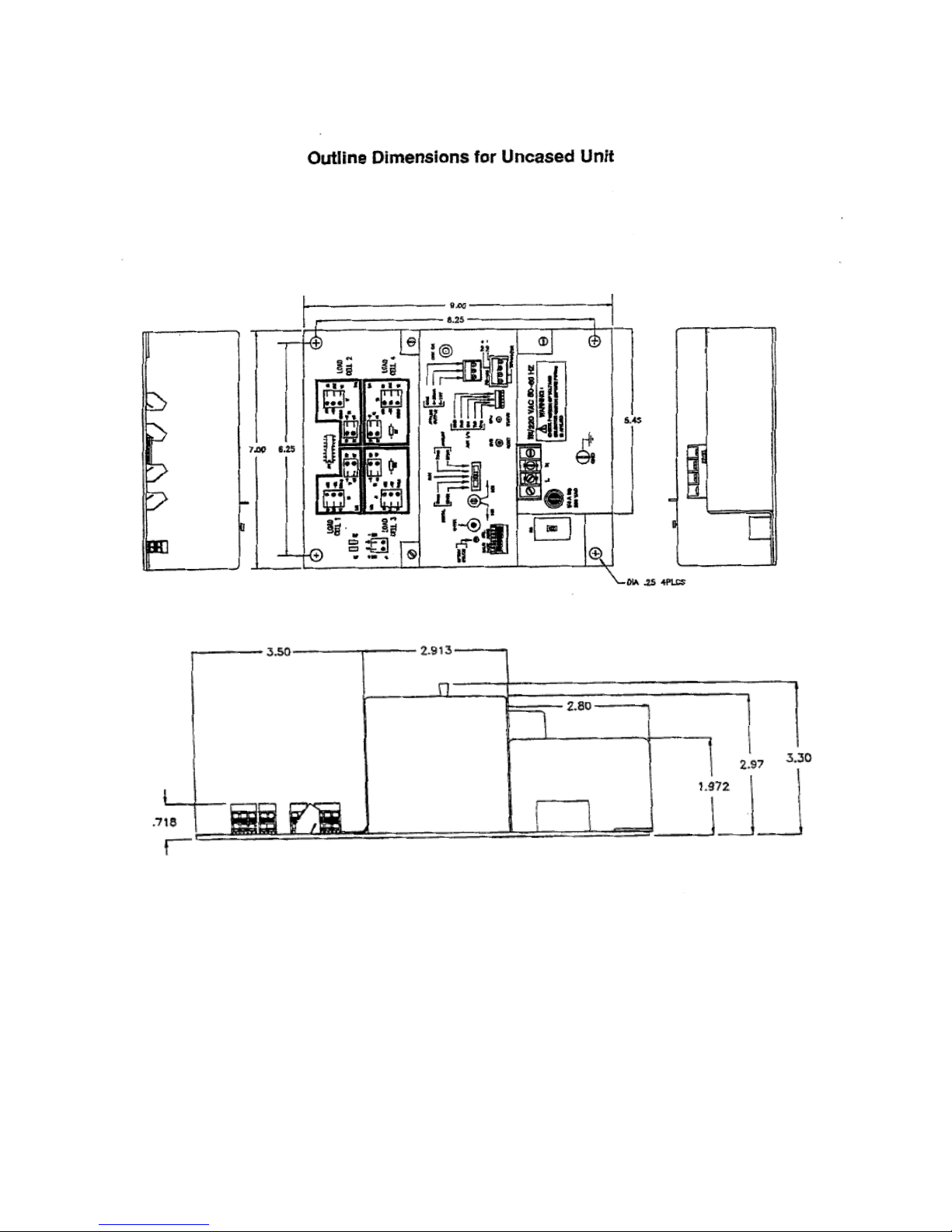

The NEMA 4 and NEMA 4X enclosures are

equipped with four pre-punched holes for

mounting to a wall or bracket. A U-bolt can be

used for mounting to a pipe support. The

instrument should be installed in a vibration-free

location within the normal length of the load cell

cables. If conduit is used, drains should be

provided to reduce the possibility of condensate

entering the enclosure. Outline dimensions for the

standard DXp¬10/15 transmitter are presented in

Figure 2-1.

2.2.2 Explosion-Proof and Division 2

Options.

DXp units may be ordered with an optional

explosion-proof enclosure for use in Division I

hazardous locations. Dimensions for the optional

explosion-proof enclosure are provided in

Appendix C.

For Division 2 applications, FM approved units are

available as non-incendive devices in NEMA 4/4X

enclosures with dimensions identical to those

presented in Figure 2-1.

Figure 2-1. DXp-10 Outline Dimensions

2-1

Page 10

Figure 2-2. Load Cell Connections.

2.3 ELECTRICAL

2.3.1 Transducer Inputs.

Up to four load cells can be connected to the

summing circuit within the DXp. Connect individual

load cells directly to the circuit board connectors

as shown in Figure 2-2. Excitation and signal

connection locations are dearly marked according

to function and standard color code.

If more than four cells are required, an external

308A summing junction box must be used. Make

all load cell connections in the 3084 unit, not the

DXp-10/15. Connect the output leads of the 3084

summing box to the load cell #1 terminal blocks in

the DXp. Sense leads from the 3084 must be

connected to the sense terminal blocks in the

DXp-10/15 (Figure 2-2). Jumpers JF1 and JP2

must be removed.

2.3.2 Serial Communication.

If a deadweight or substitution method of

calibration is being used, the load cal cable can be

shortened as required. The leads should be retinned before the final connection is made.

NOTE: If tension or universal load cells are used,

red (-signal) and white (+ signal) leads may need

to be reversed.

A terminal connector is provided for RS 485 wire

connections (Figure 2-3). Multiple DXp

transmitters, networked together, are wired in a

parallel configuration with a termination jumper

installed on the last instrument. A pair of twisted

wires (14-20 gauge) is all that is required for

interconnection. Communication lines should not

be run near ac voltage power lines.

Figure 2-4. Ac Power Connections and Fuse

2-2

Page 11

2.3.3 Analog Output.

When the analog option is installed (shown,

Figure 2-3), a three position terminal connector

is provided for 4-20 mA, 0-10 V, and common

connections. As with serial communication, the

wiring should be routed away from ac power

lines and other sources of EMI. The current

output is essentially immune to noise and can be

transmitted long distances. The voltage output is

susceptible to EMI/RFI and should be used only

for short distances.

2.3.4 Mains (AC) Power (Figure 2-4).

A screw terminal is provided for permanent

transmitter power connection. DXp transmitters

can be switch selected to operate at 115 or 220

VAC (see SW1, Figure 2-4). Before connecting

power to the unit, verify that the proper power

selection has been made. The two position

terminal block is equipped with a clear plastic

cover to prevent operator injury. Cable can be

either solid or stranded 12 or 14 gage with a

ground conductor.

The transmitter is protected with a 114 amp slow

blow fuse, located adjacent to the mains

terminal block. If the fuse opens, replace it with

the same type and current rating.

2.3.5 Auxiliary I/O Port.

The auxiliary I/0 port connection is a factory test

port and is not useful to an operator.

2-3

Page 12

SECTION 3. Configuration

3.1 GENERAL

Set-up and calibration of the DXp-10/15 is

accomplished by an operator without

programming using the DIP switches, pushbuttons, and toggle switches within the unit.

