Page 1

V150 SG2E / V190 SG2E

Instructionsforuse

Page 2

GB

Warning.

In case this appliance contains hydrocarbon refrigerant please refer to guidelines

listed below.

As the appliance contains a ammable

refrigerant, it is essential to ensure that the

refrigerant pipes are not damaged.

Standard EN378 species that the room in

which you install your appliance must have

a volume of 1m³ per 8 g of hydrocarbon

refrigerant used in the appliances. This is

to avoid the formation of ammable gas/

air mixtures in the room where the appliance is located in the event of a leak in the

refrigerant circuit. The quantity of the refrigerant used in your appliance is indicated on

the rating plate.

WARNING: Keep ventilation openings in

the appliance’s cabinet or in

the built-in structure clear of

obstruction

WARNING: Do not use other mechanical

devices or other means to ac-

celerate the defrosting process

than those recommended by

the manufacturer

WARNING: Do not damage the refrigerant

system

WARNING: Do not use electricalappli-

ances inside the refrigerated

storage compartment, unless

they are of a type recommended by the manufacturer

WARNING: Do not expose the appliance

to rain

WARNING: This appliance is not intended

for use by young children or

inrm persons unless they have

been adequately supervised by

a responsible person to ensure

that they can use the appliance

safely. Young children should

be supervised to ensure that

they do not play with the appliance

● Always keep the keys in a separate place

and out of reach of children

● Before servicing or cleaning the appliance, unplug the appliance from the

mains or disconnect the electrical power

supply

● If the supply cord is damaged, it must be

replaced by the manufacturer, its service

agent, or similarly qualied persons in

order to avoid a hazard

● RelevantforAustralia: Supply cord

tted with a plug complies with AS/NZS

3112.

● Frost formation on the interior evaporator

wall and upper parts is a natural phenomenon. Therefore, the appliance should

be defrosted during normal cleaning or

maintenance

● Please note that changes to the appliance construction will cancel all warranty

