Viking VCWH53048AG, VWH548481CS, VCWH53648KA, VCWH54848PG, VCWH53648BF INSTALLATION INSTRUCTIONS

...

Installation

Professional Indoor & Outdoor Hoods

VWH53012 / VWH53612

VWH53048 / VWH53648 / VWH54248

VWH54848 / VWH56048

VCWH53048 / VCWH53648 / VCWH54248

VCWH54848 / VCWH56048

VCIH53608 / VCIH54208 / VCIH55408 / VCIH56608

VBCV53638 / VBCV54238 / VBCV54838 / VBCV56038 / VBCV56038

VWHO3678 / VWHO4878 / VWHO6078 (Canadian Outdoor models not applicable)

Table of Contents

Warnings & Important Information

VWH/CVWH 10” H/12”H. Wall Hoods w/Standard Ventilator 30”, & 36”

Dimensions & Specifications_______________________________________________________________ 5

Clearance Dimensions_____________________________________________________________________ 6

Interior Ventilator Dimensions ____________________________________________________________ 7

VWH/CVWH 18”H. 24”Deep Wall Hoods 30”, 36”, 42”, 48”, & 60”

Dimensions & Specifications ______________________________________________________________8

Clearance Dimensions ______________________________________________________________________9

Interior Ventilator Dimensions _____________________________________________________________10

Exterior Ventilator Dimensions ___________________________________________________________11

VWHO/CVWHO 18”H. Outdoor Wall Hoods 36”, 48”, & 60”

Dimensions & Specifications ______________________________________________________________12

Clearance Dimensions ____________________________________________________________________13

VCWH/CVCWH Chimney Wall Hoods 30”, 36”, 42”, 48”, & 60”

Dimensions & Specifications ______________________________________________________________14

Clearance Dimensions ____________________________________________________________________15

Interior Ventilator Dimensions ___________________________________________________________16

Exterior Ventilator Dimensions ___________________________________________________________17

VCIH/CVCIH Chimney Island Hoods 36”, 42”, 54”, & 66”

Dimensions & Specifications ______________________________________________________________18

Clearance Dimensions ____________________________________________________________________19

Interior Ventilator Dimensions ___________________________________________________________20

Exterior Ventilator Dimensions ___________________________________________________________21

VBCV/CVBCV Wall Custom Ventilator System

Dimensions & Specifications ______________________________________________________________22

Installing Hood Canopy___________________________________________________________________23

Clearance Dimensions ____________________________________________________________________24

VBCV Ventilator Dimensions ______________________________________________________________25

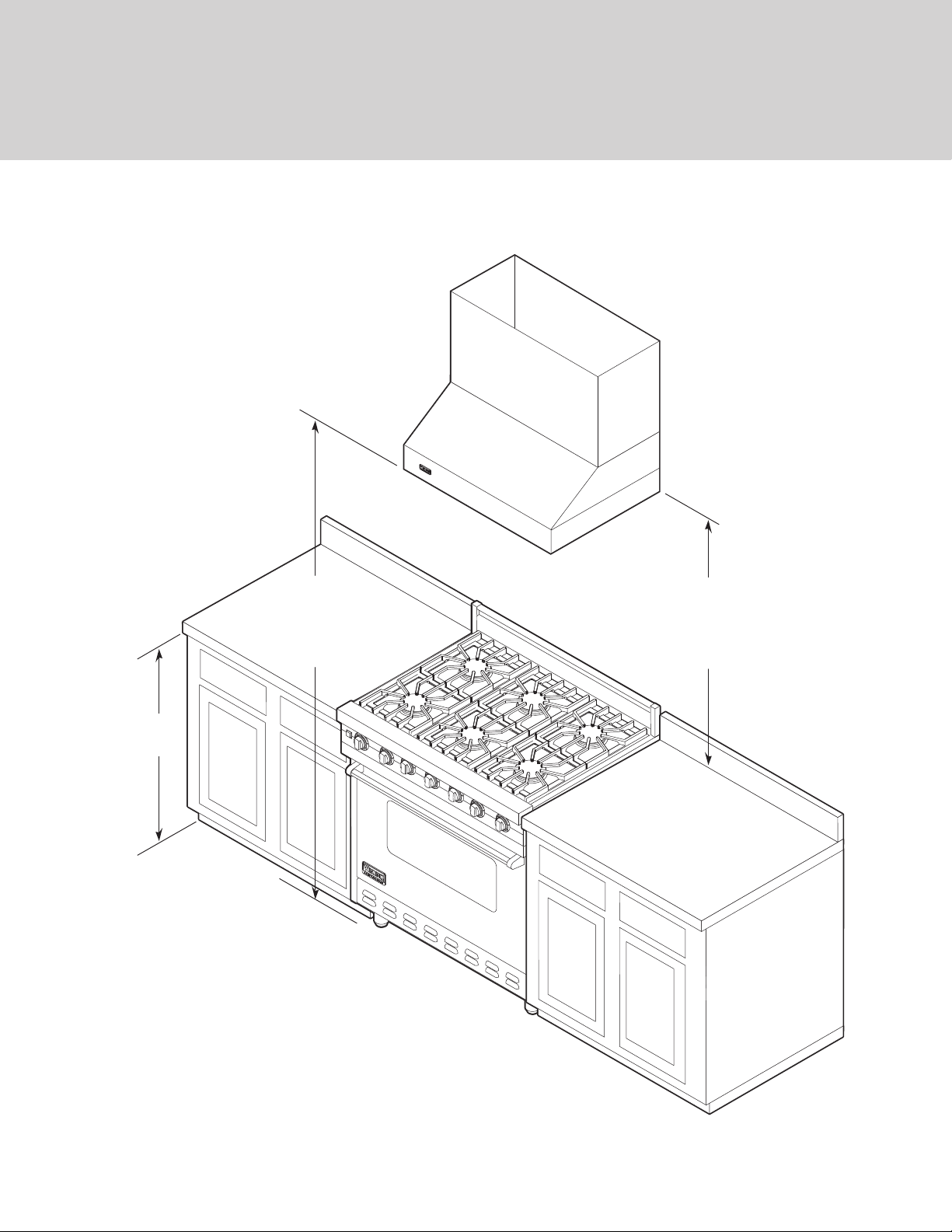

Planning Information _________________________________________________________________________27

Installation Procedures

Installation (VWH/CVWH 10”H./12”H. Wall Hoods w/Standard Ventilator)___________________28

Duct Cover Option (VWH/CVWH 12”H. Wall Hoods w/Standard Ventilator)__________________30

Installation (VWH/CVWH 12”H. Wall Hoods w/Recirculating Kit) ____________________________30

Installation (VWH/CVWH 18”H. Wall & VCWH Chimney Wall Hoods) ________________________33

Duct Cover Option (VWH/CVWH 18”H. Wall Hoods) ________________________________________34

Duct Cover Option (VCWH/CVCWH Chimney Wall Hoods) __________________________________35

Installation (VCIH Island Hoods)___________________________________________________________36

Service & Registration ________________________________________________________________________38

Wiring Diagram ______________________________________________________________________________39

_________________________________________________________________ 3-

4

2

IMPORTANT–Please Read and Follow!

NOTE:

If installing hood with warming shelf panel, install

warming shelf panel first.

WA R NI N G

IMPORTANT – PLEASE READ AND FOLLOW

• Before beginning, please read these instructions completely

and carefully.

• Do not remove permanently affixed labels, warnings, or

plates from the product. This may void the warranty.