Units connected to an LCp-40 or computer terminal can be set-up and calibrated remotely via

the serial port (see Appendix E).

3.2 SET-UP

3.2.2 Excitation Voltage.

All units are shipped from the factory set for 10

volt excitation.

3.2.3 Serial Format, Address, and

Baud Rate.

DIP switch selections for transmitter address,

baud rate and serial interface format are

presented and defined in SECTION IV, Serial

Communication.

3.2.1 Power Selection

All units are shipped from the factory configured

for 115 VAC operation. To change the voltage

selection to 230 VAC, change SW1 (see Figure

2-4) to the 230V setting. The unit will operate

within specification at 50 or 60 Hz.

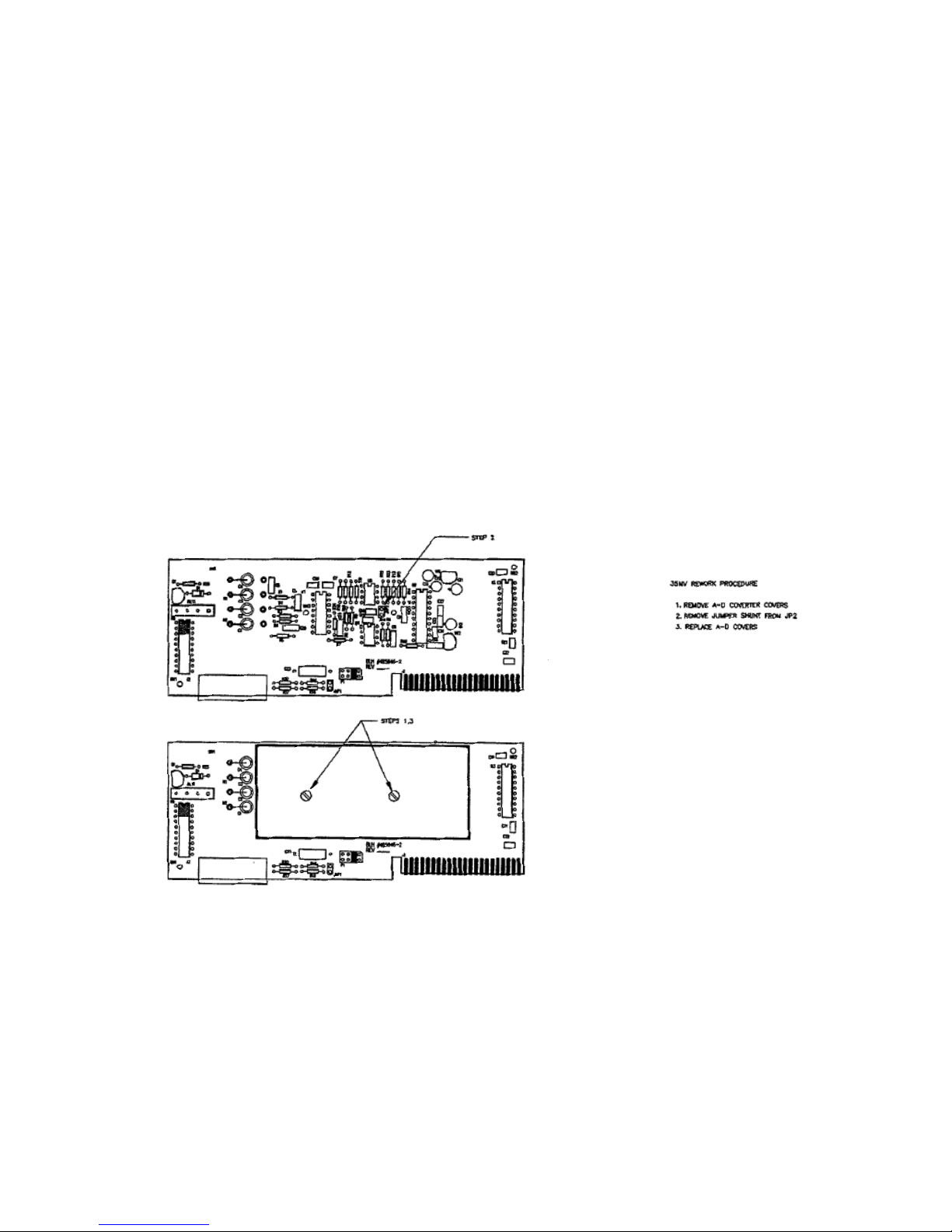

3.2.4 Input Range Selection.

Units are shipped configured for a 25 mV input

range. To increase this range to 35 my, remove

the jumper shunt from JP2 on the A-D converter

board as shown in Figure 3-1 (see Appendix A

photo for A-D board location).