and product liability

CLASS 1 LED PRODUCT

2

Page 3

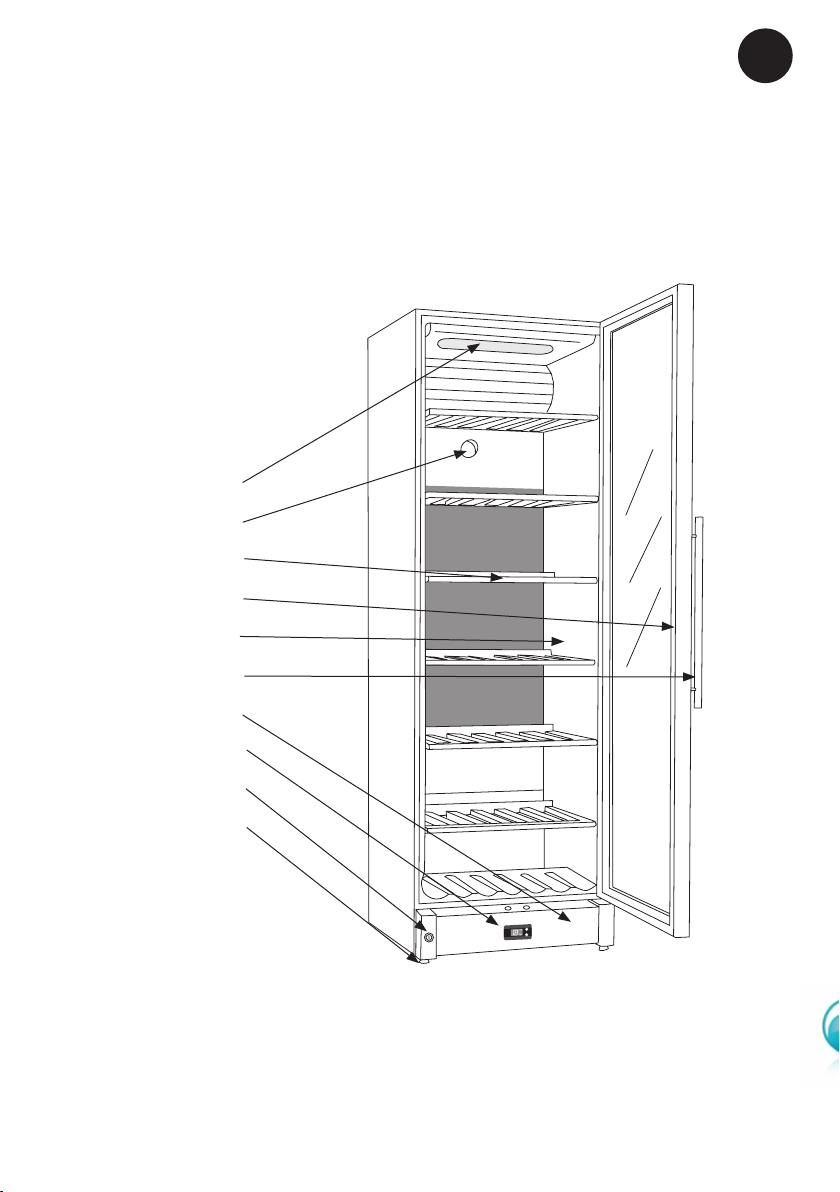

Gettoknowyourwinecooler

Lighting

Charcoal lter

Wooden shelf

Sealing strip

Nameplate

GB

Door handle

Kick plate

Control panel

Lock

Adjustable feet

g.1

3

Page 4

GB

Contents

Warning ..................................................2

Get to know your wine cooler. ................3

Before use. .............................................4

Installation and start-up ..........................4

Technical data. .......................................7

Reversible door ......................................8

Operation and function .........................10

Defrosting, cleaning and

maintenance ......................................... 12

Fault nding .......................................... 13

Warranty, spare parts and service ........ 14

Disposal ................................................15

Beforeuse.

On receipt, check to ensure that the appliance has not been damaged during

transport. Transport damage should be

reported to the local distributor before the

wine cooler is put to use.

Remove the packaging. Clean the inside of

the cabinet using warm water with a mild

detergent. Rinse with clean water and dry

thoroughly (see cleaning instructions). Use

a soft cloth.

If during transport the appliance has been

laid down, or if it has been stored in cold

surroundings (colder than +5°C), it must be

allowed to stabilise in an upright position for

at least an hour before being switched on.

Installationandstart-up.

Placement.

For safety and operational reasons, the appliance must not be installed outdoors.

The appliance should be placed on a level

surface in a dry, well ventilated room (max.

75% relative air humidity). Never place the

appliance close to sources of heat such as

cookers or radiators, and avoid placing it in

direct sunlight.

Ambienttemperature.

The climate class is stated on the nameplate (see page 7 and page 13). This species

the optimum ambient temperature. Wine

coolers with winter position, however, function at ambient temperatures as low as 5ºC.

Climateclass Optimumroomtem-

perature

SN +10 ºC to +32 ºC

N +16 ºC to +32 ºC

ST +18 ºC to +38 ºC

T +18 ºC to +43 ºC

Installation

The surface on which the appliance is to be

placed must be level. Do not use a frame or

similar.

