Viking X-9 Installation Instructions And Safety Information

Vehicular Gate Operator

UL 325 and UL991 Listed

Class I, Class II, Class III and Class IV

Installation Instructions and Safety Information

Rev. A.1 March 2005

TECHNICAL SUPPORT 1 800 908 0884

i

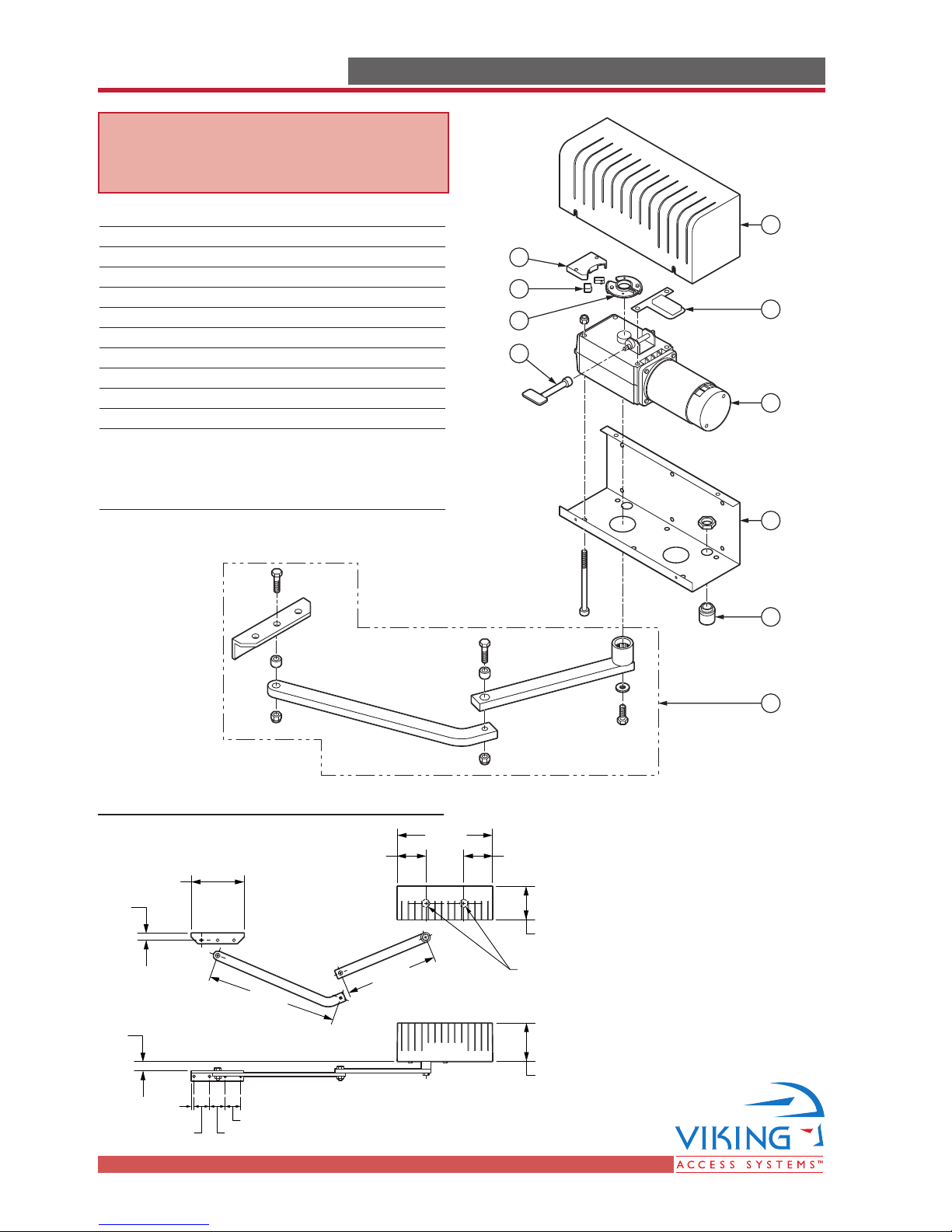

PARTS DIAGRAMPARTS DIAGRAM

Item Description

Part No.

1 Cover, Plastic VAX9PC

2 Motor/Gear Unit VAX9

3 Chassis, Motor/Gear VAX9CH

4 Strain Relief VAX9ST

5 Arm Assembly, Articulated VAX9AA

6 Holder, Limit Switch

7 Limit Switch (2) VAX9LS

8 Cam, Limit Switch VAX9LCS

9Terminal Block VAX9TB

10

Key Release VAX9KR

Weight 40 lb.