• Please observe all local and national codes and ordinances.

If no local codes are applicable, wire in accordance with the

National Electrical Code, ANSI/NFPA 70-latest edition.

• Damp environment approved models should be installed in

a covered non-enclosed area and should be protected from

the elements as much as possible.

• The installer should leave these instructions with the

consumer who should retain for local inspector’s use and

for future reference.

• Check with a qualified and trained installer or local codes

for makeup air requirement, if any.

This hood is for residential installation only and is not

designed for installation over a commercial product. Make

sure power is off at the main circuit breaker or fuse box

before making connections. To avoid risk of fire, electric

shock, or injury to persons, turn off the electricity to the

hood from the power supply before servicing or cleaning.

Viking hoods are equipped with variable speed control

blowers. These units will not function with a single speed

ventilator. All Viking Range ventilator kits are designed

specifically for use with Viking Range hoods. Use of any nonViking Range ventilator kit will void the hood warranty.

Viking hoods are equipped with the variable speed controls

for blowers. These units will not function with a single speed

ventilator. All Viking ventilator kits are designed specifically

for use with Viking hoods. Use of any non-Viking ventilator

kit will void the hood warranty.

READ AND SAVE THESE INSTRUCTIONS

To reduce the risk of fire, electric shock, or injury to

persons, observe the following:

• Use this unit only in the manner intended by the

manufacturer. If you have any questions, contact the

manufacturer.

• Before servicing or cleaning unit, switch power off at

service panel and lock service panel to prevent

power from being switched on accidentally. When

the service disconnecting means cannot be locked,

securely fasten a prominent warning device, such as

a tag, to the service panel.

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRICAL SHOCK,

OR INJURY TO PERSONS, OBSERVE THE FOLLOWING:

1. Installation work and electrical wiring must be

done by qualified person(s) in accordance with all

applicable codes and standards, including firerated construction.

2. Sufficient air is needed for proper combustion

and exhausting of gases through the flute

(chimney) of fuel burning equipment to prevent

back drafting. Follow the heating equipment

manufacturer’s guideline and safety standards

such as those published by the National Fire

Protection Association (NFPA), and the American

Society for Heating, Refrigeration and Air

Conditioning Engineers (ASHRAE), and the local

code authorities.

3. When cutting of drilling into wall or ceiling, do

not damage electrical wiring and other hidden

utilities.

4. Ducted fans mustalways be vented to the outdoors.

5. WARNING!: To reduce risk of fire, use only metal

ductwork

6. CAUTION!: To reduce risk of fire and to properly

exhaust air, be sure to duct air outside. Do not

vent exhaust air into spaces within walls or

ceilings, or into attics, crawl spaces, or garages.

7. CAUTION!: To Reduce the Risk of Fire and Electric

Shock, Install this rangehood only with remote

blower models manufactured by Viking, model

numbers – DEV900/DEV1200, VEV900, VIL1200,

OR DEV1500 or integral blowers manufactured by

Viking, model numbers – VINV300/600/1200, or

DIL1200. NOTE – Please refer inside for specific

canopy/blower combinations.

3

IMPORTANT–Please Read and Follow!

WA R NI N G

To reduce the risk of injury to persons in the event of a

rangetop grease fire, observe the following. (Based on

“Kitchen FiresafetyTips,” published by NFPA.)

1. SMOTHER FLAMES with a close fitted lid, cookie

sheet, or metal tray, then turn off the burner. BE

CAREFUL TO PREVENT BURNS. If the flames do not

go out immediately, EVACUATE AND CALL THE FIRE

DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN. You may be

burned.

3. DO NOT USE WATER, including wet dishcloths or

towels a violent steam explosion will result.

4. Use an extinguisher ONLY if

• You know it is a Class ABC extinguisher, and you

already know how to operate it.

• The fire is small and contained in the area where it

started.

• The fire department is being called.

• You can fight the fire with your back to an exit.

C A U T IO N

For general ventilating use only. Do not use to exhaust

hazardous or explosive materials and vapors.

WA R NI N G

This appliance is not to be used by persons (including

children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge,

unless they have been given supervision or instruction

concerning the use of the appliance by a person

responsible for their safety. Children should be

supervised to ensure that they do not play with the

appliance.

WA R NI N G

TO REDUCE THE RISK OF FIRE,

ELECTRICAL SHOCK, OR INJURY

TO PERSONS

Rangehoods must be installed with the

ventilators that are specified on their

carton indicating suitability with this

model. Other ventilators cannot be substituted.

4

2

1”

(5

3

.

3

c

m

)

A

1

0”

(

2

5.

4 c

m

)

1

2

”

(

3

0

.5

cm

)

A (Hood width)

30”W. 29-7/8“ (76.2 cm)

36”W. 35-7/8” (91.1 cm)

5

”

(12

.7

c

m

)

2

1”

(53

.3

c

m

)

A

1

2 ”

(30.

5

cm)

A (Hood width)

30”W. 29-7/8“ (76.2 cm)

36”W. 35-7/8” (91.1 cm)

5

”

(

1

2.7

c

m

)

1

2 ”

(30.

5

cm)

Dimensions & Specifications

(VWH 10”H./12”H. Wall Hoods w/Standard Ventilator 30”, & 36”)

NOTE: Optional duct cover sold separately.

VWH/CVWH 10”H./12”H. Wall Hoods

Description 30” 36”

Duct cover width

Duct cover depth

Duct cover height

Number of lights

Number of filters

Heat lamps

Interior ventilator kit

Interior duct size*

Interior—Maximum amps

* Disregard when using recirculating kits.

460 CFM blower is shipped with hood.

w/Standard Ventilator

29-7/8” (75.9 cm) 35-7/8” (91.1 cm)

12” (30.5 cm)

12” (30.5 cm)

2

2

N/A

460 CFM Standard

7” (17.8 cm)

5.6 A

5

* NOTE: When installing with a 24”high-shelf,

the 27” (68.6 cm) max. dimensions must be used.

2

4

"

m

i

n

.

(

6

1

.

0

c

m

)

t

o

2

7

"

m

a

x

.

*

(

6

8

.

6

c

m

)

6

0

"

mi

n

.

(

1

5

2

.

4

c

m

)

t

o

6

3

"

m

a

x

.

(

1

6

0

.

0

c

m

)

3

6

"

(

9

1

.

4

c

m

)

