Page 1

查询592D105X-035A2-15H供应商

592D

Vishay Sprague

Solid Tantalum Chip Capacitors

TANTAMOUNT®, Low Profile, Conformal Coated, Maximum CV

FEATURES

• New extended range offerings.

• 1.0mm to 2.5mm height.

• Terminations: Lead (Pb)-free (2) standard.

• Low Impedance

• 8mm, 12mm and 24mm tape and reel packaging

available per EIA-481-1 and reeling per IEC 286-3. 7”

[178mm] standard.

13” [330mm] available.

• Case code compatibility with EIA 535BAAC and

CECC 30801 molded chips.

PERFORMANCE CHARACTERISTICS

Operating Temperature: - 55°C to + 85°C. (To + 125°C

with voltage derating.)

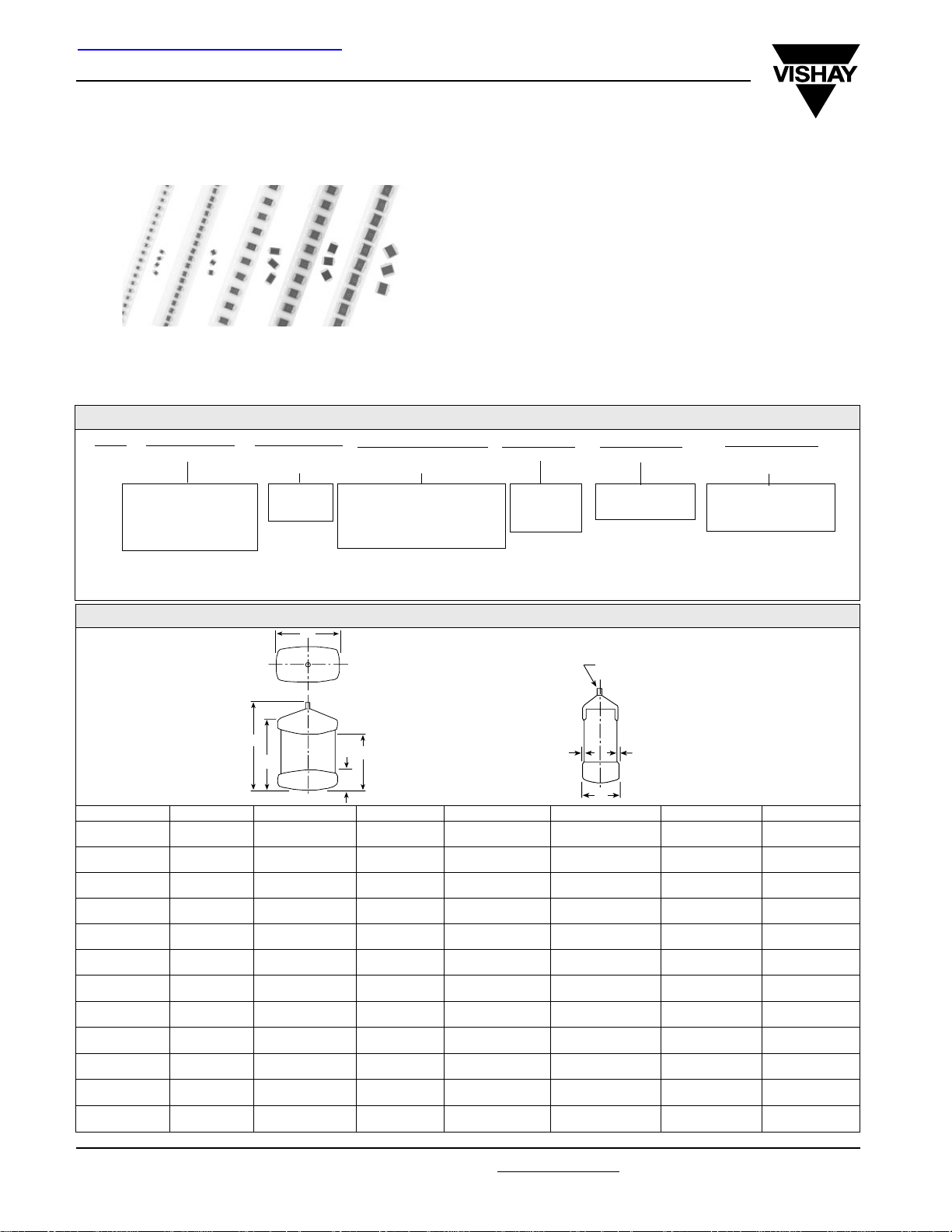

ORDERING INFORMATION

592D

TYPE

This is expressed in

picofarads. The first two

digits are the significant

figures. The third is the

number of zeros to follow.

Note: Preferred Tolerance and reel sizes are in bold.

We reserve the right to supply higher voltage ratings and tighter capacitance tolerance capacitors in the same case size.

Voltage substitutions will be marked with the higher voltage rating.

106

CAPACITANCE

X0

CAPACITANCE

TOLERANCE

X0 = ± 20%

X9 = ± 10%

010

DC VOLTAGE RATING

@ + 85°C

This is expressed in volts. To

complete the three-digit block,

zeros precede the voltage rating.

A decimal point is indicated by

an "R" (6R3 = 6.3 volts).

Capacitance Range: 1.0µF to 3300µF

Capacitance Tolerance: ±10%, ±20% standard.

Voltage Rating: 4 WVDC to 35 WVDC

B

CASE CODE

See Ratings

and Case

Codes Table.

2

TERMINATION

2 = 100% Tin

4 = Gold Plated

T=Tape and Reel

W = 13” [330mm] Reel

T

REEL SIZE AND

PACKAGING

7" [178mm] Reel

DIMENSIONS in inches [millimeters]

W

Tantalum Wire Nib

Identifies Anode

(+) Terminal

L

D

CASE CODE L (Max.) W H A B D (Ref.) J (Max.)

A

B

C

D

R

S

T

U

V

W

X

Y

Note: The anode termination (D less B) will be a minimum of 0.012" [0.3mm].

0.146 0.072 ± 0.012 0.048 ± 0.012 0.031 ± 0.012 0.087 ± 0.016 0.115 0.004

[3.7] [1.8 ± 0.3] [1.2 ± 0.3] [0.80 ± 0.30] [2.2 ± 0.4] [2.9] [0.1]

0.158

[4.0] [2.8 + 0.3-0.4] [1.2 ± 0.3] [0.80 ± 0.30] [2.5 ± 0.4] [3.5] [0.1]

0.281 0.126 ± 0.012 0.047 ± 0.012 0.051 ± 0.012 0.180 ± 0.024 0.238 0.004

[7.1] [3.2 ± 0.3] [1.2 ± 0.3] [1.3 ± 0.30] [4.4 ± 0.6] [6.0] [0.1]

0.298 0.170 ± 0.012 0.047 ± 0.012 0.051 ± 0.012 0.180 ± 0.024 0.254 0.004

[7.5] [4.3 ± 0.3] [1.2 ± 0.3] [1.3 ± 0.30] [4.6 ± 0.6] [6.4] [0.1]

0.285 0.235 ± 0.012 0.047 ± 0.012 0.051 ± 0.012 0.180 ± 0.024 0.246 0.004

[7.2] [6.0 ± 0.3] [1.2 ± 0.3] [1.3 ± 0.30] [4.6 ± 0.6] [6.2] [0.1]