Overall Dimensions

14.724"

13.975"

19.685"

7.874"

4.33" 4.33"

5.12"

.985"

Gear/Motor Unit

Can Be Mounted

Left or Right

5.90"

1.50"

.394"

2.36"

2.36"2.36"

WARNING - For Installation

By Qualified Personnel Only.

10

1

6

7

8

9

2

3

4

5

TECHNICAL SUPPORT 1 800 908 0884

1

TABLE OF CONTENTSTABLE OF CONTENTS

Parts Diagram/Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .i

Important Safety Information

Important Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Important Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Maintenance/General Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Photo Beam (non-contact sensor) Installation . . . . . . . . . . . . . . . . . . . . . . . . .6

Edge Sensor (contact sensor) Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Manual Release . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Audible Alarm Reset Switch Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Warning Placard Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Important Installation Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Plan of Installation – Open Inside . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Plan of Installation – Open Outside . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Gate Operator Installation

Step 1 through 7 – Operator Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Step 8 through 9 – Limit Switch Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Opening/Closing Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Reference Wiring Diagram; Limit Switch Connections . . . . . . . . . . . . . . . . . . .15

Control Box Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Electrical Installation

Electrical Installation (120/220 VAC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Single Unit Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Master/Slave Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Vehicular Loop Detector Installation

Loop Layout Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Installation Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Accessory Connections

Open Commands; Safety Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Radio Receiver; Hold Open Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Magnetic Lock; Solenoid; Guard Station . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Special Features

Intelligent Obstruction Sensor (Primary Entrapment Protection) . . . . . . . . . . . .25

Gate Overlap Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28-29

TECHNICAL SUPPORT 1 800 908 0884

2

WARNING - Not following these instructions may cause severe injury or death to persons.

IMPORTANT SAFETY INFORMATIONIMPORTANT SAFETY INFORMATION

IMPORTANT SAFETY INSTRUCTIONS

WARNING – To reduce the risk of severe injury or death:

1. READ AND FOLLOW ALL INSTRUCTIONS.

2. Never let children operate or play with gate controls. Keep the remote control away from children.

3. Always keep people and objects away from the gate. NO ONE SHOULD CROSS THE PATH OF

THE MOVING GATE.

4. Test the gate operator monthly. The gate MUST reverse on contact with a rigid object or when

an object activates the non-contact sensors. After adjusting the force or the limit of travel,

retest the gate operator. Failure to adjust and retest the gate operator properly can increase the

risk of injury or death.

5. Use the manual release only when the gate is not moving.

6. KEEP GATES PROPERLY MAINTAINED. Read the owner’s manual. Have a qualified service per-

son make repairs to gate hardware.

7. The entrance is for vehicles only. Pedestrians must use separate entrance.

8. Every gate operator installation MUST have secondary protection devices against entrapment,

such as edge sensors and photo beams more in particularly in places where the risk of entrapment is more likely to occur.

9. SAVE THESE INSTRUCTIONS.

IMPORTANT INSTALLATION INSTRUCTIONS

1. Install the gate operator only when:

a) The operator is appropriate for the construction of the gate and the usage Class of the gate

(refer to page 5),

b) All openings of a horizontal slide gate are guarded or screened from the bottom of the gate

to a minimum of 4 feet (1.22 m) above the ground to prevent a 2-1/4 inch (57.2 mm)

diameter sphere from passing through the openings anywhere in the gate, and in that

portion of the adjacent fence that the gate covers in the open position,

c) ALL EXPOSED PINCH POINTS ARE ELIMINATED OR GUARDED, AND

d) GUARDING IS SUPPLIED FOR EXPOSED ROLLERS.

2. The operator is intended for installation only on gates used for vehicles. Pedestrians must be

supplied with a separate access opening.

3. The gate must be installed in a location so that enough clearance is supplied between the gate

and adjacent structures when opening and closing to reduce the risk of entrapment. Swinging

gates shall not open into public access areas.

4. The gate must be properly installed and work freely in both directions prior to the installation

of the gate operator. Do not over-tighten the operator clutch or pressure relief valve to compensate for a damaged gate.

TECHNICAL SUPPORT 1 800 908 0884

3

WARNING - Not following these instructions may cause severe injury or death to persons.

