Viking Commercial V72CMW Installation Manual

Installation, Operation & Owners Guide

Models

Cheesemelter

VxxCM Series

Salamander Broiler

V36SM

Greenwood, MS 38930

(877) 307-8877

RETAIN THIS MANUAL FOR FUTURE REFERENCE

016283-000 (07/09)

©2009 Viking Commercial Division

Viking Range Corporation

Commercial Products Div.

111 Front Street

IMPORTANT FOR YOUR SAFETY… ….….

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO

INSTALL GAS EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD

START-UP AND ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS

MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE

FOLLOWED IN THE EVENT THE SMELL OF GAS IS DETECTED. THIS

INFORMATION CAN BE OBTAINED FROM THE LOCAL GAS SUPPLIER.

IMPORTANT…… .…

IN THE EVENT A GAS ODOR IS DETECTED, SHUT DOWN UNITS AT MAIN

SHUTOFF VALVE AND CONTACT THE LOCAL GAS COMPANY OR GAS

SUPPLIER FOR SERVICE.

FOR YOUR SAFETY… ….,,,

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

WARNING… ….…

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR

MAINTENANCE CAN CAUSE PROPERTY DAMAGE, INJURY OR DEATH.

READ THE INSTALLATION, OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR SERVICING THIS

EQUIPMENT.

IN THE EVENT OF A POWER FAILURE, DO NOT ATTEMPT TO OPERATE

THIS DEVICE.

©2009 Viking Commercial Division

2

Table of Contents

Section 1: Installation …

Appliances Equipped with Casters

Electrical Supply

Gas Supply

Gas Pressure Regulator ……………………………………………………………… 8

Installation Procedure

Clearances ……………………………………………………………………………... 4

Data Plate Location ………………………………………………………………........ 5

Location ………………………………………………………………………………… 4

Riser …………………………………………………………………………………….. 5

Uncrating …………………………………………………………….………………… . 4

Leveling

Statutory Regulations

Canada ………………………………………………………………………….......... 6

United States of America …………………………………………………………….. 6

Ventilation Air

………………………………………………………………………………………… 4

………………………………………………………………………………. 9

..…………………………………………………………………………………….. 7

……………………………………………………………….……….. 4

……………………………………………………………………….. 6

…………………………………………………………………………………. 9

Section 2: Operator Instructions

Lighting Instructions …………………………………………………………………………. 10

Cheesemelter .………………………………………………………………………… 10

Salamander …………………………………………………………………………… 10

Section 3: Cleaning and Maintenance

Cheesemelter ………………………………………………………………………… 11

Salamander …………………………………………………………………………… 11

Service ………………………………………………………………………………… 11

Section 4: Warranty …

…………………………………………………………….. 4

.…….…………………………………………………. 6

................................................................... 10

………………………………………… 11

……………………………………………………………… 12

©2009 Viking Commercial Division

3

Installation

Installation Procedure

Uncrating

Check the crate for any possible damage sustained during transit. Carefully remove the

appliance, removing all packing material, again check for damage. Any damage to the appliance

must be reported to the carrier immediately.

Location

Proper placement of the appliance will ensure operator convenience and satisfactory

performance. Adequate clearance must be maintained so that the combustion and ventilation air

is not obstructed for proper operation. A minimum front clearance of 36 inches (914 mm) must be

provided for servicing. The appliance must be kept free and clear of combustible materials.

Placing Appliance

Both the Cheesemelter and Salamander Broiler can be wall mounted, range mounted or mounted

on an island cooking suite.

Never install a Cheesemelter or Salamander over a Broiler, could cause

damage to unit and will void the warranty.

Clearances

The following minimum clearances must be followed:

COMBUSTIBLE NON-COMBUSTIBLE

Model BACK SIDE BACK SIDE

V36SM 6” 16” 0 0

VxxCM 6” 16” 0 0

Important

Leveling

For proper and safe operation each appliance must be level.

Wall mounted appliances; wall bracket must be mounted level, horizontally, on a wall that will

adequately support the weight of the appliance; appliance will sit level on bracket horizontally.

See instructions that come with wall bracket.

