Viking VMOS201SS, VMTK272SS, VMOC206BK, VMTK307SS, VMTK367SS Installation

Viking Installation Guide

IMPORTANT–Please Read and Follow!

• Before beginning, please read these instructions completely and carefully.

• Be sure to DISCONNECT THE PLUG of the microwave oven from the electrical outlet before installing the built-in trim kit.

Remove the turntable from the oven cavity.

• Because the kit includes metal parts, caution should be used in handling and installation to avoid the possibility of injury.

• Do not remove permanently affixed labels, warnings, or plates from the product. This may void the warranty.

• Please observe all local and national codes and ordinances.

• Theinstallershouldleavethese instructionswiththe consumerwhoshouldretainfor localinspector’suse andfor

futurereference.

• This built-in trim kit is designed for use ONLY WITH VIKING CONVECTION AND CONVENTIONAL MICROWAVE OVENS

SPECIFYING BUILT-IN TRIM KIT VMTK272, VMTK302, VMTK362, VMTK277, VMTK307 or VMTK367 on the rating label on

the bottom face plate of the oven cavity.

• YOUR OVEN CAN BE BUILT INTO A CABINET OR WALL BY ITSELF OR ABOVE ANY ELECTRIC WALL OVEN OR WARMING

DRAWER.

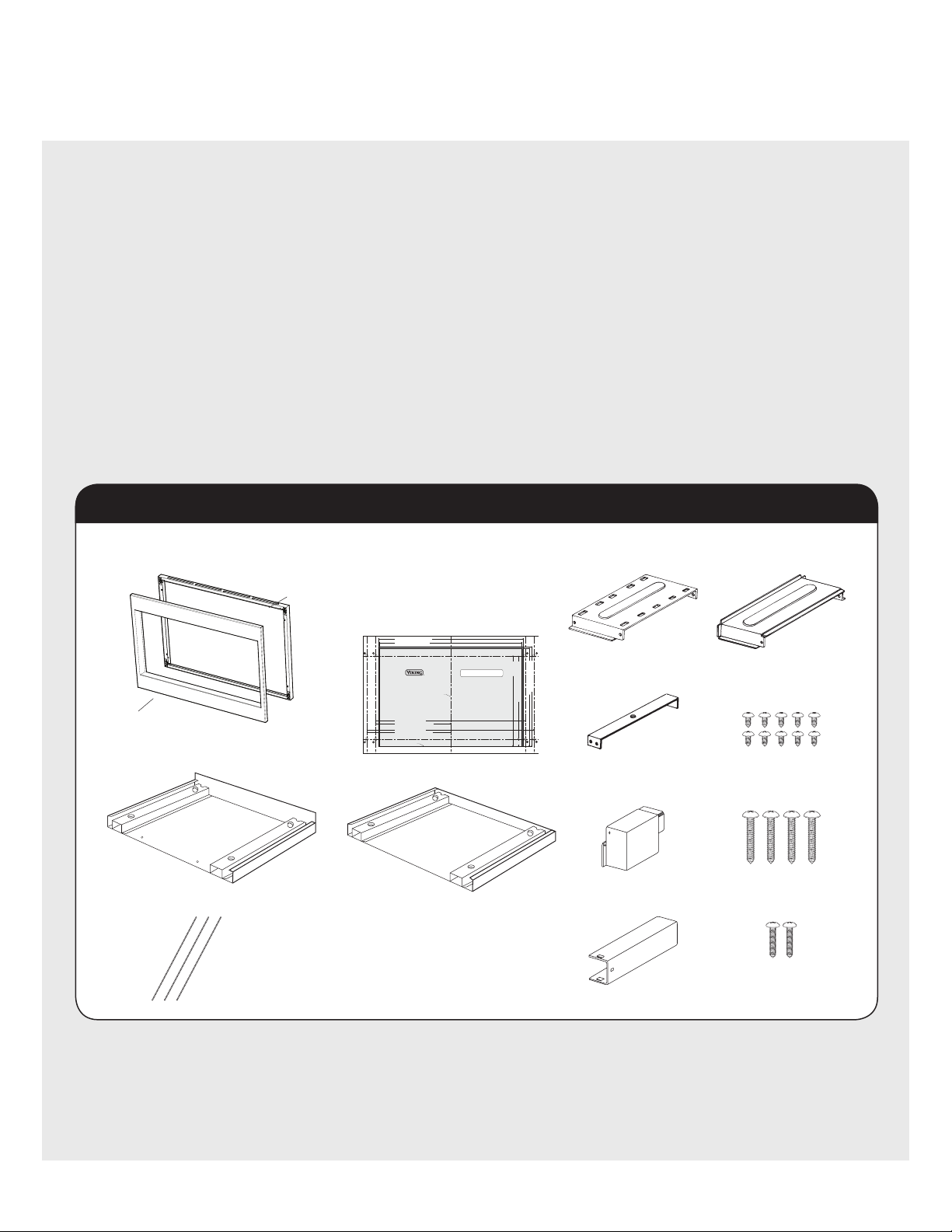

Parts Included in VMTK kits

Front Frame Assembly QTY 1

Front Frame

QTY 1

Bottom Duct Assembly QTY 1

Cushion QTY 3

Back Frame

QTY 1

27" & 30"Surface Mount

Tem p l ate 2- s ided

or 36"Surface Mount

Template single-sided

QTY 1

Maximum Cutout Opening Width 24-11/16" (627.06 mm)