IMPORTANT SAFETY INFORMATIONIMPORTANT SAFETY INFORMATION

5. The gate operator controls must be placed so that the user has full view of the gate area when

the gate is moving AND AWAY FROM THE GATE PATH PERIMETER,

6. Controls must be far enough from the gate so that the user is prevented from coming in contact

with the gate while operating the controls. Controls intended to be used to reset an operator

after 2 sequential activations of the entrapment protection device or devices must be located in

the line-of-sight of the gate. Outdoor or easily accessible controls shall have a security feature

to prevent unauthorized use.

7. All warning signs and placards must be installed where visible in the area of the gate. A minimum

of two placards shall be installed. A placard is to be installed in the area of each side of the

gate and be visible to persons located on the side of the gate on which the placard is installed.

8. For gate operators utilizing a non-contact sensor (Photo beam or like) in accordance with section

31.1.1 of the UL325 standard:

a) See instructions on the placement of non-contact sensors for each Type of application (refer

to page 6),

b) Care shall be exercised to reduce the risk of nuisance tripping, such as when a vehicle, trips

the sensor while the gate is still moving, and

c) One or more non-contact sensors shall be located where the risk of entrapment or obstruc-

tion exists, such as the perimeter reachable by a moving gate or barrier (refer to page 6).

9. For a gate operator utilizing a contact sensor (Edge sensor or like) in accordance with section

31.1.1 of the UL325 standard:

a) One or more contact sensors shall be located where the risk of entrapment or obstruction

exists, such as at the leading edge, trailing edge, and post mounted both inside and outside

of a vehicular horizontal slide gate (refer to page 7).

b) One or more contact sensors shall be located at the bottom edge of a vehicular vertical lift gate.

c) One or more contact sensors shall be located at the pinch point of a vehicular vertical pivot gate.

d) A hardwired contact sensor shall be located and its wiring arranged so that the communication

between the sensor and the gate operator is not subjected to mechanical damage.

e) A wireless contact sensor such as one that transmits radio frequency (RF) signals to the gate

operator for entrapment protection functions shall be located where the transmission of the

signals are not obstructed or impeded by building structures, natural landscaping or similar

obstruction. A wireless contact sensor shall function under the intended end-use conditions.

f) One or more contact sensors shall be located on the inside and outside leading edge of a

swing gate. Additionally, if the bottom edge of a swing gate is greater than 6 inches (152

mm) above the ground at any point in its arc of travel, one or more contact sensors shall be

located on the bottom edge (refer to page 7).

g) One or more contact sensors shall be located at the bottom edge of a vertical barrier (arm).

IMPORTANT INSTALLATION INSTRUCTIONS Continued

TECHNICAL SUPPORT 1 800 908 0884

4

WARNING - Not following these instructions may cause severe injury or death to persons.

IMPORTANT SAFETY INFORMATIONIMPORTANT SAFETY INFORMATION

GENERAL SAFETY PRECAUTIONS

The following precautions are an integral and essential part of the product and must be supplied to the user.

Read them carefully as they contain important indications for the safe installation, use and maintenance.

• These instruction must be kept and forwarded to all possible future users of the system.

• This product must be used only for that which it has been expressly designed.

• Any other use is to be considered improper and therefore dangerous.

• The manufacturer cannot be held responsible for possible damage caused by improper, erroneous or

unreasonable use.

•Avoid operating in the proximity of the hinges or moving mechanical parts.

• Do not enter the path of the moving gate while in motion.

• Do not obstruct the motion of the gate as this may cause a situation of danger.

• Do not allow children to play or stay within the the path of the moving gate.

•Keep remote control or any other control devices out of the reach of children, in order to avoid possible

involuntary activation of the gate operator.

• In case of break down or malfunctioning of the product, disconnect from the main power source. Do not

attempt to repair or intervene directly, contact only qualified personnel for repair.

• Failure to comply with the above may create a situation of danger.

• All cleaning, maintenance or repair work must be carried out by qualified personnel.

• In order to guarantee that the system works efficiently and correctly it is important to have the manufacturer’s

instructions on maintenance of the gate and operator carried out by qualified personnel.

• In particular, regular checks are recommended in order to verify that the safety devices are operating correctly.

All installation, maintenance and repair work must be documented and made available to the user.

Installer:

_____________________________________________________ ____________

Signature Date

Contact: _________________________________________________________

_________________________________________________________

MAINTENANCE

Remove the Power Harness from the Control Board (refer to page 17)

• Clean and lubricate the turning pins and gate hinges using the recommended lubricant.