Counter model only; Legs are mounted using four hex head bolts per leg and each leg is

adjustable simply by turning the inner cylinder leg, clockwise to lower and counter clockwise to

elevate. A carpenter’s level can be used on the top for leveling.

When mounted on an oven or cabinet base; legs are mounted using four hex head bolts per leg

and each leg is adjustable simply by turning the inner cylinder leg, clockwise to lower and counter

clockwise to elevate.

Minimum clearance from the bottom of the Cheesemelter or Salamander to a

cooking surface is 18”.

©2009 Viking Commercial Division

4

Optional; casters are mounted using four hex head bolts per caster; locking casters must be

installed on the front and non-locking on the back. Adjustable casters, the unit can be leveled by

loosening the two set screws in the collar on each caster and turning the collar clockwise to lower

and counter clockwise to elevate. Be sure to retighten the two set screws on each caster when

unit is level to maintain proper adjustment.

Note:

When mounted on an oven or cabinet base a carpenter’s level can be used on the plate shelf for

left to right leveling, if the unit has Open Burners, French top, Hot Top, Work Top or Griddle a

level can be placed on the flat top surface for front to rear leveling; on units with broilers use the

oven rack for front to rear leveling.

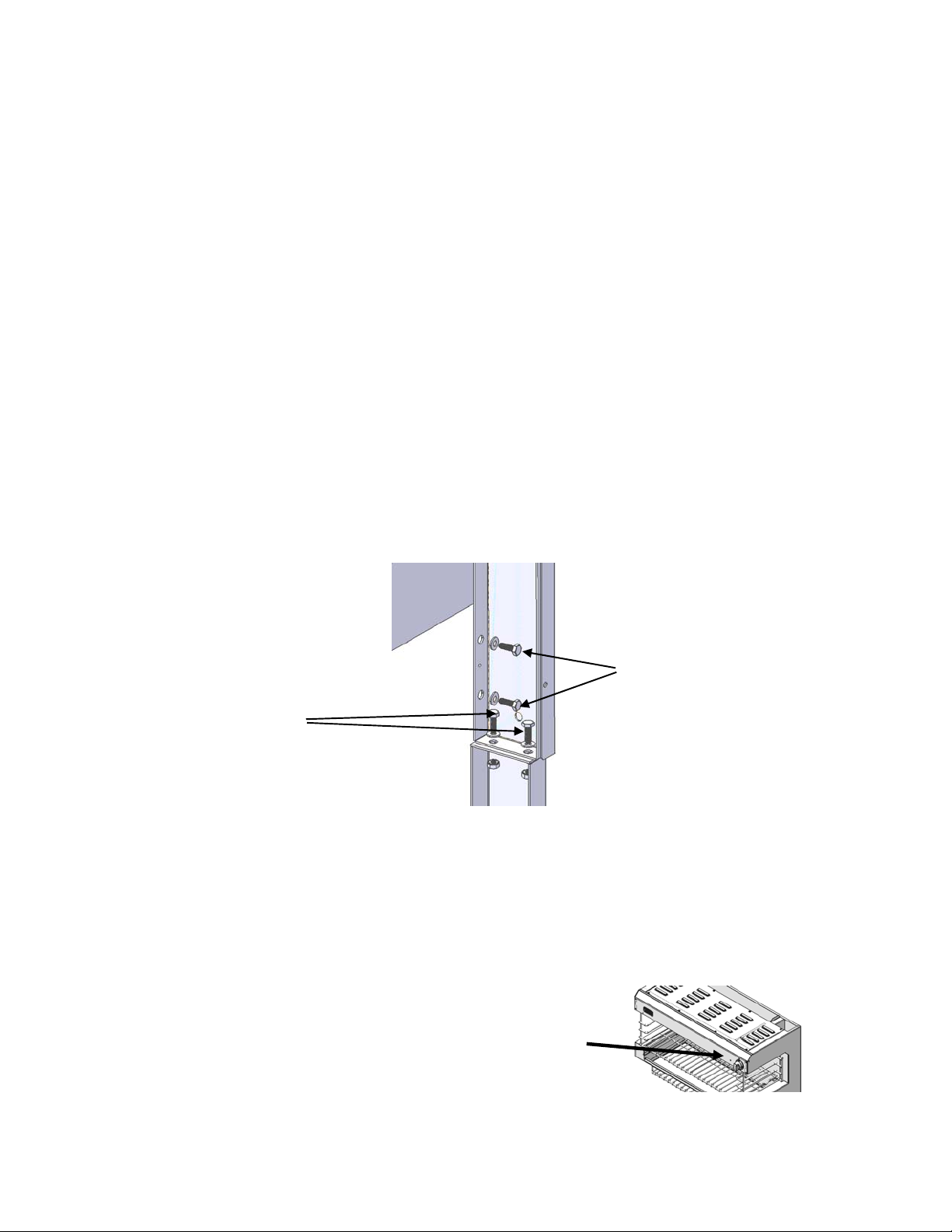

Riser Installation

1) Remove back panel from riser assembly by removing mounting screws

2) Remove the four bolts at the rear of the cook top / work top holding on the side panels

(two on each side, see diagram below)

3) Place riser on support brackets on back of oven, cabinet or refrigeration base

4) Reinstall the four bolts into the back of the cook top / work top through the riser channels,

do not tighten

5) Attach the bottom supports with supplied bolts, four on each side

6) Tighten the four bolts that attach riser to cook top / work top

7) Tighten the eight bolts that attach riser to bottom supports

8) Reinstall back cover

Riser Support Bolts

Note:

Failure to reinstall back cover could cause improper venting of exhaust gases from oven and

cook tops creating soot to clog burner(s) and flue

Range Top Bolts

Model / Serial / Data Plate Locations

Cheesemelter and Salamander located behind front

panel on right side

©2009 Viking Commercial Division

5

Statutory Regulations

The installation of this appliance must be carried out by a properly trained and qualified installer

and in accordance with the relevant regulations, codes of practice and the related publications of

the Country, State, County and City of destination.

In the United Sates of America:

