Viking VK503, K16.8 Technical Data Manual

Page 1 of 6

TECHNICAL DATA

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com

Visit the Viking website for the latest edition of this technical data page: www.vikinggroupinc.com

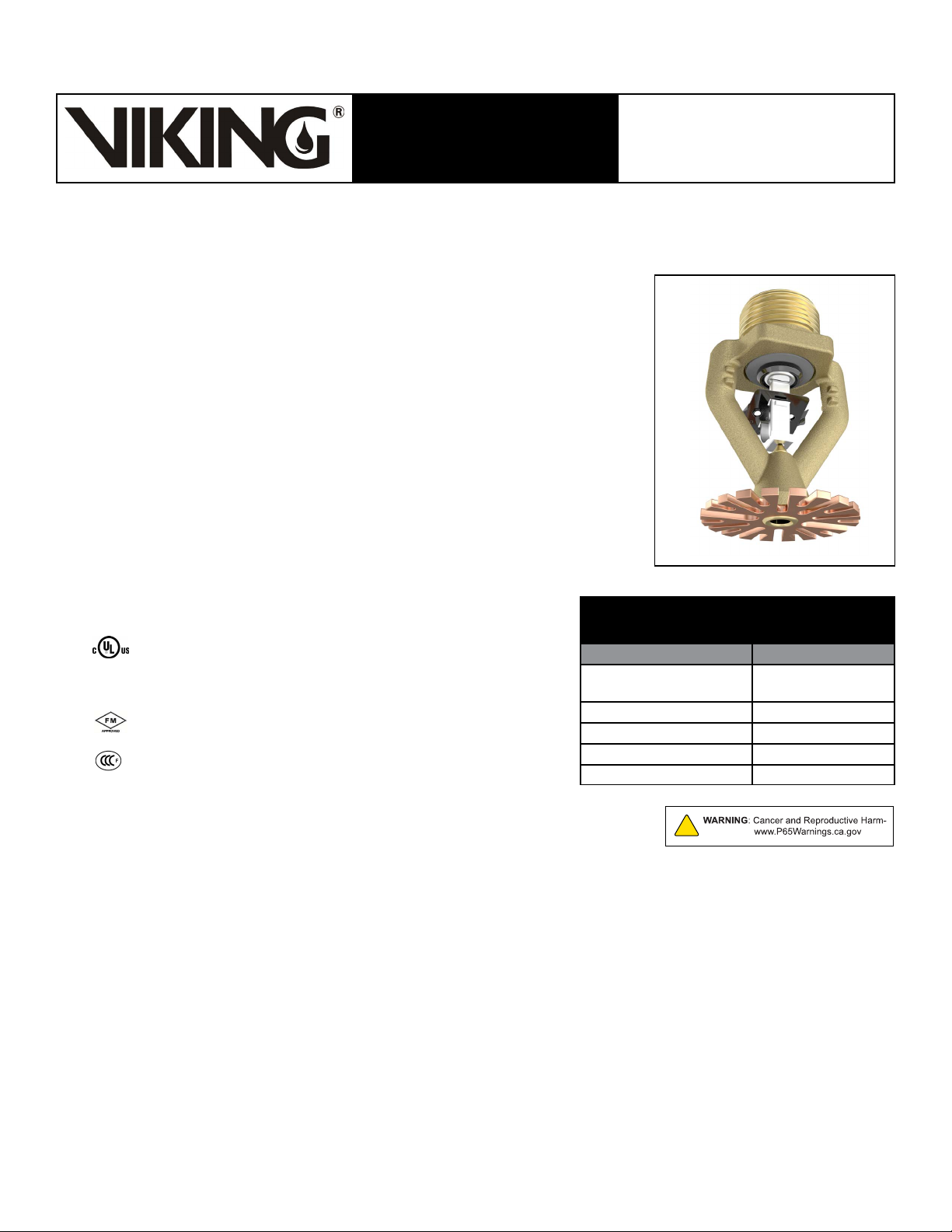

ESFR PENDENT SPRINKLER

VK503 (K16.8)

1. DESCRIPTION

Viking Early Suppression Fast Response (ESFR) Pendent Sprinkler VK503 is a fast

response fusible element type sprinkler designed for early fire suppression. With a

16.8 (242 metric*) nominal K-Factor and special deflector, this sprinkler produces large,

high-momentum water droplets in a hemispheric pattern below the deflector. This permits penetration of the fire plume and direct wetting of the burning fuel surface while

cooling the atmosphere early in the development of a high-challenge fire.