• Check that all mounting hardware of the gate operator is properly tighten.

• Ensure that the gate moves freely.

• Check for corroded parts and replace if necessary.

• Check the battery for the following:

Battery connections must be free of corrosion.

Battery voltage must be 26 VDC (fully charged battery).

Reconnect the Power Harness for the Control Board (refer to page 17)

• Check and confirm the proper operation of all safety devices (photoelectric eye, edge sensors or like).

• Check and confirm the operation of all installed accessories.

• Check and confirm the operation of all special features such as the Intelligent Obstruction Sensor, Hold

Open Timer (refer to page 20 to 27)

• Check and confirm the operation of the manual release (refer to page 7)

•Verify battery backup functionally by turning off the power source (120 VAC and 220 VAC). DO NOT

FORGET TO TURN ON THE POWER SOURCE AFTER VERIFICATION.

TECHNICAL SUPPORT 1 800 908 0884

55

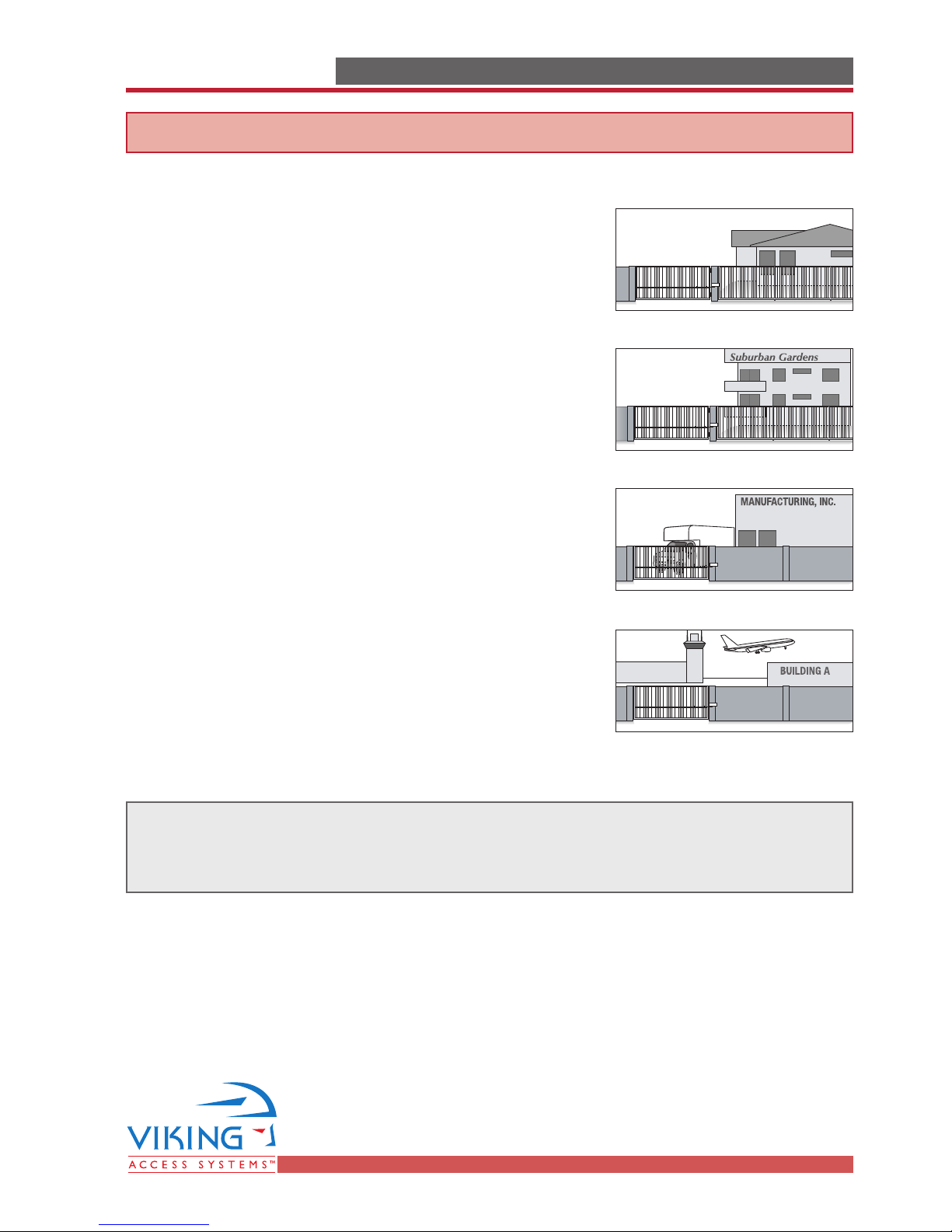

UL325 Gate Operator Classification

TERMINOLOGYTERMINOLOGY

GLOSSARY

RESIDENTIAL VEHICULAR GATE OPERATOR

CLASS I – A vehicular gate operator (or system) intended for use

in a home of one-to four single family dwelling, or a garage or

parking area associated therewith.

COMMERCIAL/GENERAL ACCESS VEHICULAR GATE OPERATOR

CLASS II – A vehicular gate operator (or system) intended for use

in a commercial location or building such as a multi-family housing unit (five or more single family units), hotel, garages, retail

store, or other building servicing the general public.

INDUSTRIAL/LIMITED ACCESS VEHICULAR GATE OPERATOR

CLASS III – A vehicular gate operator (or system) intended for

use in an industrial location or building such as a factory or

loading dock area or other locations not intended to service the

general public.

RESTRICTED ACCESS VEHICULAR GATE OPERATOR