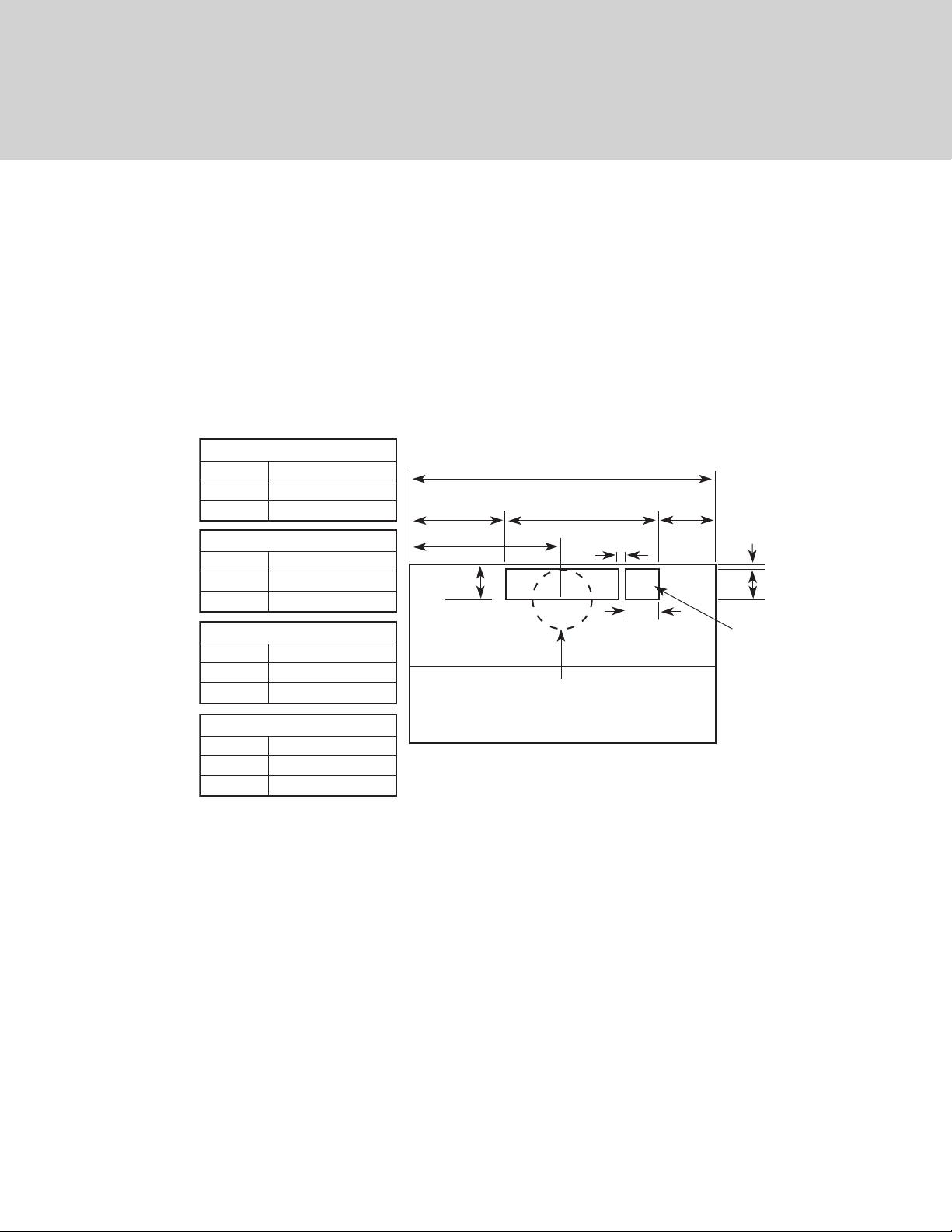

Clearance Dimensions

(VWH/CVWH 10”H./12”H. Wall Hoods w/Standard Ventilator)

6

A

B

C

D

18”

(4.6 cm)

3-7/8”

(9.8 cm)

3-4”

(1.9 cm)

7” (17.8 cm) dia.

duct location

Electrical

hookup

1/2”

(1.3 cm)

4”

(10.2 cm)

3-1/2”

(8.9 cm)

A

24”W. 23-7/8” (60.6 cm)

30”W. 29-7/8” (75.9 cm)

36”W. 35-7/8” (91.1 cm)

B

24”W. 5-1/4” (13.3 cm)

30”W. 8-1/4” (20.9 cm)

36”W. 11-1/4” (28.6 cm)

C

24”W. 11-15/16” (30.3 cm)

30”W. 14-15/16” (37.9 cm)

36”W. 17-15/16” (45.6 cm)

D

24”W. 5/8” (1.6 cm)

30”W. 3-5/8” (9.2 cm)

36”W. 6-5/8” (16.8 cm)

Interior Ventilator Dimensions

(VWH/CVWH 10”H./12”H. Wall Hoods w/Standard Ventilator)

Top View

460 CFM Interior Ventilator Installation

7

2

4

"

(

6

1

.

0

c

m

)

A

1

8

"

(

4

5

.

7

c

m

)

1

2

"

(

3

0

.

5

c

m

)

6

"

(

1

5

.

2

c

m

)

A

30" W 29-7/8" (76.2 cm)

36" W 35-7/8" (91.1 cm)

42" W 41-7/8" (106.4 cm)

48" W 47-7/8" (121.6 cm)

60" W 59-7/8" (152.1 cm)

Dimensions & Specifications

(VWH/CVWH 18”H. 24” Deep Wall Hoods 30”, 36”, 42”, 48”, & 60”)

NOTE: Optional duct cover sold separately.

Duct cover width

Duct cover depth

Duct cover height

Number of lights

Number of filters

Heat lamps

Interior ventilator kits

Exterior ventilator kits

In-line ventilator kits

Interior duct size

Exterior duct size

Interior—Maximum amps

Exterior—Maximum amps

In-Line—Maximum amps

Total Watts

* A 1,200 CFM interior- or exterior-power ventilator should be used when installed over range/rangetop with gas char-grill. Max

duct run is 50 ft.

** It is recommended that the 1,500 CFM ventilator be used with longer duct runs. Max duct run is 75 ft.

NOTE: Maximum amp rating for hoods includes recommended ventilator kit rating; A ll products must be hard wired with 2-wire

with ground. An interior- or exterior-power ventilator kit must be purchased for installation with all 18”H. hoods.

VWH/CVWH 18”H. Wall Hoods

Description 30” 36” 42” 48” 60”

29-7/8”

(75.9 cm)

2 2 2 3 4

2 2 2 3 4

1 1 1 2 3

VINV300/

600/1200

DEV900/

1200*

DIL1200 DIL1200 DIL1200 DIL1200 DIL1200

7”/10”

(17.8/25.4cm)

4.2/5.2/8.2 4.2/5.2/8.2 5.2/8.2 10.8 10.8

8.0/5.3 8.0/5.3 8.0/5.3 7.8/8.5 7.8/8.5

5.3/7.2 5.3/7.2 5.3/7.2 9.6 10.0

35-7/8”

(91.1 cm)

VINV300/

600/1200

DEV900/

1200*

7”/10”

(17.8/25.4cm)

41-7/8”

(106.4 cm)

12” (30.5 cm)

12” (30.5 cm)

VINV600/

1200

DEV900/

1200*

7”/10”

(17.8/25.4cm)

10” (24.5 cm)

47 Watts

8

47-7/8”

(121.6 cm)

VINV1200* VINV1200*

DEV1200*/

1500**

10”

(25.4 cm)

59-7/8” (152.1

cm)

DEV1200*/

1500**

10”

(25.4 cm)

3

0

”

m

i

n

.

(

7

6

.

2

c

m

)

t

o

3

6

”

m

a

x

.

(

9

1

.

4

c

m

)

6

6

” m

i

n

.

(

1

6

7

.

6

c

m

)

t

o

7

2

” m

a

x

.

(

1

8

2

.

9

c

m

)

36

”

(

9

1

.

