Vinotemp VINO-6500SSR, VINO-2500SSR User Manual

VINO-2500SSR

VINO-4500SSR

VINO-6500SSR

Installer’s Instruction

Federal law requires that WINE-MATE split cooling systems be

installed by an EPA certified refrigeration technician.

WINE-MATE split system is shipped as components and is ready for use only

after a certified refrigeration technician has properly installed, charged and tested

the system. Proper installation is critical. Vinotemp can only warrant the quality of

the components. The installation and proper operation of the system must be

warranted by the installer. Installation of the system must be done in accordance

with all state and local building codes.

The condensing unit and evaporator unit are connected by a liquid line and an

insulated suction line that are supplied by the installer. These lines must be

properly sized for the distance between the two units. After the units and the lines

are installed, the system must be pressure tested. If no leaks are found,

evacuate and charge system with R134A. Refrigerant amount will vary

depending on the length of line set.

1. Condensing Unit

• Place the condensing units WM250-650SCU in a properly ventilated

location. If it is not, heat exhausted by the condensing unit will build up

and the cooling system will not operate properly.

• Leave minimum 5 feet clearance for the exhaust side and leave minimum

1 foot clearance for the fresh air intake side.

• Condensing unit shall be elevated to avoid possible flooding and shaded

from direct sun. It shall not be exposed to temperatures higher than 110

°F or lower than 45 °F (optional low ambient kit for 20 °F).

2. Evaporator Unit

• The WM25-45SFCR evaporator units shall be installed for rack mount with

the air supply from the left front, top or side and air return on the right

front, top or side.

• Supply and return air flow from the evaporator unit shall be unobstructed

for at least 1 foot.

• There is a gravity drain line so that it can not be installed above the

evaporator unit. Otherwise a condensation pump must be used.

3. Air Sensor

• The air sensor can be located in the wine room or the return air area, but

not the supply air area.

4. Refrigeration Piping and Charging

NOTES: ALWAYS USE THE SUPERHEAT AND SUBCOOLING,

PRESSURE READINGS TO CHARGE REFRIGERANT PROPERLY, THE

LISTED CHARGES ARE FOR REFERENCE ONLY.

• The installation order starts from condensing unit (including the receiver),

liquid line filter-drier, moisture-liquid indicator (sight glass), liquid line,

evaporator unit (including liquid line solenoid valve and thermostatic

expansion valve or automatic expansion valve), suction line, and returning

to condensing unit.

• The subcooling at the condensing unit shall be around 10° F. The charge

may be complete when there are no more bubbles forming in the sight

glass.

• The evaporator’s constant pressure expansion valve is set around 38-

°F at factory. This pressure setting gives a dew point to maintain the

40

humidity for storing wine.

• The superheat at the evaporator unit shall be around 9-18°F under low

and high load at 75°F ambient temperature.

• Low side pressure: 33 psig

• High side pressure 130 -150 psig at 75 -90 °F ambient temperatures

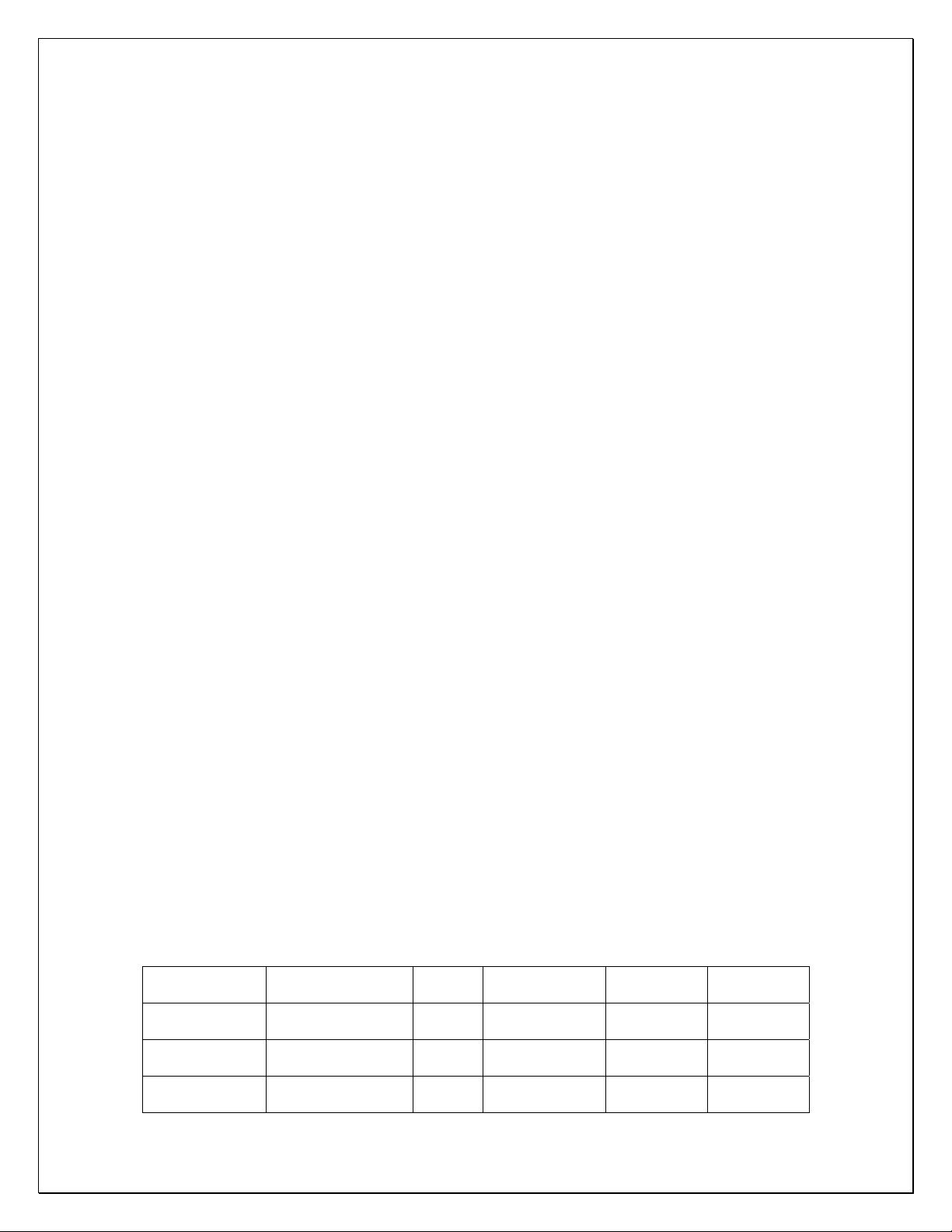

The line sizes and refrigerant charges are listed as follows.

MODEL

VINO-

2500SSR

VINO-

4500SSR

VINO-

6500SSR

REFRIGERATION

LINES

< 50 FT

< 50 FT

< 50 FT

LIQUID

LINE

1/4"

OD

1/4"

OD

1/4"

OD

SUCTION

LINE

3/8” OD 1/2” OD

1/2” OD 1/2” OD

5/8” OD 1/2” OD

DRAIN

LINE

CHARGE

R134a/

20 OZ

R134a/

26 OZ

R134a/

32 OZ

- 1 -

Loading...

Loading...