0.126 ± 0.012 0.063 ± 0.012 0.040 ± 0.012 0.031 ± 0.012 0.079 ± 0.012 0.087 0.004

[3.2 ± 0.3] [1.6 ± 0.3] [1.0 ± 0.3] [0.8 ± 0.3] [2.0 ± 0.3] [2.2] [0.1]

0.158 0.116 ± 0.012 0.079 0.031 ± 0.012 0.097 ± 0.016 0.139 0.004

[4.0] [2.8 ± 0.3] [2.0] Max. [0.8 ± 0.3] [2.5 ± 0.4] [3.5] [0.1]

0.281 0.126 ± 0.012 0.079 0.051 ± 0.012 0.180 ± 0.024 0.238 0.004

[7.1] [3.2 ± 0.3] [2.0] Max. [1.3 ± 0.3] [4.6 ± 0.6] [6.0] [0.1]

0.298 0.170 ± 0.012 0.079 0.051 ± 0.012 0.180 ± 0.024 0.254 0.004

[7.5] [4.3 ± 0.3] [2.0] Max. [1.3 ± 0.3] [4.6 ± 0.6] [6.4] [0.1]

0.285 0.235 ± 0.012 0.079 0.051 ± 0.012 0.180 ± 0.024 0.246 0.004

[7.2] [6.0 ± 0.3] [2.0] Max. [1.3 ± 0.3] [4.6 ± 0.6] [6.2] [0.1]

0.575 0.290 ± 0.010 0.079 0.050 ± 0.016 0.470 ± 0.024 0.524 0.004

[14.5] [7.37 ± 0.25] [2.0] Max. [1.3 ± 0.4] [11.9 ± 0.6] [13.2] [0.1]

0.575 0.290 ± 0.010 0.098 0.051 ± 0.016 0.470 ± 0.024 0.524 0.004

[14.5] [7.37 ± 0.25] [2.5] Max. [1.3 ± 0.4] [11.9 ± 0.6] [13.2] [0.1]

0.110 + 0.012-0.016

B

A

0.047 ± 0.012 0.031 ± 0.012 0.097 ± 0.016 0.139 0.004

J

J

H

www.vishay.com

74

For technical questions, contact tantalum@vishay.com

Document Number 40004

Revision 20-Oct-04

Page 2

592D

Vishay Sprague

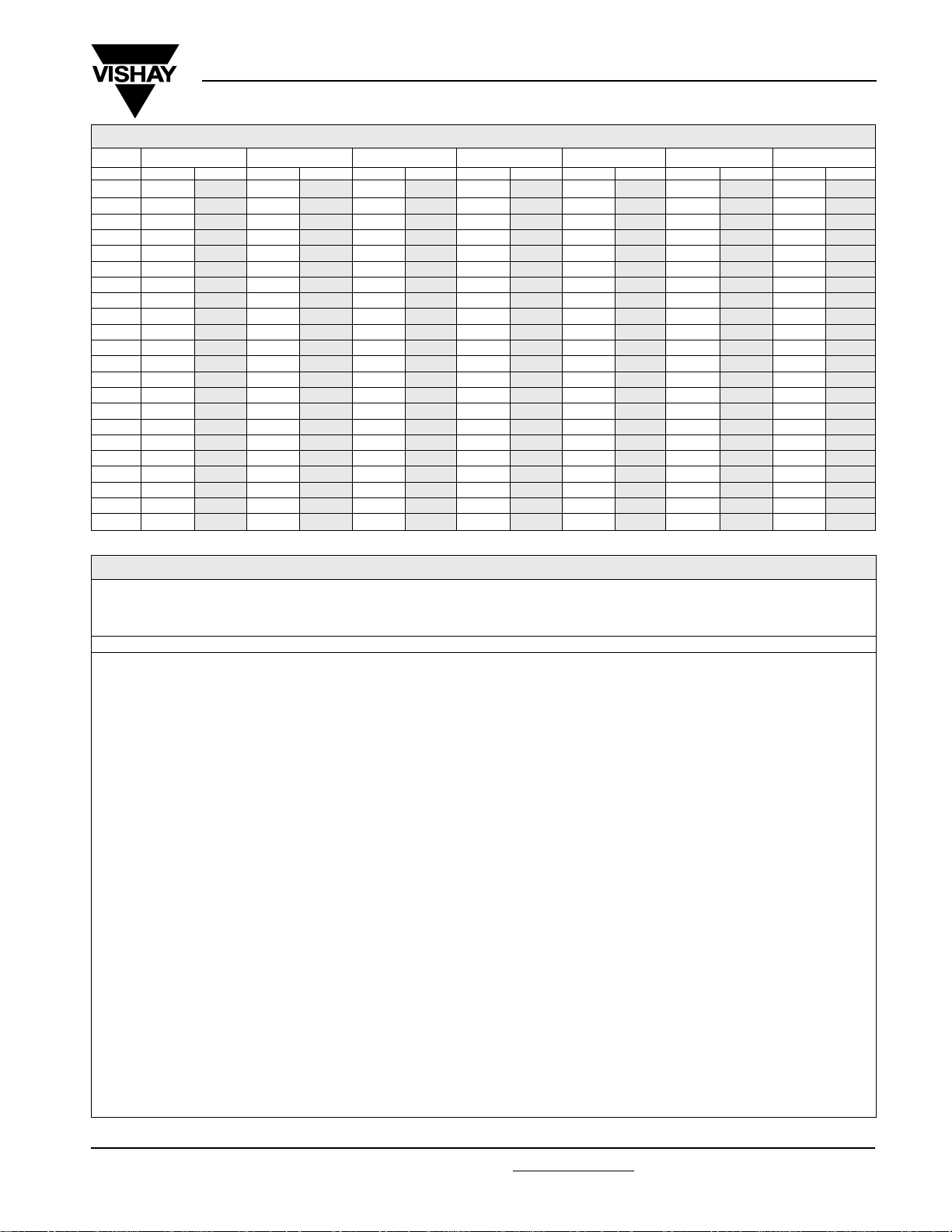

RATINGS AND CASE CODES

µF 4 V 6.3 V 10 V 16 V 20 V 25 V 35 V

STD EXT STD EXT STD EXT STD EXT STD EXT STD EXT STD EXT

1 BA

1.5 B

2.2 BACB*

3.3 CBDC

4.7 ABAC R

6.8 B A C B D C R D

10 B A C B D B R B/D R

15 B A D B* R C U* R

22 B A A/B C B D/T C R/U*/T D U*/V*

33 B B/C A/S D/T* C R/T C/D V* R

47 C B* C/D A/B R/T D U R/T*

68 D B/C D/T/R B/C D/R/U* C/T V C*

100 R/T C/D D/R B/C/T D/U R V C*/D/U

150 D/R C/T D/U R V U W

220 U/V R V D/R/U D V/W W

330 V R/U W R/U/V V W

470 W D/U/V V/U/W

680 V/W W

1000 W X/W

1500 X X/Y

2200 X/Y X/Y*

3300 Y

* Contact factory for availability

STANDARD / EXTENDED RATINGS

CAPACITANCE

(µF)