Minimum Cutout Opening Width 24-3/8" (619.13 mm)

USE THIS SIDE OF TEMPLATE FOR MODELS

Center Line

VMTK272 and VMTK302 ONLY.

1. Align the mounting template center line with the center of the cutout

and the floor line with the floor of the cutout. Tape it into place.

2. For VMTK272, predrill 4 holes marked A with a 1/16" drill bit.

For VMTK302, predrill 4 holes marked B with a 1/16" drill bit.

3. Remove template from the cabinet.

BUILT-IN TRIM KIT TEMPLATE

FOR CUSTOM SERIES MICROWAVE OVEN

Distance between holes A 25-9/16" (649.3 mm)

Distance between centerline to holes

Distance between holes B 28-9/16" (725.5 mm)

Distance between centerline to holes

Floor Line of Cutout Opening

12-13/16" (324.65 mm)

14-5/16" (362.75 mm)

*

TINSKB133MRR0

15-13/32" (391.45 mm)

Maximum Height distance between holes 14-1/4" (361.825 mm)

1-5/32"

(29.6 mm)

Duc t (A) -1 QTY 1 * Duct (A)-3 QTY 1 *

3/4" (425.5 mm)

-

Maximum Cutout Opening Height 17" (431.8 mm)

Minimum Cutout Opening Height 16

Duct (A)-2 QTY 1 *

Duct (B) QTY 1 *

Duct (C) QTY 1 *

Screw A (1/2" length)

QTY 10 *

Screw B (1-3/4" length)

QTY 4

Screw C (3/4" length)

QTY 2

*VMTK277, VMTK307 and VMTK367 O NLY.