4

c

m

)

Clearance Dimensions

(VWH/CVWH 18”H. Wall Hoods)

9

10" (25.4 cm)

dia. duct location

B

A

30" W 14-15/16" (37.9 cm)

36" W 17-15/16" (45.6 cm)

42" W 20-15/16" (53.2 cm)

48" W 23-15/16" (60.8 cm)

60" W 29-15/16" (76.0 cm)

A

5-1/2"

(14.0 cm)

B

30" W 29-7/8" (75.9 cm)

36" W 35-7/8" (91.1 cm)

42" W 41-7/8" (106.4 cm)

48" W 47-7/8" (121.6 cm)

60" W 59-7/8" (152.1 cm)

A

B

7" (17.8 cm)

dia. duct location

4-5/8"

(11.7 cm)

B

3

0" W 29-7/8" (75.9 cm)

36" W 35-7/8" (91.1 cm)

42" W 41-7/8" (106.4 cm)

48" W 47-7/8" (121.6 cm)

60" W 59-7/8" (152.1 cm)

A

3

0" W 14-15/16" (37.9 cm)

36" W 17-15/16" (45.6 cm)

42" W 20-15/16" (53.2 cm)

48" W 23-15/16" (60.8 cm)

60" W 29-15/16" (76.0 cm)

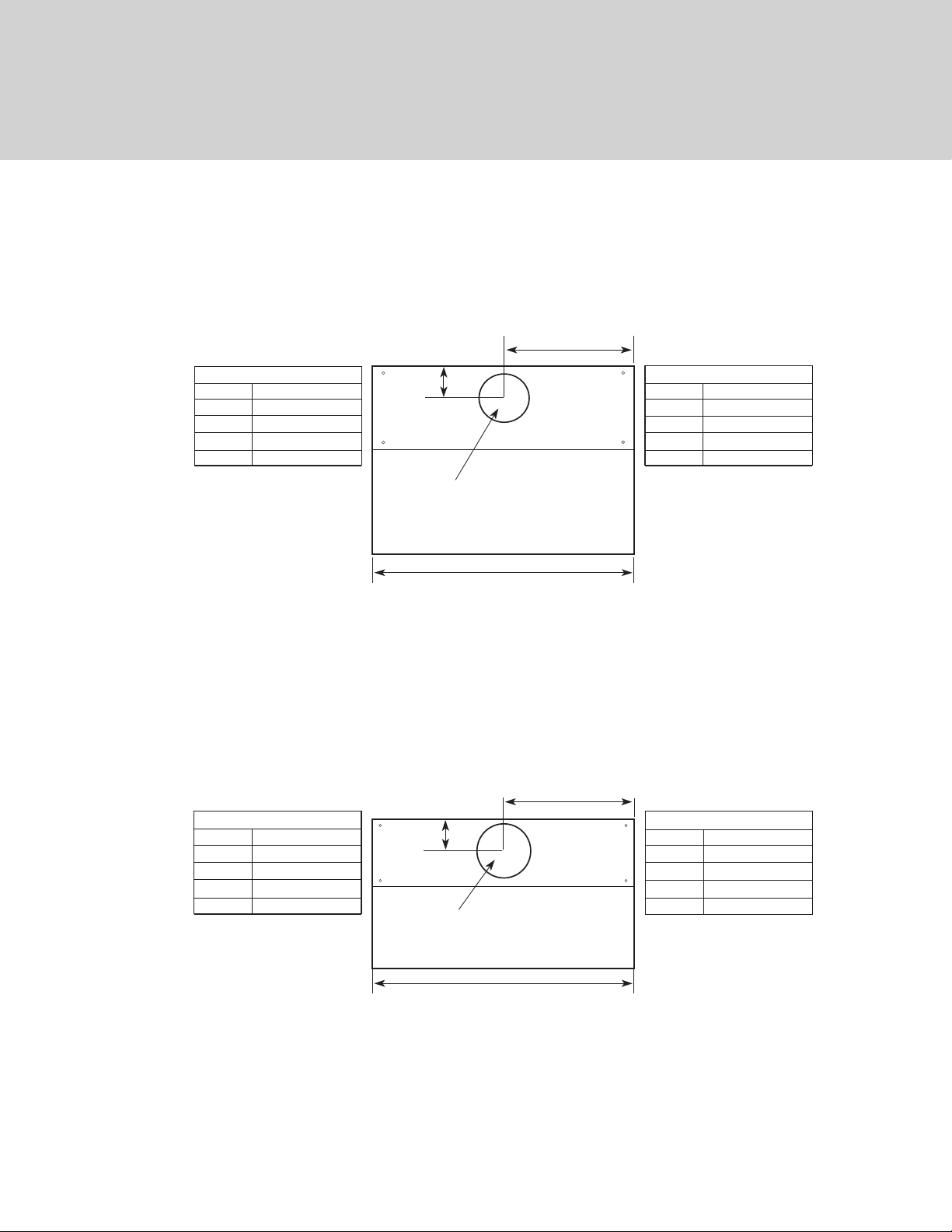

Interior Ventilator Dimensions

(VWH/CVWH 18”H. Wall Hoods)

Top View

300 or 600 CFM Interior Ventilator Installation for all Wall Hoods

Top View

1200 CFM Interior Ventilator Installation for all Wall Hoods

10

10" (25.4 cm)

dia. duct location

A

B

A

30" W 14-15/16" (37.9 cm)

36" W 17-15/16" (45.6 cm)

42" W 20-15/16" (53.2 cm)

48" W 23-15/16" (60.8 cm)

60" W 29-15/16" (76.0 cm)

B

30" W 29-7/8" (75.9 cm)

36" W 35-7/8" (91.1 cm)

42" W 41-7/8" (106.4 cm)

48" W 47-7/8" (121.6 cm)

60" W 59-7/8" (152.1 cm)

5-15/16"

(15.1 cm)

A

B

10" (25.4 cm)

dia. duct location

5-15/16"

(15.1 cm)

A

30" W 14-15/16" (37.9 cm)

36" W 17-15/16" (45.6 cm)

42" W 20-15/16" (53.2 cm)

48" W 23-15/16" (60.8 cm)

60" W 29-15/16" (76.0 cm)

B

30" W 29-7/8" (75.9 cm)

36" W 35-7/8" (91.1 cm)

42" W 41-7/8" (106.4 cm)

48" W 47-7/8" (121.6 cm)

60" W 59-7/8" (152.1 cm)

Exterior Ventilator Dimensions

(VWH/CVWH 18”H. Wall Hoods)

Top View

900 or 1200 CFM Exterior or In-Line Ventilator Installation for all Wall

Hoods

Top View

1200 or 1500 CFM Exterior or In-Line Ventilator Installation for all Wall

Hoods

11

2

7

"

(

6

8

.

6

c

m

)

A

1

8

"

(

4

5

.

7

c

m

)

6

"

(

1

5

.

2

c

m

)

A

36" W 35-7/8" (91.1 cm)

48" W 47-7/8" (121.6 cm)

60" W 59-7/8" (152.1 cm)

Dimensions & Specifications

(VWHO/CVWHO 18”H. Outdoor Wall Hoods 36”, 48”, & 60”)

Number of lights

Number of filters

Interior ventilator kits

Exterior ventilator kits

In-line ventilator kits

Interior duct size

Exterior duct size

Interior—Maximum amps

Exterior—Maximum amps

In-Line—Maximum amps

Total watts

* A 1,200 CFM interior- or exterior-power ventilator should be used with all outdoor models and when indoor models are installed

over range/rangetop with gas char-grill. Max duct run is 50 ft.

** It is recommended that the 1,500 CFM ventilator be used with longer duct runs. Max duct run is 75 ft.

NOTE: Maximum amp rating for hoods includes recommended ventilator kit rating; A ll products must be hard wired with 2-wire

with ground. An interior- or exterior-power ventilator kit must be purchased for installation with all 18”H. hoods.

