Vintec V30SGMEBK User Manual

Armoire à vin.

Wine Preservation Technology

USER MANUAL

V26SG e SS/S3 models

V30SGme/AL/S3/BK models

V30SGe/AL/S3/BK models

V40SGe/AL/S3/BK models

V30SG2e/AL/S3/BK models

V40SG2e/AL/S3/BK models

V40DG 2e AL/S3/BK models

1 |

code: VIM 201301/S/01 |

WARNING

The information in this document is subject to modification without any prior notice.

Some models are available in dedicated countries only.

VINTEC offers no guarantee for our wine cellar if it is being used for any purpose other than that for which it was specifically designed. VINTEC cannot be held responsible for any error in this manual. VINTEC is not responsible or liable for any spoilage or damage to wines or any other contents incidental or consequential to possible defects of the wine cellar. Warranty applies to the wine cellar only and not to the content of the wine cellar.

This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

R600A WARNINGS

The following models use small quantity of R600A (iso-butane) flammable refrigerant:

AL/S3/BK: |

V30SGe |

– 30g |

V30SG2e |

– 30g |

AL/S3/BK: |

V40SGe |

– 35g |

V40SG2e |

– 35g |

AL/S3/BK: |

V40DG 2e |

– 45g |

V26SGe |

– 30g |

For your safety please observe the following recommendations :

This appliance contains a small quantity of R600A refrigerant which is environmentally friendly, but flammable. It does not damage the ozone layer, nor does it increase the greenhouse effect.

During transportation and installation, ensure that the tubing of the refrigerant circuit is not damaged.

Avoid using or manipulating sharp objects near by the appliances.

Leaking refrigerant can ignite and may damage the eyes.

In the event any damage does occur, avoid exposure to open fires and any device which creates a spark. Disconnect the appliance from the mains power.

Thoroughly ventilate the room in which the appliance is located for several minutes.

Notify Customer Service for necessary action and advice.

2 |

code: VIM 201301/S/01 |

The room for installing the appliance must be at least 1 cubic metre per 8 grams of refrigerant. The refrigerant quantity contained in this appliance is listed above in grams; it is also noted on the Rating Plate of the appliance.

It is hazardous for anyone other than an Authorised Service Person to carry out servicing or repairs to this appliance.

–WARNING: Keep ventilation openings in the appliance enclosure or in the built-in structure clear of obstruction.

–WARNING: Do not use mechanical devices or other means to accelerate the defrosting process, other than those recommended by the manufacturer.

–WARNING: Do not damage the refrigerant circuit.

–WARNING: Do not use electrical appliances inside the compartments.

–WARNING: In Queensland Australia, the authorized person must hold a Gas Work Authorisation for hydrocarbon refrigerants, before carrying out servicing or repairs which involve the removal of covers.

The environment and personal safety must be considered when disposing of this appliance. Please ensure the appliance is taken to a recycle center for safe recycling. DO NOT dispose of the appliance in land fill as the insulation and refrigerant gas contained in these appliances are flammable.

Allow 24 hours before switching on the wine cellar. During this time we recommend that you leave the door open to clear any residual odors.

BEFORE LOADING & PLUGGING IN THE WINE CELLAR

Important: All models without front venting (air opening) are strictly for free standing only. (See technical chart)

Recommendations:

The location you have selected for your wine cellar should:

-be unencumbered and well ventilated;

-be well away from any heat source and direct sunlight;

-not be too damp (laundry, pantry, bathroom etc.);

-have a flat floor;

-have a standard and reliable electricity supply (standard socket to country standards, linked to the ground), it is NOT recommended to use a multi-socket or extension lead;

-have a surge protector fitted to the electrical outlet;

-away from the microwave oven. Certain microwave ovens do not have wave interference

shield. When placed within 1 meter vicinity of the wine cabinet, they may affect the operation of the wine cabinet.

3 |

code: VIM 201301/S/01 |

Notes:

-V30 models are for free standing ONLY.

-V40 & V26 models are built-in type as per the drawings thereafter.

The wine cellar should be placed where the ambient temperature is between 5ºC to 35ºC. If the ambient temperature is above or below this range, the performance of the unit may be affected. Placing your unit in extreme cold or hot conditions may cause interior temperatures to fluctuate. The ideal range of temperature may not be reached. (See Climate Class at the end of this manual)

Grounding instructions

The wine cellar must be grounded in case of an electrical short circuit. Grounding reduces the risk of electrical shock. The wine cellar is equipped with a power cord having a grounding wire and plug. The wine cellar plug must be plugged into a properly affixed and grounded electrical outlet.

Note: In locations where there is frequent lightning, it is advisable to use surge protectors.

Improper use of the grounding plug can result in the risk of electric shock. Consult a qualified electrician or service person if the grounding instructions are not completely understood.

If the supply cord is damaged, it must be replace by a qualified person in order to avoid electrical hazard.