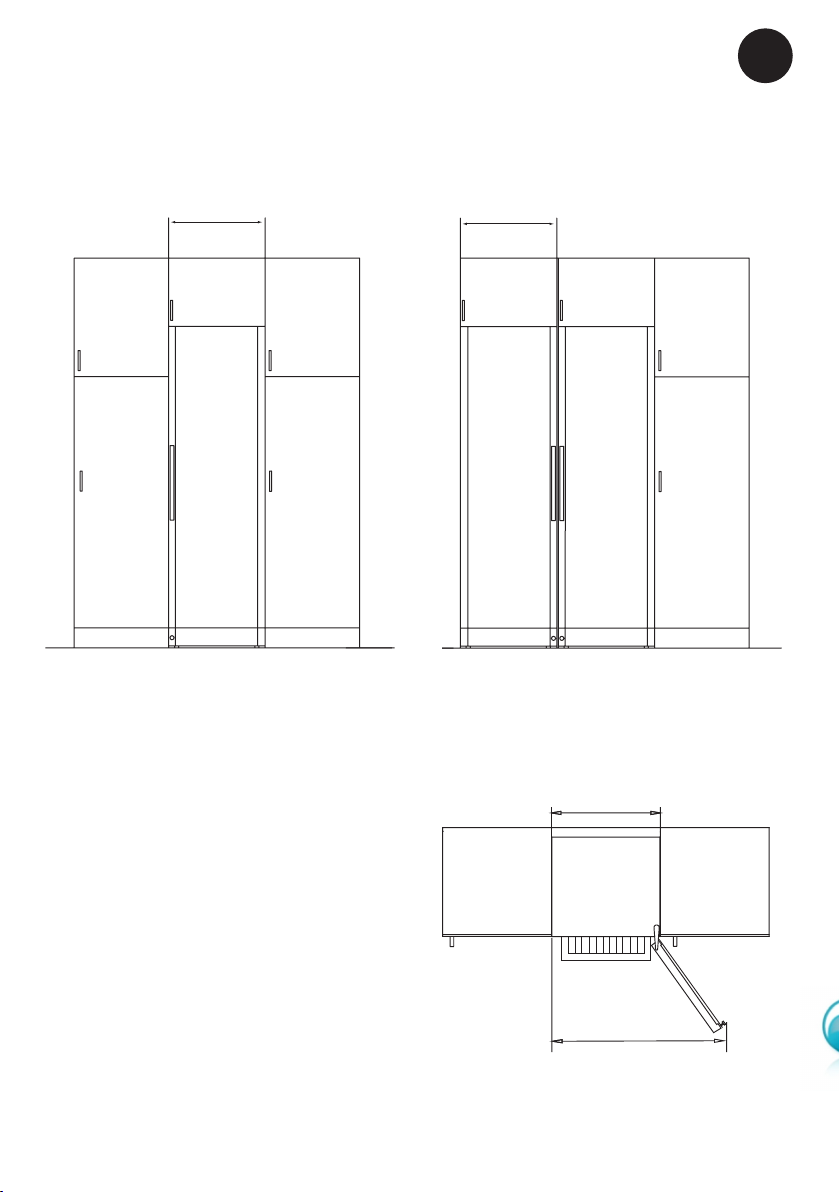

The appliance can be installed as a freestanding unit against a wall, built into a

kitchen element, or lined up with other appliances (gs 2-3).

4

Page 5

GB

600

600

600

600

600

600

g. 2

600

g. 3

Theapplianceviewedfrom

above.

If the app.liance is placed beside a wall,

there must be sufcient room for its door to

be opened wide enough to allow the shelves to be pulled out (g. 4).

1075

g. 4

5

Page 6

GB

100

Ventilation.

It is important that the appliance be well

ventilated and that air can circulate unhindered above, below and around it.

The gures below illustrate how the necessary air circulation around the appliance

can be ensured (gs 5-6).

100

The distance pieces on the rear of the appliance ensure sufcient air circulation. Fit

the two caps supplied with the appliance as

shown in g. 7.

1650/1950

g. 5

1560/1860

g. 6

g. 7

6

Page 7

Settingup.

It is important that the appliance be absolutely level. It can be levelled by screwing the

adjustable feet at the front of the appliance

up or down (gs 8-9).

Use a spirit level to check that the appliance

is absolutely level sideways.

Technicaldata.

This device complies with relevant EU

directives including Low Voltage Directive

2006/95 EEC. and Electromagnetic Compatibility Directive 2004/108/EC

The rating plate provides various technical information as well as type and serial

number.

GB

g. 8

Max. 20 kg.

7

Page 8

GB

GB

Reversibledoor.

The door can be changed from right-hinged to left-hinged and vice versa as follows:

1. Lay the appliance on its back

and loosen the upper hinge.

4. You will need to remove the magnet on the underside of the door by depressing the clips in pulling the

magnet away from the door. Also with a small Philips head screwdriver remove the Vintec logo badge

and swap the magnet where the badge was and vice versa.

5. Remove the top and bottom bushes on the door frame (the bushes are the black, round plastic pieces

which t into the top and bottom hinges) and swap them så that the bush which was on top is now on

bottom and vice versa.

6. Carefully remove the covers

on the side of the plinth using

a at-headed screwdriver.

2. Remove the upper hinge.

6. Pull up the hinge pin...

...and t it on the opposite side.

3. Rotate the glass door through

180° (on FZ 295 W, pull the

handle to loosen it on the inside from beneath the sealing

strip).

7. Unscrew the lock pin using a

at-headed screwdriver.

8

Page 9

GB

8. When the lock pin has been

loosened completely, pull

it up together with the lock

cylinder and ret on opposite

side.

11. After reversing the door, it is important to check that the sealing strip provides a tight seal all the way

round. If it does not, carefully heat the strip all the way round using a hair dryer. Then ease the strip

outwards slightly so that it forms a tight seal against the cabinet. Be careful not to heat the strip so

much that it melts!

9. Click the covers into place

on the plinth sides on the opposite side.

10. Fit the door onto the bottom

pin, t the top hinge and

tighten securely.

9

Page 10

GB

Operationandfunction.

g. 9

Electroniccontrol

The electronic control ensures that the

temperatures set at the top and at the bottom of the appliance are maintained. This is

achieved by means of an advanced control

of the refrigeration system, the heating element, and the fan. The set temperature will

be stored in the event of power failure.