CLASS IV – A vehicular gate operator (or system) intended for

use in a guarded industrial location or building such as an airport security area or other restricted access locations not servicing the general public, in which unauthorized access is prevented

via supervision by security personnel.

Install the gate operator only when:

The operator is appropriate for the construction of the gate and the Usage

Class of the gate.

TECHNICAL SUPPORT 1 800 908 0884

6

WARNING - Not following these instructions may cause severe injury or death to persons.

IMPORTANT SAFETY INFORMATIONIMPORTANT SAFETY INFORMATION

Photo Beam (non-contact sensor) Installation

a

a

N

One or more non-contact sensors shall be located where

the risk of entrapment or obstruction exists, such as the

perimeter reachable by a moving gate or barrier.

Consult the installation manual for the UL325 device

(photo beam or like) for detail information about the

usage, installation and maintenance

1

(C1)3(NC1)

24VDC

1

(C1)3(NC1)

24VDC

Turn Switch to

'Light On' Position

24 VDC Power Connections

24 VDC Power Connections

Omron Model

E3K-R10

Shown

Connection '3' (NC1)

Connection '1' (C1)

Photo beams or like must be installed to reduce the risk of entrapment.

Use only UL325 compliance devices like:

Omron E3K-R10

Ensure that any device installed is UL325 compliant and low voltage device (24 VDC).

Read the device manual for proper installation, and proper connection (especially

the polarity of the device).

Ma

Ma

Gnd

Exit

Safety Connectorands Radio St

Safety Connectorands

Gnd

Center

Gnd

Safety

GndULGnd

+28v

Photo Beam Unit Reflector

Radio St

Gnd

Radio

+28v

Gate in Open Position

Potential Entrapment

Area (Shaded)

TECHNICAL SUPPORT 1 800 908 0884

7

a

s

a

s

WARNING - Not following these instructions may cause severe injury or death to persons.