VWHO/CVWHO 18”H. Outdoor Wall Hoods

Description 36” 48” 60”

2 3 4

2 3 4

VINV1200* VINV1200* VINV1200*

DEV1200*/1500** DEV1200*/1500** DEV1200*/1500**

DIL1200 DIL1200 DIL1200

10” (25.4 cm)

10” (25.4 cm)

9.0 11.4 11.8

6.1/6.8 8.4/9.1 8.8/9.5

7.9 10.2 10.6

47 Watts

12

3

0

"

m

i

n

.

(

7

6

.

2

c

m

)

t

o

3

6

"

m

a

x

.

(

9

1

.

4

c

m

)

3

6

"

(

9

1

.

4

c

m

)

6

6

"

m

i

n

.

(

1

6

7

.

6

cm

)

t

o

7

2

"

m

a

x

.

(

1

8

2

.

9

cm

)

2

7

"

(

6

8

.

6

c

m

)

D

I

M

«

X »

+ 4

-

1

/

2

"

(

1

1

.

4

c

m

)

1

8

"

(

4

5

.

7

c

m

)

Clearance Dimensions

(VWHO/CVWHO 18”H. Outdoor Wall Hoods)

Note: Outdoor Models must be installed in a covered, non-enclosed area, and should be protected from the

elements as much as possible.

The bottom of the hood should be 30” (76.2 cm) to 36”(91.4 cm) above the grill surface. The hood should be

installed 4-1/2”(11.4 cm) plus the distance between the back trim and surface from the back wall. (Note: DIM

“X” - There is a 3”minimum clearance from the back trim to non-combustible surfaces, and a 24” minimum to

combustible surfaces.) This will require building the hood out from the wall. Any combustible material used for

this purpose must be covered with locally-supplied stainless steel. It is also recommended to use a backsplash.

13

2

4

”

(

61

.

0

c

m

)

B

A

1

8

”

(

45

.

7

c

m

)

1

2

”

(

30

.

5

c

m

)

t

o

2

4

”

(

61

.

0

c

m

)

6”

(1

5.

2

c

m

)

A (Duct width)

30”W. 12“ (30.5 cm)

36”W. 12“ (30.5 cm)

42”W. 12“ (30.5 cm)

48“W. 18“ (45.7 cm)

60”W. 24“ (61.0 cm)

66”W. 24“ (61.0 cm)

B (Hood width)

30”W. 29-7/8“ (76.2 cm)

36”W. 35-7/8” (91.1 cm)

42”W. 41-7/8” (106.4 cm)

48“W. 47-7/8” (121.6 cm)

60”W. 59-7/8” (152.1 cm)

66”W. 65-7/8” (167.3 cm)

Dimensions & Specifications

(VCWH/CVCWH

Chimney Wall Hoods 30”, 36”, 42”, 48”, 54”, & 60”)

NOTE: Optional duct cover sold separately.

Description 30” 36” 42” 48” 60”

Duct cover width

Duct cover depth

Duct cover height

Number of lights

Number of filters

Heat lamps

Interior ventilator kits

Exterior ventilator kits

In-line ventilator kits

Interior duct size

Exterior duct size

Interior—Maximum amps

Exterior—Maximum amps

In-Line—Maximum amps

Total Watts

* A 1,200 CFM interior- or exterior-power ventilator should be used when installed over range/rangetop with gas char-grill. Max duct

run is 50 ft.

** It is recommended that the 1,500 CFM ventilator be used with longer duct runs. Max duct run is 75 ft.

NOTE: Maximum amp rating for hoods includes recommended ventilator kit rating; A ll products must be hard wired with 2-wire with

ground. An interior- or exterior-power ventilator kit must be purchased for installation with all 18”H. hoods.

VCWH/CVCWH Chimney Wall Hoods

12” (30.5 cm) 12” (30.5 cm) 12” (30.5 cm) 18” (45.7 cm) 24” (61.0 cm)

12” (30.5 cm)

12” (30.5 cm) to 24”(61.0 cm)

2 2 2 3 4

2 2 2 2 3

1 1 1 2 3

VINV300/600 VINV300/600 VINV600 VINV1200* VINV1200*

DEV900/

1200*

DIL1200 DIL1200 DIL1200 DIL1200 DIL1200

7” (17.8 cm) 7” (17.8 cm) 7”(17.8 cm) 10” (25.4 cm) 10” (25.4 cm)

4.2/5.2 4.2/5.2 5.2 10.8 10.8

8.0/5.3 8.0/5.3 8.0/5.3

5.3/7.2 5.3/7.2 5.3/7.2 9.6 10.0

DEV900/

1200*

10” (25.4 cm)

47Watts

14

DEV900/

1200*

DEV1200*/

1500**

7.8/8.5 7.8/8.5

DEV1200*/

1500**

3

0

”

m

i

n

.

(

7

6

.

2

c

m

)

t

o

3

6

”

m

a

x

.

(

9

1

.

4

c

m

)

6

6

” m

i

n

.

(

1

6

7

.

6

c

m

)

t

o

7

2

” m

a

x

.

(

1

8

2

.

9

c

m

)

36

”

(

9

1

.

4

c

m

)

Clearance Dimensions

(VCWH/CVCWH Chimney Wall Hoods)

15

A

48”W. 23-15/16” (60.8 cm)

60”W. 29-15/16” (76.0 cm)

66”W. 32-15/16” (83.7 cm)

C

48”W. 18” (45.7 cm)

60”W. 24” (61.0 cm)

66”W. 24” (61.0 cm)

10” (25.4 cm) dia.

duct location

6”

(15.2 cm)

1-1/2”

(3.8 cm)

1-1/2”

(3.8 cm)

A

B

C

120 V

power

supply

B

48”W. 47-7/8” (121.6 cm)

60”W. 59-7/8” (152.1 cm)

66”W. 65-7/8” (167.3 cm)

7” (17.8 cm) dia.

duct location

B

A

30”W. 14-15/16” (37.9 cm)

36”W. 17-15/16” (45.6 cm)

42”W. 20-15/16” (53.2 cm)

120V

power

supply

1-1/2”

(3.8 cm)

6”

(15.2 cm)

12”

(30.5 cm)

1-1/2”

(3.8 cm)

A

B

30”W. 29-7/8” (75.9 cm)

36”W. 35-7/8” (91.1 cm)

42”W. 41-7/8” (106.4 cm)

Interior Ventilator Dimensions

(VCWH/CVCWH Chimney Wall Hoods

Top View

)

300 or 600 CFM Interior Ventilator Installation

for 30”, 36”, & 42” models

Top View

1200 CFM Interior Ventilator Installation

for 48”, & 60”models

16

A

48”W. 23-15/16” (60.8 cm)

60”W. 29-15/16” (76.0 cm)

66”W. 32-15/16” (83.7 cm)

C

48”W. 18” (45.7 cm)

60”W. 24” (61.0 cm)

66”W. 24” (61.0 cm)

10” (25.4 cm) dia.

duct location

6”

(15.2 cm)

1-1/2”

(3.8 cm)

1-1/2”

(3.8 cm)

A

B

C

120 V

power

supply

B

48”W. 47-7/8” (121.6 cm)

60”W. 59-7/8” (152.1 cm)

66”W. 65-7/8” (167.3 cm)

10” (25.4 cm) dia.

duct location

B

A

30”W. 14-15/16” (37.9 cm)

36”W. 17-15/16” (45.6 cm)

42”W. 20-15/16” (53.2 cm)

1

20V

power

supply

1-1/2”

(3.8 cm)

6”

(15.2 cm)

12”

(30.5 cm)

1-1/2”

(3.8 cm)

A

B

30”W. 29-7/8” (75.9 cm)

36”W. 35-7/8” (91.1 cm)

42”W. 41-7/8” (106.4 cm)

Exterior Ventilator Dimensions

(VCWH/CVCWH Chimney Wall Hoods

Top View

)

900 or 1200 CFM Exterior or In-Line Ventilator Installation

for 30”, 36”, & 42” models

Top View

900, 1200 or 1500 CFM Exterior or In-Line Ventilator Installation

for 48”, & 60”models

17

3

0

"

(

7

6

.