The electronic control has the following

functions:

● On/off switch

● Light switch*

● Temperature setting

● Temperature indication

● Alarm for too high and too low tempera-

tures

* The light may either be turned on

constantly or only when the door is open.

Temperatureindication

The display shows the actual temperature.

The upper digits of the display indicate the

temperature at the top of the appliance, and

the lower digits of the display indicate the

temperature at the bottom of the appliance.

The temperature indicator is equipped with

a built-in lter which simulates the actual

temperature in the bottles. Consequently,

the indicator does not react on short-term

uctuations of the air temperature

Temperaturesetting

The thermostat is equipped with a child lock

device. This device is activated by pushing

the “up and down” buttons simultaneously.

After approx. 3 seconds “Pof” ashes in the

display. Then the actual temperatures are

shown as usual. In addition, the set temperatures can be shown by pushing SET1 and

SET2, respectively.

The child lock device is cancelled by

pushing the “up and down” buttons simultaneously. After approx. 3 seconds “Pon”

ashes in the display, and the temperature

can be set.

Temperaturesettingatthetop

oftheappliance

Push SET1. Then the temperature at the

top of the appliance can be adjusted up and

down by means of the “up and down” buttons. The temperature can be adjusted from

8 to 22°C, however so that the temperature

cannot be set at a lower temperature than

the actual set point for the bottom temperature sensor.

10

Page 11

GB

Temperaturesettingatthebottomoftheappliance

Push SET2. Then the temperature at the

bottom of the appliance can be adjusted up

and down by means of the “up and down”

buttons. The temperature can be adjusted

from 5 to 22°C, however so that the temperature cannot be set at a higher temperature than the actual set point for the upper

temperature sensor.

Alarmdevices

There is a sub-alarm for the low-temperature sensor and an excess-alarm for the

high-temperature sensor.

The alarm consists of a beeper and a warning on the display.

Alarm for high temperature: beep sound

+ alternating display of “Hi” and actual

temperature

Alarm for low temperature: beep sound +

alternating display of “Lo” and actual temperature

The alarm temperature depends on the set

points. However, at position 5 of the subalarm is always 3 degrees. It is activated if

the temperature has been below 3°C for 10

minutes.

The beep sound can be cancelled by

pushing a random thermostat button. Push

the on/off button to erase the display alarm,

rst for cancelling the alarm, then again for

restarting the compressor.

Light

When you open the door of your cabinet,

the lights turn on in the winecooler.

In the temperature display image is

displayed when the light is lit.

To turn off the lights, press once

Permanentlighting

For presentation purposes of your wine,

you can turn the lights permanently. Please

press the light switch image twice. To

switch off the lights press on again.

Two-zonesettingforserving

temperature

Typical serving temperature settings for the

top and bottom sections are 16°C and 6°C

respectively. With these settings, a suitable

temperature gradient will be achieved in

the cabinet for the storage of various types

of wine distributed from top to bottom as

follows:

● heavy red wines +16 to +19°C

● rosé and light red wines +12 to +16°C

● white wines +10 to +12°C

● champagne and sparkling wines +6 to

+8°C

It is recommended that wine be served at a

temperature which is a couple of degrees

lower than the desired drinking temperature

as the wine will be warmed slightly when it

is poured into the glass.

Single-zonesettingforlongtermstorage

For long-term wine storage, the top and bottom sections should both be set at 12°C.

With identical settings for the top and bottom sections, the controls will maintain an

even temperature throughout the cabinet.

However, the temperature in the room will

gradually affect the temperature in the

11

Page 12

GB

Defrosting,cleaning

andmaintenance.

cabinet through its door and sides, creating

a slight temperature gradient from top to

bottom. The controls will maintain the set

temperature at the bottom of the cabinet,

and any deviation from the setting will

therefore occur at the top.

The difference will vary from 0 to 3°C, depending on the ambient temperature.

Automaticdefrosting.

The wine cooler is defrosted automatically.

Defrost water runs through a pipe and is

collected in a tray above the compressor

where the heat generated by the compressor causes it to evaporate. The defrost

water tray should be cleaned at intervals.

Cleaning.

Before cleaning the appliance, unplug it

from the main supply. The cabinet is best

cleaned using warm water (max. 65°C) with

a little mild detergent. Never use cleaning

agents that scour. Use a soft cloth. Rinse

with clean water and dry thoroughly. The

defrost water channel, in which condensation from the evaporator runs, is located

at the bottom of the rear inside wall of the

cabinet and must be kept clean. Add a few

drops of disinfectant, e.g. Rodalon, to the

defrost water drain a couple of times a year,

and clean the drain using a pipe cleaner or

similar. Never use sharp or pointed implements.