Figure 3-1. 35 mV Input Conversion Instructions

3.3 CALIBRATION

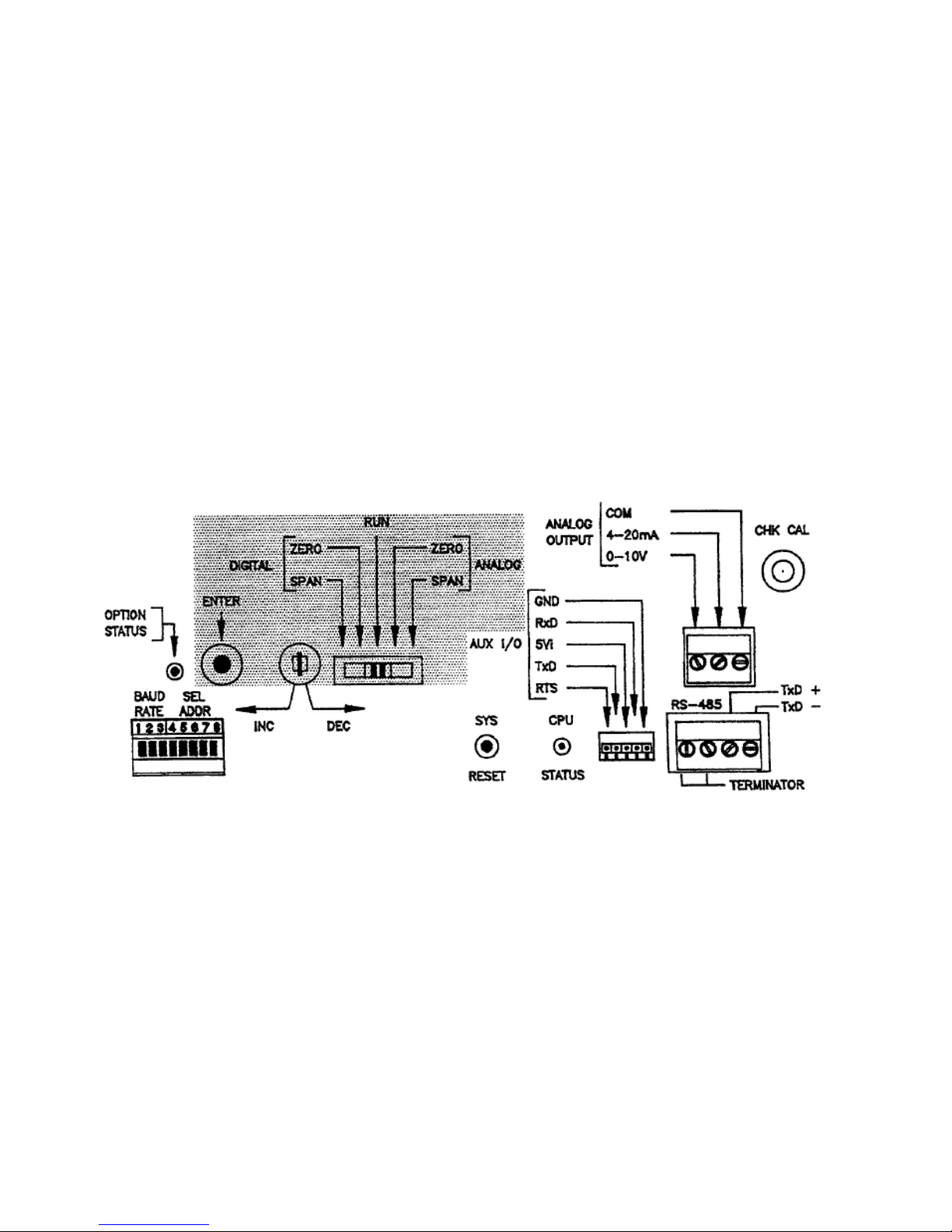

Note: All switches mentioned in paragraphs

3.3.1 – 3.3.4 are depicted in Figure 3-1.

3.3.1 Digital Calibration.

The transmit only serial output can be digitally

calibrated using the DIGITAL selector, 1NC/DEC

and ENTER switches mounted on the DXp10/L5 control panel. For those systems where

applying a full capacity dead weight or input

signal is not practical, the DXp-10/15 will

automatically calculate a linear full span

calibration based on a single span point. See

Table 3-1 for instructions.

3-1

Page 13

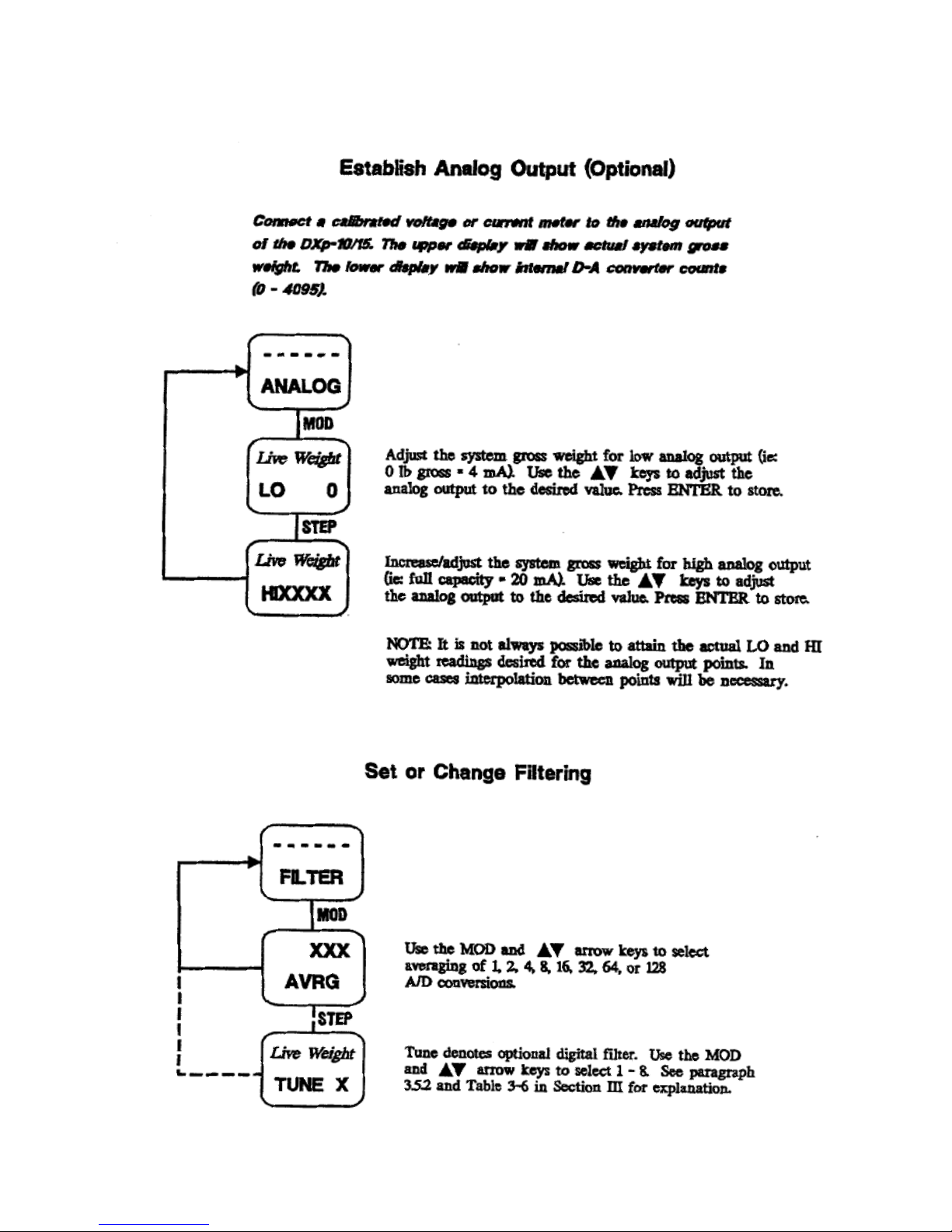

3.3.2 Analog Calibration.

The analog output is calibrated independently of

the digital calibration and can be set using span

points anywhere between zero and full scale

capacity. The 0-10 V and 4-20 mA outputs CAN

NOT be calibrated independently. See Table 3-2

for complete analog calibration instructions.

3.3.3 Monitor Mode Calibration.

The terminal/computer interface option enables

the DXp-101L5 to be calibrated remotely from a

host computer or terminal. The monitor mode

functionally accesses the software routines used

to provide remote access via the keypad of an

LCp-40 Network Controller. In response, the

DXp-10/15 transmits two lines of information

similar to the two line display on an LCp-40. In

this mode the capacity, graduations, decimal

point, 5 point linearization and other values can

be established from the host device. Help

messages also can be accessed at any time to

aid in the set-up process. The procedure

recorded in Table 3-3 shows the command

sequence required to perform remote

calibration. Consult SECTION IV for serial

communication details.

3.3.4 LCp-40 Calibration.

When networked to an LCp-40, 41, or 42

controller, the DXp-10/15 can be remotely

calibrated using the controller display and

keypad. In this configuration, up to five

linearized span points can be entered. Appendix

E presents step by step flow diagrams for

remote LCp-40 calibration and parameter setup.

Figure 3-2. Set-up and Calibration Switch Locations (Shade)

Table 3-1. DXp-10 Digital Calibration

Instructions

[1]. Connect Load Cells and Remote

Terminal.

Install the load cells and wire them to the

DXp-10/15. Connect the RS 485 serial

output to a compatible terminal/readout

device. Select a compatible serial output

format and establish that the

communication link is operating (paragraph

3.2.3).

[2]. Establish Zero.

Make sure that all dead weight (vessel,

mixer, pipes, etc) is applied as it will be

during normal operation. Move the five

position slide switch (Figure 3-2) to the

digital zero position. Press the enter

button to acquire zero and wait

approximately 5 seconds for the zero

reference value to be stored. The red

OPTION STATUS LED will resume

flashing when the storage procedure is

complete.