INSTALLING YOUR WINE CELLAR

Unpack and remove all of the protection and adhesive strips from the packaging around and inside the wine cellar.

The wine cellar must be positioned such that the plug is accessible. Release the power cord. Move your wine cellar to its final location. The wine cellar should be installed in a suitable place where the compressor will not be subject to physical contact.

Leveling your wine cellar: Wine cellar must be leveled BEFORE loading your wines. Your Vintec wine cellar is equipped with 4 adjustable feet to facilitate easy leveling. VINTEC recommends that you tighten the back feet to the maximum and adjust the front feet to level the wine cellar.

4 |

code: VIM 201301/S/01 |

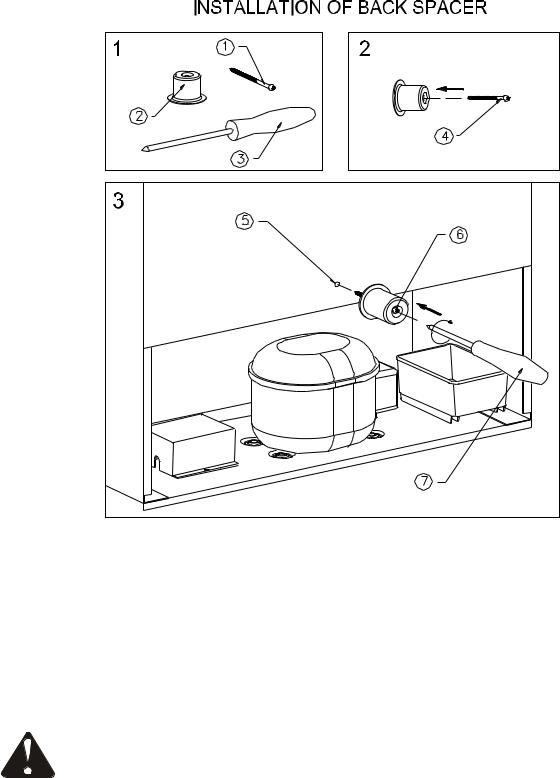

Fixing the Back spacer:

Compressor run appliances require proper ventilation for proper and longer usage. Your Vintec wine cellar is supplied with a back spacer. Affix the back spacer at the back of the cellar for air circulation and heat evacuation.

IMPORTANT - THIS SPACER MUST BE ATTACHED TO THE UNIT BEFORE

THE INSTALLATION, FOR VENTILATION PURPOSE. FAILURE TO DO SO VOIDS THE

WARRANTY

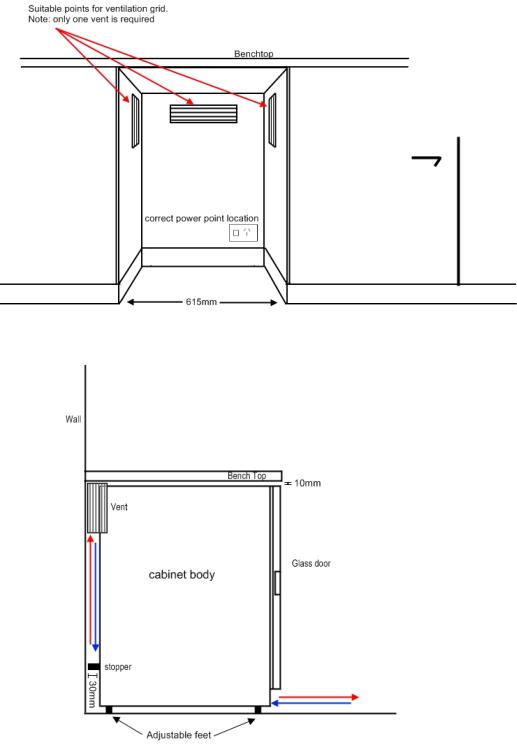

INSTALLATION INSTRUCTIONS FOR BUILT IN WINE CELLARS:

(UNDERBENCH OR IN COLUMN) FRONT VENTING WINE CELLARS ONLY.

V30 models are free standing only. Any built in voids the warranty

5 |

code: VIM 201301/S/01 |

1.Vintec “Built in” wine cellars are front venting but are not designed to be fully integrated behind a joinery door.

2.Vintec “Built in” wine cellars require 10mm clearance on both sides and top, 30mm clearance at the rear (Back spacer is provided),to facilitate installation, removal, servicing and ventilation.

3.Vintec “Built in” wine cellars draw air from the rear and expels through the metal grid under the door at the front. If a kick board is to be placed in front of the wine cellar’s grid another one must be fitted into the kick board with a minimum air flow allowance of 150cm2.

4.Vintec “Built in” wine cellars have a power switch located on the control panel so power point location is not critical.

5.The wine cellar requires a standard 240 volt/10 amp power point. (Or according to different countries specifications).