The sealing strip around the door must be

cleaned regularly to prevent discolouration

and prolong service life. Use clean water.

After cleaning the sealing strip, check that it

continues to provide a tight seal.

Dust collecting on the condenser on the

rear of the cabinet, the compressor and in

the compressor compartment is best removed using a vacuum cleaner.

12

Page 13

Faultnding.

Fault Possiblecause Remedy

The appliance is not

working.

Water collects in

the bottom of the

cabinet.

Vibration or

bothersome noise.

The appliance is switched off.

Power failure; the fuse is blown;

the appliance is not plugged in

correctly.

The defrost water pipe is

blocked.

The appliance is not level.

The appliance is resting against

other kitchen elements.

Press the on/off switch.

Check that power is connected.

Reset the fuse.

Clean the defrost water channel

and the drain hole on the rear

wall of the cabinet.

Level the appliance using a spirit

level.

GB

Compressor runs

continuously.

P1 is shown on the

display.

P2 is shown on the

display.

Containers or bottles inside the

cabinet are rattling against one

another.

High room temperature. Ensure adequate ventilation.

The upper sensor is disconnected or short-circuited.

The lower sensor is disconnected

or short-circuited.

Move the appliance away from

the kitchen elements or appliances it is in contact with.

Move containers and/or bottles

apart.

Call for service. The temperature

within the entire cabinet is maintained at the higher of the two

setpoints until the fault has been

corrected.

Call for service. The temperature

within the entire cabinet is maintained at the higher of the two

setpoints until the fault has been

corrected.

13

Page 14

GB

Warranty,sparepartsandservice.

Warrantydisclaimer

Faults and damage caused directly or

indirectly by incorrect operation, misuse,

insufcient maintenance, incorrect building,

installation or mains connection. Fire, accident, lightening, voltage variation or other

electrical interference, including defective

fuses or faults in mains installations.

Repairs performed by others than approved

service centres and any other faults and

damage that the manufacturer can substantiate are caused by reasons other than

manufacturing or material faults are not

covered by the warranty.

Please note that changes to the construction of the appliance or changes to the

component equipment of the appliance will

invalidate warranty and product liability, and

the appliance cannot be used lawfully. The

approval stated on rating plate will also be

invalidated.

Transport damage discovered by the buyer

is primarily a matter to be settled between

the buyer and the distributor, i.e. the distributor must ensure that such complaints are

resolved to the buyer’s satisfaction.

Before calling for technical assistance,

please check whether you are able to rectify

the fault yourself. If your request for assistance is unwarranted, e.g. if the appliance has failed as a result of a blown fuse

or incorrect operation, you will be charged

the costs incurred by your call for technical

assistance.

Spareparts

When ordering spare parts, please state

the type, serial and product numbers of

your appliance.This information is given on

the rating plate. The rating plate contains

various technical information, including type

and serial numbers.

Product numbers

14

Page 15

Disposal

GB

Information for Users on Collection

and Disposal of Old Equipment and

used Batteries

These symbols on the products,

packaging, and/or accompanying

documents mean that used electrical and electronic products and

batteries should not be mixed with

general household waste. For proper

treatment, recovery and recycling

of old products and used batteries,

please take them to applicable collection points, in accordance with your

national legislation and the Directives

2002/96/EC and 2006/66/EC.

By disposing of these products and

batteries correctly, you will help to

save valuable resources and prevent

any potential negative effects on

human health and the environment

which could otherwise arise from

inappropriate waste handling.

For more information about collection and recycling of old products and

batteries, please contact your local

municipality, your waste disposal

service or the point of sale where you

purchased the items.

Penalties may be applicable for incorrect disposal of this waste, in accordance with national legislation.

ForbusinessusersintheEuropeanUnion.

If you wish to discard electrical and

electronic equipment, please contact

your dealer or supplier for further

information.

[InformationonDisposalinother

CountriesoutsidetheEuropean

Union]

These symbols are only valid in the

European Union. If you wish to discard this product, please contact your

local authorities or dealer and ask for

the correct method of disposal.

Noteforthebatterysymbol(bottomtwosymbolexamples):

This symbol might be used in combination with a chemical symbol. In this

case it complies with the requirement

set by the Directive for the chemical

involved.

15

Page 16

Reserving the right to alter specications without prior notice.

0-9193127-02

Loading...

Loading...