3-2

Page 14

[3]. Load System.

Apply a known ―live‖ weight value to the

scale/vessel or input a known mV/V signal

from a BLH 625 calibrator to the DXp unit.

(NOTE: An external mV source cannot be

used to calibrate a DXp-10/15. A BLH 625

calibrator is required. If a 625 calibrator is

not available, contact a BLH field service

center for assistance.)

[4]. Establish Full Span.

Move the 5 position slide switch to the

digital span position. Use the

increment/decrement toggle switch to

increase or decrease the displayed

(terminal/output device) weight value until

the displayed value matches the known

weight value. Note that the rate of the

value change accelerates the longer the

switch is depressed. When the desired

value is displayed, press the enter button

and wait approximately five seconds for

storage. Again, the red OPTION STATUS

LED will resume flashing when storage is

complete. NOTE: There is no decimal

point available using this calibration

method. The DXp will default to the best

resolution possible based upon the scale

capacity and input signal.

[5]. Resume Normal Operation.

Return the 5 position slide switch to the run

position. Digital calibration is complete.

Table 3-2. DXp-10 Analog Calibration

Instructions

[1]. Connect Load Cells and Volt/Current Meter.

Install the load cells and wire them to the

DXp-10/15. Connect the analog output to a

voltage or current meter.

[2]. Establish Zero Reference/First Span Point.

Make sure that all dead weight (vessel,

mixer, pipes, etc.) is applied as it will be

during normal operation. Move the five

position slide switch (Figure 3-2) to the

analog zero position. Use the

increment/decrement toggle switch to

adjust the analog output so that the desired

value is displayed on the meter. Holding

the toggle switch in the depressed position

increases the rate of change. Press the

enter button to acquire zero and wait

approximately 5 seconds for the zero

reference value to be stored. The red

OPTION STATUES LED will resume

flashing when the storage procedure is

complete.

[3]. Load System.

Apply a known ―live‖ weight value to the

scale/vessel or input a known mV/V signal

from a BLH 625 calibrator to the DXp unit.

(NOTE: An external mV source cannot be

used to calibrate a DXp-10/15. A BLH 625

calibrator is required. If a 625 calibrator is

not available, contact a BLH field service

center for assistance.)

[4]. Establish Full Span.

Move the 5 position switch to the analog

span position. Use the

increment/decrement toggle switch to

increase or decrease the displayed (meter

display) weight value until the displayed

value matches the known weight value.

When the desired value is displays, press

the enter button and wait approximately 5

seconds for storage. Again, the red

OPTION STATUS LED will flash when

storage is complete.

[5]. Resume Normal Operation.

Return the 5 position slide switch to the run

position. Digital calibration is complete.

3-3

Page 15

Table 3-3A. Setup in Monitor Mode.

ASCII Command in

Order of Operation

Serial Output

Explanation

SMM

Set Monitor Mode

Access Monitor Mode

C

Setup

Access Setup to Enter/Alter System

Parameters

M

5000 – CAP LB

Modify Setup

M-I or D

500.00 (flashing)

CAP LB

Modify Capacity

I or D

400.00

Increment or Decrement Digits

E

400.00

CAP LB

Enter Capacity

E

400.00

Select Decimal Position

M-I or D

400.00

DECIMAL

Change Decimal Position

E

400.00

Enter Decimal

E

0.050

GRAD

Graduation Setting

M

I or D

E

0.050

0.050

0.050

GRAD

Modify Graduation

Increment/Decrement

Enter

E

102

OVER

Overrange Setting

M-I or D

OFF/102

Select OFF or 102%

E

20

ZERO

Change Zero Selection

M-I or D

2

ZERO

Select 2% or 20%

Full Scale Zero Allowance

E

2

ZERO

Enter Selection

E

OFF

MN BAND

Change Motion Band Selection

M-I or D

OFF

MN BAND

Select OFF, 1, or 2 counts

E

OFF

MN BAND

Enter Selection

E

SETUP

Parameter Enter/Alter Complete

E

Normal Weighing

3-4

Page 16

Table 3-3B. Calibration in Monitor Mode

ASCII Command in Order of

Operation

Serial Output

Explanation

E

CAL

Enter Calibration Mode

M

000

ZERO

Zero Setting

Z

000

Acquire

Acquire Zero

E

CLEAR

Clear Old Span Point(s)

M-Z or E

SPANS

Span Setting

M

5100.00

166329

Span 1 Value

Internal Counts

X

SPANS

Skips Span

E

Adjust

Change Spans

M

000 (flashing)

SPAN 1

Adjust Span1

M

0000 (flashing)

Acquire Span 1

M & I/D

1000.0

Enter Span 1 Weight Value

Note: Use M & E to access and

change spans 2-5 if desired.