Custom Series Convection /

Conventional Microwave Built-In Trim Kit

111 Front Street

Greenwood, Mississippi 38930 USA

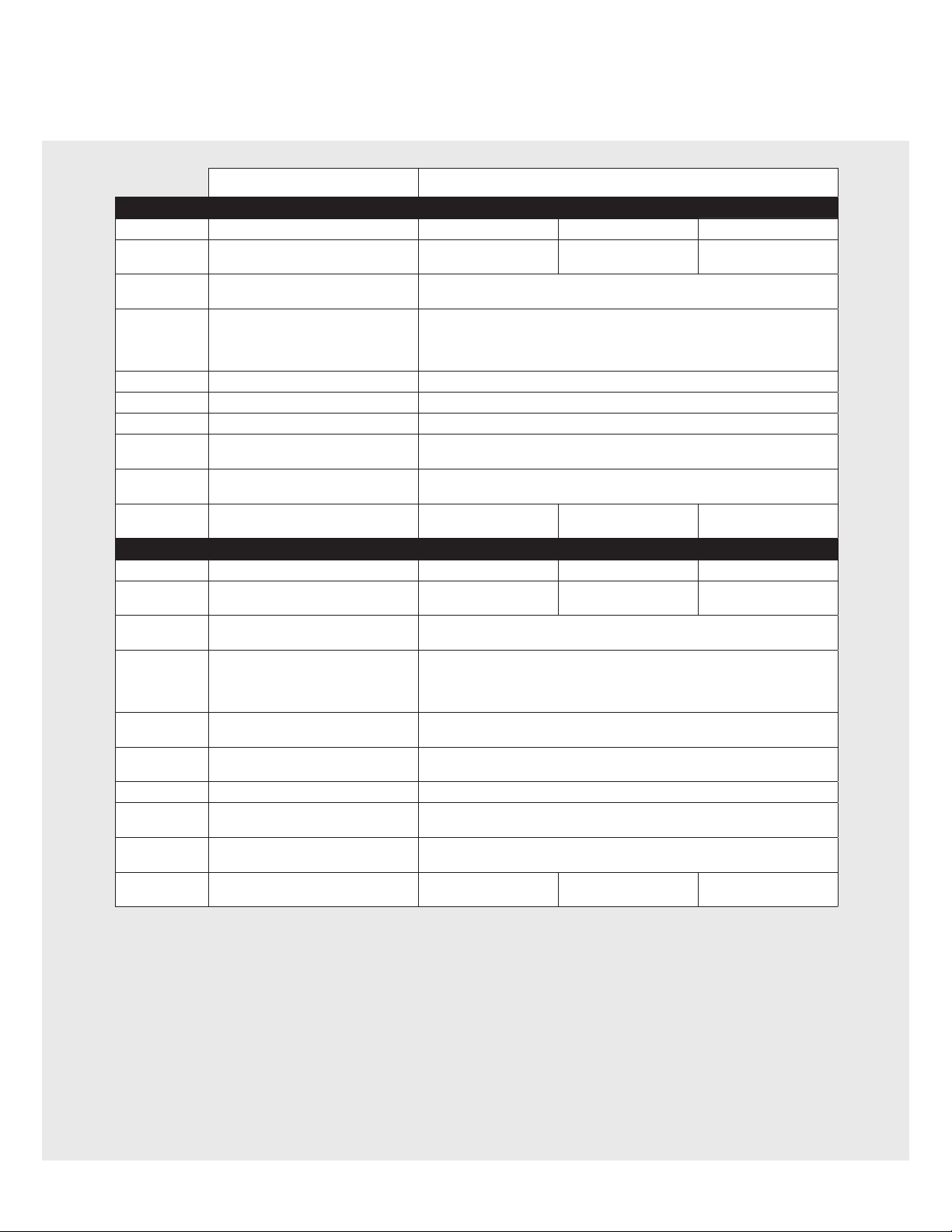

Basic Specifications

MicrowaveOven Built-InCustomTrimKits

Description CONVECTIONVMOC206 VMTK277 VMTK307 VMTK367

Overall Width 24-5/8" (62.5 cm) 26-1/2" (67. 3 cm) 29-1/2" (74.9 cm) 35-1/4" (89.5 c m)

Overall Height

from Bottom

Overall Depth

from Rear

Oven Interior

Cutout Width N/A Min. 25" (63.5 cm)

Cutout Height N/A Min. 18 -11/16" (46.9 cm)

Cutout Depth N/A Min. 20 -1/8" (51.1 c m)

Electrical

Requirements

Maximum Amp

Usage

Approximate

Shipping Wt.

Description CONVENTIONALVMOS201 VMTK272 VMTK302 VMTK362

Overall Width 24" (60.9 cm) 26-1/2" (67. 3 cm) 29-1/2" (74.9 c m) 35 -1/4" (89. 5 cm)

Overall Height

from Bottom

Overall Depth

from Rear

Oven Interior

Cutout Width N/A

Cutout Height N/A

Cutout Depth N/A Min. 20" (50.3 cm)

Electrical

Requirements

Maximum Amp

Usage

Approximate

Shipping Wt.

14-7/8" (37.7 c m ) 19-13 /16" (5 0 .1 c m) 19-13 /16" (5 0 .1 c m) 19-13 /16" (5 0 .1 c m)

19" (48.3 cm) N/A

Width

Height

Depth

Overall

120VAC/60 Hz (UL)

117VAC/60 Hz (CSA)

1.55 KW

1.5 KW

60 lbs. (27. 2 k g ) 19 lbs. (8.6 kg) 20 lbs. (9.1 k g ) 23 lbs. 10.5 kg

13- 3/8" (33.9 cm) 18-1/4" (46.3 cm) 18 -1/4" (46.3 cm) 18 -1/4" (46.3 cm)

19-1/4" (48.9 cm) N/A

Width

Height

Depth

Overall

120VAC /60 Hz N/A

1.5 KW 13 amps N/A

46 lbs. (20.9 kg) 14 lbs . (6.5 kg) 15 lbs. (6.9 kg) 18 lbs. (8.2 kg)

16-1/8"

9-5/8"

16-1/8"

1.5 cu. ft.

13 amps (UL)

13 (CS A)

17-3 /8"

10-1/2"

18-5/8"

2.0 cu. ft.

(40.9 cm)

(24.4 cm)

(40.9 cm)

(4 4 .1 c m)

(26.6 cm)

(4 7. 3 cm )

Min.

Max.

Min.

Max.