6.The power cord is 1.9m in length and is fixed on the right side at the back when looking from front of cabinet.

7.As with most appliances of today, the wine cellar has sensitive electronic components which are susceptible to damage through lightning and electricity supply faults. It is therefore advised to use a power surge protector to avoid problems of this nature.

8 Air vent within the joinery must be provided for Vintec built in wine cellars (front venting)

In Hot climate zone, an air vent or grid, with a minimum ventilation size of 200mm x 40mm MUST be cut out at the rear top of the back partitioning or at the top of either side of the partitioning, allowing cool fresh air full access to flow into the 30mm gap located at the rear of the cabinet.

This air vent or grid must not be opened on the same side as other appliances such as ovens or an area that is sealed and without access to fresh cool air. Failing to comply with the above specifications could result in WARRANTY void.

6 |

code: VIM 201301/S/01 |

INSTALLATION DRAWINGS FOR BUILT IN WINE CELLARS: (UNDERBENCH OR IN COLUMN) FRONT VENTING WINE CELLARS ONLY.

|

|

|

|

|

|

|

|

|

|

|

|

7 |

|

code: VIM 201301/S/01 |

|

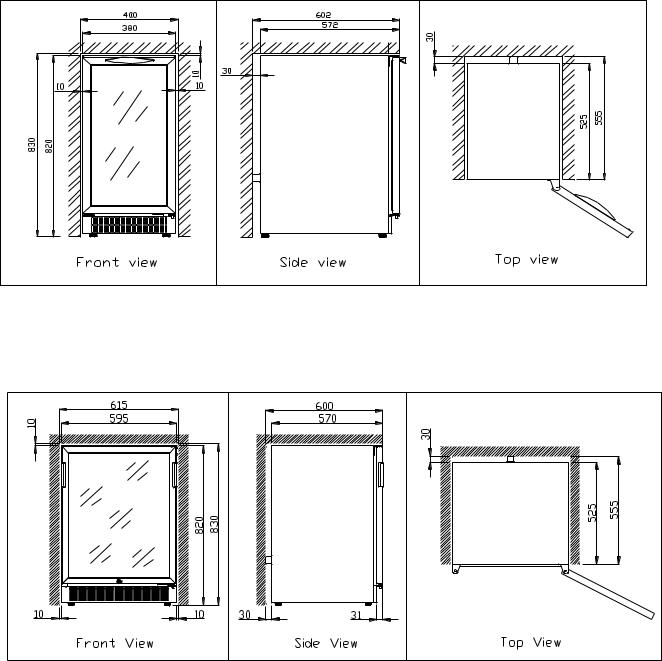

Dimensional drawings:

V26’s |

V40’s (30mm recess plinth)

8 |

code: VIM 201301/S/01 |

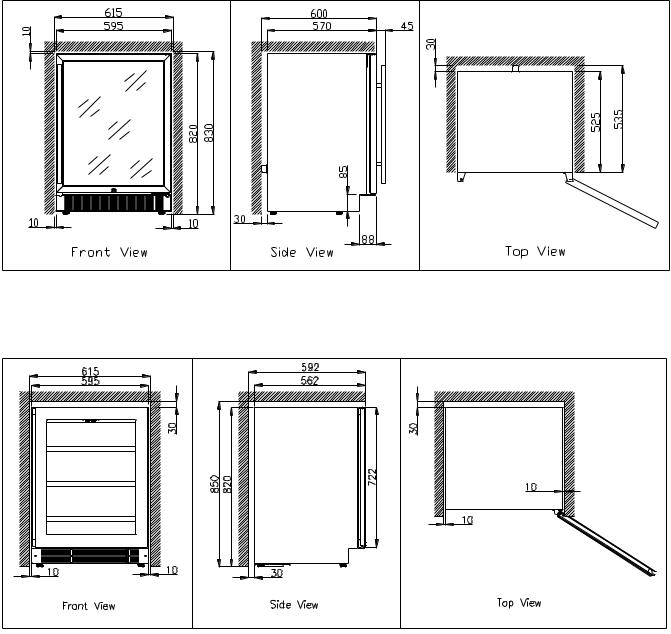

V40’s (85mm recess plinth)

V40 S3/BK models |

TURNING ON YOUR WINE CELLAR

Plug in and switch on the cellar by pressing on the power button for a few seconds. When you use the wine cellar for the first time (or restart the wine cellar after having it shut off for a long time), there will be a few degrees variance between the temperature you have selected and the one indicated on the LED readout. This is normal and it is due to the length of the activation time. Once the wine cellar is running for a few hours everything will stabilize.

Important: If the unit is unplugged, power is lost, or turned off, wait 3 to 5 minutes before restarting the unit. The wine cellar will not start if you attempt to restart before this time delay.

9 |

code: VIM 201301/S/01 |

Loading...

Loading...