E E

Normal Weighing

Exit CAL Mode

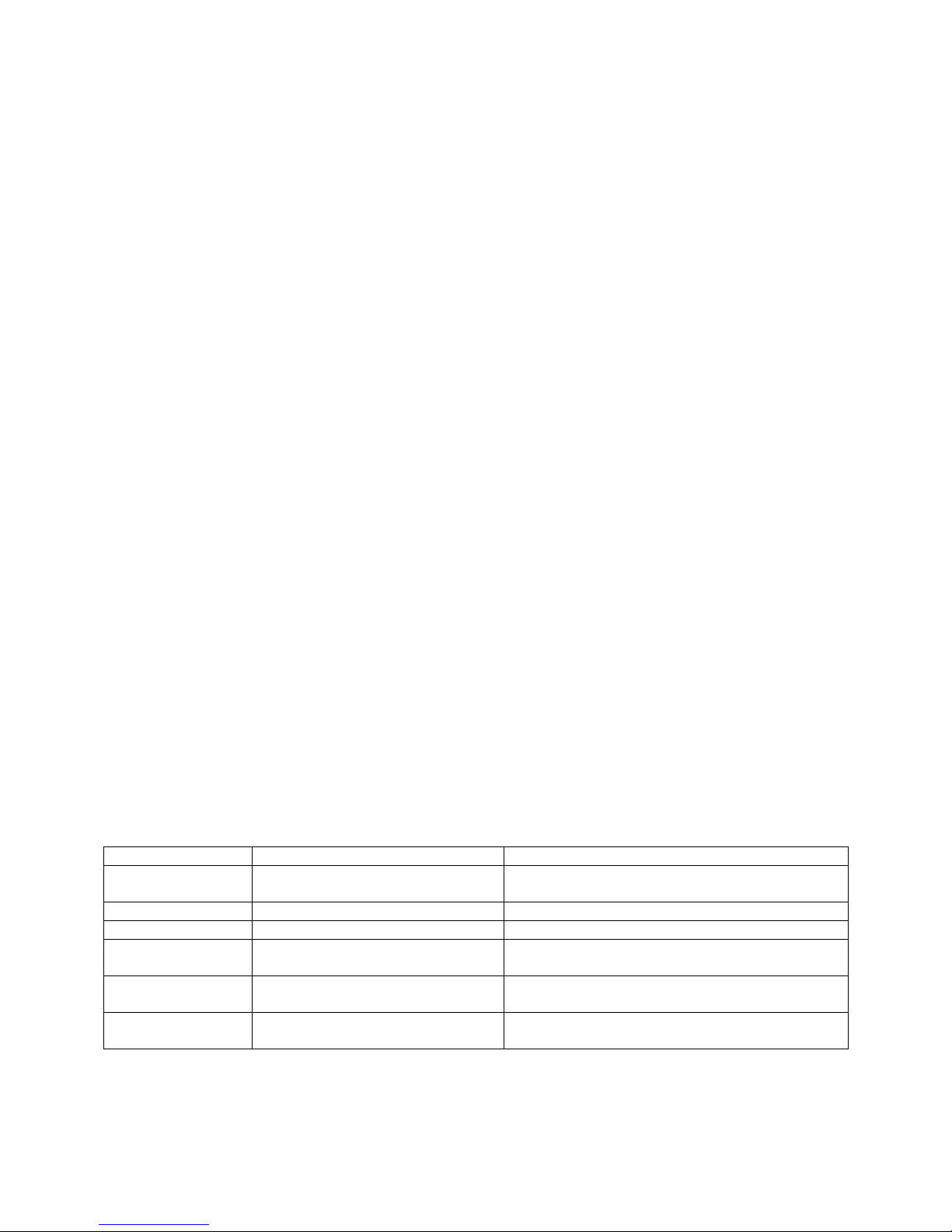

3.4 CHECK CAL

The standard transmitter is provided with a check

cal feature that can be operated manually by

pushing a button on the DXp operator panel (see

Figure 3-1) or remotely via the serial port. This

feature provides a check of the instrument

calibration to verify that drift or other problems

have not occurred. Check cal uses an internal

shunt resistor circuit to provide a fixed repeatable

signal into the input of the transmitter. The input

signal produces a known output which can be

verified by viewing the terminal/meter used to

perform calibration.

Due to the infinite variety of calibrations and

applications, a range of shunt calibration values

are available by changing the position of the

resistor circuit component carrier in socket U6 on

the A/D board. Access is obtained by removing the

card rack cover and should be performed by a

qualified technician. In most cases, a value that

produces a signal equal to 80% of system capacity

is desired. Table 3-4 lists the positions and

resulting percent of output given a typical 2.0 mV/V

load cell application.

3-5

Page 17

Table 3-4. Check Cal Percentage Selection/Module Position.

Module

Position

Resistance

(ohms)

1 Cell

2 Cells

3 Cells

4 Cells

1

13400

125%

114%

78%

59% 2 94800

125%

125%

110%

84% 3 15800

125%

97%

66%

50% 4 70400

41%

22%

15%

11% 5 546000

53%

28%

19%

14% 6 395000

74%

39%

26%

20% 7 309000

94%

50%

33%

25% 8 237000

125%

65%

44%

33%

Setting

(Flashes)

Conversions

Averaged

1 1 2 2 3 4 4 8 5

16 6 32 7 64 8 128

Percent of Full Scale (2 mV/V) Output when Check Cal Button is Pressed.

3.5 FILTER SELECTION

3.5.1 Standard Filter.

Standard filtering offers simple successive

averaging of A-D conversions to stabilize the

output signal. Pressing and holding the enter

button accesses the selection mode: the

increment/decrement toggle switch changes the

setting. As the setting is changed, the OPTION

STATUS LED flashes to indicate the selection.

Average selections of 1, 2, 4, 8, 16, 32, 64 or 128

are available (Table 3-5).

Table 3-5. Standard Filter Selections

Hold down enter key and toggle INC/DEC key for

selections.

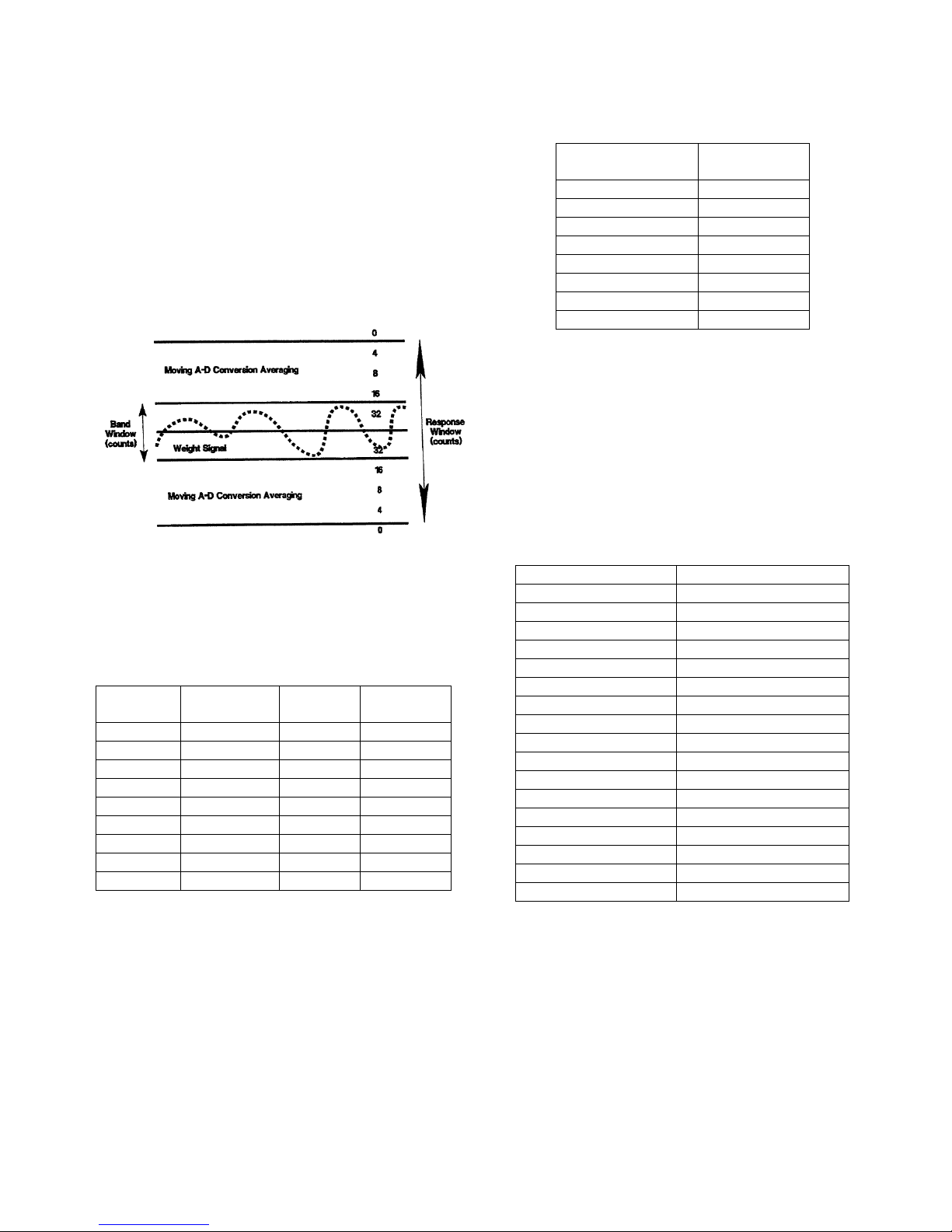

3.5.2 Optional Digital Filtering.

Optional digital filtering offers the benefits of

successive averaging without the corresponding

delay in response time to real weight changes.