IMPORTANT SAFETY INFORMATIONIMPORTANT SAFETY INFORMATION

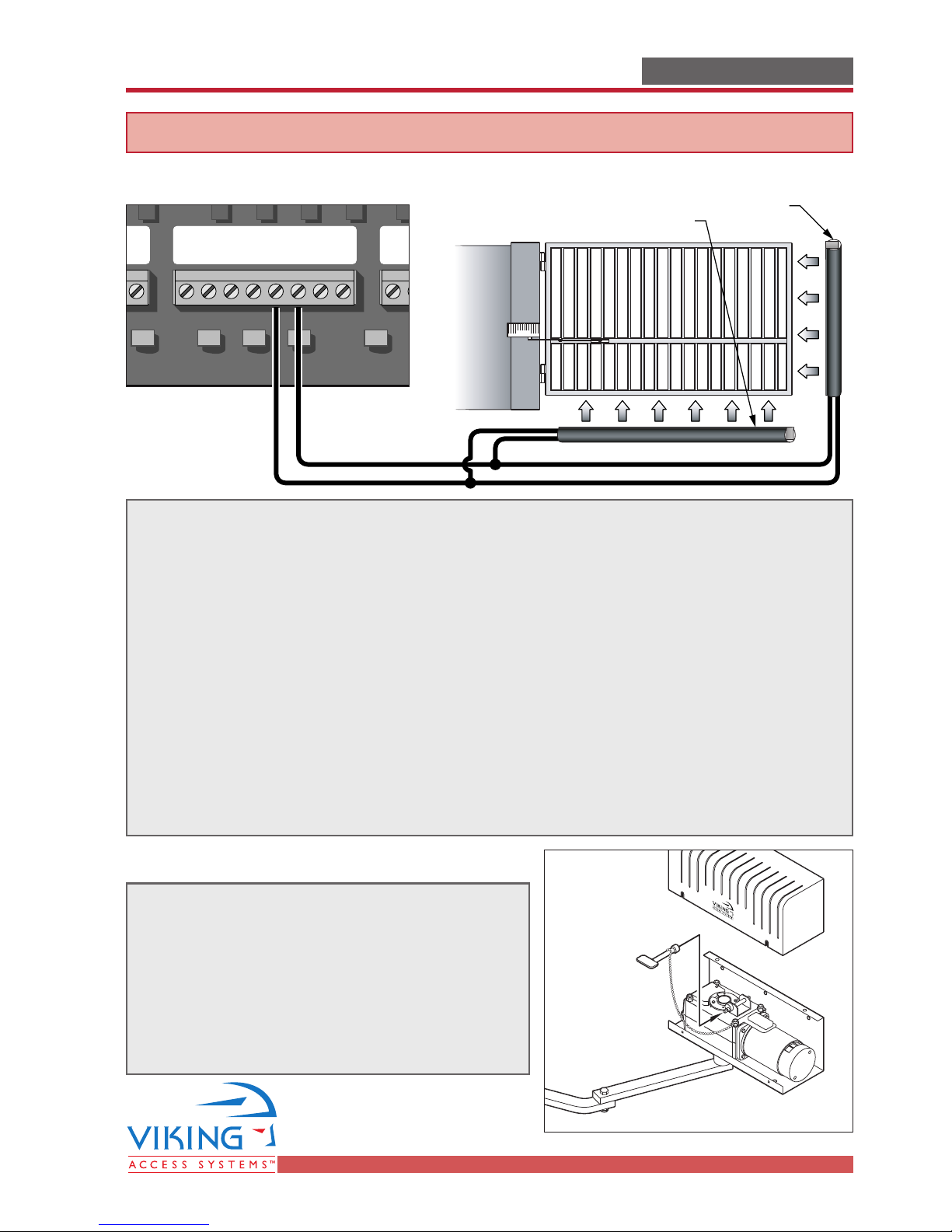

Edge Sensor (contact sensor) Installation

Edge sensor or like must be installed to reduce the risk of entrapment.

Use only UL325 compliance devices like:Use only UL325 compliance devices like:

Miller Edge 3-sided activation for an added measure of protection MGR20 or MGS20

If you install another device:

a) Ensure its compliance with UL325,

b) Use the recommended supply voltage,

c) Follow the installation guidelines of the device.

One or more contact sensors shall be located on the inside and outside leading edge

of a swing gate. Additionally, if the bottom edge of a swing gate is greater than 6

inches (152 mm) above the ground at any point in its arc of travel, one or more

contact sensors shall be located on the bottom edge.

Consult the installation manual for the UL325 device (photo beam or like) for detail

information about the usage, installation and maintenance.

Manual Release

When manual operation is required:

Remove the cover, locate the chained key and

turn the key to push the locking-pin down.

At end of operations, lock the geared motor again

by releasing locking-pin.

Attention: Lock and release operations MUST

be performed with motor NOT RUNNING.