N/A

N/A

N/A

N/A

24-3/8"

24 -11/16"

16-3/4"

17"

(61.9 c m )

(62.7 cm)

(42.5 cm)

(43.2 cm)

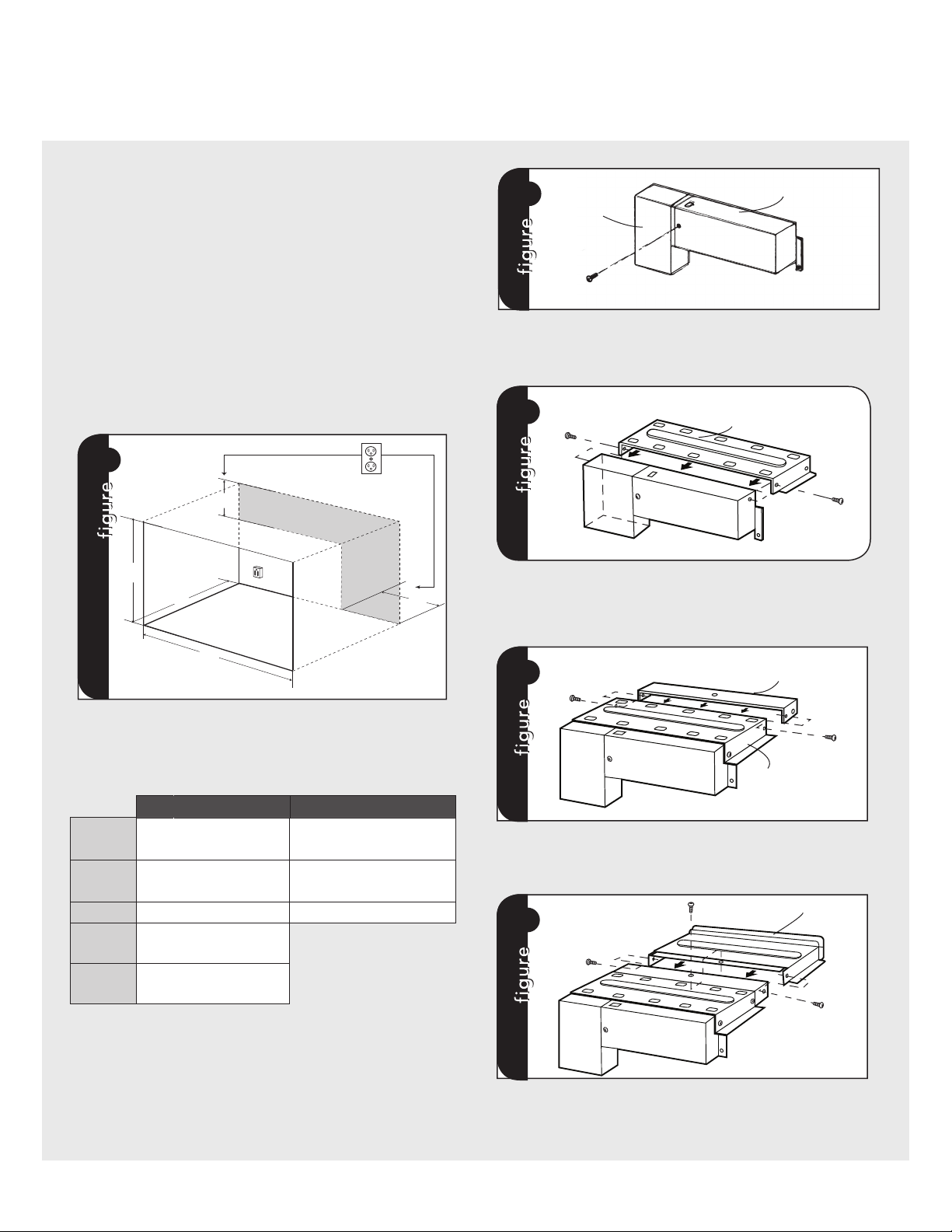

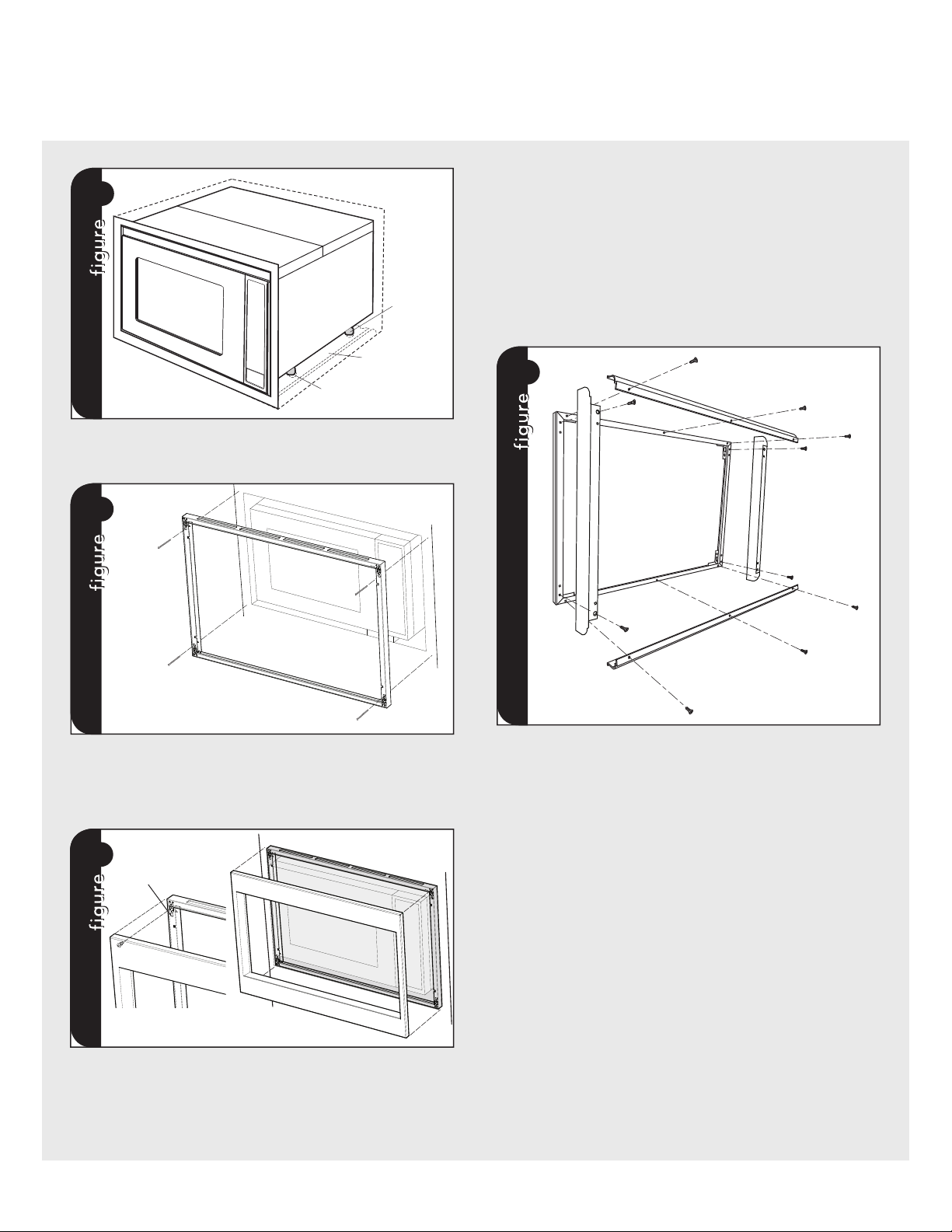

E2

Cabinet or Wall Cutout

Provide an opening in the wall or cabinet as indicated

in figure 1. The depth should be a minimum of 20-1/8"

(51.1 cm). If the Depth (C) dimension is greater than 21"

(53.3 cm), the outlet location may be in any area on the

rear wall. The floor of the opening should be constructed

of plywood strong enough to support the weight of the

oven (about 100 lbs.) and should be level for proper

operation of the oven.

Exhaust Duct Assembly

2

DUCT (B)

SCREW (A)

DUCT (C)

Note: While the proper functioning of the oven does not

require that the opening be enclosed (with sides, ceiling

and rear partition), this may be required by local code,

and it is suggested that the local code be checked for

any such requirement.

1

E

A

C

B

SurfaceMountCutoutDimensions

* For flush mount dimensions please see installation template and

FLUSH MOUNT INSTALLATION on page 5-6.

CONVECTION CONVENTIONAL

(A) Height

(B) Width

(C) Depth Min. 20 -1/8" (51.1 c m) Min. 20-1/8" (51.1 c m )

(D)

(E)

ELECTRICAL OUTLET LOCATION: Outlet should NOT be in the

shaded area as indicated on figure 1. At the rear of the opening,

provide a 3-pronged, polarized, electrical outlet, 115-120 volt AC,

15 amp or larger.

18-1/2" (46.9 c m) Min. 16-3/4" (42.5 cm)

Max. 17" (43.2 cm)

25" (63.5 cm) Min. 24-3/8" (61.9 cm)

Max. 24-11/16" (62.7 cm)

Min.

Max.6"11-1/2"

Min.

Max.4"5"

(15.2 cm)

(2 9. 2 cm)

(10.2 cm)

(12.7 cm)