Digital filtering software determines the number of

A-I) conversions to be averaged on a moving basis

(Figure 3-3). Conventional averaging takes place

at the selected rate within a window of counts

defined as 'band (Table 3-6). If the signal exceeds

the band count limits, averaging continues on a

reduced basis within the larger window of counts

designated 'response'. Once the signal exceeds

both windows, band and response, averaging

stops until the signal begins to stabilize again. This

two-dimensional approach provides fast, accurate,

and stable weight data for difficult process

weighing applications. Consult BLH technical note

7D-071' for a complete explanation of optional

digital filtering.

Pressing and holding the ENTER button accesses

the filter selection mode: the increment/decrement

toggle switch changes the setting. As the setting is

changed, the OPTION STATUS LED flashes to

indicate the selection (one flash = setting one,

etc.). Table 3-6 (upper portion) defines the

parameters of each of the eight possible

selections. Releasing the ENTER button stores the

3-6

Page 18

10.75 11 26

CD

8

•

OLII

111.14111091C9. SIC.

OUTLINE

1

selection. After selecting a filtering parameter,

Setting

(Flashes)

Averaging*

Band

(Counts)

Response

(Counts)

0 * 0 0 1 * 1 4 2 * 2 8 3 * 4

16 4 * 8 32 5 D* 1 4 6 D* 2 8 7 D* 4 16 8 D* 8 32

Setting (Flashes)

Conversions

Averaged

1 1 2 2 3 4 4 8 5

16 6 32 7 64 8 128

DXp Parameter

Default Specification

Capacity

10,000

Units

Pounds

Decimal Point

None

Grad

1

Overrange

Off

Zero Band

2% of capacity

Motion Band

Off

External Zero

0

Span 1 Units

10,000

Span 2 Units

Cleared

Span 3 Units

Cleared

Span 4 Units

Cleared

Span 5 Units

Cleared

D/A Zero Volt Output

0 (min bit of 4095)

D/A 10V Output

4095 (max bit of 4095)

Filter

1

Averaging

1

choose an averaging value (Table 3-6 lower

portion). Select averaging by holding the toggle

switch to increment or decrement to access the

selection mode. Press the ENTER button to

change. The OPTION STATUS LED flashes to

indicate the selection number (14 flashes).

Releasing the toggle switch stores the selection.

Figure 3-3. Optional Digital Filtering Operation.

Table 3-6. Optional Digital Filtering Selections.

*Insert averaging value as selected in table

above; ‘D’ doubles averaging value selection.

3.6 Factory Default Calibration

Table 3-7 presents the DXp-10/1.5 factory

calibration default parameters. All DXp units

shipped by BLH are calibrated to the specifications

shown in Table 3-7.

Table 3-7. Factory Calibration Default

Parameters

Filter Type Selection: Hold down enter key and

toggle INC/DEC key for selections.

Averaging Selection: Hold toggle switch to

INC/DEC, press enter key for selections.

* The Dxp-10 has up to 368,640 raw internal

counts.

3-7

Page 19

SECTION 4. Serial Communication

Switch

Positions

1 2 3

Baud

Rate

Interface

0 0 0

9600

Digi-System Network

1 0 0

28800

Digi-System Network

0 1 0

57600

Digi-System Network

1 1 0

1200

Continuous Output

0 0 1

9600

Continuous Output

1 0 1

1200

Terminal Interface

0 1 1

9600

Terminal Interface

1 1 1

-

Reserved Setting; used

for special protocol

interface options

Switch

Position

4 5 6 7

Address

0 0 0 0

16

1 0 0 0

1

0 1 0 0

2

1 1 0 0

3

0 0 1 0

4

1 0 1 0

5

0 1 1 0

6

1 1 1 0

7

0 0 0 1

8

1 0 0 1

9

0 1 0 1

10

1 1 0 1

11

0 0 1 1

12

1 0 1 1

13

0 1 1 1

14

1 1 1 1

15

4.1 GENERAL

The DXp-10/15 is equipped with a variety of

standard and optional serial output formats that

are selected using a series of DIP switches

(Figure 4-1). DIP switch positions 1, 2, and 3

allow three format choices; Digi-System

network, continuous output, and

terminal/computer interface (Table 4-1). All three

types of DXp interfacing will be discussed in the

following paragraphs. Positions 4-7 designate

transmitter address for applications requiring

more than one DXp unit (Table 4-2). Switch

position 8 is unused and should be left in the '0'

(ON) position.

NOTE: If the MODBUS option is installed and

enabled, use the DIP switch selections

presented in Figure 4-2• (Page 4-4).

interface is much greater than simple analog

current or voltage approximates. Simplex

outputs are transmitted in the format on page 42, top left-hand column.

Table 4.1. Serial Interface and Band Rate

Selections

4.1.1 LCp-40 Digi System Network.

Up to 16 DXp-10/1.5 transmitters can be

networked to the LCp-40 Network Controller.

The half duplex format used to run the network

is designed to provide remote operation of

gross, net, tare, zero, calibration/set-up, and

diagnostics, at high speed. This format is not

intended for direct interface with a terminal or

computer. The baud rate is selectable to

accommodate systems with very long (low baud)

or short (high baud) distances between DXp

units.

4.1.2 Standard Simplex Output

(Continuous Output).

The simplex output format is designed to

transmit gross weight data (ASCII coded) to a

remote terminal or computer. The accuracy of

this point to point, digital communication

4-1

Page 20

Figure 4-1. Serial Communication Parameter Selection Switch.

ASCII

Command

Description

Action

Response

W

Weight

Return Current Weight

Data and Mode

Information

[stx/adr/pol/data/sp/units/mode/stat/tc/CRLF]

G

GROSS

Switch to Gross Mode

[stx/adr/pol/data/sp/units/‖G‖/stat/tc/CRLF]

N

Net

Switch to Net Mode

[stx/adr/pol/data/sp/units/‖N‖/stat/tc/CRLF]

T

Tare

Switch to gross mode and

Tare

[stx/adr/pol/data/sp/units/‖N‖/stat/tc/CRLF]

Z

Zero

Switch to gross mode and

Zero

[stx/adr/pol/data/sp/units/‖G‖/stat/tc/CRLF]

L

Pounds

Switch to Pounds

[stx/adr/pol/data/sp/‖L‖/mode/stat/tc/CRLF]

K

Kilograms

Switch to Kilograms

[stx/adr/pol/data/sp/‖K‖/mode/stat/tc/CRLF]

SMC

Set Continuous

Mode

Send weight data

continuously

[stx/adr/pol/data/sp/units/mode/stat/tc/CRLF]

SMD

Set Demand

Mode

Must request data

SC

Check Cal

Remotely Operates Check

Cal

[stx/adr/pol/data/‖C‖ ―C‖/stat/tc/CRLF]

4.1.3 Computer/Terminal Interface

(Optional).

This half duplex (transmit and receive) format is

designed for two way communication between a

single D4-10/15, or a network of DXp-10/15 units,

and a computer/terminal. Protocol accommodates

all operations such as gross, net, tare, zero, as

well as remote set-up, calibration, and filter

selection. Use of this format requires customer

developed device specific software to run the

various network operations. Table 4-3 defines the

terminal interface protocol. Monitor mode (see

Table 4-3) allows many of the LCp¬40 keypad

switch functions to be implemented from the host

terminal/computer. These functions are essential

when performing remote calibration and parameter

set-up.