2

c

m

)

C

A

1

8

"

(

4

5

.

7

c

m

)

B

6

"

(

1

5

.

2

c

m

)

C

36" W 35-7/8" (91.1 cm)

42" W 41-7/8" (106.4 cm)

54" W 53-7/8" (136.8 cm)

66" W 65-7/8" (167.3 cm)

B

36" W.

42" W.

54" W.

66" W.

12" (30.5 cm)

or

24" (61.0 cm)

or

36" (91.4 cm)

A

36" W 12" (30.5 cm)

42" W 12" (30.5 cm)

54" W 18" (45.7 cm)

66" W 24" (70.0 cm)

Dimensions & Specifications

(VCIH/CVCIH Chimney Island Hoods 36”, 42”, 54”, & 66”)

NOTE: Optional duct cover sold separately.

Duct cover width

Duct cover depth

Duct cover height

Number of lights

Number of filters

Heat lamps

Interior ventilator kits

Exterior ventilator kits

In-line ventilator kits

Interior duct size

Exterior duct size

Interior—Maximum amps

Exterior—Maximum amps

In-Line—Maximum amps

total Watts

* A 1,200 CFM interior- or exterior-power ventilator should be used when installed over range/rangetop with gas char-grill. Max duct run is

50 ft.

** It is recommended that the 1,500 CFM ventilator be used with longer duct runs. Max duct run is 75 ft.

NOTE: Maximum amp rating for hoods includes recommended ventilator kit rating; A ll products must be hard wired with 2-wire with

ground. An interior or exterior-power ventilator kit must be purchased for installation with all 18”H. hoods.

VCIH/CVCIH Chimney Island Hoods

Description 36” 42” 54” 66”

12” (30.5 cm) 12” (30.5 cm) 18” (45.7 cm) 24” (70.0 cm)

12” (30.5 cm)

12” (30.5 cm) or 24”(61.0 cm) or 36”(91.4 cm)

4 4 6 8

4 4 6 8

10” (25.4 cm)

47 Watts

N/A

VINV600 VINV600 VINV1200* VINV1200*

DEV900/1200* DEV900/1200*/1500** DEV1200*/1500** DEV1200*/1500**

DIL1200 DIL1200 DIL1200 DIL1200

7” (17.8 cm) 7” (17.8 cm) 10” (25.4 cm) 10” (25.4 cm)

4.2/5.2/8.2 5.2/8.2 8.9 9.3

7.4/4.7 7.4/4.7/5.5 5.6/6.4 6.4/7.4

4.7/6.5 3.9/5.7 7.4 7.4

18

3

0

”

m

i

n

.

(

7

6

.

2

c

m

)

t

o

3

6

”

m

a

x

.

(

9

1

.

4

c

m

)

6

6

” m

i

n

.

(

1

6

7

.

6

c

m

)

t

o

7

2

” m

a

x

.

(

1

8

2

.

9

c

m

)

36

”

(

9

1

.

4

c

m

)

Clearance Dimensions

(VCIH /CVCIHChimney Island Hoods)

19

A

54”W. 26-15/16” (68.4 cm)

66”W. 32-15/16” (83.7 cm)

C

54”W. 18” (45.7 cm)

66”W. 24” (61.0 cm)

1-1/8”

(2.9 cm)

1-1/8”

(2.9 cm)

10” (25.4 cm) dia.

duct location

B

A

C

6”

(15.2cm)

120 V

power

supply

B

54”W. 53-7/8” (136.8 cm)

66”W. 65-7/8” (167.3 cm)

7” (17.8 cm) dia.

duct location

12”

(30.5 cm)

120 V

power

supply

1-1/8”

(2.9 cm)

B

A

A

36”W. 17-15/16” (45.6 cm)

42”W. 20-15/16” (53.2 cm)

1-1/8”

(2.9 cm)

6”

(15.2 cm)

B

36”W. 35-7/8” (91.1 cm)

42”W. 41-7/8” (106.4 cm)

Interior Ventilator Dimensions

(VCIH/CVCIH Chimney Island Hoods

Top View

600 CFM Interior Ventilator Installation

for all Chimney Island Hoods

)

Top View

1200 CFM Interior Ventilator Installation

for all Chimney Island Hoods

20

A

54”W. 26-15/16” (68.4 cm)

66”W. 32-15/16” (83.7 cm)

C

54”W. 18” (45.7 cm)

66”W. 24” (61.0 cm)

1-1/8”

(2.9 cm)

1-1/8”

(2.9 cm)

10” (25.4 cm) dia.

duct location

B

A

C

6”

(15.2cm)

120 V

power

supply

B

54”W. 53-7/8” (136.8 cm)

66”W. 65-7/8” (167.3 cm)

10” (25.4 cm) dia.

duct location

12”

(30.5 cm)

1-1/8”

(2.9 cm)

120 V

power

supply

1-1/8”

(2.9 cm)

6”

(15.2cm)

B

A

A

36”W. 17-15/16” (45.6 cm)

42”W. 20-15/16” (53.2 cm)

B

36”W. 35-7/8” (91.1 cm)

42”W. 41-7/8” (106.4 cm)

Exterior Ventilator Dimensions

(VCIH/CVCIH Chimney Island Hoods

Top View

900 or 1200 CFM Exterior or In-Line Ventilator Installation

for all Chimney Island Hoods

)

Top View

900, 1200 or 1500 CFM Exterior or In-Line Ventilator Installation

for all Chimney Island Hoods

21

B*

A*

Dimensions & Specifications

(VBCV Wall Custom Ventilator System 36”, 42”, 48”, & 60”)

*For best results,

center the unit over

the burners of the

cooking product

(front to back; right

to left).

Bottom Cutout Dimensions

Wall Hoods

Description A (Hood Width) B (Hood Depth)

36” W. 33-7/16” (84.9 cm) 21-7/16” (54.5 cm)

42” W. 39-7/16” (100.2 cm) 21-7/16” (54.5 cm)

48” W. 45-7/16” (115.4 cm) 21-7/16” (54.5 cm)

60” W. 57-7/16” (145.9 cm) 21-7/16” (54.5 cm)

VBCV Wall Custom Ventilator System

Description 36” 42” 48” 60”

Number of lights

Number of filters

Heat lamps

Interior ventilator kits

Exterior ventilator kits

In-line ventilator kits

Interior duct size

Exterior duct size

Interior—Maximum amps

Exterior—Maximum amps

In-Line—Maximum amps

Total Watts

2 2 3 4

2 2 3 4

1 1 2 3

VINV300/

600

DEV900/

1200*

DIL1200 DIL900/1200 DIL1200 DIL1200

7”/10”

(17.8/25.4cm)

4.2/5.2 10.8 10.8 10.8

8.0/5.3 8.0/5.3 7.8/8.5 7.8/8.5

5.3/7.2 5.3/7.2 9.6 10.0

VINV600 VINV1200* VINV1200*

DEV900/

1200*

7”/10”

(17.8/25.4cm)

DEV1200*/

1500**

10”

(25.4 cm)

10” (25.4

47 Watts

Make sure the back wall of

the custom hood canopy

is flush with the cutout so

the ventilator system may

be mounted as shown on

page 25.