1) Local Codes

2) National Fuel Gas Code ANSI Z223.1 or latest edition. Copies may be obtained from the

American Gas Association, Inc., on their web site: http://www.aga.org/

3) National Electrical Code, ANSI/NFPA-70, or latest edition. Copies may be obtained from

the National Fire Protection Association, on their web site: http://www.nfpa.org/

4) Vapor Removal From Cooking Equipment, NFPA-96, or latest edition. Copies may be

obtained from the National Fire Protection Association, on their web site:

http://www.nfpa.org/

In Canada:

1) Local Codes

2) CSA B149.1 Natural Gas and Propane Installation Code.

3) CSA C22.1 Canadian Electrical Code

4) CSA C22.2 Canadian Electrical Code

Canadian codes can be found on the CSA website: http://www.csa.ca

Appliances Equipped with Casters

Note:

The front casters of the appliance are equipped with brakes to limit movement of the appliance

without depending on the connector and any quick-disconnect device or its associated piping to

limit the appliance movement.

1) The installation shall be made with a

connector that complies with the Standard

for Connectors for Mo vable Gas Applianc es,

ANSI Z21.69/CSA 6.16, (or latest edition),

and a quick-disconnect device that complies

with Standard for Quick Disconnect of Use

with Gas Fuel, ANZI Z21.41/CSA 6.9, (or

latest edition).

2) Adequate means must be provided to limit

the movement of the appliance without

depending on the connector and the quickdisconnect device or its associated piping to

limit the appliance movement. (see fig. 1)

Fig. 1

Note:

Please be aware, required restraint is attached to a bracket, and if disconnection of the restraint

is necessary, be sure to reconnect the restraint after the appliance has been returned to its

original installed position

©2009 Viking Commercial Division

6

Gas Supply

The local gas authority should be consulted at the installation planning stage in order to establish

the availability of an adequate supply of gas and to ensure that the meter is adequate for the

required flow rate. The pipe work from the meter to the appliance must be an appropriate size.

(See Chart at end)

All fixed (non-mobile) appliances must be fitted with an accessible upstream gas shut off valve as

a means of isolating the appliance for emergency shut off and for servicing. A union or similar

means of disconnection must be provided between the gas-cock and the appliance.

A manually operable valve must be fitted to the gas supply to the kitchen to enable it to be

isolated in an emergency. Wherever practical, this shall be located either outside the kitchen or

near to an exit in a readily accessible position.