Viking Sprinkler VK503 may be used in the protection of ordinary types of storage.

However, it is primarily intended to protect the following types of storage, which tend

to produce severe-challenge fires: palletized and solid pile storage and single, double,

multiple row, and portable open rack storage (no open-top containers or solid shelves).

Viking ESFR Pendent Sprinkler VK503 provides protection of most common storage

materials, including:

--Encapsulated or unencapsulated Class I, II, III, and IV commodities*.

--Cartoned and uncartoned unexpanded plastics*.

--Cartoned expanded plastics*.

* Refer to the Approval Charts and Commodity Selection and Design Criteria Overview for cULus

Listing and FM Approval requirements that must be followed.

In addition, some storage arrangements of rolled paper, aerosols, and rubber tires may be protected by Viking ESFR Pendent Sprinkler VK503.

2. LISTINGS AND APPROVALS

cULus Listed: Category VNWH

Successfully meets UL 1767 test standard and compliance

program for ESFR sprinklers installed in-rack storage with

high clearances to ceiling (20 ft or greater)

FM Approved: Class 2027

NYC Approved: MEA 89-92-E, Volume 41

CCCF Approved: Approved by the China Certification Center for

Fire Products (CCCF)

Refer to the Approval Charts and Commodity Selection and Design

Criteria Overview for cULus Listing and FM Approval requirements

that must be followed.

SPRINKLER GENERAL INFORMATION

Item Description

Sprinkler Identification

Number (SIN)

K-factor, gpm/psi

Thread Size

Sprinkler Orientation Pendent

Maximum Working Pressure 175 psi (12 bar)

TABLE 1

VK503

½

(lpm/bar½) 16.8 (242)

3/4” NPT (20 mm BSPT)

3. TECHNICAL DATA

Specications:

Available since 2007.

Maximum Working Pressure: 175 psi (12 bar). Factory tested hydrostatically to 500 psi

(34.5 bar).

Thread size: 3/4” NPT or 20 mm BSPT

Nominal K-Factor: 16.8 U.S. (242 metric*)

* Metric K-factor measurement shown is when pressure is measured in bar. When pressure is measured in kPa, divide the metric K-factor shown by 10.0.

Overall Length: 2-7/8” (73 mm)

Deflector Diameter: 1-3/4” (44.5 mm)

Covered by one or more of the following patents: US5,829,532; US6,059,044; US6,336,509; US6,502,643; US6,868,917; AU722593; GB2336777

Material Standards:

Frame Casting: Brass UNS-C84400

Deflector: Phosphor Bronze UNS-C51000

Seat and Insert Assembly: Copper UNS-C11000 and Stainless Steel UNS-S30400

Belleville Spring Sealing Assembly: Nickel Alloy, coated on both sides with PTFE Tape

Compression Screw: Stainless Steel UNS-S31603

Form No. F_120106 18.10.11 Rev 18.2

(Replaced design criteria tables; added P65 Warning.)

Replaces Form No. F_120106 Rev 18.1

Page 2 of 6

TECHNICAL DATA

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com

Visit the Viking website for the latest edition of this technical data page: www.vikinggroupinc.com

Trigger and Support: Stainless Steel UNS-S31600

Fusible Element Assembly: Beryllium Nickel, coated with black acrylic paint.

Ordering Information: (Also refer to the current Viking price list.)