22 A 592D226X_004A2T 0.9 6 2.40 0.16

22 B 592D226X_004B2T 0.9 6 1.60 0.22

33 B 592D336X_004B2T 1.3 6 1.60 0.22

47* B* 592D476X_004B2T* 1.9* 6* 1.5* 0.23*

47 C 592D476X_004C2T 1.9 6 0.40 0.5

68 B 592D686X_004B2T 2.7 6 1.40 0.24

68 C 592D686X_004C2T 2.7 6 0.35 0.53

68 D 592D686X_004D2T 2.7 6 0.27 0.68

100 C 592D107X_004C2T 4 8 0.35 0.53

100 D 592D107X_004D2T 4 8 0.26 0.69

100 R 592D107X_004R2T 4 8 0.20 0.87

100 T 592D107X_004T2T 4 8 0.45 0.42

150 C 592D157X_004C2T 6 8 0.36 0.52

150 D 592D157X_004D2T 6 8 0.25 0.71

150 R 592D157X_004R2T 6 8 0.20 0.87

150 T 592D157X_004T2T 6 8 0.45 0.42

220 R 592D227X_004R2T 8.3 8 0.20 0.87

220 V 592D227X_004V2T 8.3 8 0.20 0.78

220 U 592D227X_004U2T 8.3 8 0.19 0.76

330 R 592D337X_004R2T 13.2 8 0.18 0.91

330 U 592D337X_004U2T 13.2 8 0.15 0.86

330 V 592D337X_004V2T 13.2 8 0.12 1.08

470 D 592D477X_004D2T 18.8 8 0.14 0.94

470 U 592D477X_004U2T 18.8 8 0.10 1.05

470 V 592D477X_004V2T 18.8 8 0.10 1.18

470 W 592D477X_004W2T 18.8 10 0.10 1.32

680 V 592D687X_004V2T 27.2 12 0.10 1.18

680 W 592D687X_004W2T 27.2 12 0.10 1.32

1000 W 592D108X_004W2T 40 14 0.200 0.94

1500 X 592D158X_004X2T 60 20 0.04 2.1

2200 Y 592D228X_004Y2T 88 25 0.04 2.3

2200 X 592D228X_004X2T 88 25 0.55 2.3

*Preliminary values, contact factory for availability. For 10% tolerance, specify "9"; for 20% tolerance, change to "0". Extended range ratings are in bold print.

CASE

CODE PART NUMBER

4 WVDC @ + 85°C, SURGE = 5.2 V . . . 2.7 WVDC @ + 125°C, SURGE = 3.4 V

Max. DCL

@ + 25°C

(µA)

Max. DF

@ + 25°C

120 Hz

(%)

Max. ESR

@ + 25°C

100kHz

(Ohms)

Max. RIPPLE

100kHz

Irms

(Amps)

Document Number 40004

Revision 20-Oct-04

For technical questions, contact tantalum@vishay.com

www.vishay.com

75

Page 3

592D

Vishay Sprague

STANDARD / EXTENDED RATINGS

CAPACITANCE

(µF)