Table 4-3a. Computer/Terminal Interface Protocol.

4-2

Page 21

Table 4-3b. Computer/Terminal Interface Protocol.

ASCII

Command

Description

Action

Response

SMM

Set Monitor Mode

Transmit display each update

Instrument display output

Lower Display/sp/Upper

Display/CR

SMR

Set Mode for Remote

Inhibit

Of Temperature

Conversions

Turn off Auto Temperature

Compensation Cycles

SMA

Set Mode for Automatic

Temperature

Compensation

Turns on Temperature

Compensation Cycles (note 1)

SFx

Set Digital Filter Value

X = 0-8

Remote Selection of Digital

Filter Value (note 2)

SVx

Set Digital Averaging

Value

x = 0-7

Remote Selection of

Digital Averaging (note 2)

I

Increment

Increment blinking digit/selection

Monitor Mode Only

D

Decrement

Decrement blinking digit/selection

Monitor Mode Only

U

Units

Select lb/kg when modifying

capacity

Monitor Mode Only

M

Modify/Shift

Same as MOD key

Monitor Mode Only

E

Enter/Step

Same as Enter/Step key

Monitor Mode Only

H

Help

Same as Help key

Monitor Mode Only

X

Exit

Same as Exit key

Monitor Mode Only

C

Cal

Same as Cal key

Monitor Mode Only

AXX

Address 01 – 16

Enable Addressed DXp Unit

Note 1: In auto mode, 90 millisecond temperature compensation cycles occur once every 2 seconds.

Temperature cycles are inhibited if there is critical positive or negative system motion.

Note 2: Remote filter and averaging selections are not stored in EEPROM. EEPROM values will be

loaded at time of unit power up. See Table 3-6 for selection definitions.

List of abbreviations.

stx= 1char. Start of Text (02H)

adr= unit address 01-16,3 chars; high add, low add, Sp

POI = Polarity sign; space (ASCII 2H) for positive data, minus (-) (ASCII 2D) for

negative data

data= 7 char; six digits with decimal point or leading space, leading zeros = spaces

sP = 1 char; ASCII space (20H)

units= 1 that; L= pounds, K= kilograms, C= Checkcal

mode= 1 char; G= gross, N= net, C= checkcal

Z= zero cal, and S= span cal

stat = 1char; M (motion), 0 (overload), Or sp

to = 1 char, temperature compensation; IR= remote

inhibit sp = auto

CR/LF= 2 char; carriage return, line feed (ODH/OAH)

"= single quotes = ASCII character or string

upper display = 7 ASCII characters

lower display = 6 ASCII characters

4-3

Page 22

4.1.4 MODBUS BTU Protocol

(Optional).

MODBUS is a protocol developed by Modicon

Inc. for communication between programmable

controllers and operator stations which support

them. For a complete description of the

MODBUS interface, request BLH technical

document TD-075. If the MODBUS option is

installed and enabled (DIP switch position 8 =

OFF), interface parameters must be selected

using the DIP switch configurations shown in

Figure 4-2

If the MODBUS option is installed but not

enabled, DIP switch selections will function as

shown in Tables 4-1 and 4-2 (page 4-1).

MODBUS protocol formats are presented on the

following pages.

Figure 4-2. DIP Switch Selections for MODBUS Protocol.

MODBUS FUNCTIONS SUPPORTED:

02 Read Input Status

03 Read Holding Registers

06 Preset Single Register

16 (10 Hex) Preset Multiple Registers

DATA FORMATS:

FORMAT #1: One 16 bit signed integer -

32768 to 32767 for all data

FORMAT #2: Two 16 bit signed integers

for weight data (the two integers must

be added together to get -65536 to

65534) One 16 bit unsigned integer for

status & setup parameters

FORMAT #3: Two 16 bit signed Integers

for weight data (the high word, 1st

integer, must be multiplied by 32768.0

then added to the low word, 2nd Integer)

One 16 bit unsigned integer for status &

setup parameters

4-4

Page 23

INPUT STATUS DEFINITIONS (Function 02)

INPUT STATUS

1 MOTION

2 UNABLE TO TARE/ZERO

BECAUSE OF MOTION

3 UNABLE TO ZERO BECAUSE

OF UMIT

4 CHECK CAL

5 ND UNDERLOAD

6 A/D OVERLOAD

7 SPARE (0)

9 IN ANALOG CAL

10 IN DIGITAL CAL

11 ACQUIRING CAL DATA

12 FILTER BEING CHANGED

13 EEPROM CODE ERROR DEFAULT DATA LOADED

14 EEPROM READ ERROR

15 EEPROM WRITE ERROR

16 EEPROM DATA ERROR FAULTED DATA REPLACED WITH

DEFAULT DATA

8 POWERUP

DXP10/15 READ ONLY REGISTERS (Function 03)

READ ONLY FORMAT #1 FORMAT #2 FORMAT #3

ADR #REG ADR #REG ADR #REG

STATUS 40001 1 40033 1 40065 1

GROSS 40002 1 40034 2 40066 2

NET 40003 1 40036 2 40068 2

DXP10/15 READ/WRITE REGISTERS (Functions 03, 06-format #1 only, 16)

READ/WRITE FORMAT #1 FORMAT #2 FORMAT #3

ADR #REG ADR #REG ADR #REG

TARE 40004 1 40038 2 40070 2

ZERO 40005 1 40040 2 40072 2

ZERO UMIT 40006 1 40042 1 40074 1

FILTER TUNE 40007 1 40043 1 40075 1

AVERAGING 40008 1 40044 1 40076 1

MOTION 40009 1 40045 1 40077 1

MOTION TIMER40010 1 40046 1 40078 1

SPAN CAL 40011 1 40047 2 40079 2

DXP10/15 WRITE ONLY COMMAND REGISTER (Functions 06, 16)

WRITE ONLY FORMAT #1

ADR #REG COMMANDS

01 = TARE net weight

COMMAND 40101 1 02= ZERO gross weight

STATUS REGISTER BIT DEFINITIONS for addresses 40001, 40033, 40065

BIT STATUS

0 MOTION

1 UNABLE TO TARE/ZERO BECAUSE OF MOTION

2 UNABLE TO ZERO BECAUSE OF LIMIT

3 CHECK CAL

4 ND UNDERLOAD

5 ND OVERLOAD

6 SPARE (0)

7 POVVERUP

4-5

Page 24

8 IN ANALOG CAL

9 IN DIGITAL CAL

10 ACQUIRING CAL DATA

11 FILTER BEING CHANGED

12 EEPROM CODE ERROR - DEFAULT DATA LOADED

13 EEPROM READ ERROR

14 EEPROM WRITE ERROR

15 EEPROM DATA ERROR - FAULTED DATA REPLACED WITH DEFAULT DATA

ZERO LIMIT, FILTER, & MOTION SETIINGS

ZERO LIMIT (note on next page)

Setting % of capacity

0 2

2 20

FILTER TUNE AVERAGING

setting band Response setting averaging

(counts) (counts)

0 OFF OFF

1 1 4 0 1

2 2 8 1 2

3 4 16 2 4

4 8 32 3 8

5* 1 4 4 16

6* 2 8 5 32

7* 4 16 6 64

8* 8 32 7 128

*tune settings 5-8 double current averaging setting

MOTION MOTION TIMER

setting counts setting time

0 OFF 0 0.8 sec

1 1 1 1.6 sec

2 2 2 32 sec

3 3 3 6.4 sec

If the count difference from conversion to conversion is greater than the motion setting, the motion status

bit is set to 1. Once the count difference from conversion to conversion returns to be equal to or less than

the motion setting, the motion bit remains set for the time selected for the Motion Timer.