Where it is not practical to do this, an automatic isolation valve system shall be fitted which can

be operated from a readily accessible position near to the exit.

In locations where the manual isolation valve is fitted or the automatic system can be reset this

notice must be posted:

“ALL DOWNSTREAM BURNER AND PILOT VALVES MUST BE TURNED OFF PRIOR TO

ATTEMPTING TO RESTORE THE SUPPLY. AFTER EXTENDED SHUT OFF, PURGE

BEFORE RESTORING GAS”

Gas Supply Notes

Before assembly and connection, check gas supply.

• The type of gas for which the unit is equipped is stamped on the data plate, see locations

chart. Connect a unit stamped “Natural” only to natural gas and stamped “Propane” only

to propane gas.

• If it is a new installation, have the gas authorities check the meter size and piping to

assure that the unit is supplied with the necessary amount of gas supply and pressure to

operate the unit(s).

• Make certain new piping and connections have been made in a clean manner and have

been purged so that piping compound, chips, etc. will not clog pilots, valves or burners.

Use pipe joint compound approved for natural and liquefied petroleum gases.

©2009 Viking Commercial Division

7

Gas Pressure Regulator

A gas pressure regulator must be installed to regulate the proper flow of gas to the appliance.

The regulator must be installed between the main gas supply line to the unit shut off valve and

the appliance and must be accessible for servicing. Proper sizing of the regulator is extremely

important, check the BTU rating of the appliance or appliances being regulated by the regulator.

Note:

Contact the factory for regulator sizing when multiple appliances are being installed in a line up or

island suite configuration and are interconnected using the front manifold connections.

Note:

Gas pressure should be checked when the unit is installed and all other equipment on the same

line is on. The operating gas pressure must be the same as that specified o the rating plate. If

necessary, pressure adjustment may be made at the pressure regulator.

The appliance and its individual shut-off valve must be disconnected from the gas supply piping

system during any pressure testing of that system where pressures are in excess of ½ PSIG

(3.45KPA)

When test pressures are ½ PSIG (3.45KPA) or less, the range must be isolated from the gas

supply system by closing its individual manual shutoff valve.

Prior to lighting, check all joints in the gas supply line for leaks. Use

soap and water solution. Do not use an open flame. After piping has

been checked for leaks, all piping receiving gas should be fully purged

to remove air.

©2009 Viking Commercial Division

8

Ventilation Air

The following notes are intended to give general guidance. For detailed recommendations, refer

to the applicable codes in the Country, State, County and City of installation.

• Do not obstruct the flow of combustion and ventilation air.

Proper ventilation is critical for optimum performance. The ideal method of ventilating gas fired

equipment is the use of properly designed canopy that should extend six inches (152mm) beyond

all sides of the appliance (s) and six feet six inches (1981mm) above the floor. Information on the

construction and installation of ventilating hoods may be obtained from the standard for "Vapor

Removal from Cooking Equipment," NFPA No. 96 (latest edition), available from the National Fire

Protection Association, on their web site: http://www.nfpa.org/

A strong exhaust will create a vacuum in the room. For an exhaust vent to work properly,

replacement air must be equal to the amount of air exhausted. An imbalance between exhaust

and replacement air can cause degradation in the appliance’s performance.

All gas burners and pilots need sufficient air to operate. Large objects should not be placed in

front of the appliance (s) that would obstruct the flow of air into the front.

Electrical Supply (Where Applicable)

Important- This appliance must be electrically grounded in accordance with local codes, or in the

absence of local codes with the National Electrical Code.

Appliances equipped with a flexible electrical supply cord are

provided with a three-prong grounding plug. It is imperative that this

plug be connected into a properly grounded three-prong receptacle.

If the receptacle is not the proper grounding type, contact an

electrician. Do not remove the grounding prong from this plug.

The convection range is designed for 120 volt power supply 15amp circuit and is provided with a

flexible electric supply cord and plug that must be plugged into the proper receptacle. Do not

connect the convection range to electrical supply until after gas connections have been made.

The wiring diagram for the convection range is located behind the front control panel.

©2009 Viking Commercial Division

9

Loading...

Loading...