15 A 592D156X_6R3A2T 0.9 6 2.50 0.15

15 B 592D156X_6R3B2T 0.9 6 1.70 0.22

22 A 592D226X_6R3A2T 1.4 6 1.5 0.23

22 A 592D226X_6R3A2T13H** 1.4 6 1.5 0.2

22 B 592D226X_6R3B2T 1.4 6 1.5 0.23

33 A 592D336X_6R3A2T 2.1 6 1.70 0.32

33 B 592D336X_6R3B2T 2.1 6 1.40 0.24

33 C 592D336X_6R3C2T 2.1 6 0.40 0.5

33 S 592D336X_6R3S2T 2.1 8 1.3 0.28

33 S 592D336X_6R3S2T12H** 2.1 10 2.0 0.17

47 A 592D476X_6R3A2T 3 8 1.40 0.21

47 B 592D476X_6R3B2T 3 8 1.40 0.21

47 C 592D476X_6R3C2T 3 6 0.40 0.5

47 D 592D476X_6R3D2T 3 6 0.30 0.65

68 B 592D686X_6R3B2T 4.3 6 0.38 0.46

68 B 592D686X_6R3B2T13H** 4.3 8 0.60 0.36

68 C 592D686X_6R3C2T 4.3 6 0.38 0.51

68 D 592D686X_6R3D2T 4.3 6 0.27 0.68

68 R 592D686X_6R3R2T 4.3 6 0.20 0.87

68 T 592D686X_6R3T2T 4.3 6 0.50 0.4

100 B 592D107X_6R3B2T15H** 6.3 10 1.0 0.28

100 C 592D107X_6R3C2T 6.3 8 0.38 0.51

100 D 592D107X_6R3D2T 6.3 8 0.26 0.69

100 R 592D107X_6R3R2T 6.3 8 0.20 0.87

100 T 592D107X_6R3T2T 6.3 8 0.45 0.42

150 D 592D157X_6R3D2T 9.5 8 0.25 0.71

150 R 592D157X_6R3R2T 9.5 8 0.20 0.87

150 U 592D157X_6R3U2T 9.5 8 0.19 0.76

220 D 592D227X_6R3D2T 13.9 8 0.22 0.75

220 R 592D227X_6R3R2T 13.9 8 0.18 0.91

220 U 592D227X_6R3U2T 13.9 8 0.15 0.86

220 V 592D227X_6R3V2T 13.9 8 0.12 1.08

330 C 592D337X_6R3C2T16H** 20.8 10 0.15 0.81

330 R 592D337X_6R3R2T 20.8 8 0.18 0.91

330 U 592D337X_6R3U2T 20.8 8 0.10 1.05

330 V 592D337X_6R3V2T 20.8 8 0.10 1.18

330 W 592D337X_6R3W2T 20.8 8 0.10 1.32

470 U 592D477X_6R3U2T 29.6 14 0.10 1.05

470 V 592D477X_6R3V2T 29.6 10 0.10 1.18

470 W 592D477X_6R3W2T 29.6 10 0.10 1.32

680 R 592D687X_6R3R2T16H** 42.8 14 0.13 1.16

680 W 592D687X_6R3W2T 42.8 10 0.100 1.32

1000 W 592D108X_6R3W2T 63 20 0.2 0.94

1000 X 592D108X_6R3X2T 63 16 0.04 2.1

1500 Y 592D158X_6R3Y2T 95 20 0.035 2.3

1500 X 592D158X_6R3X2T 95 25 0.045 1.97

2200* Y* 592D228X_6R3Y2T* 139* 35* 0.055* 1.80*

2200 X 592D228X_6R3X2T 139 35 0.055 1.80

3300 Y 592D338X_6R3Y2T 208 35 0.055 1.80

10 A 592D106X_010A2T 1 6 2.60 0.15

10 B 592D106X_010B2T 1 6 1.70 0.22

22 B 592D226X_010B2T 2.2 6 1.50 0.23

22 C 592D226X_010C2T 2.2 6 0.40 0.50

33 C 592D336X_010C2T 3.3 6 0.40 0.50

33 D 592D336X_010D2T 3.3 6 0.30 0.65

33* T* 592D336X_010T2T* 3.3* 6* 0.50* 0.40*

47 D 592D476X_010D2T 4.7 6 0.27 0.68

47 R 592D476X_010R2T 4.7 6 0.20 0.87

47 T 592D476X_010T2T 4.7 6 0.50 0.40

68 C 592D686X_010C2T 6.8 6 0.14 0.84

68 D 592D686X_010D2T 6.8 6 0.27 0.68

68 R 592D686X_010R2T 6.8 6 0.20 0.87

68 T 592D686X_010T2T 6.8 6 0.45 0.42

68* U* 592D686X_010U2T* 6.8* 6* 0.25* 0.66*

100 D 592D107X_010D2T 10 8 0.10 1.11

100 U 592D107X_010U2T 10 8 0.19 0.76

100 R 592D107X_010R2T 10.0 8 0.22 0.83

150 U 592D157X_010U2T 15 8 0.17 0.80

150 V 592D157X_010V2T 15 8 0.14 1.00

220 V 592D227X_010V2T 22 8 0.12 1.08

220 W 592D227X_010W2T 22 8 0.10 1.32

330* V* 592D337X_010V2T* 33* 8* 0.10* 1.18*

330 W 592D337X_010W2T 33 8 0.10 1.32

** xyH indicates maximum height in (mm), i.e., 1.5 max (H) = 15Hmm

*Preliminary values, contact factory for availability. For 10% tolerance, specify "9"; for 20% tolerance, change to "0". Extended range ratings are in bold print.

*Voltage range under development.

CASE

CODE PART NUMBER

6.3 WVDC @ + 85°C, SURGE = 8 V . . . 4 WVDC @ + 125°C, SURGE = 5 V

10 WVDC @ + 85°C, SURGE = 13 V . . . 7 WVDC @ + 125°C, SURGE = 8 V

Max. DCL

@ + 25°C

(µA)

Max. DF

@ + 25°C

120 Hz

(%)

Max. ESR

@ + 25°C

100kHz

(Ohms)

Max. RIPPLE

100kHz

Irms

(Amps)

www.vishay.com

76

For technical questions, contact tantalum@vishay.com

Document Number 40004

Revision 20-Oct-04

Page 4

592D

Vishay Sprague

STANDARD / EXTENDED RATINGS

CAPACITANCE

(µF)

4.7 A 592D475X_016A2T 0.8 6 3.50 0.13

6.8 A 592D685X_016A2T 1.1 6 3.50 0.13

6.8 B 592D685X_016B2T 1.1 6 1.80 0.21

10 B 592D106X_016B2T 1.6 6 1.60 0.22

10 C 592D106X_016C2T 1.6 6 1.00 0.32

15* B* 592D156X_016B2T* 2.4* 6* 1.4* 0.24*

15 D 592D156X_016D2T 2.4 6 0.50 0.50

22 C 592D226X_016C2T 3.5 6 0.50 0.46

22 D 592D226X_016D2T 3.5 6 0.40 0.60

22 T 592D226X_016T2T 3.5 6 0.6 0.36

33 C 592D336X_016C2T 5.3 6 0.25 0.66

33 D 592D336X_016D2T 5.3 6 0.30 0.62

33 R 592D336X_016R2T 5.3 6 0.27 0.75

33 T 592D336X_016T2T 5.3 6 0.6 0.36

47 R 592D476X_016R2T 7.5 6 0.25 0.77

47 T 592D476X_016T2T 7.5 6 0.45 0.42

47 U 592D476X_016U2T 7.5 6 0.25 0.66

68* C* 592D686X_016C2T* 10.9* 6* 0.50* 1.20*

68 U 592D686X_016U2T 10.9 6 0.25 0.66

68 V 592D686X_016V2T 10.9 6 0.17 0.91

100* C* 592D107X_016C2T* 16* 8* 0.30* 1.80*

100 D 592D107X_016D2T 16 8 0.15 0.97

100 U 592D107X_016U2T 16 8 0.15 0.97

100 V 592D107X_016V2T 16 8 0.15 0.97

150 W 592D157X_016W2T 24 8 0.1 1.32

220 W 592D227X_016W2T 35.2 8 0.2 0.94

4.7 A 592D475X_020A2T 0.9 6 3.80 0.13

4.7 B 592D475X_020B2T 0.9 6 3.20 0.16

6.8 B 592D685X_020B2T 1.4 6 3.10 0.16

6.8 C 592D685X_020C2T 1.4 6 1.10 0.30

10 B 592D106X_020B2T 2 6 3.00 0.16

10 D 592D106X_020D2T 2 6 0.50 0.48

15 C 592D156X 020C2T 3 6 0.60 0.42

15 R 592D156X_020R2T 3 6 0.40 0.65

22 D 592D226X_020D2T 4.4 6 0.40 0.56

22 R 592D226X_020R2T 4.4 6 0.28 0.73

22 T 592D226X_020T2T 4.4 6 0.60 0.37

22* U* 592D226X_020U2T* 4.4* 6* 0.30* 0.61*

33 R 592D336X_020R2T 6.6 6 0.28 0.73

33* V* 592D336X_020V2T* 6.6* 6* 0.26* 0.73*

2.2 A 592D225X_025A2T 0.6 6 8.00 0.09

2.2 B 592D225X_025B2T 0.6 6 6.00 0.12

3.3 B 592D335X_025B2T 0.8 6 5.60 0.12

3.3 C 592D335X_025C2T 0.8 6 2.00 0.22

4.7 C 592D475X_025C2T 1.2 6 1.60 0.25

6.8 C 592D685X_025C2T 1.7 6 1.50 0.26

6.8 D 592D685X_025D2T 1.7 6 1.30 0.31

10 B 592D106X_025B2T 2.5 6 2.00 0.115

10 D 592D106X_025D2T 2.5 6 1.20 0.32

10 R 592D106X_025R2T 2.5 6 0.48 0.56

15 R 592D156X_025R2T 3.8 6 0.40 0.61

15* U* 592D156X_025U2T* 3.8* 6* 0.40* 0.52*

22* U* 592D226X_025U2T* 5.5* 6* 0.30* 0.68*

22* V* 592D226X_025V2T* 5.5* 6* 0.30* 0.68*

*Preliminary values, contact factory for availability. For 10% tolerance, specify "9"; for 20% tolerance, change to "0". Extended range ratings are in bold print.

*Voltage range under development.