D

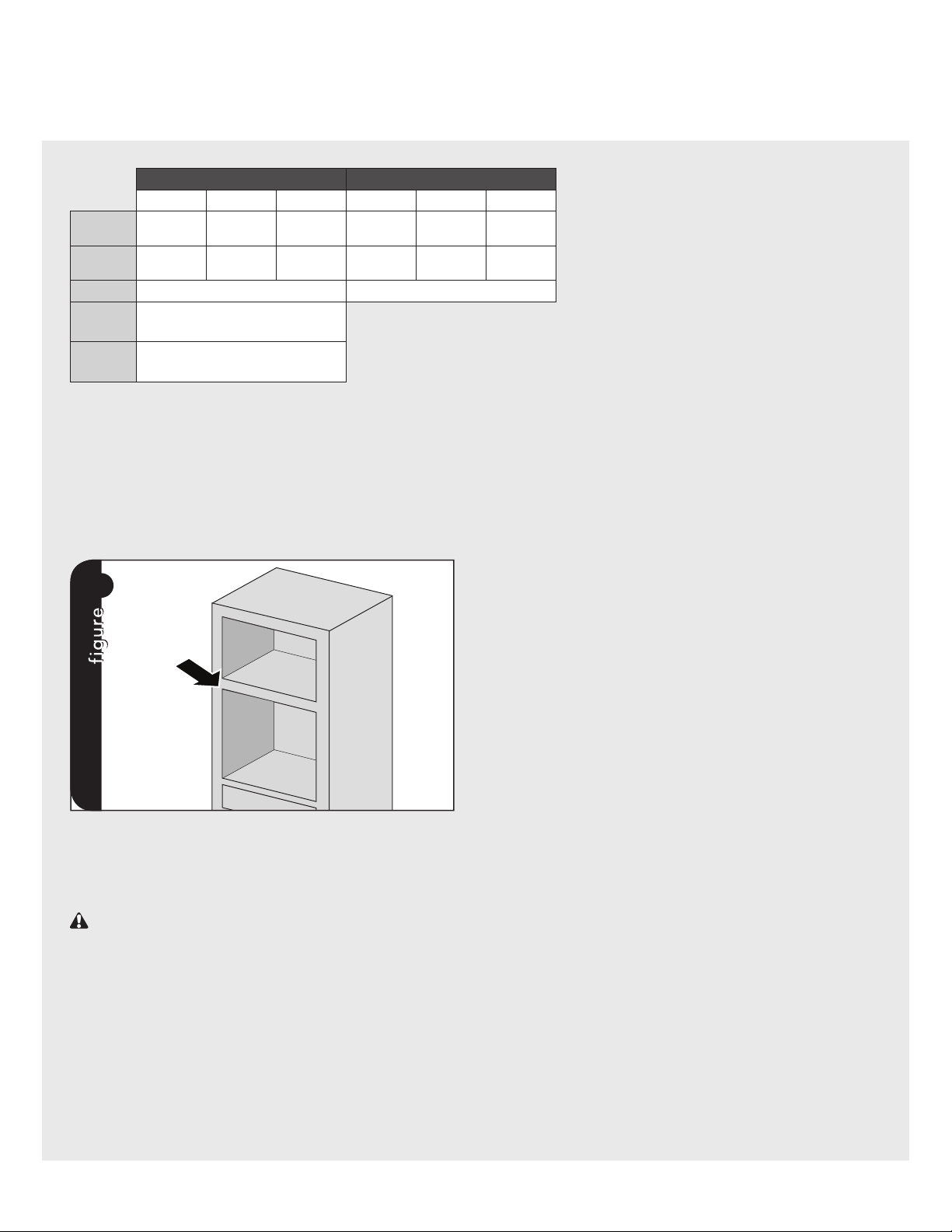

EXHAUST DUCT ASSEMBLY: Insert the edge of DUCT (B) into the

hold lip of DUCT (C). Secure together by using a SCREW (A) provided

in the kit. See figure 2.

3

SCREW (A)

EXHAUST DUCT ASSEMBLY: Position DUCT (A)-1 on the top of the

oven inserting edge of DUCT (BC) assembly into hole lip of DUCT

(A)-1. Tighten two SCREWS (A), securing DUCT (A)-1 to DUCT (BC)

assembly. See figure 3.

SCREW (A)

4

EXHAUST DUCT ASSEMBLY: Position DUCT (A)-2 on the top of the

oven and insert it into the hold lip of DUCT (A)-1. Secure DUCT (A)-2

to DUCT (A)-1 using two SCREWS (A) provided. See figure 4.

SCREW (A)

DUCT (A)-1

DUCT (BC)

SCREW (A)

DUCT (A)-2

SCREW (A)

DUCT (A)-1

DUCT (A)-3

5

SCREW (A)

SCREW

(A)

DUCT (A)-2

EXHAUST DUCT ASSEMBLY: Position DUCT (A)-3 on top of the oven

and insert it into DUCT (A)-2. Secure DUCT (A)-3 using three screws

(A) provided. See figure 5.