DEV1200*/

1500**

10”

(25.4 cm)

* A 1,200 CFM interior- or exterior-power ventilator should be used when installed over range/rangetop with gas char-grill. Max

duct run is 50 ft.

** It is recommended that the 1,500 CFM ventilator be used with longer duct runs. Max duct run is 75 ft.

NOTE: Maximum amp rating for hoods includes recommended ventilator kit rating; A ll products must be hard wired with 2-wire

with ground. An interior- or exterior-power ventilator kit must be purchased for installation with all 18”H. hoods.

22

AA

BB

Installing Hood Canopy

(Custom Hood Canopy Cutouts)

Custom Hood

Canopy

1) Position ventilator

system inside of the

custom hood canopy

and center it front to

back and left to right.

2) Bottom mounting holes

fasten ventilator system

to bottom of custom

hood canopy with the

screws provided.

Built-In Ventilator

System

3) OPTIONAL

Rear mounting holes fasten

ventilator system to rear of

custom hood canopy.

23

3

0

"

m

i

n

.

(

7

6

.

2

c

m

)

t

o

3

6

"

m

a

x

.

(

9

1

.

4

c

m

)

6

6

" m

i

n

.

(

1

6

7

.

6

c

m

)

t

o

7

2

" m

a

x

.

(

1

8

2

.

9

c

m

)

36

"

(

9

1

.

4

c

m

)

(

C

u

s

t

o

m

H

o

o

d

)

Clearance Dimensions

(VBCV/CVBCV Wall Custom Ventilator System)

24

1-1/2"

(3.81 cm)

1"

(2.54 cm)

5/8"

(1.6 cm)

21-7/8”

(55.8 cm)

17-1/4”

(43.8 cm)

7/8”

(2.2 cm)

1-1/2”

(3.8 cm)

17-1/4”

(43.8 cm)

11-1/2”

(29.2 cm)

21-7/8”

(55.8 cm)

5/8”

(1.6 cm)

6”

(15.2 cm)

5/8" (1.6 cm)

D

C

10" (25.4 cm)

dia. duct location

5-1/2"

(14.0 cm)

D

C

5/8" (1.6 cm)

7" (17.8 cm)

dia. duct location

4-5/8"

(11.7 cm)

Built-In Wall Custom Ventilator

System Dimensions

(VBCV Models)

For 900, 1200 or 1500 CFM Exterior

or In-Line Ventilator Installation

900 or 1200 CFM Exterior

or In-Line Ventilator Installation

36”, 42” W. Models

36” W. 34-1/4” (87.0 cm)

42” W. 40-1/4” (102.2 cm)

C

For 300, 600 or 1200 CFM Interior

Ventilator Installation

300 or 600 CFM Interior

Ventilator Installation

36”, 42” W. Models

D

36” W. 17-1/8” (43.5 cm)

42” W. 20-1/8” (51.1 cm)

25

5/8" (1.6 cm)

D

C

10" (25.4 cm)

dia. duct location

5-1/2"

(14.0 cm)

5/8" (1.6 cm)

C

10" (25.4 cm)

dia. duct location

5-1/2"

(14.0 cm)

D

Built-In Wall Custom Ventilator

System Dimensions

1200 or 1500 CFM Exterior or In-Line Ventilator Installation

48”, 60” W. Models

(VBCV/CVBCV Models)

1200 CFM Interior Ventilator Installation

36”, 42”, 48”, 60” W. Models

C

36” W. 34-1/4” (87.0 cm)

42” W. 40-1/4” (102.2 cm)

48” W. 46-1/4” (117.5 cm)

60” W. 58-1/4” (148.0 cm)

36” W. 17-1/8” (43.5 cm)

42” W. 20-1/8” (51.1 cm)

48” W. 23-1/8” (58.7 cm)

60” W. 29-1/8” (74.0 cm)

26

D

Roof Cap

7” round duct

D

uct cover or soffit

3

00 or 600 CFM

single blower

interior-power

typical ductwork

H

ood

Roof cap

10” round duct

Duct cover or soffit

1200 CFM

single blower

interior power

typical ductwork

Hood

Exterior blower

10” round duct

Duct cover or soffit

900, 1200, or

1500 CFM

exterior power

typical ductwork

Hood

Duct

Duct cover or soffit

Wall Installation exterior

power typical

ductwork

NOTE: Wall exhaust must be a minimum of 24” (61.0 cm)

from ground. This may vary depending on local codes

and geographic location.

Hotte

Wall Cap

Planning Information

Proper installation of ducting is extremely

important to ensure maximum performance from

any ventilation product.

• All CFMs are based on tests at 0.1 static pressure:

without applying static pressure, CFM would be

greatly overstated.

• Straight runs and gradual turns are best; for

example, each 90º elbow is equivalent to 5-10 feet

(1.52-3.05 cm) of straight run.

• Never use flexible duct; it creates back pressure/air

turbulence and greatly reduces performance.

• Proper performance is dependent on proper

ducting; make sure that a qualified and trained

installer is used.

• Check with a qualified and trained installer or local

codes for makeup air requirement, if any.

• Max. amp rating forhoods includes recommended

ventilator kit rating; all products must behard wired

direct with 2-wire with ground.

Plan wherethe duct workwillbe located. Install propersized duct work, and roof orwallcapfor the type of

blower you are using. Recommended hood locations

forthe mostcommon installations are shown. Adjust

your measurements for variousheights of ceilings,

soffits, cabinets, or ranges/rangetops.

Check Framing

NOTE:Because of the weight of the hood make sure

that the mounting screws are driven into the framing

and not just the drywall.It may be necessary to drill

additionalholes in the canopy for proper alignment.

27

1

2

3

1

4

2

1

5

Installation(VWH/CVWH 10”H./12”H. Wall Hoods w/Standard Ventilator)

Check damper for unrestricted movement, adjust if

necessary.

Flip hood over and remove electrical box cover.

Attach transition to damper. Seal with aluminum tape.

WA R NI N G

To reduce the risk of fire, electric shock, or injury to

persons, observe the following:

• Use this unit only in the manner intended by the

manufacturer. If you have any questions, contact the

manufacturer.

• Before servicing or cleaning unit, switch power off at

service panel and lock service panel to prevent

power from being switched on accidentally. When

the service disconnecting means cannot be locked,

securely fasten a prominent warning device, such as

a tag, to the service panel.

Insert6” of electrical wiring through the top of vent hood

and secure using wiring restrain. Refer to local codes.

Slide duct over transition and tape around joint.

28

5

/

1

6

”

N

u

t

d

r

i

v

e

r

Black

Black

White

White

Green

Bare or Green

7

1

1

2

8

1

2

1

3

9

CAUTION: Secure vent hood to wall using screws

6

N

u

t

d

r

i

v

e

r

5

/

1

6

”

1

2

3

10

provided. Use additional mounting screws and wall

anchors, if necessary.

CAUTION: If not using a duct cover, using screws

provided, make sure top mounting screws are secured

into soffit or cabinet framing. Use additional mounting

screws, if necessary.

Connect black to black, white to white, and the

green/bare wire under the green screw.

NOTE: Housing wiring must be properly installed for

wiring to be correct when wiring unit.