CASE

CODE PART NUMBER

16 WVDC @ + 85°C, SURGE = 20 V . . . 10 WVDC @ + 125°C, SURGE = 12 V

20 WVDC @ + 85°C, SURGE = 26 V . . . 13 WVDC @ + 125°C, SURGE = 16 V

25 WVDC @ + 85°C, SURGE = 33 V . . . 17 WVDC @ + 125°C, SURGE = 20 V

Max. DCL

@ + 25°C

(µA)

Max. DF

@ + 25°C

120 Hz

(%)

Max. ESR

@ + 25°C

100kHz

(Ohms)

Max. RIPPLE

100kHz

Irms

(Amps)

Document Number 40004

Revision 20-Oct-04

For technical questions, contact tantalum@vishay.com

www.vishay.com

77

Page 5

592D

Vishay Sprague

STANDARD / EXTENDED RATINGS

CAPACITANCE

(µF)

CASE

CODE PART NUMBER

Max. DCL

@ + 25°C

(µA)

35 WVDC @ + 85°C, SURGE = 46 V . . . 23 WVDC @ + 125°C, SURGE = 28 V

1A592D105X_035A2T 0.5 4 10.0 0.08

1B592D105X_035B2T 0.5 4 6.50 0.11

1.5 B 592D155X_035B2T 0.5 4 4.2 0.14

2.2* B* 592D225X_035B2T* 0.8* 6* 6.00* 0.12*

2.2 C 592D225X_035C2T 0.8 6 3.50 0.17

3.3 C 592D335X_035C2T 1.2 6 3.20 0.18

3.3 D 592D335X_035D2T 1.2 6 2.10 0.24

4.7 R 592 D475X_035R2T 1.6 6 1.30 0.34

6.8 D 592 D685X_035D2T 2.4 6 1.30 0.31

6.8 R 592D685X_035R2T 2.4 6 1.20 0.35

10 R 592D106X_035R2T 3.5 6 1.20 0.35

TYPICAL CURVES OF ESR - AS A FUNCTION OF FREQUENCY

Max. DF

@ + 25°C

120 Hz

(%)

Max. ESR

@ + 25°C

100kHz

(Ohms)

Max. RIPPLE

100kHz

Irms

(Amps)

"A" Case

1000

100

OHMS

1µF, 35

10

15µF, 6.3

1

100 1K 10K 100K 1M

0.1

1000

100

10

OHMS

FREQUENCY IN HERTZ

"C" Case

IMPEDANCE

ESR

IMPEDANCE

ESR

4.7µF, 25 V

"B" Case

1000

100

OHMS

10

1

100 1K 10K 100K

10µF, 10 V

FREQUENCY IN HERTZ

IMPEDANCE

4.7µF, 20 V

"D" Case

100

10

OHMS

1

IMPEDANCE

ESR

ESR

6.8µF, 25 V

1

33µF, 6.3 V

0.1

100 1K 10K 100K 1M

www.vishay.com

FREQUENCY IN HERTZ

For technical questions, contact tantalum@vishay.com

78

0.1

47µF, 6.3 V

0.01

100 1K 10K 100K 1M

FREQUENCY IN HERTZ

Document Number 40004

Revision 20-Oct-04

Page 6

TYPICAL CURVES @ + 25°C, IMPEDANCE AND ESR VS FREQUENCY

592D

Vishay Sprague

"R" Case

100

10

IMPEDANCE

ESR

1

OHMS

10µF, 25 V

0.1

100µF, 6.3 V

0.01

100 1K 10K 100K 1M

592D 1500-4V X CASE ESR/IMPEDANCE VS FREQUENCY

10

1

FREQUENCY IN HERTZ

ESR

IMPEDANCE

"S" Case

100

10

1

OHMS

0.1

0.01

100 1000 10000 100000 1000000

592D 1500-6.3V Y CASE ESR/IMPEDANCE VS FREQUENCY

10.00

1.00

FREQUENCY IN HERTZ

IMPEDANCE

ESR

33 - 6.3V

ESR

IMPEDANCE

OHMS

0.1

0.01

100 1kHz 10kHz 100kHz 1MHz 10MHz

FREQUENCY (Hz)

592D 1000-6.3V X CASE ESR/IMPEDANCE VS FREQUENCY

10.00

ESR

IMPEDANCE

1.00

OHMS

0.10

0.01

100 1kHz 10kHz 100kHz 1MHz 10MHz

FREQUENCY (Hz)

OHMS

0.10

0.01

100 1kHz 10kHz 100kHz 1MHz 10MHz

FREQUENCY (Hz)

592D 2200-4V Y CASE ESR/IMPEDANCE VS FREQUENCY

10.00

ESR

IMPEDANCE

1.00

OHMS

0.10

0.01

100 1kHz 10kHz 100kHz 1MHz 10MHz

FREQUENCY (Hz)

Document Number 40004

Revision 20-Oct-04

For technical questions, contact tantalum@vishay.com

www.vishay.com

79

Page 7

592D

Vishay Sprague

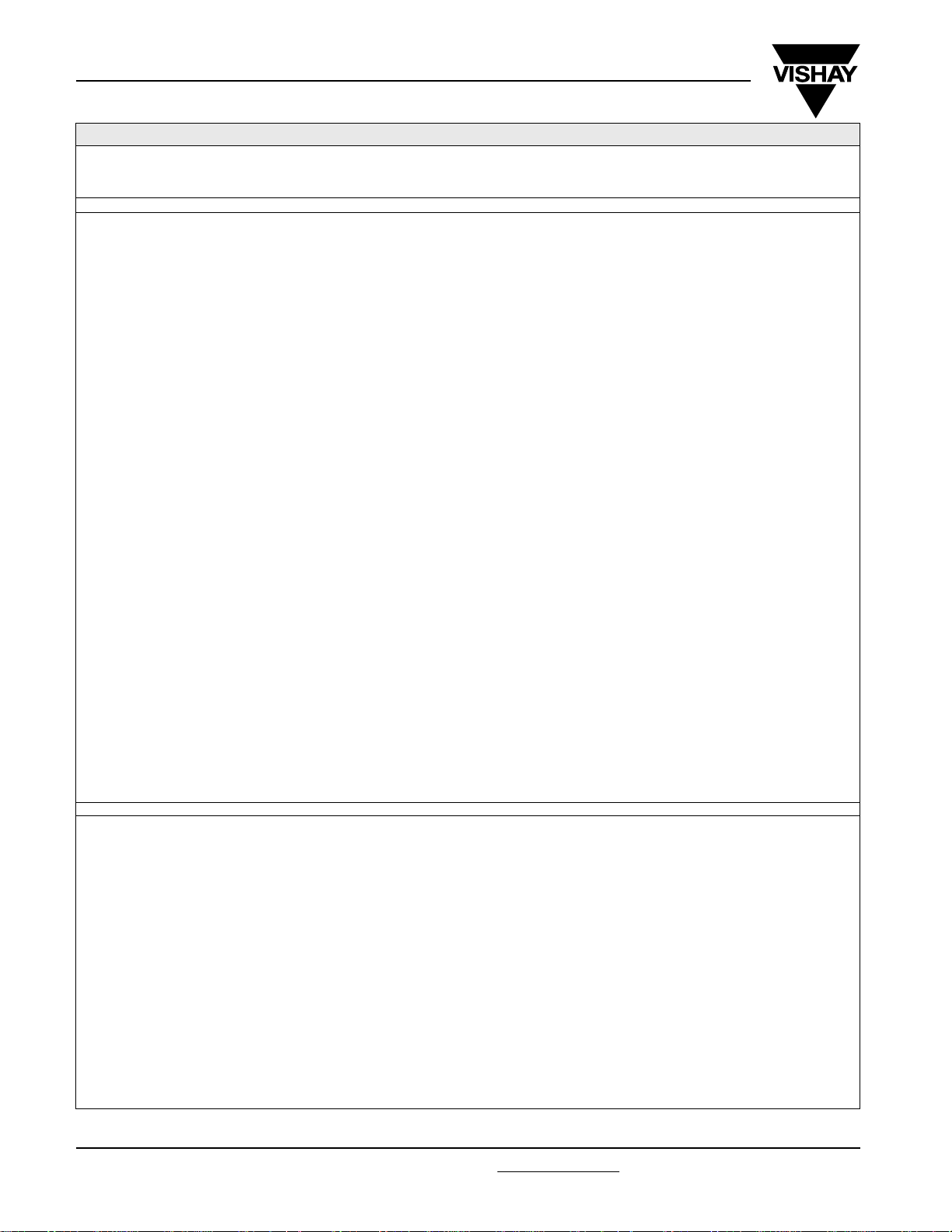

PERFORMANCE CHARACTERISTICS

1. Operating Temperature: Capacitors are designed to

operate over the temperature range - 55°C to + 85°C.