E3

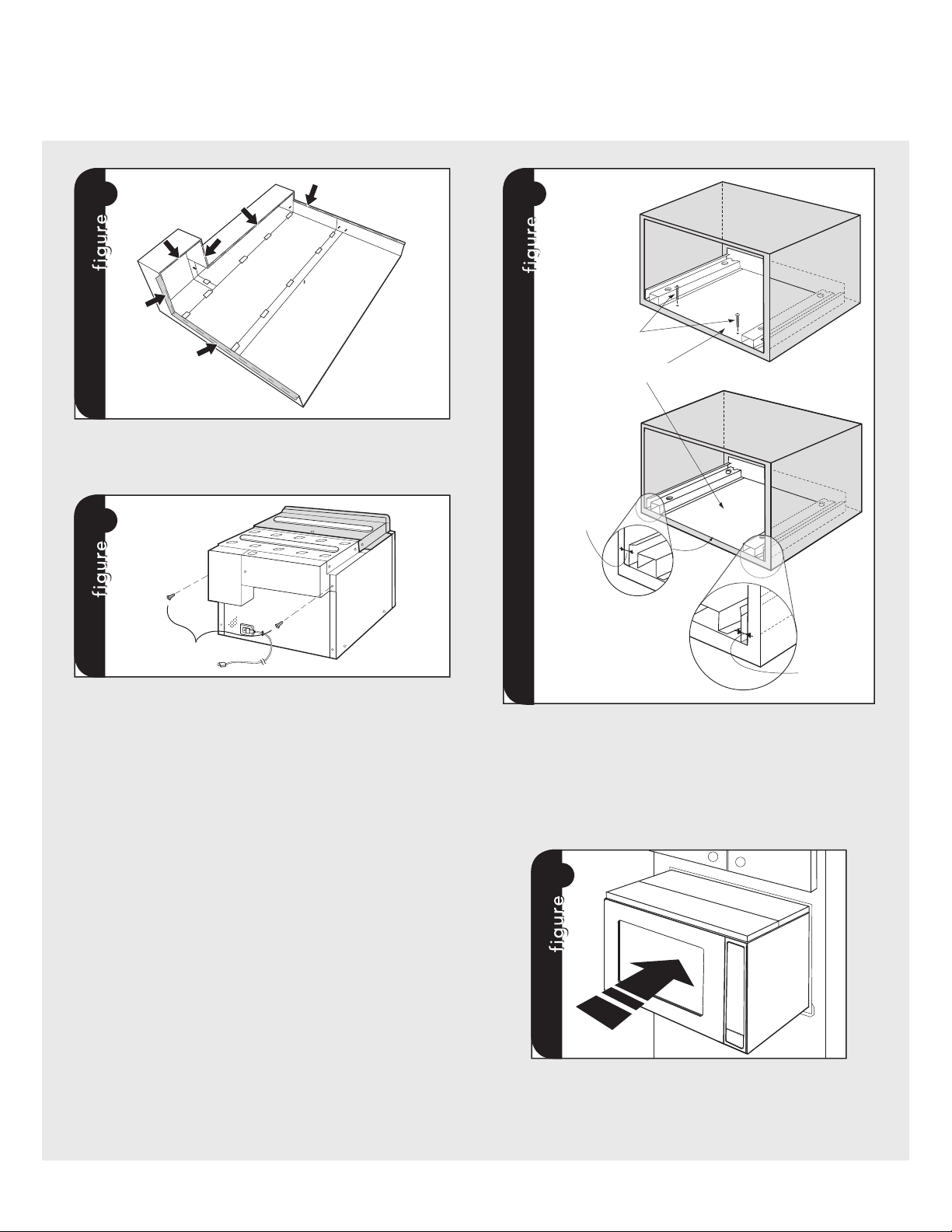

Exhaust Duct Assembly Surface Installation

5

EXHAUST DUCT ASSEMBLY: Remove the cushions from the adhesive

backing. The cushion should be applied to the flanges of the duct

assembly as indicated by arrows. See figure 5A.

5

A

B

SCREW

6

BOTTOM DUCT ASSEMBLY

GAP "A"

NOTE: CENTER

BOTTOM DUCT

ASSEMBLY IN THE

OPENING

SCREW C

DETAIL A

GAP "B"

EXHAUST DUCT ASSEMBLY: Remove SCREW from the upper right

and left corners at the rear of the oven. Place duct assembly on the

top of the unit as shown and secure the duct assembly to the oven

using the two screws just removed from the oven. See figure 5B.

*Figures 2 - 5 for models VMTK277, 307 and 367 ON LY.

MOUNTING TEMPLATE: Identify the appropriate side of template

to use with your unit. Align the mounting template center line with

the center of the cutout and the floor line with the floor of the cutout.

Tape it into place.

• For VMTK272 only, predrill

4 holes marked “A” with a

1/16" drill bit.

• For VMTK302 only, predrill

4 holes marked “B” with a

1/16" drill bit.

• For VMTK362 only, predrill

4 holes marked “C” with a

1/16" drill bit.

Remove template from the cabinet.