3-Sided Edge Sensor

3-Sided Edge Sensor

Exit

Safety Connector

Safety Connector

Gnd

Center

Gnd

Safety

GndULGnd

+28v

Gnd

R

R

TECHNICAL SUPPORT 1 800 908 0884

8

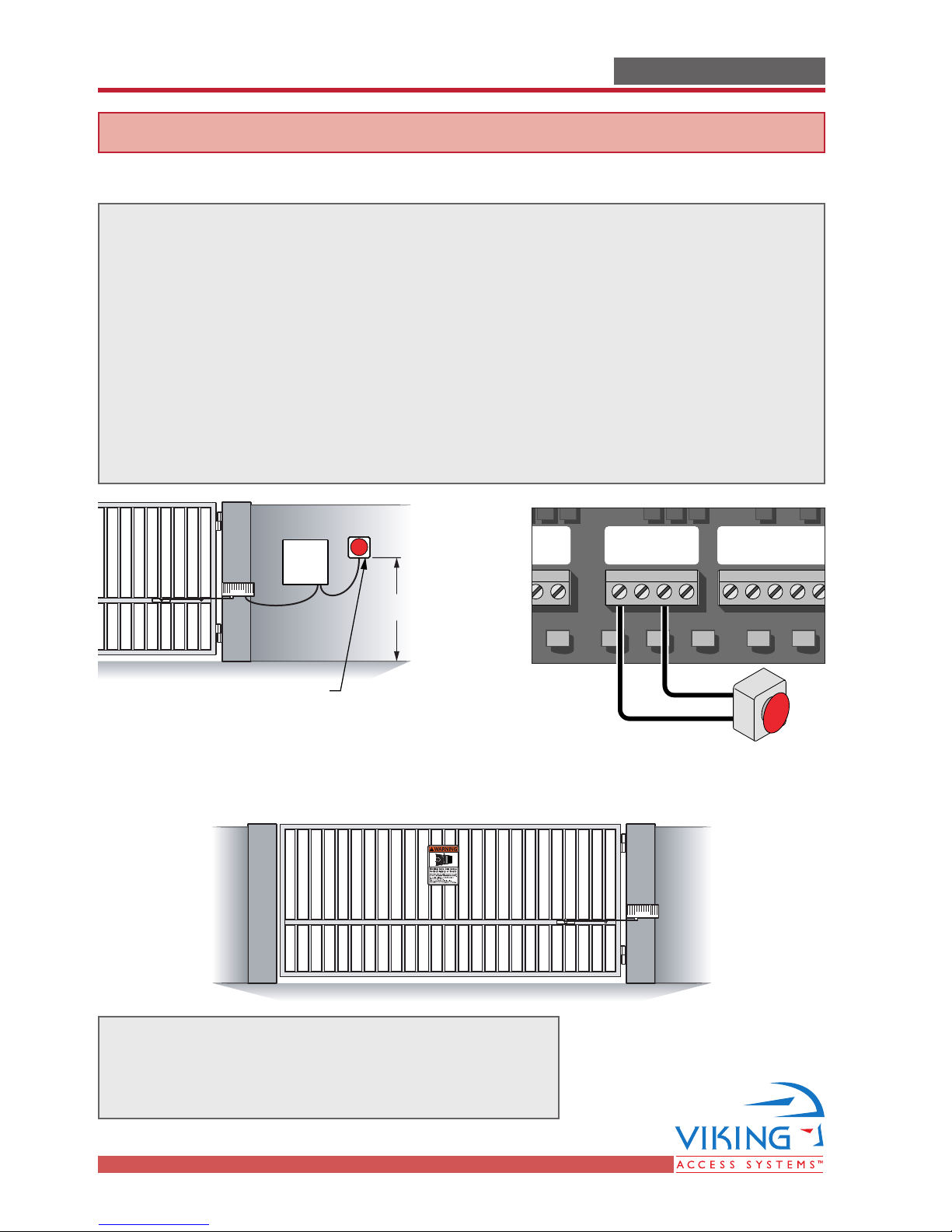

Audible Alarm Reset Switch Installation

Reset for the Audible Alarm

UL325 standard requires an audible alarm to go off after two consecutive events

detected by the primary entrapment protection of the gate operator (obstruction sensor).

The audible alarm will continue to sound for 5 minutes or until a stop command

gets actuated.

The Stop command can be actuated in two different forms

1. Using the built in stop switch in the control board or

2. Using an external stop button within the sight of the gate, away from moving

parts of the gate and out of reach of children.

WARNING - Not following these instructions may cause severe injury or death to persons.

IMPORTANT SAFETY INFORMATIONIMPORTANT SAFETY INFORMATION

Warning Placard Installation

d

d

All warning signs and placards must be installed where

visible in the area of the gate. A minimum of two

placards shall be installed. A placard is to be installed

in the area of each side of the gate and be visible.

STOP

5'

Minimum

Manual Stop

Button

N.O.

Open Comman

Gnd

Fire

Gnd

STOP

Strike

Slave Open Comman

Slave

Stop

Open

Guard Station

Guard Station

GND

Close

Stop

Open

COM

Gnd

Loading...

Loading...