Viking VK680 Technical Data Manual

QUICK RESPONSE

TECHNICAL DATA

EXTENDED COVERAGE

CONCEALED HSW

SPRINKLER VK680 (K8.0)

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com

Visit the Viking website for the latest edition of this technical data page www.vikinggroupinc.com.

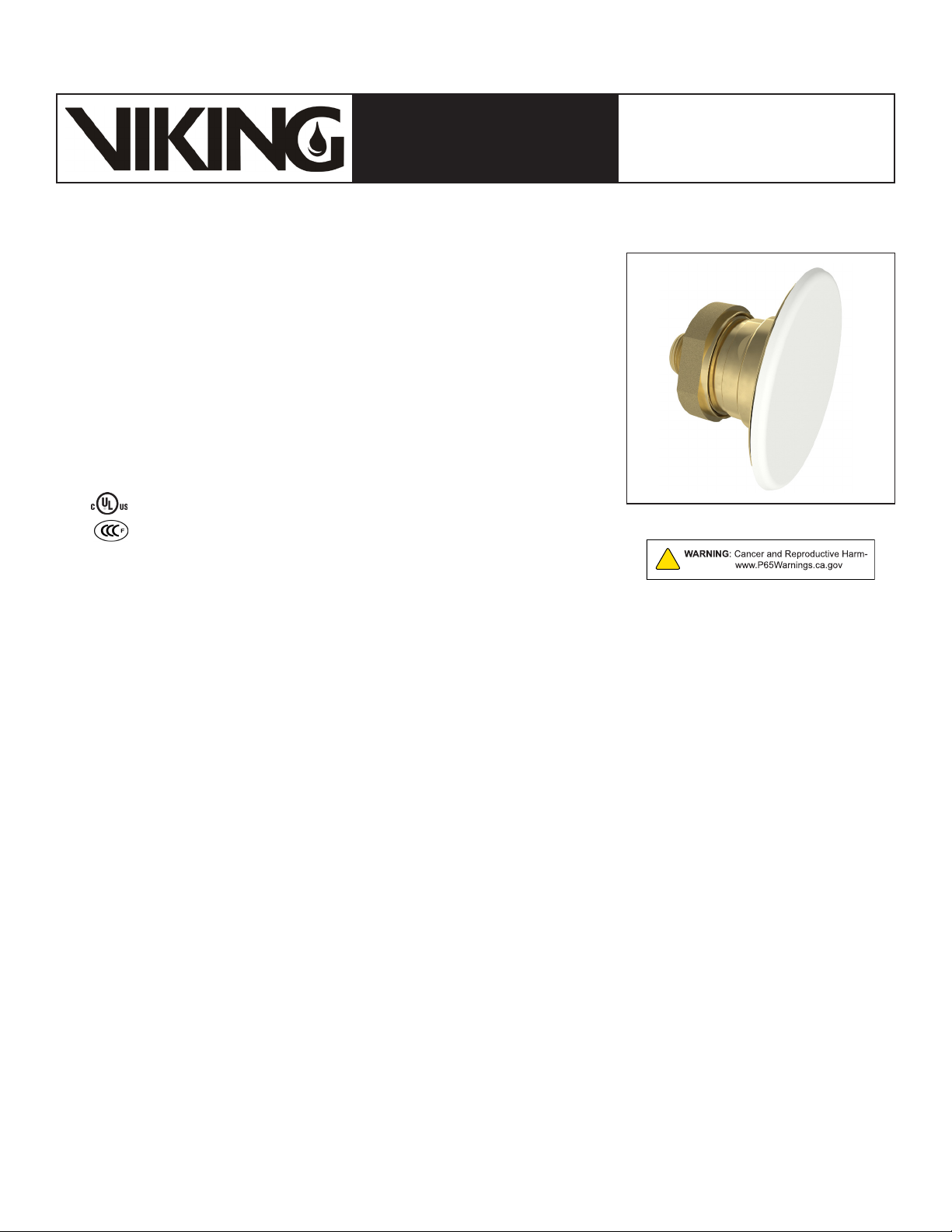

1. DESCRIPTION

Viking QREC Concealed Horizontal Sidewall Sprinkler VK680 is a small highsensitivity solder link and lever sprinkler designed for installation on concealed pipe

systems, where the appearance of a smooth wall is desired. The fast response

operating element and special flow shaper characteristics meet the challenges of

quick response extended coverage standards.

The sprinkler is hidden from view by a low profile, small diameter cover plate installed

flush to the wall. The cover plate is available in several decorative finishes to meet

design requirements. The two-piece design allows installation and testing of the

sprinkler prior to installation of the cover plate. After the system has been tested and

wall finish has been applied, the push-on design of the cover plate assembly allows

easy installation of the cover plate with up to 1/4” (6.4 mm) adjustment.

2. LISTINGS AND APPROVALS

cULus Listed: Category VNIV

CCCF Approved: Approved by the China Certification Center for Fire

Products (CCCF)

Refer to the Approval Chart and Design Criteria on this Technical Data Page

for cULus Listing requirements that must be followed.