1.1 Capacitors may be operated to + 125°C with

voltage derating to two-thirds the + 85°C rating.

+ 85°C Rating + 125°C Rating

Working

Voltage

(V)

4

6.3

10

16

20

25

35

Surge

Voltage

(V)

5.2

8

13

20

26

32

46

Working

Voltage

(V)

2.7

4

7

10

13

17

23

Surge

Voltage

(V)

3.4

5

8

12

16

20

28

2. DC Working Voltage: The DC working voltage is the

maximum operating voltage for continuous duty at the

rated temperature.

3. Surge Voltage: The surge DC rating is the maximum

voltage to which the capacitors may be subjected

under any conditions, including transients and peak

ripple at the highest line voltage. 592D228X_6R3X2T

and 592D338X_6R3V2T, not surge voltage tesed.

3.1 Surge Voltage Test: Capacitors shall withstand

the surge voltage applied in series with a 33 ohm

± 5% resistor at the rate of one-half minute on,

one-half minute off, at + 85°C, for 1000 successive

test cycles.

3.2 Following the surge voltage test, the dissipation

factor and the leakage current shall meet the initial

requirements; the capacitance shall not have changed

more than ± 10%.

4. Capacitance Tolerance: The capacitance of all

capacitors shall be within the specified tolerance

limits of the normal rating.

- 55°C

- 10%

+ 85°C

+ 10%

+ 125°C

+ 12%

6. Dissipation Factor: The dissipation factor,

determined from the expression 2πfRC, shall not

exceed values listed in the Standard Ratings Table.

6.1 Measurements shall be made by the bridge method

at, or referred to, a frequency of 120 Hz and a

temperature of + 25°C.

7. Leakage Current: Capacitors shall be stabilized at

the rated temperature for 30 minutes. Rated voltage

shall be applied to capacitors for 5 minutes using a

steady source of power (such as a regulated power

supply) with 1000 ohm resistor connected in series

with the capacitor under test to limit the charging

current. Leakage current shall then be measured.

Note that the leakage current varies with temperature

and applied voltage. See graph below for the

appropriate adjustment factor.

TYPICAL LEAKAGE CURRENT FACTOR RANGE

100

+ 125°C

10

1.0

+ 85°C

+ 55°C

+ 25°C

0°C

4.1 Capacitance measurements shall be made by means

of polarized capacitance bridge. The polarizing

voltage shall be of such magnitude that there shall be

no reversal of polarity due to the AC component. The

maximum voltage applied to capacitors during

measurement shall be 2 volts rms at 120 Hz at +25°C.

If the AC voltage applied is less than one-half volt rms,

no DC bias is required. Accuracy of the bridge shall

be within ± 2%.

5. Capacitance Change With Temperature: The

capacitance change with temperature shall not exceed

the following percentage of the capacitance measured

at + 25°C:

www.vishay.com

80

For technical questions, contact tantalum@vishay.com

0.1

Leakage Current Factor

0.01

0.001

0 10 20 30 40 50 60 70 80 90 100

- 55°C

Percent of Rated Voltage

Document Number 40004

Revision 20-Oct-04

Page 8

PERFORMANCE CHARACTERISTICS (Continued)

592D

Vishay Sprague

7.1 At + 25

°C, the leakage current shall not exceed

the value listed in the Standard Ratings Table.

7.2 At + 85

°C, the leakage current shall not exceed 10

times the value listed in the Standard Ratings Table.

7.3 At + 125

°C, the leakage current shall not exceed 12

times the value listed in the Standard Ratings Table.

8. Equivalent Series Resistance: Measurements shall

be made by the bridge method at, or referred to, a

frequency of 100 KHz and a temperature of + 25°C.

8.1 The Equivalent Series Resistance shall not exceed the

value listed in the Standard Ratings Table.

9. Life Test: Capacitors shall withstand rated DC

voltage applied at + 85°C for 2000 hours or derated

DC voltage applied at + 125°C for 1000 hours.

9.1 Following the life test, the dissipation factor and

leakage shall meet the initial requirement; the

capacitance change shall not exceed ± 10% of the

initial value.

10 Humidity Test: Capacitors shall withstand 1000 hours

at + 40°C, 90% to 95% relative humidity, with no

voltage applied

10.1 Following the humidity test, capacitance change shall

not exceed ± 10% of the initial value, dissipation factor

shall not exceed 150% of the initial requirement;

leakage currrent shall not exceed 200% of the initial

requirement at + 25°C

11. Solderability: Capacitors will meet the solderability

requirements of ANSI/J-STD-002, test B category 1.

12. Resistance to Soldering Heat: Capacitors mounted

on a substrate will withstand + 260°C for 5 seconds.

12.1 Following the resistance to soldering heat test,

capacitance, dissipation factor and DC leakage

current shall meet the initial requirement.

13. Marking: The small body area of these capacitors

does not allow elaborate marking schemes. All

required information is present on the carton or

package in which the parts are shipped; in addition,

part number, quantity and data code are indicated on

the reels.

14. Terminal Strength: Per IEC-384-3, minimum of

5N shear force.

15. Environmental: Mercury, CFC and ODS materials

are not used in the manufacture of these capacitors.

16. Flammability: Encapsulant materials meet UL94 V0

17. Capacitor Failure Mode: The predominant failure

mode for solid tantalum capacitors is increased

leakage current resulting in a shorted circuit. Capacitor failure may result from excess forward or reverse

DC voltage, surge current, ripple current, thermal

shock or excessive temperature.

The increase in leakage is caused by a breakdown of

the Ta

dielectric. For additional information on

2O5

leakage failure of solid tantalum chip capacitors, refer

to Vishay Sprague Technical Paper, “Leakage Failure

Mode in Solid Tantalum Chip Capacitors.”