Replace electrical box cover. Make connection to breaker

box.

Slide filter front over front lip. Push filter rear up, then

slide back over rear lip.

Slide filter front over front lip. Push filter rear up, then

slide back over rear lip.

29

1

2

1

2

2

Duct Cover Option

(VWH/CVWH 10”H./12”H. Wall Hoods w/Standard Ventilator)

Measure distance from ceiling to canopy.

Slide the duct cover in place and fasten from inside

canopy using the sheet metal screws provided.

Installation

(VWH/CVWH 10”H./12”H. Wall Hoods w/Recirculating Kit)

Remove damper and discard with transition.

Turn recirculating unit upside down. Place vent hood

upside down on recirculating unit.

30

7

5

/

1

6

”

N

u

t

d

r

i

v

e

r

5

1

6

2

3

4

Installation

(VWH/CVWH 10”H./12”H. Wall Hoods w/Recirculating Kit)

Attach with screws and lock washers provided.

Remove electrical box cover.

Attach with screws.

WA R NI N G

To reduce the risk of fire, electric shock, or injury to

persons, observe the following:

• Use this unit only in the manner intended by the

manufacturer. If you have any questions, contact the

manufacturer.

• Before servicing or cleaning unit, switch power off at

service panel and lock service panel to prevent

power from being switched on accidentally. When

the service disconnecting means cannot be locked,

securely fasten a prominent warning device, such as

a tag, to the service panel.

Flip hood over. Insert 6” of electrical wiring through the

top of vent hood and secure. Refer to local codes.

CAUTION: Secure vent hood. Make sure mounting screws

are secured into framing. Use additional mounting screws

and wall anchors, if necessary.

31

Black

Black

White

White

Green

Bare or Green

8

1

1

2

9

10

1

2

3

11

1

2

3

13

1

2

3

12

Installation (con’t)

(VWH/CVWH 10”H./12”H. Wall Hoods w/Recirculating Kit)

Connect black to black, white to white, and the

green/bare wire under the green screw.

NOTE: Housing wiring must be properly installed for

wiring to be correct when wiring unit.

Assemble brackets to baffles and insert charcoal filters.

Replace electrical box cover. Make connection to breaker

box.

Slide filter front over front lip. Push filter rear up, then

slide back over rear lip.

Slide spacer front over front lip. Push spacer rear up, then

slide back over rear lip.

Slide filter front over front lip. Push filter rear up, then

slide back over rear lip.

32

1

-

1

3

/

1

6”

(

4

.

6

c

m

)

1-1/2” x 3/4”

(3.8 cm) x ( 1.9 cm)

wood strip

1

5

/16”

N

ut driver

2

5

/16”

Nut driver

3

5/16”

Nut driver

5

/

1

6

”

N

u

t

D

r

i

p

e

r

1

2

1

3

4

1

2

z

5

Installation

(VWH/CVWH 18”H. Wall & VCWH Chimney Wall Hoods) *For VCWH hoods, begin with Step

3. The VCWH hoods do not require the wood strip

VWH/CVWH only! Measure down 1-13/16 (4.6 cm) from

desired height of hood and secure 1-1/2” x 3/4” wood

strip (provided locally) to wall using screws provided.

CAUTION: Secure vent hood to wall using screws

provided. Use additional mounting screws and wall

anchors, if necessary.

VWH/CVWH only! Use additional mounting screws to

secure hood to wood strip.

CAUTION: If not using a duct cover, using screws

provided, make sure top mounting screws are secured

into soffit or cabinet framing use additional mounting

screws, if necessary.

Slide filter front over front lip. Push filter rear up, then

slide back over rear lip.

Slide filter front over front lip. Push filter rear up, then

slide back over rear lip.

33

1

2

2

To install ventillation kit

refer to ventillation kit

installation instructions.

Duct Cover Option(VWH/CVWH 18”H. Wall Hoods)

Measure distance from ceiling to canopy.

Slide the duct cover in place and fasten from inside

canopy using the sheet metal screws provided.

34

3

4

2

1

2

Duct Cover Option (VCWH/CVCWH Chimney Wall Hoods)

Measure distance from ceiling to canopy.

Place duct cover top inside duct coverbase and lower until

desired height is found.Mark height. Use the retaining nuts

and boltsto fasten in place and remove tape.

Tape to avoid scratching.

Slide the duct cover in place and fasten from inside

canopy using the sheet metal screws provided.

35

1

2

Mounting options:

Using duct cover with ceiling mounting

bracket. (Option A - VCIH only)

Using threaded rod for additional support.

(Option B)

Attaching hood directly to soffit or

duct cover.

(Skip to step 3)

A1

A2

5

/

1

6

”

N

u

t

D

r

i

v

e

r

B1

Installation(VCIH/CVCIH Island Hoods)

Check framing where cutout will be.

NOTE: 200 lb. limit.

Cut appropriate size hole in ceiling. Either 7” or 10”

depending on your specific unit and ventillator kit.

Attach duct cover to optional ceiling mounting bracket.

Attach duct cover to ceiling. The ceiling bracket can be

hidden by using a locally supplied trim.

Additional support option. Drill holes in all four corners

for threaded rod and run rods from hood to ceiling.

36

4

5

/

1

6

”

N

u

t

D

r

i

v

e

r

3

To install ventillation kit

refer to ventillation kit

installation instructions.

Grease Trough

L

a

r

g

e

C

e

n

t

e

r

S

p

a

c

e

r

Side spacer

Center spacer

5

Installation(VCIH/CVCIH Island Hoods)

Run duct work down to bottom edge of duct cover/soffit

and secure in place. Make sure the duct does not stick

down past the cover.

•Install larger center spacer in middle of canopy

•Slide grease trough down into filter support with lip

facing upward

•Attach long edge of side spacers to outer side of baffle

filters to installed next to canopy. Number of filters will

vary due to size. Spacers only go on the (4) filters next to

canopy.

•Insert small center spacer (36” and 42” models only).

•Slide top part of baffle filter up and under large center

spacer.

•Push bottom of filter up and into grease trough.

Attach canopy to duct cover/soffit. Seal top of hood to

duct with aluminum tape.

37

Service & Registration

If service is required, call your dealer or authorized service agency.

The name of the authorized service agency can be obtained from the dealer or distributor in your

area.

Have the following information readily available.

• Model number

• Serial number

• Date purchased

• Name of dealer from whom purchased

Clearly describe the problem that you are having. If you are unable to obtain the name of an

authorized service agency, or if you continue to have service problems, contact Viking Range, LLC

at 1-888-(845-4641), or write to:

VIKING RANGE, LLC

PREFERRED SERVICE

111 Front Street

Greenwood, Mississippi 38930 USA

Record the information indicated below. You will need it if service is ever required. The model and serial

number for your hood is located behind the baffle filter on the left side panel in the lower right corner.

Model no. _________________________Serial no. ___________________________

Date of purchase ___________________ Date installed _____________________

Dealer’s name __________________________________________________________

Address ________________________________________________________________

________________________________________________________________________

If servicerequires installation of parts, use only authorized parts to ensure protection under the warranty.

THIS MANUAL SHOULD REMAIN WITH THE HOOD FOR FUTURE REFERENCE.

38

39

Viking Range, LLC

111 Front Street

Greenwood, Mississippi 38930 USA

(662) 455-1200

For product information,

call 1-888-(845-4641)

or visit our web site at vikingrange.com

F21287H EN

(040119)

Loading...

Loading...