Order ESFR Pendent K16.8 Sprinkler VK503 by first adding the appropriate suffix for the sprinkler finish and then the appropriate

suffix for the temperature rating to sprinkler base part number.

Finish Suffix: Brass = A

Temperature Suffix: 165 °F (74 °C) = C, 205 °F (96 °C) = E

For example, sprinkler VK503 with a Brass finish and a 165 °F (74 °C) temperature rating = Part No. 14073AC.

Accessories: (Also refer to the Viking website.)

Sprinkler Wrench: Part No. 13635W/B (double-ended wrench - Use Side A. Side B is for use with K25.2 ESFR Pendent Sprinkler

VK510) Available since 2006.

Sprinkler Cabinet: Twelve-head capacity: Part No. 01725A (available since 1971)

ESFR PENDENT SPRINKLER

VK503 (K16.8)

4. INSTALLATION

WARNING

Viking sprinklers are manufactured and tested to meet rigid requirements of the approving agency. The sprinklers

are designed to be installed in accordance with recognized installation standards. System design must be based on

ESFR design guidelines described in the latest edition of Viking technical data, applicable FM Global Loss Prevention

Data Sheets, the latest NFPA Standards, the latest standards of Verband der Sachversicherer (VdS), Loss Prevention

Council (LPCB), the Authorities Having Jurisdiction, and also with the provisions of governmental codes, ordinances,

and standards whenever applicable. Deviation from the standards or any alteration to the sprinkler after it leaves the

factory including, but not limited to: painting, plating, coating, or modification, may render the sprinkler inoperative and

will automatically nullify the approval and any guarantee made by The Viking Corporation.

A. Sprinklers must be handled with care. They must be stored in a cool, dry place in their original shipping container. Never install

sprinklers that have been dropped or damaged in any way. Such sprinklers should be destroyed immediately.

NOTE: Wet pipe systems must be provided with adequate heat.

B. The sprinklers must be installed after the piping is in place to prevent mechanical damage. Before installing, be sure to have the

appropriate sprinkler model and style, with the correct orifice size, temperature rating, and response characteristics.

C. With the sprinkler contained in the plastic protective cap, apply a small amount of pipe-joint compound or tape to the male threads

only, while taking care not to allow a build-up of compound in the sprinkler orifice.

D. Use ONLY sprinkler wrench 13635W/B (shown in Figure 1) for installing ESFR Sprinkler VK503! With the sprinkler con-

tained in the protective cap, install the sprinkler onto the piping by applying the sprinkler wrench to the sprinkler wrench

flats only, while taking care not to damage the sprinkler operating parts.

DO NOT use any other type of wrench, as this could damage the unit.

DO NOT use the sprinkler deflector or fusible element to start or thread the sprinkler into a fitting.

DO NOT exceed 50 ft. lbs. of torque (hand tight, plus approximately two full turns with the wrench) to install these sprinklers. Higher

levels of torque may distort the sprinkler inlet with consequent leakage or impairment of the sprinkler.

E. After installation, the entire sprinkler system must be tested. The test must be conducted to comply with the Installation Standards.

Make sure the sprinkler has been properly tightened. If a thread leak occurs, normally the unit must be removed, new pipe-joint

compound or tape applied, and then reinstalled. This is due to the fact that when the joint seal is damaged, the sealing compound

or tape is washed out of the joint. Immediately replace any damaged units, using the special sprinkler wrench only.

F. After installation and testing and repairing of all leaks, remove the protective caps from the sprinklers. Do NOT use any

type of tool to remove the cap. Remove the cap by hand: turn it slightly and pull it off the sprinkler. When removing caps,

use care to prevent dislodging or damaging sprinkler ejector spring and fusible element. THE CAPS MUST BE REMOVED

FROM SPRINKLERS BEFORE PLACING THE SYSTEM IN SERVICE!

G. System design must be based on ESFR design guidelines described in applicable FM Global Loss Prevention Data Sheets, the

Form No. F_120106 18.10.11 Rev 18.2

Loading...

Loading...