Note 1: Zero limit settings are stored in EEPROM and are not lost if unit powers down. Filter and motion

settings are lost if unit powers down.

Note 2: counts refers to weight graduations. If weight graduations are 2 lb increments then presetting a

register to 2 would mean 4 lbs.

4-6

Page 25

4.1.5 Fisher ProVox Protocol

(Optional)

DXp-15 transmitters may be ordered with the

Fisher ProVox protocol. Units equipped with this

option communicate with a Fisher ProVox

C16921 external interface card, configured for

the 'Toledo' interface. For a further description of

the hardware and software aspects of this

interface, refer to BLH technical document TD-

073.

Definitions for the byte and bit formats

transmitted by the DXp-15 are presented below.

To select the ProVox protocol option, DIP switch

positions 1-3 must be set to 14,1. Baud rate is

fixed at 4800 continuous output.

NOTE: Hardware requirement - An external

hardware converter is required to change the

DXp-15 RS-485 output to 20 mA current loop for

interface with the ProVox CL6921 card.

FISHER PROVOX INTERFACE

1. TRANSMTT ONLY FORMAT - approx.

every 200ms

2. BYTE FORMAT -10 BIT ASCII: 1 start,

7 data, 1 parity - even, 1 stop

3. DATA OUTPUT FORMAT GROSS/TARE or NET/TARE provided (tare always =0)

4. TOTAL (RESPONSE PACKET)

FORMAT -18 bytes - 4800 baud –

continuous

4-7

Page 26

4.1.6 Allen-Bradley Remote I/O

(Optional).

DXp-15 transmitters are available with the AllenBradley Remote 110 interface option. This

option is available via a technology licensing

agreement between BLH and Allen-Bradley.

Functionally, this interface allows up to 8 BLH

DXp-15 transmitters to communicate with an AB

PLC-5 or SLC-5 programmable logic controller

using discrete data transfers. Consult BLH

manual TM010 for complete details.

4-8

Page 27

SECTION 5. Operation

Error Message

Description

Action

E02

Signal Overrange

Check for open load cell circuit or overranged

load cell (reading in excess of 35 mV at J-Box

E03

Signal Underrange

E04

Digital Overrange

Return to setup and increase capacity

E10

Internal Autozero Measure

Is out of range

If external summing, check that SEN+ and

SEN- leads are secure

E200

Cannot Attain Capacity

Return to setup and decrease capacity or

review hardware gain setting

E201

Cannot Attain Capacity

Return to setup and increase GRAD or review

hardware gain setting.

5.1 GENERAL

As a stand-alone unit (no terminal, computer, or

LCp-40), either analog or digital, the DXp-1W15

typically transmits only gross weight data upon

power-up. If the DXp-10/15 is being operated

remotely from a host terminal, computer, or LCp40, it can perform gross, net, tare, and zero

functions.

5.2 GROSS WEIGHT WEIGHING

In the gross mode, all of the live weight of the

system is transmitted. Live weight does not

include the dead weight of a vessel or other

mechanical equipment that is zeroed out during

calibration.

5.3 ZERO OPERATION

A new zero can be acquired to compensate for

changes in the dead load of the system due to

heel build-up etc. Acquiring a new zero

reference value does not affect the slope of the

calibration. The zero function in the DXp¬10/15

can be configured for either a 2% or a 20%

ceiling (max percent of full scale capacity) if the

unit is connected to a host terminal/computer or

LCp-40.

5.4 NET WEIGHT WEIGHING

Net weight weighing is used when the operator

wants to reset to zero to compensate for the

Table 5-1. Error Codes and Flashing Display Explanations

addition of live weight, or a container, before

adding a specific amount of material. Tare is

used to establish a zero reference in net mode.

5.5 TARE OPERATION

With the DXp-10/15 in net weighing mode, the

tare operation resets the output to zero. Taring

allows the operator to achieve a new zero

reference before addition of each ingredient so

that errors do not become cumulative.

5.6 ERROR DETECTION

When the DXp is reporting weight data to a host

computer, dashes will be transmitted if an

overrange condition occurs. When connected to

an LCp-40, the node identification and dashes

will be transmitted and displayed. When used in

the monitor mode, a complete library of error

codes is available for transmission (see Table 5-

1).

5.7 CHECK CAL OPERATION

Manually depressing or remotely activating

check cal through the serial port causes the

transmitted weight data to increase by the given

percentage (see Table 34). In systems using a

host computer, this check can be made on a

routine basis to verify the accuracy of the

system.

DXp-10/15 Error Messages (As seen on an LCP-40 display or computer/terminal in monitor mode)

5-1

Page 28

DXp-10/15 Power-Up/EEPROM Errors

LCp-40 Display

DXp-10/15 CPU

Status LED

Description

Action

―EE DFAULT‖

1 Blink

Default data loaded into

EEPROM (New EEPROM)

Press Reset on DXp-10/15

Press exit on LCp-40

―EE WRITE‖

2 Blinks

EEPROM write error

Press Reset on DXp-10/15

Press exit on LCp-40

―EE READ‖

3 Blinks

EEPROM read error

Press Reset on DXp-10/15

Press exit on LCp-40

―EE XXXXXX‖

4 Blinks

EEPROM checksum error

Press Reset on DXp-10/15

Press exit on LCp-40

Operating Mode

Key Pressed

Flashing Display

Explanation

Gross

TARE

LB/KG

Cannot tare gross weight

Gross

ZERO

LB/KG

Current weight out of zero range

Gross

DISPLAY

No Change

Display set to show gross only

Net

ZERO

LB/KG

Cannot acquire zero while in net mode

Net

TARE

MOTION

Cannot tare while in motion

Net

TARE

GROSS

Cannot tare negative gross weight

Net

TARE

LB/KG

Cannot tare, gross weight beyond capacity

NOTE: If pressing reset on the DXp does not clear an ―EE‖ error, consult factory.

Flashing Display Explanations (As seen on LCp-40 display or computer terminal)

5-2

Page 29

1

Page 30

2

Page 31

3

Page 32

Appendix C: Wiring and Outline Drawings

Customer Wiring Diagram

Standard Unit Outline

Explosion-Proof Enclosure Outline

4

Page 33

5

Page 34

6

Page 35

7

Page 36

8

Page 37

Appendix E

Remote Calibration Using an LCp-40, 41, or 42

DXp-10/15 transmitters can be calibrated and configured remotely using an LCp-40

series network controller. Remote calibration/configuration provides the advantage of

displaying parameter entries for maximum setup accuracy. The following pages present

flow diagrams for each available remote parameter entry.

9

Page 38

10

Page 39

11

Page 40

12

Page 41

13

Page 42

BLH

3 Edgewater Drive,

Norwood, MA 02062 U.S.A.

Phone (781) 298-2200

Fax (781) 762-3988

www.vishaypg.com

Loading...

Loading...