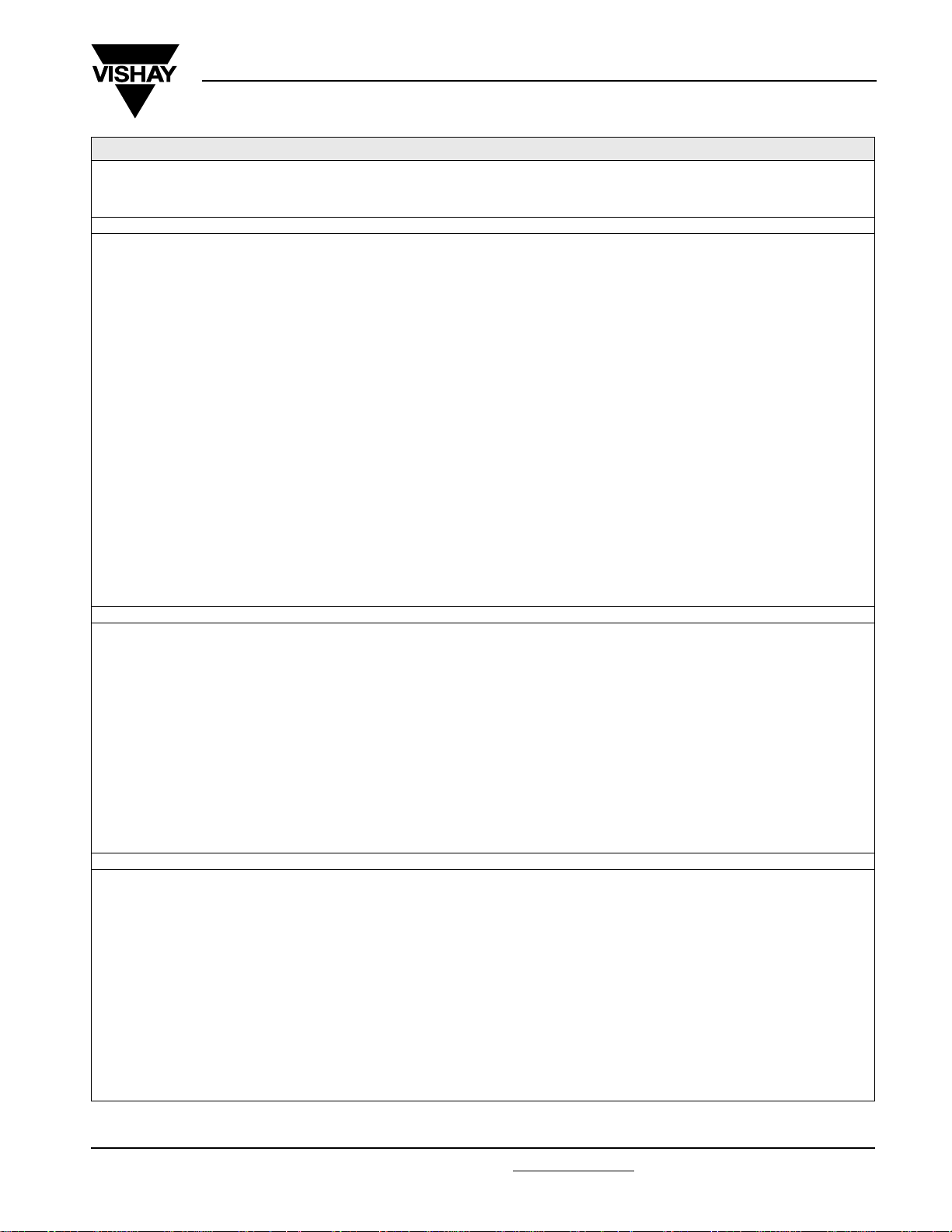

GUIDE TO APPLICATION

1.0 Recommended rated working voltage guidelines:

(-55°C to + 85°C)

Application Voltage Recommended

2. A-C Ripple Current: The maximum allowable ripple

current shall be determined from the formula:

where,

P = Power Dissipation in Watts @ + 25°C as given

in the table in Paragraph Number 6.0 (

Document Number 40004

Revision 20-Oct-04

(V) Capacitor Voltage

2.5 4

4 6.3

58

610

10 16

12 20

18 25

24 35

Rating (V)

P

I

rms

R

=

ESR

Power Dissipation)

For technical questions, contact tantalum@vishay.com

R

= The capacitor Equivalent Series Resistance

ESR

at the specified frequency.

3. A-C Ripple Voltage: The maximum allowable ripple

voltage shall be determined from the formula:

V

= Z

rms

P

R

ESR

or, from the formula:

V

= I

where,

rms

rms

x Z

P = Power Dissipation in Watts @ + 25°C as given in

the table in Paragraph Number 6.0 (Power

Dissipation).

R

= The capacitor Equivalent Series Resistance

ESR

at the specified frequency.

Z = The capacitor impedance at the specified

frequency.

www.vishay.com

81

Page 9

592D

Vishay Sprague

GUIDE TO APPLICATION (Continued)

3.1 The sum of the peak AC voltage plus the applied DC

voltage shall not exceed the DC voltage rating of the

capacitor.

3.2 The sum of the negative peak AC voltage plus the

applied DC voltage shall not allow a voltage reversal

exceeding 10% of the DC working voltage at + 25°C.

4.0 Reverse Voltage: These capacitors are capable of

withstanding peak voltages in the reverse direction

equal to 10% of the DC rating or 1 volt maximum at

+25°C and 5% of the DC voltage rating or 0.5 volt

maximum at + 85°C.

5.0 Temperature Derating: If these capacitors are to be

operated at temperatures above + 25°C, the

permissible rms ripple current or voltage shall be

calculated using the derating factors as shown:

Temperature Derating Factor

+ 25°C

+ 85°C

+ 125°C

6.0 Power Dissipation: Power dissipation will be

affected by the heat sinking capability of the mounting

surface. Non-sinusoidal ripple current may produce

heating effects which differ from those shown. It is

important that the equivalent

Irms

established when calculating permissible operating

levels. (Power dissipation calculated using + 25°C

temperature rise.)

Maximum Permissible

Case Code

A

B

C

D

R

S

T

U

V

W

X

Y

Power Dissipation

@ + 25°C (Watts) in free air

7.0 Printed Circuit Board Materials: The capacitors are

compatible with most commonly used printed circuit

board materials (alumina substrates, FR4, FR5,

G10, PTFE-fluorocarbon and porcelanized steel). If

your desired board material is not shown there please

contact the Tantalum Marketing Department for

assistance in determining compatibility.

8. Attachment:

8.1 Solder Paste: The recommended thickness of the

solder paste after application is 0.007" ± .001"

[.178mm ± .025mm]. Care should be exercised in

selecting the solder paste. The metal purity should

be as high as practical. The flux (in the paste) must

be active enough to remove the oxides formed on the

metallization prior to the exposure to soldering heat.

8.2 Soldering: Capacitors can be attached by

conventional soldering techniques - convection,

infrared reflow, wave soldering and hot plate methods.

1.0

0.9

0.4

value be

0.060

0.080

0.100

0.125

0.150

0.060

0.080

0.110

0.140

0.175

0.175

0.180

The Soldering Profile chart shows typical recomended

time/temperature conditions for soldering. Attachment

with a soldering iron is not recommended due to the

difficulty of controlling temperature and time at

temperature. The soldering iron must never come in

contact with the capacitor.

RECOMMENDED REFLOW SOLDERING PROFILE

250

200

150

100

50

TEMPERATURE DEG. CENTIGRADE

0 50 100 150 200 250 300 350

TIME (SECONDS)

9.0 Recommended Mounting Pad Geometries: The

nib must have sufficient clearance to avoid electrical

contact with other components. The width dimension

indicated is the same as the maximum width of the

capacitor. This is to minimize lateral movement.