For Light Hazard Occupancies Only

Page 1 of 5

3. TECHNICAL DATA

Specications:

Available since 2011.

Minimum Operating Pressure: 7 psi (0.5 bar)

Maximum Working Pressure: 175 psi (12 Bar). Factory tested hydrostatically to 500 psi (34.5 bar).

Thread size: 3/4” (20 mm) NPT

Nominal K-Factor: 8.0 U.S. (115.2 metric†)

† Metric K-factor measurement is in Bar. When pressure is measured in kPa, divide the metric K-factor shown by 10.0.

Available Cover Plate Horizontal Adjustment: 1/4” (6.4 mm)

Overall Length (Sprinkler Body): 2” (50.8 mm)

Patents Pending

Material Standards:

Sprinkler Body: QM Brass and Brass UNS-C84400

Belleville Spring Sealing Assembly: Nickel Alloy, coated on both sides with Teflon Tape

Seat: Brass UNS-C31400

Deflector Ring: Brass UNS-C23000

Deflector Pins: Stainless Steel UNS-S30200

Halo: Brass UNS-C31400 or Phosphor Bronze UNS-C51000

Flow Shaper: Phosphor Bronze UNS-C51000

Lever Bar Ring: Brass UNS-C31400 or Brass UNS-C84400

Compression Screw: 18-8 Stainless Steel

Fusible Link Assembly: Nickel Alloy and Eutectic Solder

Fusible Link Levers: Stainless Steel UNS-S31600

Guide Pin: Stainless Steel UNS-S43000

Shipping Cap: Polyethylene

Cover Assembly Materials:

Cover Plate Assembly: Copper UNS-C11000 and Brass UNS-C26800

Spring: Beryllium Nickel

Solder: Eutectic

Form No. F_050611 18.10.25 Rev 17.1.P65

Replaces Form No. F_050611 Rev 17.1

(Added P65 Warning.)

Page 2 of 5

F

A

C

T

O

R

Y

A

P

P

L

I

E

D

C

U

S

T

O

M

P

A

I

N

T

C

O

L

O

R

QUICK RESPONSE

TECHNICAL DATA

EXTENDED COVERAGE

CONCEALED HSW

SPRINKLER VK680 (K8.0)

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com

Visit the Viking website for the latest edition of this technical data page www.vikinggroupinc.com.

Ordering Information: (Also refer to the current Viking price list.)

Viking QREC Concealed HSW Sprinkler VK680 and Cover Plate Assembly must be ordered separately:

Sprinkler: Part No. 17114AC (includes a 165 °F (74 °C) temperature rated sprinkler with a protective plastic cap covering the unit).

Cover Plate Assembly: Base Part No. 16207 (3-5/16” diameter)

Specify finish and temperature rating of the cover plate assembly by adding the appropriate suffixes for the finish and the cover

temperature rating to the base part number:

Finish Suffix: Polished Chrome = F, Painted White = M-/W, Painted Ivory = M-/I, Painted Black = M-/B

Temperature Suffix: 135 °F (57 °C) = A

For example, cover 16207 with a Polished Chrome finish and a 135 °F (57 °C) temperature rating = 16207FA.

Available Finishes And Temperature Ratings: Refer to Table 1.

Accessories: (Also refer to the Viking website.)

Sprinkler Wrenches**:

A. Heavy Duty Wrench Part No. 16208W/R (available since 2010)

B. Head Cabinet Wrench Part Number 16267*** (available since 2010)

C. Optional Large Concealed Cover Plate Installer Tool Part No. 14867 (available since 2007)

**Requires a ½” ratchet (not available from Viking).

***Ideal for sprinkler cabinets.

Sprinkler Cabinet: Part No. 01731A (available since 1971)

4. INSTALLATION

Refer to appropriate NFPA Installation Standards.

5. OPERATION

During fire conditions, when the temperature around the sprinkler approaches its operating temperature, the cover plate detaches.

Continued heating of the exposed sprinkler causes the fusible element to disengage, releasing the sealing assembly. Water flowing

through the sprinkler orifice strikes the flow shaper, forming a uniform spray pattern to extinguish or control the fire.

6. INSPECTIONS, TESTS AND MAINTENANCE

Refer to NFPA 25 for Inspection, Testing and Maintenance requirements.

7. AVAILABILITY

The Viking Model VK680 Sprinkler is available through a network of domestic and international distributors. See The Viking

Corporation web site for the closest distributor or contact The Viking Corporation.

8. GUARANTEE

For details of warranty, refer to Viking’s current list price schedule or contact Viking directly.

All custom color painted cover plates will have an identifying label affixed

Form No. F_050611 18.10.25 Rev 17.1.P65

to the inside of the cover that indicates the custom color and will have a

Figure 1: Identification of Custom Paint for Concealed Covers

representative sample (a paint dot) of the paint on the label.

Loading...

Loading...