• For VMTK277 only, predrill

4 holes marked “A” with a

1/16" drill bit.

• For VMTK307 only, predrill

4 holes marked “B” with a

1/16" drill bit.

• For VMTK367 only, predrill

4 holes marked “C” with a

1/16" drill bit.

BOTTOM DUCT ASSEMBLY: Place the Bottom Duct in the center of

the opening so that gap "A" is equal to gap "B". 1 When the Bottom

Duct Assembly for VMTK277SS, 307SS or 376SS is positioned properly,

the front edge of the duct will be flush with the front of the cabinet.

2 The VMTK272SS, 302SS, 372SS Exhaust Duct will be positioned

properly when the edge of the duct is recessed 5mm from the front

of the cabinet. See figure 6. Secure the Bottom Duct Assembly with

the two (¾") SCREWS (C).

7

CABINET INSTALLATION: Place the oven adjacent to the wall or

cabinet opening. Plug the power cord into the electrical outlet.

Carefully guide the assembled oven into the prepared opening. Slide

the oven on the Bottom Duct Assembly. See figure 7.

E4

Surface Installation Flush Mount Installation

PARTS INCLUDED IN FLUSH MOUNT ACCESSORY KIT

8

FOOT

BOTTOM

DUCT

ASSEMBLY

DUCT RECESS

CABINET INSTALLATION: Avoid pinching the cord between the oven

and the wall. Adjust the position of the oven so that the feet of the oven

are fitted into the holes of the Bottom Duct Assembly. See figure 8.

(PURCHASED SEPARATELY):

•(2) Stainless Steel Scoops

•(10) Stainless Machine Screws

•(1) Flush Mount Template

•(2) Side Trim

* See FLUSH MOUNT TEMPLATE for additional installation instructions.

"

9

SCREW (B)

SCREW (B)

SCREW (B)

SCREW (B)

FRAME INSTALLATION: Position the BACK FRAME to align with the

predrilled holes that were drilled with the mounting template. Check

that it is level and then secure with four SCREWS (B). See figure 9.

Secure the bottom portion of the BACK FR AME with the two remaining

SCREWS (B).

SNAP

!

ATTACHM ENT

FLUSH MOUNT INSTALLATION: Place the 2 Scoops on the back of

the frame as shown and align the screw holes on the scoop with the

tapped holes in the frame. Secure the scoops to the frame using 6

of the machine screws provided in the kit. Place the side trim pieces

on the back of the frame as shown and align the top and bottom

most screw holes with the corresponding taped holes in the frame.

Secure the trim pieces with the 4 remaining machine screws provided.

Attach the frame assembly to the wooden side spacers by aligning

the mounting holes in the frame with the pre-drilled holes in the side

spacers and secure with SCREW (B) provided with the trim kit. See

figure ".

DECORATION INSTALLATION: Place the FRONT decoration onto the

FRAME and align ball studs and receivers. Secure the DECORATION

to the FRAME by firmly pushing the front frame onto the back frame

engaging the four (4) snap attachments. See figure !.

DECORATION INSTALLATION: Place the FRONT decoration onto the

FRAME and align ball studs and receivers. Secure the DECORATION

to the FRAME by firmly pushing the front frame onto the back frame

engaging the four (4) snap attachments. See figure !.

E5

Flush Mount Installation

CONVECTION CONVENTIONAL

27" 30" 36" 27" 30" 36"

(A) Height

(B) Width

(C) Depth 22-1/16" (56.1 cm) 22-1/16" (56.1 cm)

(D)

(E)

21-5/16"

(542 cm)

26 -15/16"

(68.3 cm)

Min.

Max.

Min.

Max.

21-5/16"

(542 cm)

29 -15/16"

(76 cm)

6"

11-1/2"

4"

5"

21-5/16"

(542 cm)

35-5/8"

(90.4 cm)

(15.2 cm)

(2 9. 2 cm)

(10.2 cm)

(12.7 cm)

19-7/8"

(504 cm)

26 -15/16"

(68.3 cm)

19-7/8"

(504 cm)

29 -15/16"

(76 cm)

Installation

19-7/8"

(504 cm)

35-5/8"

(90.4 cm)

#

MICROWAVE

OPENING

LOWER OVEN

OPENING

OVER OVEN INSTALLATION: Space between the microwave and the

lower oven: 2" (5.08 cm) for 27"W and 30"W. See Figure #.

The trim kits described in this installation guide, and listed

below, are NOT TO BE INSTALLED ABOVE GAS OVENS.

VMTK272SS VMTK307SS VMTK362SS

VMTK277SS VMTK302SS VMTK367SS

For more product information, call

1-888-VIKING1 (845-4641) or visit our

website at http://www.vikingrange.com

E6

Loading...

Loading...