REFLOW SOLDER PADS*

in inches [millimeters]

CASE WIDTH PAD SEPARATION

CODE (A) METALIZATION (C)

A 0.082 0.085 0.050

B 0.120 0.065 0.065

C 0.130 0.080 0.120

D 0.180 0.080 0.145

R 2.45 0.090 0.145

S 0.067 0.032 0.043

T 0.120 0.065 0.065

U 0.136 0.090 0.120

V 0.180 0.090 0.145

W 0.245 0.090 0.145

X 0.310 0.120 0.360

Y 0.310 0.120 0.360

* Pads for B, C and D case codes are otherwise pad compatible with

* Type 293D, B, C and D case codes respectively.

10.0 Cleaning (Flux Removal) After Soldering: The

592D capacitors are compatible with all commonly

used solvents such as TES, TMS, Prelete, Chlorethane,

Terpene and aqueous cleaning media. Solvents

containing methylene chloride or other epoxy solvents

should be avoided since these will attack the epoxy

encapsulation material.

B

C

B

A

[2.1] [1.7] [1.3]

[3.5] [1.7] [1.7]

[3.5] [2.3] [3.1]

[4.6) [2.3] [3.7]

[8.3] [2.3] [3.7]

[1.7] [0.8] [1.1]

[3.5] [1.7] [1.7]

[3.5] [2.3] [3.1]

[4.6) [2.3] [3.7]

[8.3] [2.3] [3.7]

[7.9] [3.0] [9.2]

[7.9] [3.0] [9.2]

www.vishay.com

82

For technical questions, contact tantalum@vishay.com

Document Number 40004

Revision 20-Oct-04

Page 10

TAPE AND REEL PACKAGING in inches [millimeters]

Top

Cover

Tape

Thickness

592D

Vishay Sprague

Standard orientation is with the

cathode (-) nearest to the

sprocket holes per EIA-481-1

and IEC 286-3.

Carrier

Embossment

Bending Radius

(Note 2)

R

Min.

Units Per Reel

Case Code

Tape

Width

Component

Pitch

7" [178]

Reel

13" [330]

Reel

A 8mm 4mm 2500 10000

B 12mm 4mm 2000 8000

C 12mm 8mm 1000 4000

D 12mm 8mm 1000 4000

R 12mm 8mm 1000 4000

S 8mm 4mm 2500 10000

T 12mm 8mm 2000 8000

U 12mm 8mm 1000 4000

V 12mm 8mm 1000 4000

W 12mm 8mm 1000 2500

X 24mm 12mm 500

Y 24mm 12mm 500

Document Number 40004

Revision 20-Oct-04

For technical questions, contact tantalum@vishay.com

www.vishay.com

83

Page 11

592D

Vishay Sprague

TAPE AND REEL PACKAGING in inches [millimeters]

Note: Metric dimensions will govern. Dimensions in inches are rounded and for reference only.

T

2

.024

[0.600]

Max.

B

Max.

1

(Note 6)

For Tape Feeder

Reference only

including draft.

Concentric around B

(Note 5)

Max.

.004 [0.10]

Max.

0

K

0

Top

Cover

Tape

Deformation

Between

Embossments

Top

Cover

Tape

.059 + .004 - 0.0

[1.5 + 0.10 - 0.0]

Center Lines

of Cavity

USER DIRECTION OF FEED

A

0

.157 ± .004

[4.0 ± 0.10]

B

0

P

1

10 Pitches Cumulative

Tolerance on Tape

± 0.008 [0.200]

.079 ± .002

[2.0 ± 0.05]

Maximum

Cavity Size

(Note 1)

Cathode (-)

Embossment

.030 [0.75]

Min. (Note 3)

.030 [0.75]

Min. (Note 4)

D1 Min. For Components

.079 x .047 [2.0 x 1.2] and Larger.

(Note 5)

.069

[1.75 ± 0.10]

F

W

± .004

20°

Maximum

Component

Rotation

(Side or Front Sectional View)

Anode (+)

DIRECTION OF FEED

B

0

A

0

(Top View)

TAPE

SIZE

8mm

12mm

12mm

Double Pitch

24mm

20° Maximum

Component Rotation

Typical

Component

Cavity

Center Line

Typical

Component

Center Line

B1 (Max.)

(Note 6)

0.179

[4.55]

0.323

[8.2]

0.323

[8.2]

0.791

[20.1]

3.937 [100.0]

.039 [1.0]

Max.

Tape

.039 [1.0] Max.

9.843 [250.0]

Camber

Allowable Camber to be .039/3.937 [1/100]

Non-Cumulative Over 9.843 [250.0]

(Top View)

D1 (Min.)

(Note 5)

0.039

[1.0]

0.059

[1.5]

0.059

[1.5]

0.059

[1.5]

F

0.138 ± 0.002

[3.5 ± 0.05]

0.217 ± 0.002

[5.5 ± 0.05]

0.217 ± 0.002

[5.5 ± 0.05]

0.453 ± 0.04

[11.5 ± 0.03]

Tape and Reel Specifications: All case sizes are available

on plastic embossed tape per EIA-481-1. Tape reeling per

IEC 286-3 is also available. Standard reel diameter is 7"

[178mm]. 13" [330mm] reels are available and recommended

as the most cost effective packaging method.

The most efficient packaging quantities are full reel increments

on a given reel diameter. The quantities shown allow for the

sealed empty pockets required to be in conformance with

EIA-481-1. Reel size and packaging orientation must be

specified in the Vishay Sprague part number.

1

0.157 ± 0.004

[4.0 ± 0.10]

0.157 ± 0.004

[4.0 ± 0.10]

0.315 ± 0.004

[8.0 ± 0.10]

0.472 ± 0.004

[12.0 ± 0.10]

R (Min.)

(Note 2)P

0.984

[25.0]

1.181

[30.0]

1.181

[30.0]

1.181

[30.0]

T

(Max.)

0.098

[2.5]

0.256

[6.5]

0.256

[6.5]

0.103

[2.6]

2

0.315 + .012 - .004

[8.0 + 0.3 - 0.1]

0.472 ± 0.012

0.472 ± 0.012

0.945 ± 0.012

W

[12.0 ± 0.30]

[12.0 ± 0.30]

[24.0 ± 0.03]

A0 B0 K

(Note 1)

Notes:

1. A0B0K0 are determined by the maximum dimensions to the ends of the terminals extending from the component body and/or the body

dimensions of the component. The clearance between the ends of the terminals or body of the component to the sides and depth of the

cavity (A0B0K0) must be within .002" [0.05mm] minimum and .020" [0.50mm] maximum. The clearance allowed must also prevent

rotation of the component within the cavity of not more than 20 degrees.

2. Tape with components shall pass around radius "R" without damage. The minimum trailer length may require additional length to

provide R minimum for 12mm embossed tape for reels with hub diameters approaching N minimum.

3. This dimension is the flat area from the edge of the sprocket hole to either the outward deformation of the carrier tape between the

embossed cavities or to the edge of the cavity whichever is less.

4. This dimension is the flat area from the edge of the carrier tape opposite the sprocket holes to either the outward deformation of the

carrier tape between the embossed cavity or to the edge of the cavity whichever is less.

5. The embossment hole location shall be measured from the sprocket hole controlling the location of the embossment. Dimensions of

embossment location and hole location shall be applied independent of each other.

6. B1 dimension is a reference dimension for tape feeder clearance only.

0

www.vishay.com

84

For technical questions, contact tantalum@vishay.com

Document Number 40004

Revision 20-Oct-04

Loading...

Loading...